但是,它们的非晶形成能力强弱仍然存在差异:一方面,非晶形成区间不同,其中U-Fe非晶形成范围为(14%~40%)Fe (原子分数,下同)[23],U-Co非晶范围为(10%~58%)Co[25];另一方面,用于非晶化能力评价的温度指标不同,最佳U-Fe非晶U69.2Fe30.8的约化晶化温度(Trm)与(TrL)分别为0.568与0.557 (Trm=Tx/Tm,TrL=Tx/TL,其中Tx、Tm、TL分别指初始晶化温度、熔化温度、液相线温度)[17],而最佳U-Co非晶U66.7Co33.3的Trm与TrL分别为0.543与0.535[19]。从成分区间判断,区间越宽非晶形成能力越好,而从温度指标判断,数值越高非晶形成能力越强。因此,这2个体系的非晶形成能力孰强孰弱不易确定。

由于U-Fe与U-Co属于典型的基础二元体系,为了后期设计出更优异的多元铀基非晶,需要澄清它们的非晶形成能力强弱情况。实际上,在非晶成分区间和温度指标之外,非晶块体样品的临界尺寸和形成非晶所需的临界冷却速率,才是评价非晶形成能力的最直接判据[11]。不过,U-Fe与U-Co体系至今都得不到块体样品,只能制备出几十微米厚度的条带样品,而早期研究工作中未曾探究它们的临界冷却速率。为此,本工作采用临界冷却速率作为判据进一步评价U-Co与U-Fe体系的非晶形成能力,其中前者以U66.7Co33.3为研究对象,而后者以U69.2Fe30.8作为研究对象。

1 实验方法

2 实验结果

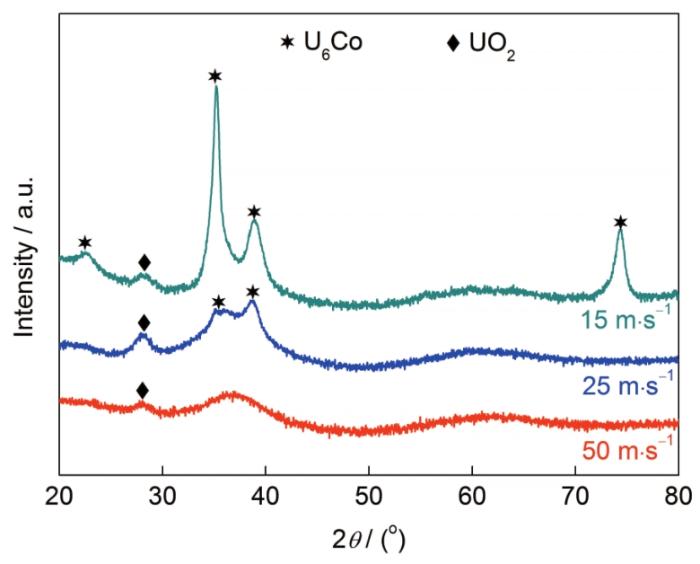

图1为在不同Cu辊线速率下制备的U66.7Co33.3合金样品的XRD谱。如果不考虑UO2衍射峰,在V=50 m/s条件下,合金完全形成了非晶相;当V=25 m/s时,合金中除了非晶主相外,开始析出体心四方结构的U6Co相(与U6Mn同型);当V降至15 m/s时,U6Co相的衍射峰变得更加显著,且从2θ位于50°~70°范围的第2个漫散峰仍然可以看出合金中也残余了非晶相,不过2种相的比例不易判断。

图1

图1

不同Cu辊线速率下U66.7Co33.3合金样品的XRD谱

Fig.1

XRD spectra of U66.7Co33.3 alloy samples prepared under different Cu-cooler linear rates

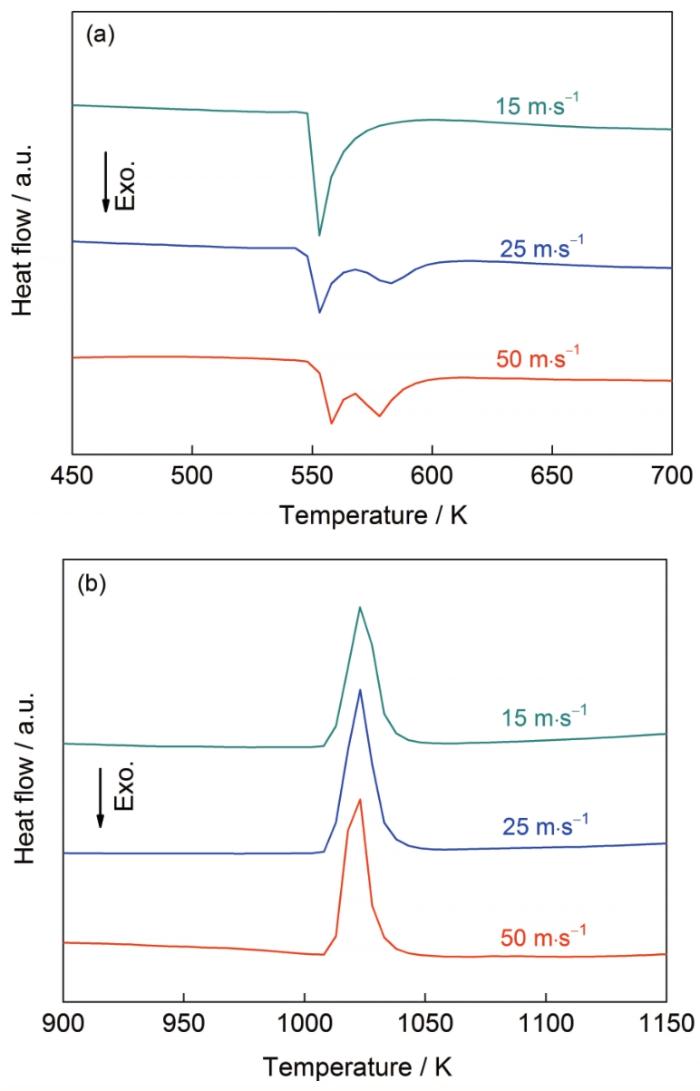

不同Cu辊线速率下U66.7Co33.3条带样品的DSC曲线如图2所示。从图2a可知,3种条带样品中的非晶相都发生了明显的放热晶化行为,其中V=15 m/s条件下的样品呈现单峰晶化模式,而V=25和50 m/s条件下样品呈现双峰晶化模式,不过前后峰的相对强度存在差异。由于这些情况下合金中U6Co相比例不同(图1),因此不难推测出这3种样品中的非晶相的化学成分都不相同,同时也意味着这3种非晶相的原子排布有所不同。图2所表现的晶化模式差异应该与3种条件下非晶相的成分和原子排布结构不同密切相关。此外,V=15 m/s条件下样品的晶化行为很显著,说明合金中残余的非晶相比例较多。与图2a不同,图2b结果显示,3种样品的熔化行为几乎一致,都呈现单峰吸热熔化模式,且Tm (1013 K)、TL (1035 K)基本不变,反映出这些样品经过晶化转变后的相组成很相近。表1给出了不同样品的非晶晶化放热焓变。可以看出它们的焓变差别不大,但随着Cu辊转速的减小,样品的焓变也减小,这是因为其中的非晶相含量减少,与图1结果相符。

图2

图2

不同Cu辊线速率下U66.7Co33.3合金样品的DSC曲线

Fig.2

DSC curves of U66.7Co33.3 alloy samples prepared under different Cu-cooler linear rates

(a) crystallization (b) melting

表1 不同Cu辊线速率下铀基非晶样品的晶化焓变

Table 1

| Alloy | V m·s-1 | Crystallization enthalpy / (J·g-1) |

|---|---|---|

| U66.7Co33.3 | 15 | 47.14 |

| 25 | 47.75 | |

| 50 | 49.28 | |

| U69.2Fe30.8 | 10 | 0.96 |

| 15 | 23.44 | |

| 20 | 23.69 |

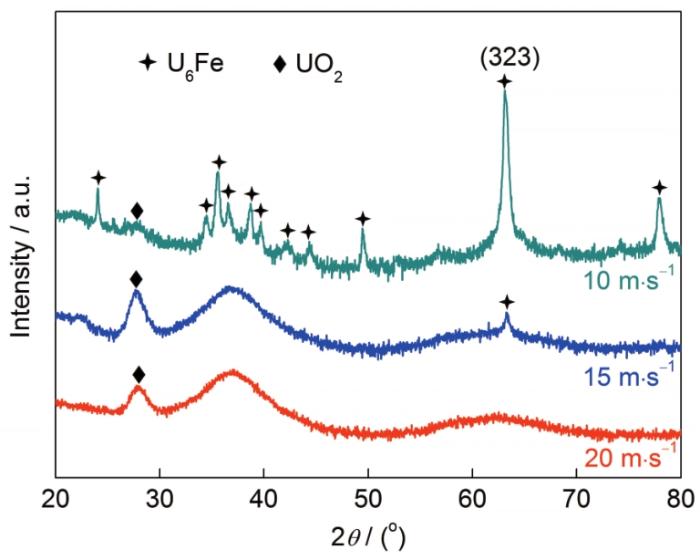

不同Cu辊线速率下U69.2Fe30.8条带样品的XRD谱如图3所示。同样,如果不考虑UO2相的衍射峰,当V=20 m/s时,该合金形成了完全的非晶相。当V=15 m/s时,合金主要形成了非晶相,但有少量与U6Co同类型的U6Fe相存在。而当V降至10 m/s时,合金中形成大量U6Fe相,非晶相是否残余难以判断。

图3

图3

不同Cu辊线速率下U69.2Fe30.8合金样品的XRD谱

Fig.3

XRD spectra of U69.2Fe30.8 alloy samples prepared under different Cu-cooler linear rates

图4给出了不同Cu辊线速率下U69.2Fe30.8合金样品的DSC曲线。从图4a可知,在V=10 m/s条件下样品的放热晶化峰非常弱,说明样品中残余了非晶相,但是含量很低。在V=15 和20 m/s时,U69.2Fe30.8合金的晶化曲线特征很相近,几乎都是单峰模式,这意味着2种条件下条带样品中非晶相的成分相差不大,进一步反映出该样品中U6Fe相析出很少。U69.2Fe30.8样品的非晶晶化焓变也由表1给出。可见,V=10 m/s条件下的放热焓远远低于其它2个条件下的数值,而后2者很接近,这与图3、图4a结果完全相符。显然,U69.2Fe30.8合金的晶化特征与U66.7Co33.3不同。然而,由图4b可以看出,该U-Fe合金的熔化特征与后者相似,都是单峰吸热熔化模式,因而也同样反映出不同U69.2Fe30.8样品在晶化转变后得到了相同的相组成。不过,与U66.7Co33.3合金相比,U69.2Fe30.8合金的Tm (约993 K)、TL (约1020 K)都偏低。

图4

图4

不同Cu辊线速率下U69.2Fe30.8合金样品的DSC曲线

Fig.4

DSC curves of U69.2Fe30.8 alloy samples prepared under different Cu-cooler linear rates

(a) crystallization (b) melting

总体来看,对于不同体系的最佳非晶合金U66.7Co33.3与U69.2Fe30.8,在不考虑UO2相的情况下,当V=25 m/s时前者未能完全形成非晶相,而V=20 m/s时后者却得到了单一的非晶相,直接说明了后者形成非晶相需要更低的临界冷速速率(具体数值难以确定),从而充分证明了U-Fe体系的非晶形成能力更高。

3 分析讨论

表2 Fe与Co元素的物理化学性质对比

Table 2

| Element | Atomic number | Outer electron configuration | Atomic size difference with U | Electronegativity difference with U |

|---|---|---|---|---|

| Fe | 26 | 3d64s2 | About 18% | 0.4 |

| Co | 27 | 3d74s2 | About 20% | 0.5 |

一方面,从热力学角度来看,根据非晶形成能力判据Tg/Tm (Tg为玻璃化转变温度)可知,Tm越低Tg/Tm越大,越有利于获得高GFA。在平衡相图中,与非晶形成相关的U-Fe体系共晶相为U6Fe (U6Mn型,Pearson符号为tI28)与Fe2U (Cu2Mg型,Pearson符号为cF24),深共晶温度为998 K,而U-Co体系为U6Co (U6Mn型,Pearson符号为tI28)与UCo相(UCo型,Pearson符号为cI16),共晶温度为1007 K,略高于前者。依据亚稳相图与亚稳深共晶概念[27],因为U6Fe与U6Co具有相同类型的晶体结构,而Fe2U比UCo的晶体结构更为复杂,所以可以推测U-Fe体系的亚稳深共晶温度比U-Co体系低得多,因而更有助于获得高的Tg/Tm。从前期热分析结果来看,U69.2Fe30.8非晶的Tx/Tm与Tx/TL分别为0.568与0.557,而U66.7Co33.3非晶分别为0.543与0.535,的确显现出了相似的趋势。

另一方面,可从非晶竞争相与熔体黏度角度进行动力学因素讨论。从非晶竞争相来看,U-Fe与U-Co 2个体系中直接与非晶竞争的晶体相都属于U6Mn型(图1和3),而根据前面的分析可知,U-Fe体系的亚稳深共晶温度应比U-Co体系低得多,这意味着非平衡凝固过程中为U6Fe相形核和长大所提供的过冷度更小,因而该相更难以从合金熔体中析出,所以更有利于形成非晶相。从熔体黏度来看,早期观点[24]认为,前锕系金属元素,如U和Pu,熔化时得益于独特的5f电子行为而具有异常高黏度[28]的特点(本质是5f电子在液态下参与成键,形成类似分子簇的短程结构,从而提高黏度),这使得前锕系元素的合金拥有较高的GFA。比如,U金属在1406 (熔点)和1573 K温度下黏度分别接近0.065和0.049 Pa·s[29],而Al金属在973和1223 K时分别靠近0.0013和0.0010 Pa·s[30]。 不难推断,Al金属熔体在1406 和1573 K温度下黏度必然小于0.0010 Pa·s,这说明在相同温度下比U熔体黏度低了至少2个数量级。另外,与Ce (熔点804 K下黏度为0.0320 Pa·s)、Pr (熔点935 K下黏度为0.0285 Pa·s)、Yb (熔点824 K下黏度为0.0267 Pa·s)[31]等拥有4f电子的元素相比,U元素在熔点附近的黏度也接近它们的2~3倍。 另有研究[32,33]表明,对于固态的U-Fe与U-Co合金,Fe的3d电子价带比Co的3d价带更靠近U的5f价带,因而Fe的3d电子更容易与U的5f电子发生杂化,由此推测在熔融状态下U与Fe原子的外层价电子更容易发生相互作用,从而使得U-Fe合金熔体具有更高的黏度,在动力学上促进U-Fe非晶的形成。

综合来看,相比于U-Co体系,U-Fe体系之所以具备更强的GFA是因为兼具热力学与动力学优势。值得一提的是,已有的铀基非晶做不成块体的主要原因之一,是用于实验的U原料纯度严重偏低[12],富含高熔点陶瓷型夹杂物,后者很容易诱发合金熔体的非均匀形核和长大,由此说明动力学条件对铀基非晶形成应该更为重要。

4 结论

U66.7Co33.3与U69.2Fe30.8合金在较高冷却速率下都可以形成接近完全非晶相,而冷却速率降低到一定程度时都会析出U6Mn型晶体相。相比而言,U-Fe合金形成完全非晶需要更低的临界冷却速率,从而证实U-Fe比U-Co体系具备更强的非晶形成能力,原因在于U-Fe非晶形成具有热力学与动力学条件的双重优势。

参考文献

The dynamic behavior hidden in the long time scale of metallic glasses and its effect on the properties

[J].Metallic glasses (MGs) have disordered microstructure and no defects like in crystalline materials and possess a suite of outstanding mechanical and functional properties, showing thus promising potential for wide applications. Due to the lack of long range structural order, it is fraught with difficulties to construct the structure-property relationship in amorphous materials. The study of relaxation dynamics provides a very important approach to understand MGs, and is vital to understand their stability and deformation behavior and remains a core issue in the field of condensed matter physics and materials science. In recent years, with the use of more advanced research methods and the deepening of research, it was found that there exists rich dynamics covered by the extremely wide time scale and the different length scales of glassy state. Different dynamic modes not only correlate with each other but also show distinction. This article reviews recent progress in the study of relaxation dynamics in MGs, and its role in understanding and modifying material properties and optimizing material preparation.

金属玻璃中隐藏在长时间尺度下的动力学行为及其对性能的影响

[J].金属玻璃微观结构无序,没有类似晶体材料中的缺陷,表现出一系列优异的力学和功能特性,具有广泛的应用前景。由于非晶结构上长程无序,难以建立结构和性能的关系。而弛豫动力学研究为认识金属玻璃提供了非常重要的窗口,对于理解其稳定性和形变行为极为关键,也一直是凝聚态物理和材料科学领域的核心问题。近年来,随着更多先进研究手段的使用和研究的不断深入,人们发现在玻璃态极长的时间跨度和不同空间尺度下蕴含着丰富的动力学行为,这些动力学模式之间彼此关联,同时也具有独特性。本文介绍了近期关于金属玻璃弛豫动力学研究的重要进展,及其对于认识和调控材料性能、优化材料制备等方面的影响。

Atomistic simulation for local atomic structures of amorphous Ni-P alloys with near-eutectic compositions

[J].100-xPx alloys with near-eutectic compositions have a strong glass forming ability (GFA), but the microstructure prototypes and their evolution in various solidification processes are still unclear now. To reveal their unique structures, a series of molecular dynamics simulations for the rapid solidification process of liquid Ni100-xPx (x=19.0, 19.4, 19.6, 19.8, 20.0, 21.0) alloys were performed at a cooling rate of 5×1012 K/s, and their local atomic configurations at 300 K were characterized by Voronoi polyhedron index 〈n3,n4,n5,n6〉and cluster type index (Zni/(ijkl)i...). The results show that the local atomic structures of Ni atoms are mainly Frank-Kasper clusters with high coordination (Z≥12) as well as their distorted configurations. Their chemical short-range orders are mostly NiZ-2P3, and these basic clusters can be further aggregated into medium-range orders (MROs) by intercross-sharing (IS) linkages. The majority of P-centered clusters are bi-capped square Archimedean anti-prism (BSAP) polyhedrons, but lots of Frank-Kasper clusters with higher coordination exist in the amorphous Ni100-xPx alloys. Their typical chemical short-range orders are Ni12P. In these short range orders (SROs) centered by P, all shell atoms are found to be Ni atoms, and no MRO can be detected except for their extended clusters linked by vertex-sharing (VS), edge-sharing (ES) and face-sharing (FS). The BSAP polyhedrons and their correlative structures play a crucial role in the formation of amorphous Ni100-xPx alloy. Their quantity is demonstrated to have a significant impact on the glass transformation of rapidly solidified Ni100-xPx alloys. It is found that the number of BSAP polyhedrons and their deformed structures at eutectic composition point x=19.6 is the largest among Ni100-xPx alloys, and the farther x deviates from the eutectic composition point, the smaller the proportion of BSAP polyhedrons and their structures more related to all P-centered clusters, which are consistent with the variation tendency of GFAs of Ni100-xPx alloys. Maybe, it could be responsible for the existence of the strongest GFAs at the eutectic composition point of Ni100-xPx alloys.]]>

近共晶成分Ni-P非晶合金微结构特征的原子模拟分析

[J].100-xPx (x=19.0、19.4、19.6、19.8、20.0、21.0)合金在冷速为5×1012 K/s下的快速凝固过程,并采用Voronoi多面体指数〈n3,n4,n5,n6〉和团簇类型指数(Zni/(ijkl)i...)对其局域原子结构进行了表征。结果发现,Ni原子的团簇属性主要是高配位(Z≥12)的Frank-Kasper团簇及其变形结构,典型的化学短程序为NiZ-2P3,基本团簇间可通过交叉共享(IS)联结形成中程序结构;而P原子的局域结构除了Z=10的BSAP多面体外,还存在大量高配位(特别是Z=12)的Frank-Kasper结构形态,典型的化学短程序为Ni12P;并且,P芯基本团簇的壳层原子全部为Ni,其间只能通过顶点共享(VS)、边共享(ES)和面共享(FS)联结形成扩展团簇。BSAP多面体及其相关结构被证实对Ni100-xPx非晶合金的形成具有重要影响,其数量在共晶点x=19.6时最多,偏离共晶点越远,所占比例越小,其结果与不同浓度下Ni100-xPx合金非晶形成能力的变化趋势一致。这可能就是Ni-P合金在共晶点具有最强非晶形成能力的原因。]]>

Structure-property correlation of high Fe-content Fe-B-Si-Hf bulk glassy alloys

[J].Bs) was less than 1.5 T. To achieve higher Bs in Fe-based amorphous alloys, the Fe content should be maximized and the metalloid and alloying elements contents should be minimized, but it makes glass formation difficult. It is difficult to reveal the effect mechanism of Fe atoms in high Fe-content amorphous alloys, due to the complexity of the amorphous structure. The present work focuses on explores the structure-property correlations of high Fe-content Fe-B-Si-Hf multi-component glassy alloys with an amorphous structure model. A series of high Fe-content alloys with the composition of [Si-B2Fe7.7Hf0.3]Fe+Fex (x=0, 1.5, 2, 2.5 and 3) was produced by adding Fe atoms to the ideal cluster formula, which is based on the composition with the best glass-forming ability of [Si-B2Fe7.7Hf0.3]Fe (Fe72.5B16.7Si8.3Hf2.5) for Fe-B-Si-Hf quaternary alloys. Liquid quench, thermal analysis and magnetic measurement results show that the critical rod size for glassy alloys gradually decreases from 2.5 mm to 1 mm as the number of Fe atoms increases from 0 to 2. The [Si-B2Fe7.7Hf0.3]Fe+Fe2 (Fe76.4B14.3Si7.1Hf2.2) bulk glassy alloy has a high saturation magnetization of 1.58 T and a low coercive force of 2.8 A/m. The decreasing of the glass transition temperature, the thermal stability, the glass-forming ability and the Curie temperature with increasing Fe content in Fe-B-Si-Hf glassy alloys was evaluated using a “dual-cluster” ({[Si-B2Fe7.7Hf0.3]+[Fe-Fe14]x/15}Fe) amorphous structure model. The result shows that the [Fe-Fe14] cluster from the α-Fe phase plays an important role in determining the properties change for this series high Fe-content Fe-B-Si-Hf glassy alloys.]]>

高Fe含量Fe-B-Si-Hf块体非晶合金的结构-性能关联

[J].2Fe7.7Hf0.3]Fe (Fe72.5B16.7Si8.3Hf2.5)为基础,通过添加Fe原子获得了[Si-B2Fe7.7Hf0.3]Fe+Fex (x=0、1.5、2、2.5和3,原子个数)系列高Fe含量的Fe-B-Si-Hf四元合金成分。液态急冷、热分析和磁性测量结果表明,随着Fe原子数量的增加,非晶合金的形成能力逐渐降低,形成棒状块体非晶样品的临界尺寸由x=0时的2.5 mm降低到x=2时的1 mm。非晶样品的玻璃态转变温度、晶化温度和Curie温度随Fe原子数量的增加也整体上表现为降低的趋势。该系列非晶样品软磁性能优异,其中[Si-B2Fe7.7Hf0.3]Fe+Fe2 (Fe76.4B14.3Si7.1Hf2.2)块体非晶合金的饱和磁化强度和矫顽力分别为1.58 T和2.8 A/m。为建立高Fe含量Fe-B-Si-Hf非晶合金的结构-性能关联,构建了{[Si-B2Fe7.7Hf0.3]+[Fe-Fe14]x/15}Fe非晶合金的“双团簇”微观结构模型。结果表明,源于α-Fe的[Fe-Fe14]团簇的数量在Fe-B-Si-Hf四元非晶合金的性能变化中起决定作用。]]>

Advances in fracture behavior and strength theory of metallic glasses

[J].Owing to the unique amorphous structure, metallic glasses (MGs) exhibit quite distinctive deformation and fracture behaviors from the conventional crystalline materials. The high strength, brittleness and macroscopic homogenous and isotropic structural features make MGs ideal model materials for the investigations of the strength theory of high-strength materials. Hence the fracture behavior and strength theory of MGs have attracted very extensive interests of researchers from the fields of materials, mechanics and physics. This paper is based on the research works of the authors on the fracture and strength of MGs in the past decade, and concentrates on discussing the current knowledge and recent advances on the fracture behavior and strength theory of ductile and brittle MGs. Firstly, the fracture behaviors of ductile and brittle MGs including tension-compression strength asymmetry, fracture mechanism and ductile-to-brittle transition will be briefly elaborated. Then the strength theories of MGs will be discussed, with our emphasis on the foundation, validation, further development and application of the ellipse criterion. At last, some unsolved issues associated with the fracture and strength of MGs are proposed.

金属玻璃的断裂行为与强度理论研究进展

[J].由于特殊的非晶态结构, 金属玻璃表现出与传统晶体材料十分不同的变形与断裂行为. 金属玻璃具有高强、脆性和宏观均匀、各向同性的特点, 使其成为研究高强度材料强度理论的理想模型材料, 因而关于金属玻璃的断裂行为与强度理论研究至今仍然吸引着材料、力学和物理等学科研究人员的广泛兴趣. 本文基于作者十多年来关于金属玻璃断裂与强度方面的研究工作, 着重阐述对韧性和脆性金属玻璃的断裂行为和强度理论方面的最新认识和研究进展, 最后提出金属玻璃断裂与强度方面尚待解决的科学问题.

Glass-forming ability and corrosion resistance of Zr-Cu-Al-Co bulk metallic glass

[J].

Atomic packing in Fe-based metallic glasses

[J].

Composition design procedures of Ti-based bulk metallic glasses using the cluster-plus-glue-atom model

[J].

Metallic glass matrix composites

[J].

Is metallic glass poised to come of age?

[J].

Deformation of metallic glasses: Recent developments in theory, simulations, and experiments

[J].

U-based binary strong glass forming system

[J].

Effect of minor alloying on the glass forming ability of U-Co alloy

[J].

微合金化对U-Co金属玻璃形成能力的影响

[J].

U-based metallic glasses with superior glass forming ability

[J].

U-involved sphere-dispersed metallic glass matrix composites

[J].

Non-isothermal crystallization behavior of U-based amorphous alloy

[J].

U-Cr binary alloys with anomalous glass-forming ability

[J].81Cr19. Under the preparation of melt-spinning, these alloys can be formed into a single amorphous phase with the capacity of crystallizing at about 700 K. The reduced crystallization temperature (Trx) of some U-Cr alloys exceeded 0.6, higher than those of U-Fe and U-Co metallic glasses, and comparable to those of ordinary bulk amorphous alloys. Being inconsistent with the prediction based on thermodynamics, kinetics and efficient structural packing, U-Cr alloy system shows anomalous strong glass-forming ability among reported actinide binary glasses. This abnormal behavior might be related to the existence of comparatively more mediate metastable phases in U-Cr system, which can be speculated from the multi-peak crystallization phenomenon. This system could be a potential system model for studying the glass formation of actinide amorphous alloys further.]]>

具有反常非晶形成能力的U-Cr二元合金

[J].81Cr19. Under the preparation of melt-spinning, these alloys can be formed into a single amorphous phase with the capacity of crystallizing at about 700 K. The reduced crystallization temperature (Trx) of some U-Cr alloys exceeded 0.6, higher than those of U-Fe and U-Co metallic glasses, and comparable to those of ordinary bulk amorphous alloys. Being inconsistent with the prediction based on thermodynamics, kinetics and efficient structural packing, U-Cr alloy system shows anomalous strong glass-forming ability among reported actinide binary glasses. This abnormal behavior might be related to the existence of comparatively more mediate metastable phases in U-Cr system, which can be speculated from the multi-peak crystallization phenomenon. This system could be a potential system model for studying the glass formation of actinide amorphous alloys further.]]>

Effect of minor alloying on the glass formation of U-based alloys

[J].

Stable U-based metallic glasses

[J].

Study on formation and corrosion resistance of amorphous alloy in U-Co system

[J].

U-Co系非晶合金的形成与耐蚀性研究

[J].

Dissimilar nanoscaled structural heterogeneity in U-based metallic glasses revealed by nanoindentation

[J].

Nanoindentation creep behavior of U65Fe30Al5 amorphous alloy

[J].65Fe30Al5. This alloy was tested by using a nanoindentation technique under different peak loads and loading rates. The results indicate that the creep displacement gradually increases with either the peak load or the loading rate in equal creeping time, but this tendency vanishes when exceeding a critical loading rate. The fitting based on an empirical creep equation reveals that the stress exponent of the alloy ascends when raising the peak load, and firstly declines with the loading rate and then keeps constant above the critical rate. Compared with conventional crystalline alloys, the U-Co-Al alloy shows a larger stress exponent, reflecting the possible existence of rich free volume in the amorphous alloy.]]>

U65Fe30Al5非晶合金的纳米压痕蠕变行为研究

[J].65Fe30Al5新型非晶合金蠕变行为的影响规律。结果表明,随着峰值载荷和加载速率的增加,在相同蠕变时间内,蠕变位移呈增大趋势,但当加载速率高于特定阈值时,蠕变位移不再增大。通过蠕变经验公式拟合发现,蠕变过程的应力指数随峰值载荷的增加不断变大,但随加载速率的增加先减小后基本恒定。与常规晶态合金相比,U65Fe30Al5非晶合金具有更大的应力指数,这反映出后者内部结构中富含自由体积。]]>

Research progress in U-based amorphous alloys

[J].

铀基非晶合金的发展现状

[J].铀基非晶合金是非晶家族中的特殊成员,受限于铀元素的高活性与放射性特点,目前这类非晶材料的研究极不充分.本文结合非晶合金的最新发展动态简要介绍了铀基非晶发展历史,较系统地总结了本团队的最新铀基非晶研究工作:首先较详细地介绍了新型铀基非晶的制备技术、成分体系、形成规律与晶化行为,澄清了其形成机制与热稳定性;结合高分辨电镜分析展示了其微观结构特点;采用纳米压痕技术揭示了这类非晶的微纳力学性能;利用电化学测试方法评估了其耐腐蚀性能.这些结果丰富了非晶材料的内涵,有助于深化对非晶物理基础科学问题的理解,并推动新型铀合金材料的发展,为这种材料的潜在工程应用奠定了基础.

Properties of metallic glasses containing actinide metals: I. Thermal properties of U-M glasses (M=V, Cr, Mn, Fe, Co, and Ni)

[A].

On the formation of metallic glasses based on U, Np or Pu

[J].

Anomalous glass-forming ability of uranium-based alloys

[J].

The nature and properties of amorphous matter

[J].

非晶态物质的本质和特性

[J].

Eutectics and the formation of amorphous alloys

[J].

Fluid flow of liquid plutonium alloys in an oscillating-cup viscosimeter

[J].

Volume contraction during melting; Emphasis on lanthanide and actinide metals

[J].

Abnormal changes in aluminum viscosity and its relationship with the microstructure of melts

[J].

Al熔体粘度的突变点及与熔体微观结构的关系

[J].通过测量Al熔体的粘度, 研究了Al熔体粘度随温度的变化规律, 发现在升温过程中熔体粘度值在780和950℃左右发生突变. 在降温过程中, 粘度的突变发生在930和750℃. Al熔体氢含量的测定表明, 氢含量随温度变化曲线也在780℃发生突变. 通过对液态Al的分子动力学模拟, 发现Al的第一近邻配位原子的排布方式随温度的变化在780℃左右与950℃左右也存在突变.

Viscosity of liquid rare-earth and actinide metals

[A].

Influence of 5f electrons on transport properties in uranium-based metallic glasses

[J].

Polarization of U 5f states in uranium multilayers

[J].