熔体过冷度(液相线温度(TL)与形核温度(TN)之差)是影响合金凝固行为最为重要的因素。随着过冷度的增大,不仅凝固组织形貌会发生显著变化[10~12],而且还可能形成亚稳相。目前对过冷M-B合金凝固行为的研究主要局限于二元合金,Quirinale等[13]在研究过冷Fe83B17合金的凝固行为时,首次发现了Fe23B6亚稳相。Liu等[14]和Wei等[15]在Co-(18.5~20.7)B (质量分数,%)合金中也发现了Co23B6亚稳相的存在,并且成功将其保留到室温,进而测定了晶体参数。Liu等[16,17]和Battezzati等[18]报道,Ni-B合金在过冷度在达到200 K以上时,会发生亚稳共晶反应L→α-Ni + Ni23B6,但Ni23B6亚稳相随后会分解成α-Ni和Ni3B。Ohodnicki等[19]基于第一性原理计算结果进一步指出,M23B6相在3种二元合金中的稳定性为Co23B6 > Fe23B6 > Ni23B6。

1 实验方法

(Fe1 - x Co x)79.3B20.7 (x = 0、0.2、0.4、0.6、0.8、1.0,原子分数,%)母合金由纯Fe (99.99%,质量分数,下同)、纯Co (99.99%)和结晶B (99.999%)在真空非自耗电弧炉中熔炼而成。为保证成分均匀,各成分的铸锭在高纯Ar气(99.999%)的保护下进行了6次翻转熔炼。

采用熔融玻璃净化结合循环过热的方法获得深过冷。实验时,先取约0.3 g充分脱水后的B2O3净化剂放入高纯石英坩埚底部,然后放入重量约为3 g的母合金,最后再放入0.3 g净化剂,连同坩埚一起置于感应加热线圈中。关闭炉门,将炉腔抽真空至5 × 10-3 Pa后反充高纯Ar气,然后开始对试样金属进行熔化-凝固循环,直至得到目标过冷度,凝固后的试样自然冷却至室温。循环加热过程中使用CIT型高精度红外测温仪(响应时间1 ms,测量误差± 1 K)监测和记录试样温度。

凝固后的试样使用电火花线切割机过形核点一分为二,取其中一半试样镶嵌后机械磨抛至镜面,用硝酸酒精溶液腐蚀,于DM1000光学显微镜(OM)和配备电子背散射衍射(EBSD)系统的Mira型扫描电镜(SEM)进行金相观察。用SmartLab型X射线衍射仪(XRD,Co靶,电压30 kV,电流30 mA)进行物相分析,扫描速率2°/min,扫描范围30°~90°。合金的凝固行为随着过冷度(

2 实验结果

2.1 铸锭组织

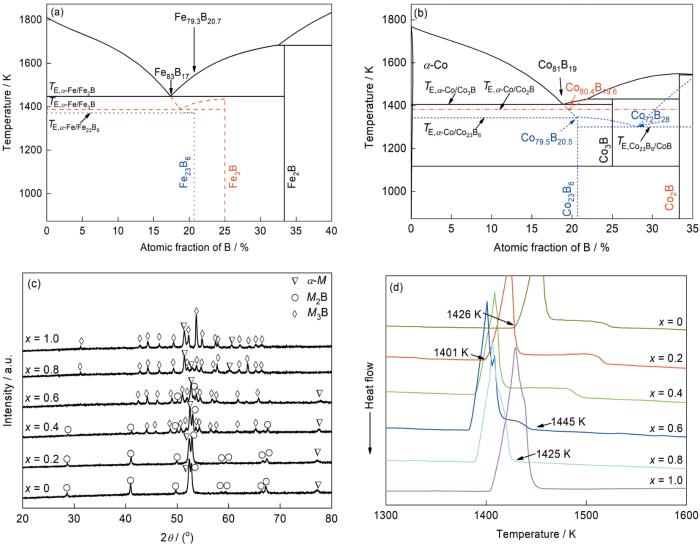

现有二元相图大多仅给出平衡相的关系,有关热力学评估也主要是针对稳定相图进行,目前尚无M-B亚稳相图可供研究使用。为此本工作采用Thermo-Calc软件中PARROT模块计算了Fe-B和Co-B体系的热力学参数[18,27~31],并利用前人的凝固实验结果对计算结果进行了评估。计算得到的Fe-B、Co-B二元合金相图分别如图1a和b所示,其中黑色实线代表稳定相图,虚线代表亚稳相图。Fe-B合金富Fe侧,α-Fe、Fe2B为稳定相,其他相均为亚稳相;Co-B合金富Co侧,稳定相除α-Co和Co2B外,高温下还包含Co3B相。定义特征温度

图1

图1

Fe-B和Co-B二元相图、(Fe1 - x Co x)79.3B20.7母合金锭的XRD谱及(Fe1 - x Co x)79.3B20.7合金加热熔化差示扫描量热(DSC)曲线

Fig.1

Fe-B and Co-B phase diagrams (a, b), XRD spectra of (Fe1 - x Co x)79.3B20.7 alloy ingots (c), and differential scanning calorimetry (DSC) curve of (Fe1 - x Co x)79.3B20.7 alloys (d) (Black arrows in Fig.1d represents starting or ending tempera-tures of melting process, TE,i/j represents the temperature of the eutectic reaction whose products are i and j)

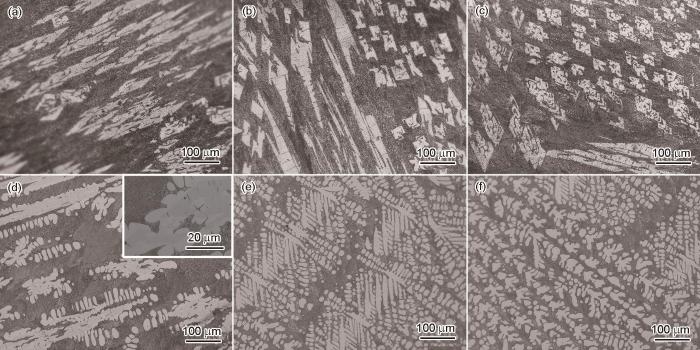

(Fe1–x Co x)79.3B20.7合金的铸锭组织如图2所示,结合图1c的XRD谱可知,x = 0、0.2、0.4时初生小平面相应为M2B,x = 0.6时高放大倍数下可以看到粗大非小平面相的内部存在第二相(见图2d插图),由XRD分析结果可知该第二相为M2B,显然凝固过程中发生了包晶反应L + M2B→M3B,凝固时的初生相应为M2B。x = 0.8、1.0时,初生非小平面相内部未发现其他相的存在,故初生相应为M3B。M2B相的Jackson因子较大[32],因此作为初生相析出时表现出比M3B相强的小平面特征。初生相之间为共晶组织,x = 0、0.2时,共晶两相为α-M和M2B;x = 0.4时,共晶组织中除α-M外同时含有M2B和M3B相,其形成机制详见讨论部分;x = 0.6、0.8、1.0时,共晶两相为α-M和M3B。

图2

图2

(Fe1 - x Co x)79.3B20.7母合金锭组织的OM像

Fig.2

OM images of (Fe1 - x Co x)79.3B20.7 alloy ingots (Inset in Fig.2d shows the higher magnification microstructure)

(a) x = 0 (b) x = 0.2 (c) x = 0.4 (d) x = 0.6 (e) x = 0.8 (f) x = 1.0

2.2 不同过冷度下合金的凝固行为

(Fe1 - x Co x)79.3B20.7合金的凝固行为随着过冷度的变化,根据不同Fe / Co比,可以分成4类,选其代表性成分,分别阐述如下。

2.2.1 (Fe1 - x Co x)79.3B20.7 (x = 0、0.2)

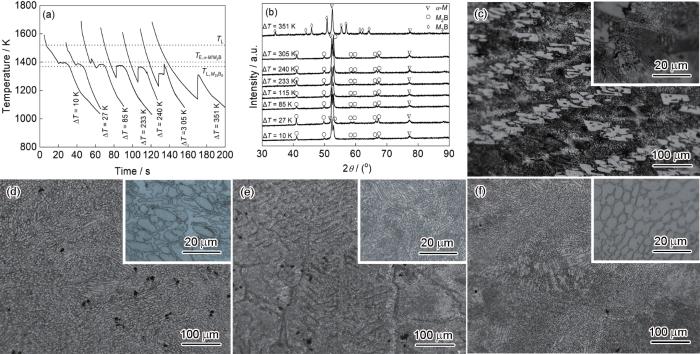

x = 0和x = 0.2合金的凝固行为类似。以x = 0.2合金为例,图3为其典型

图3

图3

(Fe0.8Co0.2)79.3B20.7合金的凝固冷却曲线、XRD谱及不同过冷度(ΔT)下合金组织的OM像

Fig.3

Cooling curves (a), XRD spectra (b), and OM images (c-f) of (Fe0.8Co0.2)79.3B20.7 alloy under different undercoolings (ΔT) (Insets in Figs.3d-f show the higher magnification microstructures, TL is the liquidus temperature of the alloy,

(c) ΔT = 10 K (d) ΔT = 233 K (e) ΔT = 305 K (f) ΔT = 351 K

2.2.2 (Fe0.6Co0.4)79.3B20.7

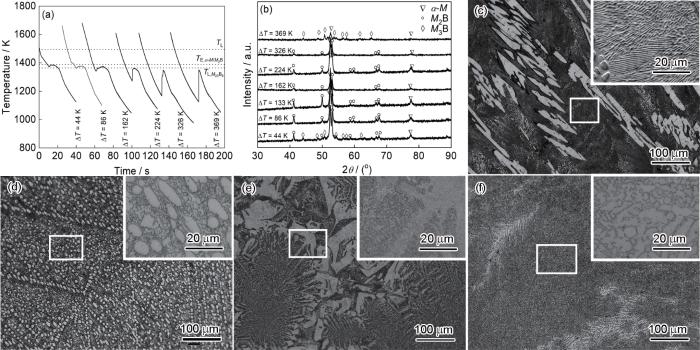

x = 0.4合金的凝固实验结果如图4所示,该合金凝固时存在3个临界过冷度

图4

图4

(Fe0.6Co0.4)79.3B20.7合金的凝固冷却曲线、XRD谱及不同过冷度下合金组织的OM像

Fig.4

Cooling curves (a), XRD spectra (b), and OM images (c-f) of (Fe0.6Co0.4)79.3B20.7 alloy under different undercoolings (Insets in Figs.4c-f are magnified views of the areas indicated by the white rectangles)

(c) ΔT = 44 K (d) ΔT = 162 K (e) ΔT = 326 K (f) ΔT = 369 K

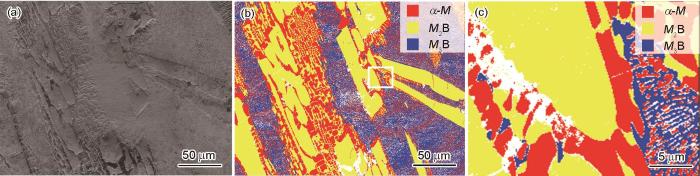

图5

图5

ΔT = 44 K时(Fe0.6Co0.4)79.3B20.7合金的组织

Fig.5

Microstructures of (Fe0.6Co0.4)79.3B20.7 alloy undercooled by 44 K

(a) SEM image (b) EBSD phase map (c) magnified view of the area marked by the white rectangle in Fig.5b

2.2.3 (Fe0.4Co0.6)79.3B20.7

图6为x = 0.6合金的凝固实验结果。该合金凝固存在3个临界过冷度:

图6

图6

(Fe0.4Co0.6)79.3B20.7合金的凝固冷却曲线、XRD谱及不同过冷度下合金组织的OM像和EBSD像

Fig.6

Cooling curves (a), XRD spectra (b), and microstructures (c-f) of (Fe0.4Co0.6)79.3B20.7 alloy under different undercoolings (Inset in Fig.6c is EBSD phase distribution map, and the other insets show the higher magnification images)

(c) ΔT = 39 K (d) ΔT = 136 K (e) ΔT = 297 K (f) ΔT = 321 K

2.2.4 (Fe1 - x Co x)79.3B20.7 (x = 0.8、1.0)

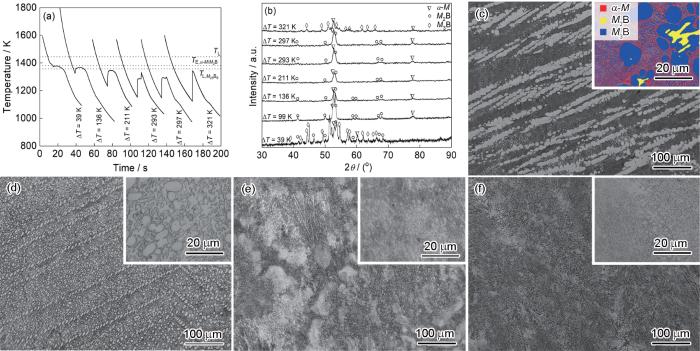

随着过冷度的增大,(Fe1 - x Co x)79.3B20.7 (x = 0.8、1.0) 2个成分的合金遵循基本相同的变化规律,只是相互间临界过冷度有所不同,此处以x = 0.8合金为例进行阐述。不同过冷度下(Fe0.2Co0.8)79.3B20.7合金的凝固实验结果如图7所示,合金凝固存在3个临界过冷度:

图7

图7

(Fe0.2Co0.8)79.3B20.7合金的凝固冷却曲线、XRD谱及不同过冷度下合金组织的OM像和EBSD像

Fig.7

Cooling curves (a), XRD spectra (b), and OM images (c-f) of (Fe0.2Co0.8)79.3B20.7 alloy under different undercoolings (Inset in Fig.7c is EBSD phase distribution map, and the other insets show higher magnification OM images)

(c) ΔT = 20 K (d) ΔT = 126 K (e) ΔT = 255 K (f) ΔT = 340 K

3 分析讨论

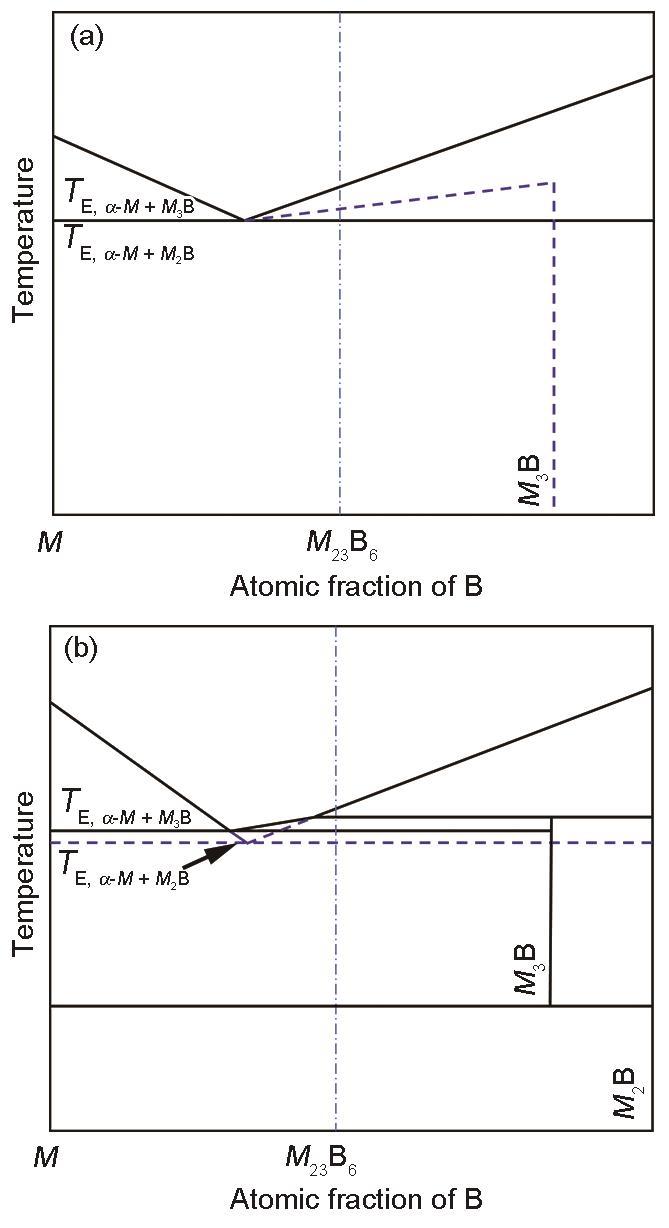

3.1 M-B伪二元相图

随着Co含量的增加(x值增大),M(Fe, Co)-B(伪)二元相图逐渐从Fe-B相图过渡至Co-B相图。比较图1a和b不难发现,其间经历了L→α-M + M2B共晶反应温度降低、共晶点成分增大,以及L→α-M + M3B共晶反应温度升高、共晶点成分少许增大的变化。其后果之一是,原来稳定的共晶反应L→α-M + M2B,变成了亚稳共晶反应;原来亚稳的共晶反应L→α-M + M3B,变成了稳定的共晶反应,并且由于M3B高温稳定相的出现,产生了L + M2B→M3B包晶反应。不难想象,由于2个共晶反应共用一条α-M液相线,在此过程中M-B相图于某一Co含量处存在L→α-M + M2B和L→α-M + M3B 2个共晶点重合的现象。

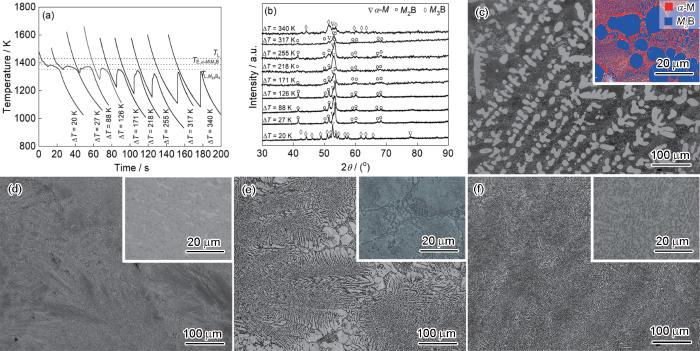

前述过冷(Fe1 - x Co x)79.3B20.7合金的凝固实验结果表明,小过冷度下凝固时,x = 0.4合金的共晶组织中同时存在α-M、M2B和M3B相,x < 0.4合金的共晶组织中只有α-M和M2B相,x > 0.4合金的共晶组织中只有α-M和M3B相。因此,x = 0.4时L→α-M + M2B和L→α-M + M3B 2个共晶反应的共晶线重合,共晶点成分相同,据此可以得到图8a所示M(Fe0.6Co0.4)-B伪二元相图的示意图。该相图下,合金凝固过程中同时出现2种共晶组织首先在热力学上是允许的。其次,考虑到α-M/M3B 2个共晶相间的成分差别小于α-M/M2B,L→α-M + M3B共晶反应要求的溶质扩散量相对较小,在动力学上具有优势,因此x = 0.4合金在小过冷度下凝固时,L→α-M + M3B共晶反应先于L→α-M + M2B发生,其共晶层片间距小于后者。

图8

图8

x = 0.4、0.6时(Fe1 - x Co x)-B伪二元系示意相图

Fig.8

Schematics of (Fe1 - x Co x)-B pseudo-binary phase diagrams (Solid lines represent stable phase diagrams, dashed lines represent metastable phase diagrams, TE,i + j represents the temperature of the eutectic reaction whose products are i and j)

(a) x = 0.4 (b) x = 0.6

x > 0.4后,

3.2 (Fe1 - x Co x)79.3B20.7 合金的凝固路径

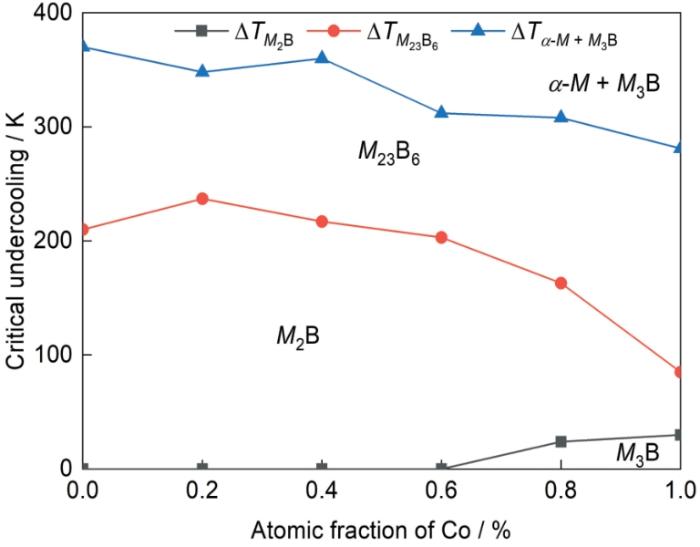

前述(Fe1 - x Co x)79.3B20.7合金的凝固实验说明,随着过冷度的增大,α-M、M3B、M2B和M23B6相之间存在着复杂的相竞争过程,并且这种竞争关系随着Co含量的不同而变化。对实验结果进行整理,可以构建(Fe1 - x Co x)79.3B20.7合金初生相与过冷度以及Co含量的关系,如图9所示。可见,x ≤ 0.6的合金在小过冷度下凝固时,首先析出的是M2B相,Co含量更高的合金析出的是M3B相。所有合金在较高的过冷度下均有初生M23B6相析出,在更高的过冷度下进行的是L→α-M + M3B共晶反应。

图9

图9

(Fe1 - x Co x)79.3B20.7合金各初生相析出的临界过冷度范围及其与Co含量的关系

Fig.9

Undercooling ranges for various primary phases to precipitate and their dependences on the Co content in (Fe1 - x Co x)79.3B20.7 alloys (

M23B6相具有复杂的单胞结构,在M-B合金中普遍以亚稳相形态存在。(Fe1 - x Co x)79.3B20.7合金在较大的过冷度下凝固时M23B6相始终以初生相析出,在此过程中M23B6相在M = Co时稳定性较高,表现为临界过冷度较小,而且某些时候还能被保留至室温。但与此同时,呈上突状的

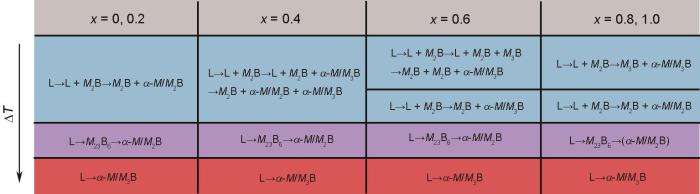

高温下富Co成分的(Fe1 - x Co x)79.3B20.7合金中M3B相可稳定存在,小过冷度下凝固时M3B相优先析出。过冷度增大后,由于M2B相形核功较小,而且M3B相本身稳定性较差,因此初生相转变为M2B相,而且M23B6相分解的产物也是α-M和M2B。总结以上(Fe1 - x Co x)79.3B20.7合金的凝固实验结果,可以进一步绘制出当Co含量不同时合金的凝固路径,如图10所示。

图10

图10

各成分合金的凝固路径示意图

Fig.10

Schematic of solidification paths for various alloys under different undercoolings

4 结论

(1) 随着Co含量的增加,M(Fe, Co)-B伪二元相图中L→α-M + M2B和L→α-M + M3B 2种共晶反应的温度和共晶点成分位置发生逆转,稳定的共晶反应由前者变为了后者,并且由于M3B高温稳定相的出现,出现了L + M2B→M3B包晶反应。

(2) 随着过冷度的增大,(Fe1 - x Co x)79.3B20.7合金的初生相依次由M3B (仅x > 0.6时)向M2B、M23B6和α-M/M3B相转变。

(3) (Fe1 - x Co x)79.3B20.7合金在较高的过冷度下凝固时,均首先凝固形成M23B6相,但绝大多数情况下随后分解为α-M/M2B,仅在x = 1.0成分合金中有时可保留至室温。

(4) x = 0.4的合金在小过冷度下凝固时,非常罕见地同时形成了α-M/M2B和α-M/M3B 2种共晶组织。

参考文献

A review on relationship between morphology of boride of Fe-B alloys and the wear/corrosion resistant properties and mechanisms

[J].

Research status and future development of (Ce, La, Y)-F-B permanent magnets based on full high-abundance rare earth elements

[J].

全高丰度稀土(Ce, La, Y)-Fe-B永磁的研究现状和未来发展

[J].随着市场对Nd-Fe-B永磁材料需求的不断增加,昂贵的Nd、Pr、Dy和Tb等关键稀土元素的消耗也日益增加,而廉价的Ce、La和Y等高丰度稀土元素积压严重。开发不含关键稀土元素的全高丰度永磁材料有望填补永磁铁氧体和黏结Nd-Fe-B磁体之间的性能空白,不仅可以满足中低端市场领域对永磁材料的多样化需求,也利于实现稀土资源的平衡利用。然而,目前针对Ce、La、Y基稀土永磁的理解和认识还有待深入,所获得的高丰度稀土永磁的性能普遍较低,难以实际应用。本文基于国内外最新进展和作者团队的研究工作,总结了近期关于不含关键稀土Nd、Pr、Dy和Tb的(Ce, La, Y)-Fe-B永磁合金和磁体的研究现状。重点关注了纳米晶快淬三元合金的相结构和冶金行为以及多元合金的成分设计与元素交互作用,详细阐述了全高丰度稀土基致密化磁体的制备工艺、显微组织与磁性能之间的关系。最后对全高丰度稀土永磁的未来发展趋势进行了展望。

A review of electrodeposited composite coatings with Ni-B alloy matrix

[J].

Several issues on the development of grain boundary diffusion process for Nd-Fe-B permanent magnets

[J].

钕铁硼永磁晶界扩散技术和理论发展的几个问题

[J].钕铁硼永磁在新能源、信息通讯和智能制造等领域有着广泛的应用。电动汽车驱动电机、风电系统发电机等对钕铁硼磁体的高温性能和矫顽力提出了更高的要求。重稀土Tb和Dy可以显著提高钕铁硼磁体的各向异性场,但降低了剩磁,增加了成本。21世纪初出现的晶界扩散技术是稀土永磁制造领域的一项重大进展。它通过将重稀土元素或稀土合金以晶界扩散的方式渗透入磁体,在有效提高磁体矫顽力的同时,大幅降低重稀土含量,提高性价比。晶界扩散技术发展至今,引起业内的广泛关注并已实现工业化,但在技术和理论层面上仍存在一些关键问题。本文基于国内外最新进展和作者团队的研究工作,总结了晶界扩散工艺目前亟需解决的问题及可能的解决措施。对厚磁体的晶界扩散技术、晶界扩散中各向异性行为的利用、低成本扩散剂的选择、晶界扩散与现存工艺的结合、晶界扩散对其他服役性能的影响以及晶界扩散的相关理论发展等问题进行了阐述,并对晶界扩散的未来发展趋势进行了展望。

Electroless Ni-B and composite coatings: A critical review on formation mechanism, properties, applications and future trends

[J].

Microstructure refinement mechanisms in undercooled solidification of binary and ternary nickel based alloys

[J].

Investigation on the phase transformation of electroless Ni-B coating after dry sliding against alumina ball

[J].

Effect of microstructure on the hardness and dry sliding behavior of electroless Ni-B coating

[J].

Electrodeposited Ni-Co alloy-particle composite coatings: A comprehensive review

[J].

Remelting of primary solid in rapid solidification of deeply undercooled alloy melts

[J].Solidification of deeply undercooled alloy melts proceeds with obvious temperature recalescence, during which part of primary solid is inevitably remelted, and the microstructural morphology is inevitably changed. During past decades, great improvement was achieved in modelling crystal growth in undercooled alloy melts, making it possible to quantitatively evaluate the remelting degree of primary solid at different undercoolings. In this paper, the progress in modelling the remelting of primary solid was introduced, and the variation of remelted fraction of primary solid as a function of the alloy feature and undercooling was presented. In combination with experimental results of crystal growth pattern and solidification structure in selected alloys, the mechanisms for grain refinement in undercooled single-phase alloys and anomalous eutectic formation in undercooled eutectic alloys were then discussed.

液态金属深过冷快速凝固过程中初生固相的重熔

[J].深过冷液态金属(合金)凝固时伴随有显著的温度再辉,初生固相因此不可避免地部分被重熔,从而影响到最终凝固组织形态。近年来,过冷熔体中晶体生长理论模型不断完善,使得定量分析初生固相重熔程度随过冷度的变化规律成为可能,本文即对这方面的研究工作进展进行综述,并结合某些合金在不同过冷度下晶体生长行为及其凝固组织的实验结果,对典型非平衡凝固组织的形成机制进行阐述。

Solidification microstructure evolution and grain refinement mechanism under high undercooling of undercooled Ni90Cu10 alloys

[J].

Secondary arm spacing of undercooled Ni50Cu50 alloy

[J].

过冷Ni50Cu50合金的二次枝晶间距

[J].过冷Ni50Cu50合金的二次枝晶间距随过冷度的增加并不以简单的幂函数规律减小,在40—120K过冷度范围内有一反常的变化理论分析指出这是枝晶生长从低过冷下的溶质扩散控制向高过冷下的热扩散控制转变过程中一次枝晶尖端半径的上升所致与常规凝固合金相比.深过冷合金的二次校晶在凝固过程中发生剧烈的粗化

Synergistic stabilization of metastable Fe23B6 and γ-Fe in undercooled Fe83B17

[J].

Solidification pathways in highly undercooled Co79.3B20.7 alloy

[J].

Metastable Co23B6 phase solidified from deeply undercooled Co79.3B20.7 alloy melt

[J].

Phase selection in undercooled Ni-3.3 wt pct B alloy melt

[J].

Solidification of highly undercooled hypereutectic Ni-Ni3B alloy melt

[J].

Undercooling of Ni-B and Fe-B alloys and their metastable phase diagrams

[J].

Ab initio theoretical study of magnetization and phase stability of the (Fe, Co, Ni)23B6 and (Fe, Co, Ni)23Zr6 structures of Cr23C6 and Mn23Th6 prototypes

[J].

Structure and glass-forming ability of Al-based amorphous alloys

[J].Although Al-based amorphous alloys have excellent mechanical properties and good corrosion resistance, their poor glass-forming ability makes large-scale samples difficult to obtain, limiting their engineering applications. Owing to the close relationship between the glass-forming ability of alloys and their structure, the development of Al-based amorphous alloys is first briefly reviewed to gain a thorough understanding of their component composition. On this basis, the microstructure, composition design theory, relationship between glass-forming ability and composition, and selection of primary phase during crystallization in Al-based amorphous alloys are discussed. Finally, the future study directions for Al-based amorphous alloys are prospected.

铝基非晶合金的结构与非晶形成能力

[J].铝基非晶合金具有优异的力学性能与良好的耐蚀性,但是其较差的非晶形成能力使得大尺寸样品不易获得,工程应用也由此受到很大限制。鉴于合金的非晶形成能力与其结构密切相关,本文简要回顾铝基非晶合金发展历程,在全面了解其组元构成的基础上,重点阐述了铝基非晶合金的微观结构,以及由此衍生出的合金成分设计理论、非晶形成能力与成分的关系、晶化过程中初生相的选择等问题。最后对铝基非晶合金未来的研究方向进行了展望。

Effects of alloying substitutions on the anti-disproportionation behavior of ZrCo alloy

[J].

Effect of substituting elements on glass-forming ability of the new Zr48Cu36Al8Ag8 bulk metallic glass-forming alloy

[J].

Research progress on the anti-disproportionation of the ZrCo alloy by element substitution

[J].

Tuning glass formation and brittle behaviors by similar solvent element substitution in (Mn, Fe)-based bulk metallic glasses

[J].

Complex concentrated alloys for substitution of critical raw materials in applications for extreme conditions

[J].

Effect of elemental substitution on the structure and hydrogen storage properties of LaMgNi4 alloy

[J].

Driving forces for crystal nucleation in Fe-B liquid and amorphous alloys

[J].

B-Fe (Boron-Iron)

[J].

Thermodynamic optimization of the boron-cobalt-iron system

[J].

On the nature of crystal growth from the melt

[J].

Nucleation-controlled microstructures and anomalous eutectic formation in undercooled Co-Sn and Ni-Si eutectic melts

[J].

Non-equilibrium solidification of undercooled metallic metals

[J].

On determining the phase-selection principle in solidification from undercooled melts-competitive nucleation or competitive growth?

[J].

Kinetics of solidification of supercooled liquid mercury droplets

[J].

Formation of crystal nuclei in liquid metals

[J].

Phase selection in solidification of undercooled Co-B alloys

[J].A series Co-(18.5-20.7) at.% B melts encompassing the eutectic composition (Co81.5B18.5) were solidified at different degrees of undercooling. It is found that the metastable Co23B6 phase solidifies as a substitute for the stable Co3B phase in the alloy melts undercooled above a critical undercooling value of ~60 K. The Co23B6 and α-Co phases make up a metastable eutectic. The corresponding eutectic composition and temperature are Co80.4B19.6 and 1343 K, respectively. On exposure of the metastable Co23B6 phase at a given temperature above 1208 K, it does not decompose even after several hours. But it transforms by a eutectoid reaction to α-Co + Co3B at lower temperature.