促进绿色低碳发展、开发更高参数的火电机组、提高能源效率、减少有害气体排放,已成为关乎我国国民经济进一步高速发展和环境保护的战略性问题[1~5]。随着超超临界(ultra-supercritical,USC)火力发电机组更高蒸汽温度和蒸汽压力的发展要求,亟待开发具有优异耐高温及耐高压性能的新型结构材料[6~8]。2007年, Yamamoto等[9~11]在高温超细强化钢的基础上调整Al、Ni、Nb等合金元素含量,研制出了含Al奥氏体耐热钢(alumina-forming austenitic steel,AFA钢)。由于Al元素的加入,在AFA钢表面可自发地形成连续、稳定、致密的Al2O3氧化膜,使其能够在850 ℃以下的高温水蒸气环境中表现出良好的高温抗氧化性能和抗蠕变性能[12],且成本较低,这引起了该领域内科研人员的广泛关注,使AFA钢有望成为700 ℃ USC火力发电站耐热结构的候选材料之一[13]。其次,AFA钢中的Laves相(Fe2(Nb, Mo, W))[14]和B2-NiAl相[15]等细小析出相,对位错及晶界等微观组织有较强的钉扎作用,从而使组织更加稳定,抑制微观组织回复,避免材料过早失效[16]。

在优化合金成分的基础上,合理的热加工处理是进一步提高AFA钢高温性能的有效途径,常见的加工方法主要有热处理及机械加工处理[17~20]。相关学者围绕AFA钢的热处理开展了一定的研究,如退火、等温时效等工艺对AFA钢性能的影响[21,22]。Zhao等[23]发现退火温度会影响AFA钢中细小析出相的分布,从而导致高温蠕变性能有所差异。AFA钢基体中存在大量的析出相,随着退火时间的增长,析出相的粗化速率加快,析出强化作用减弱,发生动态回复,组织稳定性变差,从而可导致性能变差[24]。此外,Jiang等[25]指出时效处理能促进细小析出相的生成,进一步延长了AFA钢的高温服役寿命。机械加工处理包括冷轧和热轧等,冷轧变形处理本质上是一种引入位错并改变材料中位错分布的室温变形过程[26~28]。对AFA钢进行冷轧变形处理时,会引入大量位错,位错之间相互作用,形成位错缠结或位错塞积,出现加工硬化现象,导致强度、硬度升高,塑性、韧性降低,而位错的湮灭则会导致微观组织的软化[29,30]。冷变形不仅会引入新的位错,还会减小晶粒尺寸,改变析出相的分布,增强位错强化、晶界强化和析出强化的作用[31]。随着变形量的增加,晶粒尺寸减小,根据经典的Hall-Petch公式可知晶粒尺寸越小,晶界强化效果越显著,即对材料性能提升越大[32]。此外,冷轧变形引入的位错会在高温服役过程中为元素扩散提供通道,为析出相提供形核位置,进一步促进析出相形成[33,34]。析出相的大量形成会增强对位错运动和基体回复的钉扎作用,降低位错的湮灭速率。在高温服役过程中,由于元素扩散速率较高,加快了位错湮灭而导致组织稳定性变差,但是由于AFA钢中细小析出相的析出强化作用较为显著,因此延长了AFA钢在恶劣环境中的高温服役寿命。Gao等[35]研究发现,冷变形引入的位错可以作为Al元素短程扩散的通道,加速Al2O3薄膜的形成,还会促进B2-NiAl相的形成,为连续、致密的Al2O3薄膜的持续形成提供Al元素,保证了AFA钢的高温抗氧化性能及组织稳定性。Hu等[36]提出AFA钢可通过冷变形处理引入位错,在高温服役过程中为第二相提供形核位置,使得蠕变断裂寿命几乎翻倍,并发现在进行90%变形量的冷轧变形处理后,纳米NbC相的数量大幅度增加。Trotter等[37]研究表明,在高温服役过程中,冷变形会加速纳米析出相体积分数的增加。不同变形量对AFA钢的析出强化效果的影响也会有所差异。Gao等[38]的研究表明,经冷轧处理的AFA钢在高温蠕变过程中B2-NiAl相的粗化速率超过Laves相。Zhao等[39]对AFA钢进行变形量为3%的冷轧变形处理,蠕变50 h后,纳米NbC相的尺寸为5 nm,体积分数增加,而未进行冷轧变形处理的AFA钢中纳米NbC相的尺寸增加至10 nm。热处理与机械加工处理,旨在增强AFA钢的析出强化作用,进而提升其性能表现。

本工作将热处理和机械加工处理工艺相结合,调控析出相的有效析出,分析预时效处理对冷轧4Al-2Cu-AFA钢高温时效过程中析出行为和组织演变的影响。采用X射线衍射仪(XRD)、扫描电镜(SEM)和透射电镜(TEM)等测试手段对4Al-2Cu-AFA钢的微观组织进行表征,并测试试样的力学性能。综合分析预时效处理对冷轧AFA钢在高温时效过程中微观组织演变的影响,阐明位错强化和析出强化的协同强化机制。

1 实验方法

采用真空感应炉熔炼4Al-2Cu-AFA钢,在1180 ℃下均匀化4 h,然后在1150 ℃下热轧成厚度约13 mm的板材,空冷至室温。利用电感耦合等离子体发射光谱法(ICP-OES)测定4Al-2Cu-AFA钢的实际化学成分(质量分数,%)为:Ni 19.87,Cr 14.68,Al 4.11,Mn 2.03,Nb 2.08,Mo 1.97,W 0.96,C 0.07,Si 0.18,Cu 1.93,Fe余量。使用电火花线切割机(WEDM)对热轧板材进行切割,然后分别采用冷轧(变形量10%) +时效(700 ℃,分别时效0、4、24、100、500和1000 h)、预时效处理(700 ℃,24 h) +冷轧+时效工艺处理原始热轧板材。根据处理工艺和时效时间标记样品名称,如CR10-A0、PA24-CR10-A0等,其中CR表示冷轧变形处理,A表示时效处理(后面数字表示时效时间),PA表示预时效处理。

利用WEDM切取用于表征分析的试样,需要说明的是,微观组织表征均取自RD-ND面(RD表示轧制方向,ND表示轧面法向)。随后,依次使用320、600、1000、1500和2000号砂纸对样品表面进行机械研磨,再利用2.5 μm的金刚石抛光膏进行表面抛光。采用体积比HCl∶HNO3∶H2O = 3∶1∶3的混合溶液进行侵蚀处理,时间控制在10~20 s之间。使用Smartlab(9) XRD进行定性分析(CuKα),扫描角度20°~100°,扫描速率2°/min。采用SUPRA 55场发射SEM和能谱仪(EDS)观察表征样品的微观结构。利用工作电压为200 kV的JEM-2100F TEM观察位错与析出相的作用形式及位错的存在形式,并通过选区电子衍射(SAED)辨别物相种类。用于TEM观察的试样首先利用WEDM制备出厚度约为150 μm的金属薄片,使用砂纸将薄片的厚度打磨至约60 μm,然后将其冲压成直径为3 mm的圆形薄片,并进行离子减薄处理。使用Image Pro Plus软件对TEM像中析出相的平均粒径、体积分数及铁素体的占比进行测量与统计,对AFA钢的微观组织演变进行分析。

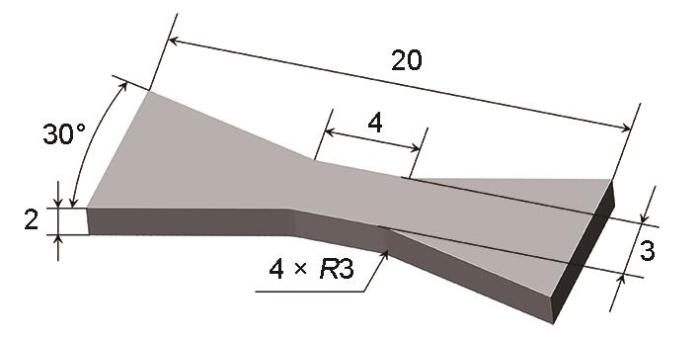

采用MHV-5Z型数字式Vickers硬度计进行硬度测试,测试前用砂纸将测试表面打磨平整,设置载荷为49 N。测试面为RD-ND面,保载时间为10 s,在每个试样的测试表面选取10个点进行硬度测量,剔除一个最大值和一个最小值,计算剩余数据的平均Vickers硬度及方差,以保证数据的精准性。根据Mtest50室温原位拉伸仪对试样尺寸的要求选取拉伸试样进行拉伸实验,拉伸载荷方向沿RD方向,拉伸试样的尺寸如图1所示,拉伸速率为0.1 mm/min。为确保力学性能测试的准确性和重复性,每组实验至少测试3个独立试样。

图1

2 实验结果

2.1 微观组织演变

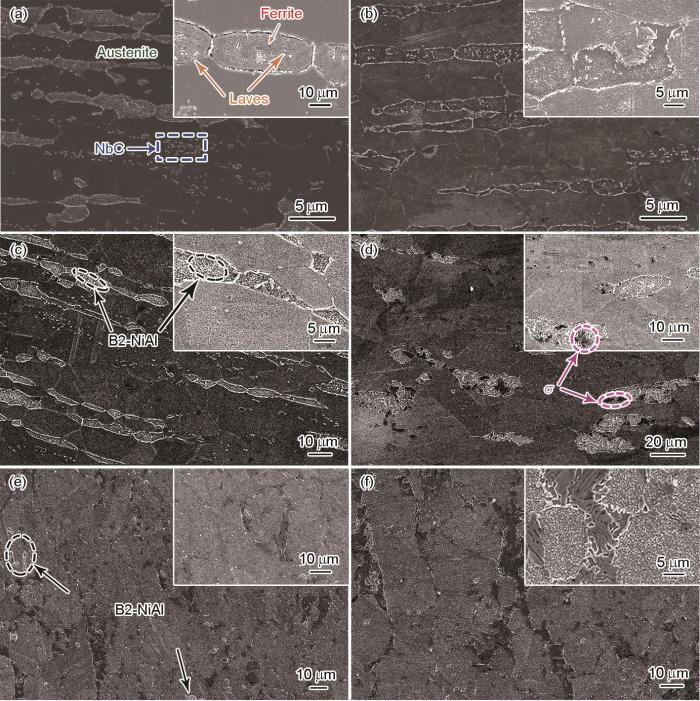

图2和3为CR10和PA24-CR10试样在700 ℃下时效不同时间后的微观组织。根据前期的成分设计研究,相较于纯奥氏体的AFA钢,含有δ-铁素体的4Al-2Cu-AFA钢展现出了更高的抗拉强度。此外,在高温时效处理期间,铁素体区域内的元素扩散速率更快,使得4Al-2Cu-AFA钢中的微观结构变化更为明显,易于观测[13]。整体上,CR10和PA24-CR10试样在高温时效过程中析出相的种类保持一致,基体主要由85%的奥氏体和15%的δ-铁素体构成,在奥氏体区和δ-铁素体区交界处及奥氏体晶界处的Laves相的种类并未改变。随着高温时效的进行,Laves相于δ-铁素体边缘析出,球状B2-NiAl相在δ-铁素体内弥散析出,形成贫Ni区并促使Laves相长大和富Cr区的出现。随着时间的延长,B2-NiAl相逐渐长大且形态由球状转为不规则形状,σ-FeCr相也在其附近不断长大,最终,2者交互覆盖整个原δ-铁素体区。

图2

图2

CR10试样在700 ℃时效不同时间后显微组织的SEM像

Fig.2

SEM images of the CR10 sample aged at 700 oC for 0 h (a), 4 h (b), 24 h (c), 100 h (d), 500 h (e), and 1000 h (f) (Insets show the corresponding microstructural details)

图3

图3

PA24-CR10试样在700 ℃时效不同时间后显微组织的SEM像

Fig.3

SEM images of the PA24-CR10 sample aged at 700 oC for 4 h (a), 24 h (b), 50 h (c), 100 h (d), 500 h (e), and 1000 h (f) (Insets show the corresponding microstructural details)

图2为CR10试样(CR10-A0至CR10-A1000)在700 ℃时效不同时间的微观组织SEM像,每张图片的右上角显示了相应试样的微观结构细节,以便从宏观和微观2个层面进行观察。从图2a可以看出,CR10-A0试样的基体由带状δ-铁素体区和奥氏体区组成。奥氏体基体中含有NbC相,在奥氏体与δ-铁素体交界处及奥氏体晶界处存在Laves相,且奥氏体晶界处Laves相的尺寸相对较小。经过4 h时效处理后(图2b),δ-铁素体区内有少量Laves相析出。当时效时间达到24 h (图2c),δ-铁素体区内有大量的球状B2-NiAl相析出。当时效时间达到100 h (图2d),在试样的铁素体区有少量σ相析出。随着时效时间进一步延长,B2-NiAl相不断长大,呈不规则形状,并与σ相交互在一起,基本覆盖了δ-铁素体区,但仍有少量B2-NiAl相保持球状。当时效时间达到1000 h时,不规则状的σ相和B2-NiAl相已完全覆盖了δ-铁素体区。

图3为PA24-CR10试样(PA24-CR10-A4至PA24-CR10-A1000)在700 ℃时效不同时间后的微观组织SEM像。对PA24-CR10试样在进行4 h时效处理后,δ-铁素体区存在球状B2-NiAl相及Laves相,在奥氏体区与δ-铁素体区交界处也存在Laves相。时效24 h后,δ-铁素体区内出现少量σ相析出。随着时效时间的延长,σ相析出数量不断增加。直到时效500 h时,不规则状σ相和B2-NiAl相已完全覆盖δ-铁素体区。

总之,随着时效处理的进行,B2-NiAl相和σ相相继析出并不断长大,最终覆盖整个δ-铁素体区,但不同工艺处理后的4Al-2Cu-AFA钢在700 ℃时效后的反应程度有差异。相较于CR10试样,PA24-CR10试样在高温时效过程中的反应更加剧烈。图2d和图3b对比显示,CR10试样在100 h时效处理后基体中开始有微量的σ相析出,而PA24-CR10试样在24 h时效后已观察到σ相的析出,可见预时效处理促进了δ-铁素体区中σ相的析出。进一步对比图2d和图3c可以看出,CR10-A100试样δ-铁素体区中σ相的覆盖比例明显低于PA24-CR10-A50试样。在CR10-A500试样中仍有极少部分δ-铁素体区未被不规则状的B2-NiAl相和σ相覆盖,而PA24-CR10-A500试样中的δ-铁素体区已完全被不规则状的B2-NiAl相和σ相覆盖。总体而言,预时效处理显著加速了AFA钢在时效过程中的相变进程,相比未经预时效处理的CR10试样,PA24-CR10试样高温时效过程中展现出更强的相变动力。

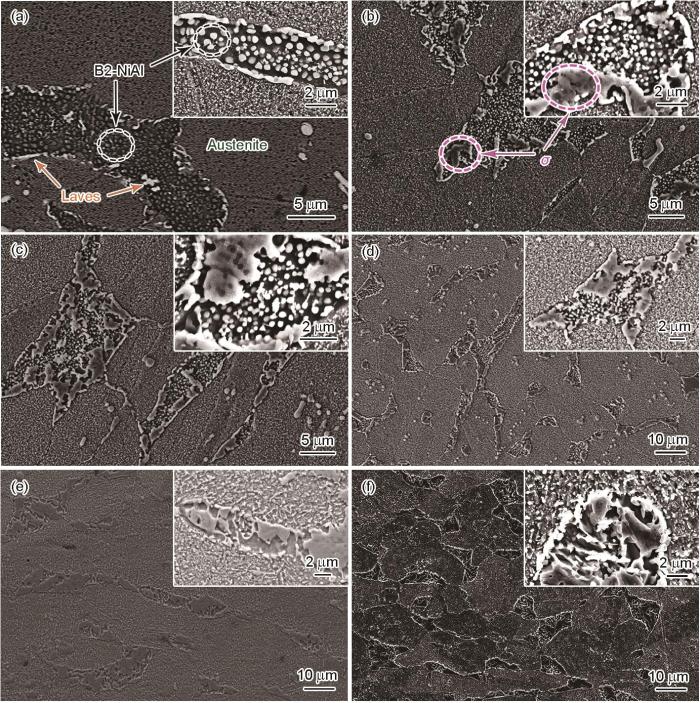

图4

图4

CR10-A0试样显微组织的TEM像、选区电子衍射(SAED)花样及EDS点扫描结果

Fig.4

TEM image of the CR10-A0 sample (a), and EDS results and correponding selected area electron diffraction (SAED) patterns (insets) of δ-ferrite (b) and Laves (c) phases

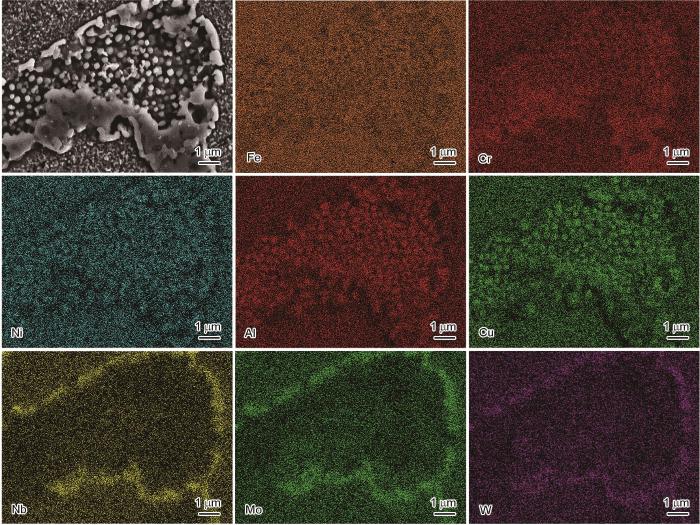

图5所示为PA24-CR10-A24试样中的δ-铁素体区SEM像及相应的EDS面扫描结果。可以看出,δ-铁素体区有少量灰黑色的σ-FeCr相呈块状析出。从Fe、Nb、Mo和W元素的EDS面扫描结果可以看出,PA24-CR10-A24试样中环绕在δ-铁素体周围的Laves相的析出显著增加。从σ-FeCr相的析出情况也可以看出,相较于未经预时效处理的冷变形试样,预时效处理后的冷变形试样中σ-FeCr相析出明显增加。随着时效时间的延长,当时效时间达到500 h后,不规则形状的B2-NiAl相和σ相紧密交织,已完全覆盖δ-铁素体区,在随后的时效过程中也未见明显变化,如图6所示。这表明δ-铁素体中的沉淀相析出转变已趋近于稳定。综合Fe、Cr、Ni、Al和Cu元素的面扫描结果可见,在δ-铁素体中,B2-NiAl相与σ相呈现出紧密交织的状态,覆盖整个δ-铁素体区。此外,Fe、Nb、Mo和W元素的面扫描结果显示,颗粒状的Laves相环绕在δ-铁素体区周围,且部分被B2-NiAl相覆盖。δ-铁素体中这种复杂的析出相形成及相互作用影响组织的稳定性,从而对材料性能进一步产生影响。

图5

图5

PA24-CR10-A24试样中δ-铁素体区的SEM像及相应的EDS面扫描结果

Fig.5

SEM image and corresponding EDS mapping results of the δ-ferritic region in the PA24-CR10-A24 sample

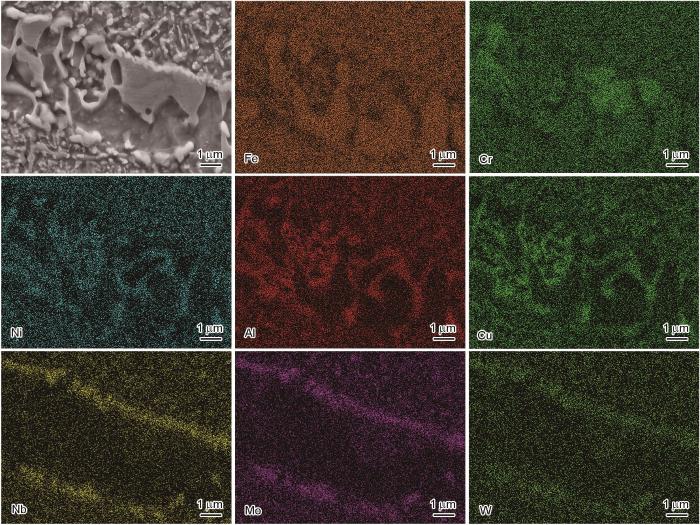

图6

图6

PA24-CR10-A500试样中δ-铁素体区的SEM像及相应的EDS面扫描结果

Fig.6

SEM image and corresponding EDS mapping results of the δ-ferritic region in the PA24-CR10-A500 sample

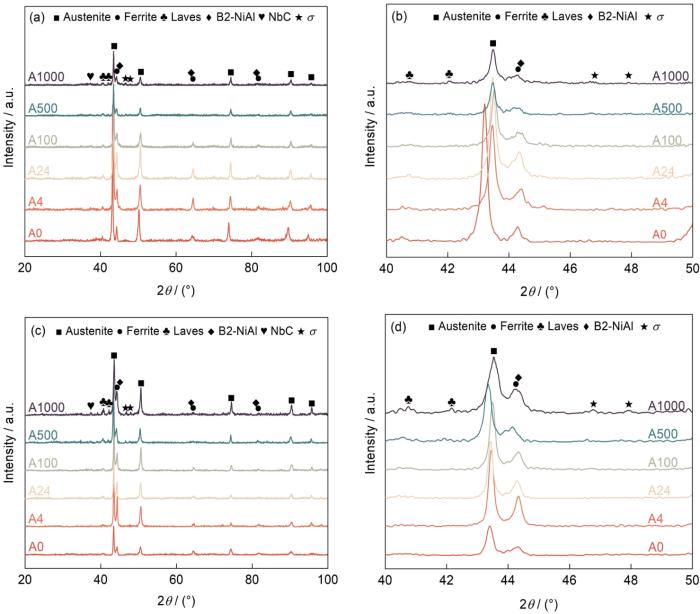

图7

图7

CR10试样和PA24-CR10试样700 ℃时效不同时间的XRD谱

Fig.7

XRD spectra of CR10 (a, b) and PA24-CR10 (c, d) samples aged at 700 oC for different time (Figs.7b and d are zoom-in views of Figs.7a and c, respectively)

2.2 硬度和拉伸性能

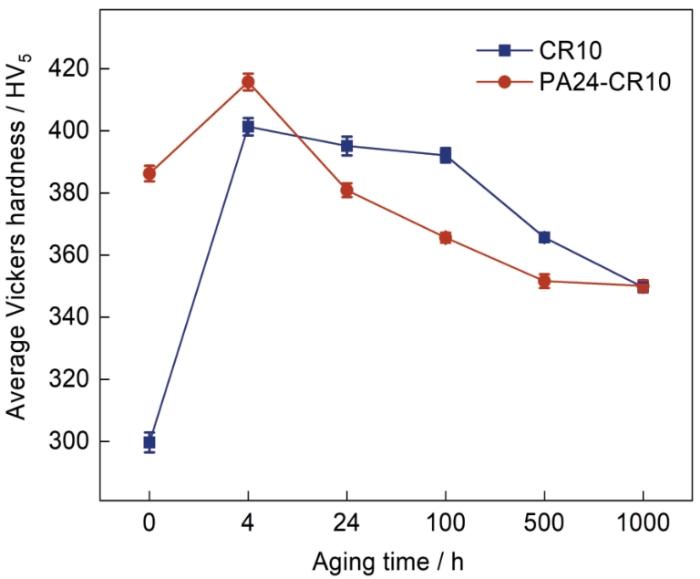

图8所示为CR10和PA24-CR10试样在700 ℃时效处理不同时间后Vickers硬度的变化。CR10试样和PA24-CR10试样经过时效处理后Vickers硬度的变化趋势基本一致,未进行时效的试样硬度较低,时效处理初期试样的硬度较高,随时效的进行硬度逐渐下降。在CR10试样中,由冷变形引入的位错导致加工硬化,引起硬度的上升。然而,随着高温时效的进行,加工硬化效果逐渐减弱,但是由于析出相数量密度的变化出现时效硬化现象。此外,预时效处理+冷轧后的试样在时效初期硬度增加值比直接冷轧的要低,主要是由于预时效处理已经使得析出相析出,并完成了向稳定析出相的转变。随后随着时效的进行硬度均呈现下降趋势,且预时效后的试样硬度下降更显著。具体来说,当时效时间达到4 h,CR10-A4试样和PA24-CR10-A4试样的硬度达到峰值,分别为401和416 HV5。随着时效时间从4 h延长至100 h,冷轧试样的硬度降低趋势较为平缓,而经历预时效处理的试样硬度下降更为显著,这与其试样中σ相的显著析出相关。当时效时间超过100 h后,冷轧试样硬度的下降速率加快,而预时效试样的硬度降低趋势有所减缓,这主要是由于此时冷轧试样中开始出现σ析出相。最终,当时效时间达到1000 h时,冷轧试样和预时效试样的Vickers硬度均降低到350 HV5附近,这表明长期时效后由于析出相转变的完成导致2者的硬度趋于稳定。

图8

图8

CR10试样和PA24-CR10试样700 ℃时效处理不同时间后Vickers硬度的变化

Fig.8

Variations in Vickers hardness of CR10 and PA24-CR10 samples aged at 700 oC for different time

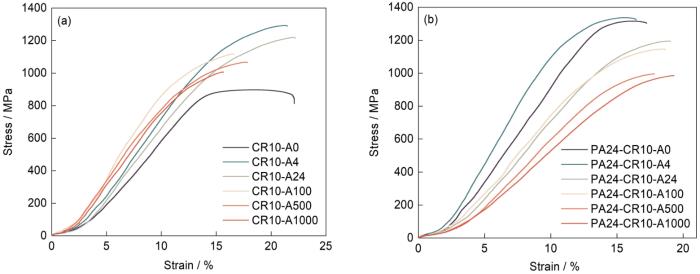

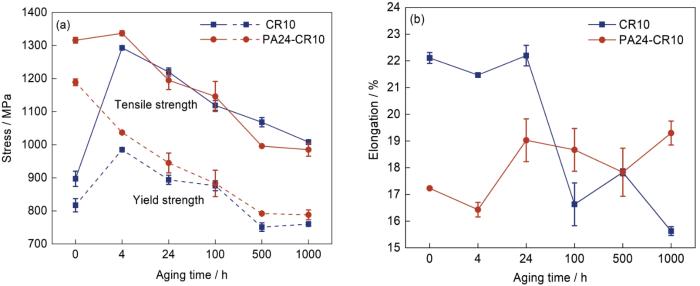

图9为CR10试样和PA24-CR10试样在700 ℃下时效不同时间后的应力-应变曲线,根据应力-应变曲线获得的时效处理后材料的力学性能如图10所示。CR10试样和PA24-CR10试样在高温时效过程中抗拉强度的变化趋势一致,随着时效时间的增加,抗拉强度先升高后降低。CR10-A0试样和PA24-CR10-A0试样中存在加工硬化现象。在随后的高温时效过程中,时效硬化使试样的强度升高,而位错密度的降低和σ相的析出是导致试样强度下降的2个关键因素。试样的延伸率均在σ相析出时出现了下降,即冷轧试样在时效100 h和预时效试样在时效4 h时都出现了延伸率下降的现象。随后由于奥氏体基体组织的回复逐渐占主导使得材料延伸率略有上升。整体来看,预时效处理可以一定程度提高材料的延伸率。

图9

图9

CR10试样和PA24-CR10试样700 ℃时效处理不同时间后的应力-应变曲线

Fig.9

Stress-strain curves of CR10 (a) and PA24-CR10 (b) samples aged at 700 oC for different time

图10

图10

CR10试样和PA24-CR10试样700 ℃时效不同时间后力学性能的变化

Fig.10

Variations in strength (a) and strain (b) of CR10 and PA24-CR10 samples aged at 700 oC for different time

初始状态即CR10-A0试样的抗拉强度为897 MPa,屈服强度为817 MPa,延伸率为22.11%;经过预时效处理的PA24-CR10-A0试样展现出更高的力学性能,抗拉强度和屈服强度分别达到1316和1189 MPa,延伸率为17.23%。CR10-A4试样和PA24-CR10-A4试样在位错强化、析出相强化和晶界强化的协同强化作用下,抗拉强度分别提升至1293和1337 MPa,屈服强度分别为985和1037 MPa,延伸率分别下降至21.47%和16.43%。延长时效时间至24 h,由于PA24-CR10-A24试样中σ相的析出,导致其强度降低趋势较CR10-A24试样更为显著。时效100 h后,CR10-A100试样中开始有σ相析出,也导致强度下降加速。随着时效时间继续延长,σ相的不断析出导致试样强度不断降低,PA24-CR10-A500试样中不规则状σ相和B2-NiAl相已完全覆盖δ-铁素体区,而CR10-A500试样中的δ-铁素体区尚未完全被析出相覆盖,因此,时效时间在500~1000 h范围内时,PA24-CR10试样的性能变化趋于平稳,而CR10试样的强度持续降低。最终时效至1000 h,CR10-A1000和PA24-CR10-A1000试样的抗拉强度和屈服强度分别降低至1000和780 MPa左右。

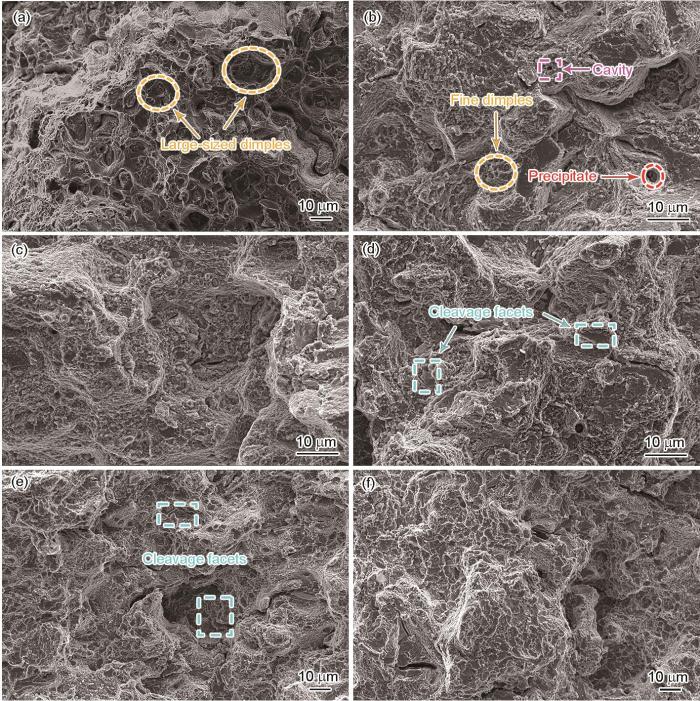

2.3 拉伸断口形貌

图11所示为CR10试样在700 ℃时效处理不同时间后的室温拉伸断口形貌SEM像。CR10-A0试样的断口处分布着大尺寸的韧窝,说明其断裂方式为韧性断裂。随着时效时间的增加,韧窝尺寸逐渐减小,这表明材料的韧性断裂机制逐渐弱化。当时效时间达到4 h,CR10-A4试样中分布着大量的小尺寸韧窝,还可以看到析出相和断裂孔洞的存在。当时效时间达到100 h时,CR10-A100试样断口处开始出现少量的解理面,且韧窝尺寸减小,断裂方式由单纯韧性断裂转变为韧性断裂和脆性断裂混合的方式,此时延伸率的降低也是由于断裂方式的改变导致的。随后,CR10-A500和CR10-A1000试样断口处解理面的数量显著增加,韧窝尺寸越来越小。

图11

图11

CR10试样在700 ℃时效处理不同时间后的拉伸断口形貌

Fig.11

Tensile fracture morphologies of the CR10 sample aged at 700 oC for 0 h (a), 4 h (b), 24 h (c), 100 h (d), 500 h (e), and 1000 h (f)

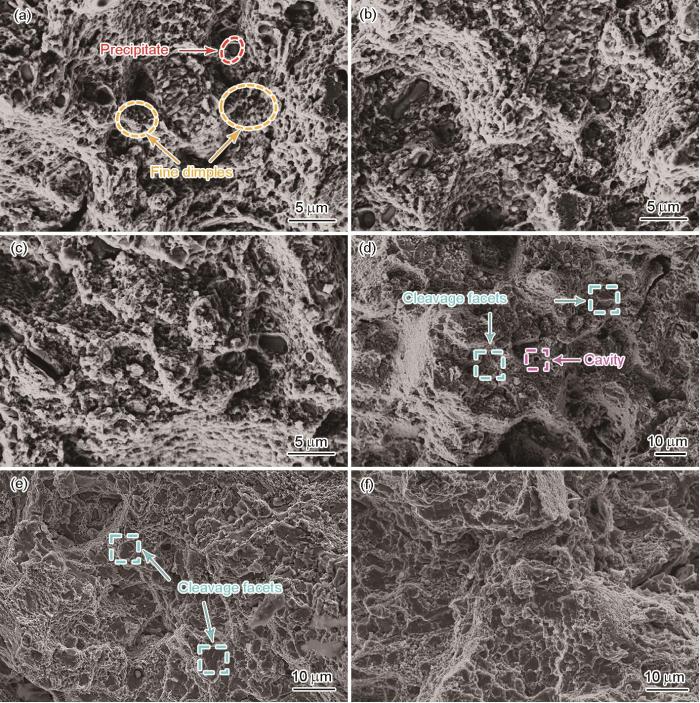

图12所示为PA24-CR10试样700 ℃时效处理不同时间后的室温拉伸断口形貌SEM像。在PA24-CR10-A0试样断口处观察到大量的小尺寸韧窝,断裂方式为韧性断裂。随着时效时间的延长,韧窝尺寸减小,材料的塑性逐渐降低。当时效时间达到100 h,试样的断口处出现解理面,标志着断裂方式由单一的韧性断裂转变为韧性断裂和脆性断裂共存的形式。随着时效时间的延长,PA24-CR10-A500和PA24-CR10-A1000试样断口处的解理面越来越多,小尺寸韧窝的数量减少。

图12

图12

PA24-CR10试样经700 ℃时效处理不同时间后的拉伸断口形貌

Fig.12

Tensile fracture morphologies of the PA24-CR10 sample aged at 700 oC for 0 h (a), 4 h (b), 24 h (c), 100 h (d), 500 h (e), and 1000 h (f)

3 预时效对析出相转变的影响机理

实验结果表明,预时效处理有利于冷轧试样在高温时效时析出相的转变。为深入分析预时效处理的影响,结合SEM,定量统计分析了B2-NiAl相和Laves相这2种析出相的平均粒径及体积分数。需要说明的是,由于PA24-CR10试样经过了24 h的预时效处理,且PA24-CR10-A500试样中δ-铁素体被不规则形状的σ相和B2-NiAl相覆盖,可能对精确测量析出相粒径和体积分数造成干扰。基于此,选用时效时间适中且相形态更利于分析的CR10-A100与PA24-CR10-A100试样作为研究对象,每种试样选取10张以上SEM照片,统计单位面积内这2种析出相的平均粒径及体积分数。此外,考虑到δ-铁素体和奥氏体中的析出相分布和密度完全不同,对δ-铁素体和奥氏体中的情况分别统计。

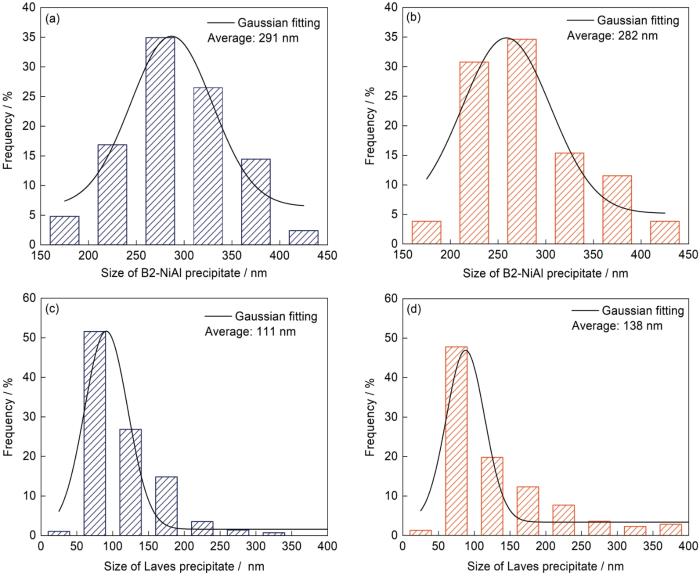

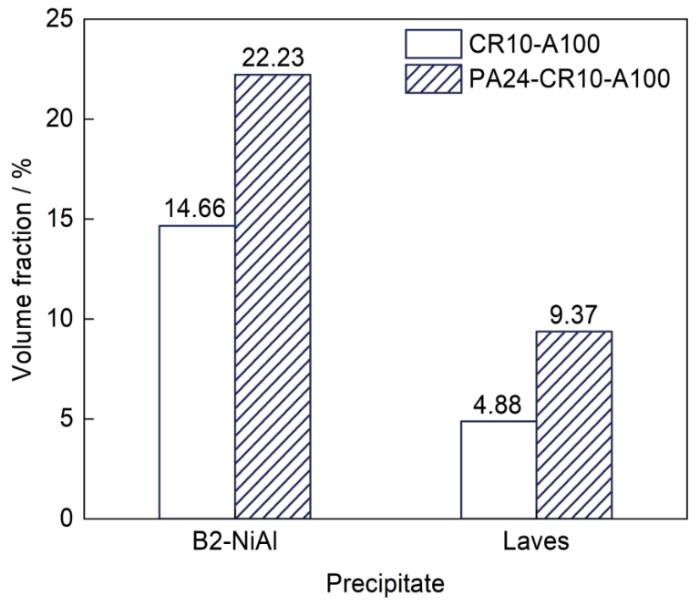

对CR10-A100与PA24-CR10-A100试样中δ-铁素体区的B2-NiAl相及奥氏体区的Laves相的粒径进行了详细的统计分析,结果如图13所示。可以看出,CR10-A100与PA24-CR10-A100试样中B2-NiAl相的平均粒径分别为291和282 nm,而Laves相的平均粒径分别为111和138 nm,这说明预时效处理对析出相粒径变化的影响有限。Laves相的平均粒径略有增加,这可以归因于奥氏体已存在的Laves相随时效时间的增加缓慢长大。图14为CR10-A100与PA24-CR10-A100试样中B2-NiAl相和Laves相的体积分数统计数据。CR10-A100试样中B2-NiAl相在δ-铁素体区的占比为14.66%,而PA24-CR10-A100试样中这一比例显著提高至22.23%。同样,Laves相在奥氏体区的体积分数从CR10-A100试样的4.88%增加到了PA24-CR10-A100试样的9.37%。这表明预时效处理显著提升了析出相的体积分数。预时效处理后的试样中析出相的尺寸变化不明显,但析出相体积分数显著增加,这进一步表明预时效处理可以促进第二相的析出,从而提高析出强化效果。

图13

图13

CR10-A100试样和PA24-CR10-A100试样中析出相的尺寸统计

Fig.13

Statistics on the size of B2-NiAl precipitates (a, b) and Laves precipitates (c, d) in CR10-A100 (a, c) and PA24-CR10-A100 (b, d) samples

图14

图14

CR10-A100试样和PA24-CR10-A100试样中析出相的体积分数统计

Fig.14

Statistics on the volume fractions of precipitates in CR10-A100 and PA24-CR10-A100 samples

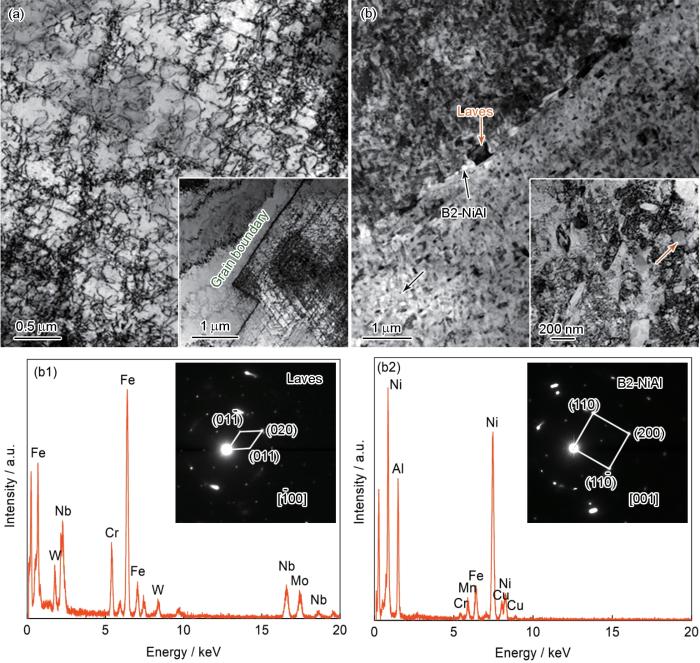

为了进一步分析预时效处理后的冷轧试样在高温时效过程中反应更剧烈的原因,对CR10-A0试样及PA24-CR10-A0试样中位错的存在情况进行了表征分析。图15为CR10-A0与PA24-CR10-A0试样显微组织的TEM像、SAED花样及EDS点扫描结果。已有文献[31]表明,AFA钢在冷轧变形的过程中会引入位错,且位错密度随着变形量的增加而增加。如图15a所示,CR10-A0试样的晶粒内存在大量位错,可沿着滑移线发生滑移,变形抗力较低,易发生变形。而在PA24-CR10-A0试样中,大量位错被纳米级B2-NiAl相及Laves相钉扎,产生位错堆积,难以发生滑移,导致局部应力集中,产生应力场和晶格畸变,如图15b所示。PA24-CR10-A0试样中被第二相颗粒钉扎的位错可为析出相的形成提供更多的形核位置,产生的应力场及晶格畸变为析出相的形核与长大提供更强的相变动力,使析出相的体积分数显著增加。

图15

图15

CR10-A0和PA24-CR10-A0试样的TEM像、SAED花样及EDS点扫描结果

Fig.15

TEM images (Insets show the corresponding grain boundary and in-grain details) (a, b), and EDS results and SAED patterns (insets) (b1, b2) of CR10-A0 (a) and PA24-CR10-A0 (b, b1, b2) samples

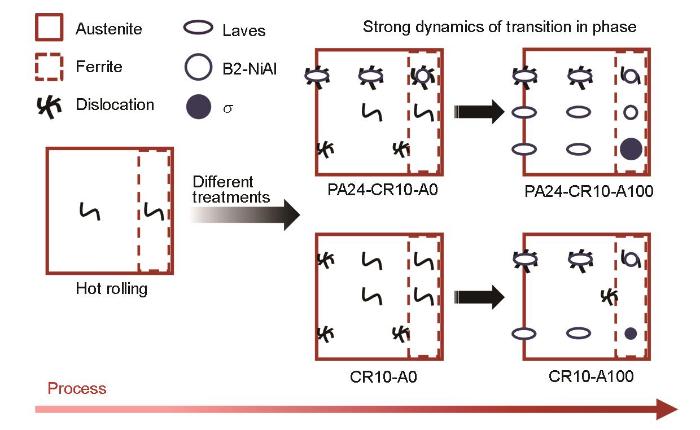

综上所述,预时效产生析出相,显著增强了对冷轧变形引入位错及晶界的钉扎作用,为析出相的形成提供更多形核位置和能量,加速微观组织演变进程。在析出强化、位错强化和晶界强化的协同强化作用下,显著提升了预时效试样中析出相的体积分数与相变动力,微观组织的演变过程如图16所示。

图16

图16

4Al-2Cu-AFA钢微观组织演变示意图

Fig.16

Schematic of microstructural evolution of 4Al-2Cu-AFA steel

4 结论

(1) 预时效处理产生纳米级Laves相和B2-NiAl相,对冷轧变形引入的位错和晶界的钉扎作用增强,晶界也会阻碍位错滑移,堆积在析出相及晶界处的位错为组织演变提供更强的相变动力,加速了预时效试样在高温时效过程中的相转变过程。

(2) 预时效处理产生的纳米级析出相与位错之间相互作用,为析出相的形成提供更多形核位置,预时效处理显著增加了冷轧变形AFA钢中Laves相和B2-NiAl相的体积分数,使析出强化、位错强化和晶界强化的协同强化作用增强。

(3) 冷轧变形试样和预时效试样在高温时效过程中强度和硬度的变化趋势一致,随着时效时间的增加,强度和硬度先升高后降低。在析出强化、位错强化和晶界强化的协同强化作用下,PA24-CR10-A4试样的强度和硬度最高,抗拉强度和Vickers硬度分别为1337 MPa和416 HV5。随着时效时间的增加,加工硬化效果的减弱及σ-FeCr相的析出使强度和硬度降低。

参考文献

Research progress of a novel martensitic heat-resistant steel G115

[J].Improving the steam temperature and the pressure of the boiler applied in the thermal power could enhance the coal-fired efficiency and reduce the emission of harmful gases. Due to the dual impact of dwindling fossil resources and an exacerbated global greenhouse effect, it is critical to develop new heat-resistant boiler materials for ultra super-critical (USC) units at temperatures of 650oC and higher. With great thermal conductivity, good fatigue resistance, and low cost, martensitic heat-resistant steel G115, based on P92 steel applied in 600oC USC units, is a promising steel to be applied to this among all candidate materials. This paper introduces the main chemical composition and the microstructure feature of G115 steel, and the research progress in the areas of microstructure stability, creep performance, fatigue resistance, steam oxidation resistance, and industrial pipe production are summarized, with a focus on the role of Cu-rich phase in G115 steel. Finally, some key points on G115 steel are proposed to provide ideas for future research.

新一代马氏体耐热钢G115的研究进展

[J].提高火电机组中耐热锅炉的蒸汽温度和压力参数可以有效提升燃煤效率,减少有害气体排放。受煤炭资源紧缺和温室效应的双重影响,发展650℃及更高温度超超临界(ultra super-critical,USC)机组中的耐热锅炉材料已迫在眉睫。我国在600℃ USC机组用耐热材料P92钢基础上研发的马氏体耐热钢G115有望成为优选材料之一。本文介绍了G115钢的成分特点、形貌特征,综述了其在组织稳定性、蠕变性能、抗疲劳性能、抗蒸汽氧化性能以及工业管材制备等方面的研究进展,重点归纳了G115钢中富Cu相的作用,展望了未来研究重点,以期为更深入研究G115钢提供可行思路。

Austenite grain growth in alumina-forming austenitic steel

[J].

Hot deformation of alumina-forming austenitic steel: EBSD study and flow behavior

[J].

EBSD analysis and mechanical properties of alumina-forming austenitic steel during hot deformation and annealing

[J].

Strengthening and toughening optimizations of novel G115 martensitic steel: Utilizing secondary normalizing process

[J].

The effect of isothermal aging on creep behavior of modified 2.5Al alumina-forming austenitic steel

[J].

Mechanisms for high creep resistance in alumina forming austenitic (AFA) alloys

[J].

The precipitation control in aged alumina-forming austenitic stainless steels Fe-15Cr-25Ni-3Al-NbWCu by W addition and its effect on the mechanical properties

[J].

Alumina-forming austenitic stainless steels strengthened by laves phase and MC carbide precipitates

[J].

Effect of alloying additions on phase equilibria and creep resistance of alumina-forming austenitic stainless steels

[J].

Alloying effects on creep and oxidation resistance of austenitic stainless steel alloys employing intermetallic precipitates

[J].

Investigations on the accelerated creep testing of alumina-forming austenitic stainless steel

[J].The heat transfer component is a major component of a nuclear power plant, the safety and service life of which are determined based on the long-term creep performance of the heat-transfer pipe material. Several long-term creep tests are usually required to determine the creep life of the heat-transfer pipe materials, which considerably restrict the evaluation efficiency of the material service performance. The objective of this study is to investigate the feasibility of accelerated creep test (ACT) to reduce the time required for evaluating the creep properties of materials. A alumina-forming austenitic (AFA) stainless steel was prepared, and the ACT was performed on a Gleeble thermal simulator. Based on the ACT developed and realized on the Gleeble thermal simulator, damage accumulation was realized by applying elastic-plastic tensile and compressive strains on the ACT specimen to simulate the accelerated changes in the microstructure of the alloy that can be usually observed during a conventional creep test (CT). The average stress with respect to all the cyclic stress relaxation stages in the ACT was considered to be the initial stress of the conventional CT, and a creep fracture test was conducted on the alloy sample. Results revealed that the ACT accelerated the microstructure evolution of the precipitated phases, dislocations, twins, and so on in a short time. Nevertheless, the repeated generation and annihilation of a large number of dislocations in the AFA alloy during the ACT provided the nucleation point and reduced the driving force associated with the nucleation of the precipitated second phase, including the Laves phase. In addition, the cyclic strain applied during the ACT will reduce the strengthening effect of the nanoscale deformation twins in the AFA alloy, resulting in differences in the evaluation effect. Thus, ACT is useful for the efficient evaluation of the creep properties of materials; however, the optimal range of test parameters must be further investigated.

形成Al2O3表层的奥氏体不锈钢加速蠕变实验研究

[J].

Influence of precipitates evolutions in δ-ferrite and austenite matrix on mechanical properties of alumina-forming austenitic steel

[J].

High temperature deformation of Laves phase precipitates in alumina-forming austenitic stainless steels

[J].

Revealing fracture mechanisms of medium manganese steels with and without delta-ferrite

[J].

High-temperature creep property deterioration of the alumina-forming austenitic steel: Effect of σ phase

[J].

Effects of alloying elements on microstructure and mechanical properties of Co-Ni-Al-Ti superalloy

[J].

Effect of Cu addition on microstructure and properties of Fe-20Ni-14Cr alumina-forming austenitic steel

[J].

Strengthening and fracture mechanisms of Fe-20Ni-14Cr-2Cu alumina-forming austenitic steel during creeping

[J].

Effects of pre-strain and two-step aging on microstructure and mechanical properties of Fe-30Mn-11Al-1.2C austenitic low-density steel

[J].Lightweight Fe-Mn-Al-C steels are promising candidates for automobile structural materials and have gained increased scientific and commercial interest owing to their outstanding mechanical properties and low density. To date, several studies have been conducted to illustrate the mechanism of phase transformation, strengthening, and strain hardening under solution and aging state. Moreover, prestrain before aging as a low-cost and simple method to tailor precipitates and control properties has been widely reported; however, it has been barely investigated in the Fe-Mn-Al-C alloy system. Therefore, in this study, the effects of pre-cold rolling and two-step aging on the microstructure and mechanical properties of Fe-30Mn-11Al-1.2C (mass fraction, %) austenitic low-density steel are investigated using EBSD, TEM, and universal testing machine. Results showed that the yield strength (YS) significantly increased via the two-step aging from 580 MPa (at solution state) to 1120 MPa, but the uniform elongation (UE) sharply decreased to approximately 0. However, after the pre-cold rolling and two-step aging, the YS of the material further improved to 1220 MPa, and the UE significantly increased to 18.2%, which implies an improvement in the comprehensive mechanical properties of the material. According to the microstructure analysis, the increase in YS after the two-step aging was caused by the ordering strengthening effect of κ' carbide. Further, the pre-cold rolling could introduce heterogeneous nucleation sites, inducing intragranular precipitation. The combination of the precipitation strengthening of the precipitates and deformation strengthening induced via the pre-cold rolling further increased the YS of the material. Moreover, these intragranular precipitates could improve the work hardening capability, which is the root cause of the high plasticity of materials. This process provides a novel idea for improving the performance of austenitic low-density steels.

预变形和双级时效对Fe-30Mn-11A1-1.2C奥氏体低密度钢显微组织和力学性能的影响

[J].

Effect of aging treatment at 700 oC on microstructure and mechanical properties of 9Cr ODS steel

[J].

700 ℃时效对9Cr ODS钢微观组织和力学性能的影响

[J].为探究近服役温度时效行为对ODS钢微观组织和力学性能的影响,通过SEM、TEM和拉伸性能测试等方法,研究了9Cr ODS钢在700℃时效不同时间后的碳化物(M23C6)、纳米氧化物演变和力学性能变化。结果表明:在时效初期(≤ 200 h),M23C6在晶界处呈条带状快速析出并聚集长大,纳米氧化物无明显变化;在时效中期(200和1000 h),M23C6和纳米氧化物稳定长大;在时效后期(2000和3000 h),M23C6达到亚微米级,纳米氧化物的平均尺寸和数密度趋于稳定,与初始态相比,其平均尺寸的增长率为19.7%,数密度的下降率为27.1%。因纳米氧化物对不断增殖位错的钉扎,在部分晶粒内出现了位错胞和回复亚晶。9Cr ODS钢的拉伸强度在时效初期快速下降。在时效中后期,虽然纳米氧化物平均尺寸增加、数密度降低,但其钉扎作用仍然显著,以及基体中不断增殖的位错使得材料的拉伸强度维持稳定,延伸率在时效1000和2000 h期间处于低谷。

Effect of high-temperature ageing on microstructure and creep properties of S31042 heat-resistant steel

[J].S31042 steel is a typical 25Cr-20Ni-type austenitic heat-resistant steel with excellent oxidation and corrosion resistance, and its creep rupture strength can be improved by the addition of Nb and N. This austenitic steel is widely used in superheater and reheater in ultrasupercritical power plants. At high temperatures, its performance is associated with the formation and evolution of Z, MX, and M23C6 phases. Till date, few studies have addressed the precipitation behavior of the Z phase in austenitic steel and the reinforcing mechanism of different M23C6 phases remains unclear. To clarify this, the ageing treatment of S31042 steel was performed at 1050oC, and the evolution behavior, thermal stability, and strengthening mechanism of the precipitates during creep tests were investigated. Furthermore, the relation between precipitate evolution and high-temperature performance was elucidated via OM, SEM, TEM, and creep tests. The supersaturation degree of the alloying components in solution-treated S31042 steel decreased after ageing at 1050oC and the driving force for M23C6 phase formation became smaller, resulting in a discontinuous distribution of the rod-like M23C6 phase along the austenite grain boundaries during the creep tests. At high stress levels, this discontinuous distribution of the rod-like M23C6 phase along the austenite grain boundaries increased the resistance to grain boundary sliding without changing the ductility, thus improving the rupture ductility of the steel. At low stress levels, the strengthening effects of the M23C6 phase discontinuously distributed along the austenite grain boundaries in aged steel were not as strong as those in solution-treated steel.

高温时效处理对S31042耐热钢组织和蠕变性能的影响

[J].以S31042奥氏体耐热钢为研究对象,采用短时高温时效处理后在700℃下对其进行长期蠕变性能测试。通过OM、SEM和TEM等手段表征了S31042钢蠕变过程析出相的类型和演化规律,并利用蠕变实验分析了高温时效处理对S31042钢高温性能的影响。结果表明,经1050℃时效10 h处理后,S31042钢组织中析出大量尺寸在100 nm左右的Z相,降低了固溶态S31042钢中合金元素Cr和Nb的过饱和度,减小了M23C6相的形核驱动力,将蠕变过程晶界上析出M23C6相的形态由连续的链状调控为断续的短棒状。短棒状M23C6相的形成能够在不影响材料塑性的前提下,增大晶界滑动的阻力,改善材料的持久塑性。

Annealing effects on precipitation and high-temperature properties of a Cu-containing alumina-forming austenitic steel

[J].

Microstructure and mechanical properties of 4Al alumina-forming austenitic steel after cold-rolling deformation and annealing

[J].

The effect of isothermal aging on microstructure and mechanical behavior of modified 2.5Al alumina-forming austenitic steel

[J].

Creep behavior, microstructure evolution and fracture mechanism of a novel martensite heat resistance steel G115 affected by prior cold deformation

[J].

Effect of cold-rolling deformation on microstructure, properties, and precipitation behavior of high-performance Cu-Ni-Si alloys

[J].

冷轧变形对高性能Cu-Ni-Si合金组织性能与析出行为的影响

[J].采用DSC、TEM、导电率和力学性能等测试方法,研究了不同冷轧变形量对Cu-3.0Ni-0.60Si-0.16Zn-0.15Cr-0.03P (质量分数,%)合金组织性能与析出行为的影响,旨在通过工艺调控提升该合金的综合性能。通过对比不同冷轧变形后合金的开始析出温度和再结晶温度以及时效后合金的组织性能,确定了高性能Cu-Ni-Si系合金的形变-时效工艺参数,明确了冷轧变形量对合金时效析出动力学的影响规律和强化相析出的调控机制;合金经过95%冷轧+ 450℃、60 min形变热处理后获得了显著优于现有Cu-Ni-Si合金(如C70250)的性能,其抗拉强度为(841 ± 10) MPa,导电率为(52.2 ± 0.3)%IACS。

Effects of cryorolling on properties and precipitation behavior of a high-strength and high-conductivity Cu-1Cr-0.2Zr-0.25Nb alloy

[J].

低温轧制对高强高导Cu-1Cr-0.2Zr-0.25Nb合金性能及析出行为的影响

[J].随着现代工业中交通、电气、航空航天、电子等领域的快速发展,对铜合金的性能要求越来越高。强度和导电率是相互矛盾的性质,实现铜合金兼具高强度和高导电率是现代铜工业发展的重要课题。采用真空熔炼、低温轧制、时效处理等工艺制备了Cu-1Cr-0.2Zr-0.25Nb (质量分数,%)合金,研究了低温轧制对Cu-1Cr-0.2Zr-0.25Nb合金显微组织、力学性能和导电性能的影响,分析了时效工艺对析出相种类、形貌和分布的影响。结果表明,Cu-1Cr-0.2Zr-0.25Nb合金主要由Cr相、富Zr相、Cr2Nb相及Cu基体相组成。450℃短时(30 min)时效后Cu-1Cr-0.2Zr-0.25Nb合金即可析出纳米级fcc结构的Cr析出相,在长时间(300 min)时效后,会形成bcc结构的Cr析出相。Cu-1Cr-0.2Zr-0.25Nb合金经过低温轧制和时效处理后,在Cu基体中形成了纳米析出相、纳米变形孪晶和位错等混合组织并获得了优异的综合性能。低温轧制Cu-1Cr-0.2Zr-0.25Nb合金450℃时效30 min后,抗拉强度为700 MPa,导电率为73.29%IACS;450℃时效300 min后,导电率可达79.81%IACS,此时,抗拉强度、屈服强度和硬度分别为646 MPa、606 MPa和212 HV。结合实验结果和对强度贡献计算表明,位错强化和析出强化是Cu-1Cr-0.2Zr-0.25Nb合金的主要强化机制。

Strengthening of high-entropy alloys via modulation of cryo-pre-straining-induced defects

[J].Owing to their attractive structure and mechanical properties, high-entropy alloys (HEAs) and medium-entropy alloys (MEAs) have attracted considerable research interest. The strength of HEAs/MEAs with a single face-centered cubic (FCC) phase, on the other hand, requires improvement. Therefore, in this study, we demonstrate a strategy for increasing the room-temperature strength of FCC-phase HEAs/MEAs by tuning cryo-pre-straining-induced crystal defects via the temperature-dependent stacking fault energy-regulated plasticity mechanism. Through neutron diffraction line profile analysis and electron microscope observation, the effect of the tuned defects on the tensile strength was clarified. Due to the cryo-rolling-induced high dislocation density, mechanical twins, and stacking faults, the room-temperature yield strength of an equiatomic CoCrFeNi HEA was increased by ∼290%, from 243 MPa (as-recrystallized) to 941.6 MPa (30% cryo-rolled), while maintaining a tensile elongation of 18%. After partial recovery via heat treatment, the yield strength and ultimate tensile strength decreased slightly to 869 and 936 MPa, respectively. Conversely, the elongation increased to 25.6%. The dislocation density and distribution of the dislocations were found to contribute to the strengthening caused by forest dislocations, which warrants further investigation. This study discussed the possibility of developing single-phase high-performance HEAs by tuning pre-straining-induced crystal defects.

Recrystallization controlling in a cold-rolled medium Mn steel and its effect on mechanical properties

[J].Owing to the excellent combination of specific strength and ductility, medium Mn steels (MMSs) with Mn contents of 3%-12% (mass fraction) are considered the most promising candidates for the third-generation advanced high-strength steel. The combination of excellent strength-ductility is mainly attributed to the active transformation-induced plasticity effect of the metastable retained austenite during deformation. Therefore, producing a considerable amount of retained austenite with reasonable stabilities in the steel by various heat treatment schedules is always important. In this study, granular- and lamellar-structured retained austenites were developed in a cold-rolled 0.15C-5Mn MMS by introducing a technical process of precontrolling ferrite recrystallization in the annealing schedule. The microstructures of the annealed samples were analyzed using SEM, EBSD, and TEM. The results show that duplex microstructures comprising various amounts of recrystallized ferrite and fresh martensite can be obtained in the cold-rolled MMS when controlling the occurrence of recrystallization at different intercritical temperatures by a preannealing process. When this microstructure is used for the final austenite reverted transformation annealing, the resultant ultrafine duplex microstructure with recrystallized ferrite and two types of heterogeneous retained austenite, i.e., lamellar and granular, is produced. The heterogeneous-structured austenite shows more sensitivity to increasing strain, i.e., various mechanical stabilities, which enable an excellent strength-ductility combination and reduced Lüders strain in the cold-rolled medium Mn steel.

冷轧中锰钢的再结晶调控及其对力学性能的影响

[J].为探究铁素体再结晶对冷轧中锰钢微观组织与力学性能的影响规律,以0.15C-5Mn (质量分数,%)冷轧中锰钢为研究对象,采用两步临界区退火的热处理方法,利用SEM、TEM和EBSD等表征手段和力学性能测试方法,研究了铁素体再结晶调控对冷轧中锰钢多样化残余奥氏体形成及其力学性能的影响。结果表明,通过在不同温度预先调控冷轧中锰钢中的铁素体再结晶,可获得由不同比例的等轴状再结晶铁素体和马氏体组成的双相细晶组织。经常规退火处理后,在终态组织中形成了不同体积分数的超细晶再结晶铁素体和呈等轴状/板条状形貌的多样化细晶残余奥氏体,使中锰钢在拉伸变形过程中表现出多样化的TRIP效应,在提升冷轧中锰钢强塑性能的同时,其Lüders变形也获得改善。

Effect of strengthening mechanisms on mechanical properties of alumina-forming austenitic steel after pre-strain

[J].

Tensile properties of chromium-bearing extra low carbon steel sheets

[J].

Effect of prestrain on fracture toughness of HSLA steels

[J].

Insights into the role of grain refinement on high-temperature initial oxidation phase transformation and oxides evolution in high aluminium Fe-Mn-Al-C duplex lightweight steel

[J].

High-temperature oxidation behavior of modified 4Al alumina-forming austenitic steel: Effect of cold rolling

[J].The oxidation behavior and mechanism of as-received and 30 % cold-rolled alumina-forming austenitic (AFA) steel were investigated in dry air at 700 °C. The results show that the mass gain per unit area curves of as-received and 30 % cold-rolled steels subject to near-parabolic law before 100 h oxidation time. Two samples both show higher high-temperature oxidation resistance due to the formation of dense Al2O3 oxide scale. Gradual spallation of outer scale results in the formation of continuous and dense alumina scale. Dislocations can act as short-circuit diffusion channel for the diffusion of Al from alloy matrix to surface, and also provide nucleation sites for B2-NiAl phase, which ensure the continuous formation of Al2O3 scale.

The effects of cold work on the microstructure and mechanical properties of intermetallic strengthened alumina-forming austenitic stainless steels

[J].

Accelerated precipitation in the AFA stainless steel Fe-20Cr-30Ni-2Nb-5Al via cold working

[J].

Co-strengthening of dislocations and precipitates in alumina-forming austenitic steel with cold rolling followed by aging

[J].

Evolution of precipitates in a Cu-containing alumina-forming austenitic steel after short-term mechanical tests

[J].