电弧熔丝增材制造(wire arc additive manufacturing,WAAM)技术以电弧为热源、金属丝材为原料,按照规划路径以“线”为基本构型单元在基板上逐层沉积,最终形成复杂形状三维零件,从而可一次快速精确成形实现“自由制造”[9,10]。与传统减材及等材制造相比[11],WAAM技术在成形过程中无需专用模具、夹具、刀具及多道繁琐工序配合,可显著提高生产效率、缩短生产周期、简化生产工序,且机器人辅助电弧增材平台不受设备成型室空间限制而具有柔性制造大尺寸零件的能力[12~14]。最重要的是,采用该技术可极大程度提高材料利用率,显著降低模具钢制造成本[15,16]。WAAM技术是汽轮机叶片用2Cr13构件低材料损耗、低成本、短周期、快速成形最具潜力和优势的制造新技术。

然而,相比于激光和电子束增材制造技术,电弧沉积过程中由于热输入较大且受冷态基板和电弧特性等扰动因素,存在构件热积累严重、散热条件差、熔池过热过烧等问题,最终导致沉积件几何精度低、晶粒尺寸粗大,严重降低构件强度、硬度与塑韧性等力学性能,并因复杂热历程差异而导致沉积件力学性能各向异性[11,17,18]。因此亟需对汽轮机叶片用2Cr13构件增材制造组织、性能各向异性演变机理开展研究。然而,目前有关电弧熔丝增材件组织、性能方面的研究主要针对优化工艺后沉积件表征方面,缺乏关键工艺参数变化下组织、性能演变规律的研究[10,19~21]。亟需建立工艺参数-热历程-组织、性能间内在关系,实现其力学性能主动控制。

本工作采用WAAM技术制备多层单道结构2Cr13构件,分析关键沉积工艺参数变化下组织、性能各向异性演变规律,提出主动控制电弧沉积过程中原位微热处理制度,为实现沉积态2Cr13力学性能主动控制提供技术支撑及理论支持。

1 实验方法

基板材料为2Cr13马氏体不锈钢,尺寸为150 mm × 150 mm × 8 mm。实验前,将待沉积面先采用角磨机进行打磨,再分别使用丙酮及无水乙醇进行擦拭以去除表面油污及氧化物等杂质。沉积材料为直径1.2 mm的2Cr13实芯焊丝(具体成分详见文献[1]),保护气氛为纯Ar气。

电弧沉积系统主要包括冷金属过渡焊设备(TPS 5000 CMT)以及用于沉积轨迹控制的六轴IRB 1600 ABB机器人。2Cr13沉积件结构为单道25层,沉积速率、沉积电压、沉积电流、送丝速率以及弧长修正系数分别恒定为0.4 m/min、12.9 V、96 A、5.2 m/min和-7%,层间停留时间分别设定为0.5、2、3.5和5 min。采用IPE 140红外测温仪对2Cr13沉积件第15层热历程进行原位测量,该设备分辨率和响应时间分别为0.1℃和1.5 ms。

采用XRD-7000 X射线衍射仪(XRD)对沉积件进行相分析,CuKα,扫描电压40 kV,扫描电流30 mA,扫描速率0.02°/s,扫描范围40°~90°。先采用线切割设备在沉积件垂直面取样,再经研磨、抛光及腐蚀后采用GX51光学显微镜(OM)、SU1510扫描电镜(SEM)和电子背散射衍射(EBSD)进行显微组织观察。

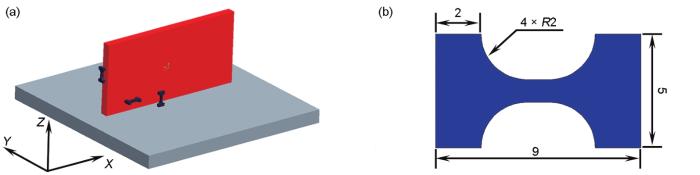

采用THV-1MD数显硬度计对抛光后试样进行Vickers硬度测量。载荷和保载时间分别为200 g和15 s,相邻压痕间距为100 μm,测量总长约为7 mm (3~4层高度)。采用CMT 5504电子万能试验机对构件进行拉伸性能测试,拉伸速率1 mm/min。图1为拉伸件取样位置及其尺寸示意图,厚度为1 mm。拉伸件中间标距位置位于第15层,其中位于X-Y面内的拉伸件沿X轴方向拉伸,位于Y-Z和X-Z面内的试样则均沿Z轴方向拉伸。

图1

图1

电弧熔丝增材制造(WAAM) 2Cr13拉伸试样取样位置及其尺寸示意图

Fig.1

Schematics of wire arc additive manufactured (WAAM) 2Cr13 part showing the positions of tensile samples (a) and its dimension (unit: mm) (b)

2 实验结果与讨论

2.1 原位热历程与宏观形貌

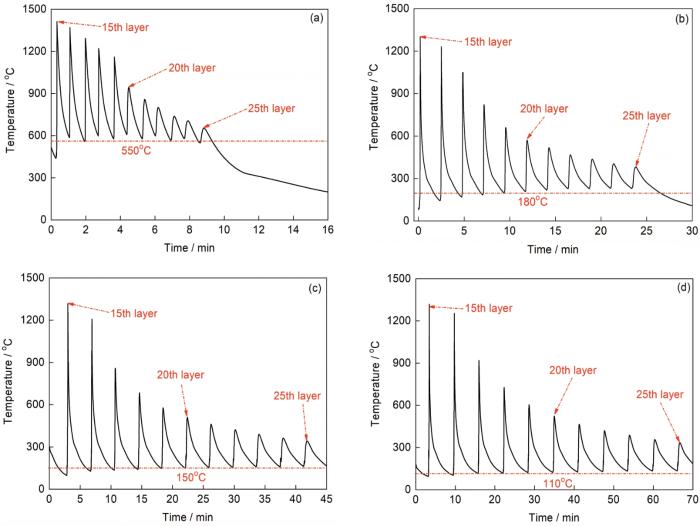

第15层中间位置原位温度测量结果如图2所示。当层间停留时间为0.5 min时,中间层先经历了一次重熔处理(沉积第16层) +三次循环淬火微热处理(沉积第17~19层)后,又在沉积第20~25层时经历了持续原位高温回火微热处理,即该沉积层在随后沉积过程中经历了一次重熔处理+多次循环淬火+高温回火微热处理(调质处理)。当层间停留时间为2~5 min时,各沉积件中间层粗晶区所经历的原位微热处理效果较为类似,即沉积第16层时经历了一次淬火微热处理,沉积第17~25层时经历了持续原位低温回火微热处理。

图2

图2

2Cr13沉积件第15层中间位置原位温度测量曲线

Fig.2

In situ temperature measuring curves of WAAM 2Cr13 parts at the middle position of the 15th layer with different dwelling time

(a) 0.5 min (b) 2 min (c) 3.5 min (d) 5 min

从图2还可看出,不同层间停留时间下各沉积件的层间停留温度基本保持不变,停留时间为0.5、2、3.5及5 min时所对应峰底温度分别约为550、180、150及110℃,这说明了连续沉积过程中待沉积层对中间层热输入效果与中间层自身热散失效果已达平衡状态。随停留时间不断延长,峰底温度经历了快速下降(0.5~2 min)后再缓慢降低并趋于平缓(2~5 min)过程,与层间停留时间为0.5 min沉积件相比,停留时间从2 min延长至5 min时,待沉积层对中间层后热作用效果逐渐弱化。各沉积件峰值温度随沉积高度不断增加而逐渐降低,这是因为随沉积过程继续进行,待沉积层(第16~25层)与中间层距离逐渐增加而导致沉积该层时熔池底部热源对中间层热输入效果逐渐变差。

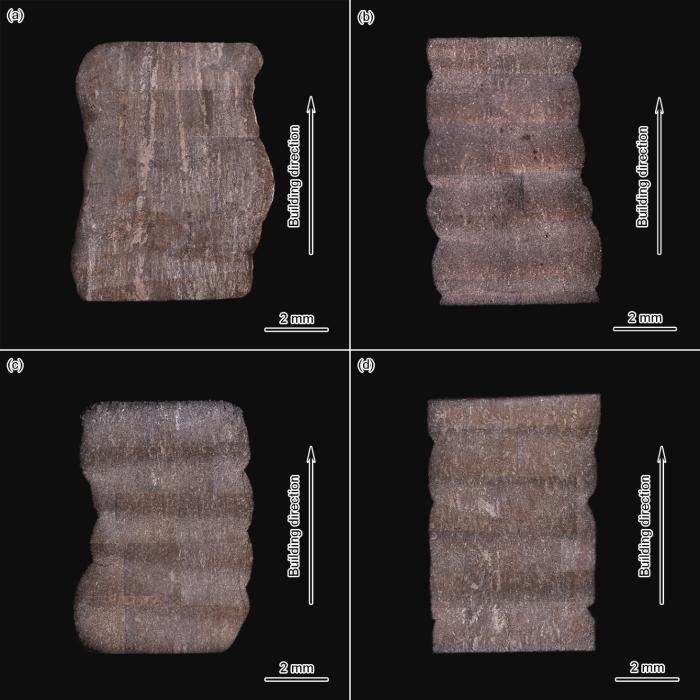

图3为各沉积件在不同温度下中部垂直面腐蚀后宏观形貌。未发现有诸如裂纹和层间剥离等缺陷存在,4种沉积态试样均获得了较高致密度且相连层间发生了冶金结合。当层间停留温度为550℃时,长条状晶粒沿沉积高度方向呈外延状生长,而当层间停留温度为110~180℃时,其晶粒呈周期性层带状生长,周期高度与每层层高相近。

图3

图3

2Cr13沉积件中间部位腐蚀后宏观形貌OM像

Fig.3

OM images of as-deposited etched WAAM 2Cr13 parts in the middle region for different interlayer dwelling temperatures

(a) 550oC (b) 180oC (c) 150oC (d) 110oC

2.2 相成分与显微组织

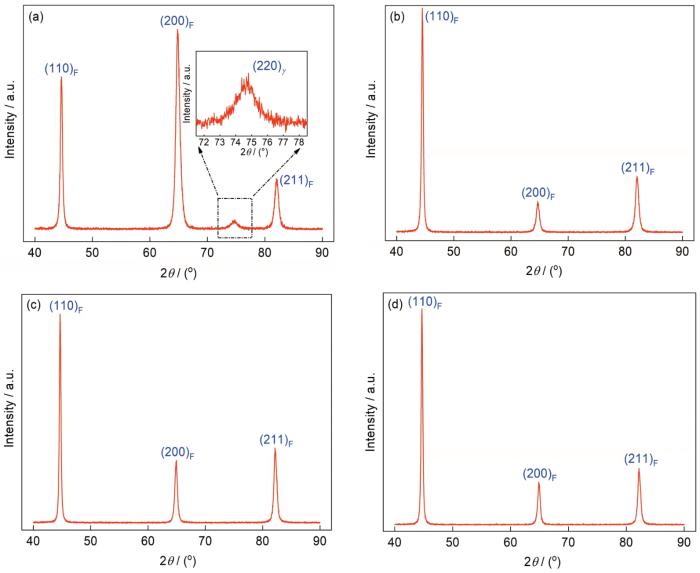

图4为不同层间停留温度下沉积件中间位置的XRD谱。2Cr13钢调质态组织为白色颗粒状(Fe, Cr)23C6碳化物沿马氏体晶界析出[7]。而XRD结果则表明各沉积态构件内均未发现有M23C6型富Cr碳化物存在。这也许是因为在WAAM快速熔凝过程中因凝固时间极短而导致富Cr碳化物未有充分时间析出,亦或是液态熔池在后续沉积过程中对已沉积层具有原位微热处理效应而使初生富Cr碳化物重新溶入基体中。类似结论也在采用激光选区熔化技术制备的AISI 420等钢中得到了验证[22,23]。根据Alvarez等[24]绘制的Cr13型马氏体钢连续冷却转变(CCT)相图可知,当连续冷却速率大于等于2℃/s时,在低倍显微镜下将不再观察到凝固态组织中有白色颗粒状M23C6碳化物析出。结合图2中热循环曲线可知,WAAM过程中冷却速率已显著大于M23C6碳化物临界转变速率。故而在本工作的各沉积件XRD谱中均未检测有该碳化物衍射峰存在。

图4

图4

2Cr13沉积件在不同层间停留温度下的XRD谱

Fig.4

XRD spectra of WAAM 2Cr13 parts with the interlayer dwelling temperatures of 550oC (a), 180oC (b), 150oC (c), and 110oC (d) (Inset in Fig.4a shows the austenitic diffraction peak; F—ferrite, γ—austenite)

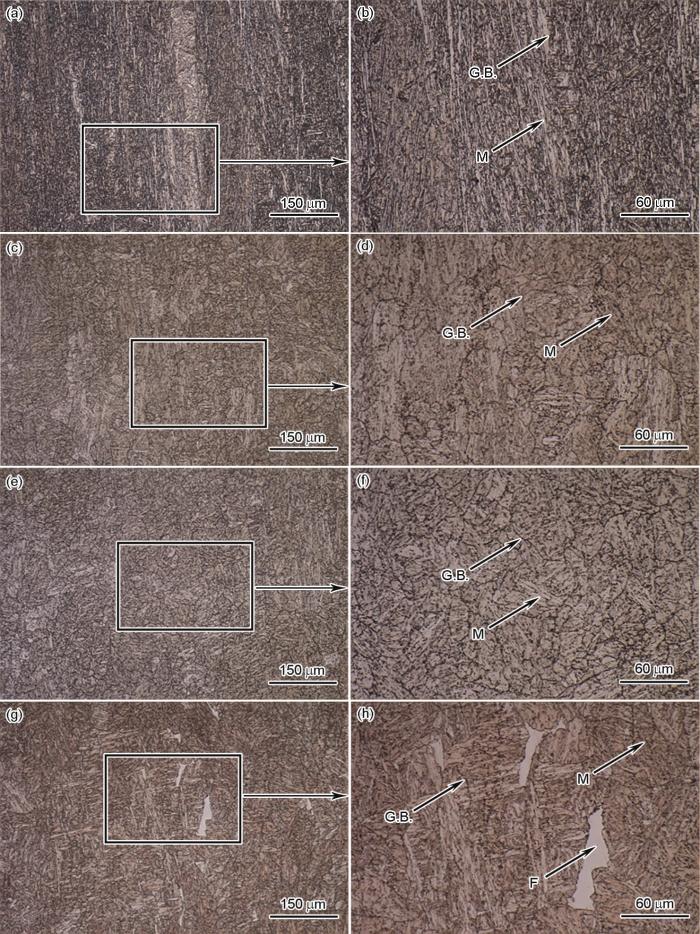

图5为各沉积件垂直面的中间位置显微组织的OM像。550℃沉积件显微结构为外延状铁素体内分布着近100%细小针状马氏体。110~180℃沉积件显微结构类似,均为块状铁素体内分布着板条状马氏体,并在铁素体晶界处有亮白色不规则块状物析出。该块状物与马氏体的硬度测试结果分别约为214和437 HV。故可得知110~150℃沉积件中该块状物为高温残留δ-铁素体。

图5

图5

2Cr13沉积件中间层组织形貌的OM像

Fig.5

Low (a, c, e, g) and locally high (b, d, f, h) magnified OM images in the middle layer of WAAM 2Cr13 parts (M—martensite, G.B.—grain boundary)

(a, b) 550oC (c, d) 180oC (e, f) 150oC (g, h) 110oC

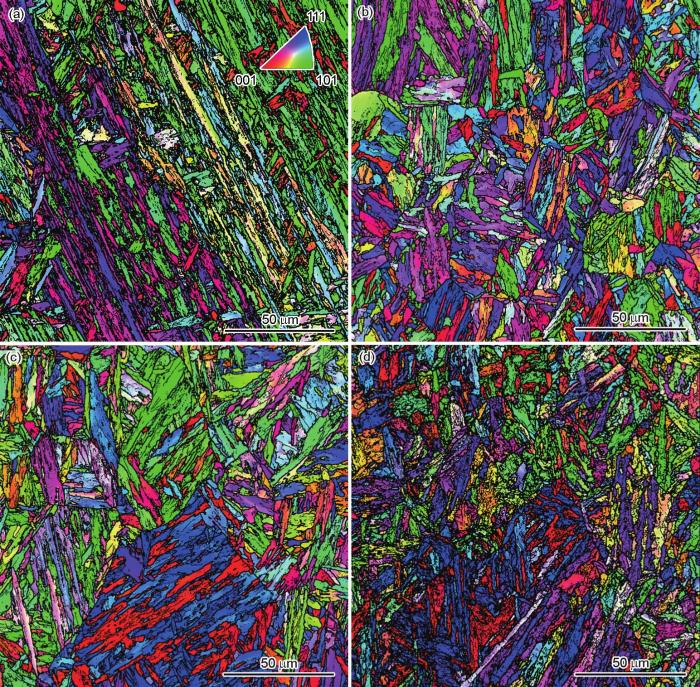

图6

图6

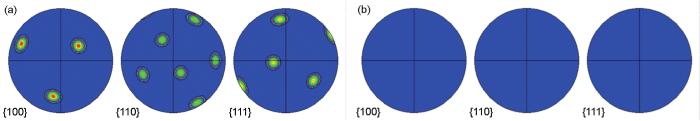

不同层间停留温度下的2Cr13沉积件垂直面的EBSD分析

Fig.6

EBSD analyses in the vertical plane of WAAM 2Cr13 parts for different interlayer dwelling temperatures

(a) 550oC (b) 180oC (c) 150oC (d) 110oC

图7

图7

不同层间停留温度下垂直面铁素体相极图

Fig.7

Pole figures of ferrite phase in the vertical plane for different interlayer dwelling temperatures

(a) 550oC (b) 180oC (c) 150oC (d) 110oC

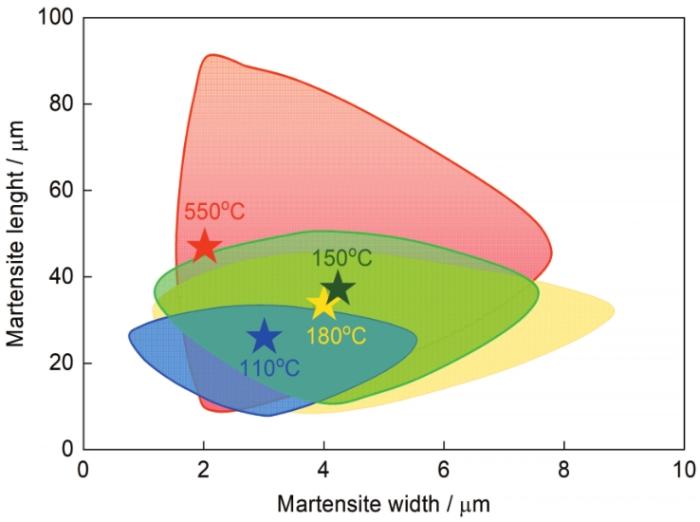

由图6可以看出,层间停留温度为550℃时,沉积态组织主要为沿沉积高度方向外延状铁素体内分布着细长针状马氏体及少量小尺寸马氏体弥散于各长条状马氏体束间隙。层间停留温度为110~180℃时,各构件内组织形貌较类似,均为块状铁素体内分布着板条状马氏体,且在同一区域内各马氏体生长方向一致,而各区域间马氏体则大致沿沉积高度方向生长。对图6中马氏体长度与宽度进行数理统计,结果如图8所示,图中五角星代表长度与宽度平均值,纯色半透明区域为其误差范围。各沉积件内马氏体宽度和长度的平均值、最大值及最小值见表1所列。结合图8及表1得知,550℃沉积件内各马氏体间尺寸差异性较大,且其长宽比亦较大而呈细长外延状大致沿沉积高度方向定向生长。110~180℃沉积件内马氏体平均长宽比随沉积时间增加逐渐趋于稳定化,约为12∶1。

图8

图8

2Cr13沉积件内马氏体尺寸分布图

Fig.8

Size distributions of the martensite of WAAM 2Cr13 parts (Pentagram: the average value of martensite length and width, translucent region: error range)

表1 马氏体尺寸统计结果 (μm)

Table 1

| Temperature / oC | Martensitic width | Martensitic length | ||||

|---|---|---|---|---|---|---|

| Avg. | Max. | Min. | Avg. | Max. | Min. | |

| 550 | 2.0551 | 7.6409 | 1.4412 | 46.5887 | 90.1088 | 9.4287 |

| 180 | 3.8704 | 7.4573 | 1.1424 | 33.3170 | 46.5893 | 9.8124 |

| 150 | 4.0764 | 8.6813 | 1.0726 | 37.2420 | 50.9243 | 12.6153 |

| 110 | 2.9474 | 5.4694 | 0.7246 | 26.7257 | 34.3252 | 9.8958 |

由图2得知,550℃沉积件热历程显著异于110~180℃沉积件,最终导致550℃沉积件因热历程差异而使其显微组织显著不同于其他构件。当层间停留温度为550℃时,在已沉积层表层进行相邻层沉积时,该层在凝固后又随即发生重熔处理。在重熔过程中初生马氏体在液态熔池强烈热流搅动作用下发生枝晶破碎而增加形核率,且在凝固时因冷速较快而使得马氏体晶粒来不及长大,最终获得了如图6a中较为细长的针状马氏体。沉积件内热流自上而下沿沉积高度反向自液态熔池中心传递,铁素体上下表面在强烈的热冲击作用下发生破碎,而其余面因近似平行于热流流动方向而未破碎、且因周围晶粒挤压亦未进一步粗化,故而形成了具有明显方向性的长条状铁素体晶粒。当层间停留温度从180℃逐渐降至110℃时,马氏体尺寸表现出一定程度细化。如图2b~d所示,峰底温度随层间停留时间增加而从180℃逐渐降至110℃,热量散失逐渐增加,从而导致冷凝速率逐渐增加,但增长幅度也较为有限,故尺寸仅略有细化。

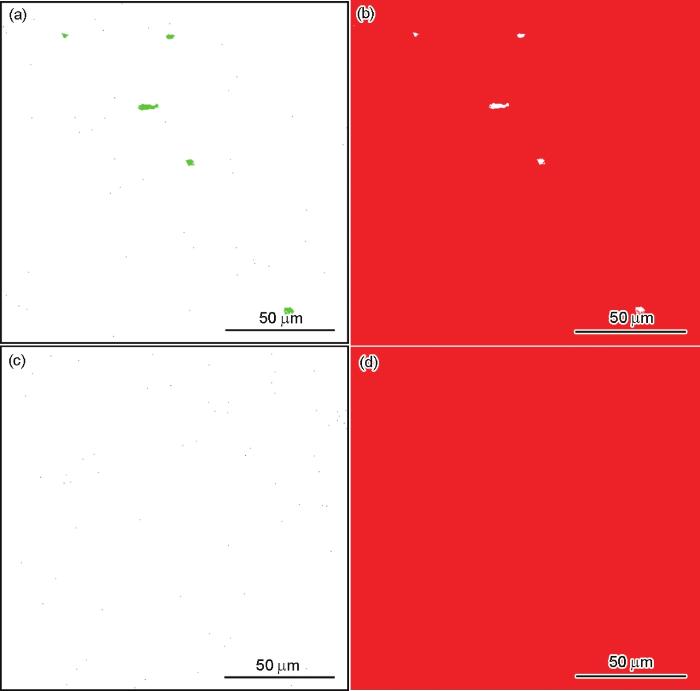

图9

图9

2Cr13沉积件中间层EBSD相分数分布图

Fig.9

EBSD phase fraction maps in the middle layer of WAAM 2Cr13 parts at 550oC (a, b) and 150oC (c, d)

(a, c) austenite phase (green) (b, d) ferrite phase (red)

图10

图10

不同层间停留温度下2Cr13沉积件Y-Z面奥氏体相极图

Fig.10

Pole figures of austenite phase in the Y-Z plane of WAAM 2Cr13 parts for different interlayer dwelling temperatures

(a) 550oC (b) 150oC

2.3 力学性能

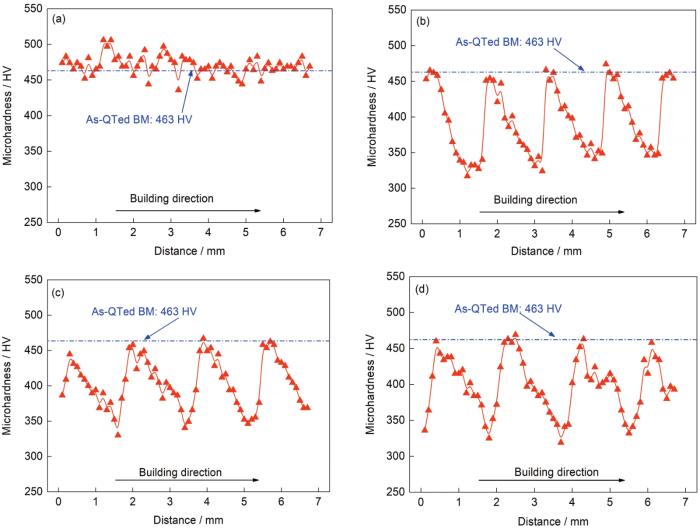

图11

图11

2Cr13沉积件中间部位沿沉积高度方向的硬度曲线

Fig.11

Microhardness curves of WAAM 2Cr13 parts along the building direction across several layers in the middle region (As-QTed BM: 2Cr13 base metal after quenching and tempering treatment)

(a) 550oC (b) 180oC (c) 150oC (d) 110oC

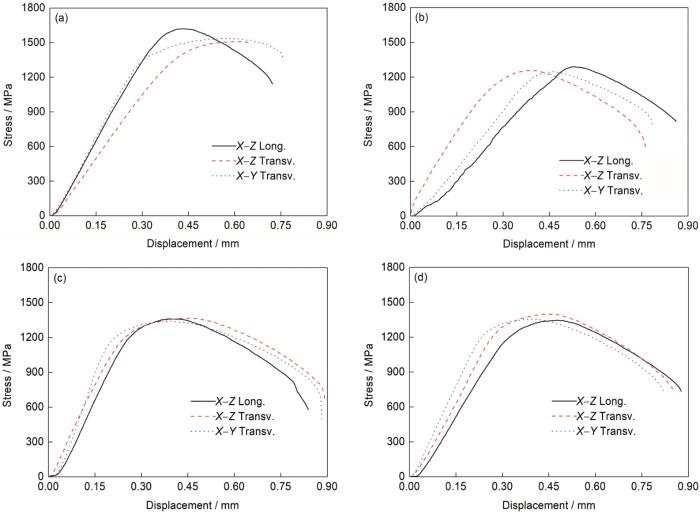

对各沉积件中间层不同沉积面拉伸性能进行对比研究,结果见图12拉伸应力-位移曲线。沉积件拉伸应力随拉伸长度增加先递增至最高点后又逐渐降低并最终断裂,各曲线均呈明显的圆拱状分布,表现出较好的拉伸塑性性能。与110~180℃沉积件拉伸曲线相比,550℃沉积件拉伸曲线长度变短而高度变大,这说明了550℃沉积件具有较高拉伸强度及较差拉伸塑性。同一沉积件不同沉积面拉伸曲线变化趋势比较相近而无明显差异。

图12

图12

2Cr13沉积件中间位置不同沉积面应力-位移曲线

Fig.12

Stress-displacement curves of WAAM 2Cr13 parts in different planes in the middle region

(a) 550oC (b) 180oC (c) 150oC (d) 110oC

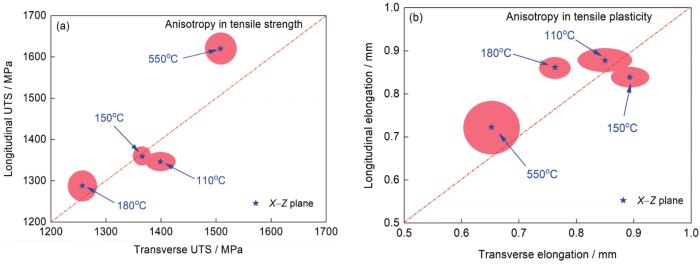

图13

图13

2Cr13沉积件中间位置拉伸性能的各向异性

Fig.13

Tensile anisotropy of WAAM 2Cr13 parts in the middle region (Pentagram: the average value of martensite length and width, translucent region: error range)

(a) ultimate tensile strength (UTS) (b) elongation

在电弧打印2Cr13沉积件中,已沉积部位内热流自熔池底部自上而下进行传递,且其温度梯度距熔池距离越近则数值越大。正是因为沉积件内方向性极强热流分布常导致沉积态组织呈外延状生长,具有明显的各向异性性能,因此,亟需对各沉积件X-Z面内横向与纵向拉伸性能作进一步分析。相比于110~180℃沉积件,550℃沉积件横向与纵向拉伸性能(UTS和延伸长度)各向异性现象较明显,纵向强度及塑性均优于横向性能。结合图6a可发现550℃沉积件为外延状铁素体基体上分布着沿沉积高度方向生长的细长针状马氏体,其横向拉应力因与长条状马氏体生长方向一致而具有纤维强化作用。

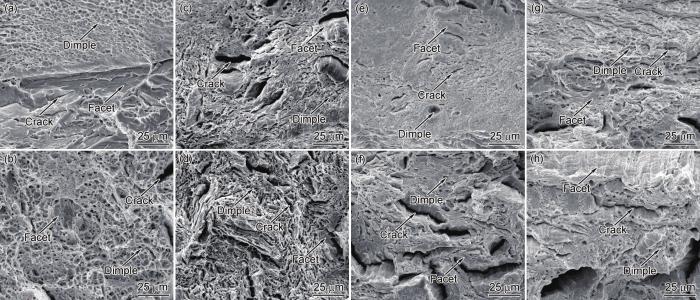

图14

图14

2Cr13沉积件不同层间停留温度拉伸断口形貌

Fig.14

Tensile fracture morphologies of WAAM 2Cr13 parts with different interlayer dwelling temperatures of 550oC (a, b), 180℃ (c, d), 150oC (e, f), and 110oC (g, h)

(a, c, e, g) in the transverse direction (b, d, f, h) in the longitudinal direction

3 结论

(1) 550℃沉积件中间层原位微热处理制度为:一次重熔+多次循环淬火+持续高温回火,而110~180℃沉积件则均为:一次淬火+持续低温回火。各构件虽在继续沉积时熔池对中间层热输入与该层热散失达平衡态,但热积累效果随停留时间延长逐渐弱化。

(2) 各沉积件内均存在大量铁素体相,且衍射峰位置相近、强度相似;此外,550℃沉积件还存在有少量逆变奥氏体相。550℃沉积件为外延状铁素体内分布着近100%细小针状马氏体;110~180℃沉积件均为块状铁素体内分布着板条状马氏体,并在铁素体晶界处有少量不规则块状δ-铁素体残留。

(3) 550℃沉积件内针状马氏体因重熔碎晶呈细长外延状并具有较强织构取向。110~180℃沉积件各区域间板条状马氏体大致沿沉积高度方向生长却无明显织构取向,虽其长宽比均约为12∶1,但平均尺寸因层间停留温度降低导致冷凝速率增加而略呈细化趋势。

(4) 550℃沉积件因细晶强化作用获得了较高硬度与拉伸强度性能,沿沉积高度方向获得了稳定的近调质态显微硬度,但因外延状晶粒分布而具有明显的拉伸性能各向异性。110~180℃沉积件力学性能因具有相近板条状马氏体组织特征而较为相近、且拉伸性能呈各向同性,但周期性晶粒尺寸分布使其显微硬度沿高度方向呈周期性演变。

参考文献

A spatial periodicity of microstructural evolution and anti-indentation properties of wire-arc additive manufacturing 2Cr13 thin-wall part

[J].

Pockmarks on ground surface of nitrided 2Cr13 steel

[J].

2Cr13钢渗氮后磨削面的“麻点”问题

[J].

Effect of Ce on inclusions and impact property of 2Cr13 stainless steel

[J].

Effects of laser shock peening on cavitation erosion and cavitation-silt erosion resistance of 2Cr13 stainless steel

[D].

激光冲击强化2Cr13不锈钢抗气蚀和空化—颗粒侵蚀行为研究

[D].

Microstructural evolution and mechanical characterization of wire arc additively manufactured 2Cr13 thin-wall part

[J].

Turbulent flow measurements in continuous steel casting mold water model

[J].

Effects of heat treatment process on microstructure, strength and toughness of 2Cr13 stainless steel

[J].

热处理工艺对2Cr13不锈钢组织和强韧性的影响

[J].

Research on CAD&FEM of turbine blade die forging

[D].

汽轮机叶片模锻工艺CAD与模锻过程有限元分析

[D].

Wire arc additive manufacturing—A revolutionary method in additive manufacturing

[J].

Microstructure and properties research of Al-Zn-Mg-Cu alloy with high strength and high elongation fabricated by wire arc additive manufacturing

[J].

A review on wire arc additive manufacturing: Processing parameters, defects, quality improvement and recent advances

[J].

A review on wire arc additive manufacturing: Monitoring, control and a framework of automated system

[J].

Microstructure and mechanical properties of 5356 aluminum alloy fabricated by TIG arc additive manufacturing

[J].5356 aluminum alloy has been widely applied in transportation, aerospace and other fields owing to its low density, excellent fatigue property, and superior corrosion resistance. Aluminum alloy is widely manufactured by the arc additive technique that operates at a fast manufacturing speed with simple equipment and high material utilization. The property of 5356 aluminum alloy is closely related to its microstructure. To better control the property of this alloy for the additive manufacturing of forming parts, it is necessary to study the evolution of its microstructure. In this work, 5356 aluminum alloy forming parts were produced by tungsten inert gas welding (TIG) arc additive manufacturing, and their microstructures and mechanical properties were analyzed. The 5356 aluminum alloy formed by TIG additive manufacturing was composed of α-Al matrix and β(Al3Mg2) phase. As the deposition height increased, the layer microstructure transformed from equiaxed grains to columnar grains and tended to stabilize at thermal equilibrium. The top layer exhibited a dendritic microstructure with serious segregation of the Mg element. The middle and lower microstructures were varied and included equiaxed grains, columnar grains, and a mixture of these, with improved Mg-element segregation. As the deposition height increased, the microhardness in the layer first decreased and then stabilized. The microhardness was larger in the interlayers than in the deposition layers. The pores gathered in the interlayers might explain the lower yield strength of the thin-walled parts than the theoretically calculated value. The tensile strength, yield strength, and elongation were all anisotropic, and the tensile property was better in the transverse than in the longitudinal direction. This result was attributable to pore accumulation between the layers of the thin-walled parts and to the uneven microstructure.

5356铝合金TIG电弧增材制造组织与力学性能

[J].采用钨极惰性气体保护焊(TIG)电弧增材制造工艺制备5356铝合金成形件,并对成形件的组织和力学性能进行研究。结果表明,5356铝合金增材制造的相组成为α-Al基体和β(Al<sub>3</sub>Mg<sub>2</sub>)相;随沉积高度增加,沉积层显微组织由等轴晶向柱状晶转变,达到热平衡状态后趋于稳定,这是因为增材制造具有热积累效应;最顶层组织呈现树枝状,且Mg元素偏析严重;中下部组织形态多样,包括等轴晶组织、柱状晶组织及其混合组织,同时Mg元素偏析得到改善。力学性能测试结果显示,随沉积高度的增加,层内显微硬度先降低后趋于稳定,这是因为沉积层组织在增材制造过程中经历逐渐粗化的过程,导致显微硬度下降,达到热平衡状态后显微组织相对稳定,显微硬度也趋于稳定。沉积层层间位置的硬度大于层内,这是因为层间结合处为细小的等轴晶组织。聚集在层间的气孔可能是导致薄壁件屈服强度低于理论计算值的原因。抗拉强度、屈服强度以及伸长率都表现了各向异性,横向拉伸性能优于纵向,这是因为薄壁件层间气孔聚集以及显微组织不均匀。

Study on the uniformity of structure and mechanical properties of TC4-DT alloy deposited by CMT process

[J].

CMT增材制造TC4-DT合金组织均匀性与力学性能一致性研究

[J].

Life-cycle energy and carbon saving potential of wire arc additive manufacturing for the repair of mold inserts

[J].

Scaling Up metal additive manufacturing process to fabricate molds for composite manufacturing

[J].

Improving mechanical strength and isotropy for wire-arc additive manufactured 304L stainless steels via controlling arc heat input

[J].

Mechanical characterization and fatigue assessment of wire and arc additively manufactured HSLA steel parts

[J].

Deposition structure dependence of microstructural evolution and mechanical anisotropy of H13 buildups using cold metal transfer technology

[J].

A hypoeutectic Al-Ni-Mg in situ composite processed by wire-arc additive manufacturing: Phase evolution and mechanical behavior

[J].

Mechanical properties and microstructural characteristics of wire arc additive manufactured 308 L stainless steel cylindrical components made by gas metal arc and cold metal transfer arc welding processes

[J].

In situ heat treatment in selective laser melted martensitic AISI 420 stainless steels

[J].

Microstructure and mechanical properties of mould steels AISI 420 and S136 by selective laser melting manufacturing

[J].

AISI420与S136模具钢SLM成形组织及性能

[J].

Continuous cooling transformations in martensitic stainless steels

[J].

Effect of selective laser melting process parameters on the microstructure and properties of a precipitation hardening stainless steel

[J].

Effect of heat treatment on microstructural heterogeneity and mechanical properties of maraging steel fabricated by wire arc additive manufacturing using 4% nitrogen shielding gas

[J].