长期以来,偏晶合金的凝固行为受到广泛关注。早期,人们认为重力引起的两液相间的比重差导致偏析型组织形成,在空间微重力环境下应形成弥散型复合凝固组织,然而,空间的实验结果出乎人们预料,虽然在微重力条件下凝固的试样中不再存在比重偏析,但仍然呈现了两相分离的组织[6~9]。这些结果表明,重力不是决定偏晶合金凝固组织形成的唯一因素,相间界面能、熔体内温度梯度、浓度梯度及其导致的熔体对流和弥散相液滴迁移等均影响偏晶合金的凝固过程及组织。此后,人们在地面、空间开展了大量的凝固实验[10~20],并结合实验开展了建模与模拟[21~30]工作,研究表明,偏晶合金凝固组织的形成过程十分复杂,是合金热力学、凝固动力学(第二相液滴的形核、长大/粗化、空间迁移、碰撞凝并等)以及重力等外场共同作用的结果,尤其是在重力条件下的熔体对流使各种影响因素的作用相互混淆[31],给凝固过程研究带来极大困难;快速/亚快速凝固不仅能提高液-液相变的过冷度和弥散相液滴的形核率,而且能缩短偏晶合金熔体穿越不混溶温度区间的时间,从而有效抑制相偏析,促进偏晶合金形成弥散型凝固组织,有利于偏晶合金凝固过程研究;微重力环境能有效弱化或消除重力导致的熔体对流及其混淆作用,有利于揭示偏晶合金凝固过程及凝固组织形成机理[19,26~28],是研究偏晶合金凝固过程的有效途径之一。

本工作对Gd-Co-Ti合金开展了落管微重力条件下的凝固实验,建立了Gd-Co-Ti合金凝固理论模型,将实验与模拟相结合,研究了Gd-Co-Ti合金凝固组织的形成过程。

1 实验方法

以纯度大于或等于99.9% (质量分数,下同)的Gd、Co和Ti为原料,按Gd-2%Co-2%Ti (质量分数)合金成分进行配料。实验过程如下:首先将金属原料置于电弧熔炼炉内的水冷铜坩埚中,在高纯Ar气保护下将金属原料反复熔炼4次以上,确保获得成分均匀的母合金锭;随后,将母合金锭置于底部带有喷嘴的石英管中,在高纯Ar气气氛下采用高频感应加热对其进行重熔并喷铸到铜模内,获得直径3 mm、长度50~60 mm的圆柱形母合金料棒;最后,将适量的圆柱形母合金料棒置于底部带有喷嘴的石英管中,并将其装入50 m真空落管顶端的感应加热装置内,抽真空至1 × 10-4 Pa,利用高频感应加热熔化试样并过热约100 K,保温3 min后短暂向石英管中通入高纯Ar气(约0.12 MPa)使合金熔体经喷嘴分散成不同尺寸(285、355、420、445和710 μm)的液滴。这些液滴在自由落体运动过程中实现快速/亚快速冷却,尺寸较小的样品在下落过程中凝固,呈球形。收集球形样品后对其进行研磨、抛光,制备金相样品。利用Axio Observer Z1光学显微镜(OM)和配有能谱仪(EDS)的Inspect F50扫描电子显微镜(SEM)观察合金的显微组织并测定合金中相的化学组分。采用SISC IAS V8.0定量金相分析软件统计第二相粒子的尺寸分布和平均半径。

2 结果与讨论

2.1 合金凝固组织

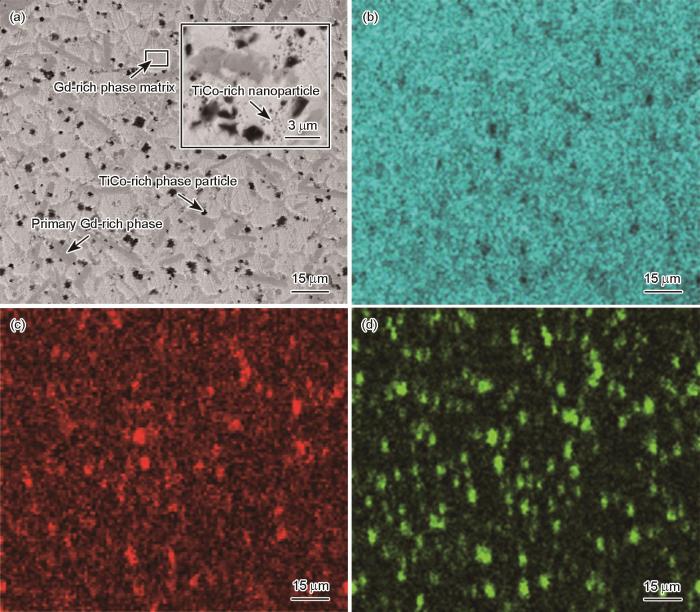

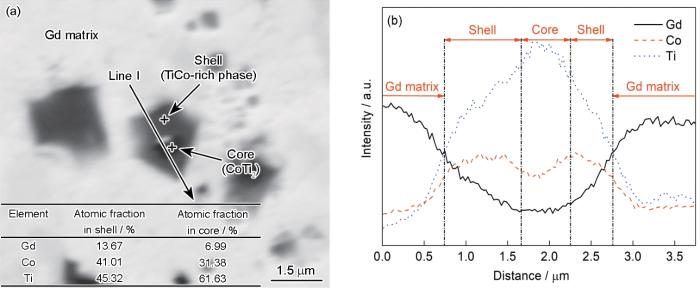

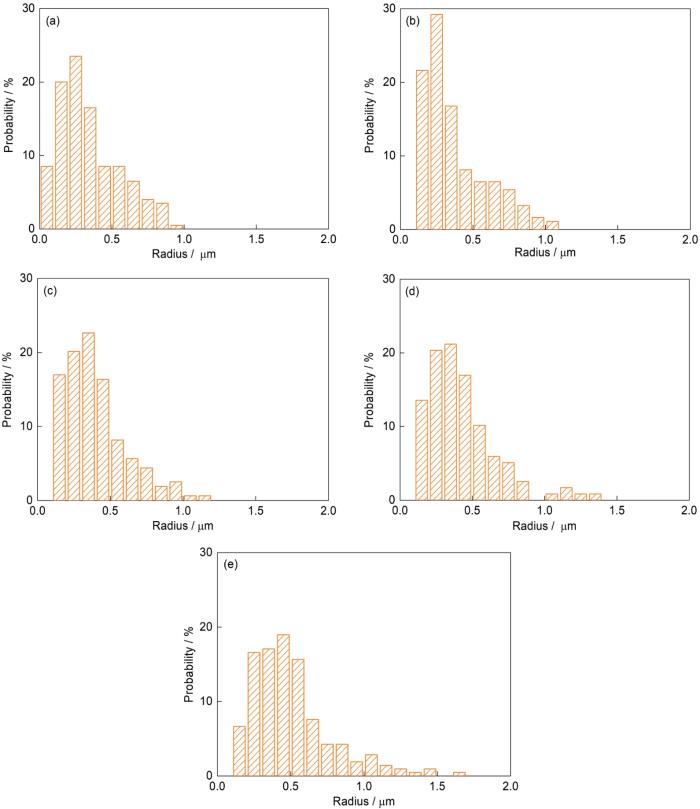

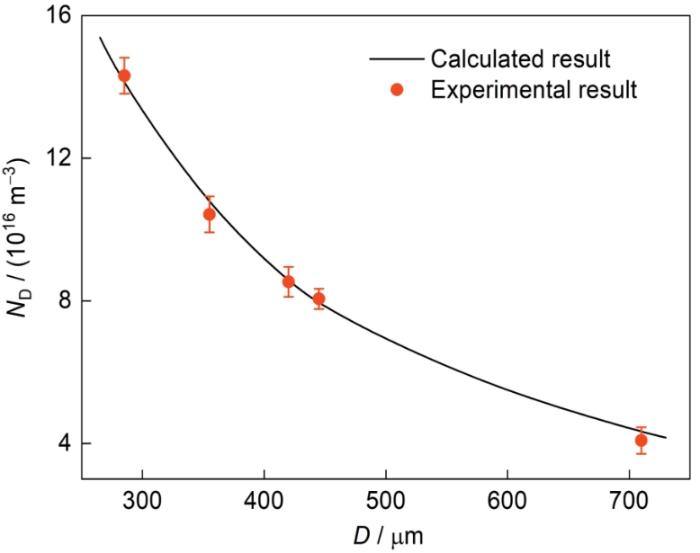

图1为Gd-2%Co-2%Ti合金样品的宏观形貌及不同尺寸样品心部显微组织的SEM像。可以看出,样品表面附近区域黑色粒子的数密度较样品内部低;各样品的组织均由浅灰色的基体相、深灰色的粗大块状相和均匀分布于基体内的黑色粒子与灰色纳米粒子组成。为了确定各相的组成,对直径为445 μm的Gd-2%Co-2%Ti合金样品开展了进一步表征分析。图2为该样品心部显微组织的SEM像和元素面分布图。可见,浅灰色基体为富Gd相,深灰色的块状相为初生富Gd相,黑色粒子为富TiCo相。黑色富TiCo相粒子具有壳核结构,外层壳为富TiCo相,内层核为CoTi2化合物,如图3所示。根据Gd-Co-Ti合金相图与前期研究[32,33]可知,尺寸较小的灰色纳米粒子为合金凝固后冷却过程中沉淀析出的富TiCo相。图4和5分别为不同尺寸合金样品中黑色富TiCo相粒子的二维尺寸分布图和数密度。可见,随着合金样品尺寸的增加,富TiCo相粒子的尺寸分布宽度逐渐增大,数密度逐渐减小。

图1

图1

Gd-2%Co-2%Ti合金样品的宏观形貌和直径分别为285、355、420、445和710 μm的样品心部微观组织的SEM像

Fig.1

Macromorphology of Gd-2%Co-2%Ti alloy sample (a) and SEM images showing the microstructures at the center region of the samples with diameters of 285 μm (b), 355 μm (c), 420 μm (d), 445 μm (e), and 710 μm (f)

图2

图2

直径为445 μm的Gd-2%Co-2%Ti合金样品心部显微组织的SEM像和元素面分布图

Fig.2

SEM image of Gd-2%Co-2%Ti alloy sample with a diameter of 445 μm (a), and corresponding EDS element mappings of Gd (b), Co (c), and Ti (d) at the center region

图3

图3

直径为445 μm的Gd-2%Co-2%Ti合金样品中富TiCo相粒子的SEM像及其外层壳与内层核的EDS点扫描结果,及Gd、Co、Ti元素沿直线I的线扫描结果

Fig.3

SEM image of shell/core TiCo-rich particle and the EDS point scanning results (inset) for the shell and core (a) and element line scanning results for Gd, Co, and Ti along line I in Fig.3a (b) of the Gd-2%Co-2%Ti alloy sample with a diameter of 445 μm (Shell and core represent the outer shell and inner core of TiCo-rich particle, respectively)

图4

图4

直径分别为285、355、420、445和710 μm的Gd-2%Co-2%Ti合金样品中富TiCo相粒子的二维尺寸分布

Fig.4

2D size distributions of the TiCo-rich particles in the Gd-2%Co-2%Ti alloy samples with diameters of 285 μm (a), 355 μm (b), 420 μm (c), 445 μm (d), and 710 μm (e)

图5

图5

Gd-2%Co-2%Ti合金样品中富TiCo相粒子的数密度(ND)随样品尺寸(D)的变化

Fig.5

Number density (ND) of the TiCo-rich particles in the Gd-2%Co-2%Ti alloy sample vs sample size (D)

2.2 合金凝固路径及组织形成分析

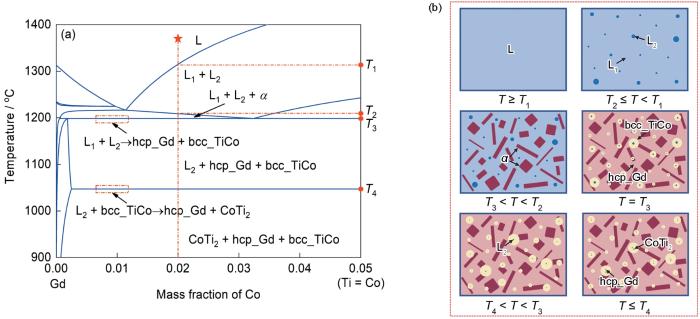

基于Gd-Co-Ti合金的热力学数据[32]计算了Gd-Co-Ti体系相图。图6为Gd-Co-Ti体系wCo∶wTi = 1∶1的垂直截面图(wCo和wTi分别表示溶质Co和溶质Ti的质量分数)和平衡条件下Gd-2%Co-2%Ti合金的凝固过程示意图。可见,当Gd-2%Co-2%Ti合金熔体温度高于平衡组元互溶温度T1 = 1315.0 ℃时,所有组元可完全互溶,形成均一熔体;当合金熔体温度低于T1时,合金熔体进入组元难混溶区间,发生液-液相变(L→L1 + L2),从基体熔体中析出富TiCo相液滴L2;当温度低于液-液-固相变开始温度T2 = 1208.9 ℃时,进入合金的液-液-固三相区,从基体熔体L1中不断析出初生富Gd相,富TiCo相液滴则继续长大;当温度降至零变反应1温度T3 = 1198.6 ℃时,发生零变反应1 (L1 + L2→hcp_Gd + bcc_TiCo,此时体系处于四相平衡,体系的自由度为零),基体熔体L1与富TiCo相液滴L2的表层反应生成富Gd固相(hcp_Gd相)和富TiCo固相(bcc_TiCo相)壳,此时壳的内部仍为液态L2,较小尺寸L2液滴表层的富TiCo固相在生长时仍保持球形,较大尺寸L2液滴表层的富TiCo相则由于生长的各向异性而变为非球形;随着温度的继续降低,进入液-固-固相区,富TiCo固相壳内的液相L2中溶质Ti和Co的溶解度不断降低,液相L2内不断析出bcc_TiCo相,该反应导致富TiCo固相壳向内部生长;当温度降至零变反应2温度T4 = 1047.1 ℃时,发生零变反应2 (L2 + bcc_TiCo→hcp_Gd + CoTi2),富TiCo相壳内的液相L2与富TiCo固相反应,生成富Gd固相(hcp_Gd相)和CoTi2化合物,至此,液-液相变区间内形核的L2相液滴完全凝固,形成凝固组织中具有壳核结构的黑色富TiCo相粒子,与实验结果一致。零变反应1发生后,在继续冷却的过程中,溶质Ti和Co在基体Gd中的溶解度不断降低,导致TiCo脱溶析出、形成富TiCo纳米粒子。本工作主要关注液-液相变过程及其导致的原位富TiCo相粒子复合凝固组织的形成。

图6

图6

Gd-Co-Ti体系溶质Co和Ti质量比wCo∶wTi = 1∶1的垂直截面图和平衡条件下Gd-2%Co-2%Ti合金的凝固过程示意图

Fig.6

Verical section of wCo∶wTi = 1∶1 for the phase diagram of the Gd-Co-Ti system (a) and schematic of the solidification process of the Gd-2%Co-2%Ti alloy under equilibrium conditions (b) (wCo and wTi—mass fractions of solutes Co and Ti, respectively. L1 + L2 represents liquid-liquid phase transformation region. T—temperature. T1, T2, T3, and T4 represent the equilibrium binodal line temperature, onset temperature of liquid-liquid-solid phase transformation, and temperatures of the invariant reactions 1 and 2, respectively)

2.3 原位粒子复合凝固组织形成过程模型

由上述凝固组织及其形成过程的分析可知,在液-液相变区间,富TiCo相液滴从合金熔体中形核、析出并发生扩散长大;进入液-液-固相区后,富TiCo相液滴继续长大;当合金熔体降温至零变反应1温度时,在富TiCo相液滴的表面形成富TiCo固相壳。此后涉及富TiCo相的相变过程和零变反应均在富TiCo固相壳的内部进行,不会改变富TiCo固相的数密度与空间分布。

f(R, r, t)满足如下连续方程[35]:

式中,

当均一的Gd-Co-Ti合金熔体冷却至液-液不混溶区间时,ID可用经典形核理论来表示[37]:

式中,N0为单位体积基体熔体中的原子数目;nc为

vD可表示为[38]:

式中,

富TiCo相液滴形核后,在界面张力梯度下发生Marangoni迁移,uM可表示为[39]:

式中,λm和λβ 分别为基体熔体和富TiCo相液滴的热导率,ηm和ηβ 分别为基体熔体和富TiCo相液滴的黏度,

液滴在落管中自由下落时,温度场满足如下方程[35]:

式中,λmix为合金的热导率;ρβ 、ρm和ρmix分别为富TiCo相液滴、基体熔体和合金的密度;

液滴内的浓度场满足如下方程[35]:

式中,φl为富TiCo相液滴的体积分数,

采用有限体积法将上述富TiCo相液滴的半径分布函数、温度场和浓度场控制方程离散,并与Gd-Co-Ti合金相图耦合求解,可以模拟落管条件下Gd-Co-Ti合金液滴凝固组织形成过程。

在模拟计算过程中,ηm用下式计算[40]:

式中,NA为Avogadro常数。

Di 用Sutherland-Einstein方程计算[41]:

式中,ri 为溶质i的原子半径。

由于本工作选取的合金成分中Ti和Co的质量比约为1∶1,富TiCo相液滴中Ti和Co的原子比约为2.27,液滴的扩散长大需要更多的溶质Ti,且溶质Ti的扩散系数小于溶质Co,因此,在计算过程中认为富TiCo相液滴的扩散长大由溶质Ti控制,上述式(

研究[41]表明,液-液界面能对温度的依赖关系可用如下经验公式计算:

用上述相同的方法拟合确定了h:选取不同的h计算直径为420 μm的Gd-2%Co-2%Ti合金试样在落管条件下的凝固过程及样品心部富TiCo相的数密度,将计算结果与实验结果进行比较,确定h = 190 W/(m2·K);然后,利用上述σ0和h计算不同尺寸Gd-Co-Ti合金样品凝固组织的形成过程,计算值与实验统计值吻合良好,如图5所示,进一步验证σ0和h选取的正确性以及所建模型的可靠性。

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Thermal conductivity of liquid Gd | 16.0 | W·K-1·m-1 | |

| Thermal conductivity of liquid Co | 42.42 | W·K-1·m-1 | |

| Thermal conductivity of liquid Ti | 36.82 | W·K-1·m-1 | |

| Thermal conductivity of solid Gd | 8.0 | W·K-1·m-1 | |

| Thermal conductivity of solid Co | 69.04 | W·K-1·m-1 | |

| Thermal conductivity of solid Ti | 21.8 | W·K-1·m-1 | |

| Density of liquid Gd | 7410 - 0.46(T - 1585) | kg·m-3 | |

| Density of liquid Co | 7750 - 1.09(T - 1768) | kg·m-3 | |

| Density of liquid Ti | 4130 - 0.23(T - 1941) | kg·m-3 | |

| Density of solid Gd | 7900 | kg·m-3 | |

| Density of solid Co | 8860 | kg·m-3 | |

| Density of solid Ti | 4510 | kg·m-3 | |

| Specific heat capacity of liquid Gd | 213 | J·kg-1·K-1 | |

| Specific heat capacity of liquid Co | 590 | J·kg-1·K-1 | |

| Specific heat capacity of liquid Ti | 700 | J·kg-1·K-1 | |

| Specific heat capacity of solid Gd | 116 | J·kg-1·K-1 | |

| Specific heat capacity of solid Co | 427 | J·kg-1·K-1 | |

| Specific heat capacity of solid Ti | 500 | J·kg-1·K-1 | |

| Latent heat of solidification of pure Gd | 9.87 × 104 | J·kg-1 | |

| Latent heat of solidification of pure Co | 2.63 × 105 | J·kg-1 | |

| Latent heat of solidification of pure Ti | 3.66 × 105 | J·kg-1 |

2.4 合金凝固组织形成过程

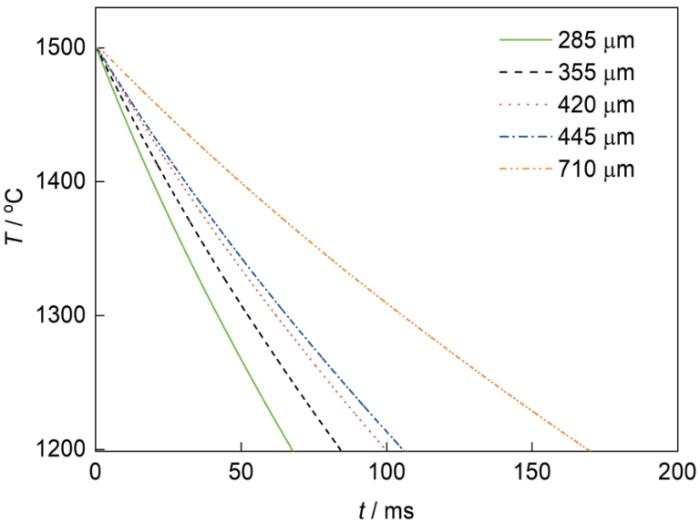

图7为不同尺寸Gd-2%Co-2%Ti合金样品心部温度随时间的变化。可见,样品的尺寸越大,其冷却速率越慢。图8为直径为445 μm的Gd-2%Co-2%Ti合金样品心部基体熔体过饱和度,富TiCo相液滴的形核率、数密度、平衡体积分数、实际体积分数以及初生富Gd固相平衡体积分数随时间的变化。可见,当合金熔体冷却至液态组元不混溶温度区间后,随着温度的降低,熔体过饱和度逐渐增大。当过饱和度增大至6.11 × 10-3 (摩尔分数)时,富TiCo相液滴的形核率达到106 m-3·s-1,表明液-液相变开始,富TiCo相液滴开始从合金熔体中形核析出。此后,合金熔体的过饱和度并未立即下降,而是继续增加直至达到8.23 × 10-3 (摩尔分数)。这是因为形核开始后基体熔体过饱和度的变化取决于2方面:(1) 富TiCo相液滴的形核和扩散长大消耗溶质,使熔体过饱和度降低;(2) 合金熔体不断冷却使熔体过饱和度增加。在初始形核期间,富TiCo相液滴的形核率、体积分数均较低,此时液滴形核和长大所导致的过饱和度减小相对弱于熔体冷却所导致的过饱和度增加,因此,熔体过饱和度不仅不减小,反而增加。过饱和度的增加导致富TiCo相液滴的形核率急剧上升,因此,在形核开始后不久,富TiCo相液滴形核和长大成为决定过饱和度变化的主要因素,过饱和度迅速减小,形核停止。随着温度继续下降,初生富Gd固相开始从合金熔体中形核析出,大量溶质Ti和Co被排出到基体液相中,过饱和度再次增加,但该阶段内熔体的过饱和度始终没有达到形核所需的临界值,因此,未发生富TiCo相液滴再次形核的现象,即:富TiCo相液滴的形核仅发生在液-液相变温度区间。由于快速/亚快速凝固条件下合金熔体的冷却速率较大,属于非平衡凝固,因此,富TiCo相液滴的实际体积分数与平衡体积分数存在差异。

图7

图7

不同尺寸Gd-2%Co-2%Ti合金样品心部温度随时间(t)的变化

Fig.7

Dependence of temperature at the center of the Gd-2%Co-2%Ti alloy samples with different diameters on time (t)

图8

图8

直径为445 μm的Gd-2%Co-2%Ti合金样品心部基体熔体过饱和度(S),富TiCo相液滴的形核率(ID)、ND、平衡体积分数(φ

Fig.8

Supersaturation of the matrix liquid (S), nucleation rate (ID) and number density (ND) of the TiCo-rich droplets (a), equilibrium volume fraction (φ

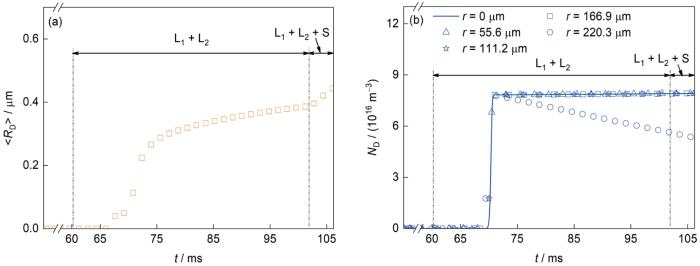

图9为直径为445 μm的Gd-2%Co-2%Ti合金样品心部富TiCo相液滴的平均半径(<RD>)和距离样品中心不同位置处富TiCo相液滴数密度随时间的变化。结合图8a可以看出,在富TiCo相液滴形核阶段,由于小液滴的不断形成,富TiCo相液滴的平均半径缓慢增加。形核停止后,富TiCo相液滴在较高的过饱和度下快速长大,其平均半径迅速增加。随后过饱和度降低,富TiCo相液滴的长大速率下降。当合金熔体进入液-液-固三相区后,初生富Gd固相的体积分数迅速增大,过饱和度再次增加,导致富TiCo相液滴的长大速率仍相对较快,如图9a所示。由于样品表面区域的温度梯度相对较大,富TiCo液滴的Marangoni迁移作用较强,且液滴Marangoni迁移后得不到补充,因此,表面附近区域富TiCo液滴/粒子的数密度较低,见图9b,与实验结果(图1a)相符。

图9

图9

直径为445 μm的Gd-2%Co-2%Ti合金样品心部富TiCo相液滴的平均半径(<RD>)和距离样品中心不同位置(r)处富TiCo相液滴的ND随时间的变化

Fig.9

Average radius (<RD>) of the TiCo-rich droplets at the center region (a) and ND of the TiCo-rich droplets at different positions (r) from the center (b) of the alloy sample with a diameter of 445 μm as a function of t (L1 + L2 + S represents liquid-liquid-solid three-phase region)

2.5 样品尺寸对组织演变的影响

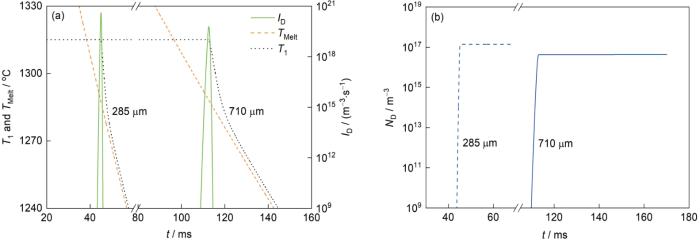

图10为直径为285和710 μm的Gd-2%Co-2%Ti合金样品心部平衡组元互溶温度、熔体温度和富TiCo相液滴的形核率、数密度随时间的变化。可见,样品尺寸越小,形核阶段冷却速率越大,弥散相液滴的形核过冷度(即平衡组元互溶温度与熔体温度之差)也越大,有利于富TiCo相液滴的形核,因此,凝固组织中富TiCo相粒子的数密度越大,平均半径越小。

图10

图10

直径为285和710 μm的Gd-2%Co-2%Ti合金样品心部平衡组元互溶温度(T1)、熔体温度(TMelt)以及富TiCo相液滴的ID、ND随时间的变化

Fig.10

T1, melt temperature (TMelt), ID (a) and ND (b) of the TiCo-rich droplets at the center region of the Gd-2%Co-2%Ti alloy samples with diameters of 285 and 710 μm as a function of t

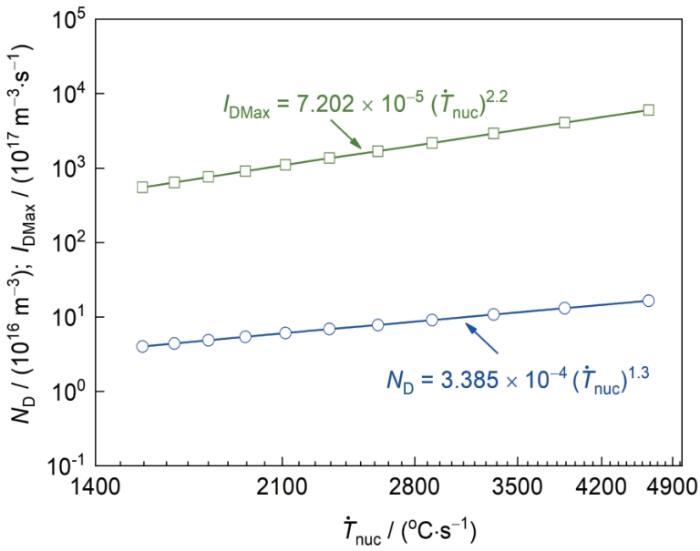

图11为Gd-2%Co-2%Ti合金样品心部富TiCo相液滴的最大形核率(IDMax)和凝固后富TiCo相粒子ND随形核阶段冷却速率(

图11

图11

Gd-2%Co-2%Ti合金样品心部富TiCo相液滴的最大形核率(IDMax)和凝固后富TiCo相粒子ND随形核阶段冷却速率(

Fig.11

Maximum nucleation rate (IDMax) of the TiCo-rich droplets and ND of the TiCo-rich particles at the center region of the Gd-2%Co-2%Ti alloy samples as a function of the local cooling rate (

3 结论

(1) 在落管微重力条件下凝固时,Gd-2%Co-2%Ti合金凝固组织中存在由液-液相变阶段形核析出的富TiCo相粒子和由冷却过程中TiCo脱溶析出形成的富TiCo纳米粒子。

(2) 在落管微重力条件下,在Gd-Co-Ti合金凝固过程中,除表面附近区域外,其他位置富TiCo相液滴的数密度在形核后基本保持不变,富TiCo相液滴的Ostwald熟化作用较弱,样品心部绝大部分区域富TiCo相粒子的空间分布较为均匀,富TiCo相液滴的尺寸主要受形核和长大过程控制。

(3) Gd-Co-Ti合金样品的尺寸越大,形核阶段熔体的冷却速率越小,熔体获得的过冷度越小,富TiCo相液滴的最大形核率越小,凝固组织中富TiCo相粒子的数密度越低,平均尺寸越大。富TiCo相液滴的最大形核率IDMax和TiCo相液滴/粒子的数密度(ND)与形核阶段冷却速率(

参考文献

Magnetic behavior of heavy rare earth RTiFe11 - x Co x alloys

[J].

Structure and magnetic properties of Gd4(Co, Ti)41 alloys

[J].

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J].

Novel insight into mechanism of secondary phase's morphology evolution in hypomonotectic Cu-Pb-Sn alloy during solidification

[J].

Segregation driven by collision and coagulation of minor droplets in Al-Bi immiscible alloys under aerodynamic levitation condition

[J].

Progress in the solidification of monotectic alloys

[J].

偏晶合金凝固过程研究进展

[J].

Aluminium-indium-experiment SOLUOG—A sounding rocket experiment on immiscible alloys

[A].

The influence of microgravity on the solidification of Zn-Bi immiscible alloys

[J].

Binary systems with miscibility gap in the liquid state

[A].

In-situ composite microstructure formation of immiscible alloy solidified in space

[J].

In situ study on the oscillation of mobile droplets and force analysis during the directional solidification of Al-Bi alloy

[J].

Control of competitive phase selection by in-situ nanoparticles

[J].

Dynamics of core-shell particle formation in drop-tube processed metastable monotectic alloys

[J].

Selection of a micro-alloying interface active component to stabilize the interface between droplets and liquid matrix in monotectic alloys

[J].

Microstructure formation in directionally solidified Pb-Al alloy

[J].

Pb-Al合金定向凝固组织形成过程

[J].

A simple criterion for the selection of interfacial active element to control liquid-liquid decomposition of immiscible alloys

[J].

Effect of micro-alloying element Bi on solidification and microstructure of Al-Pb alloy

[J].

微量元素Bi对Al-Pb合金凝固过程及显微组织的影响

[J].

Growth dynamics of the segregated phase in Zn-6wt%Bi immiscible alloy superheated in super high static magnetic field

[J].

Solidification of Al-Bi-Sn immiscible alloy under microgravity conditions of space

[J].

Influence of high magnetic field on the liquid-liquid phase separation behavior of an undercooled Cu-Co immiscible alloy

[J].

Numerical simulation of macro-segregation formation during solidification process of immiscible alloys

[J].

难混溶合金凝固过程中宏观偏析形成的数值模拟

[J].

A model describing the microstructure evolution during a cooling of immiscible alloys in the miscibility gap

[J].

Study on the solidification of Ag-Ni monotectic alloy

[J].

Ag-Ni偏晶合金凝固过程研究

[J].

A comparative study of metastable phase separation for undercooled liquid Fe35Cu65 alloy under natural and forced cooling conditions

[J].

Microstructure evolution of immiscible alloy solidified under the effect of composite electric and magnetic fields

[J].

A computational and experimental study of ultrasonicated phase separation process for liquid Al-Bi immiscible alloy

[J].

Evolution kinetics of microgravity facilitated spherical macrosegregation within immiscible alloys

[J].

Experimental investigation and numerical simulation on liquid phase separation of ternary Fe-Sn-Si/Ge monotectic alloy

[J].

液态三元Fe-Sn-Si/Ge偏晶合金相分离过程的实验和模拟研究

[J].

A surface energy driven dissolution model for immiscible Cu-Fe alloy

[J].

Solidification of Al-Bi alloy and influence of microalloying element Sn

[J].

Al-Bi合金凝固过程及微合金化元素Sn的影响

[J].

Progress of research on solidification process and microstructure control of immiscible alloys

[J].

偏晶合金凝固过程及凝固组织控制方法研究进展

[J].

Experimental and thermodynamic assessment of the Co-Gd-Ti system

[J].

Rapid/sub-rapid solidification microstructure formation and control of liquid-liquid phase separation alloy under ground/space conditions

[D].

地面/空间液-液相分离合金快速/亚快速凝固组织形成及调控

[D].

The kinetics of the liquid-liquid decomposition under the rapid solidification conditions of gas atomization

[J].

Formation of the microstructure in a rapidly solidified Cu-Co alloy

[J].

Liquid-liquid phase transformation kinetics of an atomized Al-Pb alloy drop

[J].

Al-Pb合金雾化液滴的液-液相变动力学

[J].

Repeated nucleation of minority phase droplets induced by drop motion

[J].

Modeling of marangoni-induced droplet motion and melt convection during solidification of hypermonotectic alloys

[J].

Thermophysical property measurements of liquid gadolinium by containerless methods

[J].

A Calphad-compatible method to calculate liquid/liquid interfacial energies in immiscible metallic systems

[J].