镁合金作为当前最理想的轻量化材料,在汽车工业、航天航空等领域有着广阔的应用前景[1~3]。然而,镁合金受其hcp结构的限制,在室温条件下能够激活的独立滑移系不足,导致其塑性较差[4]。热轧制作为一种常见的加工技术,通过显著细化镁晶粒,可有效提高合金塑性[5]。然而,在常规轧制加工过程中,镁合金中易形成强基面织构,不利于滑移系统的开启[6]。添加稀土元素(RE)可在轧制过程中有效弱化镁合金的基面织构[7],但稀土元素提高了成本,限制了镁合金在基础工业中的大规模应用。研究[8]表明,Ca可作为稀土元素的有效替代品被添加到镁合金当中,常见的合金体系包括Mg-Zn-Ca和Mg-Sn-Ca等。Bian等[9]通过轧制工艺制备了Mg-Al-Zn-Mn-Ca板材,发现这种不含稀土元素的镁合金经常规热轧退火处理后,表现出了与稀土镁合金相似的织构特征。因此,Mg-Al-Zn-Mn-Ca镁合金作为一种新型的低成本、高性能合金,受到了广泛关注与研究。

Wang等[10]研究了轧制工艺对Mg-1.6Al-0.8Zn-0.4Mn-0.5Ca合金(AZMX1100)织构和力学性能的影响,发现经单向轧制及退火处理后的板材表现出沿横向(TD)扩展和轧制方向(RD)收拢的织构特征,交叉轧制后的板材则表现出沿RD扩展的椭圆形织构特征。然而,具有这种扩展椭圆形织构的镁合金板材在变形过程中仍然存在着较强的各向异性,降低了合金板材在室温下的成形性。Li等[11]研究了Zn含量对热轧后的铸造Mg-1.2Al-0.5Ca-0.4Mn-xZn合金板力学性能和结构演化的影响,发现随着Zn含量的增加,Mg-1.2Al-0.5Ca-0.4Mn-xZn合金薄片的室温拉伸成形性提高。

鉴于此,本工作在Mg-1.6Al-0.8Zn-0.4Mn-0.5Ca的基础上适当增加了Zn含量。对熔炼得到的Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材进行单向热轧制变形,研究了热轧态Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材在退火过程中的结构演化。热轧制后形成的椭圆形织构沿TD扩展,特别是在室温变形条件下,表现出了较强的各向异性[10]。近年来,一种旨在改善镁合金板材织构的新型综合加工工艺得以开发,该工艺通过将热轧制和剪切-单道次弯曲相结合实现。Song等[12]研究表明,AZ31镁合金经过上述新型加工工艺以及后续退火处理后,板材表现出向RD倾斜的双峰织构特征。依据Taylor模型分析,这种双峰织构的形成主要与二阶锥面滑移有关[13]。基于此,本工作采用本团队开发的热轧制-剪切-弯曲(HRSB)工艺,使Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材由椭圆形织构转变为非基面织构类型,并系统研究了这种非基面织构的形成机理,旨在为开发低成本、各向同性的Mg-Al-Zn-Mn-Ca系列合金板材提供新思路。

1 实验方法

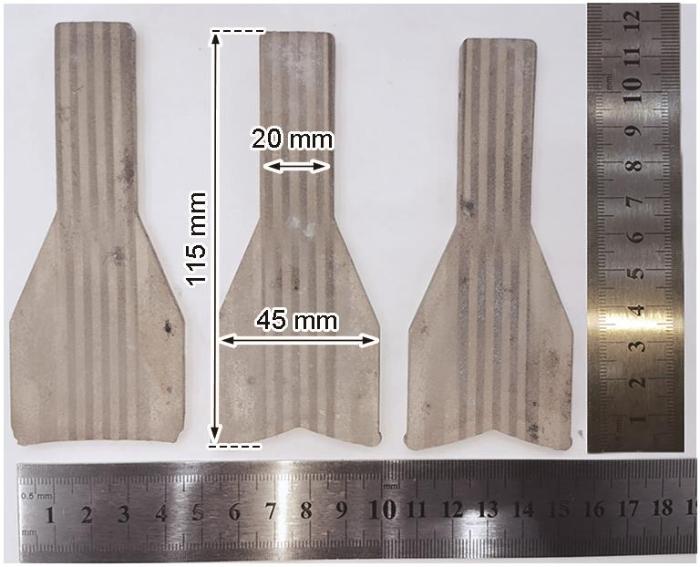

铸态Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金的主要化学成分(质量分数,%)为:Al 2.2,Zn 2.3,Mn 0.39,Ca 0.47,Mg余量。其制备工艺如下:将Mg基体在700 ℃熔化,随后向熔体中加入纯Al锭、纯Zn锭以及Mg-5%Mn、Mg-20%Ca中间合金。待合金元素全部溶解进Mg基体后,将熔体在720 ℃保温20 min。在SF6和CO2气体保护下对熔体进行精炼处理,同时搅拌、打渣。将熔体升温至740 ℃,并保温20 min,待渣/液分离后进行打渣。最后将熔体倒入尺寸为150 mm × 20 mm × 100 mm的350 ℃模具中进行凝固。采用ICP-5000电感耦合等离子体原子发射光谱仪测量铸态镁合金的实际化学成分。如图1所示,将铸态镁合金切割成3.5 mm厚的薄片,并在保温炉内进行均匀化处理(450 ℃保温12 h)。以每次15%的减薄率进行轧制,共6个道次,热轧制后合金的厚度为1.32 mm,轧机辊径为175 mm,轧机转速为600 r/min,每个道次之间对板材进行400 ℃保温5 min的处理。

图1

图1

热轧制前铸态Mg-2Al-2Zn-0.4Mn-0.5Ca 镁合金薄片的宏观形貌

Fig.1

Macroscopic photograph of the as-cast Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets before hot rolling

利用Empyrean 2 X射线衍射仪(XRD)测定未退火以及不同温度退火(350、400、450 ℃)后的热轧态板材的宏观织构。对未退火的热轧态Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材进行最后的剪切-弯曲处理,板材厚度为1.25 mm。剪切-弯曲相关流程及具体参数参照文献[14]。随后分别在400、450 ℃下退火1 h。选取400 ℃退火后的非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca板材,沿RD和TD切割成狗骨头状拉伸试样,然后在SANS试验机上以1 × 10-3 s-1的应变速率进行室温单轴拉伸实验,力学试样的尺寸和取样方式与文献[15]一致,采用3个平行样以提高实验准确性。采用配有电子背散射衍射(EBSD)探头的Apreo 2S场发射电子显微镜(FE-SEM)对退火后的样品进行显微组织观察,扫描步长为0.5 µm。采用Channel 5和OIM analysis软件提取和分析EBSD数据。通过转轴和取向差识别{

2 实验结果

2.1 热轧态Mg-2Al-2Zn-0.4Mn-0.5Ca 镁合金板材的织构特征

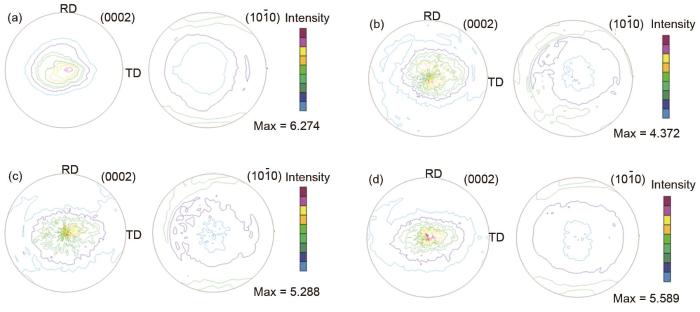

为了研究后续剪切-弯曲工艺对Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材织构的影响,采用XRD测量前期热轧制过程中的织构演化。热轧制后镁合金板材的宏观织构如图2a所示,板材表现出了弱基面织构特征,织构最大极密度为6.274。因为极低的临界分切应力(CRSS),镁合金的基面<a>滑移常作为室温下协调塑性变形的主要机制[17]。然而,基面滑移会导致基面织构的形成[18],不利于板材的后续成形。研究[19]表明,升高轧制温度能够显著弱化基面织构。此外,添加Ca、Zn以及RE元素可以增加非基面滑移的活性[8],起到弱化基面织构效果。因此,经过400 ℃、6道次热轧制后,Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的基面织构得到弱化,并没有表现出与纯Mg以及AZ31系合金类似的强基面织构特征[20,21]。图2b~d为不同温度退火后Mg-2Al-2Zn-0.4Mn-0.5Ca 镁合金板材的织构演化。退火温度为350 ℃时,基面织构进一步弱化,从(0002)极图中可以看出,最大极密度为4.372。随着退火温度升高,400 ℃时织构开始出现沿TD扩展的织构分量,此特征在450 ℃时表现得尤为显著。沿TD扩展的椭圆形织构特征,与静态再结晶(SRX)形核和晶粒优先长大相关[22]。Wang等[23]研究表明,当退火温度较低(200~300 ℃)时,Al2Ca相、压缩孪晶、2个孪晶之间的相交处、二次孪晶与晶界相交处以及非基底滑移共同诱发了TD取向晶粒的优先形核;当退火温度较高(300~450 ℃)时,晶粒长大开始在再结晶过程中占据主导地位。Al、Zn、Ca元素在晶界处发生偏析,促使TD取向晶粒优先长大,并抑制了退火过程中RD取向晶粒的长大过程。

图2

图2

热轧制及退火态Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的织构演化

Fig.2

Texture evolutions of hot-rolled (a) and as-annealed (b-d) Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets (RD—rolling direction, TD—transverse direction)

(b) 350 oC for 1 h (c) 400 oC for 1 h (d) 450 oC for 1 h

2.2 剪切-弯曲工艺处理后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的微观组织及织构特征

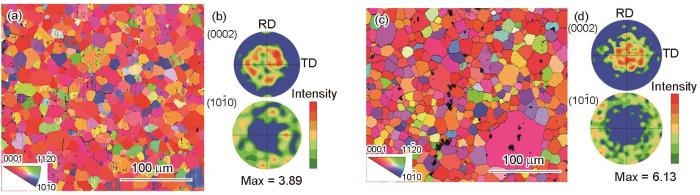

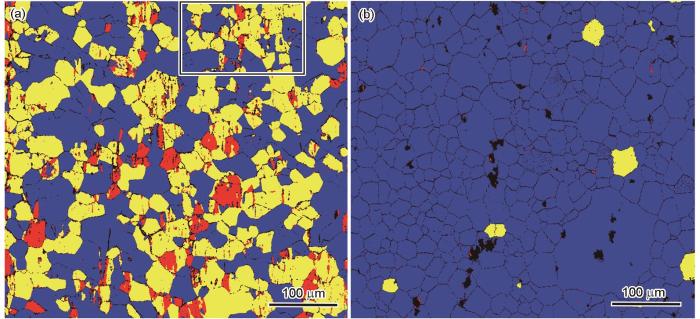

图3为经HRSB工艺以及退火处理后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的微观组织。如图3a和b所示,400 ℃退火1 h后,仍可在试样组织中观察到HRSB工艺引入的{

图3

图3

不同退火温度下热轧制-剪切-弯曲(HRSB)处理后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的微观组织

Fig.3

Inverse pole figures (IPFs) (a, c) and pole figures (PFs) (b, d) of Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets processed by hot rolling-shearing-bending (HRSB) at various annealing temperatures

(a, b) 400 oC for 1 h (c, d) 450 oC for 1 h

图4

图4

HRSB工艺处理后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材在不同退火温度下的晶粒取向分布(GOS)图

Fig.4

Grain orientation spread (GOS) maps of Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets after processed by HRSB at various annealing temperatures (The blue areas represent recrystallized grains, the yellow areas represent subgrains, and the red areas represent deformed grains)

(a) 400 oC for 1 h (b) 450 oC for 1 h

2.3 非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca 合金板材的力学性能

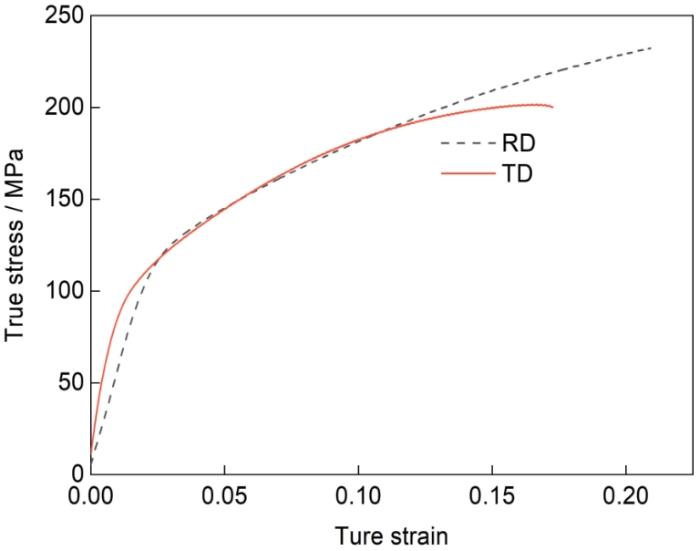

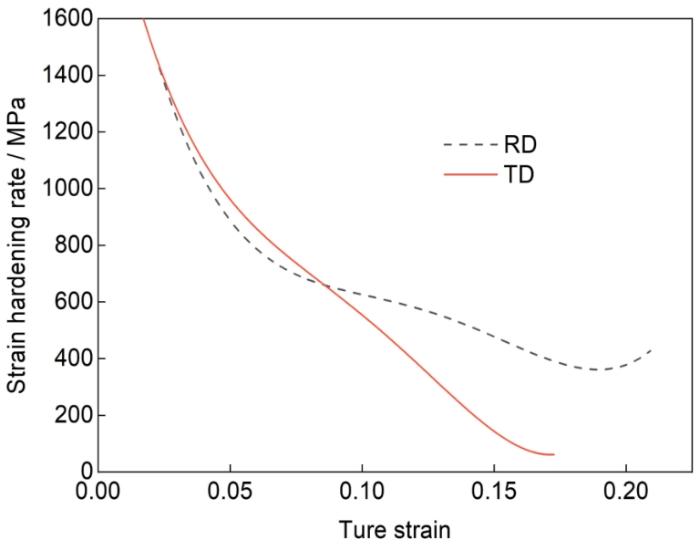

为了理解非基面织构对Mg-2Al-2Zn-0.4Mn-0.5Ca合金板材室温力学性能的影响,图5为经HRSB及400 ℃退火处理后,沿RD和TD拉伸后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的室温真应力-应变曲线,相关的力学性能数据如表1所示。经过HRSB处理后,板材沿RD的屈服强度(YS)、抗拉强度(UTS)以及延伸率(FE)分别为112 MPa、232 MPa以及20.9%;沿TD的YS、UTS以及FE分别为95 MPa、201 MPa以及17.3%。尽管Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材沿2个方向进行拉伸后,其屈服强度及抗拉强度分别存在一定差异,但具有相似的屈强比(0.483和0.472)。这表明环形织构的形成降低了Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的各向异性,一定程度上改善了室温力学性能的非对称性。图6为经HRSB及400 ℃退火处理后,沿RD和TD拉伸后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的加工硬化曲线。可以看出,沿2个方向拉伸后的样品经历了不同的加工硬化阶段。较TD拉伸样品,沿RD拉伸的样品还经历了一个平缓的加工硬化阶段。TD曲线表现出的变化趋势主要由滑移位错所主导,而RD曲线的变化趋势则受到滑移位错和形变孪晶共同影响[25,26]。

图5

图5

HRSB处理及400 ℃退火1 h后,非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材沿不同方向拉伸后的室温真应力-应变曲线

Fig.5

Room temperature true stress-strain curves after tensile tests along RD and TD for Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets with non-basal texture after HRSB treatment and annealing at 400 oC for 1 h

表1 沿不同方向拉伸后试样的室温力学性能

Table 1

| Loading direction | YS MPa | UTS MPa | FE % | YS / UTS |

|---|---|---|---|---|

| RD | 112 | 232 | 20.9 | 0.483 |

| TD | 95 | 201 | 17.3 | 0.472 |

图6

图6

HRSB处理及400 ℃退火1 h后,非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材沿不同方向拉伸后的室温加工硬化曲线

Fig.6

Room temperature true strain hardening curves after tensile tests along RD and TD for Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets with non-basal texture after HRSB treatment and annealing at 400 oC for 1 h

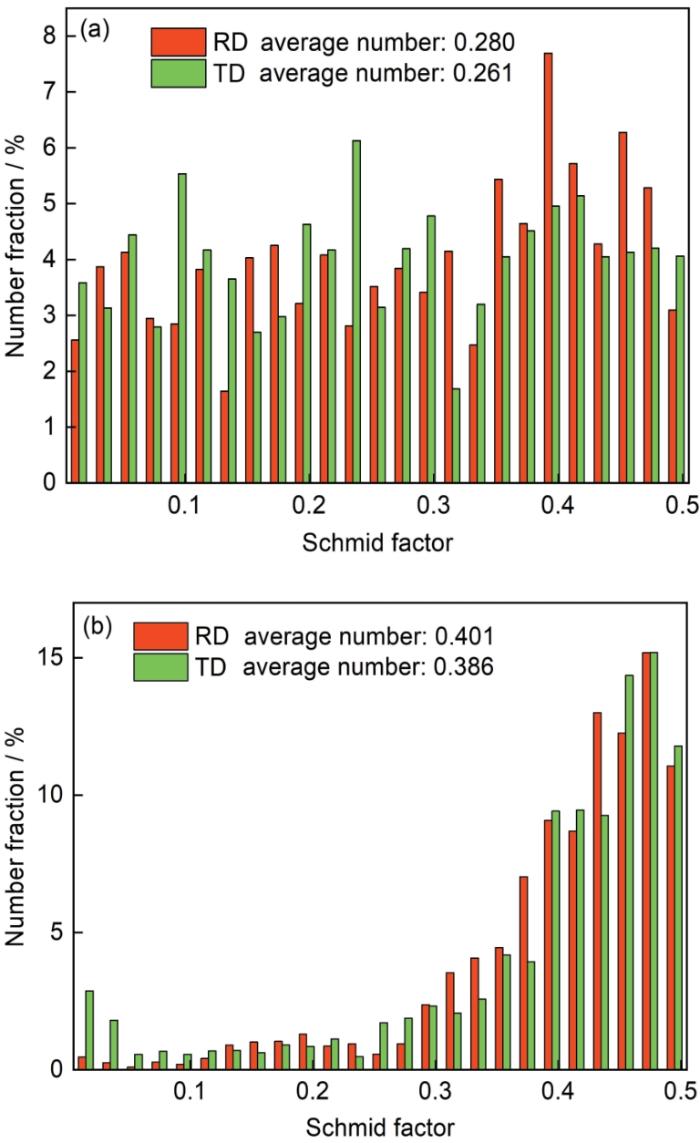

图7为拉伸变形前,具有非基面织构的Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材在RD和TD 2个方向上,基面<a>滑移和柱面<a>滑移的Schmid因子(SF)分布。对于滑移系统而言,在RD和TD 2个加载方向上,基面和柱面滑移的SF分布变化并不明显,这归因于400 ℃退火后环形织构的形成。因此,2个加载方向上合金力学性能的差异主要是由形变孪晶所带来的。值得注意的是,从原始板材的SF分布来看,这种具有非基面织构的Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材室温拉伸时柱面<a>滑移比基面<a>滑移表现得更活跃。

图7

图7

拉伸前非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca 镁合金板材沿不同方向滑移系统的Schmid因子(SF)分布

Fig.7

Distribution of schmid factor (SF) in basal <a> slip (a) and prismatic <a> slip (b) systems of non-basal textured Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheet in different loading directions before uniaxial tension

3 分析与讨论

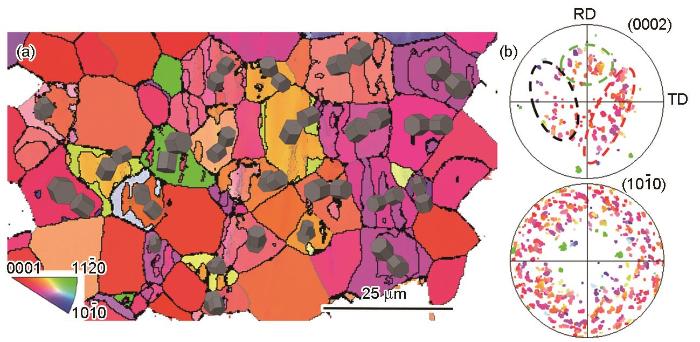

由于{

图8

图8

400 ℃退火1 h后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的电子背散射衍射(EBSD)像以及孪晶与相应基体的几何位置关系

Fig.8

EBSD image of the selected region in Fig.4a of Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheet annealed at 400 oC for 1 h (The grey cubes represent schematic illustration of the matrix and twin) (a) and the geometric relationship between twins and their corresponding matrix positions (The black and green dashed lines represent the majority of the matrix orientation distribution, and the red dashed line represents the orientation distribution of {

图9

图9

图8所示区域的晶界图及局部取向差(KAM)图

Fig.9

Grain boundary map (a) and kernel average misorientation (KAM) map (b) of the selected region in Fig.8 (Red lines in Fig.9a represent {

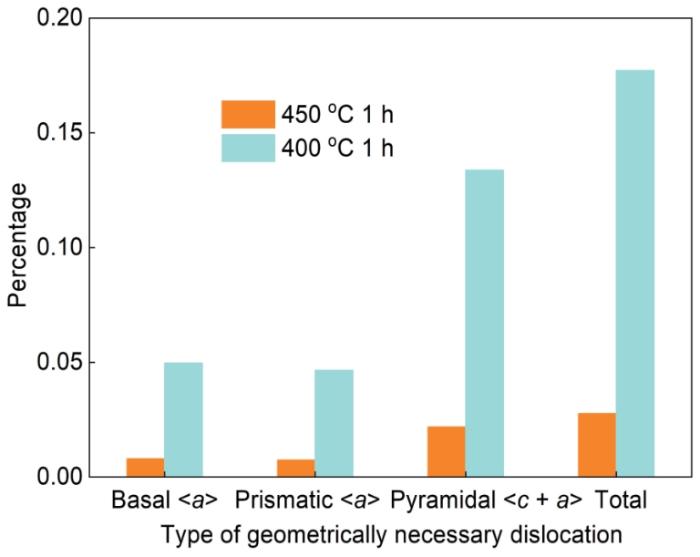

图8b中黑色椭圆形区域内的晶粒,其c轴由ND向RD倾斜。如前文所述,轧制变形过程中向RD分散的双峰织构主要与锥面<c + a>滑移有关。退火温度达到450 ℃时,大部分晶粒已经发生完全再结晶(图4b),因此位错密度较低。退火温度为400 ℃时,仍可观察到由滑移位错留下的小角度晶界(图4a)。采用Pantleon[29]提出的一种非负位错密度估算法,计算图4所示的2个区域的几何必需位错(GND)密度的估算值,如图10所示。计算结果表明,在HRSB过程中,锥面<c + a>滑移被大量激活,成为位错的主要组成部分。锥面<c + a> GND的估算值远高于基面和柱面<a>。因此,非基面滑移所引起的取向梯度可以促进亚晶粒的形成,使得c轴由ND向RD倾斜的晶粒优先形核[21]。

图10

图10

图4所示区域非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材各滑移系统的几何必需位错(GND)密度估算值分布

Fig.10

Distributions of estimated geometrical necessary dislocation (GND) density for each slip system of non-basal textured Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets annealed at different temperatures of the regions in Figs.4a and b

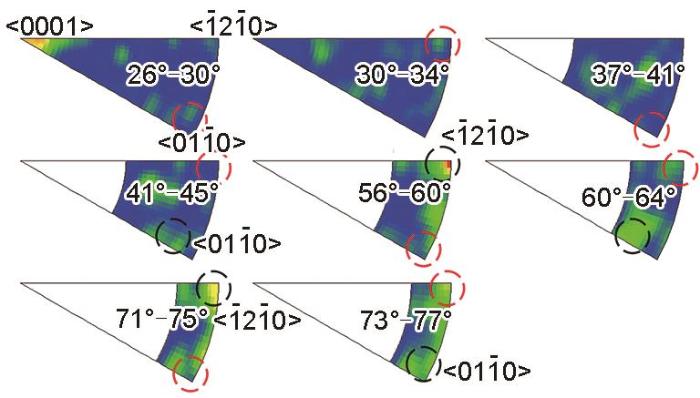

图8b中绿色椭圆形区域内的晶粒,其c轴由ND向TD倾斜。图11为HRSB处理及400 ℃退火1 h后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材中8种特殊晶界的旋转轴分布。结果表明,退火400 ℃退火1 h后,样品中除保留了密排六方金属中的常规低能晶界[30] (28°<

图11

图11

HRSB处理及400 ℃退火1 h后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材中8种特殊晶界的旋转轴分布图

Fig.11

Rotation axis distribution maps of 8 special grain boundaries in Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheet processed by HRSB and annealed at 400 oC for 1 h (The red dashed lines represent the conventional low-energy grain boundaries that occur during the annealing process of hcp metals, while the black dashed lines represent the newly generated low-energy grain boundaries)

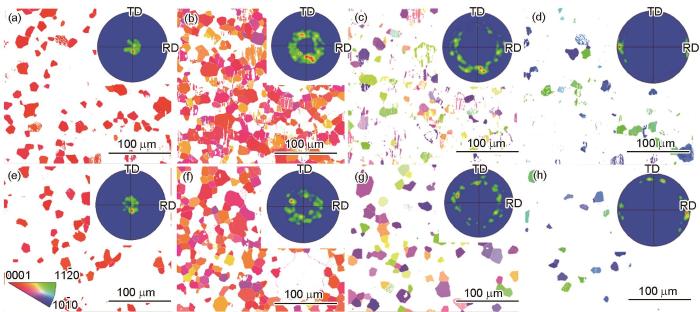

为了描述退火温度对Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材织构演化的影响,将织构依照取向差分成4组,分别是0°~20° (在这个范围内的织构通常称为基面取向)、20°~45°、45°~70°和70°~90°,如图12所示。当退火温度为400 ℃时(图12a~d),仍可观察到取向差大于20°的基体激活{

图12

图12

不同退火温度后非基面织构Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的织构组分分布

Fig.12

Texture component distributions of non-basal textured Mg-2Al-2Zn-0.4Mn-0.5Ca magnesium alloy sheets annealed at 400 oC (a-d) and 450 oC (e-h) for 1 h (Insets are corresponding (0002) pole figures)

(a, e) 0°-20° group (b, f) 45°-70° group (c, g) 20°-45° group (d, h) 70°-90° group

4 结论

(1) 热轧制后Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材表现出弱基面织构特征,退火温度高于350 ℃时,开始出现沿TD扩展的椭圆形织构。

(2) 热轧制-剪切-弯曲及退火处理后,Mg-2Al-2Zn-0.4Mn-0.5Ca镁合金板材的力学各向异性显著降低。400 ℃退火时板材表现出环形的织构特征,锥面<c + a>滑移引起的取向梯度使RD取向晶粒优先形核,Al、Zn、Ca等溶质原子共偏析形成的新低能晶界抑制了基面取向晶粒的再结晶长大过程,使TD取向晶粒优先长大。区域内未发生再结晶的{

参考文献

Machinability and surface integrity analysis of magnesium AZ31B alloy during laser assisted turning

[J].

Deformation mechanism and dynamic recrystallization of Mg-5.6Gd-0.8Zn alloy during multi-directional forging

[J].Multi-directional forging (MDF) is an effective way to fabricate wrought magnesium alloy with ultrafine grains and random texture. Therefore, microstructure evolution and dynamic recrystallization (DRX) of magnesium alloys during MDF process have been widely investigated. Mg-Zn-RE alloys containing long-period stacking ordered (LPSO) phase have received considerable attention owing to their excellent mechanical properties. In addition, LPSO phase has great effects on the deformation mechanism and DRX behavior. Still, limited comprehensive studies can be found in the literature dealing with the microstructure evolution, deformation mechanism and DRX of magnesium alloys containing LPSO phase in MDF deformation. In this work, MDF was applied to a Mg-5.6Gd-0.8Zn (mass fraction, %) alloy containing LPSO phase. Microstructure characteristics, deformation mechanism and DRX behavior of the material in different passes were examined. Results show that there are several stages of the microstructure evolution. Twinning was activated only in a small part of grains in the early stage of deformation. As the forging direction changes, the number of twinned grains and the volume fraction of DRX grains increased. A mixed structure with coarse deformed grain and DRX grains was sustained till last forging pass, and the average size of DRX grains is about 4 μm with a random orientation. {101ˉ2} tensile twinning is the main deformation mechanism and the selection of twin variants was dominated by the Schmid law. Change in forging direction is beneficial to twinning stimulation in grains of different orientations. Kink and slipping deformation could effectively accommodate the plastic strain where the operation of twinning was hindered. Kink deformation resulted in lattice rotation predominately about the <101ˉ0> axis. DRX grains nucleated at different places during the forging process. Not only the grain boundaries and the twinned region, but also kink boundaries can induce the nucleation of DRX grains. Eventually, the twinned regions were transformed to a strip-like recrystallization structure. Under the combined influence of twinning and kinking, as well as DRX induced by twins, kink bands and grain boundaries, the initial coarse grains were significantly refined.

Mg-5.6Gd-0.8Zn合金多向锻造过程中的变形机制及动态再结晶

[J].

Magnesium research and applications: Past, present and future

[J].

Twinning-induced plasticity with multiple twinning modes and disclinations in Mg alloys

[J].

Experimental and computational investigation of Mg AZ31 grain refinement by shear-enhanced rolling

[J].

Review: Magnesium sheet alloy development for room temperature forming

[J].

Rare earth texture analysis of rectangular extruded Mg alloys and a comparison of different alloying adding ways

[J].

Effects of dilute additions of Zn and Ca on ductility of magnesium alloy sheet

[J].

A heat-treatable Mg-Al-Ca-Mn-Zn sheet alloy with good room temperature formability

[J].

Reduction per pass effect on texture traits and mechanical anisotropy of Mg-Al-Zn-Mn-Ca alloy subjected to unidirectional and cross rolling

[J].

Role of Zn on the room temperature formability and strength in Mg-Al-Ca-Mn sheet alloys

[J].

Improved stretch formability of AZ31 sheet via texture control by introducing a continuous bending channel into equal channel angular rolling

[J].

Towards tailoring basal texture of rolled Mg alloy sheet by recrystallization for high room-temperature formability: A review

[J].

Microstructure and texture evolution of AZ31 magnesium alloy thin sheet processed by hot-rolling-shearing-bending

[J].

Effect of pre-deformation on mechanical behavior and microstructure evolution of AZ31 Mg alloy sheet with bimodal non-basal texture at room temperature

[J].An AZ31 Mg alloy sheet with bimodal non-basal texture exhibits good formability at room temperature. However, its initial yield stress (YS) is relatively low during uniaxial tension along the rolling direction (RD) at room temperature, which limits its potential for further application. Recent studies have demonstrated that introducing {101¯2} extension twin (ET) through predeformation can improve the mechanical properties of Mg alloy sheets with a basal texture at room temperature. However, the predeformation process for Mg alloy sheets with non-basal texture has rarely been investigated, along with their subsequent plastic deformation behavior at room temperature. Therefore, to investigate the room temperature deformation behavior and microstructure evolution of an AZ31 Mg alloy sheet with bimodal non-basal texture after predeformation, this work exerted a 5% thickness reduction on the sheet via cryogenic rolling. Then uniaxial tension experiments at room temperature and microstructure characterization experiments were conducted to illuminate the effect of predeformation on the mechanical behavior and microstructure evolution of the fabricated sheet. The findings indicate that when loaded along the RD, the YS and fracture elongation (FE) of the predeformed sample are 212.5% larger and 56.9% smaller than those of the non-predeformed sample. When loaded along the transverse direction (TD), the YS and FE of the predeformed sample are 6.7% smaller and 37.9% larger than those of the non-predeformed sample. The difference in YS in the predeformed samples is primarily attributed to easier activation of basal <a> slip in grains with a TD texture component in the TD sample than in grains with a bimodal non-basal texture component in the RD sample. The difference in FE in the predeformed samples is due to the inhibition of the expansion of preexsiting {101¯2} ETs in the RD sample, resulting in the early occurrence of {101¯1} compression twins (CTs). In comparison, the expansion of preexsiting {101¯2} ETs can be effectively performed in the TD sample. Additionally, some {101¯1}-{101¯2} double twins (DTs) would be activated at the later stage of tensile deformation to sustain and/or accommodate local plastic strain.

预变形对双峰分离非基面织构AZ31镁合金板材室温力学行为及微观组织演变的影响

[J].为揭示双峰分离非基面织构AZ31镁合金板材预变形后的室温变形行为及微观组织演化规律,对该板材施加压下量5%的深冷轧制预变形,结合室温单轴拉伸和微观组织表征实验,研究预变形对制备板材力学行为及微观组织演变的影响。结果表明,沿轧制方向(RD)试样的初始屈服强度和断裂延伸率较未预变形试样分别提升212.5%和降低56.9%。沿板材横向(TD)试样的初始屈服强度和断裂延伸率较未预变形试样分别降低6.7%和提升37.9%。不同方向试样初始屈服强度的差异主要是由于TD试样中TD织构组分所对应的晶粒比RD试样中双峰分离非基面织构组分所对应的晶粒更容易激活基面<a>滑移。断裂延伸率的差异主要是由于在RD试样中,{101¯2}拉伸孪晶的扩张受到抑制,会较早出现{101¯1}压缩孪晶,而在TD试样中,{101¯2}拉伸孪晶可以有效扩张,且后期出现一定数量的{101¯1}-{101¯2}双孪晶来承载/协调塑性应变。

Microstructure evolution and twinning behavior of AZ31 magnesium alloy sheets with bimodal texture during cold deep-drawing deformation

[J].

The different hardening effects of tension twins on basal slip and prismatic slip in Mg alloys

[J].

Effect of initial texture on texture and microstructure evolution of ME20 Mg alloy subjected to hot rolling

[J].

Annealing behaviour of Mg-3Al-1Zn alloy sheet obtained by a combination of high-temperature rolling and subsequent warm rolling

[J].

Improvement in mechanical properties of rolled AZ31 alloy through combined addition of Ca and Gd

[J].

Local and global deformation behaviour in rolled pure magnesium sheets at room temperature under different strain rates

[J].

Formation of the elliptical texture and its effect on the mechanical properties and stretch formability of dilute Mg-Sn-Y sheet by Zn addition

[J].

Unveiling annealing texture formation and static recrystallization kinetics of hot-rolled Mg-Al-Zn-Mn-Ca alloy

[J].The development of Mg-Al-Zn-Mn-Ca series alloys provides a potential prospect to achieve high strength and formability at room temperature (RT). The formation of elliptical annular texture is treated as a crucial factor for the enhanced RT formability. However, the origin of such an elliptical annular texture formation has been rarely reported. Herein, we unveiled the formation and evolution of elliptical annular texture in the hot-rolled Mg-1.6Al-0.8Zn-0.4Mn-0.5Ca (AZMX1100, wt.%) alloy after annealing at different temperatures for 1 h, and its static recrystallization (SRX) kinetics in given annealing temperature for different time. The results revealed that the formation of elliptical annular texture in the hot-rolled AZMX1100 alloy after annealing was derived from nucleation-oriented SRX mechanism, which took place in 200-300 °C, induced by cracked chain-shaped Al2Ca phases, contraction twins, intersections of double twins, intersections of double twins and grain boundaries and non-basal slips. On further annealing from 300-450 °C, the grains with 45°-70° transverse direction (TD) preferentially grew, which made elliptical annular texture extended along the TD. Based on the Johnson-Mehl-Avrami-Kolmogorov (JMAK) model, Avrami exponent n value was estimated to be 0.68-1.02, attributed to non-random SRX nucleation, giving rise to the lower activation energy QR of nucleation of ~74.24 kJ/mol. Since the co-segregation of Al, Zn and Ca atoms in grain boundaries created a strong interaction of solutes and grain boundaries, the hot-rolled AZMX1100 alloy exhibited the higher activation energy Qg (~115.48 kJ/mol) of grain growth.

Hot pack rolling nearly lamellar Ti-44Al-8Nb-(W, B, Y) alloy with different rolling reductions: Lamellar colonies evolution and tensile properties

[J].

Influence of basal slip activity in twin lamellae on mechanical behavior of Mg alloys

[J].

Twinning and texture development in two Mg alloys subjected to loading along three different strain paths

[J].

Effect of initial state on hot deformation and dynamic recrystallization of Ni-Fe based alloy GH984G for steam boiler applications

[J].

Twin recrystallization mechanisms in magnesium-rare earth alloys

[J].

Resolving the geometrically necessary dislocation content by conventional electron backscattering diffraction

[J].

Atomic structures of symmetric tilt grain boundaries in hexagonal close packed (hcp) crystals

[J].

Intrinsic ductility of Mg-based binary alloys: A first-principles study

[J].

Explaining texture weakening and improved formability in magnesium rare earth alloys

[J].

Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy

[J].

Twinning effects in deformed and annealed magnesium-neodymium alloys

[J].