脉冲电流能显著影响金属的凝固组织形成过程[6,7]。早在1990年,Nakada等[8]便开始研究脉冲电流对Sn-Pb合金凝固过程的影响。此后,人们对脉冲电流作用下金属的凝固行为开展了广泛研究,涉及纯金属[9~11]、共晶型合金[12,13]和液-液分相过程[14~16]等。研究结果表明,脉冲电流具有细化凝固组织、减轻元素偏析、提高合金性能等效果。近年研究[17~21]发现,脉冲电流可以有效调控合金凝固过程中弥散相的沉淀析出过程,具有促进弥散相形核析出、提高弥散相形核率和数量密度、细化凝固组织中弥散相粒子尺寸等作用。可见,脉冲电流在控制Al粒子的沉淀析出过程、减小粒子尺寸、制备微/纳米Al粒子强化的铅基合金复合材料方面具有很大潜力。然而目前的相关研究较少,尤其是脉冲电流作用下Pb-Al合金的液-固分相过程研究还鲜见报道。

本工作以Pb-Al液-固分相合金为对象,实验与模拟相结合,研究该合金在脉冲电流作用下连续凝固时Al粒子的沉淀析出过程,讨论脉冲电流的作用机理及脉冲电流作用下合金液-固分相凝固组织的演变规律,分析采用脉冲电流控制合金液-固分相过程制备原位复合材料的可能性。

1 实验方法

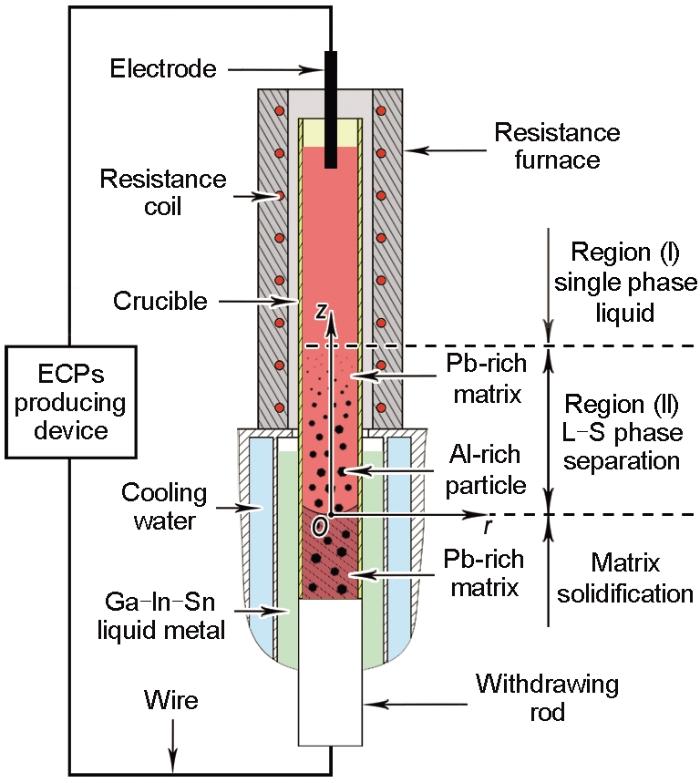

图1给出了实验装置及合金凝固过程示意图。合金成分为Pb-0.15Al (质量分数,%,下同),该合金在凝固过程中会发生液-固分相。实验过程如下:首先将纯度为99.99%的Pb、Al原料称重配制,放入壁厚1 mm、内径4 mm的Al2O3坩埚中;使用电阻炉将合金原料加热至1073 K并保温30 min,期间充分搅拌确保得到均匀熔体;将预热后的Mo丝电极插入合金熔体,沿试样轴向施加脉冲电流,并将坩埚以10 mm/s的提拉速率沿重力方向下拉进入Ga-In-Sn液态金属,使合金熔体冷却凝固;凝固后的圆柱形样品直径为4 mm、长度为100 mm,将其沿轴向切割后进行镶嵌并研磨抛光。使用MERLIN Compact的扫描电镜(SEM)观察合金的微观组织,采用SISC IAS V8.0定量金相分析软件统计凝固组织中Al粒子的尺寸。

图1

图1

实验装置及合金凝固过程示意图

Fig.1

Schematic of the Bridgman-type solidification setup equipped with the ECPs producing device and the L-S phase separation process in a continuous solidifying Pb-Al alloy (rOz—the coordinate system, ECP—electric current pulse, L-S—liquid-solid)

在不施加脉冲电流的条件下,将直径0.1 mm的W-Re热电偶置于合金熔体的中心位置,使用XSR90-04V0型温度记录仪测定合金冷却凝固过程中熔体中心处的冷却曲线。使用电容储能式脉冲电源产生脉冲电流:储能电容器的电容为210 μF,放电频率为100 Hz。实验时通过调节储能电容器的充电电压来改变脉冲电流的峰值电流密度(jmax)。

2 实验结果

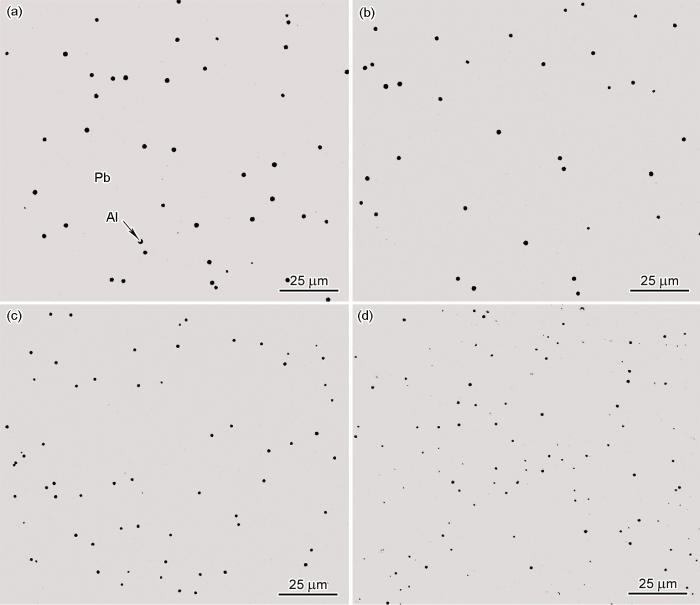

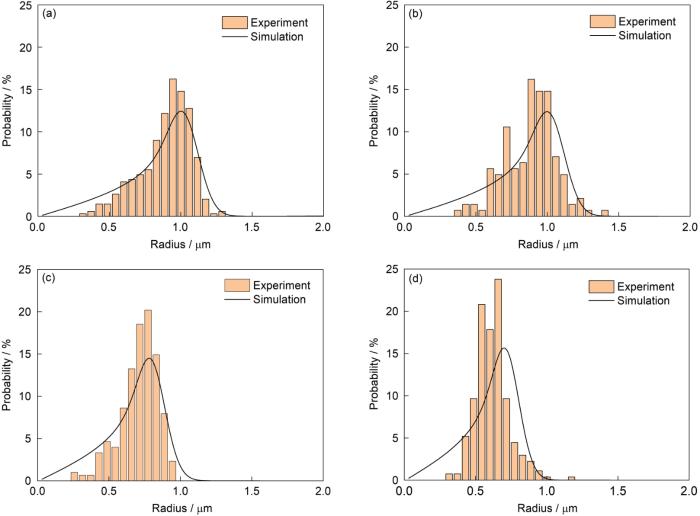

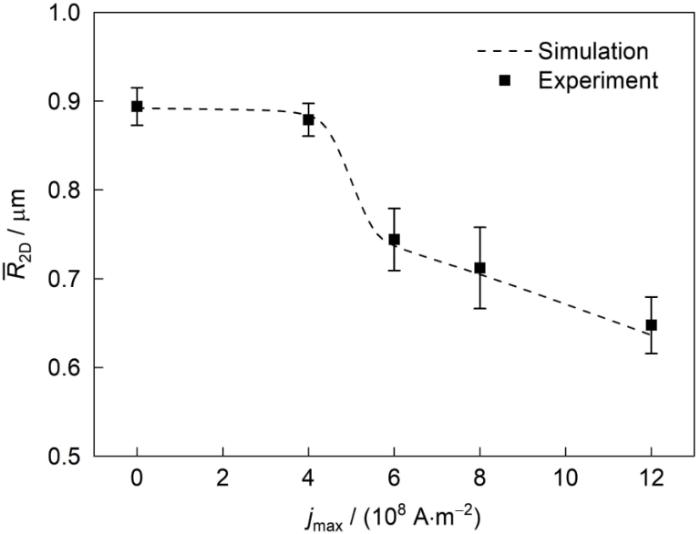

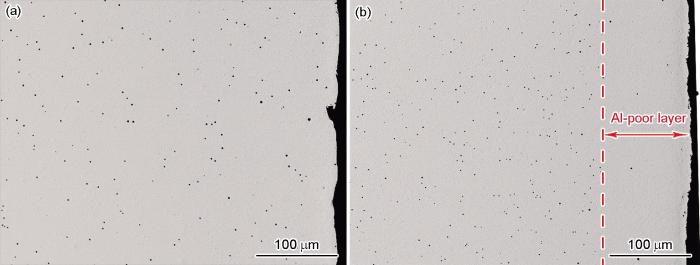

图2给出了不同峰值电流密度条件下Pb-0.15Al合金的凝固组织。图中黑色相和白色相分别为Al粒子和Pb基体。可见,在拉速为10 mm/s的连续凝固条件下,不施加脉冲电流时即可得到Al粒子均匀分布于Pb基体的复合凝固组织。施加脉冲电流以后,当峰值电流密度较小(jmax ≤ 4 × 108 A/m2)时,Al粒子的尺寸及分布与不施加脉冲电流时基本相同;当峰值电流密度较大(jmax > 4 × 108 A/m2)时,富Al粒子显著细化,且随jmax增大,细化效果增强,Al粒子的分布更加均匀弥散。图3所示为Al粒子的二维尺寸分布图。可知,Al粒子尺寸为单峰分布,且随着电流密度的增大,Al粒子尺寸分布的峰值提高、宽度下降且向左偏移。凝固组织中Al粒子的二维平均半径随jmax的变化情况在图4中给出。图5为试样表面处的凝固组织。可见,与不施加脉冲电流时相比,施加脉冲电流以后,试样表面出现了贫Al层。

图2

图2

不同峰值电流密度(jmax)条件下Pb-0.15Al合金凝固组织的背散射电子(BSE)像

Fig.2

Backscattered electron (BSE) images of the microstructures of the Pb-0.15Al alloys continuously solidified under the effect of ECPs with peak current densities (jmax) being 0 A/m2 (a), 4 × 108 A/m2 (b), 8 × 108 A/m2 (c), and 1.2 × 109 A/m2 (d), respectively

图3

图3

不同jmax条件下Pb-0.15Al合金凝固组织中Al粒子的二维尺寸分布

Fig.3

2D size distributions of the Al-rich particles in the Pb-0.15Al alloys continuously solidified under the effect of ECPs with jmax being 0 A/m2 (a), 4 × 108 A/m2 (b), 8 × 108 A/m2 (c), and 1.2 × 109 A/m2 (d), respectively

图4

图4

Pb-0.15Al合金凝固组织中Al粒子的二维平均半径(

Fig.4

Average 2D radius (

图5

图5

有/无脉冲电流下Pb-0.15Al合金试样表面处凝固组织的BSE像

Fig.5

BSE images of the surface microstructures of the Pb-0.15Al alloys solidified without ECPs (a) and with the ECPs of jmax = 8 × 108 A/m2 (b)

3 分析讨论

3.1 模型与模拟方法

式中,

式中,

式中,

式中,

连续凝固过程中,合金试样的温度场满足如下控制方程[32]:

式中,

合金熔体的浓度场满足如下控制方程[33]:

式中,

式中,

| Parameter | Value | Unit |

|---|---|---|

| Dynamic viscosity of Pb | 0.0004636exp(1036.7 / T) | Pa·s |

| Thermal conductivity of liquid Pb | 15.88 | W·m-1·K-1 |

| Density of liquid Pb | 10670 - 1.32(T - 600.4) | kg·m-3 |

| Density of solid Al | 2700 | kg·m-3 |

| Specific heat of liquid Pb | 127.61 | J·kg-1·K-1 |

| Latent heat of solidification of Pb | 24700 | J·kg-1 |

| Electrical conductivity of liquid Pb | (0.0479T + 66.6)-1 | 10-8 S·m-1 |

| Electrical conductivity of solid Al | [15(exp(0.00057T)–1)]-1 | 10-8 S·m-1 |

3.2 Pb-Al液-固分相合金凝固组织演变过程

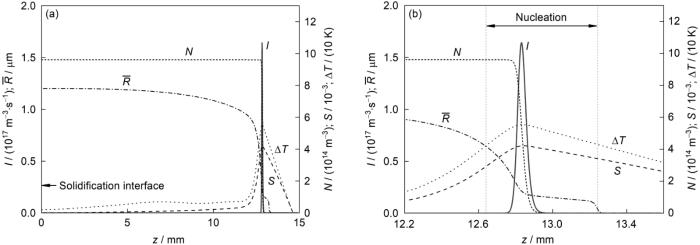

当Pb-Al液-固分相合金的连续凝固过程进入稳定凝固状态以后,凝固界面前沿的合金熔体可以划分为如图1所示的2个区域,即均一熔体区和液-固分相区。在液-固分相区内,合金熔体的过冷度(

图6

图6

不施加脉冲电流时Pb-0.15Al合金凝固界面前沿中心轴线处基体熔体过冷度(

Fig.6

Supercooling (

3.3 Joule热效应的影响

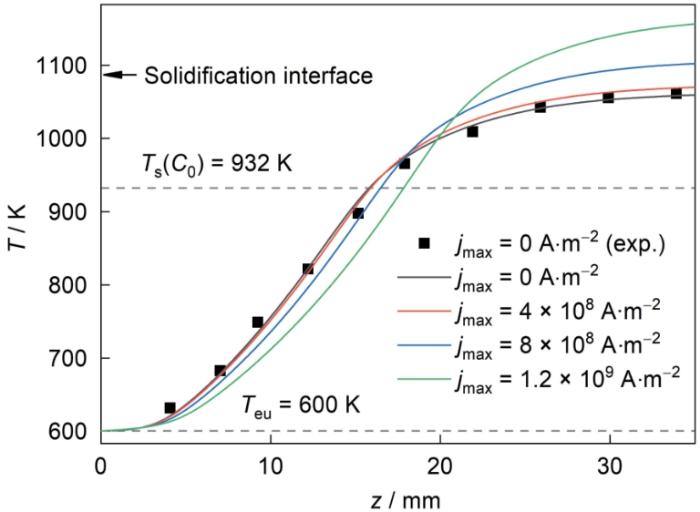

首先,电流的Joule热效应使熔体的温度场发生变化。图7给出了不同峰值电流密度条件下凝固界面前沿试样中心轴线处的温度分布曲线。可见,随着jmax的增大,熔体的温度逐渐升高,相当于提高了熔体的保温温度,使熔体在冷却凝固过程中的温度梯度增大。

图7

图7

不同峰值电流密度条件下,Pb-0.15Al合金凝固界面前沿试样中心轴线处的温度分布曲线

Fig.7

Calculated temperature profile (solid lines) along the central z axis in front of the solidification interface when solidifying Pb-0.15Al alloys at the rate of 10 mm/s with the ECPs of different jmax together with the experimental results (symbols) without ECPs (Ts(C0)—solubility line temperature of initial composition alloy, Teu—eutectic reaction temperature of Al-Pb alloy)

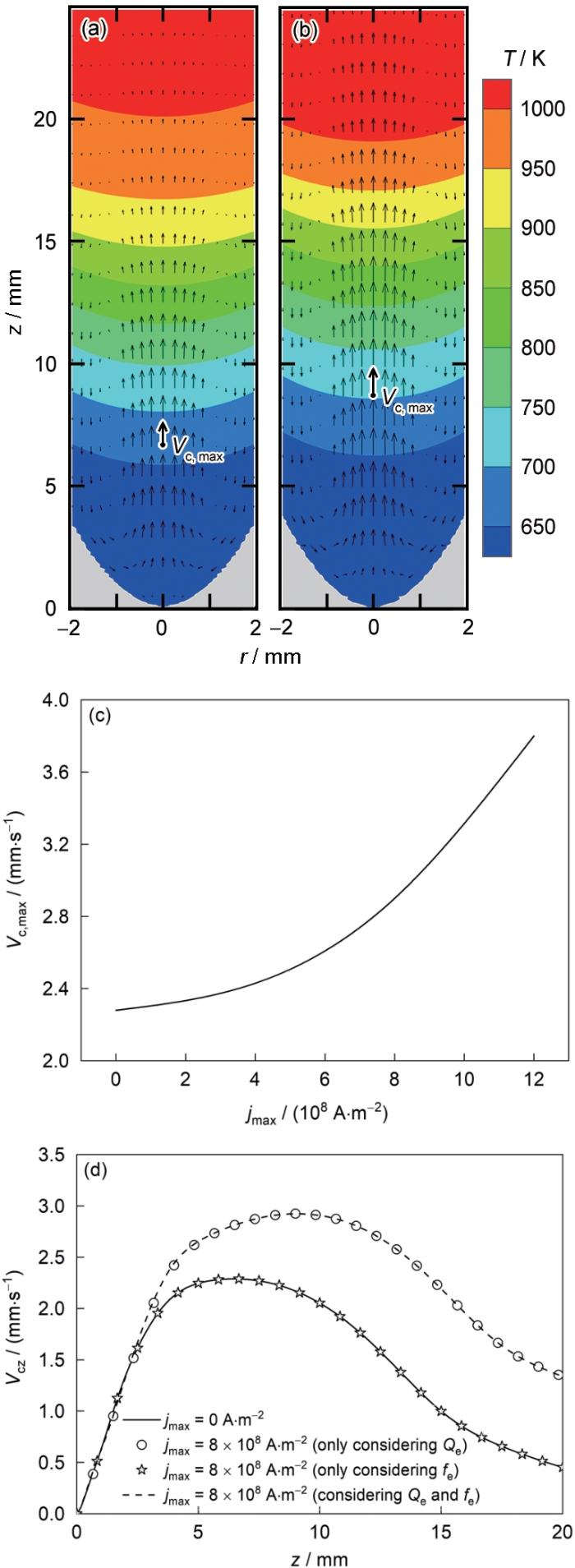

图8

图8

凝固界面前沿Pb-0.15Al合金熔体内的温度场和流场,最大对流速率(Vc,max)随jmax变化曲线,及凝固界面前沿中心轴线处,熔体对流运动速度的z分量(Vcz)沿z轴变化曲线

Fig.8

Temperature and flow fields of the melt in front of the solidification interface when solidifying Pb-0.15Al alloys without ECPs (a) and with the ECPs of jmax = 8 × 108 A/m2 (b), the maximum of the melt convection rate (Vc,max) vsjmax (c), and z-component of the melt convection velocity (Vcz) along the central z-axis (d) (Qe—Joule heat of ECPs, fe—electromagnetic force of ECPs)

图9

图9

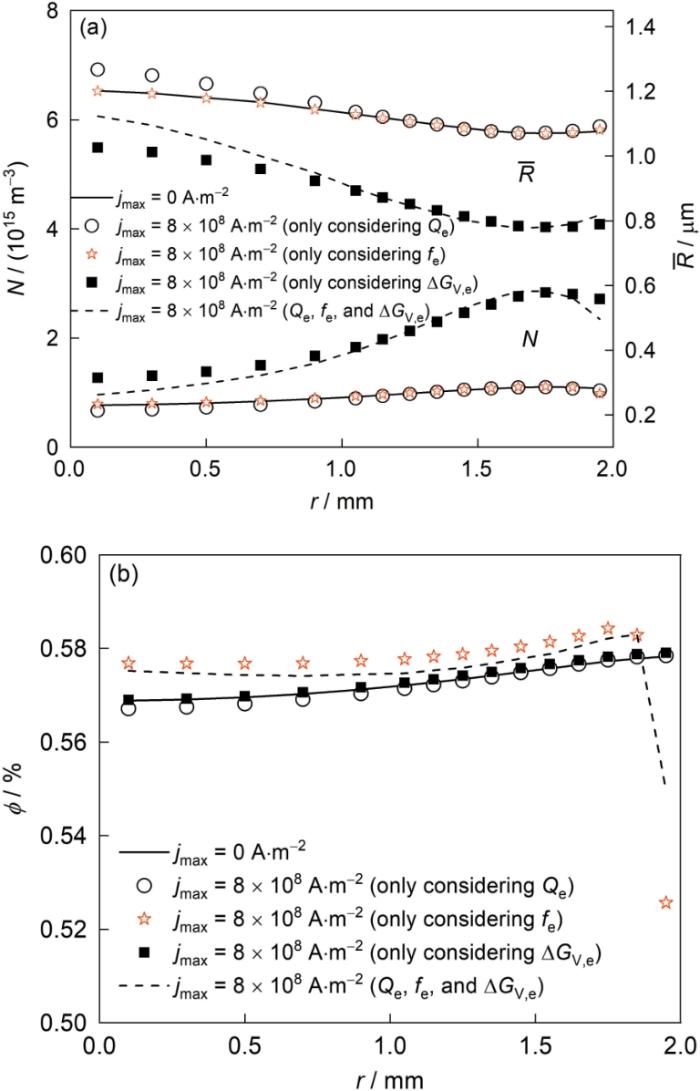

Pb-0.15Al合金凝固组织中Al粒子的数量密度、平均半径和体积分数沿试样径向的分布

Fig.9

Variations of

3.4 电磁力的影响

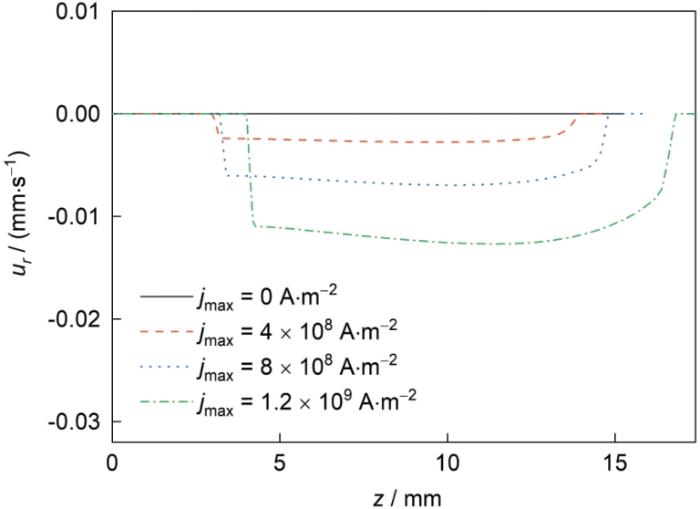

首先,脉冲电流对熔体施加电磁力(fe)可能会影响熔体的对流运动。图8d给出了凝固界面前沿中心轴线处熔体对流运动速度的z分量(

其次,脉冲电流对Al粒子施加电磁力会影响粒子的空间迁移。电致粒子迁移沿试样径向,速率ue与(jR)2正相关(

图10

图10

试样表面附近平均尺寸粒子迁移速度的r分量(

Fig.10

r-component of the average size particles' move-ment velocity at the position of r = 2 mm (

3.5 电磁能促进Al粒子形核的影响

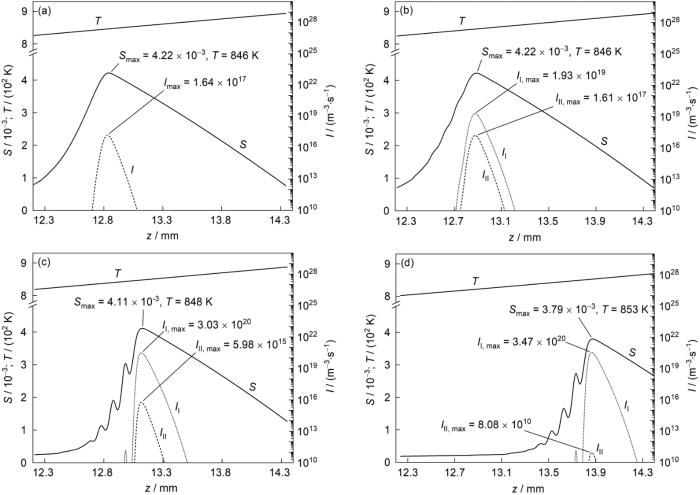

施加脉冲电流时,电流的作用是不连续的,可以将一个脉冲周期分成2个阶段,即有电流作用的阶段(I)和无电流作用的阶段(II)。阶段(I)持续的时间(

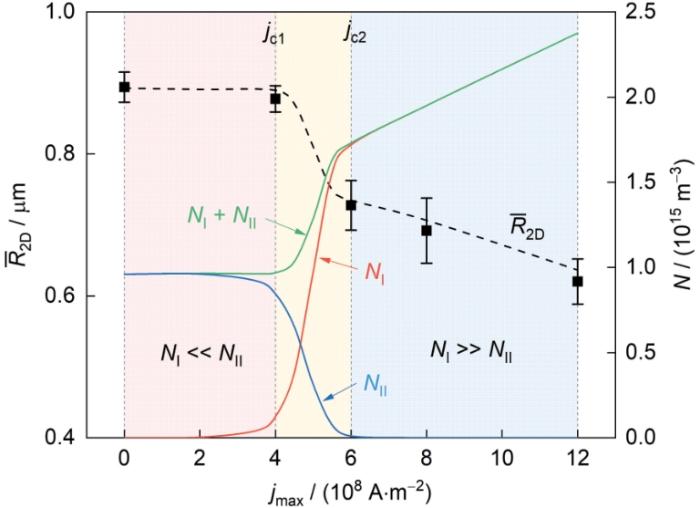

图11给出了凝固组织中

图11

图11

凝固组织中Al粒子的N及

Fig.11

Curves of

图12

图12

不同jmax条件下Pb-0.15Al合金中心轴线处熔体温度(

Fig.12

Curves of

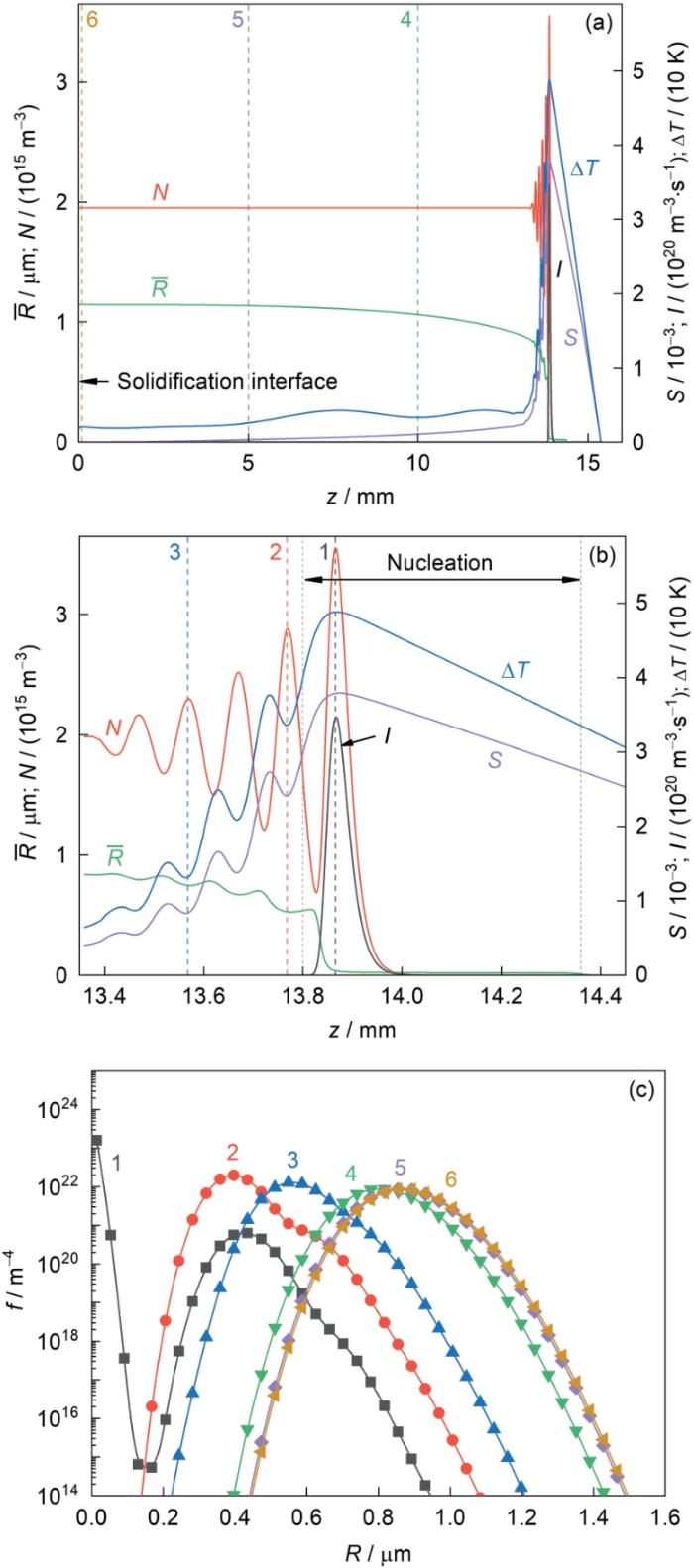

图13a和b给出了jmax = 8 × 108 A/m2时凝固界面前沿中心轴线处ΔT、S、I、N及

图13

图13

峰值电流密度为8 × 108 A/m2时凝固界面前沿中心轴线处,

Fig.13

Curves of

4 结论

(1) 脉冲电流显著影响Pb-Al合金的液-固分相凝固过程和凝固组织。一方面,脉冲电流能有效提高Pb-Al合金液-固分相过程中Al粒子的形核驱动力,降低其形核能垒,提高粒子形核率,降低粒子尺寸,促进Pb-Al合金形成原位微/纳米Al粒子复合凝固组织;另一方面,脉冲电流使熔体中的Al粒子在电磁力的作用下向试样心部迁移,导致试样表面形成贫Al层,可用于控制制备由表面Pb壳和原位Al粒子铅基合金内核组成的壳/核型特种复合材料。

(2) 用脉冲电流细化Pb-Al合金液-固分相凝固过程中原位析出的Al粒子时

(3) Pb-Al液-固分相合金在脉冲电流作用下凝固时,电流的非连续性导致Al粒子的形核率随时间发生变化,使形核位置附近粒子的数量密度、平均半径以及熔体的过饱和度沿试样轴线呈现波动变化。在溶质扩散及Al粒子长大和空间迁移的作用下,这种波动变化的幅度会在形核结束后的凝固过程中迅速减小、消失,最终形成Al粒子均匀分布的凝固组织。

参考文献

Preparation and performance of a novel lead-based alloy anode for zinc electrowinning

[D].

锌电积用新型铅基合金阳极的制备及性能研究

[D].

The development and potential applications of a Pb-Al alloy

[J].

Development of Al-Pb system research

[J].

Al-Pb体系研究进展

[J].

Isopiestic measurements and assessment of the Al-Pb system

[J].

Solidification of Pb-Al alloys under the influence of electric current pulses

[J].

Microstructural evolution and mechanism of solidified TiAl alloy applied electric current pulse

[J].As a new type of lightweight and high temperature structural material, TiAl alloy has become the most ideal candidate in the fields of aerospace, military and civil products, and it has a good perspective in the industrialization. Refining and improving the microstructure of TiAl alloys has higher theoretical significance and engineering value. In this work, the solidified Ti-48Al-2Cr-2Nb alloy applied electric current pulse is studied, and its microstructural evolution and mechanism are analyzed. The results show that the electric current pulse refines the primary dendrite arm spacing, columnar crystal size and interlamellar spacing of the Ti-48Al-2Cr-2Nb alloy. The primary phase is α without electric current pulse, the angle of the Ti-48Al-2Cr-2Nb alloy that between the lamellar orientation and the growth direction is usually bigger, even perpendicular to the growth direction approximately. The applied electric current pulse causes the dendrite to melt and break, and promotes the occurrence and increase of the primary β phase, the lamellae orientation having a small angle or 45° between the growth direction is further increasing. The electric current pulse reduces the solid-liquid phase free energy and atomic diffusion activation energy, reduces the nucleation barrier and the critical nucleation energy, thereby atomic diffusion and the crystallization nucleation is promoted to a certain extent, the primary dendritic spacing and columnar crystals are remarkably refined. The electric current pulse causes the transformation of the primary phase and its corresponding crystal orientation relationship is the main reason for the change of lamellar orientation.

脉冲电流作用下TiAl合金凝固组织演变及形成机理

[J].利用OM和TEM研究了脉冲电流作用下Ti-48Al-2Cr-2Nb合金的凝固组织,并分析了其微观组织演变及形成机理。结果表明,脉冲电流细化了TiAl合金的一次枝晶臂间距、柱状晶尺寸和片层间距。未加载电流的TiAl合金凝固的初生相为α相,TiAl合金的片层取向与柱状晶生长方向夹角较大,甚至垂直于生长方向。脉冲电流作用导致枝晶发生熔断和破碎,促进了β枝晶相的析出及增多,片层取向与晶体生长方向夹角较小或成45°生长的片层进一步增多。脉冲电流降低了固-液相之间的自由能及原子扩散激活能,减少形核位垒及晶核的形核功,从而在一定程度上促进原子扩散,增大了形核率,细化一次枝晶臂间距及柱状晶;初生相的转变析出及其特殊的位向关系是片层取向变化的主要原因。

Regulating the non-metallic inclusions by pulsed electric current in molten metal

[J].Non-metallic inclusions generally reduce the properties of steels, such as reducing transverse mechanical properties, initiating cracks, reducing fatigue life and inducing corrosion. Reducing the number and changing the morphology of inclusions can significantly improve the performance of steels. Therefore, inclusion removal and its morphology control in steel have always been the focus issue. Although the bottom-blown argon, electromagnetic stirring and filtration can remove inclusions to a certain extent, these methods are difficult to effectively remove inclusions smaller than 20 μm in size and cannot effectively control the morphology of the inclusions. Recently, electric current has become a new method for inclusion removal and morphology control. This article briefly reviews the hazards of inclusions and their control methods, and reviews the effects of current on the removal, orientation and morphological evolution of inclusions in metal melts in detail, and introduces three mechanisms of current-controlled inclusion separation: electrophoresis, electrical free energy driving and electromagnetic repulsion. Electrophoresis theory believes that inclusions in the melt are charged, and they migrate parallel to the direction of the current under the action of the electric field force. While the electrical free energy driving and electromagnetic repulsion hold that inclusions migrate perpendicular to the direction of the current. The current waveforms significantly affect the removal efficiency of inclusions. Compared with direct current and alternating current, the pulsed electric current has a stronger ability to remove inclusions, especially pulsed electric current can effectively separate inclusions with a size larger than 5 μm in the molten steel. In addition, the pulse current can not only control the orientation and morphology of the inclusions, but also affect the morphology of the bubbles; the inclusions tend to be refined, spheroidized and arranged parallel to the current under the action of the pulse current. Finally, the research status of current-controlled inclusion separation is summarized, and future research trends are analyzed. At the same time, the application and prospect of pulsed current in anti-clogging of submerged entry nozzle was also analyzed. Due to the low energy consumption, excellent inclusion removal efficiency and easy process equipment, pulsed current separation technique is expected to become a new technology for removing inclusions and suppressing nozzle blockage in the future.

脉冲电流调控金属熔体中的非金属夹杂物

[J].通常非金属夹杂物会降低钢铁材料的性能,例如降低横向力学性能、萌生裂纹、减低疲劳寿命和诱发腐蚀。减少夹杂物的数量和改变夹杂物的形态可以显著提升钢铁材料的性能。所以,钢中夹杂物的去除以及形态控制一直以来都是研究的热点。虽然通过底吹Ar气、电磁搅拌和过滤方法可以在一定程度上去除夹杂物,但是上述方法难以有效地去除尺寸小于20 μm的夹杂物,并且不能有效地控制夹杂物的形态。最近,电流成为一种夹杂物去除与形态控制的新方法。本文简要综述了夹杂物的危害及其控制手段,并且详细回顾了电流对金属熔体中夹杂物的去除、取向和形态演变的影响,并介绍了电流控制夹杂物的3种机理:电泳、电自由能驱动、电磁斥力。电泳理论认为熔体中的夹杂物带有电荷,夹杂物在电场力的作用下平行于电流方向迁移。电自由能驱动理论和电磁斥力理论认为夹杂物垂直于电流方向迁移。电流波形显著影响夹杂物的去除效果,与直流电、交流电相比,脉冲电流具有较强的夹杂物去除能力,尤其是脉冲电流能够有效分离钢液中尺寸为5 μm以上的夹杂物。此外,脉冲电流不仅可以控制夹杂物取向与形态,还可以对气泡的形态产生影响;脉冲电流作用下夹杂物趋于细化、球化并平行于电流排列。最后,对电流控制夹杂物的研究现状进行了总结,并分析了未来的研究趋势。同时,对脉冲电流在抑制浸入式水口堵塞中的应用进行分析与展望。由于脉冲电流能耗低、夹杂物去除效果好以及工艺装备简易的优点,有望成为未来去除夹杂物、抑制水口堵塞的新技术。

Modification of solidification structures by pulse electric discharging

[J].

Investigating the grain refinement mechanisms of pulsed electric current, ultrasonic and melt stirring solidification of pure aluminium

[J].A comparison study between an electric current applied in the pulsed mode (ECP), ultrasonic treatment (UST), and melt stirring treatment (MST) was performed to understand the origin of equiaxed grains during the solidification of pure Al. ECP and UST were applied at 760 degrees C and 700 degrees C before the onset of nucleation, and at one temperature range after the onset of nucleation at 661 degrees C. UST produces excellent refinement in all three temperature ranges compared to ECP. Interestingly, application of the MST process at 661 degrees C over the surface of the solidifying melt also resulted in significant refinement comparable to that of UST (grain size of similar to 260-460 mu m).ECP, UST, and MST techniques differ in terms of the dominant mechanism influencing the grain refinement. Therefore, the present work analyses and discusses the grain refinement mechanisms based on nucleation, fragmentation, and a crystal separation mechanism for the origin of fine grains.

The relevance of forced melt flow to grain refinement in pure aluminum under a low-frequency alternating current pulse

[J].

Electric current pulse induced grain refinement in pure aluminium

[J].

Electrochemical corrosion behaviors of Pb-Ag anodes by electric current pulse assisted casting

[J].

Research on grain refinement in hypoeutectic Al-Si alloy during solidification under an alternating electric current pulse

[J].

Real-time observation on evolution of droplets morphology affected by electric current pulse in Al-Bi immiscible alloy

[J].

Solidification microstructure characteristics of Cu-Pb alloy by ECP treatment

[J].

Effect of electric current pulses on solidification of immiscible alloys

[J].

Influence of electric current pulses on the solidification of Cu-Bi-Sn immiscible alloys

[J].Continuous solidification experiments were carried out with Cu-Bi-Sn alloys under the effects of Electric Current Pulses (ECPs). A model describing the microstructure evolution was developed. The formation of the microstructure in the continuously solidified alloys was calculated. The calculations demonstrated that ECPs mainly affect the solidification process through changing the energy barrier for the nucleation of the minority phase droplets (MPDs). When the matrix liquid has a lower electric conductivity compared to the MPD, the ECPs lead to a decrease in the energy barrier for the nucleation of the MPDs which then promote the formation of a finely dispersed microstructure. When the matrix liquid has a higher electric conductivity compared to the MPD, the ECPs cause an increase in the energy barrier for the nucleation and lead to the formation of a phase segregated microstructure.

Effect of electric current pulse on microstructure and corrosion resistance of hypereutectic high chromium cast Iron

[J].

The difference in effects of electric current pulses on inoculation of austenite and M7C3 carbides

[J].

Bidirectional pulsed current effect on the precipitation behavior of Cu6Sn5: An in situ observation

[J].

Effect of high density current pulses on microstructure and mechanical properties of dual-phase wrought superalloy

[J].

Modeling and simulation of the microstructure evolution during a cooling of immiscible alloys in the miscibility gap

[J].The microstructure development during a cooling period of alloys being immiscible in the liquid state such as Al-Pb or Al-Bi has gained renewed scientific and technical interest during the last decades. Experiments have been performed to investigate the phase transformation kinetics in the liquid miscibility gap and numerical models have been developed to simulate and analyze the solidification process. The recently developed computational modeling techniques can, to some extent, be applied to describe the decomposition, the spatial phase separation and the microstructure evolution during a cooling period of an immiscible alloy through the miscibility gap. This article overviews the researches in this field.

An analytical model for the interaction between an insoluble particle and an advancing solid/liquid interface

[J].

Study of the continuous solidification of monotectic alloys under the effect of electric current

[D].

电流作用下偏晶合金连续凝固过程研究

[D].

Convective effect on the microstructure evolution during a liquid-liquid decomposition

[J].

Repeated nucleation of minority phase droplets induced by drop motion

[J].

Microstructure formation in directionally solidified Pb-Al alloy

[J].Pb is widely used as grid material for lead-acid batteries, an electrowinning electrode and a nuclear radiation shield. To improve the performance of these materials, alloying elements such as Ag, Sb, and Ca are commonly added. Pb's conductivity and strength can be improved using Al as an alloying element. However, the phase diagram of the Pb-Al alloy is characterized by the large liquid-liquid and liquid-solid miscibility gaps. When a homogeneous single-phase Pb-Al liquid is cooled into the miscibility gaps, Al-rich droplets/particles precipitate first from the melt, causing the Pb-Al alloy to form a microstructure with coarse Al-rich particles or serious phase segregation. Understanding the evolution of microstructure in the liquid-solid phase separation has remained a scientific challenge thus far. The solidification of the Pb-Al alloy is investigated using directional solidification experiments in this work. A numerical model is developed to describe the microstructure formation in a directionally solidified liquid-solid phase separation alloy using the population dynamics method. The evolution of the microstructure is simulated. The simulation results agree well with the experimental results. They show that a supercooling zone appears in front of the solidification interface, where the liquid-solid phase separation of the Pb-Al alloy occurs. In this zone, Al-rich particles (dispersed phase) form and grow by solute diffusing as they move toward the solidification interface. The nucleation rate and the number density of Al-rich particles increase as the solidification rate increases, whereas the average radius of the particles decreases. The Al-rich particles' Stokes movement velocity has the same direction as the melt's solidification velocity, resulting in an enrichment of Al-rich particles in front of the solidification interface. Because of the convective flow of the melt in front of the solidification interface, the cooling rate of the melt is unevenly distributed along the radial direction, resulting in an uneven distribution of nucleation rate, number density, and average radius of Al-rich particles. The formation of a solidification microstructure with the dispersive distribution of Al-rich particles is dependent on the solidification rate being fast enough to ensure that all size particles in the liquid-solid phase separation region move toward the solidification interface under the effect of the Stokes movement of Al-rich particles and the convective flow of melt.

Pb-Al合金定向凝固组织形成过程

[J].实验考察了Pb-Al液-固分相合金的定向凝固行为,建立了Pb-Al合金定向凝固模型,结合实验模拟分析了凝固组织形成过程。研究表明,在Pb-Al合金液-固分相过程中,凝固界面前沿存在一过冷区,富Al (弥散相)粒子在此区间内形核,并在向凝固界面移动过程中进行扩散长大,随着凝固速率的提高,弥散相粒子形核率升高、数量密度增大、平均半径减小。富Al粒子Stokes运动的方向与合金凝固方向相同,导致粒子在凝固界面前富集;熔体的对流运动导致弥散相粒子的形核率及数量密度沿试样径向不均匀分布。在弥散相粒子Stokes运动和熔体对流作用下,形成弥散型凝固组织的必要条件为合金的凝固速率足够高,能保证凝固界面前沿液-固分相区间内所有尺寸粒子均向凝固界面迁移。

Homogeneous nucleation within the liquid miscibility gap of Zn-Pb alloys

[J].

Effect of electric current pulses on grain size in castings

[J].

Study on the solidification of Ag-Ni monotectic alloy

[J].The Ag-Ni alloy has high electrical conductivity, good thermal conductivity, high specific heat capacity, and excellent electrical wear resistance if the Ni-rich phase is dispersedly distributed in the Ag-based matrix. It has been widely used in the medium load contactors, magnetic starters, relays, etc. However, Ag-Ni alloy is a typical monotectic system. Generally, the liquid-liquid phase transformation leads to the formation of a solidification microstructure with serious phase segregation. So far, there have been few studies on the solidification process of Ag-Ni alloys and powder-metallurgical techniques are commonly used to prepare Ag-Ni alloys in industry. In this work, casting experiments and microhardness test were carried out with the Ag-Ni monotectic alloy. The samples with composite microstructure, in which the Ni-rich particles dispersed homogeneously in Ag matrix, were obtained. The microhardness of Ag-Ni alloy increases with the increase of nickel content and the cooling rate of the sample during solidification. When the cooling rate during the liquid-liquid phase transition of the Ag-4.0%Ni alloy reaches 1800 K/s, the microhardness of the Ag-4.0%Ni alloy is close to that of the Ag-10.0%Ni sheet electrical contacts produced by powder metallurgy. A model describing the microstructure evolution during cooling Ag-Ni monotectic alloy melt has been proposed. The process of microstructure formation has been simulated and discussed in details. The results indicate that the cooling rate during the nucleation of the Ni-rich droplets/particles has a dominant influence on the solidification microstructure. The average radius of the Ni-rich particles increases with the increase of nickel content, while it decreases with the increase of the cooling rate during solidification. The average radius of the Ni-rich particles shows an inverse square root dependence on the cooling rate during the nucleation of the Ni-rich droplets/particles. The Ostwald coarsening of the Ni-rich droplets/particles is very weak during cooling Ag-Ni monotectic alloy melt. Rapid/sub-rapid solidification has a good application prospect in the preparation of the high-performance Ag-Ni contact materials.

Ag-Ni偏晶合金凝固过程研究

[J].对Ag-Ni偏晶合金开展了快速/亚快速凝固实验,获得了富Ni相粒子均匀弥散分布于Ag基体的合金样品,Ag-Ni合金显微硬度随着合金Ni含量增加和试样凝固过程冷却速率升高而增大,当Ag-4.0%Ni合金液-液相变开始阶段熔体冷却速率达1800 K/s时,其显微硬度接近粉末冶金生产的Ag-10.0%Ni片状电触头的硬度。建立了描述Ag-Ni合金凝固组织演变的动力学模型,模拟计算了Ag-Ni合金凝固组织形成过程,分析讨论了合金成分和试样直径(冷却速率)对Ag-Ni合金凝固组织形成过程的影响。结果表明:富Ni相液滴/粒子形核阶段熔体的冷却速率对合金凝固组织弥散度具有决定性影响;合金的Ni含量越高、试样冷却速率越低,凝固组织中富Ni相粒子平均尺寸越大;Ag-Ni合金熔体冷却凝固时,富Ni相液滴/粒子的尺寸主要受形核和长大控制,Ostwald粗化作用很弱。

Solidification microstructure and dynamics of metastable phase transformation in undercooled liquid Cu-Fe alloys

[J].

Microstructure formation in a directionally solidified immiscible alloy

[J].