随着可持续发展和绿色环保对轻质材料需求的不断增加,高强度镁合金的研究受到广泛关注,是21世纪最具发展潜力的绿色工程材料。然而,其强塑性低和耐蚀性差严重限制了镁合金的工业应用。沉淀强化是提高镁合金力学性能的最有效方法之一[1]。长周期有序堆垛(LPSO)结构具有良好的热稳定性[2,3],可以有效提升Mg-TM-RE (TM = Zn、Cu、Ni、Co,过渡族元素;RE = Y、Dy、Ho、Gd、Tb、Er、Tm,稀土元素)系合金的室温和高温性能[4]。LPSO结构由AB'C'A堆垛单元和不同层数的Mg原子层有序堆垛组成[5~7],不仅结构有序而且化学有序,其中B'和C'富含溶质元素TM和RE。随过渡元素、稀土元素及制备工艺的不同,LPSO结构有较多类型[8~12],其中以18R和14H最为主要。在变形过程中由于异号基面滑移的协同运动,LPSO结构形成扭折,是其强韧化镁合金的主要原因之一[13,14]。扭折形成伴随溶质元素的再分布,可有效稳定扭折界面,从而提升其对性能的贡献[15~17]。而且,晶粒内局部区域存在扭折和孪晶共生,协同提升其塑形[18]。

由于六方结构Mg及镁合金独立滑移系的数量有限,孪生在其塑性变形中起到重要作用。{

1 实验方法

以高纯Mg (99.99%)、Zn (99.99%)、Mg-25Y (质量分数,%)和Mg-30Zr (质量分数,%)中间合金为原料,通过高频感应炉在Ar气保护下制备Mg97ZnlY2 和Mg96.6Zn1Y2.2Zr0.2 (原子分数,%)镁合金。铸锭经过500℃、12 h的均匀化处理后,线切割制备4 mm × 4 mm × 8 mm的块状试样。压缩变形实验在Gleeble 1500热/力模拟试验机上进行,压缩方向平行于长轴方向,温度为室温,变形速率1 × 10-3 s-1,压缩应变分别为24.1%和36.2%。实验后立即将试样放入水中冷却至室温以保存变形微观结构。透射电镜(TEM)样品主要采用离子减薄制备。用低速锯取下特征位置样品,机械研磨至40 μm,利用Gatan微凹仪挖坑,最后用Gatan 691离子薄化器减薄。为了减少氩离子轰击时对样品的损伤,减薄初始采用4.5 kV、6°入射角,然后逐步降低电压并减小入射角,最后调整至3 kV、3°入射,在结束前降低电压至1.2 kV、3°低能量清扫表面。高倍高角环形暗场像(HAADF)在配备了双球差矫正器的Titan3TM G2 60-300型TEM上获取,操作电压300 kV。拍摄原子尺度扫描透射电子显微镜(STEM)图像时,电子束汇聚角约为25 mrad,束斑直径在0.1 nm以下,所对应分辨率优于0.08 nm。其中TEM像拍摄时电子束平行<

2 实验结果与讨论

2.1 镁合金中{

hcp结构Mg及镁合金含有6个{

图1

图1

hcp结构Mg及镁合金中{

Fig.1

Three crystallographically types of twin-twin interactions formed from six {

(a) co-zone twins: T1-T4 twin-twin pair with the intersection line along <

(b) non co-zone twins: T1-T2 twin-twin interaction with the intersection along <

(c) non co-zone twins: T1-T3 twin-twin interaction with the intersection line along <

(d) configuration of {

(e) {

2.2 LPSO/SFs结构间{10

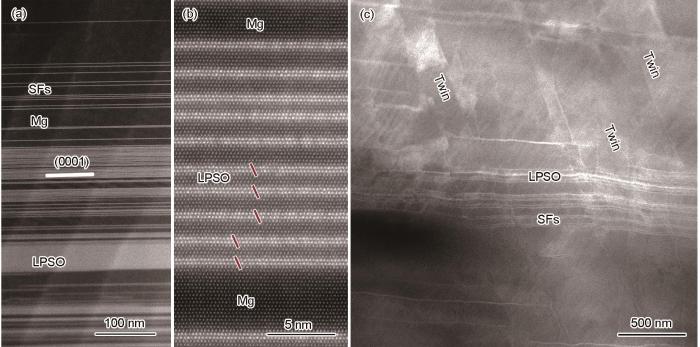

图2

图2

含LPSO结构Mg-Zn-Y镁合金室温压缩前后的微观结构

Fig.2

Microstructures of Mg-Zn-Y alloy with LPSO structures before (a, b) and after (c) compression at room temperature

(a) low-magnification HAADF-STEM image showing the basal planes of LPSO structures and SFs enriched with Zn and Y atoms are parallel to the basal plane of the matrix in the Mg-Zn-Y alloy

(b) atomic-scale HAADF-STEM image showing AB'C'A building blocks (red lines) in the LPSO

(c) the multiple twins were triggered during compression, and they intersected with the SFs

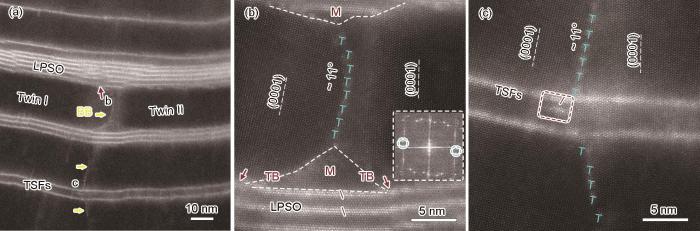

图3a为SFs间2组{

图3

图3

LPSO/SFs间{

Fig.3

BB and PP interfaecs introduced by the co-zone {

(a) low-magnification HAADF-STEM image of the wavy {

(b) atomic-resolution HAADF-STEM image showing the TB deflected from the basal plane of ~4° (Inserted inverse fast Fourier transform (IFFT) image shows a periodic array of dislocations in the twin boundary, which was processed by masking (0002) reflection of the matrix and {

(c) TB framed by cyan rectangle in Fig.3b deflecting from the {

(d) the corresponding IFFT image of Fig.3c processed by masking (0002) of the matrix and {

(e) high-magnification HAADF-STEM image showing the impingement of multiple twins, leaving a triangular matrix, denoted by M in Fig.3a

(f) twin boundaries and BB boundary delineated by dashed lines, and the corresponding FFT images of TB1, TB2, and BB boundary

图3e为宽间距SFs内部的高倍HAADF-STEM像,左右两侧分别为2个钝角三角形区域。图3f为图3e不同界面TB1、TB2和孪晶I和II界面对应的FFT图,可见其中包含3个孪晶以及BB界面。表明孪晶I和II与基体为{

图4为LPSO/SFs间{

图4

图4

LPSO/TSFs间{

Fig.4

TEM images of BB interface and {

(a) high-magnification HAADF-STEM image showing the twin-induced BB boundary within the LPSO structures, where the TB is delineated by a white dashed line

(b) enlarged image of cyan rectangle framed area showing that the BB coexists with {

(c) enlarged image of yellow rectangle framed area indicating that the BB (~7°) is connected with TB, and the FFT image is inserted

(d) a set of dislocations are displayed at the BB boundary generated by masking (0002) reflections (shown by the cyan dashed circles) of the two crystals

(e) geometric phase analysis (GPA) further confirming the position of dislocation cores (The colour bar indicates change in strain intensity from -0.25 (compressive) to 0.25 (tensile))

图5进一步显示了间距约为20 nm的LPSO结构与TSFs间形成的BB界面(约11°)。图5b和c分别为5a中b和c区域对应的原子分辨率HAADF-STEM像,表明其中BB界面是由间距为1.5 nm的周期性位错组成。图5b表明BB左右两侧区域的基面与基体基面呈{

图5

图5

LPSO与TSFs间Mg片层内{

Fig.5

Microstructure of BB interfaces formed in the Mg layers sandwiched between LPSO and TSFs with a spacing of ~20 nm

(a) high-magnification HAADF-STEM image of BB boundary between LPSO and TSFs, shown by the yellow arrows (b, c) atomic-resolution HAADF-STEM image of the BB boundary of ~11° denoted by b and c in Fig.5a. The array of dislocations processed by masking (0002) reflections of the left and right twin (cyan-color dashed-line circles in the inset FFT pattern) are imposed on the BB boundaries. The original triangular LPSO remains at the intersection between the intersection of left and right twins, where the AB'C'A building blocks are denoted by the red lines in Fig.5b, and very small local SFs with matrix orientation, which was framed by the dashed rectangle in Fig.5c (Inset shows the FFT pattern of the left and right twin. The shearing of LPSO caused by the twin intersection was indicated by the red arrows in Figs.5a and b)

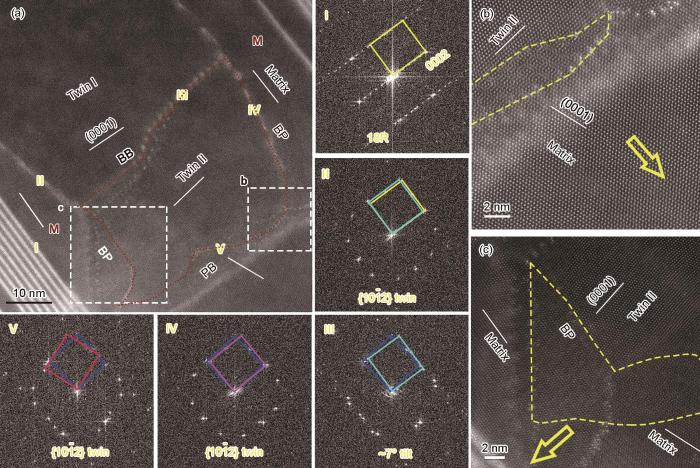

当受到间距为70 nm的LPSO结构限制时,{

图6

图6

LPSO结构间{

Fig.6

High-magnification HAADF-STEM image of a region containing {

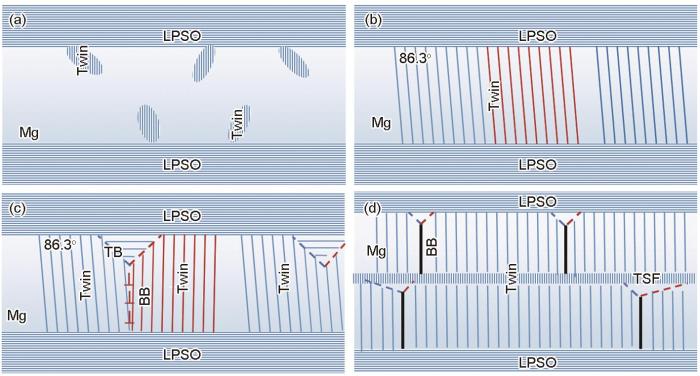

在LPSO/SFs间距为20~100 nm时(图3~6),{

图7

图7

LPSO间{

Fig.7

Schematics of the nucleation (a), propagation of {

2.3 LPSO结构扭折与{

图8

图8

LPSO/SFs内扭折界面(KB)与{

Fig.8

Low-magnification HAADF-STEM images of a region containing twin and kink boundary (KB) between the high-density SFs or LPSO structure

(a) the matrix with KB was surrounded by the twins

(b) KB connected with TB, which was also connected with a triangle matrix (denoted by red arrows)

(c) zoom-in image of the area “M” shows the triangle matrix 3 relates to a BB boundary

(d) atomic-resolution HAADF-STEM image of the area d in Fig.8c indicating that the triple intersection consists of BP, KB, and PB

(e) magnification image of area e in Fig.8b suggesting the formation of dislocations with c Burgers vectors in the LPSO structure (red ⊥) due to the twin shear

图8b~d表明LPSO相产生小角度扭折与Mg片层内形成{

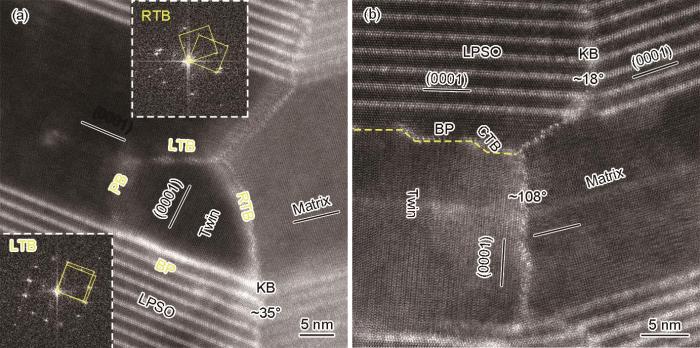

当LPSO结构间距减小至30 nm时,其KB与Mg片层内TB相连,孪晶在单侧扭折带内形核长大,如图9所示。图9a显示LPSO结构内35° KB与其间约20 nm Mg片层中TB相连。微小不规则孪晶由BP、PB、左侧孪晶界面(LTB)和右侧孪晶界面(RTB)组成,其与KB左右两侧区域对应的FFT (图9a内插图LTB和RTB)表明它们分别为{

图9

图9

LPSO结构扭折促进{

Fig.9

Atomic-resolution HAADF-STEM image of TB connecting with KB between LPSO structures, where the twinning just nucleated in the left side of the kink (a), and nearly occupied the left side of the kink (b) (LTB—left twin boundary, RTB—right twin boundary, CTB—coherent twin boundary)

3 结论

(1) LPSO/SFs抑制{

(2) LPSO/SFs/TSFs层间{

(3) LPSO层间孪晶交汇与变形扭折可共存。扭折界面处位错促进{

参考文献

Precipitation and hardening in magnesium alloys

[J].

Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa

[J].

Long-period ordered structure in a high-strength nanocrystalline Mg-1 at% Zn-2 at% Y alloy studied by atomic-resolution Z-ontrast STEM

[J].

Formation and mechanical properties of Mg97Zn1RE2 alloys with long-period stacking ordered structure

[J].

The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys

[J].

Polytypes of long-period stacking structures synchronized with chemical order in a dilute Mg-Zn-Y alloy

[J].

Microstructural characterization of long-period stacking ordered phases in Mg97Zn1Y2 (at. %) alloy

[J].Transmission electron microscopy characterization of two major long-period stacking ordered (LPSO) phases in Mg–Zn–Y alloy, i.e., 18R- and 14H-LPSO are reported. The space group and atomic-scale microstructures of both compounds were determined using a combination of electron diffraction, convergent beam electron diffraction, high-resolution transmission electron microscopy, and Z-contrast scanning transmission electron microscopy. The 18R-LPSO phase is demonstrated to have a point group and space group 3m and R3m (or 3m and R3m), with the lattice parameter a = 1.112 nm and c = 4.689 nm in a hexagonal coordinate system. The 14H-LPSO phase has a point group 6/mmm and a space group P63 /mmc, and the lattice parameter is a = 1.112 nm and c = 3.647 nm. In addition, insertion of extra thin Mg platelets of several atomic layers, results in stacking faults in the LPSO phase. These results may shed some new light on a better understanding of the microstructure and deformation mechanisms of LPSO phases in Mg alloys.

Growth and transformation mechanisms of 18R and 14H in Mg-Y-Zn alloys

[J].

Formation of long-period stacking ordered structures in Mg88 M5Y7 (M = Ti, Ni and Pb) casting alloys

[J].

New polytypes of long-period stacking ordered structures in Mg-Co-Y alloys

[J].

New polytypes of long-period stacking ordered structures in a near-equilibrium Mg97Zn1Y2 alloy

[J].

Crystallographic account of an ultra-long period stacking ordered phase in an Mg88Co5Y7 alloy

[J].

Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure

[J].

Strengthening mechanisms acting in extruded Mg-based long-period stacking ordered (LPSO)-phase alloys

[J].The unusual increase in the strength by extrusion is a unique feature of recently developed Mg alloys containing the LPSO phase. In this study, we first elucidated the detailed mechanisms that induce this drastic strengthening. The dependencies of the deformation behavior of a Mg88Zn4Y7 extruded alloy, which contains similar to 86-vol% LPSO phase, on the temperature, loading orientation, and extrusion ratio were examined. It was found that the yield stress of the alloy is drastically increased by extrusion, but the magnitude of the increase in the yield stress is significantly different depending on the loading orientation. That is, the strengthening of the LPSO phase by extrusion shows a strong anisotropy. By the detailed analyses, this was clarified to be derived from the variation in the deformation mechanisms depending on the loading orientation and extrusion ratio. Basal slip was found to govern the deformation behavior when the loading axis was inclined at a 45 to the extrusion direction, while the predominant deformation mechanism varies from basal slip to the formation of deformation kink bands as the extrusion ratio increased when the loading axis was parallel to the extrusion direction. Moreover, it was clarified in this study that the introduction of a deformation-kink-band boundary during extrusion effectively acts as a strong obstacle to basal slip. That is, "the kink band strengthening" was first quantitatively elucidated, which contributes to the drastic increase in the yield stress of the extruded LPSO-phase alloys in the wide temperature range below 400 degrees C. (C) 2018 Acta Materialia Inc. Published by Elsevier Ltd.

Atomic-scale segregations at the deformation-induced symmetrical boundary in an Mg-Zn-Y alloy

[J].

Dislocation configuration and solute redistribution of low angle kink boundaries in an extruded Mg-Zn-Y-Zr alloy

[J].

Effect of temperature on deformation mechanisms of the Mg88Co5Y7 alloy during hot compression

[J].The deformation mechanisms and microstructure evolution of Mg88Co5Y7 (at.%) alloy with long period stacking ordered (LPSO) phase during compression at 373-673 K have been studied using transmission electron microscopy. The alloy consists of alpha-Mg matrix, interdendritic LPSO phase, and other Mg-Co-Y intermetallic compounds. Increasing temperature leads to a general decrease in strength of the Mg88Co5Y7 alloy. A large number of {10 (1) over bar2} tension twins and deformation bands are activated in the matrix, whereas basal slip and deformation kink dominate in the LPSO structures during compression at 373 and 473 K. Non-basal slip in matrix and almost no dynamic recrystallization are responsible for high strength and the good ductility of sample deformed at 573 K. Recrystallization of Mg matrix occurs upon deformation at 673 K, dramatically lowering the corresponding strength. Further, the grain boundary pinning effect from LPSO phase, MgYCo4 phase, and broken Mg-3(Co, Y) segments is supposed to account for the relatively high strength of Mg88Co5Y7 alloy at high temperatures.

Synergetic deformation mechanisms in an Mg-Zn-Y-Zr alloy with intragranular LPSO structures

[J].

Twinning and the ductility of magnesium alloys: Part I: “Tension” twins

[J].

The accommodation around {1012}<1011> twins in magnesium

[J].

Activation mode dependent {

The effect of twin-twin interactions on the nucleation and propagation of {

Twin-twin interactions in magnesium

[J].

Co-zone {

Observations on the intersection between {

The effect of twin-twin interaction in Mg-3Al-1Zn alloy during compression

[J].

Abnormal migration of twin boundaries in rolled AZ31 alloy containing intersecting {

Single and double twin nucleation, growth, and interaction in an extruded magnesium alloy

[J].

Twinning-associated boundaries in hexagonal close-packed metals

[J].

Toward understanding twin-twin interactions in hcp metals: Utilizing multiscale techniques to characterize deformation mechanisms in magnesium

[J].

Deformation twinning

[J].

Interplay between {

Deformation twinning induced decomposition of lamellar LPSO structure and its re-precipitation in an Mg-Zn-Y alloy

[J].The high hardness or yield strength of an alloy is known to benefit from the presence of small-scale precipitation, whose hardening effect is extensively applied in various engineering materials. Stability of the precipitates is of critical importance in maintaining the high performance of a material under mechanical loading. The long period stacking ordered (LPSO) structures play an important role in tuning the mechanical properties of an Mg-alloy. Here, we report deformation twinning induces decomposition of lamellar LPSO structures and their re-precipitation in an Mg-Zn-Y alloy. Using atomic resolution scanning transmission electron microscopy (STEM), we directly illustrate that the misfit dislocations at the interface between the lamellar LPSO structure and the deformation twin is corresponding to the decomposition and re-precipitation of LPSO structure, owing to dislocation effects on redistribution of Zn/Y atoms. This finding demonstrates that deformation twinning could destabilize complex precipitates. An occurrence of decomposition and re-precipitation, leading to a variant spatial distribution of the precipitates under plastic loading, may significantly affect the precipitation strengthening.

Unravelling the local ring-like atomic pattern of {

Understanding the interactions between deformation twins and plate-like phases in magnesium alloys is one of the key issues to tailor the microstructure of magnesium alloys for better mechanical properties. The {102} twin boundary with the local ring-like atomic pattern in magnesium alloy, accompanied by the interaction between deformation twin and solute atoms, has been investigated using aberration-corrected scanning transmission electron microscopy. We found that these boundaries featured local overlapping morphology near the intersection between deformation twins and stacking faults (SFs) enriched with solute atoms. The overlapping morphology is proposed to be induced by the asynchronous shuffling of the SFs and matrix during the twinning. The local ring-like atomic patterns shown here imply that the shearable specific SFs in magnesium alloys will increase twinning energy and resultantly hinder twinning propagation.

Basal shearing of twinned stacking faults and its effect on mechanical properties in an Mg-Zn-Y alloy with LPSO phase

[J].

Twinning-like lattice reorientation without a crystallographic twinning plane

[J].

Periodic segregation of solute atoms in fully coherent twin boundaries

[J].The formability and mechanical properties of many engineering alloys are intimately related to the formation and growth of twins. Understanding the structure and chemistry of twin boundaries at the atomic scale is crucial if we are to properly tailor twins to achieve a new range of desired properties. We report an unusual phenomenon in magnesium alloys that until now was thought unlikely: the equilibrium segregation of solute atoms into patterns within fully coherent terraces of deformation twin boundaries. This ordered segregation provides a pinning effect for twin boundaries, leading to a concomitant but unusual situation in which annealing strengthens rather than weakens these alloys. The findings point to a platform for engineering nano-twinned structures through solute atoms. This may lead to new alloy compositions and thermomechanical processes.

The interaction between (

Interactions between kinking and {

Elastic properties of an Mg-Zn-Y alloy single crystal with a long-period stacking-ordered structure

[J].

Role of yttrium in activation of <c + a> slip in magnesium: An atomistic approach

[J].

Deformation mechanism and dynamic recrystallization of Mg-5.6Gd-0.8Zn alloy during multi-directional forging

[J].Multi-directional forging (MDF) is an effective way to fabricate wrought magnesium alloy with ultrafine grains and random texture. Therefore, microstructure evolution and dynamic recrystallization (DRX) of magnesium alloys during MDF process have been widely investigated. Mg-Zn-RE alloys containing long-period stacking ordered (LPSO) phase have received considerable attention owing to their excellent mechanical properties. In addition, LPSO phase has great effects on the deformation mechanism and DRX behavior. Still, limited comprehensive studies can be found in the literature dealing with the microstructure evolution, deformation mechanism and DRX of magnesium alloys containing LPSO phase in MDF deformation. In this work, MDF was applied to a Mg-5.6Gd-0.8Zn (mass fraction, %) alloy containing LPSO phase. Microstructure characteristics, deformation mechanism and DRX behavior of the material in different passes were examined. Results show that there are several stages of the microstructure evolution. Twinning was activated only in a small part of grains in the early stage of deformation. As the forging direction changes, the number of twinned grains and the volume fraction of DRX grains increased. A mixed structure with coarse deformed grain and DRX grains was sustained till last forging pass, and the average size of DRX grains is about 4 μm with a random orientation. {101ˉ2} tensile twinning is the main deformation mechanism and the selection of twin variants was dominated by the Schmid law. Change in forging direction is beneficial to twinning stimulation in grains of different orientations. Kink and slipping deformation could effectively accommodate the plastic strain where the operation of twinning was hindered. Kink deformation resulted in lattice rotation predominately about the <101ˉ0> axis. DRX grains nucleated at different places during the forging process. Not only the grain boundaries and the twinned region, but also kink boundaries can induce the nucleation of DRX grains. Eventually, the twinned regions were transformed to a strip-like recrystallization structure. Under the combined influence of twinning and kinking, as well as DRX induced by twins, kink bands and grain boundaries, the initial coarse grains were significantly refined.

Mg-5.6Gd-0.8Zn合金多向锻造过程中的变形机制及动态再结晶

[J].

Kink formation and concomitant twin nucleation in Mg-Y

[J].

The interaction of deformation twins with long-period stacking ordered precipitates in a magnesium alloy subjected to shock loading

[J].

Atomic structures of symmetric tilt grain boundaries in hexagonal close packed (hcp) crystals

[J].