Ti-Al基合金以其高强度、低密度以及优异的抗氧化性能被广泛应用于航空航天工业[1]。但是,Ti3Al基合金相对较差的成型性等问题限制了其进一步应用[2]。其中,合金成分设计及优化是克服这些问题的方法之一。Banerjee等[3]通过在Ti3Al基合金中添加Nb,制备出具有O相的Ti2AlNb合金。相比于传统的Ti-Al基合金相,Ti2AlNb合金具有更好的可加工性和比强度、优异的耐腐蚀性能和高温蠕变性能[4~9]。Ti-22Al-25Nb (原子分数,%,下同)合金是第二代Ti2AlNb合金,主要由B2相(有序bcc相)、α2相(hcp相,Ti3Al)和O相(有序正交相,Ti2AlNb)组成[10,11]。其中,B2相是该合金的基体相,一般认为是塑性相;O相是合金中的强化相;α2相是合金中的硬质相。在该合金中,O/α2相具有重要的析出强化作用,其中细针状的O/α2相有利于提高合金拉伸强度,而较粗的O/α2相有利于提升合金延展性[12~14]。

本工作采用SPS工艺制备了掺V的Ti2AlNb合金和作为对照的Ti2AlNb合金,并通过不同的热处理工艺获得了不同的显微组织。通过分析析出相尺寸和各相体积分数,研究了显微组织与热处理工艺之间的关系。此外,还探讨了掺V合金在时效处理后弯曲组织的形成机制,解释了V的添加对Ti2AlNb合金力学性能的影响机制。

1 实验方法

Ti-22Al-25Nb合金的硬度随V添加量的增加(0~4%,原子分数)先上升后下降,当V含量为1%时,合金的硬度达到峰值[28]。因此,本工作将1%的V粉末(直径约为80 μm,纯度为99.99%)加入雾化制粉法制备的Ti-22Al-25Nb预合金粉末(粒径约为170 μm)中,并将2种粉末混合得到名义成分为Ti-22Al-25Nb-1V的混合粉末。将混合粉末置于QM-3SP4行星球磨机中,在高纯Ar气保护下以400 r/min的转速下球磨10 h,球料比15∶1。

将混合粉末放在石墨模具中,利用Dr. Sinter SPS-625放电等离子烧结设备在Ar气气氛保护下升温到1100 ℃后保温10 min,加热速率为100 ℃/min,烧结压力为40 MPa,保温后随炉冷却。最后得到直径20 mm、长10 mm的圆柱形块体。同时制备了名义成分为Ti-22Al-25Nb的合金作为对比样,以研究V对Ti2AlNb合金显微组织和硬度的影响。热处理实验在SK-G06123K管式炉中进行,2种合金均在1300 ℃保温4 h,然后水淬,随后在800、850、900、950、1000和1050 ℃时效2 h后水淬。为了避免合金在热处理过程中被空气氧化,所有试样在热处理前均采用石英管密封处理。

采用D8 Advanced X射线衍射仪(XRD)和S-4800扫描电镜(SEM)表征合金的微观组织。XRD表征所用试样通过将合金表面用砂纸逐级打磨至3000号制得。SEM表征所用试样需用砂纸将表面逐级打磨至7000号后进行机械抛光,抛光至无明显划痕后使用Kroll试剂对合金表面进行腐蚀。使用JEM-2100F透射电子显微镜(TEM)观察和分析合金中B2相、O相和α2相之间的取向关系和微观结构,并利用TEM选区电子衍射(SAED)和能谱仪(EDS)确定析出相类型。TEM表征所用试样采用线切割从合金上切取厚度为300 μm的薄片,通过砂纸逐级打磨减薄至50 μm厚,随后冲成直径3 mm的圆片,最后经Gatan 691离子减薄仪减薄制得TEM试样。利用Sigma 300热场SEM配备的电子背散射衍射(EBSD)对相分布进行表征,EBSD分析所用试样为线切割所得试样经砂纸逐级打磨后机械抛光,之后用Model 1061 SEM Mill离子束切割抛光仪进行离子抛光制得。合金的析出相尺寸和晶粒尺寸利用Image-Pro Plus软件统计。显微硬度测试在NH-6L型显微硬度计上完成,所用载荷为0.2 kg,保压时间5 s。

2 实验结果

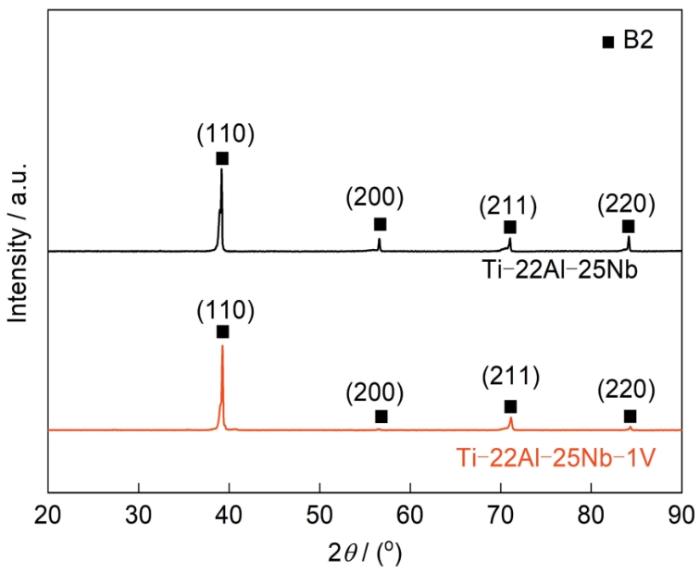

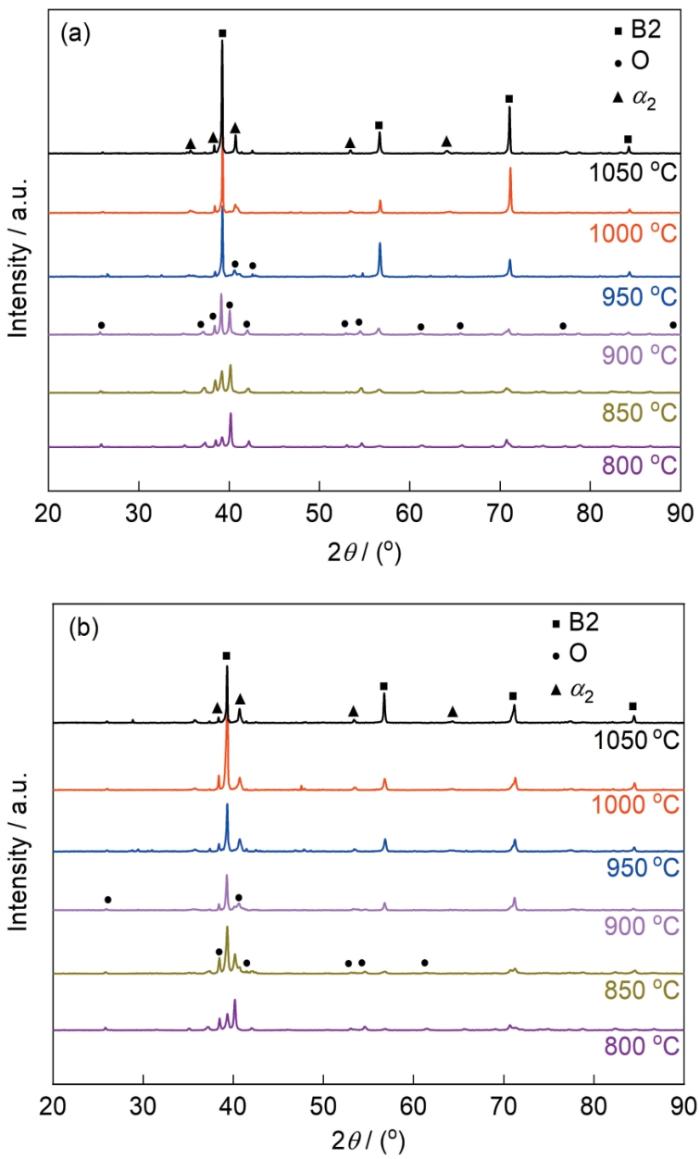

烧结后Ti-22Al-25Nb和Ti-22Al-25Nb-1V试样的真实化学成分如表1所示。可以看出,试样的真实化学成分基本符合名义成分。图1为2种合金在1300 ℃固溶后的XRD谱。可以看出,2种合金在1300 ℃固溶后均仅有B2基体相,未出现V单质的特征峰,说明V原子完全固溶于基体中。掺V合金的B2相(200)晶面特征峰强度减小,说明V原子的固溶可能引起了B2相的晶格畸变。时效处理后2种合金的XRD谱如图2所示。可以看出,2种合金在1000~1050 ℃时效后,除了B2基体相外,还出现了α2相的衍射峰。未掺V合金在时效温度为950 ℃时出现了O相衍射峰,此时未掺V合金包含B2相、α2相和O相。而掺V合金在时效温度为900 ℃时析出O相。这表明未掺V合金的B2 + α2两相区和B2 + α2 + O三相区的温度界线在950~1000 ℃之间,而掺V合金其界线在900~950 ℃之间,掺V合金的O相析出温度低于未掺V合金。

表1 Ti-22Al-25Nb和Ti-22Al-25Nb-1V烧结试样的真实化学成分 (atomic fraction / %)

Table 1

| Sample | Al | Nb | V | Ti |

|---|---|---|---|---|

| Ti-22Al-25Nb | 22.11 | 25.21 | - | Bal. |

| Ti-22Al-25Nb-1V | 22.06 | 25.23 | 0.95 | Bal. |

图1

图1

Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金1300 ℃固溶后的XRD谱

Fig.1

XRD spectra of Ti-22Al-25Nb and Ti-22Al-25Nb-1V alloys after solution treatment at 1300 ºC

图2

图2

Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金在不同温度时效处理后的XRD谱

Fig.2

XRD spectra of Ti-22Al-25Nb (a) and Ti-22Al-25Nb-1V (b) alloys after solution treatment at 1300 ºC and aging at different temperatures

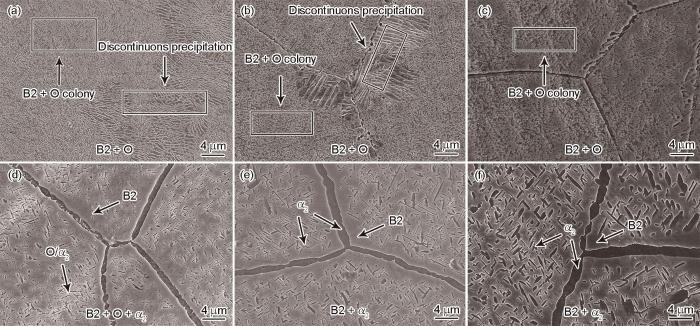

图3为Ti-22Al-25Nb合金经时效处理后的SEM像。结合图2a可以发现,未掺V合金在800~900 ℃时效时,合金组织由B2 + O相组成,其中O相以B2 + O魏氏板条组织的形式析出(图3a~c)。当时效温度为950 ℃时,未掺V合金组织由B2、O和α2三相组成(图3d),合金中开始出现细小短棒状α2相,而O相在α2相周边析出,共同以短棒状O/α2相随机分布在整个B2相基体中。当时效温度为1000~1050 ℃时,未掺V合金组织由B2相和α2相组成,其中α2相以2种形式存在:一种在晶界处;另一种以短棒状(灰黑色部分)随机分布在B2相基体中(图3e和f)。随着时效温度的升高,合金晶界处α2相厚度逐渐变大,短棒状析出物逐渐变粗。未掺V合金在850 ℃时效2 h后,晶界附近发生了层状不连续析出,在下文被证明为β + O相的层状结构。

图3

图3

Ti-22Al-25Nb合金经过不同温度时效处理后的SEM像

Fig.3

SEM images of the Ti-22Al-25Nb alloy after solution treatment at 1300 ºC and aging at 800 ºC (a), 850 ºC (b), 900 ºC (c), 950 ºC (d), 1000 ºC (e), and 1050 ºC (f)

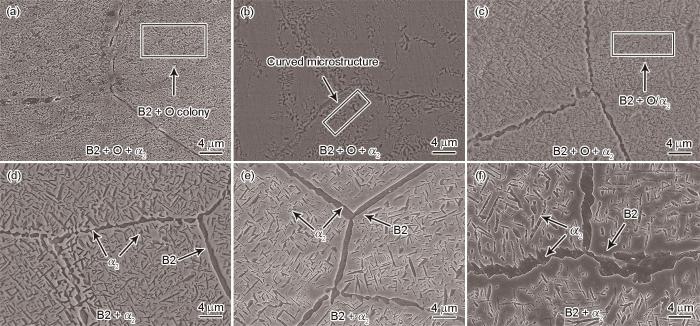

图4为Ti-22Al-25Nb-1V合金经时效处理后的SEM像。当时效温度低于900 ℃时,合金组织主要由B2和O相组成,O相主要以B2 + O魏氏板条组织存在(图4a和b),这表明在时效处理过程中发生了B2 → O + B2相变[29]。与未掺V合金的时效析出行为不同的是,掺V合金在800~900 ℃时效处理后仍然保留了少量α2相,这些α2相主要存在于晶界附近。当时效温度超过900 ℃时(图4c~f),合金中析出大量短棒状O/α2相,这些相均匀分布在B2相基体内部。在相同热处理条件下,相比于未掺V合金,掺V合金析出的O/α2相更细,分布更均匀和密集。总体来说,B2相基体内的析出相随着时效温度的不同发生变化,在1050 ℃时效时为较粗短棒状α2相,950 ℃时效时析出相为细针状O/α2相,而800 ℃时效时析出相为B2 + O魏氏板条组织。与未掺V合金相似的是,合金晶界α2相厚度和短棒状析出物尺寸也随着时效温度升高而变大。此外,掺V合金在时效处理后的晶界附近观察到弯曲组织(图4b)。

图4

图4

Ti-22Al-25Nb-1V合金经过不同温度时效处理的SEM像

Fig.4

SEM images of the Ti-22Al-25Nb-1V alloys after solution treatment at 1300 ºC and aging at 800 ºC (a), 850 ºC (b), 900 ºC (c), 950 ºC (d), 1000 ºC (e), and 1050 ºC (f)

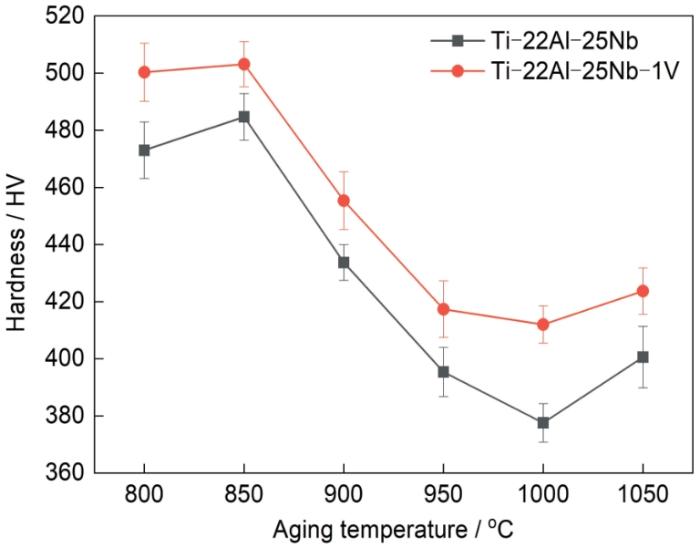

图5为Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金在不同时效温度下的Vickers硬度变化曲线。在相同的热处理条件下,掺V合金相比未掺V合金表现出更高的硬度。2种合金的硬度随时效温度变化的趋势相似:随着时效温度的升高,合金的硬度逐渐增加,在时效温度为850 ℃时达到峰值。进一步升高时效温度将导致硬度急剧下降,且在950~1050 ℃时效后可能趋于平稳。

图5

图5

Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金Vickers硬度随时效温度的变化

Fig.5

Vickers hardnesses of the Ti-22Al-25Nb and Ti-22Al-25Nb-1V alloys after solution treatment at 1300 ºC and aging at 800-1050 ºC

3 分析讨论

表2 1300 ℃固溶处理和不同温度时效后Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金中B2、O和α2相的体积分数 (%)

Table 2

| Temperature / oC | Alloy | B2 phase | O phase | α2 phase |

|---|---|---|---|---|

| 800 | Ti-22Al-25Nb | 18.33 | 81.67 | - |

| Ti-22Al-25Nb-1V | 21.33 | 73.68 | 4.99 | |

| 850 | Ti-22Al-25Nb | 27.93 | 72.07 | - |

| Ti-22Al-25Nb-1V | 38.80 | 51.22 | 9.98 | |

| 900 | Ti-22Al-25Nb | 42.03 | 57.97 | - |

| Ti-22Al-25Nb-1V | 49.62 | 31.08 | 19.30 | |

| 950 | Ti-22Al-25Nb | 71.81 | 14.71 | 13.48 |

| Ti-22Al-25Nb-1V | 74.48 | - | 25.52 | |

| 1000 | Ti-22Al-25Nb | 81.53 | - | 18.47 |

| Ti-22Al-25Nb-1V | 85.03 | - | 14.97 | |

| 1050 | Ti-22Al-25Nb | 84.04 | - | 15.96 |

| Ti-22Al-25Nb-1V | 80.91 | - | 19.09 |

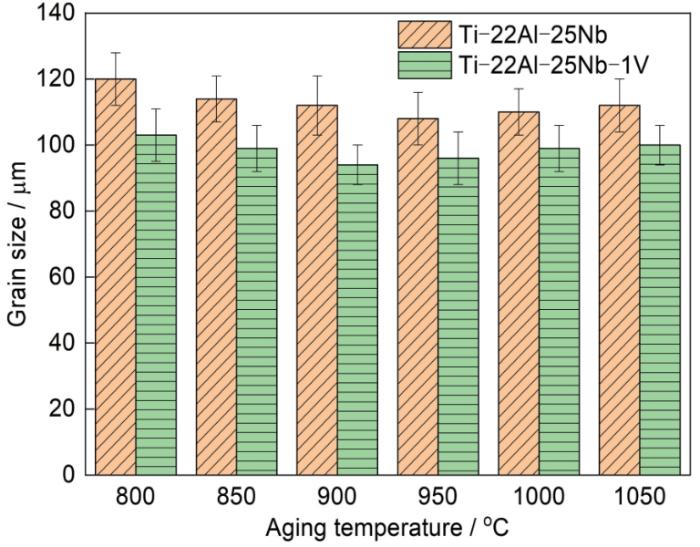

图6

图6

Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金B2相晶粒尺寸随时效温度的变化

Fig.6

B2 phase grain sizes of the Ti-22Al-25Nb and Ti-22Al-25Nb-1V alloys after solution treatment at 1300 ºC and aging at different temperatures

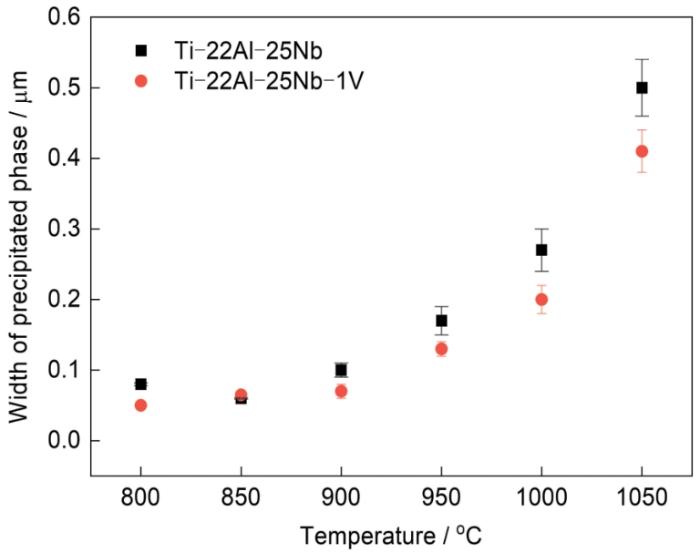

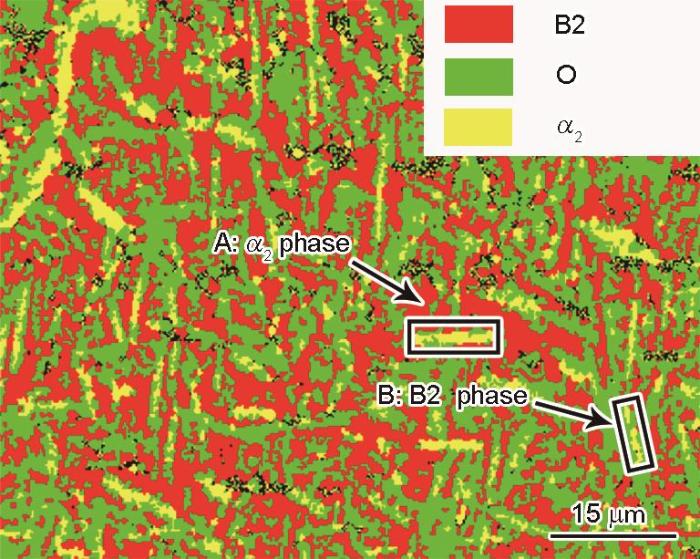

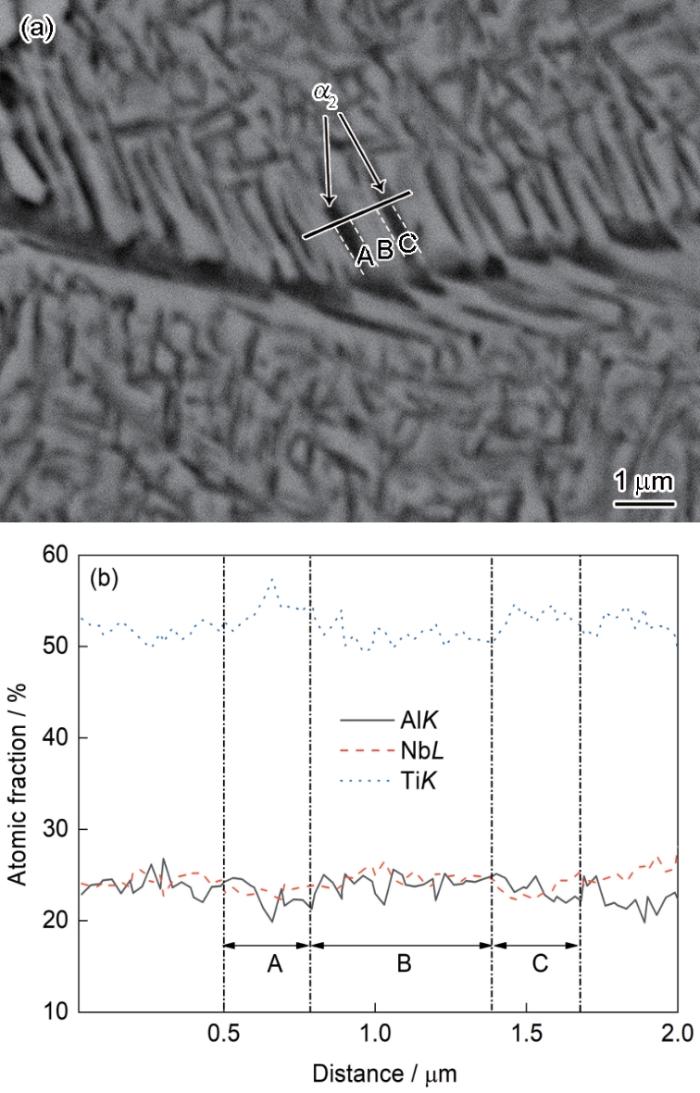

此外,析出相的形貌和尺寸也会对合金的硬度产生影响。对Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金析出相的尺寸进行统计,结果如图7所示。随着时效温度的降低,晶粒内的析出相尺寸逐渐变小。从较粗的短棒状α2相,到细针状O/α2相,最后变为均匀析出在B2相基体中的板条O相。在同一热处理条件下,由于V的添加稳定了B2相,抑制了B2 + α2 → O转变,进而细化了析出相[30,31],使得掺V合金的显微硬度高于未掺V合金。研究[32]指出,析出相的逐渐细化主要是由于Nb原子扩散诱导的B2 + α2 → O相变所致。图8为Ti-22Al-25Nb-1V合金在900 ℃时效后的相分布图,可以解释α2相这种细化过程。图8中箭头A所示为较大的初始短棒状α2相,周围为B2基体,随着B2 + α2 → O转变,短棒状α2相周围逐渐变成O相,α2相变细(如图8中箭头B所示),最后α2相完全转变为O相。图9为Ti-22Al-25Nb-1V合金在900 ℃时效后的SEM背散射电子(BSE)像以及相应的EDS线扫结果。其中图9a的衬度主要与材料中元素的原子序数相关,含Nb量越高,衬度越亮。α2相含Nb较少,其在图9a中呈灰黑色。通过对相邻α2相进行线扫描可以发现,在α2相之间的Nb含量较高。而B2 + α2 → O相变主要由Nb在α2相中的畸变能驱动[32]。由此可以推测Nb对O相形成的作用:随着Nb原子扩散,短棒状α2相中Nb过饱和,晶格无法保持hcp结构,Nb向周围扩散逐渐形成富Nb区。当α2相周围Nb浓度达到临界值时,α2相由hcp结构转变为正交结构,将诱发O相形成[33]。最终B2相基体中的Nb扩散至剩余的α2相(贫Nb),发生B2 + α2 → O转变,O相最终由Nb扩散而诱发形成。

图7

图7

Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金析出相尺寸随时效温度的变化

Fig.7

Widths of the precipitated phase of the Ti-22Al-25Nb and Ti-22Al-25Nb-1V alloys after solution treatment at 1300 ºC and aging at different temperatures

图8

图8

Ti-22Al-25Nb-1V合金在900 ℃时效后的相分布图

Fig.8

Phase map of the Ti-22Al-25Nb-1V alloy after solution treatment at 1300 ºC and aging at 900 ºC

图9

图9

Ti-22Al-25Nb-1V合金在900 ℃时效后的SEM背散射电子(BSE)像以及相应的EDS线扫描结果

Fig.9

SEM backscattered electron (BSE) image (a) and corresponding linear scan analyses alone the line in Fig.9a (b) of the Ti-22Al-25Nb-1V alloy after solution treatment at 1300 ºC and aging at 900 ºC

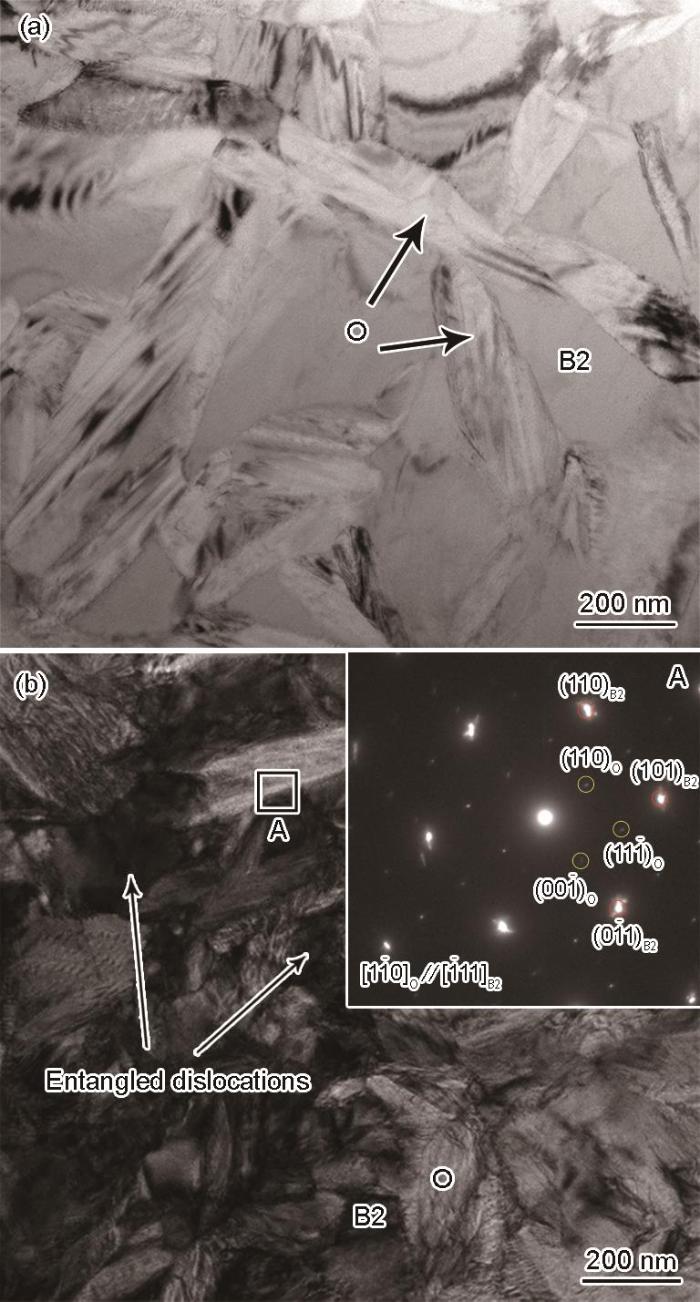

在800 ℃进行时效处理时,虽然掺V合金的O相含量低于未掺V合金,但魏氏板条中O相宽度的减小有助于提高其硬度。值得注意的是,在850 ℃时效处理时,相比于未掺V合金,掺V合金的O相含量更低(表2),并且析出相的尺寸略大(图7),这本应导致硬度降低。然而,掺V合金的硬度反而高。这可能是由于V的添加可能会引起晶格畸变和位错,进而影响显微硬度。因此对Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金在850 ℃时效后的组织进行了TEM表征,结果如图10所示。2种合金组织均以B2 + O相为主,其中浅色部分为O相,深色部分为B2相。O相以针状均匀分布在B2相基体中。相比于未掺V合金,掺V合金的针状O相密度更高。如图10a所示,在未掺V合金中,未观察到明显的位错等晶体缺陷。而在掺V合金中存在明显的位错缠结(图10b),这表明V的添加可能导致合金中B2相的晶格畸变,从而诱导更高的位错密度。因此,掺V合金表现出了更高的硬度。从图10b中对应A区的SAED花样(图10b中插图)可以看出,B2相与O相的取向关系为经典的Burgers取向关系:(001)O//(011)B2和[

图10

图10

Ti-22Al-25Nb和Ti-22Al-25Nb-1V合金在850 ℃时效后的TEM像

Fig.10

TEM images of Ti-22Al-25Nb (a) and Ti-22Al-25Nb-1V (b) alloys after solution treatment at 1300 ºC and aging at 850 ºC (Inset in Fig.11b shows the SAED pattern of region A)

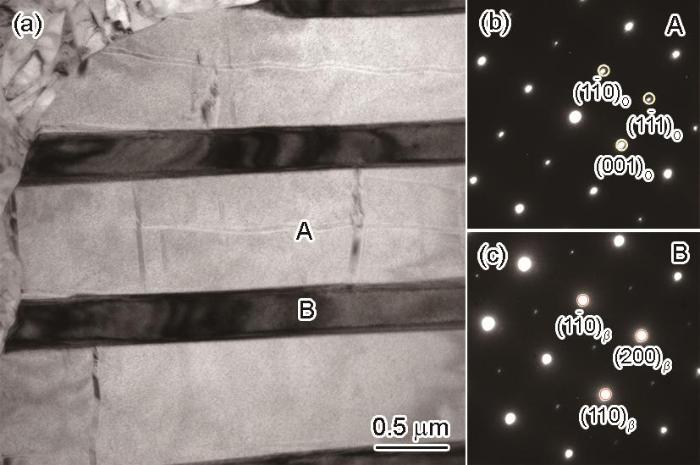

图3和4表明,在800和850 ℃时效处理后的合金组织中还分别存在着不连续析出组织和弯曲组织,这可能是造成其显微硬度差异的原因之一。图11和12分别为这2种组织的TEM表征结果。研究[32]表明,在较高的固溶温度和较低的时效温度下,在B2/O相附近的晶界处会发生不连续析出。为了研究这种层状不连续析出组织的组成和微观结构,对Ti-22Al-25Nb合金进行了TEM分析,结果如图11所示。图11a所示为层状不连续析出结构的TEM明场像,结合图11b和c所示的SAED花样分析结果,可以确定浅色区域A为O相,深色区域B为β相,这种层状结构为β + O相,其中β相(无序bcc相)与B2相(过饱和有序bcc相)结构相似,但其Al溶质热力学过剩较少。与掺V合金相比,850 ℃时效后的未掺V合金具有较高的O相含量和较小的析出相尺寸,但其硬度更低,表明层状不连续析出将降低合金的硬度。

图11

图11

Ti-22Al-25Nb合金中不连续析出组织的TEM分析

Fig.11

TEM bright field image (a) and corresponding SAED patterns of regions A (b) and B (c) in Fig.11a showing the discontinuous microstructure for the Ti-22Al-25Nb alloy after solution treatment at 1300 ºC and aging at 850 ºC

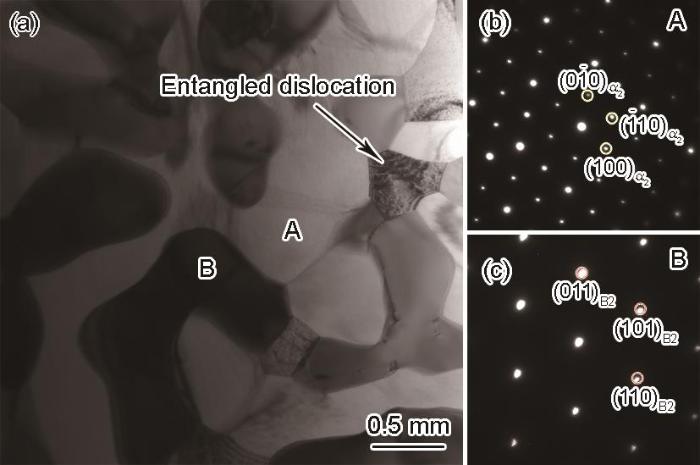

图12

图12

Ti-22Al-25Nb-1V合金中弯曲组织的TEM分析

Fig.12

TEM image (a) and corresponding SAED patterns of regions A (b) and B (c) in Fig.12a showing the curved microstructure for the Ti-22Al-25Nb-1V alloy after solution treatment at 1300 ºC and aging at 850 ºC

在弯曲组织中存在位错缠结(图12a),这可能与B2相中的晶格畸变有关。当V掺入Ti2AlNb合金中时,它可比Nb更有效地稳定B2相。具体而言,添加1%V相当于替换1.58%的Nb[26,34]。由于V的原子半径(0.134 nm)小于Nb的原子半径(0.146 nm),在B2相中V替代Nb会对晶格产生影响,引起晶格畸变。根据图2,通过Rietveld精修计算得到时效处理后B2相的晶面间距和晶格参数(表3)。计算结果证实,固溶时效处理后合金的B2相晶格常数和(110)、(200)及(211)晶面间距减小:晶格常数的减小说明V溶入B2相中;(110)晶面间距比(200)和(211)晶面减小幅度更大,表明bcc结构B2相晶格中V的分布表现出各向异性。这种各向异性可能导致B2相的结构和析出相形态发生变化。

表3 不同时效处理后合金中B2相晶格常数与晶面间距

Table 3

| Temperature / oC | Alloy | a / nm | d(110) / nm | d(200) / nm | d(211) / nm |

|---|---|---|---|---|---|

| 800 | Ti-22Al-25Nb | 0.32518 | 0.22994 | 0.16259 | 0.13275 |

| Ti-22Al-25Nb-1V | 0.32455 | 0.22949 | 0.16227 | 0.13250 | |

| 850 | Ti-22Al-25Nb | 0.32512 | 0.22989 | 0.16256 | 0.13273 |

| Ti-22Al-25Nb-1V | 0.32455 | 0.22949 | 0.16227 | 0.13250 | |

| 900 | Ti-22Al-25Nb | 0.32506 | 0.22985 | 0.16253 | 0.13271 |

| Ti-22Al-25Nb-1V | 0.32398 | 0.22909 | 0.16199 | 0.13226 | |

| 950 | Ti-22Al-25Nb | 0.32428 | 0.22930 | 0.16214 | 0.13239 |

| Ti-22Al-25Nb-1V | 0.32368 | 0.22888 | 0.16184 | 0.13214 | |

| 1000 | Ti-22Al-25Nb | 0.32413 | 0.22919 | 0.16206 | 0.13232 |

| Ti-22Al-25Nb-1V | 0.32365 | 0.22886 | 0.16182 | 0.13213 | |

| 1050 | Ti-22Al-25Nb | 0.32446 | 0.22943 | 0.16223 | 0.13246 |

| Ti-22Al-25Nb-1V | 0.32398 | 0.22909 | 0.16199 | 0.13226 |

4 结论

(1) Ti-22Al-25Nb-1V合金的Vickers硬度得到提升,这主要是由于V的添加留下更多可钉扎晶界的α2相使得B2晶粒细化,另外V的添加可以稳定Ti2AlNb中的B2相,抑制B2 + α2 → O相变,使得O/α2相得到细化。

(2) Ti-22Al-25Nb合金中产生β + O相的层状不连续析出,V的添加可以减少这种不连续析出。V和Nb会在B2相中偏析诱导形成弯曲组织B2 (富Nb和V) + α2 (贫Nb和V),从而进一步增强掺V合金的硬度。

(3) 在B2相晶格中引入V会导致晶格畸变以及各向异性。晶格畸变使得位错密度增加,晶格各向异性导致B2相的结构和析出相形态发生变化,这些都将提高Ti-22Al-25Nb-1V合金的硬度。

参考文献

High-strength titanium-based alloy for low-temperature superplastic forming

[J].

Microstructural modulation of TiAl alloys for controlling ultra-precision machinability

[J].

A new ordered orthorhombic phase in a Ti3Al-Nb alloy

[J].

Microstructure evolution and phase transformations in Ti-22Al-25Nb alloys tailored by super-transus solution treatment

[J].

Formation of diverse B2 + O structure and hardness of Mo-modified Ti-22Al-25Nb alloys upon cooling

[J].

Effect of the primary O phase on thermal deformation behavior of a Ti2AlNb-based alloy

[J].

Quasi cleavage fracture of the bimodal size lamellar O phase microstructure of a Ti2AlNb-based alloy

[J].

Thermal stability of microstructures in low-density Ti2AlNb-based alloy hot rolled plate

[J].

低密度Ti2AlNb基合金热轧板微观组织的热稳定性

[J].采用OM、SEM、XRD和TEM研究了低密度Ti2AlNb基合金热轧板在600~1100℃保温12 h微观组织的热稳定性。结果表明,Ti2AlNb基合金原始态热轧板主要由α2、B2以及O相组成,颗粒状的α2相分布在B2相基体中。Ti2AlNb基合金热轧板600℃保温12 h,颗粒状的α2相分布在B2相基体中,B2相基体中分布着大量细小的O相板条。随着温度的升高,合金热轧板800~900℃保温12 h的微观组织由α2、B2以及O相三相构成,α2相颗粒逐渐球化,O相板条粗化并固溶于B2相基体中。当温度升高至950℃时,B2相基体中的O相板条消失。合金热轧板在950~1000℃保温12 h形成α2 + B2两相区,α2相颗粒球化并趋向于分布在B2相基体的晶界处。当温度升高至1100℃时,合金基体为B2单相,B2晶界处分布着极少量的残留α2相颗粒。Vickes显微硬度分布结果显示,随着温度的升高,合金板材在600℃时硬度达到峰值(509 HV),这与大量细小的O相板条有关。

Synthesis, structure and mechanical properties of Ti-Al-Nb coatings formed by electron beam additive technique

[J].

Orthorhombic phase transformations in titanium alloys and their applications

[J].The link and difference between orthorhombic phase transformations in <em>β</em>-type titanium alloys and in Ti3Al containing high concentrations of transition metal elements such as Nb are first outlined in this paper. Recent investigations on these transformations conducted in the authors' group are reviewed followed by discussions of remaining problems. Three examples were presented to illustrate the applications of the orthorhombic phase transformations: design and development of superelastic titanium alloys for biomedical use, preparation of ultra-fine basketweave microstructure of titanium alloy wire for fastener manufacturing, and sheet and foil production of alloys based on Ti2AlNb.

钛合金中的正交相变及其应用

[J].

Annealing response of the intermetallic alloy Ti-22Al-25Nb

[J].

Microstructural evolution and tensile behavior of Ti2AlNb alloys based α2-phase decomposition

[J].

Morphology and quantitative analysis of O phase during heat treatment of hot-deformed Ti2AlNb-based alloy

[J].

Fabrication of a powder metallurgy Ti2AlNb-based alloy by spark plasma sintering and associated microstructure optimization

[J].

Phase transformation and microstructure control of Ti2AlNb-based alloys: A review

[J].

Mechanical properties of the Ti2AlNb intermetallic: A review

[J].

Orthorhombic precipitate variant selection in a Ti2AlNb based alloy

[J].

Effect of cooling rate on phase transformation in Ti2AlNb alloy

[J].

Densification mechanism of Ti-Al-Nb alloys pressurelessly sintered from Al-Nb master alloy powder for cost-effective manufacturing

[J].

Mechanical behaviour of induction sintered blended elemental powder metallurgy Ti alloys

[J].

Powder metallurgy of titanium—Past, present, and future

[J].

High-temperature deformation behavior of the extruded Ti-22Al-25Nb alloy fabricated by powder metallurgy

[J].

Fabrication of a high strength and ductility Ti-22Al-25Nb alloy from high energy ball-milled powder by spark plasma sintering

[J].

Influence of mechanical alloying on the microstructure and mechanical properties of powder metallurgy Ti2AlNb-based alloy

[J].

Improvement of room temperature ductility for Mo and Fe modified Ti2AlNb alloy

[J].

The effect of quaternary additions on the microstructures and mechanical properties of orthorhombic Ti2AlNb-based alloys

[J].

Deformation kinking in duplex titanium alloy with widmannstatten laths under high strain rates

[J].

On the B2 → O phase transformation in Ti-Al-Nb alloys

[J].

Mechanism and morphology evolution of the O phase transformation in Ti-22Al-25Nb alloy

[J].

Research on hot deformation behavior of Mo‐containing Ti2AlNb‐based alloy

[J].

Plastic deformation mechanism and interaction of B2, α2, and O phases in Ti-22Al-25Nb alloy at room temperature

[J].

Microstructural evolution and creep deformation behavior of novel Ti-22Al-25Nb-1Mo-1V-1Zr-0.2Si (at.%) orthorhombic alloy

[J].

Effects of plastic deformation and aging treatment on phase precipitation in Ti2AlNb Alloy

[J].