轻质高强轻金属由于具有较低密度、优异的力学性能和比强度等优点,在航空、航天和汽车等领域有着广泛的应用。随着航空、航天、高速交通工具的快速发展,对轻质和高强提出了更高的要求[1]。铝合金具有比强度高、密度低、耐腐蚀性能优良以及易回收等优点,作为结构材料具有广阔的应用前景,因此发展高强度铝合金成为国内外研究的焦点之一[2,3]。高强度纳米结构铝合金的制备方法包括剧烈塑性变形[4]、非晶晶化法[5]、磁控溅射法[6]、电解沉积法[7]等。近些年来基于铝基非晶合金体系制备纳米结构铝合金得到了快速发展[8],这些纳米结构铝合金不仅具有界面清洁、晶粒度易于控制等优点[9],而且具有超高强度,达到了吉帕级别[10]。其微观组织通常为高体积分数纳米尺度金属间化合物和纳米晶Al,主要通过非晶态铝基合金粉末或者带材在烧结过程中同时实现致密化和晶化而成。如Zhuo等[11]制备出Al85Ni4Ag6Y5合金,压缩强度达到了1000 MPa;Kawamura等[12]研究表明,Al85Ni5Y8Co2合金的压缩强度达到了1400 MPa;Wang等[13]制备出Al84Ni7Gd6Co3纳米结构铝合金,压缩屈服强度达到1700 MPa。然而,这些高强度纳米结构铝合金的塑性较差,在拉伸条件下的塑性变形接近零。这主要存在2个原因:(1) 在高应力下纳米化合物容易产生裂纹,导致材料过早断裂;(2) 高体积分数的纳米化合物相减少了整体材料的塑性变形空间。

如何提升塑性成为获得高强高韧纳米结构铝合金亟需解决的难题,目前人们提出利用多种新的材料结构,来协同优化材料的强度和塑性[14]。多级结构是突破塑性瓶颈,优化金属整体力学性能的一个重要途径,通过材料本身的结构调控实现综合力学性能的提升[15],包括双峰结构、谐波结构、梯度纳米结构[16]、双相结构、层状异构单金属/多金属复合结构等[17~22]。这些异质结构金属材料都有一个共同的特征,材料结构单元的尺寸(如晶粒尺寸)或者成分在空间上呈不均匀分布,且通过应变分配[23]、应变传递[24]、界面限制效应[25]、背应力强化[26]等方式来实现力学性能的突破。目前基于这一结构设计理念,非晶和纳米结构金属的塑性得到了显著提高。如He等[27]对Ti60Cu14Ni12Sn4Ta10和Ti50Cu23Ni20Sn7合金研究表明,具有纳米结构基体和微米尺度韧性枝晶相的钛合金获得了2400 MPa的抗拉强度和14.5%的塑性应变。Han等[28]对5083Al铝合金进行研究,制备出双尺度结构合金:平均晶粒尺寸为200 nm的超细晶区域和平均晶粒尺寸为1 µm的区域,发现塑性比单一超细晶结构铝合金得到了显著提高。Hofmann等[29]对Zr36.6Ti31.4Nb7Cu5.9Be19.1等非晶合金进行研究,制备出韧性粗晶相均匀分布在非晶基体中的结构,发现粗晶相可以显著提高非晶合金拉伸塑性。

利用增材制造技术可以制备出复杂和拓扑优化的点阵材料,通过与其他材料复合获得多种新型异质异构材料。如Pawlowski等[30]将熔点低的A356熔渗到选区激光熔化(SLM)制备的三维连续316L不锈钢骨架中,通过凝固得到A356/316L双连通复合材料,发现连续的316L骨架可以阻碍A356合金内的裂纹扩展。Zhang等[18]用Mg熔体无压力渗入SLM成形NiTi合金点阵结构,制备出一种新型的Mg/NiTi双连通复合材料,发现连续的NiTi合金点阵结构可以有效促进载荷在不同相间的传递,使得复合材料获得了良好的塑性和阻尼吸能能力。Rahmani等[31]采用放电等离子烧结制备出SLM成形Ti6Al4V点阵材料和AlSi10Mg粉末相结合的块体材料,发现连续Ti6Al4V点阵结构材料可以使得冲击功均匀分布在整个试样中,从而降低了接触区域的应力集中现象,提高了材料的损伤容限。Rahmani等[32]将WC-Co硬质合金粉末填充至SLM成形Ti三维梯度点阵结构的孔隙中,然后对坯料进行放电等离子烧结来制备WC-Co/Ti双连通复合材料,获得了较好的塑性。

钛合金的强度与纳米结构铝合金接近,作为多级结构材料在加载过程中可以表现出较好的力学匹配,例如纳米结构铝合金的裂纹萌生和扩展可以被周围的钛合金抑制。目前已经研发出一系列Ti/Al复合材料[33]。本工作利用增材制造技术制备出复杂和个性化的金属点阵材料,基于SLM工艺,制备出TC4三维点阵结构,并填充铝基非晶粉末,利用热挤压过程非晶原位晶化和致密化,获得高强韧的钛合金点阵结构增韧纳米结构铝合金的复合材料,研究了复合材料的制备工艺、微观组织和力学性能,以期为获得高强韧、高比强金属材料的结构设计、制备和强韧化机理提供指导。

1 实验方法

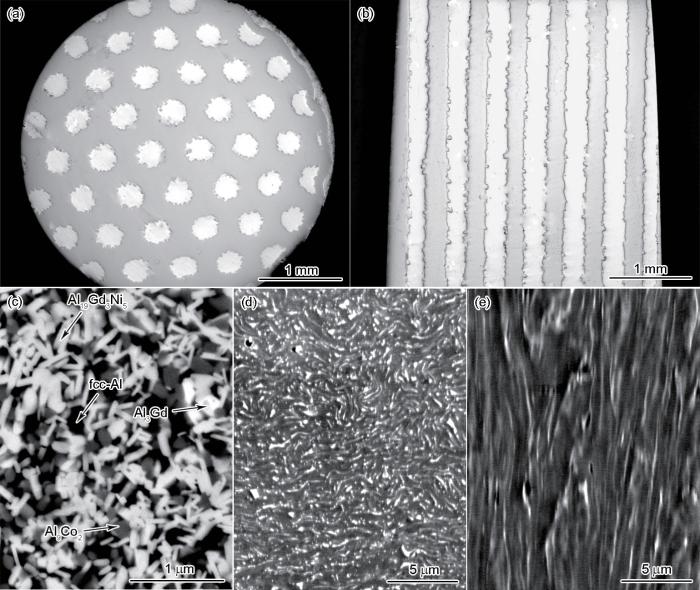

TC4合金粉末采用电极感应熔炼气雾化制备,粒径为15~53 μm,如图1a所示。Al84Ni7Gd6Co3非晶合金粉末通过真空气雾化制备,筛粉选取粒径小于20 μm的粉末,如图1b所示。TC4三维点阵结构设计为三维六角密堆拓扑结构,其圆孔呈平面密排分布,任意一个圆孔被周围6个圆孔紧密环绕,6个圆孔的中心相连构成正六边形,孔径为1 mm,最小壁厚为0.5 mm,孔隙率为40%,结构图如图1c所示。采用SLM制备TC4合金点阵结构,合金粉末颗粒表面光洁度好,卫星球粉数量少。SLM采用EOSINT M280型金属激光打印机,成形过程中采用高纯Ar 气作为保护气体,加工参数为:激光功率170 W,光斑直径0.1 mm,扫描间距0.1 mm,铺粉厚度0.04 mm,扫描速率1.2 m/s,激光在同一层扫描时并不改变角度,只沿平行方向做往返运动,到下一层扫描时,激光会在上一层角度的基础上顺时针旋转67°,依次递推,直到TC4三维点阵结构成型完成。图1d为点阵结构实物图。可见其圆孔分布均匀,与设计尺寸基本保持一致。热挤压前将TC4三维点阵结构放入电阻炉中在Ar气氛保护下、800℃保温4 h,随炉冷却。图1e和f为SLM制备的TC4合金点阵结构退火后横截面的显微组织,主要为α相和β相,白色β相沿着暗色α相界面处分布,形成交织的网篮组织,α相的平均厚度为0.8 μm,β相的平均厚度为0.1 μm。微观组织中的晶粒、α相和β相尺寸测量方法如下:在扫描电子显微镜(SEM)下至少拍摄10张相同倍数(3000倍)的照片,使用图像分析软件通过等效直径法和截线法分别测量晶粒尺寸和相的厚度,求其平均值。纳米结构铝合金区域由Al84Ni7Gd6Co3非晶合金粉末通过热挤压过程中晶化获得。玻璃化转变温度(Tg)约为290℃,晶化温度(Tx)约为310℃[34]。复合材料制备工艺示意图如图2所示。首先将TC4点阵结构放至纯Cu包套中,再将Al84Ni7Gd6Co3非晶合金粉末注入点阵结构并通过包套密封,然后在空气中进行冷压成形,压力为700 MPa,保压时间为3 min,如图2a所示。将冷压得到的TC4/Al84Ni7Gd6Co3混合体在500℃保温后进行正挤压(如图2b所示),挤压速率为2.7 mm/s,挤压比约为8,挤压后悬空冷却至室温,去除包套得到复合材料棒材,其横截面直径为3.3 mm,长度约为126 mm,其横截面和纵截面的结构示意图如图2c所示。

图1

图1

TC4合金粉末和Al84Ni7Gd6Co3非晶合金粉末的SEM像以及TC4点阵结构的示意图、宏观形貌和微观组织

(a) SEM image of the TC4 powders (b) SEM image of the Al84Ni7Gd6Co3 amorphous powders

(c) schematic of the TC4 lattice (unit: mm) (d) TC4 lattices fabricated by selected laser melting process

(e, f) top views of the TC4 lattice after 4 h at 800oC followed by furnace cooling with low (e) and high (f) magnifications

Fig.1

Morphologies and microstructure of TC4 lattices by 3D printing and the powders needed for manufacturing Al84Ni7Gd6Co3/TC4 composite

图2

图2

热挤压制备Al84Ni7Gd6Co3/TC4复合材料的示意图

(a) cold press (b) hot extrusion

(c) hot extruded sample (d) dimension of the tensile sample (unit: mm)

Fig.2

Schematic showing the used processing route for manufacturing Al84Ni7Gd6Co3/TC4 composite

材料密度在Sartorius/BS 224 B型电子天平上采用Archimedes排水法测试得到。复合材料的Vickers硬度利用THVP-30大屏数显自动转塔Vickers硬度计测得,测定参数为:载荷100 g,保压时间15 s。为了确保测量数据的准确性,选择复合材料中远离界面的两侧区域、TC4合金点阵结构区域和铝合金区域分别测量25个点,取其平均值。在进行显微结构分析前,先将样品机械磨抛后用试剂腐蚀,侵蚀剂配方为5 mL HF + 10 mL HNO3 + 85 mL H2O,利用DMI5000M光学显微镜(OM)和Nova Nano SEM 430型SEM观察微观组织及断口形貌,利用SEM配备的IE350能谱仪(EDS)进行成分分析。X射线衍射(XRD)测定采用D8 Advance设备,高分辨全能型微纳米焦点CT (μ-CT)检测采用Diondo D2设备,加速电压为110 kV、电流为110 μA、分辨率为10 μm,在X射线的照射下转动样品获得不同角度的二维投影像,随后二维投影像被数学重构为有吸收衬度的二维切片,最后利用Avizo软件进行三维重构并分析材料内部缺陷的位置、尺寸和数量。对试样纵截面表面进行机械抛光和氩离子抛光,利用Nova Nano SEM 430型SEM采集电子背散射衍射(EBSD)数据,具体参数为加速电压20 kV,扫描步长0.05 μm,采用HKL-Channel 5软件对EBSD测试数据进行分析处理。选用挤压后圆棒样品的中间段进行组织观察和拉伸性能测试。室温拉伸性能测试在CMT4204微机控制电子万能试验机上参照GB/T 228.1—2010《金属材料拉伸试验方法》进行,随机选择3个拉伸试样进行拉伸性能测试,应变速率为1 × 10-4 s-1,拉伸试样的尺寸如图2d所示。

2 实验结果与讨论

2.1 微观组织

图3

图3

Al84Ni7Gd6Co3/TC4复合材料的XRD谱

Fig.3

XRD spectrum of the Al84Ni7Gd6Co3/TC4 composite

图4a为Al84Ni7Gd6Co3/TC4复合材料沿挤压方向的μ-CT三维重构结构图,橘色部分为TC4点阵结构,红色部分为Al84Ni7Gd6Co3合金区域。可以看出,复合材料中的TC4点阵结构保持热挤压前的点阵结构特征,连续性较好并且没有发生明显的弯曲或扭转变形,且2种材料分布均匀。图4b为复合材料纵截面二维投影图。可见,2种材料的界面平整、结合良好,没有观察到分层或分离现象,点阵结构通孔的平均直径由挤压之前的1 mm变为0.311 mm,点阵结构通孔间的平均最小壁厚由挤压之前的0.5 mm变为0.215 mm。图4c和d分别为复合材料三维孔隙缺陷分布图和孔隙尺寸的统计结果,没有观察到100 µm以上的大尺寸孔隙和点阵损伤,最大孔隙直径为92 μm,绝大部分孔隙直径小于35 μm,孔隙率为0.006%,形成了较为致密的结构。获得较高致密度的主要原因:一方面是由于热挤压过程中大塑性变形有利于进一步改善TC4点阵与铝合金之间的界面结合和孔隙闭合;另一方面,在高温下Al元素容易扩散,有助于填充较小孔隙。

图4

图4

Al84Ni7Gd6Co3/TC4复合材料的μ-CT三维重构显微组织图以及孔隙表征

(a) 3D morphology (b) 2D projection on y-z plane of the sample

(c) pore distributions (d) pore size distributions in the specimen along the extrusion direction

Fig.4

3D rendering of Al84Ni7Gd6Co3/TC4 composite based on the μ-CT

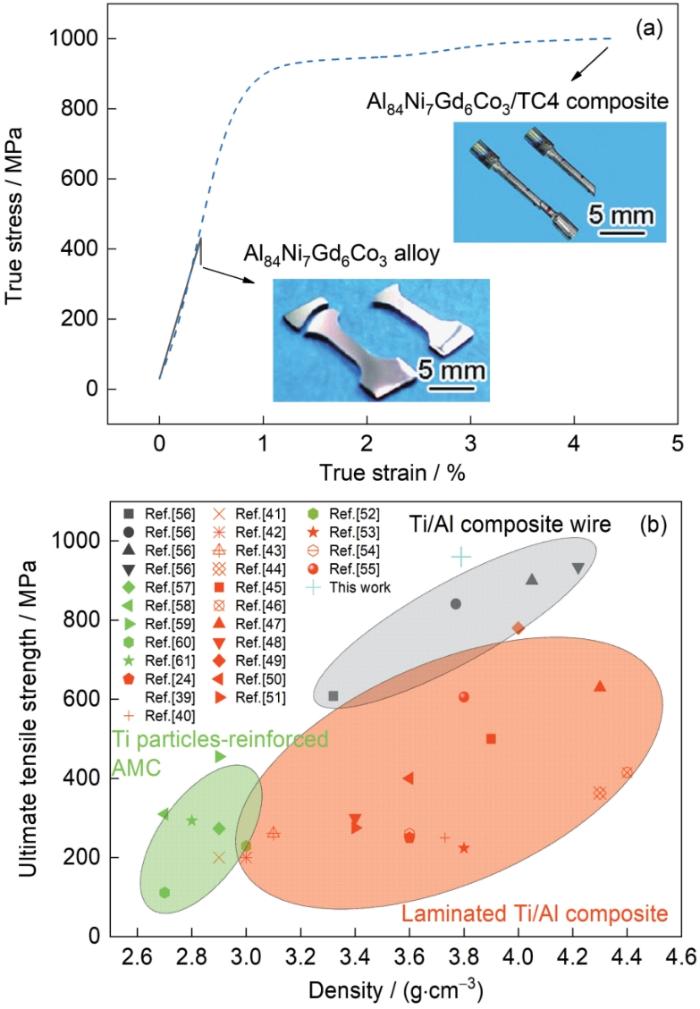

图5a和b分别为Al84Ni7Gd6Co3/TC4复合材料横截面和纵截面的OM像。可以看出,存在较暗的灰色区域和较亮的白色区域,灰色区域为TC4点阵结构,白色区域为Al84Ni7Gd6Co3合金区域。图5c为Al84Ni7Gd6Co3合金区域横截面的SEM背散射(BSE)像,结合已报道的纯Al84Ni7Gd6Co3合金的热压结果[34],纳米棒状相为Al19Gd3Ni5金属间化合物,等轴颗粒是Al3Gd和Al9Co2金属间化合物的混合物,此外还含有纳米晶fcc-Al。棒状Al19Gd3Ni5的体积分数约为20%,宽度约为30 nm,长度约为130 nm。Al3Gd和Al9Co2等轴混合相的体积分数约为60%,平均尺寸为100~250 nm。剩余部分为fcc-Al,晶粒尺寸约为80 nm。图5d为TC4点阵结构区域横截面的SEM二次电子(SE)像。白色部位为β相,黑色部位为α相,α相和β相的片条厚度相对于挤压前明显减小,α相的平均厚度约为0.47 μm,β相的平均厚度约为0.04 μm,薄片在不同方向折叠和扭结,形成特定的“卷曲”类型的微观结构。片条扭曲是由于在挤压前的TC4合金退火组织中存在片条取向和强度差异,在挤压过程中,软取向片条易沿挤压方向发生转动,而硬取向片条不易发生转动,形成变形过程中的不协调性,导致片条发生扭曲[35]。图5e为TC4合金的纵截面微观组织的SE像。可以看出,片状的α相和β相沿着挤压轴方向伸长,呈现出片条状的组织。

图5

图5

Al84Ni7Gd6Co3/TC4复合材料横截面和纵截面的微观组织

(a, b) OM images of the transversal section (a) and longitudinal section (b)

(c) BSE-SEM image of the Al84Ni7Gd6Co3 alloy area of transversal section

(d, e) SE-SEM images of the TC4 lattice showing the microstructures of the transversal section (d) and longitudinal section (e)

Fig.5

Microstructures of the Al84Ni7Gd6Co3/TC4 composite

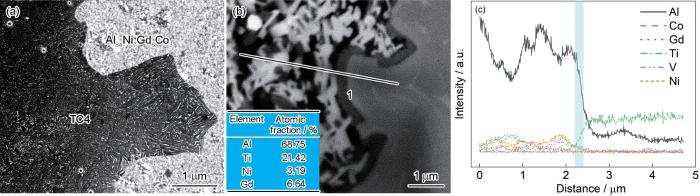

图6a为Al84Ni7Gd6Co3/TC4复合材料界面处的SEM像。可以看出,TC4点阵结构在界面附近区域的α、β片状结构的尺寸存在梯度分布,离界面越近片状结构尺寸越大,这是由于在热挤压过程中挤压棒材的径向应变分布不均匀,离界面较远的点阵结构区域变形受Al84Ni7Gd6Co3纳米结构铝合金的限制越小,从而使变形程度增加,导致α、β层状结构的尺寸减小,呈现梯度分布[36]。界面处形成了界面扩散反应层,厚度约为200 nm,如图6b所示。EDS元素线扫描显示Ti和Al沿着界面呈相反的浓度梯度分布,如图6c所示。通过元素点扫描结果(图6b中插图)可知,界面反应层主要为金属间化合物Al3Ti。Al3Ti扩散反应层的形成和生长是典型的反应扩散模式[37],扩散初期Ti和Al发生互扩散直至固溶体Al(Ti)和Ti(Al)过饱和,此时在Ti/Al界面局部区域沉淀析出Al3Ti颗粒,此时界面处会依次出现Ti(Al)、Al3Ti、Al(Ti) 3个单相区,相界面处产生浓度突变,各相内部出现Al、Ti元素的浓度梯度。Al不断扩散至附近的TC4合金区域,当临近Al3Ti/Ti界面处的Al在Ti中的浓度超过临界平衡浓度,在界面处逐渐析出Al3Ti相,同样地,在Ti不断地向Al层的扩散过程中实现了Al3Ti向Al层中的生长。由于Ti和Al之间的相互扩散率不同,在Al3Ti层中可以形成微型Kirkendall空洞[38],在挤压的作用下孔洞被消除形成致密的组织。从图6b还可以看出,界面处存在微米级别的凹凸不平,这主要是由于SLM制备的金属表面存在较大粗糙度导致,其次是由于TC4合金点阵结构尚残留少量未熔化的颗粒或者飞溅颗粒,这些颗粒在热挤压过程中焊在了界面处。图7为Al84Ni7Gd6Co3/TC4复合材料界面附近的EBSD分析结果,其中图7a为SEM像,图7b为相图,图7c为EBSD取向差分布图,其中大角度晶界用黑线表示(HAGBs,15° < θ,θ为取向差角),小角度晶界用红线表示(LAGBs,2° ≤ θ ≤ 15°),图7d为内核平均取向差(KAM)图,图7e为极图,图7f为反极图(IPF)。可以看出,TC4区域大部分为α相,β相因含量较少难以分辨出;由于Al84Ni7Gd6Co3铝合金区域的晶粒尺寸小于500 nm,因此未分辨出其中的晶粒和各相尺寸。TC4出现比较明显的丝织构,即α相的<01

图6

图6

Al84Ni7Gd6Co3/TC4复合材料的界面特征

(a, b) low (a) and high (b) magnified SEM images (Inset in Fig.6b shows the EDS results of point 1)

(c) EDS line scanning result along line in Fig.6b

Fig.6

SEM analyses of the Al84Ni7Gd6Co3/TC4 composite near the interface

图7

图7

Al84Ni7Gd6Co3/TC4复合材料纵截面界面区域的EBSD分析结果

(a) SEM image (b) phase distribution map (c) EBSD orientation map

(d) EBSD kernel average misorientation (KAM) color map with respect to the geometrically necessary dislocation (GND) density (ρGND)

(e) {01

Fig.7

EBSD results of the Al84Ni7Gd6Co3/TC4 composite near the interface along extrusion direction

2.2 拉伸力学性能和强韧性机理

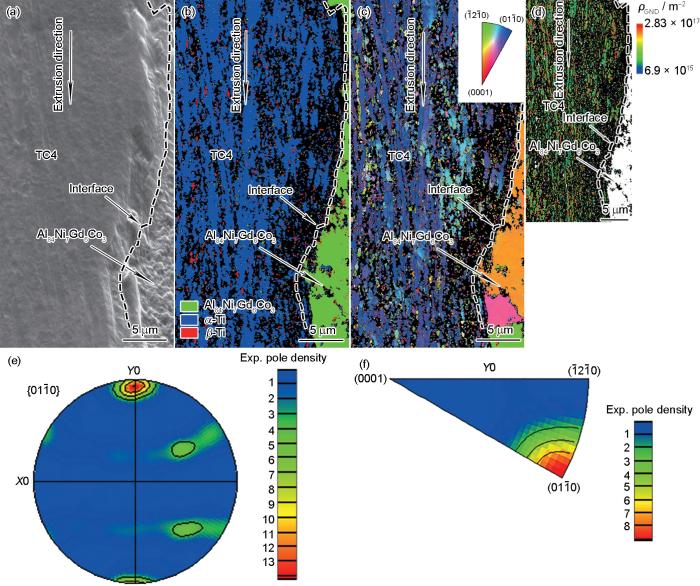

图8a给出了Al84Ni7Gd6Co3/TC4复合材料和相同工艺下制备的纯Al84Ni7Gd6Co3合金的拉伸力学性能。结果表明,纯Al84Ni7Gd6Co3合金在弹性变形阶段发生了断裂,拉伸强度仅约为400 MPa。由于存在高体积分数脆性化合物相,导致纳米结构铝合金的拉伸性能普遍较低,塑性很差。相比之下,TC4点阵结构增韧的复合材料的屈服强度约为881 MPa,抗拉强度约为960 MPa,拉伸塑性应变> 3%。该材料密度为4.18 g/cm3,比强度约230 MPa/(g·cm-3),比弹性模量约27 GPa/(g·cm-3)。图8b总结了本工作和目前报道[24,39~61]的Al/Ti异质异构复合材料的密度与力学性能,其中包括铝合金和钛合金的结合。可知Al84Ni7Gd6Co3/TC4复合材料具有较高拉伸强度和比强度,表明钛合金点阵结构可以有效抑制纳米结构铝合金的脆性,获得良好的强韧性。

图8

图8

Al84Ni7Gd6Co3/TC4复合材料和纯Al84Ni7Gd6Co3纳米结构铝合金的拉伸性能,及本工作和目前报道[24,39~61]的Al/Ti异质异构复合材料的密度与力学性能对比

Fig.8

Tensile true stress-strain curves of the Al84Ni7Gd6Co3/TC4 composite and the pure Al84Ni7Gd6Co3 alloy (Insets in Fig.8a show the corresponding photographs of tensile samples) (a) and comparisons between the present materials and the other reported Ti/Al composites with the ultimate tensile strength as a function of density (Data for the other materials are taken from the literatures [24,39-61]. AMC—aluminum-based matrix composite) (b)

本工作对该复合材料的混合定律进行了半定量对比分析,由于采用与复合材料相同的热挤压参数(如挤压温度500℃)无法制备出纯单一的TC4合金,因此分别测量了复合材料中的TC4点阵结构区域和纳米结构铝合金区域中心位置的Vickers硬度,并根据硬度与抗拉强度的关系计算出其各自的理论抗拉强度[62],其换算公式为:

式中,HV为Vickers硬度,σ为抗拉强度。复合材料中TC4点阵结构区域和纳米结构铝合金区域的Vickers硬度分别为4126和3195 MPa,由

式中,σ1、σ2和f1、f2分别是复合材料两相的强度和体积分数。由混合定律可得出复合材料的抗拉强度为1251 MPa,大于复合材料的实验值960 MPa。这主要是由于纳米结构铝合金区域在变形过程中依然发生了脆性断裂,因此其实际强度依然小于其理论强度。这也更好地解释了后面的变形机制,即纳米结构铝合金区域只发生了弹性变形,在达到屈服强度之前就开始萌生微裂纹,由于TC4点阵结构区域的限制,使得整体材料尚未发生破坏性断裂失效,当裂纹尖端的局部应力大于TC4合金的屈服强度时,TC4点阵结构区域开始发生塑性变形和加工硬化现象。

图9为Al84Ni7Gd6Co3/TC4复合材料拉伸断口的μ-CT三维层析成像图和SEM像。可以看出,Al84Ni7Gd6Co3合金区域存在大量且均匀分布的横向微裂纹,成圆盘状,直径约为300 µm,与挤压后的点阵结构通孔尺寸一致,这些横向微裂纹的间距约为200 µm。而TC4点阵结构的断裂面沿着最大切应力方向与轴向约呈45°,如图9c所示。图10为Al84Ni7Gd6Co3/TC4复合材料断口形貌的SEM像。图10中Ⅰ区处为Al84Ni7Gd6Co3合金区域,没有发现韧窝特征(图10b),属于沿晶脆性断裂,这是由于高体积分数脆性金属间化合物导致。TC4区域有2种不同的断口形貌,分为等轴状有明显韧窝壁的大尺寸深韧窝(如图10c所示)和尺寸小且呈抛物线形的浅韧窝(如图10d所示)。由Al84Ni7Gd6Co3合金萌生的裂纹在加载过程中扩展至TC4中,初期阶段导致TC4区域的断裂为微孔剪切机制,随着裂纹前沿继续扩展,逐渐转换为微孔聚集型断裂[63]。

图9

图9

Al84Ni7Gd6Co3/TC4复合材料的断裂特征

(a) μ-CT 3D morphology of the fracture surface

(b) morphology and spatial distribution of the micro cracks and volume of cracks along the tensile direction

(c, d) low (c) and high (d) magnified SEM images of fractured samples after polishing along longitudinal section

Fig.9

Fracture behavior characterizations of the Al84Ni7Gd6Co3/TC4 composite

图10

图10

Al84Ni7Gd6Co3/TC4复合材料断口形貌的SEM像

Fig.10

Low (a) and locally high magnified fracture SEM images of areas Ⅰ (b), Ⅱ (c), and Ⅲ (d) of Al84Ni7Gd6Co3/TC4 composite

这些结果表明,在拉伸过程中,Al84Ni7Gd6Co3合金区域由于脆性大首先萌生微裂纹,随着加载增加微裂纹迅速扩展至界面处;当加载持续增加时,纳米铝合金内部产生更多的微裂纹,当裂纹尖端的应力大于点阵结构TC4合金的屈服强度时,TC4点阵结构区域开始产生塑性变形,塑性变形吸收微裂纹尖端的能力对裂纹产生了钝化作用;同时有些微裂纹由原始方向在界面处偏转90°并沿着界面扩展,如图9d所示;随着拉应力的持续增加,界面处裂纹尖端的应力大于TC4点阵结构的断裂强度,裂纹开始沿着最大剪应力方向扩展,并最终跨越TC4点阵结构的单个单元形成主裂纹;最后主裂纹逐渐扩展,直至整个样品断裂。可以看出,TC4点阵结构对纳米结构Al84Ni7Gd6Co3合金的脆性断裂产生了显著的限制作用,避免了微裂纹的过早扩展,进而提升整体材料的强度和韧性。

图11为拉伸断裂后复合材料纵截面界面附近EBSD结果,其中图11a为SEM像,图11b为相图,图11c为EBSD 取向差分布图,图中大角度晶界用黑线表示,小角度晶界用红线表示,图11d为KAM图,图11e为极图,图11f为IPF。从图11c中可知,拉伸变形后α相的<01

图11

图11

拉伸断裂后纵截面界面区域的EBSD分析

(a) SEM image (b) phase distribution map

(c) EBSD orientation map (d) EBSD KAM color map with respect to ρGND

(e) {01

Fig.11

EBSD results of the fractured Al84Ni7Gd6Co3/TC4 composite near the interface along tensile direction

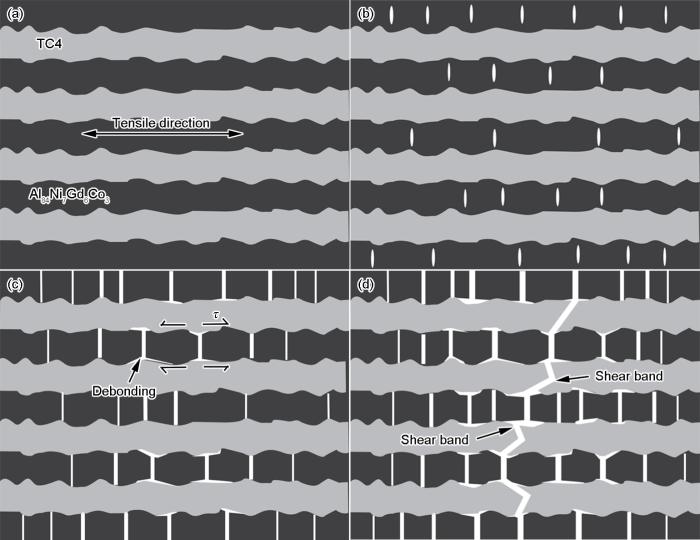

图12为Al84Ni7Gd6Co3/TC4复合材料在拉伸过程中裂纹萌生与扩展以及材料失效模型的示意图。在弹性变形早期,铝合金层和钛合金层均承受相同的应变。由于两部分金属的弹性模量接近,Al84Ni7Gd6Co3 的弹性模量约为119 GPa[13],而TC4的弹性模量约为112 GPa[64],因而TC4点阵结构区域与Al84Ni7Gd6Co3区域在弹性变形阶段表现出的应力差异较小,同时界面层良好的黏和作用促进了应力的传递,缓解了界面的应力集中,故界面处2种材料未发生明显的脱黏现象,从而有别于已报道的部分纤维状增强体强化复合材料的界面脱黏现象[65]。随着拉伸的继续进行,纳米结构Al84Ni7Gd6Co3合金区域在某些局部缺陷区域过早萌生微裂纹,由于此时应力低于钛合金点阵结构的屈服强度或者抗拉强度,裂纹扩展受到抑制,因此微裂纹尺寸限制在点阵结构通孔的尺寸范围内;随着持续加载,纳米结构Al84Ni7Gd6Co3铝合金受到的均匀轴向拉应力增加,导致铝合金区域多处产生微裂纹,这些微裂纹均匀产生并终止于界面处;当裂纹尖端应力高于TC4层的屈服强度时,TC4点阵结构区域产生塑性变形,抑制裂纹的扩展,而且部分微裂纹在界面处横向偏转90°,造成局部脱黏,释放了部分裂纹尖端的能量;随着裂纹尖端局部应力大于TC4点阵结构区域的断裂强度,裂纹在最大切应力方向沿着点阵结构区域扩展,最终形成主裂纹,导致整体材料断裂失效。由上述可以看出,在拉伸加载过程中,TC4点阵结构区域对高强纳米结构铝合金区域的裂纹萌生和扩展产生了显著的限制效应,从而抑制了脆性高强纳米结构铝合金的过早断裂,同时纳米结构铝合金区域提升了TC4点阵结构区域加工硬化能力,从而使得复合材料在获得高强度的同时没有发生破坏性断裂失效,突破了点阵结构材料和三维互穿材料塑性较差的难题。

图12

图12

Al84Ni7Gd6Co3/TC4复合材料在拉伸过程中裂纹萌生与扩展示意图

(a) early elastic deformation stage (b) initial cracking at the Al84Ni7Gd6Co3 alloy

(c) appearance of delamination (d) finally fractured

Fig.12

Schematics of crack generation and propagation model for Al84Ni7Gd6Co3/TC4 composite under tensile load (τ—shear force)

3 结论

(1) 基于选区激光熔化和热挤压工艺,制备出TC4三维点阵结构与超高强度纳米结构Al84Ni7Gd6Co3铝合金结合的多级结构复合材料,钛合金区域保持完整的点阵结构特征、无明显弯曲或扭转变形,钛合金区域的α相和β相的片条组织变得细小并形成了拉长的片条状结构特征。

(2) Al84Ni7Gd6Co3/TC4复合材料界面结合良好,无明显孔隙并形成了厚度约为200 nm的界面扩散Al3Ti反应产物层。

(3) Al84Ni7Gd6Co3/TC4复合材料具有良好的拉伸力学性能,抗拉强度约为960 MPa且塑性应变> 3%,比强度达230 MPa/(g·cm-3),比弹性模量达27 GPa/(g·cm-3)。

(4) TC4点阵结构区域对高强纳米结构铝合金区域的裂纹萌生和扩展产生了显著的限制效应,从而抑制了脆性高强纳米结构铝合金的过早断裂,同时纳米结构铝合金区域提升了TC4点阵结构区域加工硬化能力,从而使得复合材料在获得高强度的同时没有发生破坏性断裂失效。

参考文献

Precipitation strengthening of aluminum alloys by room-temperature cyclic plasticity

[J].High-strength aluminum alloys are important for lightweighting vehicles and are extensively used in aircraft and, increasingly, in automobiles. The highest-strength aluminum alloys require a series of high-temperature "bakes" (120° to 200°C) to form a high number density of nanoparticles by solid-state precipitation. We found that a controlled, room-temperature cyclic deformation is sufficient to continuously inject vacancies into the material and to mediate the dynamic precipitation of a very fine (1- to 2-nanometer) distribution of solute clusters. This results in better material strength and elongation properties relative to traditional thermal treatments, despite a much shorter processing time. The microstructures formed are much more uniform than those characteristic of traditional thermal treatments and do not exhibit precipitate-free zones. These alloys are therefore likely to be more resistant to damage.Copyright © 2019 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Achieving an ultra-high strength in a low alloyed Al alloy via a special structural design

[J].

Development of high strength aluminum alloys and processing techniques for the materials

[J].

高强铝合金的发展及其材料的制备加工技术

[J].

Preparation techniques for nanostructured metallic materials via plastic deformation

[J].

纳米结构金属材料的塑性变形制备技术

[J].本文总结了制备纳米结构金属材料的塑性变形技术, 包括大应变量变形技术(冷轧、累积叠轧、等通道挤压和高压扭转)、高应变速率变形技术(动态塑性变形)和高应变梯度变形技术(表面机械研磨和表面机械碾压), 分析了变形方式及变形参数对晶粒细化的影响规律, 展望了利用塑性变形技术制备纳米结构金属材料的发展趋势及挑战.

Phase transformation from an amorphous alloy into nanocrystalline materials

[J].

非晶态合金向纳米晶体的相转变

[J].

Effects of deposition parameters on residual stresses, hardness and electrical resistivity of nanoscale twinned 330 stainless steel thin films

[J].

Ultrahigh strength and high electrical conductivity in copper

[J].Methods used to strengthen metals generally also cause a pronounced decrease in electrical conductivity, so that a tradeoff must be made between conductivity and mechanical strength. We synthesized pure copper samples with a high density of nanoscale growth twins. They showed a tensile strength about 10 times higher than that of conventional coarse-grained copper, while retaining an electrical conductivity comparable to that of pure copper. The ultrahigh strength originates from the effective blockage of dislocation motion by numerous coherent twin boundaries that possess an extremely low electrical resistivity, which is not the case for other types of grain boundaries.

Development and applications of highly functional Al-based materials by use of metastable phases

[J].

Synjournal of nanocrystalline materials from amorphous solids

[J].

Al based alloys containing amorphous and nanostructured phases

[J].

Hierarchical ultrafine-grained/nanocystalline Al-based bulk alloy with high strength and large plasticity

[J].

Nanocrystalline aluminum bulk alloys with a high strength of 1420 MPa produced by the consolidation of amorphous powders

[J].

Hybrid nanostructured aluminum alloy with super-high strength

[J].

Mechanical behaviors of nanotwinned metals and nanotwinned covalent materials

[J].Metallic and covalent materials are important structural materials. Traditional strategies for strengthening materials compromise their ductility and toughness. Recent experimental results show that twinning can simultaneously improve the strength (hardness) and toughness of copper and diamond; as the inverse relationship between the strength and toughness of materials is broken, this has become a hot research topic. By studying the strengthening mechanism of nanotwinned copper and diamond, methods to simultaneously improve strength and toughness may be found. Herein, this paper presents a comprehensive overview of the recent developments in the experimental and theoretical studies of nanotwinned metals and covalent materials. The microstructures, fabrication methods, and mechanical properties of nanotwinned metals and covalent materials are summarized. Further, the strengthening mechanism of nanotwinned metals and the hardening mechanism of covalent materials are introduced. Finally, the research trend on the mechanical behavior of nanotwinned materials is discussed in detail.

纳米孪晶金属和纳米孪晶共价材料的力学行为

[J].

Hierarchical nanostructured aluminum alloy with ultrahigh strength and large plasticity

[J].High strength and high ductility are often mutually exclusive properties for structural metallic materials. This is particularly important for aluminum (Al)-based alloys which are widely commercially employed. Here, we introduce a hierarchical nanostructured Al alloy with a structure of Al nanograins surrounded by nano-sized metallic glass (MG) shells. It achieves an ultrahigh yield strength of 1.2 GPa in tension (1.7 GPa in compression) along with 15% plasticity in tension (over 70% in compression). The nano-sized MG phase facilitates such ultrahigh strength by impeding dislocation gliding from one nanograin to another, while continuous generation-movement-annihilation of dislocations in the Al nanograins and the flow behavior of the nano-sized MG phase result in increased plasticity. This plastic deformation mechanism is also an efficient way to decrease grain size to sub-10 nm size for low melting temperature metals like Al, making this structural design one solution to the strength-plasticity trade-off.

Compositionally graded metals: A new frontier of additive manufacturing

[J].

Towards strength-ductility synergy through the design of heterogeneous nanostructures in metals

[J].

3D printed Mg-NiTi interpenetrating-phase composites with high strength, damping capacity, and energy absorption efficiency

[J].A 3D printed magnesium alloy with an interpenetrating NiTi phase shows remarkable strength, damping, and self-healing properties.

Metal frame reinforced bulk metallic glass composites

[J].

Fabrication of Mg-based composites reinforced by SiC whisker scaffolds with three-dimensional interpenetrating-phase architecture and their mechanical properties

[J].Mg and Mg alloys, as important lightweight metal materials, have attracted great attention due to their excellent properties, such as low density, high specific strength, and good damping properties; however, their extensive applications are strictly limited by their low strength. The strength of Mg and Mg alloys can be effectively increased by introducing reinforcement phases into their matrices, i.e., via fabricating Mg-based composites. Nevertheless, the mechanical properties of Mg-based composites demonstrate a strong dependence on their microstructures. Here, new Mg-based composites reinforced by SiC whisker scaffolds with three-dimensional interpenetrating-phase architecture were fabricated through pressureless infiltration of the melt of pure Mg or AZ91D Mg alloy into the porous scaffolds of SiC whiskers. These whiskers were preferentially stacked in-plane within lamellae in the composites using gravity-assisted sedimentation and subsequent densification during the fabrication process. The microstructures and mechanical properties of the composites, particularly their fracture toughness, were characterized and analyzed. The wettability between the SiC whisker scaffolds and the melt was improved by introducing surface reactions between them which was accomplished by a pre-oxidation treatment of the scaffolds before infiltration. The pre-oxidation temperature was adjusted to ensure an adequate filling of the scaffolds without voids while avoiding the formation of excessive reaction products. The resulting composites exhibited a high flexural strength with a certain extent of fracture toughness as evidenced by stable crack propagation with rising R-curve behavior. In comparison to pure Mg, the composites infiltrated with AZ91D Mg alloy as the matrix contained a larger amount of coarsened precipitates, resulting in apparent brittleness despite increased strength.

三维互穿结构SiC晶须骨架增强镁基复合材料制备及其力学性能

[J].选用SiC晶须骨架作为增强相,利用重力辅助沉降、压缩致密化、骨架烧结及无压熔渗的方法制备了具有微观三维互穿结构的SiC晶须骨架增强镁基复合材料,并对其微观组织结构与力学性能(特别是断裂韧性)进行了表征与分析。通过对SiC晶须骨架进行预氧化处理,提高了增强相与基体之间的润湿性,并通过调节预氧化温度控制析出相含量和孔洞等缺陷,优化了复合材料的弯曲强度与断裂韧性,获得了稳定的裂纹扩展行为(上升的R曲线)。相比于以纯Mg为基体的复合材料,以AZ91D镁合金为基体的复合材料中析出相含量高且发生粗化,使得材料强度提高的同时断裂韧性降低。

Alumina-aluminum interpenetrating-phase composites with three-dimensional periodic architecture

[J].

Architecture of high-strength aluminum-matrix composites processed by a novel microcasting technique

[J].As important lightweight structural materials, cast aluminum alloys have been largely used in the transportation and aerospace industries. In general, Al–Si-based alloys comprise more than 90% of all castings due to their excellent castability and corrosion resistance. However, even though various reinforcements have been introduced, the strength of these alloys is not that high, which severely limits their use for certain high-performance applications. Here, we report on a new strategy and technology to reinforce Al–Si alloys to increase their yield strength into the ~400–660 MPa range, a level that is 29–113% higher than that of all current cast Al–Si alloys, laboratory or commercial, and comparable to that of many high-strength steels but with ~40% lower density. By introducing continuous Ti–6Al–4V reinforcements into the Al–Si matrix through a novel microcasting process, the yield strength of the resulting alloy can be enhanced to between 4 and 6 times higher than that of the pure Al–Si alloy. The extraordinary reinforcing effect originates from the occurrence of multiscale strengthening mechanisms, including macroscale compound strengthening (the rule of mixtures amended by crack arrest mechanism), mesoscale strain-gradient strengthening, and microscale interface-affected-zone and nanoparticle strengthening. The core principle of our material design is to make all components of the composite fully participate in plastic (compatible) deformation, and thus, continuous reinforcements, instead of discrete reinforced structures (e.g., particles, whiskers, and short fibers), were introduced into the Al–Si alloy. Combined with 3-D printing technology, the present microcasting process can realize strengthening at the designed position by architecting specific reinforcements in the matrix.

Stress partitioning behavior of multilayered steels during tensile deformation measured by in situ neutron diffraction

[J].

Role of layered structure in ductility improvement of layered Ti-Al metal composite

[J].

Strain field in a brittle/ductile multilayered steel composite

[J].

Back stress strengthening and strain hardening in gradient structure

[J].

Novel Ti-base nanostructure-dendrite composite with enhanced plasticity

[J].Single-phase nanocrystalline materials undergo inhomogeneous plastic deformation under loading at room temperature, which results in a very limited plastic strain (smaller than 0-3%). The materials therefore display low ductility, leading to catastrophic failure, which severely restricts their application. Here, we present a new in situ-formed nanostructured matrix/ductile dendritic phase composite microstructure for Ti-base alloys, which exhibits up to 14.5% compressive plastic strain at room temperature. The new composite microstructure was synthesized on the basis of the appropriate choice of composition, and by using well-controlled solidification conditions. Deformation occurs partially through dislocation movement in dendrites, and partially through a shear-banding mechanism in the nanostructured matrix. The dendrites act as obstacles restricting the excessive deformation by isolating the highly localized shear bands in small, discrete interdendritic regions, and contribute to the plasticity. We suggest that microscale ductile crystalline phases might therefore be used to toughen nanostructured materials.

Deformation behavior of bimodal nanostructured 5083 Al alloys

[J].

Designing metallic glass matrix composites with high toughness and tensile ductility

[J].

Damage-tolerant metallic composites via melt infiltration of additively manufactured preforms

[J].

Lightweight 3D printed Ti6Al4V-AlSi10Mg hybrid composite for impact resistance and armor piercing shielding

[J].

Perspectives of metal-diamond composites additive manufacturing using SLM-SPS and other techniques for increased wear-impact resistance

[J].

Research progress on titanium/aluminum composite plate

[J].

钛/铝复合板研究进展

[J].

Effect of ball milling on structure and thermal stability of Al84Gd6Ni7Co3 glassy powders

[J].

Effect of hydrostatic extrusion at 600-700oC on the structure and properties of Ti-6Al-4V alloy

[J].

Microstructure and tensile properties of Ti-45.5Al-2Cr-2Nb-0.15B alloy processed by hot extrusion

[J].

Ti-45.5Al-2Cr-2Nb-0.15B合金热挤压组织与拉伸性能研究

[J].采用包套近等温热挤压得到Ti-45.5Al-2Cr-2Nb-0.15B合金棒材. 结合有限元数值模拟,研究了挤压变形组织的形成及各部位差异, 获得了棒材不同部位组织与室温拉伸性能的关系.结果表明, 热挤压变形有效细化了片层晶粒尺寸, 棒材轴向各部位组织和室温断后延伸率较为均匀,但径向芯部与边缘差别较大, 且这种径向组织性能差异未能通过后续α单相固溶热处理消除.挤压棒材各部位片层晶粒尺寸随有效应变的增大而减小, 本工作所得挤压棒材中有效应变大于2.25处具有细小均匀组织,而组织类型差异主要由变形过程中的坯料温度变化所致, 其中尾部边缘坯料温度受低温模具激冷作用而迅速下降,相应亚稳α相分解析出γ片层并在后续变形中失稳弯曲而形成界面扭曲的残余片层晶粒.各部位的断后延伸率随片层晶粒尺寸的增大而减小,但芯部断后延伸率较低主要归因于组织中存在片层界面与挤压方向接近垂直的片层晶粒.

Formation process of the bonding joint in Ti/Al diffusion bonding

[J].

Analysis of peeling strength and bonding mechanism of Ti/Al foil interface using ultrasonic consolidation process

[J].

超声固结钛/铝箔材界面剥离强度与结合机理分析

[J].

Deformation behavior of brittle/ductile multilayered composites under interface constraint effect

[J].

Effect of wavy profile on the fabrication and mechanical properties of Al/Ti/Al composites prepared by rolling bonding: Experiments and finite element simulations

[J].

Enhanced materials performance of Al/Ti/Al laminate sheets subjected to cryogenic roll bonding

[J].

Extraordinary room temperature tensile ductility of laminated Ti/Al composite: Roles of anisotropy and strain rate sensitivity

[J].

Fabrication and characterization of high-bonding-strength Al/Ti/Al-laminated composites via cryorolling

[J].

Improving the tensile ductility of metal matrix composites by laminated structure: A coupled X-ray tomography and digital image correlation study

[J].

Influence of annealing on the microstructure and mechanical properties of Ti/Al and Ti/Al/Nb laminated composites

[J].

Laminated Ti-Al composites: Processing, structure and strength

[J].

Manipulating the plastic strain delocalization through ultra-thinned hierarchical design for strength-ductility synergy

[J].

Microstructure and fracture mechanism of Ti/Al layered composite fabricated by explosive welding

[J].

Microstructure and mechanical properties of Ti/Al/Ti laminated composites prepared by hot rolling

[J].

Microstructure and properties of Ti/Al lightweight graded material by direct laser deposition

[J].A novel Ti/Al lightweight graded material was fabricated successfully using the direct laser deposition process, with the composition continuously changing from 100 vol.-% Ti6Al4V to 100 vol.-% AlSi10Mg. Microstructures and phase transformations were characterised, and the mechanical properties of the Ti/Al lightweight graded material were investigated. It was found that element concentrations followed a nearly linear relationship along the compositional gradient. The maximum hardness reached 619 HV in the ‘II’ zones, and then it decreased gradually to 214 HV at the outermost layer, with the increase in the proportion of AlSi10Mg. The values for the ultimate tensile strength were above 400 MPa, and the fracture surfaces indicated a transition from ductile to brittle fracture along the graded direction.

Microstructure, mechanical properties and formability of Ti/Al/Ti laminated composites fabricated by hot-pressing

[J].

Novel twin-roll-cast Ti/Al clad sheets with excellent tensile properties

[J].Pure Ti or Ti alloys are recently spot-lighted in construction industries because they have excellent resistance to corrosions, chemicals, and climates as well as various coloring characteristics, but their wide applications are postponed by their expensiveness and poor formability. We present a new fabrication process of Ti/Al clad sheets by bonding a thin Ti sheet on to a 5052 Al alloy melt during vertical-twin-roll casting. This process has merits of reduced production costs as well as improved tensile properties. In the as-twin-roll-cast clad sheet, the homogeneously cast microstructure existed in the Al alloy substrate side, while the Ti/Al interface did not contain any reaction products, pores, cracks, or lateral delamination, which indicated the successful twin-roll casting. When this sheet was annealed at 350 degrees C-600 degrees C, the metallurgical bonding was expanded by interfacial diffusion, thereby leading to improvement in tensile properties over those calculated by a rule of mixtures. The ductility was also improved over that of 5052-O Al alloy (25%) or pure Ti (25%) by synergic effect of homogeneous deformation due to excellent Ti/Al bonding. This work provides new applications of Ti/Al clad sheets to lightweight-alloy clad sheets requiring excellent formability and corrosion resistance as well as alloy cost saving.

Plastic deformation behaviors of Ti-Al laminated composite fabricated by vacuum hot-pressing

[J].

Revealing extraordinary tensile plasticity in layered Ti-Al metal composite

[J].Layered Ti-Al metal composite (LMC) fabricated by hot-pressing and hot-rolling process displays higher ductility than that of both components. In this paper, a combination of digital image correlation (DIC) and X-ray tomography revealed that strain delocalization and constrained crack distribution are the origin of extraordinary tensile ductility. Strain delocalization was derived from the transfer of strain partitioning between Ti and Al layer, which relieved effectively the strain localization of LMC. Furthermore, the extensive cracks of LMC were restricted in the interface due to constraint effect. Layered architecture constrained the distribution of cracks and significantly relieved the strain localization. Meanwhile, the transfer of strain partitioning and constrained crack distribution were believed to inhibit the strain localization of Ti and change the deformation mechanisms of Ti. Our finding enriches current understanding about simultaneously improving the strength and ductility by structural design.

Simultaneously achieving high tensile strength and fracture toughness of Ti/Ti-Al multilayered composites

[J].

Ti-Al composite wires with high specific strength

[J].

Achieving high combination of strength and ductility of Al matrix composite via in-situ formed Ti-Al3Ti core-shell particle

[J].

Processing and tensile properties of A356 composites containing in situ small-sized Al3Ti particulates

[J].

Microstructure and mechanical behavior of Al-TiAl3 composites containing high content uniform dispersion of TiAl3 particles

[J].

Microstructures and mechanical properties of Al3Ti/Al composites produced in situ by high shearing technology

[J].

Comprehensive structural and mechanical characterization of in-situ Al-Al3Ti nanocomposite modified by heat treatment

[J].

General relationship between strength and hardness

[J].

An investigation of ductile fracture behavior of Ti6Al4V alloy fabricated by selective laser melting

[J].

Scanning speed effect on mechanical properties of Ti-6Al-4V alloy processed by electron beam additive manufacturing

[J].