取向硅钢是制造传输及配电变压器铁心的基础材料,以制造流程长、工艺复杂、技术含量高著称。取向硅钢制造流程的核心是初次再结晶Goss取向({011}<100>)晶粒通过异常长大机制形成单一织构,二次再结晶Goss晶粒取向偏差角是决定产品性能的重要指标。取向硅钢二次再结晶织构与初次再结晶晶粒尺寸分布和抑制力水平等关键因素密切关联[1,2,3,4]。随着对高效低成本制造的追求,低温板坯加热流程逐渐成为先进取向硅钢技术的标志[5,6]。而低温制造流程下初次再结晶晶粒尺寸分布宽度变大,严重制约二次再结晶的稳定性和成品Goss织构的尖锐度。因此,解析取向硅钢二次再结晶过程织构演变及影响因素,可为取向硅钢特别是低温流程下高端取向硅钢的研制提供理论基础。

关于取向硅钢二次再结晶Goss织构的形成机制,主要有2种观点,即由Harase和Shimizu[7]提出的重位点阵(CSL)晶界模型以及Hayakawa和Shimizu[8]提出的高能(HE)晶界模型。CSL晶界模型认为,CSL晶界相比普通晶界可动性更高,Goss晶粒周围存在较高比例的CSL晶界是Goss晶粒发生二次再结晶的原因[9,10,11]。Kumano和Ushigami[12]研究发现,对于二次再结晶温度较低的普通取向硅钢起主要作用的是Σ5晶界,而二次再结晶温度较高的高磁感取向硅钢起主要作用的则是Σ9晶界。HE晶界模型认为,取向差角位于20°~45°的HE晶界为无序混乱结构,吸收和释放空位能力更强,晶界处析出相更快粗化,因而具有高迁移率[13,14,15,16,17]。CSL晶界模型以及HE晶界模型至今仍存在争论,二者均不能有效解释Goss织构锋锐度问题[18,19]。实际上,高磁感取向硅钢在较高的二次再结晶温度下,Σ9晶界(38.9°<110>)可兼具CSL晶界和HE晶界的特性,呈现出可动性优势。文献[20,21,22]的研究基于Hillert[23]晶粒长大动力学模型,引入受Σ9晶界影响的晶界可动性,描述了不同偏差角Goss晶粒二次再结晶过程中的取向选择。但该模型未细致引入不同偏差角Goss取向晶粒与基体间的晶界特征,也未分析诸多因素对二次再结晶过程中织构演变的影响。

本工作针对取向硅钢二次再结晶Goss织构的发展过程及多因素耦合影响规律,将不同偏差角Goss取向晶粒与基体主要织构组分间的晶界特征,引入到二次再结晶动力学模型中,通过实验和计算解析二次再结晶过程中的取向选择行为,提出取向硅钢初次再结晶组织与抑制力水平等因素的综合调控方法。

1 计算模型与实验方法

1.1 取向分辨的长大速率模型

在取向硅钢初次再结晶基体中,{111}<112>与{114}<481>为主要织构组分,这2种组分均能与Goss取向构成Σ9晶界[26,27],分别为35.4°<110>和39.4°<110>,接近准确的Σ9晶界(38.9°<110>)。根据CSL晶界能与偏差角关系的研究[28],当Σ9晶界绕<110>轴的取向差角偏离38.9°时,其晶界能亦发生相应变化。取准确Σ9晶界的相对晶界能γΣ9/γm=0.5,可推知Goss与{111}<112>和{114}<481>间的相对晶界能分别为γΣ9-{111}<112>/γm≈0.9和γΣ9-{114}<481>/γm≈0.7。当Goss取向偏差角增大时,其与{111}<112>和{114}<481>之间的Σ9晶界的共格关系逐渐减弱,相对晶界能系数随之增大。同时,若初次再结晶基体中{111}<112>和{114}<481>织构组分所占分数减小,则CSL晶界的出现频率降低,同样会使相对晶界能系数增大,影响二次再结晶过程中的取向选择。基于一定的初次再结晶基体织构环境,可获得不同偏差角Goss取向晶粒的相对晶界能系数,进而可实现对不同偏差角Goss取向晶粒二次再结晶长大速率差异性的描述。

1.2 实验方法

本工作以Fe-3.25%Si (质量分数)高磁感取向硅钢(AlN为主抑制剂)为研究对象,采用经过连铸、热轧、常化、一次冷轧、脱碳退火等工序大生产制备的初次再结晶板带,以15 ℃/h的加热速率进行慢升温退火至1200 ℃,获得二次再结晶成品板带。此外,采用中断式退火实验的方法,确定二次再结晶开始温度为1000 ℃;然后在1000 ℃保温不同时间,获得二次再结晶晶粒长大至不同尺寸的中间状态,以研究二次再结晶过程中的组织和织构演变。利用JSM-7001F型扫描电子显微镜(SEM)配备的HKL Channel 5电子背散射衍射(EBSD)系统,统计分析初次再结晶和二次再结晶不同阶段的组织和织构特征。

2 实验与计算结果

2.1 二次再结晶织构演变实测

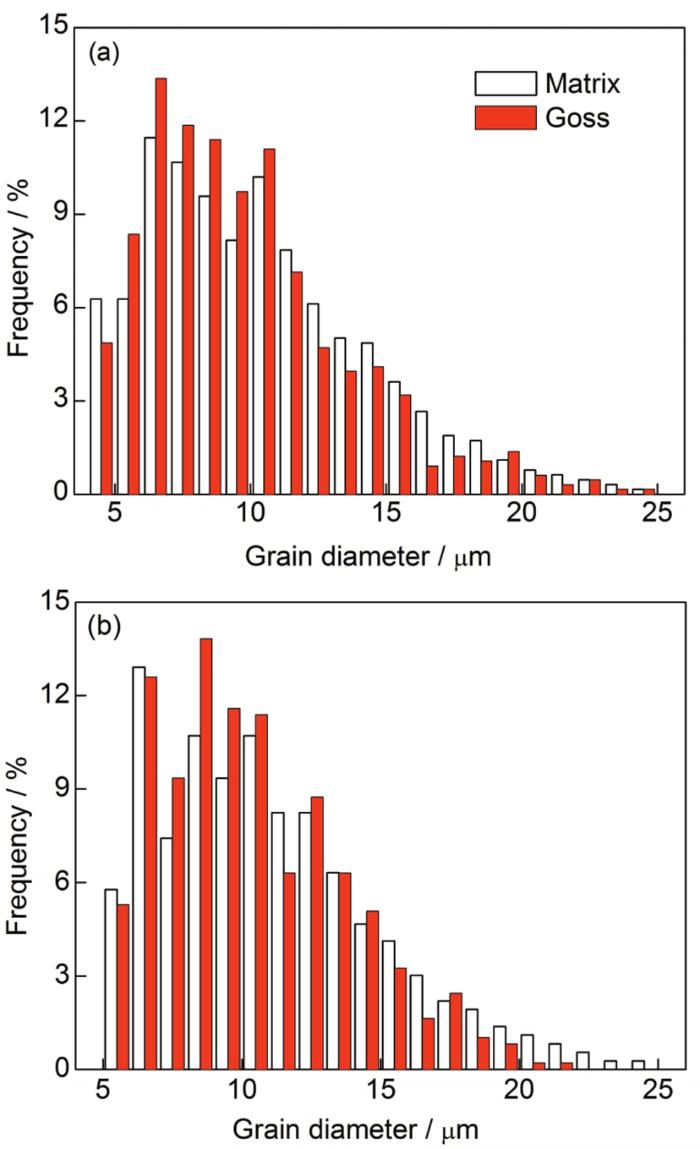

图1

图1

初次再结晶后与二次再结晶开始时Fe-3.25%Si取向硅钢中基体和Goss晶粒尺寸分布

Fig.1

Grain size distributions of matrix and Goss grains in Fe-3.25%Si grain-oriented silicon steel after primary recrystallization (a) and at the beginning of secondary recrystallization (b)

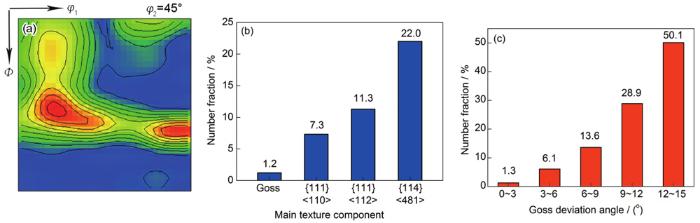

图2为Fe-3.25%Si取向硅钢初次再结晶织构特征与Goss晶粒取向偏差角分布。基体织构主要由能够与Goss晶粒构成Σ9晶界的{114}<481>与{111}<112>组分构成,所占分数分别为22.0%和11.3%。初次再结晶Goss晶粒数量仅占1.2%,而且Goss晶粒主体集中于大偏差角。偏差角6°以内的Goss晶粒仅占7.4%,偏差角6°~9°占13.6%,偏差角9°~15°的Goss晶粒比例达到79.0%。可见,在整个初次再结晶组织中,较低取向偏差角的Goss晶粒比例仅为1‰数量级。

图2

图2

Fe-3.25%Si取向硅钢初次再结晶织构及Goss晶粒取向偏差角分布

Fig.2

φ2=45° section of ODF (levels: 1, 2, 3⋯) (a), number fraction of several main texture components (b) and deviation angle distribution of Goss grains (c) in primarily recrystallized Fe-3.25%Si grain-oriented silicon steel (ODF—orientation distribution function; φ1, φ2, Φ—Euler angles)

Color online

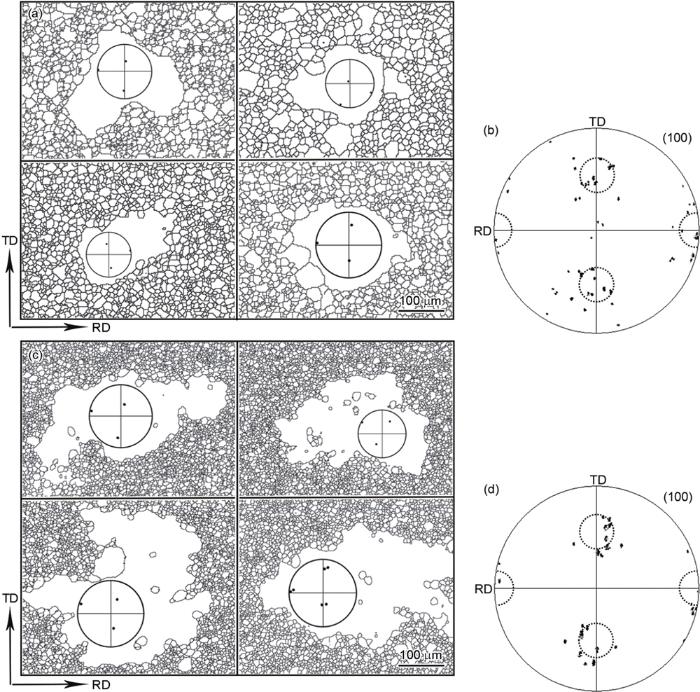

图3为慢升温至二次再结晶开始温度(1000 ℃)后保温不同时间的Fe-3.25%Si取向硅钢的组织特征与二次再结晶晶粒取向。退火100 s后,二次再结晶晶粒平均尺寸约为200 μm,其取向围绕Goss取向呈现很大程度的漫散,不仅包括大偏差角Goss晶粒,也包括与Goss取向偏差角大于15°的非Goss晶粒(图3a和b)。进一步延长退火时间至200 s,二次再结晶平均晶粒尺寸达到约500 μm,取向漫散范围显著缩小,大部分为偏差角15°以内的Goss晶粒,非Goss取向晶粒减少(图3c和d)。这表明,在二次再结晶形核阶段,大偏差角Goss晶粒以及非Goss晶粒都可以形核;但在二次再结晶晶粒长大过程中,Goss晶粒具有长大速率优势,从而逐渐形成相对非Goss晶粒的显著晶粒尺寸优势,成为二次再结晶晶粒的主体。

图3

图3

慢升温至1000 ℃保温100和200 s后Fe-3.25%Si取向硅钢的组织及二次再结晶晶粒取向

Fig.3

Microstructures of different secondary recrystallizaton grains (a, c) and (100) pole figures of secondary recrystallization grains (b, d) in Fe-3.25%Si grain-oriented silicon steel after annealing at 1000 ℃ for 100 s (a, b) and 200 s (c, d) (TD—transverse direction, RD—rolling direction)

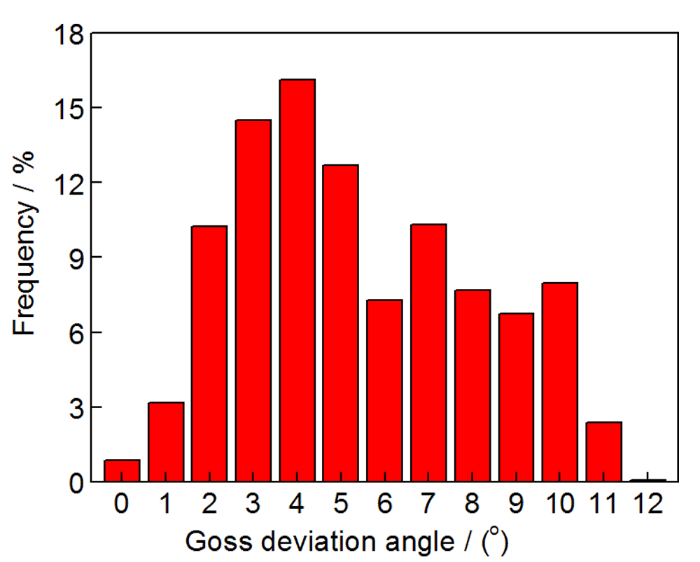

图4为经1200 ℃退火完成二次再结晶后Fe-3.25%Si取向硅钢的组织及取向分布。可以看到,二次再结晶十分完善,晶粒尺寸可达2~3 cm。二次再结晶晶粒全部为Goss取向晶粒,且取向偏差角进一步缩小。图5为统计的二次再结晶Goss晶粒取向偏差角分布,偏差7°以内的Goss晶粒分数达70%以上,平均偏差角约为6°。已有研究[22]发现,初次再结晶基体中所占分数较低的Goss晶粒,在二次再结晶完成后形成强Goss织构,且偏差角较小的Goss取向晶粒所占分数更高。图3,4,5中的实测统计进一步表明,在二次再结晶不同阶段取向选择行为具有不同特征:二次再结晶早期,Goss取向偏差角较大,且这一时期偏差程度变化较小;二次再结晶中后期,Goss晶粒可消耗掉所有非Goss晶粒,包括二次再结晶早期异常长大的非Goss晶粒,即小偏差角Goss晶粒具有更大的长大速率优势。纵观整个二次再结晶过程,从二次再结晶早期形核阶段的混乱取向分布开始,Goss晶粒逐步占据二次再结晶晶粒的主体,并在二次再结晶中后期发展成为全部为较小偏差角的Goss晶粒。因此,取向硅钢二次再结晶过程,实际上是二次再结晶晶粒取向竞争和选择的过程。

图4

图4

二次再结晶完成后Fe-3.25%Si取向硅钢的宏观组织与二次再结晶晶粒取向分布

Fig.4

Macrostructure (a) and (100) pole figure (b) of Fe-3.25%Si grain-oriented silicon steel after complete secondary recrystallization

图5

图5

二次再结晶完成后Goss取向二次再结晶晶粒的偏差角分布

Fig.5

Deviation angle distribution of Goss secondary recrystallization grains

2.2 取向分辨的二次再结晶尺寸计算

根据图2所示的初次再结晶基体织构的组分构成,可由

根据图1,二次再结晶开始前平均基体晶粒尺寸

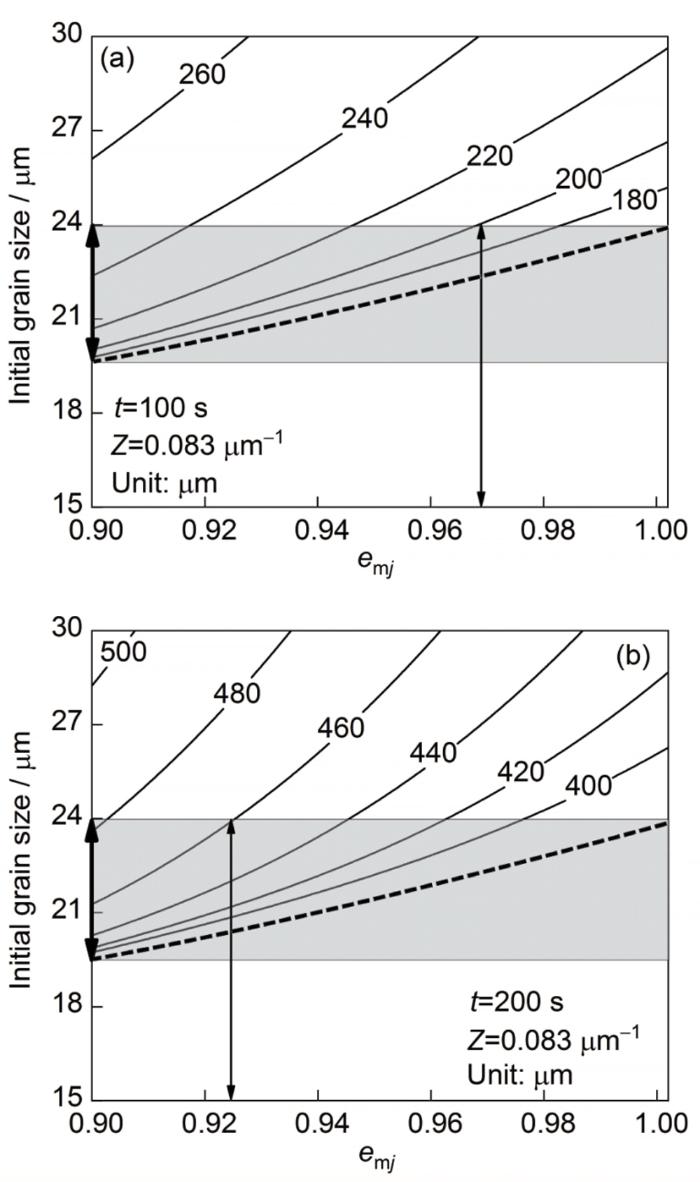

图6

图6

经1000 ℃保温不同时间后二次再结晶晶粒尺寸等值线

Fig.6

Grain size contours with variables of emj and initial grain size at the beginning of secondary recrystallization after annealing at 1000 ℃ for 100 s (a) and 200 s (b) (emj—relative grain boundary energy coefficient, Z—Zener factor, t—annealing time, sold line—grain size contour, dash line—critical condition of secondary recrystallization)

上述计算结果与实测所得二次再结晶晶粒尺寸与取向演变相符,表明本工作引入依赖取向的相对晶界能系数的二次再结晶动力学模型,可以较准确地描述二次再结晶过程的取向选择性。据此可认识到,尺寸不占优势且数量分数很低的初次再结晶Goss晶粒,尤其是占初次再结晶晶粒分数仅约1‰的小偏差角Goss晶粒,在二次再结晶过程中能够通过速率优势累积尺寸优势,使异常长大Goss晶粒取向偏差角显著减小,从而形成了二次再结晶过程中Goss晶粒的择优取向选择性。

3 二次再结晶取向选择行为的调控

在通过初次再结晶基体组织与织构特征等手段进行取向选择行为调控时,抑制力因素也会产生重要影响。在Fe-3.25%Si取向硅钢制备过程中,特别是板坯低温加热流程,由于板坯加热时初生抑制剂相难以有效固溶,导致初次再结晶抑制剂不足,造成初次再结晶晶粒尺寸分布宽度变大。若在初次再结晶晶粒长大早期,通过较低温渗氮提升抑制力,则可在二次再结晶开始时获得与之对应的较小平均晶粒尺寸,但初次再结晶基体中的大尺寸晶粒仍会干扰二次再结晶过程。

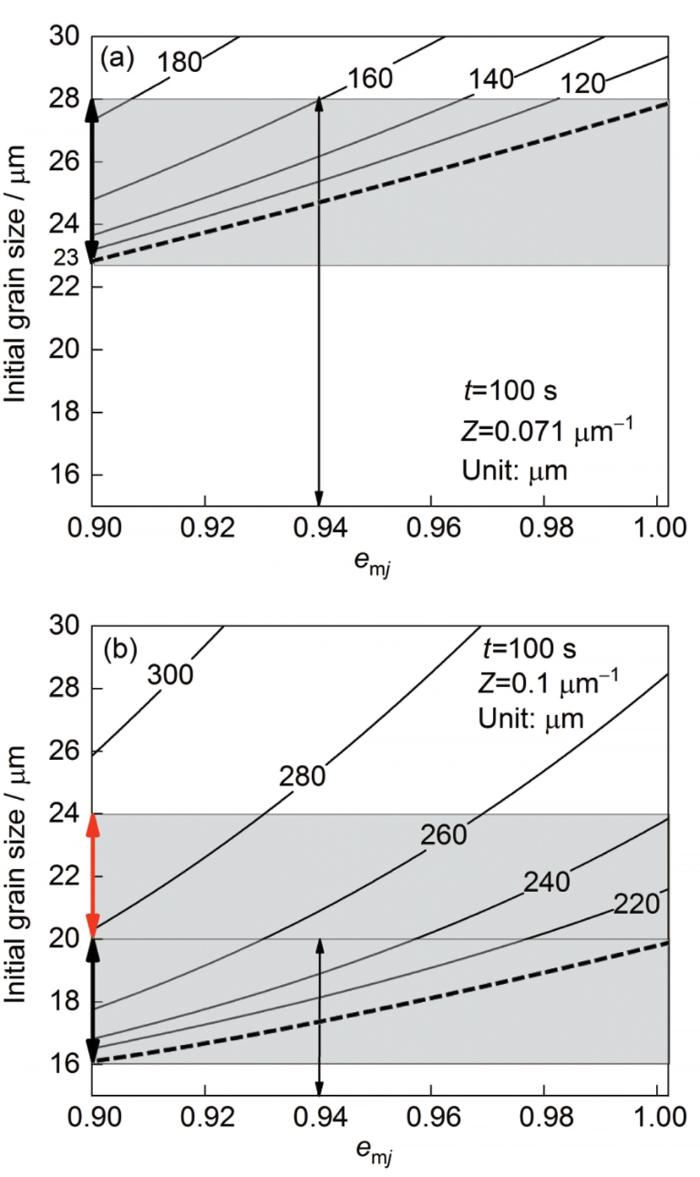

本工作在上述计算基础上,针对抑制力因素进行了计算推演,以便为在多参数耦合作用下的取向硅钢二次再结晶取向选择行为调控提供可行路径。选取Z=0.071和0.1 μm-1的2个抑制力水平,对应二次再结晶开始时的基体晶粒平均尺寸分别为14和10 μm。图7为2个抑制力水平下经1000 ℃保温100 s后二次再结晶晶粒尺寸等值线图。可见,在不同抑制力水平下,相同取向偏差角的Goss晶粒,二次再结晶晶粒尺寸呈现出较大差异。如图中emj=0.94的晶粒,Z=0.071 μm-1时二次再结晶晶粒仅能长大至160 μm,而Z=0.1 μm-1时则可达到250 μm。即抑制力增强有利于二次再结晶晶粒获得尺寸优势,促进取向选择行为。但随抑制力提高,二次再结晶的初始晶粒尺寸敏感区域缩小,由Z=0.071 μm-1时的23~28 μm缩小至Z=0.1 μm-1时的16~20 μm。在敏感区内,小偏差角Goss晶粒比大偏差角Goss及非Goss晶粒具有更显著的相对长大优势,但绝对长大速率低。

图7

图7

不同抑制力水平下经1000 ℃保温100 s后二次再结晶晶粒尺寸等值线图

Fig.7

Grain size contours with variables of emj and initial grain size under Z=0.071 μm-1 (a) and Z=0.1 μm-1 (b) after annealing at 1000 ℃ for 100 s

在高抑制力水平下,位于敏感区之上的各取向大尺寸晶粒,均能以较高速率长大,从而导致二次再结晶取向选择的复杂化。如对于图7b中20~24 μm区域的初始晶粒尺寸,小偏差角Goss晶粒相对大偏差角Goss及非Goss晶粒的长大优势较低,而且大偏差角Goss和非Goss晶粒的绝对长大速率较高,这使小偏差角Goss晶粒需要更长的长大过程,才可能形成主导地位。实际上,这种情况下小偏差角Goss取向晶粒的长大空间受到制约,尽管最终二次再结晶Goss取向晶粒仍表现出尺寸上的优势,但往往不能实现小偏差角Goss晶粒的完善二次再结晶,即成品板中含有一定量的大偏差角Goss乃至非Goss晶粒。

综上,针对Fe-3.25%Si取向硅钢不同板坯加热流程,抑制力水平及补强时机,需要与初次再结晶晶粒尺寸分布及织构特征匹配,在保证Goss取向晶粒二次再结晶稳定发生的前提下,增强小偏差角Goss晶粒的取向选择优势,从而降低成品平均取向偏差角、提高产品性能。

4 结论

(1) 通过实测统计表征了取向硅钢二次再结晶过程中的取向选择性。二次再结晶早期出现的Goss晶粒取向漫散度较大;随着二次再结晶晶粒的长大,Goss取向漫散范围显著减小,并成为二次再结晶晶粒主体。

(2) 在二次再结晶动力学模型中引入受CSL晶界影响的相对晶界能系数,可描述不同偏差角度Goss取向晶粒二次再结晶过程中的长大速率差异,进而实现对二次再结晶过程取向选择行为的表征。

(3) 通过具有取向分辨功能的二次再结晶动力学模型,提出通过抑制力水平对取向硅钢二次再结晶Goss晶粒取向选择行为进行调控时,初次再结晶晶粒尺寸分布与织构特征等需要综合考虑多因素耦合匹配关系。

参考文献

Mechanism of secondary recrystallization of Goss grains in grain-oriented electrical steel

[J]., which is the easy magnetization axis of alpha-iron. Secondary recrystallization is the phenomenon in which a certain very small number of {110} (Goss) grains grow selectively (about one in 10(6) primary grains) at the expense of many other primary recrystallized grains. The question of why the Goss orientation is exclusively selected during secondary recrystallization has long been a main research subject in this field. The general criterion for secondary recrystallization is a small and uniform primary grain size, which is achieved through the inhibition of normal grain growth by fine precipitates called inhibitors. This paper describes several conceivable mechanisms of secondary recrystallization of Goss grains mainly based on the selective growth model.]]>

Developments in the production of grain-oriented electrical steel

[J].

Energy efficient electrical steels: Magnetic performance prediction and optimization

[J].

Effect of normalizing on textures of thin-gauge grain-oriented silicon steel

[J].The main purpose of normalizing for traditional high temperature Hi-B silicon steel is to obtain enough inhibitors and ensure abnormal growth of Goss grains during final annealing treatment. While compared with high temperature Hi-B silicon steel, inhibitors in thin-gauge grain oriented silicon steel, which is prepared by low temperature method, are obtained mainly by nitriding other than by normalizing. In this work, two kinds of thin-gauge grain-oriented silicon steel specimens with and without normalizing were prepared. Effects of normalizing on microstructures and textures of thin-gauge grain-oriented silicon steels were investigated by EBSD and XRD techniques. The results showed that there were significant differences in the primary recrystallization textures between the specimens processed with or without normalizing, which were named as normalizing specimens and non-normalizing specimens respectively, and so did secondary recrystallization textures. It could be found that compared with the non-normalizing specimens, the intensities of {411}<148> and {111}<112> primary recrystallization textures are lower in normalizing specimens, while the intensity of Goss texture is higher. The secondary recrystallization texture of normalizing specimens, which had excellent magnetic properties, were characterized as sharp Goss texture, while Brass texture and deviated Goss texture secondary recrystallization textures were obtained in the non-normalizing specimens. Besides, higher proportion of 20°~45° high-angle boundary surrounding Goss grains were shown in the normalizing specimens. However, the average grain size of normalizing and non-normalizing specimens were almost identical (20 μm), and their grain size distribution was similar. For the thin-gauge grain-oriented silicon steel prepared by low temperature method, normalizing exerted crucial effects on magnetic properties by increasing the proportion of Goss oriented “seeds” prior to cold rolling and providing appropriate environment for Goss recrystallied grains.

常化处理对薄规格取向硅钢织构的影响

[J].利用EBSD和XRD技术对比分析了常化和不常化2种工艺对薄规格取向硅钢组织及织构的影响. 结果表明, 2种工艺条件下的初次再结晶和二次再结晶织构存在着明显的差异. 经过常化处理的样品初次再结晶组织中{411}<148>和{111}<112>织构组分比不常化样品的低, 但Goss织构组分比不常化样品的高; 常化处理的样品二次再结晶织构多为锋锐的Goss织构, 磁性能优异, 而不常化处理的样品二次再结晶织构多为Brass织构和偏Goss织构. 此外, 经过常化处理样品的初次再结晶组织中Goss取向晶粒周围分布的20°~45°大角度晶界所占比例高于不常化处理样品. 2种样品初次再结晶后的平均晶粒尺寸差别并不明显, 均为20 μm, 而且整体晶粒尺寸分布也相近. 常化处理对最终磁性能有决定性影响, 主要体现在提高冷轧前Goss取向“种子”的比例以及优化再结晶组织中Goss取向晶粒周围的织构环境.

Calculation of magnetostriction coefficient for laser-scribed grain-oriented silicon steel based on magnetic domain interaction

[J].Grain-oriented silicon steel is a key material used for iron cores of transformers because grain-oriented is most desirable for magnetic cores. With the rapid development of modern power industry, the requirement for grain-oriented silicon steel with lower magnetostriction and iron loss have exigent. Although the application of laser-scribed technology can effectively reduce iron loss by refining main magnetic domain in high permeability grain-oriented silicon steels, the influence of laser-scribing on the magnetostriction of grain-oriented silicon steel is still controversial due to the complex magnetic domain structure led by interaction among crystal orientation, surface tension and scribing parameters. In this work, a magnetostriction model for laser-scribed grain-oriented silicon steel is proposed based on the relationship between magnetostrictive coefficient and two kinds of 90° magnetic domain, stress closure domain and transverse domain, and the interaction effects of laser scribing parameters and orientation deviation angle (tilt angle of [001] easy axis out of sheet surface) are analyzed. The orientation deviation angle determines which 90° domain structure of either transverse domain or stress closure domain acts as the dominant factor for magnetostrictive behavior. The stress closure domain and stray magnetic field introduced by laser scribing can reduce the magnetostriction coefficient originated from orientation deviation angle. The theoretical calculation on the effects of laser-scribed energy density and laser-scribed spacing on magnetostriction coefficient is in agreement with the direct experimental measurement. The proposed model concerning the interaction between laser-scribing parameters and orientation deviation angle can provide the theoretical basis to reduce the noise of laser-scribed grain-oriented silicon steel.

基于磁畴结构交互作用的激光刻痕取向硅钢磁致伸缩系数计算

[J].基于取向硅钢磁畴结构与磁致伸缩系数的定量关系,综合考虑激光刻痕参数和取向偏差角对应力封闭畴与横向畴2种90°磁畴结构的影响,提出反映刻痕参数与取向偏差角交互作用的磁致伸缩系数计算模型。计算结果表明,取向偏差角的大小决定了激光刻痕条件下磁致伸缩行为是由横向畴还是应力封闭畴主导;激光刻痕产生的局部封闭畴与杂散磁场可降低取向偏差角引起的磁致伸缩系数。刻痕能量密度和刻痕线间距等参数对取向硅钢磁致伸缩系数影响的计算结果与实测结果相吻合,表明本工作所提模型可为降低激光刻痕取向硅钢的噪音提供理论基础。

Recent development of low-loss grain-oriented silicon steel

[J].

Distribution of {110}<001> oriented grains in the primary recrystallized 3% Si-Fe alloy

[J].

The role of grain boundary character distribution in Goss texture development in electrical steels

[J].

Evolution of local texture and grain boundary characteristics during secondary recrystallisation of Fe-3%Si sheets

[J].

Coincidence grain boundary and texture evolution in Fe-3%Si

[J].

Coincidence site lattice (CSL) grain boundaries and Goss texture development in Fe-3%Si alloy

[J].

Grain boundary characteristics of isolated grains in conventional grain oriented silicon steel

[J].

The role of grain boundary character distribution in secondary recrystallization of electrical steels

[J].

A new model of Goss texture development during secondary recrystallization of electrical steel

[J].

A role of fractions of mobile grain boundaries in secondary recrystallization of Fe-Si steels

[J].

Importance of fractions of highly mobile boundaries in abnormal growth of Goss grains

[J].

An analytical method for characterizing grain boundaries around growing Goss grains during secondary recrystallization

[J].

Grain misorientations in theories of abnormal grain growth in silicon steel

[J].

On abnormal growth of Goss grains in grain-oriented silicon steel

[J].

Modeling of secondary recrystallization in 3% silicon steels

[J].

Dynamic observation of the growth of secondary recrystallized grains of Fe-3%Si alloy utilizing synchrotron X-ray topography

[J].

Theoretical analysis and computer simulation of secondary recrystallization in grain-oriented silicon steel

[R].

On the theory of normal and abnormal grain growth

[J].

Grain boundary migration in Fe-3.5%Si bicrystals with [001] tilt boundaries

[J].

Recrystallization and Related Annealing Phenomena

[M]. 2nd Ed.,

Correlation between primary and secondary recrystallization texture components in low-temperature reheated grain-oriented silicon steel

[J].

Coincidence grain boundary and role of primary recrystallized grain growth on secondary recrystallization texture evolution in Fe-3%Si alloy

[J].

Abnormal grain growth of Goss grains in Fe-3%Si steel driven by sub-boundary-enhanced solid-state wetting: Analysis by Monte Carlo simulation

[J].