Kissinger方法[12]广泛应用于研究玻璃的晶化动力学行为[13,14],通过绘制升温速率(Φh)与特征温度(Tc)之间的关系曲线,即ln(Φh / Tc2)-1 / Tc,由曲线斜率求得晶化激活能。常规差示扫描量热仪(DSC)的Φh (< 10 K/s)范围较窄,Kissinger图通常表现为直线,表明晶化过程具有单一的激活能,如果将Φh扩展至更宽范围(如达到104 K/s数量级),那么Tc与Φh之间的依赖关系有待于进一步研究。最近,杨群等[15,16]利用快速扫描量热(FDSC)技术对Ni80P20合金和铝基非晶合金的玻璃转变和过冷液体性质进行了表征。Orava等[17]研究了相变材料Ge2Sb2Te5 (GST)在宽Φh范围内的过冷液体行为和晶化动力学。综上,FDSC的应用为在宽温度范围内揭示过冷液体性质和晶体生长动力学提供了工具[18]。根据Angell[19]所述,在玻璃转变温度(Tg)以上,强液体表现出接近Arrhenius关系的行为,而脆性液体表现出偏离Arrhenius关系的行为,具体体现为黏性流动激活能的变化。对于脆性液体而言,该激活能在Tg附近很高,随着温度的升高显著降低。液体中原子迁移与温度间的依赖性可由黏度(η)表征,高温时,η和扩散系数(D)遵守Stokes-Einstein[1]关系:ηD = kBT (式中,kB为Boltzmann常数,T为热力学温度),即η和D是耦合的。但是在一些金属[20]、有机物[21]和氧化物[22,23]玻璃形成体中,当温度降至Tg附近时,这种关系不再适用,即晶体生长动力学与黏性流动之间发生解耦(或去耦合)。对于Zr61Ti2Cu25Al12非晶合金,其解耦情况有待于进一步研究。

基于此,本工作利用FDSC将Φh提高至104 K/s数量级,研究Zr61Ti2Cu25Al12非晶合金在超宽温度范围内过冷液体的动力学行为和晶化过程中晶体生长动力学与黏性流动之间的依赖关系。以期为非晶合金过冷液体和晶化动力学研究提供理论依据,为Zr61Ti2Cu25Al12非晶合金的制备和加工,尤其是过冷液态下的塑性成形提供技术指导。

1 实验方法

以纯度均大于99.95% (质量分数)的Zr、Ti、Cu和Al为原料,按照名义成分为Zr61Ti2Cu25Al12配料60 g,采用水冷铜坩埚感应悬浮熔炼炉在高纯Ar气(99.999%,体积分数)保护下反复翻转熔炼母合金3次以上以保证成分均匀,随后通过铜模吸铸成直径为3 mm的棒状试样。非晶合金条带制备是在高纯Ar气保护下通过感应加热放置于带喷嘴石英管中的破碎合金锭,待熔化后将高温熔体喷射到高速旋转的铜辊表面,其线速度约为60 m/s,最终获得的带材尺寸约为0.5 mm (宽) × 0.02 mm (厚)。采用D8 ADVANCE X射线衍射仪(XRD,CuKα,波长λ = 0.154 nm)表征样品结构,衍射角2θ = 20°~80°,扫描速率为4°/min。采用JEM-F200高分辨透射电子显微镜(HRTEM)进行微观结构表征,样品通过电解双喷制备,电解液为液氮保护下的10%HClO4 + 90%C2H5OH (体积分数)溶液,工作电压和电流分别为22 V和30~40 mA。采用Mettler Toledo Flash DSC 2 + FDSC和Netzsch STA 449F3常规DSC对合金进行热分析,连续Φh分别为100~5.5 × 104 K/s和0.05~1.33 K/s。FDSC配置XENF20_65299传感器芯片,允许温度上限1273 K,极限升降温速率分别为6 × 104和-4 × 104 K/s,制冷器型号为Huber TC100。实验前采用标准试样In (99.999%,质量分数)对传感器芯片温度和热量值进行校准[24,25],测试过程中保护气体N2 (99.99%,体积分数)的流速为50 mL/min,传感器支架温度为173 K。FDSC样品制备是在仪器自带的光学显微镜下将非晶薄带切成小于芯片面积的合适尺寸,对应质量小于1 μg,其值可通过熔化焓(ΔHm)相等来确定。对FDSC熔化峰面积积分得ΔHm为0.066 mJ,通过常规DSC在Φh = 0.33 K/s时测试的比熔化焓为106 J/g,2者熔化焓相等即可计算出FDSC样品质量为:0.066 × 10-3 J / (106 J/g) = 6.2 × 10-7 g。常规DSC样品制备是通过金刚石切片机从棒状试样上切制而成,质量约20 mg,实验中采用Al2O3坩埚,保护气体N2流速为50 mL/min。

2 实验结果

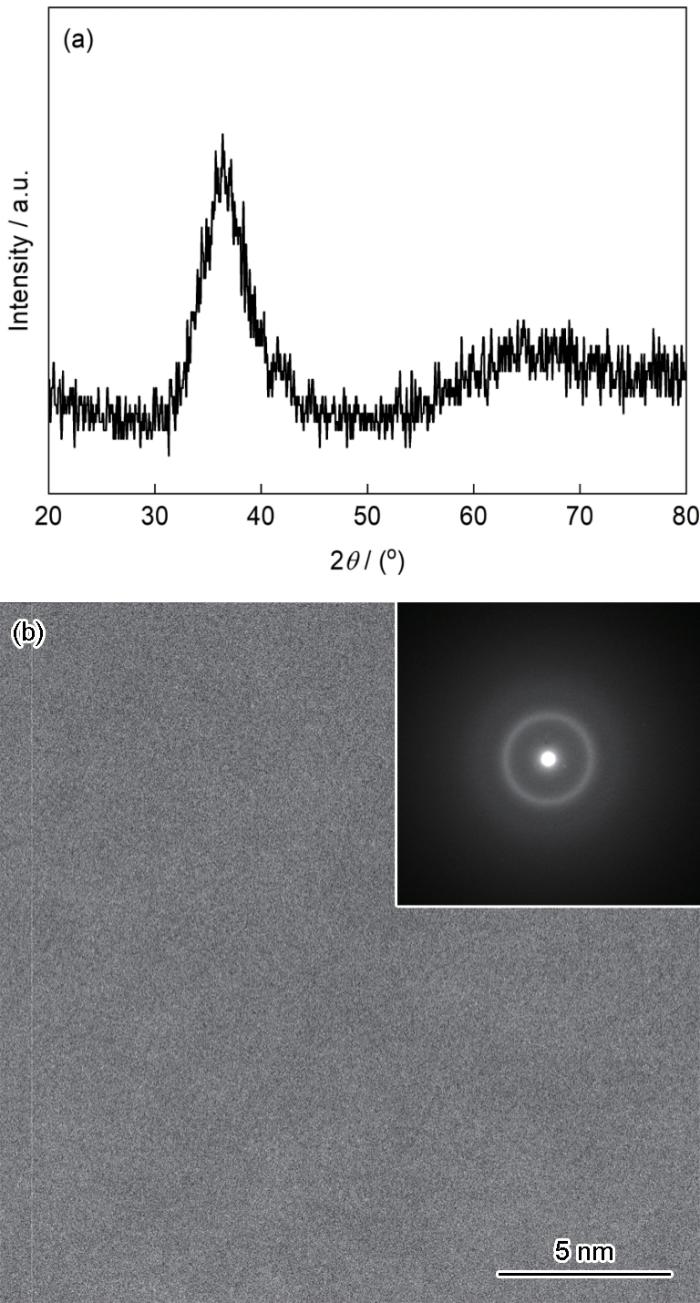

图1

图1

直径为3 mm Zr61Ti2Cu25Al12合金铸态棒的XRD谱和HRTEM像

Fig.1

XRD spectrum (a) and HRTEM image (Inset shows selected area electron diffraction (SAED) pattern) (b) of Zr61Ti2Cu25Al12 as-cast rod with a diameter of 3 mm

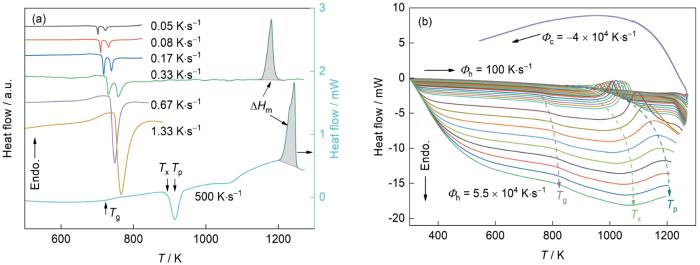

图2a和b分别为Zr61Ti2Cu25Al12非晶合金的常规DSC和FDSC热流曲线,作为对比图2a中也包含了500 K/s的曲线。从图2a可以看出,常规DSC连续升温过程中,玻璃化转变和晶化过程所表现出的动力学特性体现为2个方面:(1) Tg、晶化开始温度(Tx)、晶化峰值温度(Tp)和过冷液相区宽度ΔTx (= Tx - Tg)随Φh增大而增大;(2) 低Φh阶段的两步晶化逐渐演变为高Φh阶段的同步晶化,具体表现为: Φh从0.05 K/s升高到0.17 K/s过程中,热流曲线呈现出2个完全独立的晶化放热峰,当Φh = 0.33 K/s时,第一步晶化还未结束而第二步晶化过程已经开始,随着Φh达到0.67 K/s,两步晶化过程完全合并为单一的晶化峰。

图2

图2

Zr61Ti2Cu25Al12合金的常规差示扫描量热(DSC)和快速扫描量热(FDSC)热流曲线

Fig.2

Heat flow curves of conventional DSC at low heating rate (Φh) from 0.05 K/s to 1.33 K/s (As a comparison, 500 K/s is also included in Fig.2a) (a) and FDSC at high Φh from 100 K/s to 5.5 × 104 K/s (Φh = 100, 200, 400, 600, 800, 1000, 1500, 2000, 2500, 3000, 3500, 4000, 4500, 5000, 6000, 7000, 8000, 9000, 10000, 15000, 20000, 25000, 30000, 35000, 40000, 45000, 50000, 55000 K/s) (b) for Zr61Ti2Cu25Al12 metallic glass (DSC—differential scanning calorimetry, FDSC—fast differential scanning calorimetry, Φc─cooling rate, T─temperature, Tg─glass transition temperature, Tx─crystallization temperature, Tp─crystallization peak temperature, ΔHm─melting enthalpy)

图2b的FDSC降温速率Φc = -4 × 104 K/s,降温过程热流曲线未显示出晶化放热峰,随后以不同Φh循环扫描。随着Φh从100 K/s到5.5 × 104 K/s逐渐增大,与常规DSC相似,特征温度也随之向高温方向移动,Φh越大,这种偏移幅度越不明显,表明高Φh阶段较低Φh阶段动力学效应不明显。另外,相比于Tx和Tp,Tg随Φh增加较缓,这使得ΔTx随Φh增大而增大,表现出明显的动力学特征。

3 分析讨论

3.1 过冷液体的动力学行为

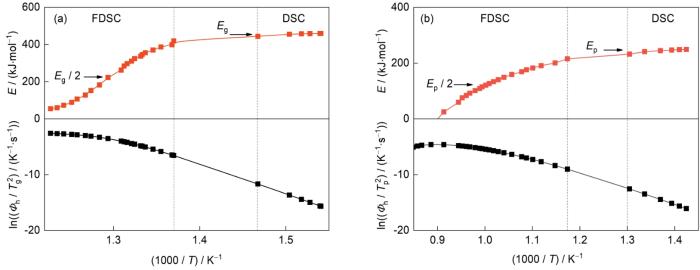

式中,E为激活能,R为理想气体常数,Const为常数。由于常规DSC的连续升温速率有限,Kissinger曲线通常表现为线性[26],曲线斜率(-E / R)所表示的黏性流动或晶化激活能为定值,分别约为450和245 kJ/mol,如图3常规DSC所示。FDSC是常规DSC在高温范围的扩展,在常规DSC所测速率范围之外,曲线出现了明显的外凸弯曲,激活能逐渐降低,具体数据为:对于Tg,玻璃化转变激活能从Eg = 450 kJ/mol降至Eg / 2 (对应温度为770 K)历经的温度范围为94 K,得出单位温度下的激活能降为2.4 kJ/(mol·K),即温度每升高1 K激活能约降为2.4 kJ/mol;对于Tp,激活能降至初始值一半(对应温度为1000 K)历经的温度范围为234 K,得出单位温度下的激活能降为0.5 kJ/(mol·K)。由此可知,抑制黏性流动或晶化的能垒随温度升高逐渐降低,意味着黏性流动或晶化阻力减小,过冷液体结构更容易发生变化,从而更趋向于脆性液体。相比于晶化激活能,玻璃化转变的黏性流动激活能对温度变化更加敏感,随温度升高其值下降更剧烈,“脆性”行为表现更明显。

图3

图3

Zr61Ti2Cu25Al12合金玻璃化转变激活能(Eg)和晶化激活能(Ep)及对应的Kissinger图

Fig.3

Changes in activation energy for glass transition (a) and crystallization (b) of Zr61Ti2Cu25Al12 amorphous alloy and corresponding Kissinger plots (E─activation energy, Eg─activation energy relative to Tg, Ep─activation energy relative to Tp)

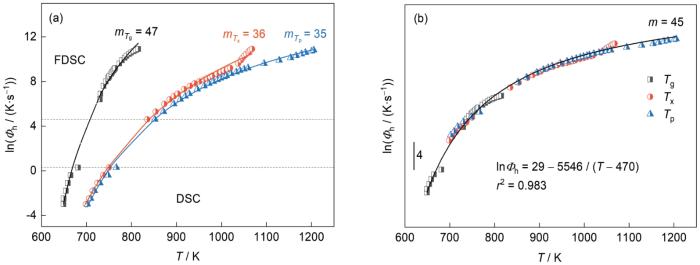

图4

图4

Zr61Ti2Cu25Al12合金特征温度与升温速率(Φh)之间的关系及经时间维度调整后的曲线

Fig.4

Dependence of the characteristic temperatures in Zr61Ti2Cu25Al12 alloy on the natural logarithm of the Φh (a) and adjusted with proper time dimension shift (b) (m─fragility index;

表1 Zr61Ti2Cu25Al12合金特征温度的lnΦh-T拟合参数及决定系数(r2)

Table 1

| Characteristic temperature | B0 | D0 | T0 K | r2 |

|---|---|---|---|---|

| Tg | 23.5 | 7.2 | 509.8 | 0.992 |

| Tx | 19.0 | 12.5 | 446.9 | 0.997 |

| Tp | 17.9 | 11.7 | 451.9 | 0.998 |

将各特征温度对应的拟合参数分别代入即可得出过冷液体的m分别为:

3.2 晶体生长动力学与黏性流动间的解耦

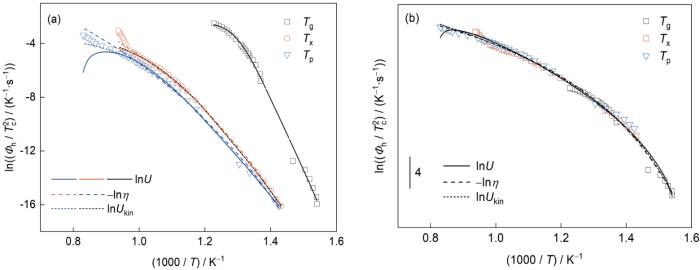

图5

图5

Zr61Ti2Cu25Al12合金特征温度的Kissinger图及经时间维度调整后的曲线

Fig.5

Kissinger plots for characteristic temperatures of Zr61Ti2Cu25Al12 metallic glass (a) and adjusted with proper time dimension shift (b) (U─crystal growth rate; η─viscosity; Ukin─kinetic coefficient for crystal growth; Tc─characteristic temperatures Tg, Tx, and Tp)

式中,U为晶体生长速率;ΔG为晶态和液态间的Gibbs自由能差,可以通过ΔHm与液相线温度(Tl)近似求得:ΔG = ΔHm (Tl - T) / Tl;Ukin为晶体生长的动力学系数,其值为ΔG无限大时U的极限值,可通过Ukin-η-1关系与η相联系,这与晶体生长过程中D与η符合Stokes-Einstein关系相类似。Cohen和Grest[34]应用自由体积模型和逾渗理论描述玻璃转变过程时给出了η的广义方程:

根据η与Ukin在高温时反相关可得:

式中,Ac和A为无量纲参数,Bc、B、C和T1为温度量纲参数。

表2 Zr61Ti2Cu25Al12合金特征温度的lnU-1000 / T和lnUkin-1000 / T拟合参数及决定系数

Table 2

| Fitting formula | Characteristic temperature | A | 2B / K | 4C / K | T1 / K | r2 |

|---|---|---|---|---|---|---|

| lnU-1000 / T | Tg | -0.3292 | 31.6 | 2.0 | 771.0 | 0.997 |

| Tx | 0.8188 | 892.8 | 91.0 | 903.5 | 0.996 | |

| Tp | 0.3166 | 443.8 | 62.6 | 1013.6 | 0.993 | |

| lnUkin-1000 / T | Tg | -0.8558 | 27.9 | 1.8 | 769.3 | 0.997 |

| Tx | -0.8916 | 427.3 | 47.4 | 899.1 | 0.997 | |

| Tp | -1.3308 | 220.7 | 31.8 | 967.7 | 0.999 |

式中,A0和C0为常数,T2为VFT温度,图5a中虚线所示为通过VFT方程拟合的η与T的关系曲线(-lnη-1000 / T),拟合参数具体数值见表3。作为对比,由Cohen和Grest[34]的黏度公式得出的曲线(lnUkin-1000 / T)也包括在内,如图5a中短虚线所示,拟合参数具体数值见表2中的lnUkin-1000 / T。由此可知,通过上述方法研究非晶合金的晶化过程时同时考虑了热力学(ΔG)和动力学(η)因素,从图5a中可以看出,在中低温范围内,各曲线近似重合并与实验数据非常吻合,该温区内晶化受动力学因素控制,从而也证明了常规DSC忽略了对晶体生长的热力学影响,在熔点附近的高温区,曲线之间发生大的偏离,其归因于随温度升高热力学因素显著降低,尽管动力学因素增大,但其增大量小于热力学因素的显著减小量,从而使得lnU在达到最大值后迅速降低。在研究非晶合金晶化过程中,如上文所述,Tg只是晶化过程的先导,但是对整个超宽温度范围内过冷液体的晶化和黏性流动进行综合分析仍是有必要的。根据3.1节中提到的将非晶合金的玻璃化转变和晶化过程合并为单一激活过程,图5b为沿时间维度相关纵轴平移后拟合的曲线。可以看出,在超宽过冷液相区范围内,采用单一的激活过程可以很好地描述过冷液体的黏性流动和晶化过程,各拟合曲线r2均在0.98以上。

表3 Zr61Ti2Cu25Al12合金特征温度的-lnη-1000 / T拟合参数及决定系数

Table 3

| Characteristic temperature | A0 Pa·s | C0 K | T2 K | r2 |

|---|---|---|---|---|

| Tg | 8.7835 | 3396.1 | 514.7 | 0.991 |

| Tx | 0.0184 | 4744.9 | 464.3 | 0.997 |

| Tp | 0.0095 | 5867.8 | 421.2 | 0.997 |

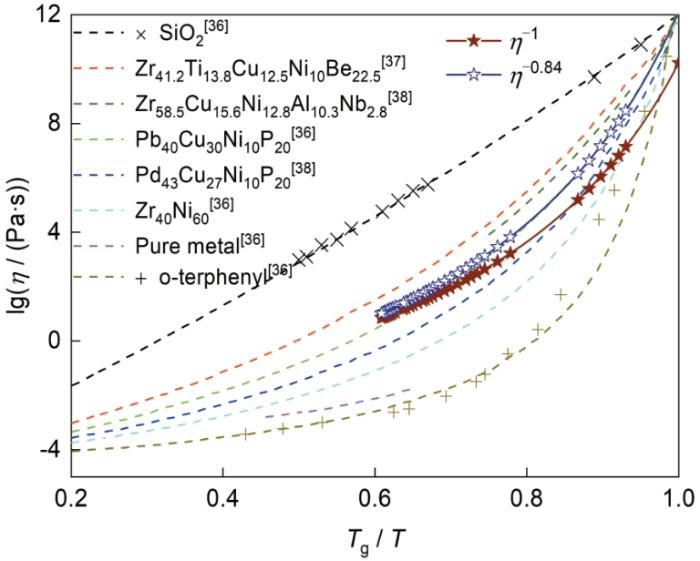

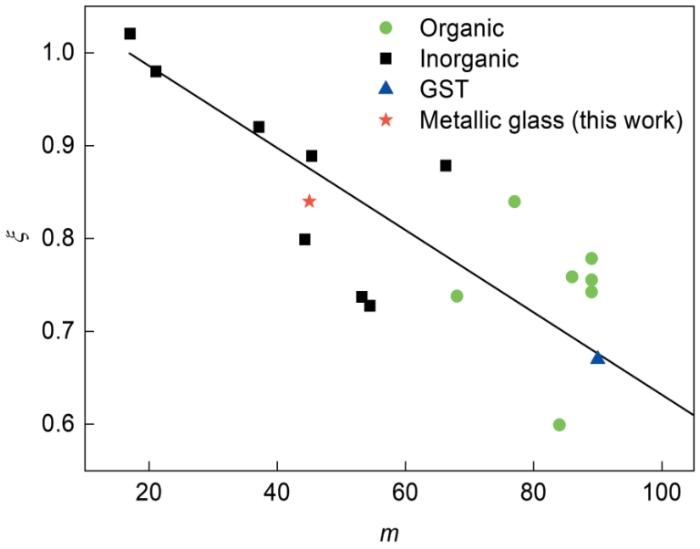

图6为玻璃形成熔体η随约化温度变化的Angell图,其中也包含了一些文献[36~38]中相关金属玻璃作为对比。在熔点附近的高温区域,Ukin ∝ η-1,但当温度逐渐降低接近Tg时,这种关系不再适用[20~23],晶体生长速率可能会变得比通过上述黏度关系预测得更快。本工作表明,Zr61Ti2Cu25Al12非晶合金在Tg处η较1012 Pa·s低2~3个数量级,如图6中η-1曲线所示,表明其生长动力学与黏性流动间发生了解耦,这与文献[22,39]所报道的部分材料在低温Tg附近不符合此关系相一致,这种解耦可能与D和η之间的Stokes-Einstein关系的破坏有关,当高温合金液冷却至Tg时,在过冷液体内的不同位置以不同速率发生局部结构弛豫,即动力学在空间上是不均匀的,这种非均匀性的一个体现即是D和η之间的解耦。进一步,Ediger等[22]提出这种解耦可以表示为:Ukin ∝ η-ξ,其中0 < ξ < 1,即通过引入解耦指数(ξ)使得此关系在高温区和低温区都能得到很好的符合,表明了Ukin对η的幂律依赖性。本工作引入ξ = 0.84对原曲线进行调整使得温度在接近Tg时η达到1012 Pa·s,从而在由高温到低温的整个温度范围内很好地描述η和T之间的依赖关系,如图6中η-0.84曲线所示。从某种意义上讲,ξ是作为一个与液体强度正相关的参数而被引入的,其值越大越接近1,液体强度越强越接近Arrhenius行为,其值越小越接近0,液体脆度越大越偏离Arrhenius行为。本工作的Zr61Ti2Cu25Al12非晶合金ξ为0.84,说明其过冷液体具有一定的强度,通过ξ调整后的曲线在Angell图中所处的位置可以看出,该合金属于中等强度非晶合金,其η与T之间的依赖关系与其他锆基体系相似,尤其是接近Tg附近时,曲线斜率所表示的m ≈ 45,介于2个锆基和2个钯基之间,而与较脆的Zr40Ni60和纯金属相差较远。

图6

图7

图7

解耦指数(ξ)与脆度系数(m)之间的关系

Fig.7

Decoupling exponent (ξ) representing the decoupling of crystal growth kinetics from viscous flow plotted as a function of the supercooled liquid m (GST—Ge2Sb2Te5)

4 结论

(1) 采用快速扫描量热和常规量热相结合的方法,对Zr61Ti2Cu25Al12非晶合金在5 × 10-2~5.5 × 104 K/s 6个数量级的Φh范围进行热流曲线测量,显示出其过冷液体随Φh变化的动力学行为:过冷液体的动力学行为滞后于温度的快速变化,在更高更宽的温度范围内,特征温度与Φh符合VFT方程。

(2) 相比于Tp附近高温的宽温度范围,Tg附近低温的窄温度范围内,Zr61Ti2Cu25Al12非晶合金过冷液体的结构变化较大,表现出更脆的液体行为,但从Tg到Tp的超宽温度范围来看,m的小幅变化(m = 35~47)意味着其过冷液体结构随温度变化比较平缓,从而表现出具有一定的“强”液体行为,使得该合金具有一定的玻璃形成能力;应用将玻璃化转变过程和晶化过程合并为单一转变过程的思想,通过时间维度坐标平移,得出从玻璃转变到熔点整个温度范围内的平均m ≈ 45。

(3) Zr61Ti2Cu25Al12非晶合金晶化过程中晶体生长的温度依赖性表明:生长激活能随温度升高逐渐降低,单位温度下的激活能约降为0.5 kJ/(mol·K);晶体生长动力学与黏性流动在Tg附近发生解耦,这可能与动力学在空间的不均匀性有关,通过引入指数ξ = 0.84使得过冷液体从高温到低温较宽的温度范围内很好地符合η与T的依赖关系。

参考文献

The nature and properties of amorphous matter

[J].

非晶态物质的本质和特性

[J].

Bulk glass-forming metallic alloys: Science and technology

[J].

High-temperature bulk metallic glasses developed by combinatorial methods

[J].

The elastic properties, elastic models and elastic perspectives of metallic glasses

[J].

Nanoindentation investigation on creep behavior of Zr-based bulk metallic glass

[J].

Microstructure and corrosion behavior of Fe-15Mn-5Si-14Cr-0.2C amorphous steel

[J].Amorphous steels exhibit ultra-high strength but room-temperature brittleness and strain-softening behavior as loading, which restricted the application of amorphous steels as high-performance structural material. Developing in situ crystals is an effective way to toughen the amorphous alloys. However, the crystals may sacrifice the corrosion resistance of amorphous steels. In this work, austenite and ferrite duel phases were introduced to the amorphous phase, via transformation induced plasticity (TRIP) of the austenite as loading, to enhance the ductility and improve the work-hardening behavior; and via the synergy of ferrite and amorphous phase to ensure the corrosion resistance. A novel amorphous steel Fe-15Mn-5Si-14Cr-0.2C was fabricated by magnetic suspension melting in a water-cooled copper crucible, and negative pressure suction casting into a copper mold. The microstructure and mechanical properties of the amorphous steel were characterized by XRD, EBSD and the electronic universal testing machine. The corrosion behavior in artificial seawater was studied on an electrochemical work station with a three-electrode system, and the corrosion morphology and corrosion products were characterized by SEM with EDS analysis. The results showed that the as-cast amorphous steel consisted of the amorphous matrix, CFe15.1 super-cooled austenite and Fe-Cr ferrite phases. From surface to inner, amorphous phases mainly exist in the margin, while crystalline phases are abundantly distributed in the center. The amorphous steel exhibited excellent comprehensive mechanical properties at room temperature, and its yield strength, fracture strength and plastic strain were up to 978 MPa, 2645 MPa and 35.8%, respectively. In artificial seawater, compared with 304 stainless steel, the amorphous steel showed high self-corrosion potential, low self-corrosion current density and high polarization resistance, large resistance arc radius, only one high frequency resistance arc and low corrosion kinetic rate. Moreover, the stable and dense passivation film was observed on the corrosion surface. Their excellent corrosion resistance and mechanical properties endow the amorphous steel with the potential to become a novel corrosion-resistant structural material for marine engineering.

Fe-15Mn-5Si-14Cr-0.2C非晶钢微观组织与腐蚀行为

[J].采用水冷铜坩埚磁悬浮熔炼-铜模负压吸铸法制备了Fe-15Mn-5Si-14Cr-0.2C非晶复合材料棒状试样,通过XRD和EBSD对合金的微观组织进行表征,并研究试样室温压缩力学性能;采用电化学工作站三电极体系测试试样在人工海水中的腐蚀行为,并利用SEM和EDS观察和分析电化学腐蚀后的形貌及腐蚀产物。结果表明,Fe-15Mn-5Si-14Cr-0.2C非晶复合材料试样组织由非晶相+晶体相(CFe15.1过冷奥氏体相和Fe-Cr铁素体相)组成,试样在室温环境下的综合力学性能优异,屈服强度、断裂强度和塑性应变分别为978 MPa、2645 MPa和35.8%。试样在人工海水中表现出良好的耐蚀性,与304不锈钢相比,Fe-15Mn-5Si-14Cr-0.2C非晶复合材料自腐蚀电位大,自腐蚀电流密度低,极化电阻高,容抗弧半径大且只有一个高频容抗弧,只受电极电位的影响,腐蚀的动力学速率低,钝化膜稳定致密,具有成为新一代海洋工程耐蚀材料的潜力。

Locating bulk metallic glasses with high fracture toughness: Chemical effects and composition optimization

[J].

Locating malleable bulk metallic glasses in Zr-Ti-Cu-Al alloys with calorimetric glass transition temperature as an indicator

[J].

Bending fatigue behavior of thin Zr61Ti2Cu25Al12 bulk metallic glass beams for compliant mechanisms application

[J].

Zr61Ti2Cu25Al12 metallic glass for potential use in dental implants: Biocompatibility assessment by in vitro cellular responses

[J].

Plastic rheological behaviors of Zr61Cu25Al12Ti2 and Zr52.5Cu17.9Ni14.6Al10Ti5 amorphous alloys in the supercooled liquid region

[J].

Zr61Cu25Al12Ti2和Zr52.5Cu17.9Ni14.6Al10-Ti5块体非晶合金过冷液相区的塑性流变行为

[J].

Reaction kinetics in differential thermal analysis

[J].

Glass transition on long time scales

[J].

Crystallization kinetics of an Au-based metallic glass upon ultrafast heating and cooling

[J].

Revealing glass transition and supercooled liquid in Ni80P20 metallic glass

[J].

非晶态Ni80P20合金的玻璃转变和过冷液体性质

[J].

Revealing hidden supercooled liquid states in Al-based metallic glasses by ultrafast scanning calorimetry: Approaching theoretical ceiling of liquid fragility

[J].

Characterization of supercooled liquid Ge2Sb2Te5 and its crystallization by ultrafast-heating calorimetry

[J].Differential scanning calorimetry (DSC) is widely used to study the stability of amorphous solids, characterizing the kinetics of crystallization close to the glass-transition temperature T(g). We apply ultrafast DSC to the phase-change material Ge(2)Sb(2)Te(5) (GST) and show that if the range of heating rates is extended to more than 10(4) K s(-1), the analysis can cover a wider temperature range, up to the point where the crystal growth rate approaches its maximum. The growth rates that can be characterized are some four orders of magnitude higher than in conventional DSC, reaching values relevant for the application of GST as a data-storage medium. The kinetic coefficient for crystal growth has a strongly non-Arrhenius temperature dependence, revealing that supercooled liquid GST has a high fragility. Near T(g) there is evidence for decoupling of the crystal-growth kinetics from viscous flow, matching the behaviour for a fragile liquid suggested by studies on oxide and organic systems.

Progress of differential scanning calorimetry and its application in polymer characterization

[J].

示差扫描量热法进展及其在高分子表征中的应用

[J].

Formation of glasses from liquids and biopolymers

[J].Glasses can be formed by many routes. In some cases, distinct polyamorphic forms are found. The normal mode of glass formation is cooling of a viscous liquid. Liquid behavior during cooling is classified between "strong" and "fragile," and the three canonical characteristics of relaxing liquids are correlated through the fragility. Strong liquids become fragile liquids on compression. In some cases, such conversions occur during cooling by a weak first-order transition. This behavior can be related to the polymorphism in a glass state through a recent simple modification of the van der Waals model for tetrahedrally bonded liquids. The sudden loss of some liquid degrees of freedom through such first-order transitions is suggestive of the polyamorphic transition between native and denatured hydrated proteins, which can be interpreted as single-chain glass-forming polymers plasticized by water and cross-linked by hydrogen bonds. The onset of a sharp change in d<r(2)>dT(<r(2)> is the Debye-Waller factor and T is temperature) in proteins, which is controversially indentified with the glass transition in liquids, is shown to be general for glass formers and observable in computer simulations of strong and fragile ionic liquids, where it proves to be close to the experimental glass transition temperature. The latter may originate in strong anharmonicity in modes ("bosons"), which permits the system to access multiple minima of its configuration space. These modes, the Kauzmann temperature T(K), and the fragility of the liquid, may thus be connected.

Kinetic stages in the crystallization of deeply undercooled body-centered-cubic and face-centered-cubic metals

[J].

Crystallization near glass transition: Transition from diffusion-controlled to diffusionless crystal growth studied with seven polymorphs

[J].

Crystal growth kinetics exhibit a fragility-dependent decoupling from viscosity

[J].

Does viscosity describe the kinetic barrier for crystal growth from the liquidus to the glass transition?

[J].

Fast scanning power compensated differential scanning nano-calorimeter: 1. The device

[J].

Fast scanning power compensated differential scanning nano-calorimeter: 2. Heat capacity analysis

[J].

Analysis of crystallization kinetics

[J].

The effect of scanning rate on glass transition temperature of splat-cooled Te85Ge15

[J].

The law of the relation between the viscosity of liquids and the temperature

[J].

Analysis of recent measurements of the viscosity of glasses

[J].

Die abhängigkeit der viscosität von der temperatur bei unterkühlten flüssigkeiten

[J].

Correlations of the nonexponentiality and state dependence of mechanical relaxations with bond connectivity in Ge-As-Se supercooled liquids

[J].

Thermal and viscoelastic properties of a strong bulk metallic glass former

[J].

A method for evaluating viscosities of metallic glasses from the rates of thermal transformations

[J].

Liquid-glass transition a free-volume approach

[J].

Thermodynamics of the glass transition: Empirical aspects

[J].

Thermodynamics and kinetics of bulk metallic glass

[J].

Equilibrium viscosity of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass-forming liquid and viscous flow during relaxation, phase separation, and primary crystallization

[J].

Kinetics, thermodynamics, and structure of bulk metallic glass forming liquids

[J].

Thermodynamic aspects of the vitrification of toluene, and xylene isomers, and the fragility of liquid hydrocarbons

[J].