镁合金具有密度低、比强度高、阻尼减震性能好、导热性能优良和易于回收等诸多优点,在汽车、电子、国防军工和航空航天等领域得到了广泛的应用,被称为21世纪的绿色工程结构材料[1~5]。然而,由于Mg及其合金的hcp晶体结构,在室温条件下仅能启动有限数量的滑移系统,导致其室温下塑性成型能力较差,这严重限制了Mg及其合金更进一步的发展与应用[6~9]。众所周知,除基面滑移之外,形变孪生,尤其是{

本工作采用分离式Hopkinson (SHPB)实验装置在室温条件下对沿RD预压缩4%真应变的轧制态AZ31镁合金试样进行沿ND不同应变速率的高速冲击实验。基于电子背散射衍射(EBSD)技术对比分析了应变速率对退孪生行为的影响,并对原始和预压缩AZ31镁合金试样沿板法向的高速变形行为进行了对比分析。

1 实验方法

实验材料选用经300℃保温120 min 均匀化处理,厚度为8 mm轧制态AZ31 (Mg-3%Al-1%Zn-0.2%Mn,质量分数)镁合金板材。均匀化处理的目的是消除轧制态板材中的变形孪晶。采用电火花线切割从原始试样上分别沿RD、TD和ND获取长、宽和高分别为25、20和8 mm的长方体试样。为引入大量的{

2 实验结果

2.1 原始AZ31镁合金试样的微观组织特征

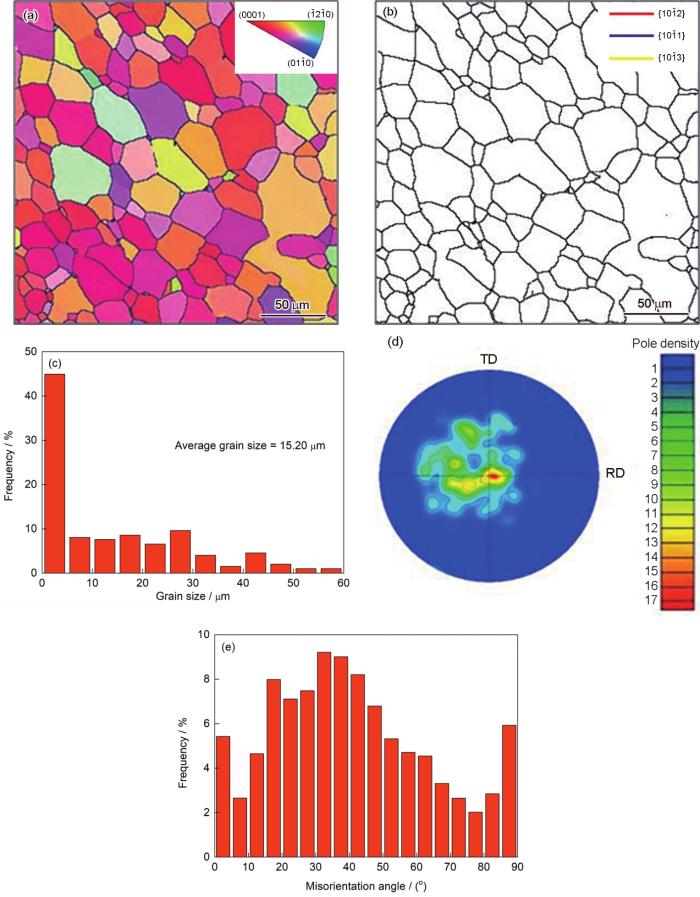

图1

图1

均匀化处理后轧制态AZ31镁合金板材的反极图、晶界图、晶粒尺寸分布图、{0001}极图和取向差角分布图

Fig.1

EBSD analysis results of the rolled AZ31 magnesium alloy sheet after homogenization (TD and RD represent transverse direction and rolling direction of the sheet, respectively)

(a) inverse pole figure (b) grain boundary figure

(c) grain size distribution (d) {0001} pole figure

(e) misorientation angle distribution

2.2 预压缩AZ31镁合金试样的微观组织特征

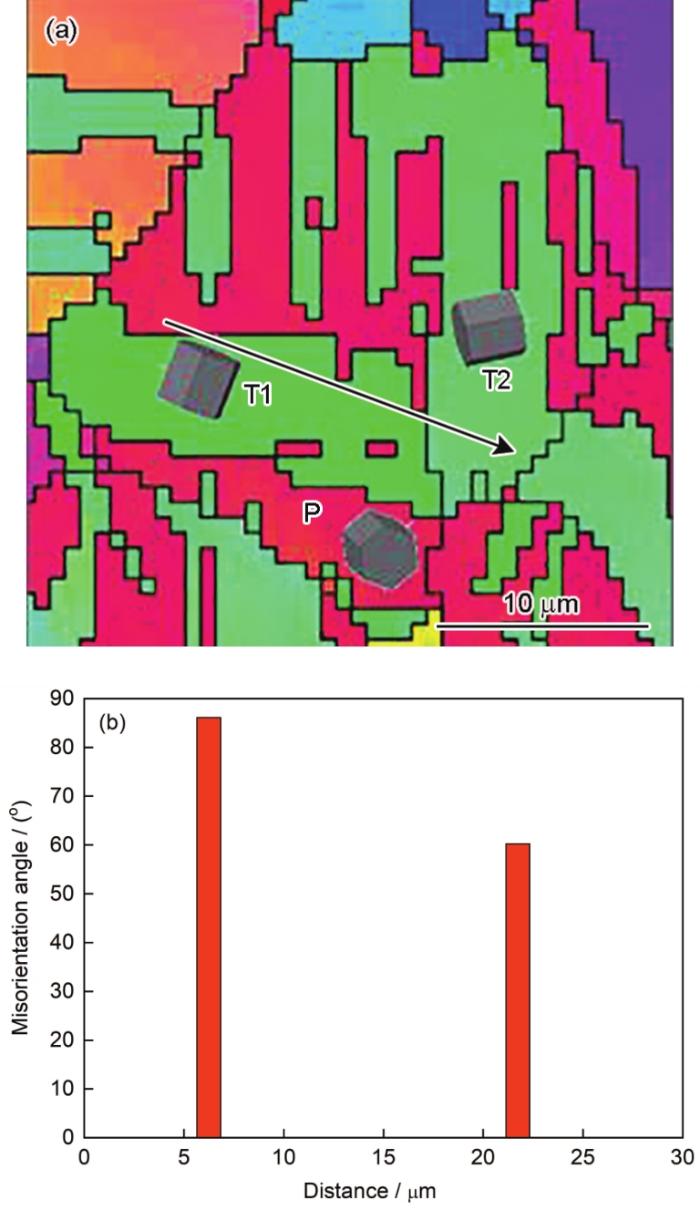

对AZ31镁合金原始试样沿RD进行4%预压缩后的EBSD分析结果如图2所示。可见,原始试样预压缩后生成大量带状的{

图2

图2

沿轧制方向预压缩4%后轧制态AZ31镁合金板材的反极图、晶界图、{0001}极图、晶粒尺寸分布图和取向差角分布图

Fig.2

EBSD analysis results of the rolled AZ31 magnesium alloy sheet precompressed along RD with a true strain of 4%

(a) inverse pole figure (b) grain boundary figure

(c) grain size distribution (d) {0001} pole figure

(e) misorientation angle distribution

图3

图3

图2a中矩形区域局部放大图及沿图3a中箭头方向的取向差角分布图

Fig.3

Local enlarged figure of the rectangular region in Fig.2a (a) and misorientation angle distribution along the direction indicated by the arrow in Fig.3a (b)

2.3 不同应变速率下的退孪生行为

沿RD预压缩4%的轧制态AZ31镁合金板材在受到沿ND,应变速率分别为700、1000、1300和1600 s-1高速冲击压缩后的EBSD分析结果分别如图4~7所示。从图4a可以看出,当冲击应变速率为700 s-1时,相比于预压缩试样,冲击后试样中的拉伸孪晶数量明显减少,部分母晶粒中的孪晶尺寸减小至形核初期的颗粒状态甚至完全消失,与此同时,由于孪晶尺寸的减小,孪晶界对母晶粒的分割作用也随之减弱,平均晶粒尺寸从预变形时的4.62 μm增加到5.46 μm (图4c)。{0001}极图中c轴平行于RD的拉伸孪晶织构强度明显降低,基面织构强度增大,最大极密度为7.65 (图4d)。此外,根据取向差角分布图(图4e)可知,90°附近的拉伸孪晶特征取向差角峰值降低,由于发生交割孪晶的减少,60°处取向差角的小的峰值也随之降低。

图4

图4

预压缩轧制态AZ31镁合金沿法向(ND)冲击应变速率为700 s-1时的反极图、晶界图、晶粒尺寸分布图、{0001}极图和取向差角分布图

Fig.4

EBSD analysis results of the precompressed rolled AZ31 magnesium alloy impacted along normal direction (ND) under the strain rate of 700 s-1

(a) inverse pole figure (b) grain boundary figure

(c) grain size distribution (d) {0001} pole figure

(e) misorientation angle distribution

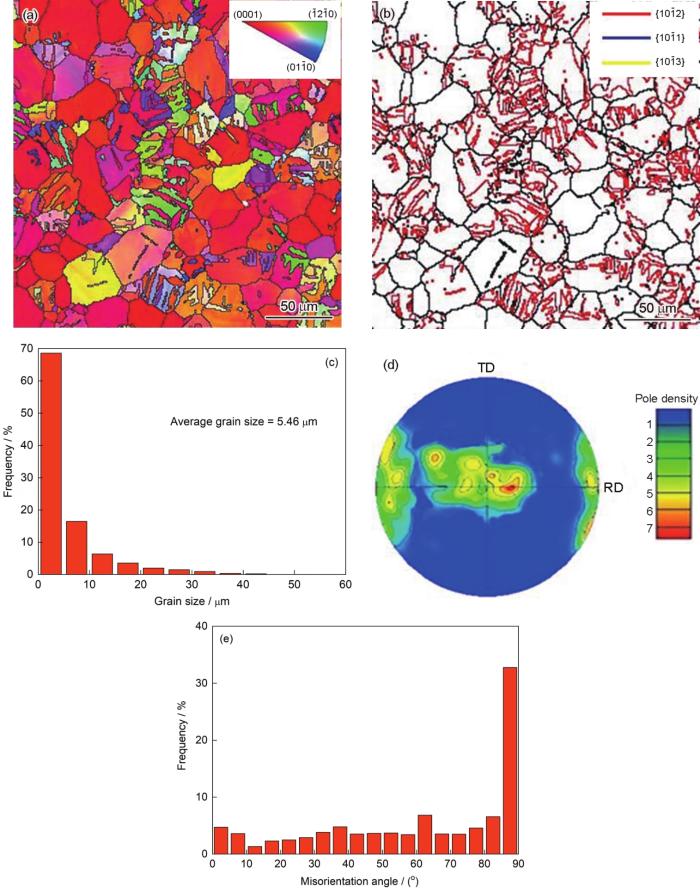

图5

图5

预压缩轧制态AZ31镁合金沿ND冲击应变速率为1000 s-1时的反极图、晶界图、晶粒尺寸分布图、{0001}极图和取向差角分布图

Fig.5

EBSD analysis results of the precompressed rolled AZ31 magnesium alloy impacted along ND under the strain rate of 1000 s-1

(a) inverse pole figure (b) grain boundary figure

(c) grain size distribution (d) {0001} pole figure

(e) misorientation angle distribution

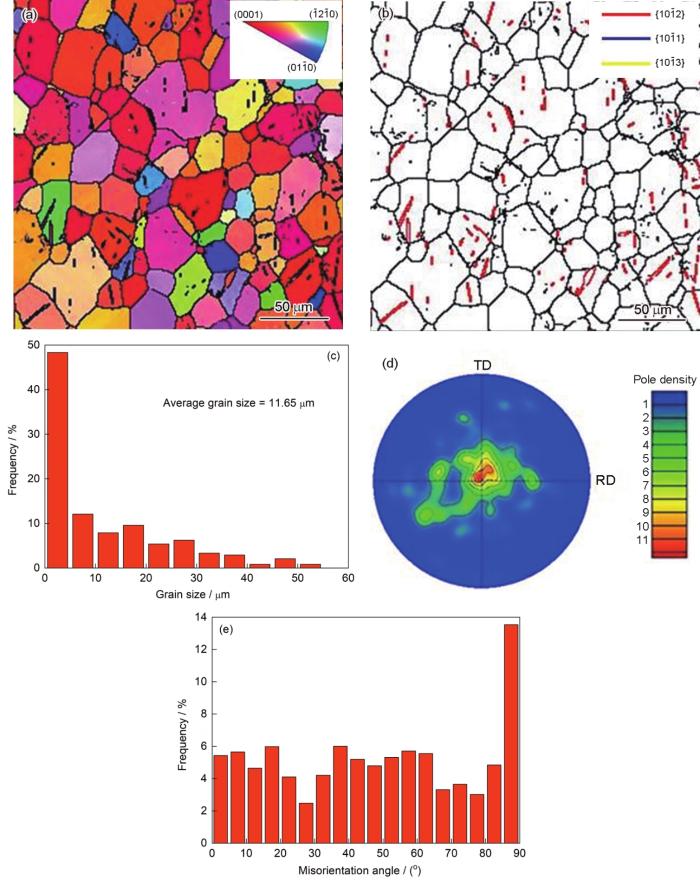

图6

图6

预压缩轧制态AZ31镁合金试样沿ND冲击应变速率为1300 s-1时的反极图、晶界图、晶粒尺寸分布图、{0001}极图和取向差角分布图

Fig.6

EBSD analysis results of the precompressed rolled AZ31 magnesium alloy specimen impacted along ND under the strain rate of 1300 s-1

(a) inverse pole figure (b) grain boundary figure

(c) grain size distribution (d) {0001}pole figure

(e) misorientation angle distribution

图7

图7

预压缩轧制态AZ31镁合金试样沿ND冲击应变速率为1600 s-1时的反极图、晶界图、晶粒尺寸分布图、{0001}极图和取向差角分布图

Fig.7

EBSD analysis results of the precompressed rolled AZ31 magnesium alloy specimen impacted along ND under the strain rate of 1600 s-1

(a) inverse pole figure (b) grain boundary figure

(c) grain size distribution (d) {0001}pole figure

(e) misorientation angle distribution

进一步对比图4~7可知,随着沿ND冲击应变速率的增大,预压缩试样受到的冲击应力和最大真应变也逐渐增加,这导致退孪生效应逐渐增强,{

为了分析高速冲击过程中拉伸孪晶的退孪生演变过程,对预压缩试样和沿ND进行不同应变速率下冲击压缩实验后的试样中每个母晶粒内孪晶数量所占百分比进行了分析,结果如图8所示。可知,预压缩试样中不含有拉伸孪晶和只含有1个拉伸孪晶的母晶粒仅占2.8%和4.2%;75%的母晶粒内部含有3个以上的拉伸孪晶,这说明在预压缩过程中绝大多数晶粒都发生了孪晶变形,且孪晶变形重复发生。当预压缩试样受到沿ND方向应变速率为700 s-1的高速冲击时,10.7%的母晶粒中没有孪晶,即发生完全退孪生,内部含有3个及以上拉伸孪晶的母晶粒占53.8%。随着冲击应变速率的增加,完全退孪生的晶粒的数量逐渐增多,当冲击应变速率增大至1600 s-1时,完全退孪生的母晶粒达到92%,内部含有1个和2个拉伸孪晶的母晶粒仅分别占6.7%和1.3%。这表明退孪生程度与冲击应变速率有密切关系,预压缩试样中的拉伸孪晶随着应变速率的增大逐渐恢复为细小的带状并直至消失。

图8

图8

预压缩轧制态AZ31镁合金试样和经不同应变速率冲击试样内母晶粒中的孪晶数量分布图

Fig.8

Number of tensile twins in precompressed rolled AZ31 magnesium alloy specimen (a) and impacted along ND under 700 s-1 (b), 1000 s-1 (c), 1300 s-1 (d), and 1600 s-1 (e)

沿ND不同的冲击应变速率下预压缩AZ31镁合金试样中退孪晶后残余的{

图9

图9

沿ND不同冲击应变速率下预压缩AZ31镁合金试样中残余拉伸孪晶面积分数和孪晶厚度

Fig.9

Remaining tensile twin area fractions and twin thicknesses of the precompressed AZ31 magnesium alloy specimen impacted along ND under different strain rates

2.4 不同应变速率下的高速变形行为

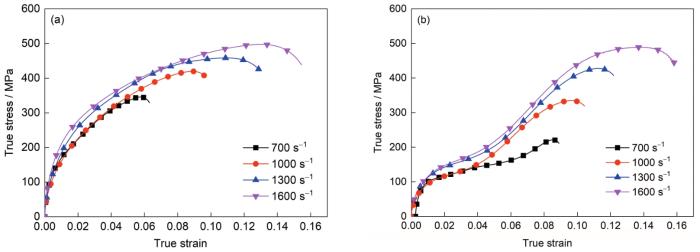

当沿ND的冲击应变速率为700、1000、1300和1600 s-1时,原始及预压缩轧制态AZ31镁合金试样的真应力-真应变曲线如图10所示。从图10a可知,当原始轧制板材试样受到沿ND的高速冲击载荷时,不同应变速率下的真应力-真应变曲线形态均为上凸形,且不存在明显的屈服阶段。随着应变速率的增大,材料在弹性变形和塑性变形阶段同一真应变下的真应力均逐渐增大,即表现出正应变速率强化效应,但这种强化效应并不明显。从图10b可知,当预压缩试样受到沿ND的高速冲击载荷时,各真应力-真应变曲线形态均为下凹形,在弹性变形和塑性变形之间存在明显的屈服平台,这一特征与由拉伸孪生主导的高速变形行为相同。当真应变小于0.01时,应变速率强化效应并不明显;但当真应变大于0.04之后呈现出明显的正应变速率强化效应。对比2种试样在相同应变速率下的真应力-真应变曲线可以明显看出:对应于同一真应变,原始试样的真应力明显高于预压缩试样;而对应于同一真应力,预压缩试样的真应变高于原始试样,这表明原始试样具有更高的抗冲击强度,而预压缩试样则表现出更好的塑性。从变形机制角度分析,这是由于原始试样沿ND冲击时的主要变形机制为非基面滑移[27],而当预压缩试样沿ND冲击时的主要变形机制为退孪生。非基面滑移的临界剪切应力(CRSS)明显高于退孪生,这导致达到相同塑性真应变时对原始试样需要加载更大的冲击应力。

图10

图10

原始及预压缩轧制态AZ31镁合金沿ND在不同冲击应变速率下的真应力-真应变曲线

Fig.10

True stress-strain curves of the as-received (a) and precompressed (b) AZ31 magnesium alloy impacted along ND under different strain rates

原始与预压缩轧制态AZ31镁合金试样沿ND冲击时的屈服应力与峰值应力随应变速率的变化规律如表1所示。经对比可知,相同冲击应变速率下原始试样具有更高的屈服应力和峰值应力。此外,2种试样的屈服应力与峰值应力均随应变速率的增加而增大,原始试样的屈服应力平均增幅为7.76%,大于预压缩试样的4.18%;原始试样峰值应力平均增幅为11.36%,小于预压缩试样的21.88%,这表明预压缩试样沿ND冲击表现出更加明显的正应变速率强化效应和应变速率敏感性。

表1 原始试样与预压缩AZ31镁合金试样沿ND在不同应变速率下冲击的屈服应力与峰值应力 (MPa)

Table 1

| Specimen | ||||||||

|---|---|---|---|---|---|---|---|---|

| σs | σp | σs | σp | σs | σp | σs | σp | |

| As-received | 113.2 | 345.6 | 128.9 | 419.7 | 135.4 | 458.6 | 144.5 | 498.1 |

| Precompressed | 98.7 | 228.1 | 102.5 | 348.8 | 107.3 | 415.2 | 112.2 | 488.8 |

为定量化地对比2种试样沿ND的应变速率敏感性,引入应变速率敏感指数m,其表达式如下式所示[28]:

表2 应变速率为700和1600 s-1时原始试样与预压缩试样沿ND冲击的应变速率敏感指数

Table 2

| Specimen | |||||

|---|---|---|---|---|---|

| As-received | 0.227 | 0.269 | 0.232 | 0.166 | 0.224 |

| Precompressed | 0.301 | 0.179 | 0.295 | 0.438 | 0.303 |

3 分析讨论

图11所示为理想基面织构中的一个晶粒在沿RD预压缩和后续沿ND高速冲击的取向变化。利用晶体转动理论可以合理解释本工作中预压缩轧制态AZ31镁合金的退孪生行为:由于镁合金中{

图11

图11

退孪生晶粒取向变化示意图

Fig.11

Schematics showing the change of orientation during detwinning

(a) initial orientation (b) after precompression along RD (c) after impaction along ND

已有研究[31]指出,退孪生不是大的孪晶劈裂成小的孪晶,而是大孪晶尺寸逐渐减小,直至消失。本工作中随着沿ND应变速率的增大,单一母晶粒内所含{

对比分析相同应变速率下不同的{

4 结论

(1) 原始轧制态AZ31镁合金板材具有典型强基面织构,当沿RD进行应变量为4%的准静态预压缩后,大量{

(2) 当预压缩AZ31镁合金试样受到沿ND应变速率逐渐增大的高速冲击时,试样内部退孪生行为愈发明显,平均晶粒尺寸逐渐增大,基面织构逐渐增强,与此同时孪晶织构强度逐渐降低。残余孪晶面积分数和孪晶平均宽度随着冲击应变速率的增加逐渐减小。当冲击应变速率达到1600 s-1时,预压缩试样达到完全退孪晶状态,微观组织特征与原始试样基本相同。

(3) 对比原始与预压缩AZ31镁合金试样沿ND的高速变形行为可知,相同冲击应变速率下原始试样具有更高的强度,而预压缩试样则表现出更好的塑性。从变形机制角度分析,这是由于预压缩试样沿ND冲击时主导塑性变形的变形机制为退孪生,相比于原始试样沿ND冲击的变形机制为非基面滑移具有更低的临界剪切应力。对比平均应变速率敏感指数可知,预压缩试样相比于原始试样表现出更加明显的应变速率敏感性。

参考文献

Effect of texture on high temperature deformation behavior at high strain rates in a Mg-3Al-1Zn alloy

[J].

Nucleation and propagation of {

The mechanism of {

Mg的{

Anisotropy and deformation mechanisms of as-extruded Mg-3Zn-1Y magnesium alloy under high strain rates

[J].

高应变速率下Mg-3Zn-1Y镁合金的各向异性及变形机制

[J].采用分离式Hopkinson压杆装置(SHPB)测试了挤压态Mg-3Zn-1Y稀土镁合金在应变速率分别为1000、1500和2200 s<sup>-1</sup>时的动态真应力-真应变曲线;采用OM和SEM等分析了其高速变形过程中的组织演变规律及断口形貌,从微观变形机制的角度探讨了具有强烈初始基面织构的挤压态镁合金产生各向异性的原因。分析结果表明:在高速变形条件下,由于加载方向不同,挤压态Mg-3Zn-1Y镁合金的压缩行为表现出较明显的各向异性。挤压态Mg-3Zn-1Y镁合金宏观上的各向异性是由于不同的微观变形机制所引起的。沿挤压方向压缩时,当应变较小时,变形机制主要为拉伸孪晶,当应变增加时,会有柱面滑移参与变形,当应变达到一定值时滑移成为其主要的变形方式。而沿挤压横向压缩时,随着应变速率增加,变形方式由压缩孪生为主变为基面滑移和二次锥面滑移协同变形。

A new mechanism for twin growth in Mg alloys

[J].

Twinning characteristic of AZ31 magnesium alloy during dynamic plastic deformation

[J].

动态塑性变形下AZ31镁合金的孪生特征

[J].

Intragranular twinning, detwinning, and twinning-like lattice reorientation in magnesium alloys

[J].

Influence of local strain on twinning behavior during compression of AZ31 magnesium alloy

[J].

Study of twinning behavior of AZ31 Mg alloy during plane strain compression

[J].

AZ31镁合金在平面应变压缩过程中的孪生行为研究

[J].采用EBSD技术研究了AZ31镁合金在平面应变压缩过程中的孪生行为. 结果表明, 当压缩方向为TD, 约束方向为RD时, 孪生类型主要以{101-2}拉伸孪晶为主, 孪生变体的选择主要由沿TD的孪生Schmid因子(m)决定, 并受RD的影响. 可用孪生应变张量来解释不同类型孪生晶粒的差异. 对于晶粒内部只发生1个{101-2}孪生变体的情况, 孪生变体在约束方向上的平均孪生应变张量会使得样品伸长; 对于晶粒内部含有2个及以上变体的情况, 孪生m较大的变体在约束方向上的平均孪生应变张量使得样品伸长, 而m较小的变体使得样品在约束方向缩短, 在平面应变压缩变形过程中, 不同类型的孪生变体相互协调变形.

Study on the microstructural evolution and mechanical properties control of a strong textured AZ31 magnesium alloy sheet during cryorolling

[J].

强织构AZ31镁合金板材深低温轧制过程中微观组织演变及力学性能控制研究

[J].取初始织构为c轴与板面法向垂直的强织构AZ31镁合金板材为初始样品,经液氮温度深低温轧制多道次至不同变形量,研究所得轧制板材的显微组织与织构演变,及其对轧制力学性能的影响。利用SEM、EBSD和XRD表征分析了轧制板材的显微组织和织构,应用准静态单轴拉伸实验分别测试了深低温轧制板材沿轧向(RD)和横向(TD)的室温力学性能。研究表明,{101?2}拉伸孪晶是深低温轧制强织构AZ31镁合金板材中的主导孪晶类型,其对轧制板材的微观组织和织构影响较为显著。轧制变形后,大量的拉伸孪晶晶界不但对晶粒起到了分割碎化作用,并且由于孪晶对取向的剧烈改变,使得板材在轧制变形后c轴平行于ND的织构组分加强。深冷轧制板材的强度有所提高,但是延伸率却急剧下降,沿着RD方向的强度要高于TD方向的强度。

Role of {

Study of reversible motion of {

Effects of {

Twin-twin interactions and contraction twin formation in an extruded magnesium alloy subjected to an alteration of compressive direction

[J]. J.

Improving the mechanical properties of a hot-extruded AZ31 alloy by {

Texture evolution of rolled Mg-3Al-1Zn alloy undergoing a {

The effects of pre-strain and subsequent annealing on the yielding behavior in a rolled magnesium alloy AZ31

[J].

Enhancing the strength of rolled ZK60 alloys via the combined use of twinning deformation and aging treatment

[J].

Influence of {

De-twinning and texture change in an extruded AM30 magnesium alloy during compression along normal direction

[J].Twinning and de-twinning are the salient deformation mechanisms in hexagonal close-packed (hcp) metals. The aim of this study was to examine and quantify the de-twinning process involving a reversible motion of twin boundaries in an extruded AM30 magnesium alloy after re-compression along the normal direction (ND) of pre-compressed samples along the extrusion direction (ED). {10<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_1.png"/>1¯2} extension twins were first introduced at a compressive strain of 3.7% along the ED. The subsequent compressive deformation along the ND induced a gradual shrinkage of twins with increasing cumulative true strain, and the complete de-twinning occurred at a strain of ~7.7%. The twin width decreased linearly with increasing true strain. Texture measurements verified the rotation of <em>c </em>-axes of hcp unit cells towards the anti-compression direction due to {10<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_2.png"/>1¯2} extension twinning after compression along the ED, and a gradual return of <em>c </em>-axes to the initial orientation due to twin shrinking or de-twinning during the following compression along the ND. The {10<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_3.png"/>1¯2} twinning corresponded to the formation of new texture components C{<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_4.png"/>1¯2<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_5.png"/>1¯0}<0001> and D{01<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_6.png"/>1¯0}<0001> and a decrease in the initial texture components A{0001}<2<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_7.png"/>1¯<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_8.png"/>1¯0> and B{0001}<10<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_9.png"/>1¯0>, while the twin shrinking or de-twinning was characterized by a gradual vanishing of components C{<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_10.png"/>1¯2<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_11.png"/>1¯0}<0001> and D{01<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_12.png"/>1¯0}<0001> and an increase in the components A{0001}<2<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_13.png"/>1¯<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_14.png"/>1¯0> and B{0001}<10<graphic xmlns:xlink="http://www.w3.org/1999/xlink" xlink:href="1005-0302-31-3-264/img_15.png"/>1¯0>.

Study on twinning behaviors during multi-directional compression for AZ31 magnesium alloy by EBSD

[J]. J.

多向压缩路径下AZ31镁合金孪生行为的EBSD研究

[J].

Effects of untwinning and {

退孪生行为以及{

Modeling the effect of twinning and detwinning during strain-path changes of magnesium alloy AZ31

[J].

Influence of pre-twinning on high strain rate compressive behavior of AZ31 Mg-alloys

[J].

Twin-twin interactions in magnesium

[J].

Individual effect of recrystallisation nucleation sites on texture weakening in a magnesium alloy: Part 1—double twins

[J].

Role of {

Compressive behavior and constitutive analysis of AZ31B magnesium alloy over wide range of strain rates and temperatures

[J].

Detwinning behavior of an extruded AZ31 magnesium alloy during uniaxial compression

[J].

挤压态AZ31镁合金单向压缩过程中的退孪生行为

[J].

Effects of grain size, texture and twinning on mechanical properties and work-hardening behavior of AZ31 magnesium alloys

[J].

Study on twinning-detwinning behavior of magnesium alloy by Situ EBSD

[J].

镁合金中孪生-退孪生行为的原位EBSD研究

[J].

High strain rate deformation behaviors experimental study and numerical simulation of rolled AZ31 magnesium alloy loaded along different directions

[J].

不同加载方向时轧制态AZ31镁合金高速变形行为的实验研究与数值模拟

[J].