近年来,在基体中引入第二相粒子的颗粒增强型耐磨钢引起了广泛关注[6~8]。已有研究[9]表明,通过高钛微合金化(Ti质量分数为0.20%~0.80%)及铸坯(锭)原位内生反应在钢基体中引入超硬TiC颗粒,可实现不增加硬度的同时材料耐磨性的大幅提高。与常规钛微合金钢不同的是,新型高钛耐磨钢由于其Ti含量远高于常规钛微合金钢,导致TiC粒子呈现出独特的“微米-亚微米-纳米”三峰分布特征;微米级TiC颗粒来源于在凝固末期发生的L→γ+TiC共晶反应,亚微米TiC颗粒主要是从凝固后的高温奥氏体中析出,而纳米级TiC颗粒主要是在热轧过程中通过形变诱导析出方式从奥氏体中析出[10]。研究还发现,材料耐磨性的提高主要归因于钢中微米级颗粒对磨损沟槽的有效阻碍作用,而亚微米和纳米级颗粒由于其尺寸显著小于沟槽宽度和深度,则起不到相应作用[9]。高钛耐磨钢中Ti含量升高使微米级TiC含量增加,而对亚微米、纳米级TiC含量的影响不大,因此材料的强度(硬度)随Ti含量升高变化也不大,从而能够实现不增加钢材硬度的同时提高其耐磨性[11]。但是,由于大颗粒的微米级TiC硬度极高(3200 HV),析出相和基体界面处变形的不协调很容易在基体中诱发裂纹;同时,它与基体之间的热膨胀差异而导致的镶嵌应力也容易促使TiC自身发生断裂,裂纹进一步扩展到基体后则诱发基体断裂[12]。因此,钢中微米级TiC颗粒的存在将导致材料韧塑性的下降。有研究[13]表明,钢中夹杂物与基体间的应力随着夹杂物尺寸的增大而增大,热轧变形可望在一定程度上碎化钢中大尺寸TiC,特别是对韧塑性危害极大的片状共晶TiC,逐步实现钢中TiC的细化和均匀化,有利于提高钢材的韧塑性。然而,当前关于高钛耐磨钢的研究主要集中于Ti含量对钢板组织和性能的影响规律,而对轧制变形量的影响及其微观机理的研究尚未见报道。

本工作以Ti含量为0.61%的低合金马氏体耐磨钢为研究对象,通过不同总变形量的轧制和轧后热处理得到全马氏体基体组织,研究了轧制变形量对材料的基体组织、TiC析出相及力学性能的影响,分析了高钛耐磨钢中的各种强化机制并揭示了轧制变形量对其影响规律,以期为高钛耐磨钢的工业生产和应用提供理论和实验依据。

1 实验方法

实验用高钛耐磨钢的化学成分为(质量分数,%):C 0.31,Si 0.28,Mn 0.51,Ti 0.61,Cr 0.82,Ni 0.61,Mo 0.29,B 0.0015,Al 0.021,P 0.004,S 0.005,Fe余量。高钛耐磨钢采用150 kg真空冶炼炉冶炼,浇铸成100 mm×120 mm×90 mm的铸锭,然后经过不同变形量的轧制得到不同厚度的钢板。高钛耐磨钢的轧制及热处理工艺如图1所示,不同压缩比的轧制实验压下量分配见表1。轧制前将铸锭置于箱式电阻炉中加热至1200 ℃保温2 h,开轧温度1100~1150 ℃,终轧温度830~850 ℃。按照表1中设定的5种轧制工艺进行轧制:通过不同总变形量的轧制得到厚度分别为30、18、12、9和3 mm的钢板,经过每个道次轧制后钢板的实际厚度见表1,对应轧制压缩比分别为3∶1、5∶1、7.5∶1、10∶1和30∶1,以No.90-3样品为例,经过2道次轧制后等温至950 ℃继续轧制,再经过6道次轧制后等温至850 ℃继续轧制至目标厚度,热轧后水淬至室温。将热轧后的钢板放置于电阻炉中加热至900 ℃完全奥氏体化,保温0.5 h出炉后立即水淬至室温得到完全的马氏体组织,之后在200 ℃下进行回火处理0.5 h。

图1

图1

高钛耐磨钢轧制与热处理工艺示意图

Fig.1

Schematic of rolling and heat treatment process of high-Ti wear-resistant steel (W.Q.—water quenching, A.C.—air cooling)

表1 不同轧制变形量高钛耐磨钢轧制工艺

Table 1

| Sample No. | The actual thickness of the plate after each pass / mm | Total reduction ratio |

|---|---|---|

| 90-30 | 90-72-58-(950 ℃)-44-35-(850 ℃)-30 | 3∶1 |

| 90-18 | 90-72-58-(950 ℃)-44-33-(850 ℃)-24-18 | 5∶1 |

| 90-12 | 90-72-58-(950 ℃)-44-33-24-18-(850 ℃)-14-12 | 7.5∶1 |

| 90-9 | 90-72-58-(950 ℃)-44-33-24-18-(850 ℃)-13-9 | 10∶1 |

| 90-3 | 90-72-58-(950 ℃)-44-33-24-18-13-9-(850 ℃)-6-4-3 | 30∶1 |

用于铸态组织和TiC析出观察的金相试样取自热轧前的铸锭(1/4厚度处)。使用线切割的方法从热处理后的钢板切取金相试样,经过研磨抛光后,用4% (体积分数)硝酸酒精溶液腐蚀,用于组织形貌观察。通过研磨后自动抛光(抛光剂为SiO2悬浊液)的试样,可用于观察试样中TiC粒子的形貌和分布。金相组织观察和TiC形貌及元素分析通过GX51型光学显微镜(OM)和配有Oxford X-Max 50能谱仪(EDS)的S-4300型扫描电子显微镜(SEM)进行。使用Image J软件按照等积圆面积法统计微米级TiC粒子的粒径,使用截线法对原奥氏体晶粒尺寸进行统计。使用H-800型透射电子显微镜(TEM)对不同尺寸的TiC粒子进行观察,使用配有EDAX Genesis能谱仪的Tecnai G2 F20型高分辨透射电子显微镜(HRTEM)对钢中第二相形貌、粒子成分进行分析。碳膜复形样品按以下步骤制取:将金相样品经过4%硝酸酒精溶液腐蚀后真空喷碳,喷碳完成后用小刀将碳膜划成小块放入4%硝酸酒精溶液中脱模,将脱下的碳膜依次放入酒精和蒸馏水中清洗,用直径3 mm的Cu网捞起干燥后进行TEM观察。拉伸实验使用WE-300型标准拉伸试验机在室温下进行。拉伸试样为标准板拉伸试样(GB/T 228.1-2010规定的标准板拉伸尺寸),固定标距为50 mm。冲击实验使用FWC332-1800-G型标准冲击试验机在室温下进行。冲击试样为V型缺口试样,缺口深度2 mm。冲击试样尺寸为10 mm×10 mm×55 mm,(No.90-12样品实际尺寸为9 mm×10 mm×55 mm),拉伸和冲击试样取样方向为平行于轧制方向,每组试样取3个平行试样。使用D8 ADVANCE型X射线衍射仪(XRD)测定样品中的位错密度。

通过物理化学相分析实验对高钛耐磨钢中第二相粒子进行鉴定与分析。将抛光后的样品电解得到电解残渣,对电解残渣通过X'Pert Pro MPD型X射线衍射仪和HK-8800型等离子体发射光谱仪(ICP)分析得到样品中第二相的类型和含量,利用小角度X射线散射法(SAXS)检测第二相粒子的粒径分布。

2 实验结果

2.1 基体组织

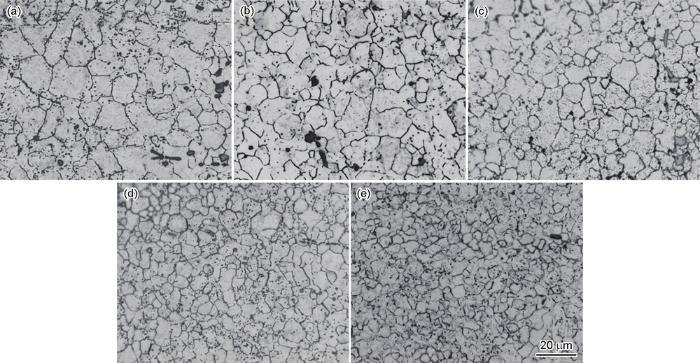

图2给出了高钛耐磨钢在不同轧制工艺条件下基体组织的SEM像。可见,经过淬火加回火热处理后,各组样品基体组织均为板条马氏体组织。同时,还可以观察到大尺寸TiC分布在基体中,TiC粒子的形状包括棒状、多边形块状和球形颗粒状。此外,还可以看到基体中弥散分布着一些小颗粒TiC,这些TiC粒子直径为几百纳米,是在凝固后高温固态析出的[10]。随着轧制压缩比增加,棒状TiC逐渐断裂碎化,多边形块状和球形颗粒状TiC粒子逐渐增多,即TiC粒子的平均尺寸和长宽比减小。图3所示为不同轧制工艺下奥氏体晶粒的OM像。经过定量金相统计,得到Nos.90-30、90-18、90-12、90-9和90-3样品对应的奥氏体晶粒平均尺寸分别为8.1、6.5、5.1、4.9和3.5 μm。可以看出随着轧制压缩比的增加,高钛耐磨钢原奥氏体晶粒进一步细化,与No.90-30样品相比,No.90-3样品的原奥氏体晶粒尺寸从8.1 μm左右细化到了3.5 μm左右。与此同时,马氏体板条束宽度也随之细化。关于晶粒细化的原因,一方面与应变诱导析出的纳米TiC粒子有关,这些细小的TiC粒子会对晶界迁移产生钉扎作用[14],另一方面轧制压缩比的增加会导致形核率的增大从而细化晶粒。

图2

图2

不同轧制工艺的高钛耐磨钢基体组织的SEM像

Fig.2

SEM images of matrix microstructure in high-Ti wear-resistant steel samples No.90-30 (a), No.90-18 (b), No.90-12 (c), No.90-9 (d) and No.90-3 (e)

图3

图3

不同轧制工艺高钛耐磨钢原奥氏体晶粒的OM像

Fig.3

OM images of prior-austenite microstructures in high-Ti wear-resistant steel samples No.90-30 (a), No.90-18 (b), No.90-12 (c), No.90-9 (d) and No.90-3 (e)

2.2 TiC析出相

为了排除基体组织对析出相观察的干扰,将铸态和不同轧制压缩比的样品抛光后不经腐蚀直接在OM下观察,结果如图4所示。使用Image J软件按照等积圆面积法对粒径大于0.3 μm的TiC析出相进行定量金相统计,结果列于表2中。由于高钛耐磨钢中添加了0.61%的Ti,微米级TiC是在凝固末期从钢液中直接析出[10],在铸态样品中呈网状分布(图4a)。经过3∶1压缩比的轧制后,TiC分布均匀性虽然稍有改善,但仍保留着大部分铸态时的网状分布特征,且TiC粒子尺寸较为粗大,平均直径为3.07 μm,最大TiC粒子尺寸达到了13.67 μm,在此种轧制工艺下TiC粒子的碎化效果有限(图4b)。随着轧制压下量增加,TiC粒子分布均匀性明显改善,且粒子尺寸明显减小(图4c~f)。对于No.90-3样品,TiC粒子分布较为均匀,粒子平均直径减小到2.51 μm,最大粒子的尺寸也下降到8.08 μm,在此种轧制工艺下,TiC粒子得到了充分的碎化和均匀化。

图4

图4

铸态和不同轧制工艺的高钛耐磨钢中TiC析出相的OM像

Fig.4

OM images of TiC particles in as-cast high-Ti wear-resistant steel (a) and samples No.90-30 (b), No.90-18 (c), No.90-12 (d), No.90-9 (e) and No.90-3 (f)

表2 高钛耐磨钢中TiC粒子金相统计结果

Table 2

| Sample No. | Volume fraction % | Average area μm2 | Average diameter μm | Maximum diameter μm | Aspect ratio |

|---|---|---|---|---|---|

| 90-30 | 1.11 | 10.19 | 3.07 | 13.67 | 2.85 |

| 90-18 | 1.09 | 9.31 | 2.85 | 11.84 | 2.47 |

| 90-12 | 1.07 | 8.45 | 2.66 | 9.96 | 2.21 |

| 90-9 | 1.08 | 7.87 | 2.57 | 9.12 | 2.03 |

| 90-3 | 1.10 | 7.22 | 2.51 | 8.08 | 1.94 |

图5a~c为不同轧制变形量下高钛耐磨钢中析出相的TEM像。可见,不同轧制工艺下试样中均分布着大量近球形纳米级析出物,尺寸分布在3~50 nm范围内。对于轧制压缩比为3∶1的试样,析出相尺寸多为几十纳米,尺寸为5~10 nm的析出相较少(图5a),随着轧制压缩比增加,5~10 nm的析出相明显增加(图5b和c)。与图4中的微米级析出相在凝固后期从液态中析出不同,图5中观察到的纳米级析出物主要是在轧制过程中形变诱导析出[10]。图5d为No.90-12样品中一个尺寸约10 nm析出相的HRTEM像,对析出相进行选区电子衍射(SAED)花样标定和EDS分析(图5e和f)可以得出,析出相为具有NaCl结构的(Ti, Mo)C,Mo原子在TiC析出过程中扩散到TiC晶格中置换了一部分Ti原子,最终得到了(Ti, Mo)C复合析出相[15]。由于碳膜覆盖在Cu网上进行观察,EDS中不可避免地出现了Cu元素峰。

图5

图5

TiC析出相的TEM像、HRTEM像、SAED花样和EDS结果

Fig.5

TEM images of TiC precipitate in samples No.90-30 (a), No.90-12 (b) and No.90-3 (c), and HRTEM image (d), SAED pattern (e) and EDS result (f) of TiC particle in sample No.90-12 (d(111)—interplanar spacing of (111))

综上所述,在高钛耐磨钢基体中观察到3种不同尺度的TiC粒子(图4中的微米级TiC粒子和亚微米级TiC粒子以及图5中的纳米级TiC粒子)。对No.90-18试样中TiC粒子的粒径尺寸进行定量统计,结果见图6。图6a给出的是利用定量金相统计得到的粒径分布,限于OM的分辨率,为保证统计结果的精确性,该方法只统计了粒径0.3 μm以上的粒子;图6b给出的是利用SAXS测出的尺寸0~300 nm粒子的粒径分布,由于仪器分辨率限制,尺寸大于300 nm粒子不能测出。需要指出的是,该结果并非由相分析直接得出,而是由高钛耐磨钢的初始成分计算得出的总的TiC体积分数减去金相统计的粒径300 nm以上TiC粒子的体积分数,得到粒径300 nm以下TiC的体积分数,再结合相分析结果计算得出粒径在300 nm以下TiC粒子各个粒径区间的体积分数,具体方法参见文献[10],综合图6a和b即可得到该样品的全尺度粒径分布。上述不同尺度的TiC粒子在高钛耐磨钢中发挥的作用也各不相同,微米级TiC粒子可显著提升材料耐磨性,但对韧塑性有一定的危害;纳米级TiC可以对材料产生沉淀强化和细晶强化作用;亚微米级TiC与微米级TiC相比尺寸较小,因而对耐磨性影响不大,而与纳米级TiC相比尺寸又偏大,因而其沉淀强化和细晶强化作用也较小。

图6

图6

No.90-18样品中的TiC粒径分布图

Fig.6

TiC particle diameter distributions of sample No.90-18 measured by quantitative metallography (a) and SAXS (b)

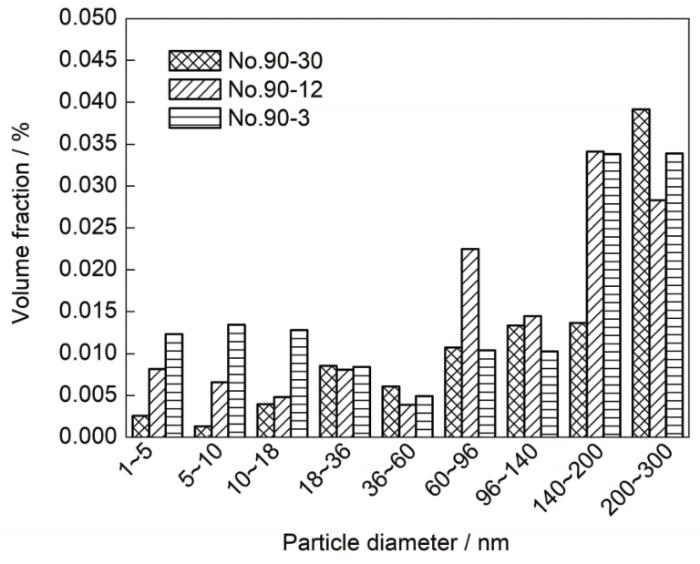

图7给出了不同轧制压缩比样品热处理后的相分析粒径分布,图中只统计了直径300 nm以下的粒子。可见,随着轧制压缩比增加,粒径在15 nm以下粒子的体积分数明显增加。高钛耐磨钢中纳米级TiC为轧制过程中形变诱导析出的产物。随着轧制压缩比增大,奥氏体在未再结晶区的变形量增加,奥氏体中位错密度上升,为TiC粒子提供更多的形核位置,提高了其形核率,从而最终导致纳米级TiC粒子的细化,在大压缩比试样中析出更多小尺寸TiC粒子。

图7

图7

不同轧制工艺高钛耐磨钢中的TiC粒径分布图

Fig.7

TiC particle diameter distribution of high-Ti wear- resistant steel with different rolling processes

2.3 力学性能

高钛耐磨钢的拉伸性能和室温冲击性能如图8所示。图8a给出了强度随轧制压缩比变化的情况。可以看到随轧制压缩比增加,抗拉强度和屈服强度均有上升,分别从压缩比为3∶1时的1202和1437 MPa提高到压缩比为30∶1时的1311和1484 MPa。这主要与基体中析出的纳米级TiC粒子增多导致晶界强化和沉淀强化作用增强有关,此外,位错密度的增加也会导致材料强度的上升,这一点将在3.1节中详细说明。图8b给出了高钛耐磨钢延伸率随轧制压缩比变化的情况。可见,总延伸率也随轧制压缩比增加呈上升的趋势,由压缩比为3∶1时的7.4%上升到压缩比为30∶1时的9.9%。总延伸率由2部分组成:均匀变形阶段延伸率与非均匀变形阶段(颈缩发生后)延伸率,随着轧制压缩比增大,非均匀延伸率增大,而均匀延伸率基本不变,非均匀延伸率的增大是导致总延伸率增大的原因。由图8c可以看到,随着轧制压缩比增加,高钛耐磨钢的冲击性能呈上升的趋势,其中No.90-9冲击样品由于实际厚度为9 mm,因此将其实际冲击功数值乘以10/9换算为10 mm厚标准冲击样品数值以便对比。压缩比为3∶1时,冲击功仅为11 J,压缩比增加到10∶1时,冲击功上升至24 J。

图8

图8

不同轧制工艺高钛耐磨钢的拉伸和冲击性能

Fig.8

Strength (a), elongation (b) and Charpy impact absorbed energy (c) of high-Ti wear-resistant steel with different rolling processes

3 分析讨论

3.1 强化机理分析

金属材料的强化机制主要有:沉淀强化、位错强化、固溶强化和晶界强化。

3.1.1 沉淀强化

式中,f为第二相的体积分数,d为第二相颗粒的尺寸。滑移位错以Orowan机制绕过不可变形颗粒时,由于位错弯曲将增大位错的线张力,因此需要更大的外加应力才能使位错越过第二相颗粒而继续滑移,由此导致了材料的强化。由

表3 不同轧制工艺高钛耐磨钢中各种强化增量及实测屈服强度与式(6)和(7)计算结果的比较 (MPa)

Table 3

| Sample No. | σ0 | Δσp | Δσd | Δσs | Δσg | σy(6) | σy(7) | σy(exp) | |

|---|---|---|---|---|---|---|---|---|---|

| 90-30 | 57 | 80 | 410 | 466 | 230 | 418 | 1495 | 1171 | 1202 |

| 90-18 | 57 | 77 | 406 | 466 | 256 | 413 | 1522 | 1192 | 1217 |

| 90-12 | 57 | 142 | 424 | 466 | 290 | 447 | 1650 | 1260 | 1220 |

| 90-9 | 57 | 165 | 425 | 466 | 295 | 456 | 1680 | 1274 | 1227 |

| 90-3 | 57 | 176 | 436 | 466 | 347 | 470 | 1741 | 1340 | 1311 |

3.1.2 位错强化

低碳马氏体钢中存在大量位错,位错强化是低碳马氏体钢的主要强化方式。通常采用Taylor公式来计算位错强化增量(

式中,ΔK为衍射峰宽化量;D为材料的有效晶粒尺寸,即被大角度晶界所包围的晶粒尺寸;m为矫正系数,取0.263;K为每个峰对应的衍射矢量模;C为位错衬度系数。图9为高钛耐磨钢的XRD谱,将测量结果和文献[21]中各参数取值代入

图9

图9

不同轧制工艺高钛耐磨钢的XRD谱

Fig.9

XRD spectra of high-Ti wear-resistant steel with different rolling processes(a) full peaks pattern(b) local magnification pattern of (200) diffraction peak

表4 不同轧制工艺高钛耐磨钢中的衍射峰半高宽(FWHM)和位错密度

Table 4

| Sample No. | FWHM / (°) | Dislocation density 1015 m-2 | ||

|---|---|---|---|---|

| (110) | (200) | (211) | ||

| 90-30 | 0.319 | 0.609 | 0.613 | 2.154 |

| 90-18 | 0.320 | 0.571 | 0.585 | 2.116 |

| 90-12 | 0.345 | 0.598 | 0.618 | 2.301 |

| 90-9 | 0.337 | 0.608 | 0.626 | 2.311 |

| 90-3 | 0.347 | 0.643 | 0.613 | 2.443 |

3.1.3 固溶强化

式中,

3.1.4 晶界强化

3.1.5 各种强化方式的叠加

由于不同的强化方式或大或小均存在一定的交互作用,因此不同强化效果的叠加是一个很复杂的问题,至今尚未完全解决。对于低碳微合金钢,经常采用简单的线性叠加,如

式中,

Kocks和Mecking[28]将晶内阻止位错运动的障碍分为2类:一类为“软”障碍,如固溶原子等;另一类为“硬”障碍,如析出相和位错等;并认为滑动位错遇到软障碍只发生微小弯曲,则这种障碍的强化可以近似地与晶格摩擦力线性相加。但当滑动位错遇到硬障碍时,则因受其钉扎而明显弯曲,其强化效应是不能线性叠加的。滑动位错通过强障碍的临界应力(τ)表示为τ=Gb/L (其中,L为滑移面上的障碍物间距)。当滑移面上存在2类不同的障碍物A和B时,则障碍物间距由1/L2=1/L

将计算结果列于表3中,可见,均方根叠加后与实测结果总体符合较好,最大偏差不超过50 MPa。从表中可以看出,在各种强化方式中固溶强化和位错强化提供的强度增量最多,是高钛耐磨钢中最主要的强化方式;而造成各组样品强度差异的主要原因是析出强化和晶界强化的变化:随着轧制压缩比增大,钢中纳米析出TiC增多(主要是粒径小于15 nm的TiC粒子),析出强化增量增加。此外,晶粒尺寸也随着轧制压缩比增大而减小,晶界强化增量增加。这2方面的因素综合作用致使高钛耐磨钢屈服强度随着轧制压缩比增加而增大。

3.2 轧制变形量对塑韧性的影响

图10

图10

No.90-18样品冲击断口处TiC粒子的SEM像和EDS结果

Fig.10

SEM image (a) and EDS result (b) of TiC particle in fracture morphology

式中,

高钛耐磨钢的非均匀延伸率随轧制变形量的增大而提高,显然也与大颗粒TiC的细化和均匀化有关。试样产生颈缩后,颈缩区域处于三向拉应力状态,将促进TiC的断裂和微裂纹的扩展,而TiC的细化和均匀化则能够在一定程度上延缓这一过程。此外原奥氏体晶粒尺寸的细化可使马氏体板条细化,延缓裂纹扩展,从而提升材料的塑性。钢的均匀延伸率是加工硬化率和流变应力的共同作用结果。根据拉伸失稳判据

4 结论

(1) 通过淬火加低温回火处理得到了马氏体基体组织+TiC颗粒增强相的复合组织。随着轧制变形量增加,高钛耐磨钢热处理后的原奥氏体晶粒尺寸从8.1 μm细化到了3.5 μm,铸态析出的微米级网状TiC逐渐细化和均匀化,同时尺寸小于15 nm的TiC颗粒占比增加。

(2) 随着轧制变形量的增大,高钛耐磨钢的强度、韧性和塑性均有提高:屈服强度、抗拉强度和总延伸率从压缩比为3∶1时的1202 MPa、1437 MPa和7.4%分别提高到压缩比为30∶1时的1311 MPa、1484 MPa和9.9%,而室温Charpy冲击功从压缩比为3∶1时的11 J大幅提高到压缩比为10∶1时的24 J。高钛耐磨钢在轧制压缩比为10∶1时即可获得良好的韧塑性,进一步增大压缩比对钢的韧塑性提升不明显。

(3) 通过对高钛耐磨钢各种强化方式的定量分析表明,采用沉淀强化和位错强化均方根叠加方式计算得到的屈服强度与实测值吻合较好,纳米级TiC的析出强化和晶界强化是造成高钛耐磨钢强度增加的主要原因。

(4) 高钛耐磨钢的韧性和塑性随强度的提高不降反升,主要是因为大颗粒TiC在轧制变形过程中发生细化和均匀化。

参考文献

Microstructure and abrasive wear behavior of medium carbon low alloy martensitic abrasion resistant steel

[J].

Effect of tempering temperature on microstructure and mechanical properties of high Ti microalloyed directly quenched high strength steel

[J].Over the past years, Ti microalloying technique has not been developed sufficiently compared to Nb and V. due to its special metallurgy characteristics. Higher chemical activity of Ti results in larger inclusions when Ti combines with O, N and S. In addition, higher temperature sensitivity of TiC precipitation leads to the instability of steel strips. Owning to the above reasons, the conventional high strength steels with the microstructure of martensite, bainite or the composite of the two were microalloyed with (0.01%similar to 0.03%)Ti (mass fraction) for austenite grain refinement during soaking. The addition of high Ti (>0.1%) in microalloyed high strength martensitic or bainitic steels were rarely touched upon. The effects of tempering temperature on the microstructure and mechanical properties of high Ti microalloyed directly quenched high strength steel were investigated by TEM, SEM and physical-chemical phase analysis. The results show that with the increase of tempering temperature, the tensile curve has an obvious turning point. The tensile strength gradually decreases first and then increases, while the yield strength increases slowly. At tempering temperature 600 degrees C, the experimental steel shows the best mechanical properties with tensile strength at 1043 MPa, yield strength at 1020 MPa and the elongation of 16%, while the Charpy impact energy is 67.7 J at -40 degrees C. The main reason is that the amount of nanometer precipitates reaches the maximum, their distributions are also relatively uniform and the size is significantly small. The solid solution strengthening and precipitation strengthening increment of the experiment steel tempering at 600 degrees C were about 149.82 and 171.72 MPa, respectively.

回火温度对高Ti微合金直接淬火高强钢组织及性能的影响

[J].利用TEM, SEM及物理化学相分析法, 研究了回火温度对高Ti微合金直接淬火高强钢显微组织和力学性能的影响. 结果表明, 随着回火温度的升高, 抗拉曲线出现明显的转折点, 抗拉强度先降低后升高, 而屈服强度缓慢升高. 回火温度为600 ℃时, 实验钢具有最佳的综合力学性能; 抗拉强度为1043 MPa, 屈服强度为1020 MPa, 延伸率为16%, -40 ℃冲击功为67.7 J. 其主要原因是600 ℃时, 纳米级的析出相数量最多, 体积分数最大, 分布最均匀. 600 ℃回火时, 实验钢的固溶强化和沉淀强化的强度增量分别约为149.82 和171.72 MPa.

Wear behavior and work hardening of high strength steels in high stress abrasion

[J].

Influence of hardness on the wear resistance of 17-4 PH stainless steel evaluated by the pin-on-disc testing

[J].

Effects of composition and microstructure on the abrasive wear performance of quenched wear resistant steels

[J].Wear resistant steels are commonly categorized by their hardness, and in the case of quenched wear resistant steels, their Brinell hardness grades are widely considered almost as standards. In this study, the abrasive wear performance of 15 commercially available 400 HB grade quenched wear resistant steels from all over the world were tested with granite gravel in high stress conditions. The aim was to evaluate the real wear performance of nominally similar steels. Also properties such as hardness, hardness profiles, microstructures and chemical compositions of the steels were studied and reasons for the differences in their wear performance further discussed. In terms of mass loss, over 50% differences were recorded in the abrasive wear performance of the studied steels. Variations in the chemical compositions were linked to the auto-tempered microstructures of the steels, and the microstructural characteristics were further linked to their ultimate wear behavior. (C) 2014 Elsevier B.V.

Microstructure and abrasive wear study of (Ti,W)C-reinforced high-manganese austenitic steel matrix composite

[J].

Evaluation of electroslag remelting in TiC particle reinforced 304 stainless steel

[J].

Study on relative wear resistance and wear stability of high-speed steel with high vanadium content

[J].

TiC precipitation behavior and its effect on properties in high titanium and high wear-resistant steels

[D].

高钛高耐磨钢中TiC析出行为及对性能的影响

[D].

TiC precipitation behavior and its effect on abrasion resistance of high titanium wear-resistant steel

[J].

高钛耐磨钢中TiC析出行为及其对耐磨粒磨损性能的影响

[J].

Precipitation process of TiC in low alloy martensitic steel and its effect on wear resistance

[J].

Stability of (Ti, M)C (M=Nb, V, Mo and W) carbide in steels using first-principles calculations

[J].The lattice parameters, formation energies and bulk moduli of (Ti,M)C and M(C,Va) with the B1 crystal structure have been investigated using first-principles calculations, where M = Nb, V, Mo and W. The replacement at 0 K of Ti by Mo or W in the TiC lattice is found to be energetically unfavorable with respect to the formation energy. However, it decreases the misfit strain between the carbide and ferrite matrix, a factor which is of critical importance during the early stages of precipitation, thus favoring the substitution of Ti by Mo, as is observed in practice. The effect of Mo in enhancing the coarsening resistance of (Ti,Mo)C precipitates is discussed in terms of its role in the nucleation process, but followed by a more passive contribution during coarsening itself. The role of tungsten has been predicted to have a similar effect to molybdenum on the nucleation and coarsening process. Analysis of precipitates in Ti-, Ti-Mo- and Ti-W-bearing steels shows results consistent with the calculations. (C) 2011 Acta Materialia Inc. Published by Elsevier Ltd.

Evolution behavior of cracks and inclusions in slab during rolling

[D].

轧制过程中轧件裂纹和夹杂物演变行为研究

[D].

Precipitation of TiC in high Ti steel

[J].

高钛钢中TiC析出机制

[J].

Precipitation hardening in metals

[J].

Prior austenite grain size and tempering effects on the dislocation density of low-C Nb-Ti microalloyed lath martensite

[J].

A quantitative evaluation of microalloy precipitation strengthening in martensite and bainite

[J].

An improved X-ray diffraction analysis method to characterize dislocation density in lath martensitic structures

[J].

Dislocation density within lath martensite in Fe-C and Fe-Ni alloys

[J].

The role of carbon in the strength of ferrous martensite

[J].

Experimental evaluation of the particle size dependence of the dislocation-particle interaction force in TiC-precipitation-strengthened steel

[J].

The ductile-brittle transition in the fracture of α-iron: I

[J].

Study on structure control unit of strength and toughness of low alloy martensitic steel

[D].

低合金马氏体钢强韧性组织控制单元的研究

[D].

Superposition of alloy hardening, hardening strain, and dynamic recovery

[A].

The deformation of plastically non-homogeneous materials

[J].