热加工是变形高温合金得到优异的力学性能和理想组织的最重要工序之一。动态回复和动态再结晶伴随着整个热加工过程。科研人员[7~18]对高温合金及合金钢的热加工行为进行了较多研究,认为温度、应变速率和应变是影响热变形行为和组织的主要因素,并给出了相应的热变形方程和热加工条件。高温合金微观组织中的晶界和沉淀强化相是影响热变形为和组织演变的主要因素。研究者[19~23]系统研究了初始组织为单一组织状态的合金的热变形行为及动态再结晶,例如In718、In625、U720Li和Rene88DT等,但针对粗晶和细晶2种状态的对比研究报道较少。一般来讲,纯金属或合金中的第二相颗粒或溶质原子对动态再结晶行为有重要的影响,例如铝合金中尺寸细小的共格Al3(Er, Zr)相由于限制了位错运动而增加了再结晶抗力[24],热等静压态粉末FGH96合金中大尺寸的蝶形γ'相诱导位错再结晶形核[25],以及变形U720合金通过形成树枝状的γ'相能够在特定温度区间改善热加工塑性[26]。但关于第二相颗粒对高温合金热加工行为和再结晶组织演变及形核机制的影响研究却相对较少。

本工作系统研究了初始晶粒尺寸分别为180、90、45和15 μm的GH4096合金试样,在温度范围1050~1120℃、应变速率0.001~0.1 s-1条件下的热变形行为及组织演变规律,建立了热变形本构方程,并分析了动态再结晶行为机制。通过不同的热处理工艺得到不同状态的γ'相,研究了其对热变形行为和再结晶组织演变的影响规律,旨在为获得工程化生产的高均质化GH4096合金提供理论指导。

1 实验方法

实验采用真空感应熔炼+电渣重熔连续定向凝固工艺熔炼制备直径270 mm的GH4096合金定向凝固铸锭,合金的主要化学成分(质量分数,%)为:Cr 16.0,Co 13.0,W 4.0,Mo 4.0,Ti 3.80,Al 2.20,Nb 0.70,C 0.050,B 0.015,Zr 0.050,Ni余量。定向凝固铸锭经过高温均匀化热处理后,进行约束镦粗开坯,并经3D整体锻造制备得到不同晶粒组织的坯料。一部分热压缩试样取自开坯和3D整体锻造不同火次过程中的坯料,其平均晶粒尺寸分别为180、90、45和15 μm,试样分别标记为d1、d2、d3和d4,用来研究初始晶粒尺寸对热变形行为和动态再结晶组织的影响,应变速率0.1 s-1。另一部分热压缩试样取自经过高温均匀化热处理的铸锭,采用不同的冷却速率得到γ'相平均尺寸为1和2 μm的样品,分别标记为c1和c2,用来研究γ'相对热变形行为和再结晶组织的影响。

热变形实验采用尺寸为直径14 mm、高21 mm的圆柱形试样,利用MTS伺服液压热模拟设备进行压缩实验,实验温度范围为1050~1120℃,应变速率分别为0.001、0.01和0.1 s-1,工程应变在30%~80%之间。试样上下端面涂有玻璃防护润滑剂,以尽可能减小端面摩擦力,热压缩用模具的温度与试样加热温度一致,试样随炉升至实验温度保温15 min后开始压缩,压缩完成后迅速水淬,以保留高温下变形组织。热压缩后的试样沿轴向进行线切割,对试样的剖面依次进行砂纸磨光、机械抛光或电解抛光、腐蚀。采用PM3金相显微镜(OM)对初始组织及热压缩后的微观组织进行观察,采用JSM-7800F扫描电镜(SEM)对压缩后的组织和γ'相进行观察,采用JSM-7800F电子背散射衍射(EBSD)系统对压缩后样品微观组织中的晶界、亚晶界进行识别分析,并采用TECNAI G2 F20透射电镜(TEM)对热变形后的微观组织进行观察。

2 结果与讨论

2.1 热变形前的初始组织

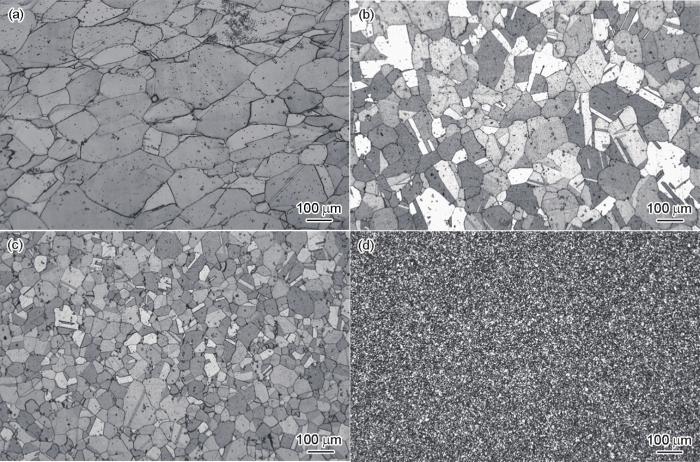

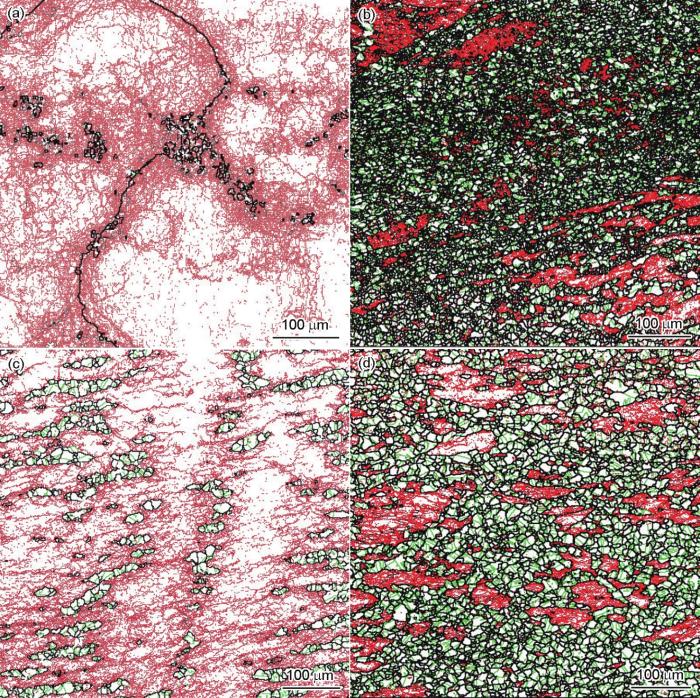

图1为GH4096合金锻态试样d1~d4的显微组织,晶粒均呈现近似等轴状。相较于其他3种试样,细晶状态下的试样d4中一次γ'相数量较多,尺寸较大,起到了钉扎晶界作用。

图1

图1

4种具备不同初始晶粒尺寸的试样(d1~d4)热压缩前金相组织

Fig.1

OM images of d1-d4 samples with different initial grain sizes before hot deformation

(a) d1 (180 μm) (b) d2 (90 μm) (c) d3 (45 μm) (d) d4 (15 μm)

图2

图2

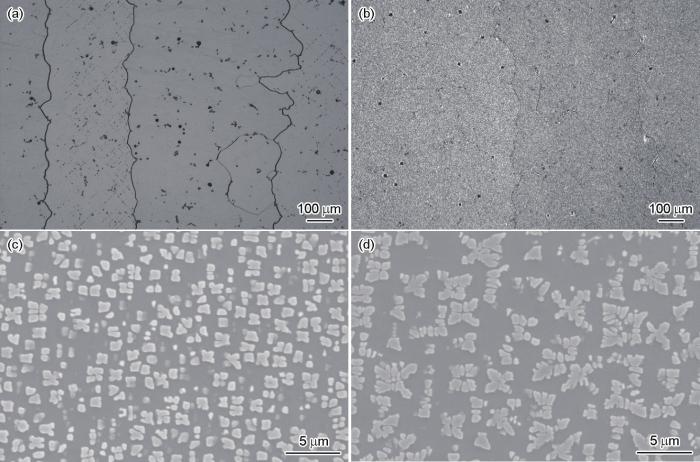

2种铸态试样(c1和c2)经不同工艺处理后热压缩前的组织

Fig.2

OM images (a, b) and SEM images of γ' phase (c, d) of as-cast samples treated by different processes before hot compression (a, c) c1 (1 μm) (b, d) c2 (2 μm)

2.2 初始晶粒尺寸对流变行为的影响

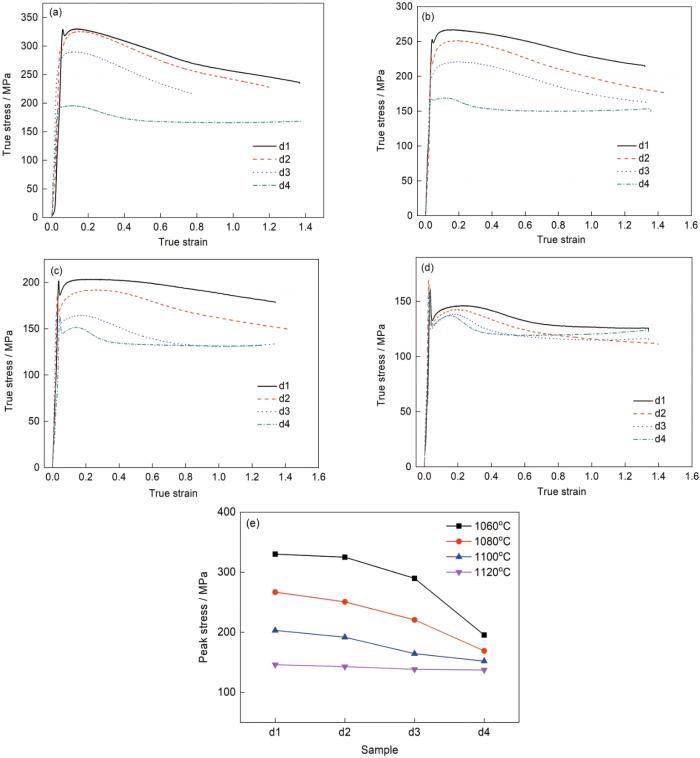

图3a~d给出了试样(d1~d4)在应变速率为0.1 s-1和不同温度热压缩条件下的真应力-真应变曲线。当热变形温度为1060~1100℃时,随着初始晶粒尺寸的减小(即晶界数量和面积的增加),热变形流变应力显著降低。而当热变形温度达到1120℃时,初始晶粒尺寸对流变应力的影响程度降低,达到稳态时应力已经非常接近。图3e给出了初始晶粒尺寸对峰值流变应力的影响,温度≤ 1100℃时,随着初始晶粒尺寸的降低,峰值应力显著降低,而在1120℃热变形时,具有不同初始晶粒尺寸的试样热变形峰值应力之间的差值减小。对于d4试样来说,晶粒尺寸为15 μm,存在相当数量的、尺寸较大的一次γ'相,且一次γ'相与基体失去共格关系,在亚固溶温度范围内(合金强化相γ'相全溶温度为1110℃,低于全溶温度则为亚固溶温度)热变形过程中d4试样相较于其他3组试样流变应力更低,从某种程度上钉扎晶界的非共格一次γ'相对降低热变形抗力有一定贡献。选取了主要元素成分与晶粒尺寸相同的粉末冶金FGH96合金热变形行为[27]进行对比,挤压态FGH96合金中的一次γ'相尺寸和数量明显少于变形GH4096合金;在1050℃、0.1 s-1热变形条件下,挤压态FGH96合金和变形GH4096的峰值流变应力分别为290和195 MPa,相差约100 MPa;而当热变形温度接近于γ'相的全溶温度时,变形抗力差距减小,2种合金的峰值流变应力均为150 MPa左右,从实验的角度上证实了在亚固溶温度下热变形时,一次γ'相可降低热变形流变应力。Zhang等[28]研究指出,对于具有高γ'相含量的高温合金双相细晶组织来说,特殊的γ-γ'相界面能够显著提升热塑性、降低加工流变应力。

图3

图3

不同初始组织试样(d1~d4)在应变速率为0.1 s-1和不同温度下热压缩的真应力-真应变曲线及峰值流变应力曲线

Fig.3

True stress-strain curves (a-d) and peak stress curves (e) of samples d1-d4 under thermal compression at the strain rate of 0.1 s-1 and different temperatures

(a) 1060oC (b) 1080oC (c) 1100oC (d) 1120oC (e) comparison of peak stress

2.3 γ' 相对流变行为的影响

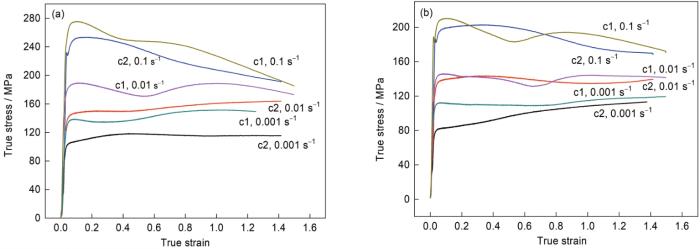

热变形温度为亚固溶温度(1060和1080℃)时,2种铸态试样c1和c2的热变形行为如图4所示。c2试样的峰值流变应力一定程度上低于c1,温度越低流变应力差异越明显,应变速率越低流变应力差异越明显。当应变速率为0.1 s-1时,流变软化现象越明显。粗化的γ'相诱导动态再结晶发生动态软化是导致c2流变应力低于c1的主要原因。铸态试样的缓冷处理使得弥散细小的γ'相发生粗化,导致附近基体中Ti、Al或Nb等原子的贫化。基体中溶质原子对位错有钉扎作用,原本与基体呈共格关系的细小弥散的γ'相阻碍位错运动,难以形成特定的位错结构及增加相应界面取向梯度。随着γ'相的粗化,基体中溶质原子浓度的降低以及与基体逐渐丧失共格关系的γ'相会减小位错运动的阻力,热变形过程中位错更容易开动、滑移,随着变形量的进一步增加,出现位错诱导相界或原始晶界再结晶形核[29]。从另一方面来说,当基体中Ti、Al或Nb等溶质原子贫化时,一定程度上减弱了固溶强化作用,降低了基体强度。Lu等[30]发现GH4742合金在较低温度下热变形,粗化的γ'相可降低变形抗力,有利于动态再结晶。前期针对晶粒度约为ASTM 4级的锻态GH4096合金研究[31]得到,在亚固溶温度范围下热变形时,粗化的γ'相可降低变形抗力。当温度升至1080℃,接近γ'相全溶温度,则γ'相尺寸越小,其动态再结晶的软化效果减弱。Fahrmann和Suzuki[26]在研究Udimet 720合金时发现,热处理后的冷却速率从30℃/s降至0.03℃/s后形成粗化的树枝晶γ'相,极大改善了材料的热加工塑性,并在一定温度范围内有效降低了材料的拉伸强度,较慢的冷却速率形成的γ'相组织能够促进基体中的(111)<110>滑移系的开动,进而得到优异的热加工塑性。

图4

图4

2种铸态试样(c1和c2)在亚固溶温度1060和1080℃下的热压缩流变真应力-真应变曲线

Fig.4

True stress-strain curves of the two samples c1 and c2 in the as-cast state under hot compression at the sub-solvus solution temperatures of 1060oC (a) and 1080oC (b)

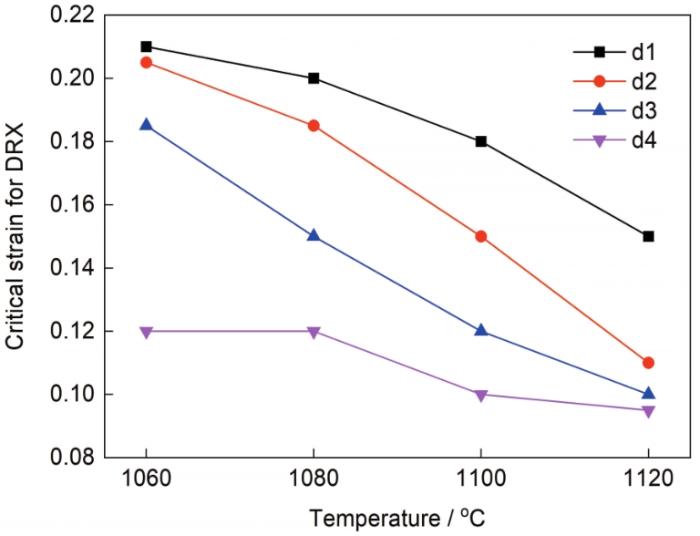

根据应力-应变曲线,对比分析了c1和c2试样的动态再结晶临界应变,如图5所示。在亚固溶温度范围内进行热变形时,粗化的γ'相可降低再结晶临界应变,温度越高,临界再结晶应变越大。在过固溶温度范围内进行热变形时,由于γ′相尺寸差异减小,因此对再结晶行为的影响程度大大降低。

图5

图5

c1和c2试样热压缩过程的动态再结晶临界应变(应变速率为0.1 s-1)

Fig.5

Critical strain of dynamic recrystallization (DRX) of samples c1 and c2 in as-cast state at the strain rate of 0.1 s-1

2.4 基于不同初始晶粒尺寸的热变形本构方程建立

本工作采用Sellars和McTegart[8]提出的双曲正弦函数形式的本构方程描述合金热变形的流变应力与应变速率、变形温度的关系:

式中,

当ασ < 0.8时,

对

根据

同样地,根据

由于流变应力是随着应变不断变化的,所以通过本构方程预测合金流变行为是必不可少的。根据

表1 不同初始组织试样(d1~d4)在不同真应变下热变形的常数α值 (MPa-1)

Table 1

| Sample | 0.1 | 0.2 | 0.4 | 0.6 | 0.8 | 1.0 |

|---|---|---|---|---|---|---|

| d1 | 0.0068 | 0.0066 | 0.0067 | 0.0070 | 0.0073 | 0.0076 |

| d2 | 0.0073 | 0.0069 | 0.0069 | 0.0072 | 0.0078 | 0.0079 |

| d3 | 0.0080 | 0.0079 | 0.0086 | 0.0092 | 0.0099 | 0.0098 |

| d4 | 0.0098 | 0.0098 | 0.0104 | 0.0104 | 0.0103 | 0.0102 |

表2 不同初始组织试样(d1~d4)的平均α值、应力指数n和热变形激活能Q

Table 2

| Sample | α / MPa-1 | n | Q / (kJ·mol-1) |

|---|---|---|---|

| d1 | 0.0070 | 4.64 | 1713 |

| d2 | 0.0074 | 4.27 | 1489 |

| d3 | 0.0087 | 4.09 | 1230 |

| d4 | 0.0010 | 3.27 | 400 |

图6

图6

d2试样峰值应力与应变速率和温度倒数的函数关系

Fig.6

Peak stress of sample d2 as a function of strain rate (

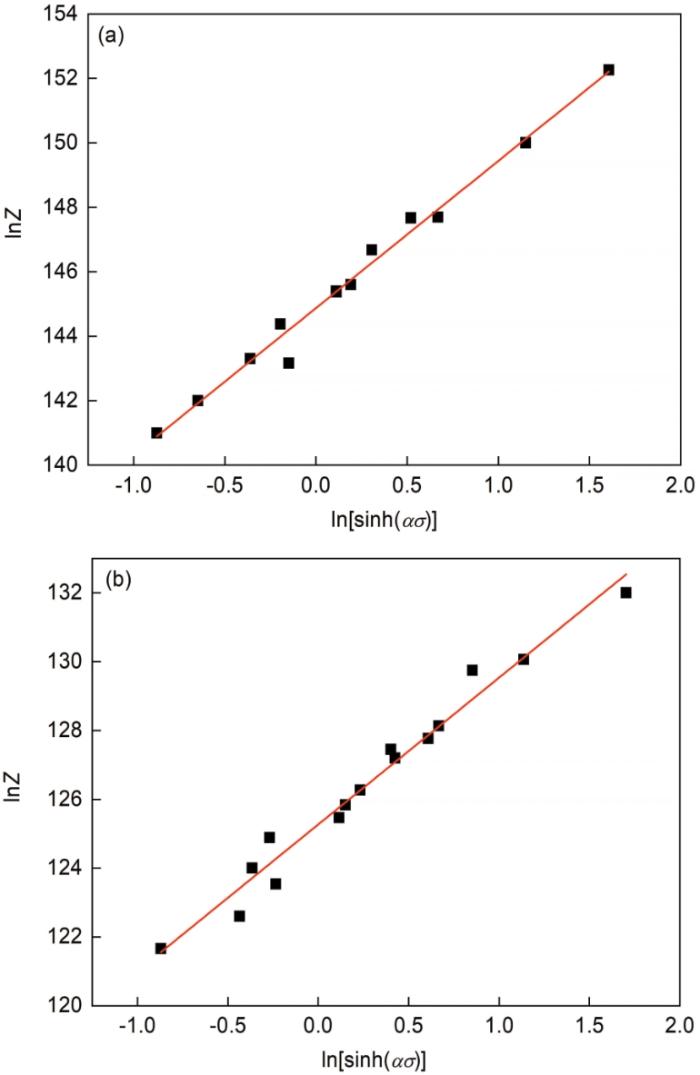

变形温度和应变速率之间可相互补偿,称为温度补偿的应变速率,定义为Z参数,见

图7

图7

不同初始组织试样(d1和d2) Z参数与峰值应力的函数关系

Fig.7

Peak stress of samples d1 (a) and d2 (b) as a function of Z parameters

2.5 初始晶粒尺寸对热变形组织演变规律的影响

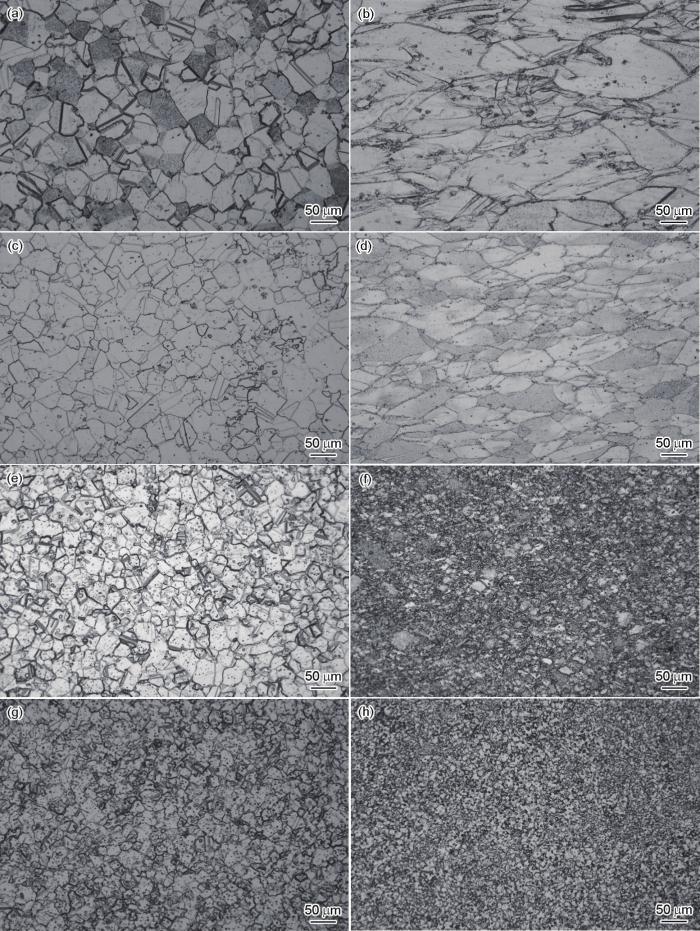

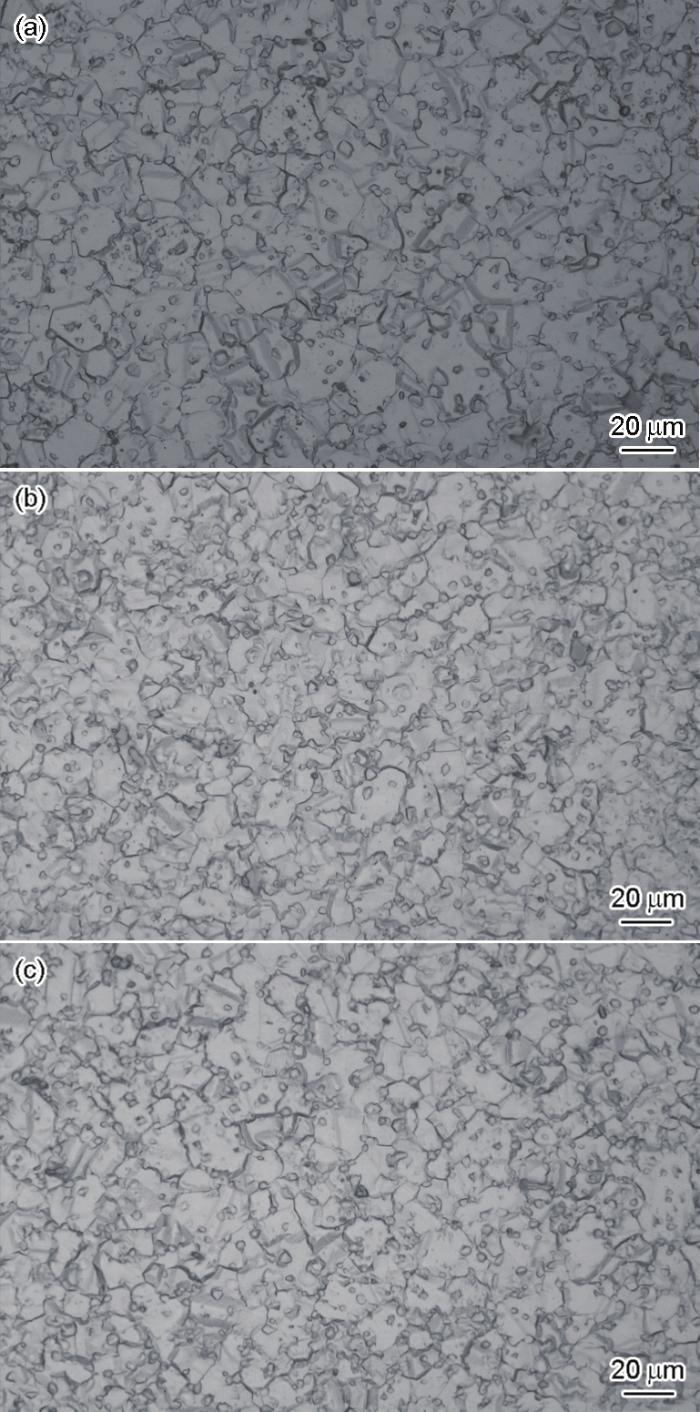

具有不同初始晶粒尺寸试样d1~d4在不同热变形条件下的微观组织如图8所示。工程应变50%、应变速率为0.1 s-1时,温度对动态再结晶的影响最为显著。当温度为1120℃时,4种试样都发生了完全再结晶,初始晶粒尺寸越大,动态再结晶后的新晶粒尺寸越大。当温度为1080℃时,不同初始晶粒尺寸对发生动态再结晶程度的影响较大,初始晶粒尺寸较大的d1和d2试样只观察到了拉长的变形晶粒,金相组织下难以观察到新的再结晶晶粒。d3试样在1080℃只发生了部分动态再结晶,只有当累计变形量达到一定值后,才能实现完全动态再结晶。此外,在亚固溶温度范围热变形时,再结晶的晶粒尺寸不会随着初始晶粒尺寸的改变而变化,初始晶粒尺寸只会影响发生再结晶的体积分数。值得注意的是,如图9所示,对于初始晶粒尺寸为15 μm的d4试样,在低于1100℃进行热变形时,随着应变的增加,发生再结晶的晶粒不再发生细化,工程应变从30%增加到50%,再增加到70%时,晶粒尺寸仍为15 μm左右。对于d4试样,当热变形温度降低至1080和1060℃时,晶粒进一步细化,新的再结晶晶粒尺寸细于初始晶粒尺寸,说明发生了动态再结晶,而当实现了完全动态再结晶以后,继续增加变形量,晶粒尺寸保持不变。因此,对于GH4096合金而言,当热变形温度为亚固溶温度范围时,发生完全动态再结晶的晶粒尺寸不会随着应变的增加而变化。这使工程化生产GH4096合金大尺寸坯料时,采用多个循环的3D整体锻造(多向锻造)获得无变形死区、无混晶组织的高均质化的细晶锻坯成为可能[37]。

图8

图8

不同初始晶粒尺寸的试样(d1~d4)在应变速率为0.1 s-1和工程应变为50%时不同温度下热压缩后的金相组织

Fig.8

OM images of samples d1 (a, b), d2 (c, d), d3 (e, f), and d4 (g, h) under hot compression at different temperatures, the strain rate of 0.1 s-1, and the engineering strain of 50% (a, c, e, g) 1120oC (b, d, f, h) 1080oC

图9

图9

d4试样在1100℃、0.1 s-1下经过不同工程应变热压缩后的OM像

Fig.9

OM images of fine grained d4 sample deformed at 1100oC, 0.1 s-1 and different engineering strains

(a) 30% (b) 50% (c) 70%

为说明初始晶粒尺寸对动态再结晶的影响,依据应力-应变曲线得到了不同初始组织试样的再结晶临界应变。材料发生动态再结晶都具有一定的变形条件参数即Z,一般来说,当应变ε为一定值时,随着Z参数的增加,再结晶的驱动力会减小。当Z参数一定时,随着ε的增加,DRX面积分数会明显增加。因此,存在一个再结晶的临界应变εc,当应变大于εc时,DRX才发生,根据应力-应变曲线就可以确定εc。根据Poliak等[38]和Stewart等[39]提供的方法,即由加工硬化率与应变微分关系可以求出εc。如图10所示,当应变速率为0.1 s-1时,在所有热变形温度下,随着初始晶粒尺寸的减小,发生动态再结晶的临界应变减小,因此,初始晶粒尺寸的细化能促进动态再结晶更早发生。有研究[40]指出,对于GH4720Li合金,更大的初始晶粒尺寸会导致DDRX的延迟,细小初始晶粒尺寸的试样由于更多的晶界数量和面积能够快速实现完全动态再结晶,这与本工作的规律是一致的。

图10

图10

不同初始组织试样(d1~d4)热压缩过程中的动态再结晶临界应变

Fig.10

Dynamic recrystallization critical strain of the samples d1-d4 during thermal compression

2.6 初始晶粒尺寸对动态再结晶行为及软化机制的影响

针对d2试样研究了亚固溶温度下的动态再结晶组织演变规律,并对动态再结晶及软化机制进行分析。图11a~d所示为d2试样在1100℃热压缩后不同取向角度界面的EBSD组织分布图,其中黑色粗实线表示取向差> 15°的大角度界面(high angle grain boundary,HAGB),红色细实线表示取向差在1°~5°范围内的亚界面(subboundary),黑色细实线代表取向差在5°~15°范围之间的小角度界面(low angle grain boundary,LAGB),绿色细实线代表孪晶界。图11a所示为经过工程应变为50%的热变形后原始晶界上发生动态再结晶,再结晶晶粒尺寸细小,在靠近动态再结晶处有大量亚晶分布,沿着变形晶粒内部方向亚晶数量逐渐减少、密度降低。当应变增加至70% (图11b),动态再结晶分数继续增加,形成了典型的再结晶项链组织。当应变继续增加至80%时(图11c和d),动态再结晶分数继续增加达到50%,由于热变形时间较长并伴随产生一定变形热,随着变形量的增加形成的新动态再结晶晶粒尺寸保持不变,在新的再结晶晶粒的晶界附近处仍可见较高密度的亚晶界面,以此循环往复,再结晶以原始晶界弓出亚晶形核的方式逐渐吞噬整个原始晶粒而实现完全动态再结晶。图11e~g对不同变形量下的不同取向差角度界面进行了统计,随着变形量的增加,亚界面和小角度晶界的比例降低,大角度晶界特别是孪晶数量呈现较大比例增加,因此再结晶的过程就是亚晶不断形核长大而被消耗,最后形成大角度界面的再结晶晶粒的过程。

图11

图11

d2试样在1100℃下热压缩后通过EBSD采集到的晶界-亚晶界再结晶组织演化及取向差统计

Fig.11

Grain boundary-subgrain boundary recrystallization structure evolution diagrams (a-d) and orientation analyses (e-g) of d2 sample obtained by EBSD after hot compression at 1100oC (HAGB—high angle grain boundary, LAGB—low angle grain boundary, SB—subgrain boundary) (a, e) 50% engineering strain (b, f) 70% engineering strain (c, d, g) 80% engineering strain

图12为细晶d4试样在1100℃热压缩后不同取向角度界面的EBSD组织分布图,对应不同颜色的实线的标记规则与图11相同,其中一次γ'相被清晰地标记成细实线或粗实线,说明其取向差已经大于5°。当工程应变为30%时,可观察到极少量的亚晶界面;应变增加至50%,亚晶数量有所增加,但亚晶整体数量仍较少,显示已经发生了完全动态再结晶。对于细晶d4试样来说,在亚固溶温度1100℃进行热变形时,随着应变的增加,微观组织中晶粒的尺寸保持不变,这进一步验证了图8中的现象。对比图11和12,在同样的热变形温度1100℃下,原始组织的粗晶和细晶试样得到的动态再结晶晶粒平均尺寸相同均为15 μm左右。同样地,当热变形温度继续降低时规律是一样的,可以认为在亚固溶温度下热变形时,动态再结晶的晶粒尺寸与初始晶粒尺寸无关。

图12

图12

d4试样在1100℃下热压缩后晶界-亚晶界组织的EBSD像

Fig.12

EBSD images of the grain boundary-subgrain boundary recrystallization structure of d4 sample after hot compression at 1100oC

(a) 30% engineering strain (b) 50% engineering strain

为分析初始晶粒尺寸对动态再结晶机制的影响,选取d2和d4试样进行了TEM观察,结果如图13和14所示。图13显示,在1100℃、0.1 s-1条件下d2试样经过30%和50%变形量的热压缩后,晶界附近塞积了大量位错,晶界呈现弯曲弓出的形态。在图13b中观察到了原始晶界处形成了亚晶结构,这与图11中晶界-亚晶界的组织结构特征是一致的,原始晶界是再结晶优先形核的位置。相较于晶内,晶界附近的位错密度更高,累积的储存能更大,储存能的累积量决定了再结晶的热力学条件。亚固溶温度变形时,由于晶界迁移速率小,要在很短时间内形成稳定的核心,必须更多地依赖于晶界迁移驱动力,即要求有更高的累积储存能量。在变形晶粒内部储存能比晶界区小得多,相较于晶内,晶界率先达到形核条件,因此原始晶界附近为优先形核的位置,亚固溶温度下完全再结晶所需的变形量较大。图14所示为d4试样在1100℃、0.1 s-1条件下经过不同变形量后的TEM像。图14a观察到了短的位错线切入到一次γ'相,图14b中相邻的一次γ'相发生合并,位错切入到一次γ'相中并形成堆垛层错(stacking fault,SF),随着变形量的继续增加,如图14c和d中所示,观察到了无位错切入的一次γ'相和堆垛层错剪切的一次γ'相,而大角度晶界处和基体内并未发现位错滑移形成高密度位错塞积的情况。当初始试样为双相细晶组织时,比如d4试样含有较高体积分数的一次γ'相,一次γ'相与基体之间形成了非共格界面(如图12所示),这种非共格相界面具有较强的快速迁移能力,热塑性变形过程中一次γ'相能够参与变形,当位错和层错切入到一次γ'相中,在继续变形过程中,位错能够轻松湮灭而整体保持了较低的位错密度,这是发生了动态再结晶的结果[27,32]。对于GH4096合金锻态组织在亚固溶温度下进行热变形,当初始晶粒尺寸较大时,热变形动态软化机制主要为应变诱导原始晶界弓出亚晶形核的再结晶软化机制;当初始晶粒为细小的双相组织时,其动态软化机制为晶界和第二相非共格界面协同滑移的软化机制。

图13

图13

粗晶d2试样在1100℃、0.1 s-1,工程应变为30%和50%时热压缩后显微组织的TEM像

Fig.13

TEM images of coarsen grained d2 samples after hot compression at 1100oC, 0.1 s-1

(a) 30% engineering strain (b) 50% engineering strain

图14

图14

细晶d4试样在1100℃、0.1 s-1,不同应变热压缩后显微组织的TEM像

Fig.14

TEM images of fine grained d4 samples after hot compression at 1100oC, 0.1 s-1 and different engineering strains (SF—stacking fault)

(a) 30% engineering strain (b) 50% engineering strain (c, d) 70% engineering strain

2.7 γ' 相对动态再结晶行为及软化机制的影响

图15所示为铸态c1和c2试样在亚固溶温度1060和1080℃热变形(50%、0.1 s-1)后晶界-亚晶界EBSD组织分布图。与图11类似,在靠近原始晶界处和已经发生动态再结晶晶粒附近的亚晶界密度较高,距离大角度晶界越远,亚晶界的密度越小。可以看出,c2试样动态再结晶分数显著高于c1。经统计,c2试样在1060℃热压缩后的再结晶分数接近80%,1080℃下也超过60%。c1试样在1060℃下,只在粗大柱状晶的原始晶界附近观察到了零星的动态再结晶晶粒。c1试样的亚晶界数量明显高于c2试样。当温度从1060℃增加逐渐接近于γ'相全溶温度时,在1080℃下 γ'相尺寸减小的同时γ'相体积分数也在减小,γ'相尺寸的减小大大阻碍了再结晶。因此当γ'相尺寸减小而引起再结晶抗力增加时,热变形温度应该控制在更低的温度范围。

图15

图15

铸态试样(c1和c2)热压缩(50%、0.1 s-1)后晶界-亚晶界EBSD像

Fig.15

EBSD images of grain boundary-subgrain boundary of cast samples c1 (a, c) and c2 (b, d) after hot compression (50%, 0.1 s-1)

(a, b) 1060oC (c, d) 1080oC

图16

图16

c2试样经过1060℃、50%、0.1 s-1热变形后显微组织的SEM像及γ'相与再结晶晶粒的交互作用

Fig.16

SEM images of c2 sample after thermal deformation at 1060oC, 50%, and 0.1 s-1, showing the interaction between γ' phase and recrystallized grains

(a) coasening of the γ' phase in the DRX grain boundary (b) DRX grains interacting with γ' phase

图17

图17

铸态试样(c1和c2)经过1060℃、0.1 s-1热压缩(50%)后显微组织的TEM像

Fig.17

TEM images of as-cast c1 and c2 samples after hot compression 50% at 1060oC, 0.1 s-1 (a, b) c1 sample, grain boundary absorbing lots of dislocation lines (c, d) c2 sample, showing γ' stimulated DRX nucleation

式中,

对于包含多种相的合金而言,第二相颗粒对再结晶的重要影响可以归结为3个方面:(1) 可以增加再结晶的储存能和驱动力;(2) 大尺寸的颗粒可以直接成为再结晶的形核位置;(3) 密集分布的细小颗粒对再结晶晶界有显著的钉扎作用。前2个方面的影响主要是促进再结晶,第3方面主要是阻碍再结晶。因此,对于热变形过程中的再结晶行为,特别是再结晶动力学,以及再结晶晶粒尺寸和织构等,依赖于这3个方面中的哪个占主导作用。是否会促进再结晶的发生取决于是否会出现由第二相颗粒产生位错引起的驱动力增加以及颗粒诱导形核(particle stimulated nucleation)。合金中第二相颗粒的尺寸、间距和体积分数等组织特征影响着再结晶的贡献程度和最终的组织特征。有学者[43]在研究Al-Si、Al-Cu合金时指出,相较于基体,当含有尺寸大于1 μm的第二相颗粒且颗粒间距较大时,能够促进动态再结晶发生,同一种合金随着颗粒尺寸和间距的变化,呈现出不同的抑制再结晶或促进再结晶现象,第二相颗粒还能通过对晶界的钉扎作用来影响晶界的形态。

对于层错能较高、容易产生动态回复的合金,动态回复容易使第二相颗粒附近形成的几何必需位错湮灭,因此难以通过第二相颗粒来促进再结晶的发生。对于层错能低的镍基变形合金GH4096来说,铸锭均匀化热处理后通过缓慢的冷却速率或锻态下形成的双相细晶组织,得到粗化的第二相γ'相颗粒,在亚固溶温度下热变形时可有效实现动态软化并促进动态再结晶的发生,同时在较低温度下热变形可得到尺寸非常细小的再结晶晶粒。

3 结论

(1) GH4096合金在热变形温度为1060~1120℃范围内,随着热变形前锻态组织中初始晶粒尺寸的减小,即平均晶粒尺寸从180 μm减小至15 μm,热变形流变峰值应力降低,热变形温度越高流变应力差异越小。建立了与初始晶粒尺寸有关的热变形本构方程。随着初始晶粒尺寸的减小,热变形激活能降低。

(2) 对于锻态GH4096合金,随着初始晶粒尺寸的减小,相同热变形条件下的动态再结晶分数更高,发生动态再结晶的临界应变降低。在过固溶温度下热变形时,随着初始晶粒尺寸的减小,动态再结晶晶粒尺寸减小;在亚固溶温度下热变形时,动态再结晶晶粒尺寸与初始晶粒尺寸无关,且与变形量无关。

(3) 对于锻态GH4096合金,在亚固溶温度下热变形时,初始晶粒尺寸大的粗晶试样动态软化机制为原始晶界弓出亚晶形核的动态再结晶机制;对于初始晶粒尺寸细小的双相细晶试样,热变形是以原始晶界及强化相的非共格相界面协同滑移为主导的动态软化机制。

(4) 对于铸态GH4096合金,随着γ'相尺寸和间距的增加,亚固溶温度下热变形抗力降低,发生再结晶的临界应变降低,动态再结晶分数增加,亚固溶温度下的动态软化机制主要为原始晶界弓出再结晶形核和粗化第二相诱导再结晶形核软化机制。

参考文献

Development and testing of novel casted & wrought GH4096 alloy labyrinth disk

[J].

新型铸&锻GH4096合金篦齿盘研制与考核

[J].

Development of wrought superalloy in China

[J].

中国变形高温合金研制进展

[J].

The disk superalloys and disk manufacturing technologies for advanced aero engine

[J].

先进航空发动机涡轮盘合金及涡轮盘制造

[J].

Structure and hot deformation behavior of ESR-CDS René88DT

[J].

电渣重熔连续定向凝固René88DT合金的组织与热变形行为

[J].

Research progress of wrought superalloys in China

[J].Wrought superalloys are high temperature alloys produced by casting-forging-hot rollingcold drawing, including disc, plate, bar, wire, tape, pipe etc. These products are widely used in aviation, aerospace, energy, petrochemical, nuclear power and other industrial fields. In this paper, domestic progress of wrought superalloys in recent ten years was reviewed, including advances in fabrication process, research in new alloys (GH4169G, GH4169D, GH4065 and GH4068 alloy et al.) and new techniques (deforming of FGH4096 alloy, nitriding of NGH5011 alloy and 3D printing of In718 alloy et al.).

国内变形高温合金研制进展

[J].

Present research situation and prospect of hot working of cast & wrought superalloys for aero-engine turbine disk in China

[J].In recent years, the demand for high-performance aero-engines has become crucial in China, and the service environment of turbine disk alloy becomes increasingly severe. A series of high resistant cast & wrought superalloys for turbine disks, such as GH4065, GH4720Li, GH4068, and GH4151, with working temperatures > 700°C, have been studied, produced, and applied widely. The current studies on cast & wrought alloys for turbine disks in China were summarized under the categories of homogenization treatment, cogging, disk forging, and microstructure and property regulation to promote the development of these superalloys and improve their comprehensive properties. The difficulties encountered during the research and preparation of these hard-to-deform superalloys and explored the alloys' potential development trend were outlined. The review would improve the production stability of the disk superalloys and promote their development.

国内航空发动机涡轮盘用铸锻难变形高温合金热加工研究现状与展望

[J].

On the mechanism of hot deformation

[J].

High temperature deformation behavior of hot isostatically pressed P/M FGH4096 superalloy

[J].

Tensile deformation behavior of superalloy 718 at elevated temperatures

[J].

Hot deformation behaviour of Mg-3Al alloy—A study using processing map

[J].

Deformation characteristics of isothermally forged UDIMET 720 nickel-base superalloy

[J].

Effect of processing parameters on hot compressive deformation behavior of a new Ni-Cr-Co based P/M superalloy

[J].

Hot deformation behavior of hot extruded Al-6Mg alloy

[J].

Characterization of hot deformation behavior of a P/M nickel-base superalloy using processing map and activation energy

[J].

Optimization of hot working parameters for thermo-mechanical processing of modified 9Cr-1Mo (P91) steel employing dynamic materials model

[J].

An advanced cast-and-wrought superalloy (TMW-4M3) for turbine disk applications beyond 700oC

[A].

Hot deformation behavior of the post-cogging FGH4096 superalloy with fine equiaxed microstructure

[J].

Hot deformation behavior of a medium carbon microalloyed steel

[J].

High-temperature deformation of inconel 718PlusTM

[J].

Control of grain size via forging strain rate limits for R'88DT

[A].

Hot deformation characteristics of GH625 and development of a processing map

[J].

Hot deformation behavior of delta-processed superalloy 718

[J].

Effects of Er and Zr additions on precipitation and recrystallization of pure aluminum

[J].

Recrystallization of the hot isostatic pressed nickel-base superalloy FGH4096: I. Microstructure and mechanism

[J].

Effect of cooling rate on gleeble hot ductility of UDIMET alloy 720 billet

[A].

Effect of original microstructure on thermal compression deformation behavior and microstructure of FGH96 alloy

[J].

原始组织对FGH96合金热压缩变形行为和组织的影响

[J].

Deformation mechanisms and microstructural evolution of γ + γ' duplex aggregates generated during thermomechanical processing of nickel-base superalloys

[A].

Microstructure evolution and deformation mechanisms of the electroslag refined-continuous directionally solidified (ESR-CDS®) superalloy Rene88DT during isothermal compression

[J].

Effect of slow cooling treatment on hot deformation behavior of GH4742 superalloy

[J].

Impact of γ' (Ni3(Al, Ti)) phase on dynamic recrystallization of a Ni-based disk superalloy during isothermal compression

[J].

Study of hot deformation behavior of Ni-Cr-W base superalloy

[D].

Ni-Cr-W基高温合金的热变形行为研究

[D].

Effect of the δ phase on the hot deformation behavior of Inconel l718

[J].

Dependency of recrystallization mechanism to the initial grain size

[J].

Dynamic recrystallization in ultra fine-grained 304 stainless steel

[J].

Grain size effect on the warm deformation behaviour of a Ti-IF steel

[J].

Application of multiple integral forging in preparation of wrought superalloy FGH96 turbine disk

[J].

多向整体锻造在变形FGH96合金涡轮盘制备中的应用

[J].

Initiation of dynamic recrystallization in constant strain rate hot deformation

[J].

Kinetics and critical conditions for the initiation of dynamic recrystallization in 304 stainless Steel

[J].

The feasibility and process control of uniform equiaxed grains by hot deformation in GH4720Li alloy with millimeter-level coarse grains

[J].For nickel-based GH4720Li superalloys, fine-grained structures can be obtained via hot deformation in a two-phase area. However, obvious recrystallized grains' coarsening occurs because of the lack of prime γ' pinning grain boundary when hot deformation occurs in a single-phase area. Much attention is directed to the hot deformation of GH4720Li alloys with fine grains. Moreover, several studies have reported the hot deformation behavior of coarse-grained GH4720Li alloys, with maximum grain sizes of several hundred microns. However, only a few studies report about the hot deformation of GH4720Li alloy with millimeter-level coarse grains. Coarse grains recrystallize incompletely and can reduce the hot deformation plasticity of GH4720Li alloy. Thus, to clarify the coordination feasibility between recrystallization and the hot deformation plasticity of GH4720Li alloy with millimeter-level coarse grains, the hot deformation behavior of GH4720Li alloy with millimeter-level coarse grains was investigated under different deformation parameters (deformation temperature of 1130, 1160, and 1190°C; strain rates of 0.001, 0.01, 0.1, and 1 s-1; and engineering strain of 50%) and compared with the hot deformation behavior of fine-grained GH4720Li alloy. The results show that the GH4720Li sample with millimeter-level coarse grains is more sensitive to the deformation temperature, but the fine-grained GH4720Li alloy is more sensitive to strain rate. The completely recrystallized structure of the GH4720Li sample with millimeter-level coarse grains can be obtained in the range of 1160-1190°C and 0.001-0.01 s-1. However, a meager strain rate can cause an undesirable and obvious grain growth. After comprehensively combining the recrystallization control range and the hot deformation plasticity of millimeter-level coarse-grained GH4720Li alloy, it was found that the millimeter-level coarse-grained GH4720Li alloy should be thermally deformed at a moderate deformation temperature and a reduced strain rate of 1160oC and 0.01 s-1, respectively, to obtain the uniform equiaxed grains structure without cracking, and better deformation.

GH4720Li合金毫米级粗大晶粒热变形获得均匀等轴晶粒的可行性及工艺控制

[J].

Precipitation and recrystallisation in Al-Mn-Zr with and without Sc

[J].

Dynamic softening mechanisms of GH4720Li alloy during hot deformation

[J].

GH4720Li合金热变形过程动态软化机制

[J].以锻态GH4720Li镍基沉淀强化型高温合金为研究对象,对合金进行了不同工艺参数下的热压缩实验。采用OM、SEM、EBSD和TEM研究了热压缩过程中再结晶晶粒的形成和晶粒内亚结构的演变规律,分析了合金在不同热变形工艺参数下的动态软化机制。研究表明,合金在所有热变形工艺参数下均发生了非连续动态再结晶行为。变形组织分析表明,高温低应变速率能够抑制非连续动态再结晶行为的发生,而提高应变速率能促进非连续动态再结晶行为,且能够获得等轴状尺寸均匀的晶粒组织。未完全溶解细小γ'强化相的钉扎作用能够使变形晶粒内形成高密度位错亚结构和亚晶界,亚晶界角度通过连续的吸收位错而不断地升高,进而以“强化相诱发连续动态再结晶”方式形成细小的再结晶晶粒组织。不同热变形工艺下孪晶界的演变规律分析表明,热变形温度与应变速率通过影响合金的动态再结晶行为来改变孪晶界的数量。