合金化是一种非常有效的改善镁合金织构类型的手段,尤其是添加稀土元素[12,13]。Hantzsche等[12]研究表明,适量的稀土元素Ce、Nd和Y对纯Mg轧板的织构均有弱化作用,对比添加相同Ce、Nd和 Y稀土含量的镁合金最大基面织构强度,发现Ce的织构弱化作用最为明显,即添加少量的Ce元素可有效弱化基面织构。同时,Ce元素在Mg基体中的固溶度较低,其添加易形成含Ce的第二相颗粒,起到第二相强化作用,有利于增强镁合金的强度[14]。此外,虽然稀土元素大多价格昂贵,但Ce作为一种较为廉价的稀土元素[15],且在较少的添加量下能够有效地弱化镁合金基面织构,因此在提升镁合金成形性方面具有重要的研究价值。

近年来,多元微合金化策略下开发的Mg-Al-Ca-Mn合金由于可实现快速挤压且成本低廉而显示出巨大的工业应用前景[16,17]。然而,稀土元素Ce对挤压态Mg-Al-Ca-Mn合金微观组织、织构及力学性能的影响却鲜有报道。因此,本工作采用Ce微合金化Mg-0.3Al-0.2Ca-0.5Mn (质量分数,%,下同;简称AXM)挤压态板材,系统地研究了不同Ce含量(0、0.05%和0.5%,质量分数)下挤压态AXM合金微观组织、织构和力学性能的演化规律。为了准确阐明AXM合金的织构演化机制,利用中子衍射技术获得具有更高统计性的体织构信息,同时再结合电子背散射衍射(EBSD)获取的微观织构进行全面分析。本工作旨在通过优化合金成分,开发低成本、高成形性的新型低合金化AXM系列合金板材,亦为其织构调控提供参考。

1 实验方法

实验所用材料为不同Ce含量的Mg-0.3Al-0.2Ca-0.5Mn-xCe (x = 0、0.05、0.5)挤压态镁合金板材,其实际化学成分如表1所示。挤压工艺如下:将镁合金铸锭加工成圆柱形挤压坯料(直径95 mm),然后在挤压比35∶1、挤压速率约15 m/min和挤压温度440℃的条件下进行热挤压,最终获得横截面尺寸为 5 mm × 40 mm 的挤压板。

表1 实验所用镁合金实测化学成分 (mass fraction / %)

Table 1

| Designation | Nominal alloy | Al | Ca | Mn | Ce | Mg |

|---|---|---|---|---|---|---|

| AXM | Mg-0.3Al-0.2Ca-0.5Mn | 0.35 | 0.22 | 0.48 | Bal. | |

| AXM + 0.05Ce | Mg-0.3Al-0.2Ca-0.5Mn-0.05Ce | 0.32 | 0.24 | 0.52 | 0.05 | Bal. |

| AXM + 0.5Ce | Mg-0.3Al-0.2Ca-0.5Mn-0.5Ce | 0.32 | 0.22 | 0.48 | 0.53 | Bal. |

镁合金体织构的测量在中国先进研究堆中子织构谱仪[18]上进行,实验采用的块体样品尺寸为10 mm × 10 mm × 10 mm (切割两块尺寸为10 mm × 10 mm × 5 mm的样品进行叠加,叠加时保持挤压方向一致),测量时采用的中子波长为0.148 nm。织构测量时,根据所测晶面的衍射角范围,将探测器安放在某个固定的2θ衍射角,依次转动取向角chi和phi,获得不同取向位置的中子衍射信号。该谱仪配备了二维位置灵敏探测器,可同时覆盖较大的取向角(chi)和2θ范围,因此测量时可增大chi角的角度间隔,同时有可能一次实现多个晶面的极图测量,从而减少测量时间。本工作中chi角的角度间隔设为15°,测量范围为0°~90°,phi角的角度间隔设为5°,测量范围为0°~360°,每一个测试点均进行固定时长的衍射数据收集。分别利用D8 X射线衍射仪(XRD)、配备INCA-X-Max能谱仪(EDS)和Instruments Symmetry EBSD的Sigma 500扫描电子显微镜(SEM)进行物相分析和微观组织观察,使用AZtecCrystal软件对所采集的EBSD图像进行晶粒取向、晶粒尺寸等数据分析。选取不同Ce含量的镁合金挤压板沿挤压方向(ED)和横向(TD)切割工字形的拉伸试样,利用AGS-X-100kN拉伸试验机对合金进行室温拉伸,应变率为1 × 10-3 s-1,每次实验重复3次取平均值。

2 实验结果

2.1 不同Ce含量下AXM合金板材微观组织演化

图1为挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材显微组织的EBSD像和晶粒尺寸分布图。可以看出,挤压后的AXM + xCe (x = 0、0.05、0.5)合金内部发生了动态再结晶,并形成相对均匀的等轴再结晶晶粒,其平均晶粒尺寸依次为14.63、14.41和13.06 μm。随着Ce含量的增加,合金晶粒尺寸略有减小,表明Ce元素的添加对挤压态AXM板材的晶粒尺寸影响不明显。

图1

图1

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材显微组织的EBSD像和晶粒尺寸分布图

Fig.1

EBSD images (a, c, e) and grain size distributions (b, d, f) of the as-extruded AXM (a, b), AXM + 0.05Ce (c, d), and AXM + 0.5Ce (e, f) alloy sheets (dave—average grain size)

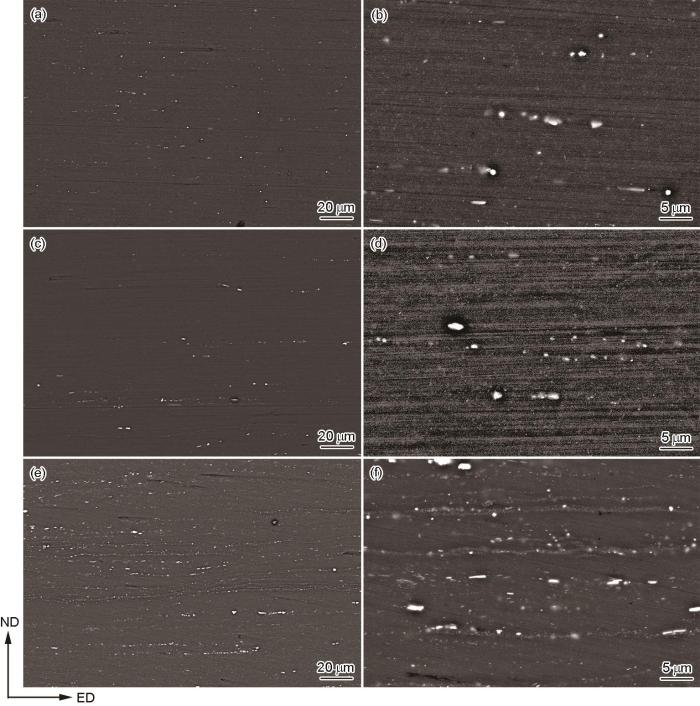

图2为AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材的SEM背散射电子(BSE)像。可见,随Ce含量的增加,第二相颗粒的含量也呈增多趋势;3个合金样品中都存在一些尺寸大于1 μm的第二相颗粒,且沿着挤压方向呈条带状分布,同时也存在许多尺寸较小的第二相颗粒弥散分布于Mg基体中。

图2

图2

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材的SEM背散射电子(BSE)像

Fig.2

Low (a, c, e) and high (b, d, f) magnified SEM-backscattered electron (BSE) images of the as-extruded AXM (a, b), AXM + 0.05Ce (c, d), and AXM + 0.5Ce (e, f) alloy sheets (ND—normal direction, ED—extrusion direction)

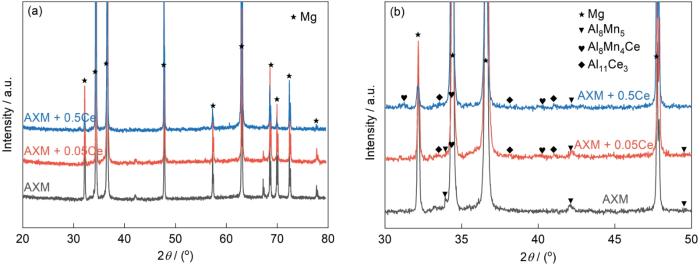

图3

图3

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材的XRD谱

Fig.3

XRD spectra of the as-extruded AXM, AXM + 0.05Ce, and AXM + 0.5Ce alloy sheets (a), and partially enlarged XRD spectra (b)

图4

图4

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材的高倍SEM-BSE像和EDS分析

Fig.4

High magnification SEM-BSE images (a-c) and EDS analyses (d-f) of the as-extruded AXM (a, d), AXM + 0.05Ce (b, e), and AXM + 0.5Ce (c, f) alloy sheets, where Figs.4d-f are line-scan results of the typical second-phase particle at square regions A, B, and C in Figs.4a-c, respectively

2.2 不同Ce含量下AXM合金板材体织构演化

图5为不同Ce含量AXM合金板材TD-ED面的(10

图5

图5

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材(10

Fig.5

(10

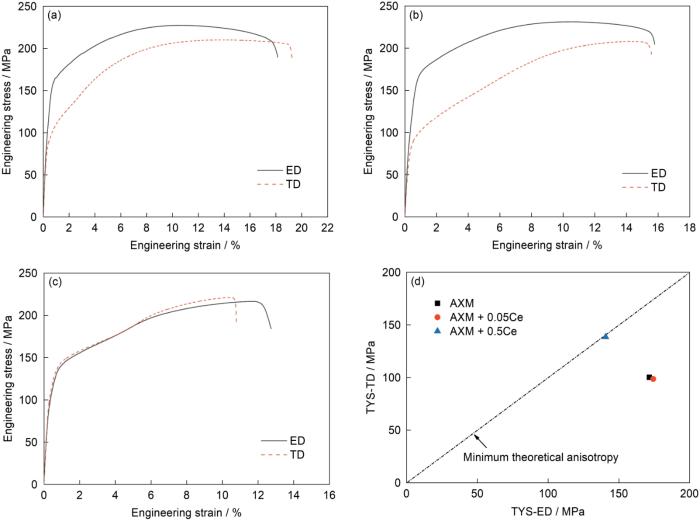

2.3 不同Ce含量下AXM合金板材的力学性能

图6a~c为添加不同含量Ce元素的挤压态AXM合金分别沿TD和ED方向拉伸的室温力学性能曲线,相关的力学性能列于表2中。与AXM合金板材相比,AXM + 0.05Ce合金板材沿ED和TD方向的拉伸屈服强度和抗拉强度变化不大,但AXM + 0.5Ce合金板材沿ED方向的拉伸屈服强度和抗拉强度明显降低,沿TD方向则显著增大。此外,Ce元素的添加,使得合金板材的断裂延伸率无论沿ED还是TD方向都明显降低。图6d为3种合金板材分别沿TD和ED方向的拉伸屈服强度关联图,图中位于虚线上的点表示沿TD和ED的拉伸屈服强度比等于1,即材料的各向异性程度最低。可以看出,AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材沿着TD和ED方向的拉伸屈服强度比分别为0.58、0.57和0.98,表明添加0.05%Ce未能降低AXM合金板材的拉伸屈服强度各向异性,而添加0.5%Ce时各向异性得到明显改善。

图6

图6

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材沿横向(TD)和挤压方向(ED)的室温拉伸力学性能及TD和ED方向拉伸屈服强度比

Fig.6

Mechanical properties at room temperature of the as-extruded AXM (a), AXM + 0.05Ce (b), and AXM + 0.5Ce (c) alloy sheets along ED and TD; and tensile yield strength (TYS) ratio along ED and TD (d)

表2 不同Ce含量挤压态AXM合金板材的力学性能

Table 2

| Sample | TYS / MPa | UTS / MPa | EL / % | |||

|---|---|---|---|---|---|---|

| ED | TD | ED | TD | ED | TD | |

| AXM | 171.6 ± 0.5 | 100.2 ± 1.8 | 226.8 ± 0.7 | 208.3 ± 1.0 | 19.1 ± 0.9 | 19.8 ± 0.6 |

| AXM + 0.05Ce | 174.3 ± 1.3 | 98.6 ± 2.4 | 233.1 ± 1.8 | 202.5 ± 4.1 | 13.7 ± 1.3 | 12.8 ± 2.4 |

| AXM + 0.5Ce | 140.7 ± 1.5 | 138.5 ± 2.6 | 218.0 ± 1.5 | 219.1 ± 2.1 | 13.1 ± 1.1 | 11.3 ± 0.7 |

Note: UTS—ultimate tensile strength, EL—elongation

3 分析讨论

3.1 Ce含量对AXM合金板材织构的影响机制

表3 AXM、AXM + 0.05Ce和AXM + 0.5Ce合金的轴比c / a

Table 3

| Sample | a / nm | c / nm | c / a |

|---|---|---|---|

| AXM | 0.321424 | 0.521882 | 1.62365 |

| AXM + 0.05Ce | 0.321317 | 0.521645 | 1.62346 |

| AXM + 0.5Ce | 0.321447 | 0.521800 | 1.62328 |

Note: c and a—lattice constants

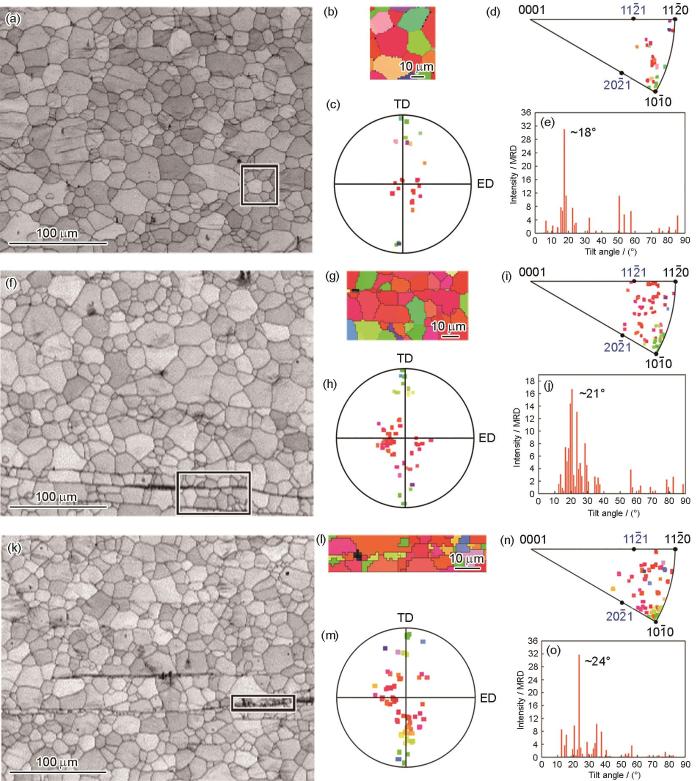

另一个影响RE织构形成的因素是热挤压过程中第二相颗粒对动态再结晶行为的影响。由于Ce在Mg基体中的固溶度较低,随着Ce含量的增加,AXM合金板材中的第二相颗粒含量逐渐增加,其对晶粒形核的影响也更加显著,进而影响织构的形成与演化。图7为AXM合金中选取的小晶粒区域、AXM + 0.05Ce和AXM + 0.5Ce合金中选取的第二相富集区域的EBSD分析。从极图散点图(图7c、h和m)和基极取向分布图(图7e、j和o)可以看出,AXM合金基极分布最集中的位置偏离ND约18º,为典型的基面取向。与AXM合金相比,2种含Ce的镁合金板材中处于第二相颗粒富集区域的再结晶晶粒基极分布最集中的位置分别偏离ND约21°和24°,均超出了(0002)极图中基面织构范围,发生了非基面的择优取向。进一步反映在反极图散点图(图7d、i和n)中,2种含Ce镁合金板材均形成了一个向ED偏转的织构组分,其取向沿着<11

图7

图7

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材的带对比图以及方框处的EBSD像、(0002)极图散点图、ED方向反极图散点图和基极取向分布图

Fig.7

EBSD analyses of the as-extruded AXM (a-e), AXM + 0.05Ce (f-j), and AXM + 0.5Ce (k-o) alloy sheets

(a, f, k) band contrast maps of the as-extruded AXM (a), AXM + 0.05Ce (f), and AXM + 0.5Ce (k) alloy sheets, respectively

(b, g, l) EBSD images of square regions in Figs.7a (b), f (g), and k (l), respectively

(c, h, m) (0002) PFs with scatter data of square regions in Figs.7a (c), f (h), and k (m), respectively

(d, i, n) inverse pole figures (IPFs) with scatter data along ED of square regions in Figs.7a (d), f (i), and k (n), respectively

(e, j, o) basal pole tilt distribution maps of square regions in Figs.7a (e), f (j), and k (o), respectively

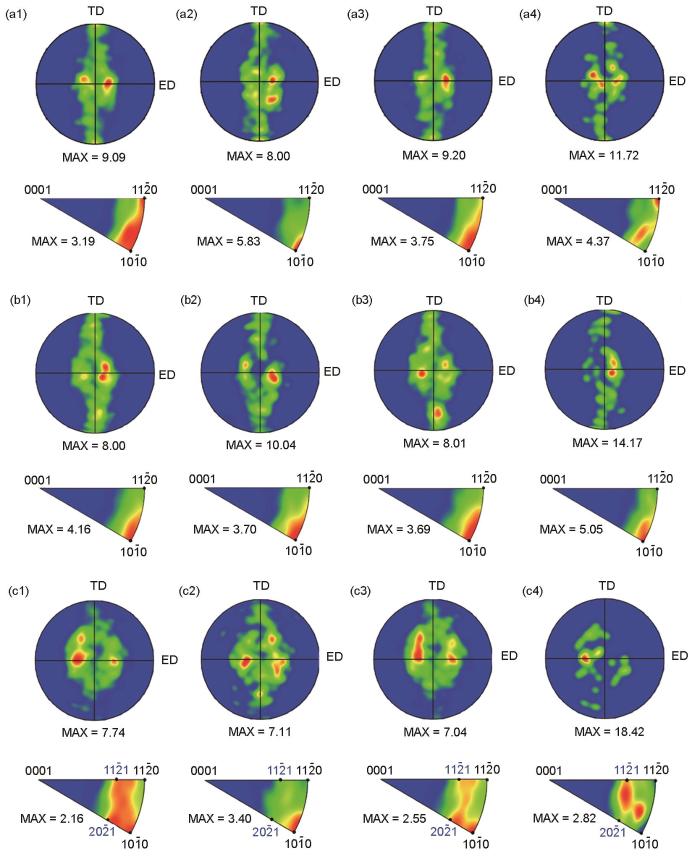

晶粒形核后的择优生长行为对合金板材的最终织构分布起着决定作用。图8为挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材样品测试范围内全部晶粒及不同尺度范围晶粒(< 10 μm、10~25 μm、> 25 μm)的(0002)极图和相应的反极图。可以看出,与图5的中子织构极图相比,EBSD给出的极图分布与其相符,反映出织构类型随Ce含量的增加而发生转变。但由于EBSD采集的晶粒数较少,统计性相对较差,其所获得的织构强度规律与中子测试结果存在一定差异。由于测试方法的不同,EBSD在微观织构分析上具有显著优势。从图8可见,AXM和AXM + 0.05Ce合金中尺寸< 10 μm的再结晶晶粒形成的织构主要为<10

图8

图8

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材不同尺寸晶粒的(0002)极图和相应的反极图

Fig.8

(0002) PFs and corresponding IPFs along ED of grain size of the as-extruded AXM (a1-a4), AXM + 0.05Ce (b1-b4), and AXM + 0.5Ce (c1-c4) alloy sheets

(a1-c1) all grains (a2-c2) grain size < 10 μm

(a3-c3) grain size 10-25 μm (a4-c4) grain size > 25 μm

根据以上讨论可以得出,在含Ce的AXM合金中,再结晶晶粒的形核和择优长大共同促进了AXM + 0.5Ce合金非基面织构的形成。当添加0.05%Ce时,虽然再结晶晶粒形核时有非基面织构产生,但其(0002)晶面织构依然未发生明显的ED偏转,即未有明显的非基面织构形成。这很可能是由于添加的Ce含量少,形成的可促进PSN机制的粗大第二相颗粒数量非常有限,尚不足以影响整体的织构分布。

3.2 Ce含量对AXM合金板材力学性能的影响机制

一般来说,力学性能主要取决于材料自身的微观结构状态[29]。以上讨论了添加Ce元素的AXM合金的微观结构变化,主要包括固溶原子、晶粒尺寸、第二相颗粒和织构。由于稀土元素Ce的固溶度低,且Ce含量对AXM基合金晶粒尺寸影响较小,因此固溶原子和晶粒细化对3种合金板材力学性能造成的影响差异不大。但是随着Ce元素的添加,AXM基合金板材的第二相颗粒数量和织构分布都发生了明显的改变。因此其力学性能的改变主要源于第二相强化和织构弱化效应。

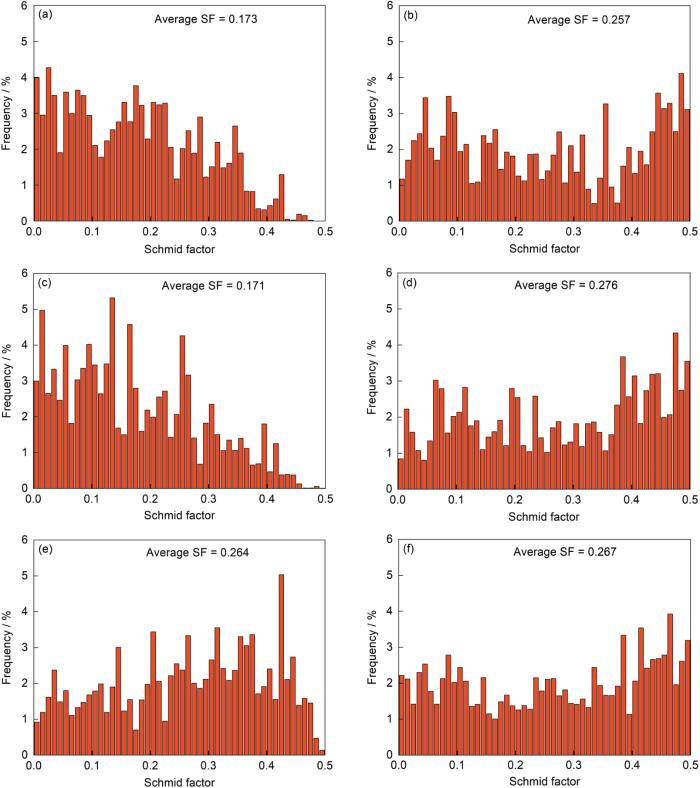

与AXM合金相比,AXM + 0.05Ce合金板材沿TD拉伸的TYS略低(表2),因此织构可能是影响合金TYS的主要因素。研究[30]表明,因为与其他滑移和形变孪生相比,基面滑移具有最低的临界剪切应力(CRSS),室温下镁合金的主要变形机制是基面滑移。图9为挤压态合金板材沿着ED和TD的(0001)<11

图9

图9

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材沿着ED和TD的(0001)<11

Fig.9

Schmid factor (SF) distribution maps of (0001)<11

当进一步增加Ce含量后,AXM + 0.5Ce合金板材沿TD的TYS明显增加,主要是因为第二相颗粒明显增多,其强化效应起到了主导作用;而沿ED的TYS却出现显著降低,主要原因是AXM + 0.5Ce合金板材(0002)极图的双峰织构更加向ED倾斜 (图5),导致基面滑移的SF明显增大,沿ED拉伸时基面滑移更容易被激活,此时织构弱化对TYS的贡献占据主导作用。

3.3 Ce含量对AXM合金板材力学性能各向异性的影响机制

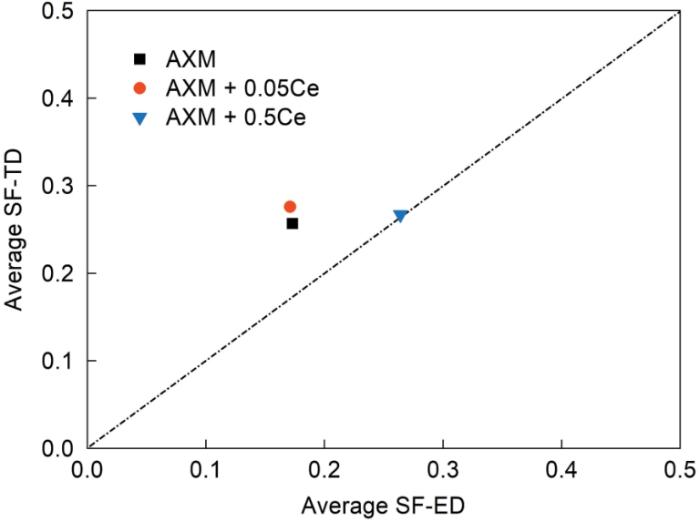

挤压和轧制等变形工艺通常容易使材料形成强的且分布对称性差的基面织构,导致材料的TYS具有强各向异性[29,32]。因此,合金材料力学性能各向异性的改善与其织构息息相关[33,34]。图10为挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金沿着ED和TD的(0001)<11

图10

图10

挤压态AXM、AXM + 0.05Ce和AXM + 0.5Ce合金板材沿着TD和ED的(0001)<11

Fig.10

Average Schmid factor ratios along TD and ED of (0001)<11

4 结论

(1) 随Ce含量的增加,挤压态AXM合金板材中的第二相颗粒逐渐从Al8Mn5转变为Al8Mn4Ce和Al11Ce3颗粒,且第二相颗粒数量明显增多。主要原因是稀土元素Ce在Mg基体中的固溶度比较低,导致其主要以第二相的形式存在于Mg基体中。

(2) 在合金板材挤压过程中,含Ce第二相颗粒的增多促进了非基面取向的再结晶晶粒的形核和择优生长,引起了AXM + 0.5Ce合金从双峰基面织构向双峰非基面织构的转变,最终优化了合金板材的织构分布。

(3) 因为基面织构的优化,AXM + 0.5Ce合金板材沿TD和ED的拉伸屈服强度比值接近于1,该合金的拉伸性能各向异性得以改善。

参考文献

The potential of SLM technology for processing magnesium alloys in aerospace industry

[J].

Latest research advances on magnesium and magnesium alloys worldwide

[J].

Magnesium matrix composites for biomedical applications: A review

[J].In recent years, a new wave of bioactive, biocompatibility and biodegradable metallic materials were developed for orthopedic applications. Pure Magnesium, Magnesium alloys, Magnesium alloy-based composites are extensive material to the biomedical applications, by virtue of its high biocompatibility and reasonable strength. Pure magnesium, Magnesium alloys can corrode too fast during the physiological conditions and loses their properties before bone heal. The new era for the development of magnesium-based composites can satisfy the orthopedic applications. Magnesium-based composites, as bio-materials, can produce adjustable mechanical properties like Ultimate tensile strength, ductility, elastic modulus, and corrosion resistance in the physiological conditions. In the Mg based composites, the matrix materials are biomedical magnesium alloys base like Mg-Ca, Mg-Al, Mg-Zn, and Mg-REE alloy and The reinforcements are based on hydroxyapatite (HAP), calcium polyphosphate (CPP), and beta-tricalcium phosphate (beta-TCP) particles. This comprehensive review is focused on different grades of biodegradable magnesium matrix composites including their mechanical properties and corrosion resistance. (C) 2018 Published by Elsevier B.V. on behalf of Chongqing University.

Magnesium and its alloys applications in automotive industry

[J].

Texture weakening and ductility variation of Mg-2Zn alloy with Ca or RE addition

[J].

Recent research and developments on wrought magnesium alloys

[J].

Strategies for enhancing the room-temperature stretch formability of magnesium alloy sheets: A review

[J].

Texture and stretch formability of AZ61 and AM60 magnesium alloy sheets processed by high-temperature rolling

[J].

Prediction of the plastic anisotropy of magnesium alloys with synthetic textures and implications for the effect of texture on formability

[J].

The texture and anisotropy of magnesium-zinc-rare earth alloy sheets

[J].

Anisotropy of wrought magnesium alloys: A focused overview

[J].

Effect of rare earth additions on microstructure and texture development of magnesium alloy sheets

[J].

A review on the effect of rare-earth elements on texture evolution during processing of magnesium alloys

[J].

Effect of micro-alloyed Ce on the microstructure evolution and mechanical properties of rolled Mg-0.6Al-0.5Mn-0.2Ca alloy sheets

[J].

Influence of Ce content on the microstructures and tensile properties of Mg-1Gd-0.5Zn alloys

[J].

Effect of annealing on microstructure evolution and age-hardening behavior of dilute Mg-Al-Ca-Mn alloy

[J].

Strong and ductile age-hardening Mg-Al-Ca-Mn alloy that can be extruded as fast as aluminum alloys

[J].

The latest progress on neutron texture diffractometer at China Advanced Research Reactor

[J].

Tailoring the microstructure and enhancing the corrosion resistance of extruded dilute Mg-0.6Al-0.5Mn-0.25Ca alloy by adding trace Ce

[J].

The evolution of coarse grains and its effects on weakened basal texture during annealing of a cold-rolled magnesium AZ31B alloy

[J].

Shear band-related recrystallization and grain growth in two rolled magnesium-rare earth alloys

[J].

Improvement of mechanical properties and reduction of yield asymmetry of extruded Mg-Sn-Zn alloy through Ca addition

[J].

Influence of minor Ce additions on the microstructure and mechanical properties of Mg-1.0Sn-0.6Ca alloy

[J].The microstructure and mechanical properties of Mg-Sn-Ca-Ce alloys with different Ce contents (0.0, 0.2, 0.5, 1.0 wt%) were studied at room temperature. Ce additions to ternary Mg-Sn-Ca alloy resulted in grain refinement as well as a change in the category of second phase from CaMgSn to (Ca, Ce)MgSn and Mg12Ce. The volume fraction of second phase increased with rising Ce content, which aggravated the restriction of DRXed grain growth during the extrusion process and eventually led to texture weakening of as-extruded Mg-Sn-Ca based alloys. In terms of plasticity, owing to vigorously activated basal slip and homogeneous distributed tensile strain in tension, the tensile ductility of as-extruded alloys reached the maximum value of 27.6% after adding 0.2 wt% Ce, which enhanced by about 26% than that of ternary Mg-Sn-Ca alloy. However, further Ce additions (0.5 and 1.0 wt%) would coarsen the second phase particles and then impair ductility. The tension-compression yield asymmetry of as-extruded Mg-Sn-Ca ternary alloy was alleviated greatly via Ce additions, due to the joint effects of grain refinement, increased amount of strip distributed second phase particles and texture weakening.

Effects of Gd/Nd ratio on the microstructures and tensile creep behavior of Mg-8Al-Gd-Nd alloys crept at 423 K

[J].

The influence of Ce on the microstructure and rolling texture of Mg-1%Mn alloy

[J].

Role of second phases and grain boundaries on dynamic recrystallization behavior in ZK60 magnesium alloy

[J].

Simultaneous improvement of strength and ductility in ZK60 magnesium alloy by constructing the bimodal grain structure

[J].

Influence of Ca and Zn synergistic alloying on the microstructure, tensile properties and strain hardening of Mg-1Gd alloy

[J].

Texture role in the mechanical property improvement contributed by grain refinement for Mg-2.6Nd-0.55Zn-0.5Zr alloy subjected to extrusion process

[J].

Investigation of shear and tensile mechanical properties of ZK60 Mg alloy sheet processed by rolling and sheet extrusion

[J].

Effects of samarium content on microstructure and mechanical properties of Mg-0.5Zn-0.5Zr alloy

[J].Effects of samarium (Sm) content (0, 2.0, 3.5, 5.0, 6.5 wt%) on microstructure and mechanical properties of Mg-0.5Zn-0.5 Zr alloy under as-cast and as-extruded states were thoroughly investigated. Results indicate that grains of the as-cast alloys are gradually refined as Sm content increases. The dominant intermetallic phase changes from Mg3Sm to Mg41Sm5 till Sm content exceeds 5.0 wt%. The dynamically precipitated intermetallic phase during hot-extrusion in all Sm-containing alloys is Mg3Sm. The intermetallic particles induced by Sm addition could act as heterogeneous nucleation sites for dynamic recrystallization during hot extrusion. They promoted dynamic recrystallization via the particle stimulated nucleation mechanism, and resulted in weakening the basal texture in the as-extruded alloys. Sm addition can significantly enhance the strength of the as-extruded Mg-0.5Zn-0.5 Zr alloy at room temperature, with the optimal dosage of 3.5 wt%. The optimal yield strength (YS) and ultimate tensile strength (UTS) are 368 MPa and 383 MPa, which were enhanced by approximately 23.1% and 20.8% compared with the Sm-free alloy, respectively. Based on microstructural analysis, the dominant strengthening mechanisms are revealed to be grain boundary strengthening and dispersion strengthening.

The texture and its optimization in magnesium alloy

[J].he crystallographic orientations are generally non-random in wrought Mg alloy, which will lead to their macroscopic physical properties to be anisotropic. Understanding the texture evolution in processing of Mg alloy billets and its effect on mechanical properties is therefore an important project for all scientists and engineers in material area. This paper is concerned with the description of texture, with the mechanisms of texture evolution and with the interrelationships between texture and mechanical properties in Mg alloy. It is a full review of understanding of the basic mechanism on texture evolution, of texture altering by alloying or processing, and of the mechanism of texture weakening. Moreover, it provides theories necessary and available techniques to develop high-performance Mg wrought with optimized texture in the field.

Plastic anisotropy and deformation behavior of extruded Mg-Y sheets at elevated temperatures

[J].

Tension-compression asymmetry and the underlying slip/twinning activity in extruded Mg-Y sheets

[J].