作为一种天然存在的金属元素,Nb具有一定的延展性、可塑性和高度耐腐蚀性。含Nb高性能钢被广泛地应用于航空航天、汽车与交通、能源及建筑工程等高端制造领域[1~3],钢中Nb元素以固溶体和沉淀形式存在[4~6]。固溶Nb能阻止奥氏体晶粒的长大,抑制形变奥氏体发生再结晶。作为一种强碳化物形成元素,Nb易生成碳化物,弥散分布在基体中,起到相变强化、沉淀硬化和晶粒细化等重要作用。Nb元素的平衡分配系数小于1,属于正偏析元素,在钢液凝固过程中偏聚于液相,与偏聚的C元素生成液析碳化物[7]。这类碳化物的热稳定性高,在均匀退火及热处理过程中不能完全消除[8],在再加热过程中无法起到钉扎奥氏体晶界、阻止奥氏体晶粒长大的作用。液析碳化物影响了Nb元素在基体中的固溶效果,对后续淬火/回火过程中细小二次碳化物的析出不利。液析碳化物的存在破坏了钢基体的连续性,降低了材料的强度和韧性。在外力作用下,液析碳化物会成为裂纹源,降低钢的使用寿命[9,10]。为了改善液析碳化物,研究铌合金钢凝固过程中的析出特性和微观偏析是非常有必要的。

研究者们基于密度泛函理论的第一性原理从原子尺度对析出行为进行了广泛的研究,将0 K、0 Pa下的形成能作为判断析出物热力学稳定性的依据[11,12],分析析出物的析出顺序[12]。但是析出物的实际生成并不在0 K条件下,因此有必要研究温度对Gibbs自由能改变量(ΔG)的影响[13],综合考虑基态能量(热力学温度T = 0 K)、晶格振动、电子和磁性对自由能的贡献。Klymko和Sluiter[14]采用第一性原理与简谐近似相结合的方法研究了不同温度下形成NbC时自由能的改变,简谐近似利用平衡体积下的声子谱得到振动自由能随温度的变化,忽略了体积对温度的依赖,这将影响振动自由能的准确性[15]。目前,基于密度泛函理论的第一性原理与准谐Debye模型相结合的方法是计算晶格振动自由能的有效手段之一[16]。

在钢液凝固过程中,溶质元素在固/液相之间重新分配,产生偏析。常见的微观偏析理论模型有Level rule模型[17]、Scheil模型[18]、Brody-Fleming模型[19]、Ohnaka模型[20]、Clyne-Kurz模型[21]和Voller-Beckermann模型[22,23]等。平衡凝固条件下固相中溶质质量分数与液相中溶质质量分数的比值称为溶质平衡分配系数(k),该参数决定了凝固过程中溶质元素在固/液相间的再分配,是微观偏析模型中的重要参数。这些理论模型只考虑了液相与一种固相的转变,因此将溶质平衡分配系数视作一个常数,且只考虑了溶质元素在单一固相中的扩散。凝固过程中的相变受到钢原始成分的影响,相变路径不单一,因此为了提高模型预测的准确度,对微观偏析模型的修正具有现实意义。

本工作以中碳Nb合金化钢为研究对象,分析Nb含量对液析碳化物NbC形貌和分布特征的影响。将基于密度泛函理论的第一性原理与准谐Debye模型相结合,定量分析析出NbC的ΔG随温度的变化,对比晶格振动和电子对ΔG的贡献。并建立了耦合凝固相变的微观偏析模型,分析凝固过程中的L + δ→L + γ相变对中碳Nb合金化钢溶质元素偏析的影响,研究凝固过程中Nb含量对δ/γ相变点以及液析碳化物NbC析出行为的影响。本工作旨在为理解高温下初生NbC碳化物的沉淀行为提供坚实的理论基础。

1 实验方法

1.1 实验材料

本实验设计了4种Nb含量的中碳钢,其化学成分如表1所示。成分设计的原则是保证C和Mn的含量相同,改变Nb含量,4种钢分别命名为0.1Nb、0.6Nb、1.1Nb和1.6Nb。实验材料以高纯金属和电解铁为原材料,经真空冶炼后浇铸为钢锭,将钢锭在1200~1250 ℃保温一段时间后轧制成尺寸为170 mm × 20 mm的热轧板材。利用线切割从板材上切下尺寸为20 mm × 20 mm × 120 mm的试样,并密封于耐高温的真空石英管内,将石英管置于高温热处理加热炉中随炉升温至1200 ℃并保温48 h,进行均匀化退火。将均匀化后的样品加工成直径6 mm、长70 mm的试样,在Gleeble 3800热模拟试验机上以10 ℃/s的加热速率升温到1250 ℃,保温300 s,再以0.1 ℃/s冷速冷却至室温。然后将试样切割、镶样,经磨抛后用4% (体积分数)硝酸酒精溶液腐蚀,采用MERLIN Compact扫描电镜(SEM)观察液析碳化物的形貌及分布。从样品横截面截取透射电镜(TEM)试样,采用Talos F200X TEM观察析出物形貌,通过附带的能谱仪(EDS)面扫功能得到析出物的元素分布情况。

表1 实验用钢的化学成分 (mass fraction / %)

Table 1

| Sample | C | Mn | Nb | P | S | Fe |

|---|---|---|---|---|---|---|

| 0.1Nb | 0.2 | 2.0 | 0.1 | < 0.005 | < 0.005 | Bal. |

| 0.6Nb | 0.2 | 2.0 | 0.6 | < 0.005 | < 0.005 | Bal. |

| 1.1Nb | 0.2 | 2.0 | 1.1 | < 0.005 | < 0.005 | Bal. |

| 1.6Nb | 0.2 | 2.0 | 1.6 | < 0.005 | < 0.005 | Bal. |

1.2 第一性原理与准谐Debye模型的结合

1.2.1 理论方法体系

Gibbs自由能改变量用于评估化合物AmBn (m和n分别是A和B原子的个数)的热力学稳定性。ΔG为负值代表化合物的形成会释放能量,AmBn 为稳定相;ΔG为正值代表化合物的形成会吸收能量,AmBn 为非稳定相。ΔG的计算公式如下:

式中,

晶格振动、热电子激发和系统磁性都会对Gibbs自由能作出贡献[24],本工作的对象是无磁性的,因此只需考虑晶格振动和电子对Gibbs自由能的影响:

联立

式中,ΔE0是0 K时的形成能;ΔGvib(T)和ΔGel(T)分别为不同温度下晶格振动和电子引起的自由能的改变量,体现了晶格振动和电子对体系总能量变化的贡献。

1.2.2 计算细节和晶体结构

基态能量以及电子结构采用基于第一性原理密度泛函理论的Vienna ab initio simulation package (VASP)软件包计算[28]。分别采用投影缀加平面波和广义梯度近似(GGA)的Perdew-Burke-Ernzerhof泛函[29]来描述电子与离子实的相互作用和交换关联相互作用。选取Nb_pv作为Nb原子的赝势,标准赝势作为C原子的赝势。Nb和C的价电子分别为4s24p64d45s1和2s22p2。结构充分弛豫,每个原子的受力小于0.2 eV/nm,能量收敛精度为10-5 eV。利用VASP软件包中密度泛函微扰理论(DFPT)得到原子的实空间力常数,然后用PHONOPY程序包[30]处理力常数获得声子谱,NbC声子谱计算采用2 × 2 × 2的超胞。

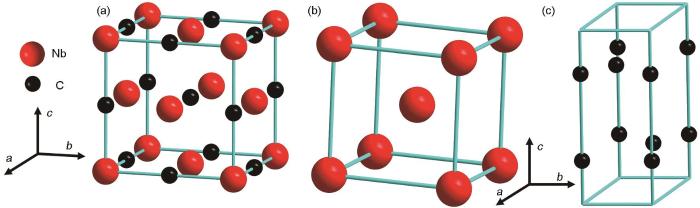

图1

1.3 微观偏析模型与凝固相变的耦合

式中,

式中,t为局部凝固时间,

式中,D0, i 为溶质元素i的扩散常数,cm2/s;Qi 为溶质元素i的扩散激活能,J/mol;R为气体常数。材料中的C含量w(C) (质量分数,%)和凝固时的冷却速率都会影响二次枝晶间距。Won和Thomas[32]根据已有的实验数据进行拟合回归分析得到:

表2 溶质元素的扩散常数、扩散激活能和平衡分配系数[33]

Table 2

| Element | ||||||

|---|---|---|---|---|---|---|

| C | 0.0127 | 81370.80 | 0.0761 | 134557.44 | 0.19 | 0.340 |

| Nb | 50.2000 | 251960.48 | 0.8300 | 266478.96 | 0.40 | 0.220 |

| Mn | 0.7600 | 224429.76 | 0.0550 | 249366.40 | 0.76 | 0.780 |

2 结果与分析

2.1 实验结果

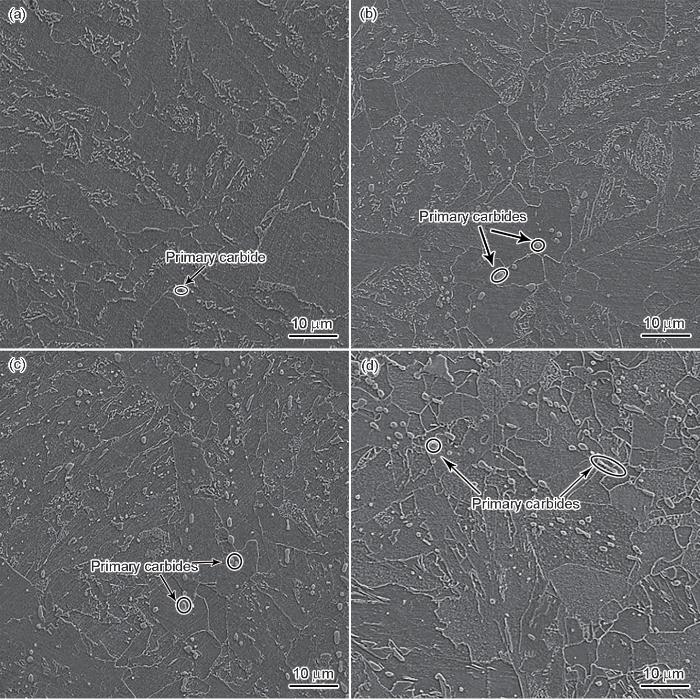

图2

图2

不同Nb含量钢的SEM像

Fig.2

SEM images of steels with different Nb contents

(a) 0.1Nb (b) 0.6Nb (c) 1.1Nb (d) 1.6Nb

图3

图3

碳化物的TEM明场像及Nb、C元素分布图

Fig.3

Bright-field TEM image of the carbide (a) and element distributions of Nb (b) and C (c)

2.2 第一性原理结合准谐Debye模型的结果与分析

2.2.1 基态性质

表3 NbC、Nb和C在0 K、0 Pa结构优化后的晶格常数、晶胞角度和形成能

Table 3

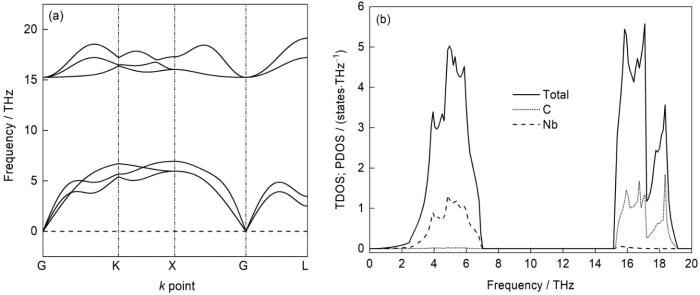

2.2.2 声子谱和声子态密度

振动声子谱可用于判断体系的动力学稳定性。图4a给出了NbC的声子谱。在第一Brillion区中声子谱没有虚频,意味着NbC是动力学稳定的。

图4

图4

NbC的声子谱及声子态密度

Fig.4

Calculated phonon dispersion spectra (a) and total or partial density of states (TDOS, PDOS) (b) for NbC

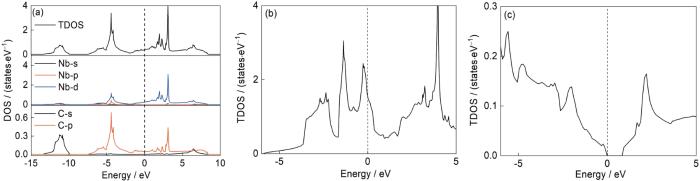

2.2.3 电子结构

Fermi能级附近的自由电子会参与热激发,从而产生电子自由能。因此需要分析NbC、Nb和C的电子结构。本工作计算了NbC的电子TDOS和PDOS,以及Nb和C的TDOS,结果如图5所示。

图5

图5

NbC的电子总态密度和分态密度,及Nb、C的总态密度

Fig.5

TDOS and PDOS for NbC (a), and TDOS for Nb (b) and C (c)

图5中0 eV处垂直的虚线是Fermi面。在Fermi面NbC和Nb的TDOS不为零,C的TDOS为零,因此NbC和Nb的电子对自由能的贡献需要考虑,C的电子自由能可以忽略。NbC的TDOS值穿过Fermi面,说明NbC呈金属性。在Fermi面附近,NbC的TDOS主要来源于Nb-4d轨道和C-2p轨道。在-4.5 eV附近Nb-4d轨道和C-2p轨道存在明显的共振,说明在该价带区域Nb和C形成了d-p杂化轨道,Nb和C原子之间存在共价键。

2.2.4 晶格振动和电子对NbC自由能的热力学影响机制

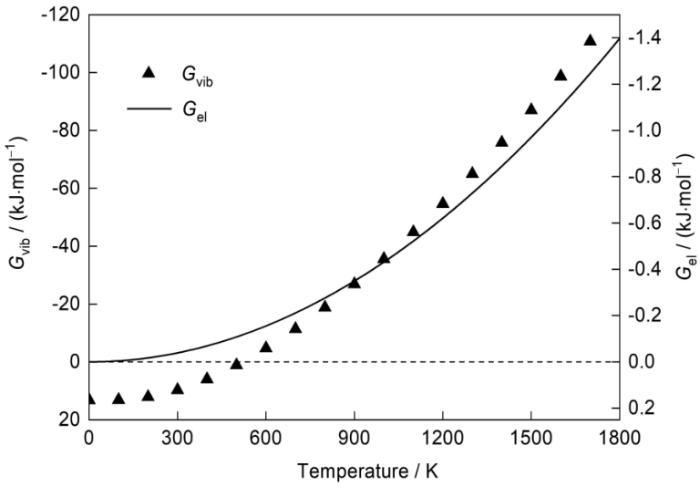

图6

图6

NbC的振动自由能和电子自由能随温度的变化

Fig.6

Calculated Gibbs free energies including the lattice vibrational and electronic contributions (Gvib, Gel) as a function of temperature for NbC

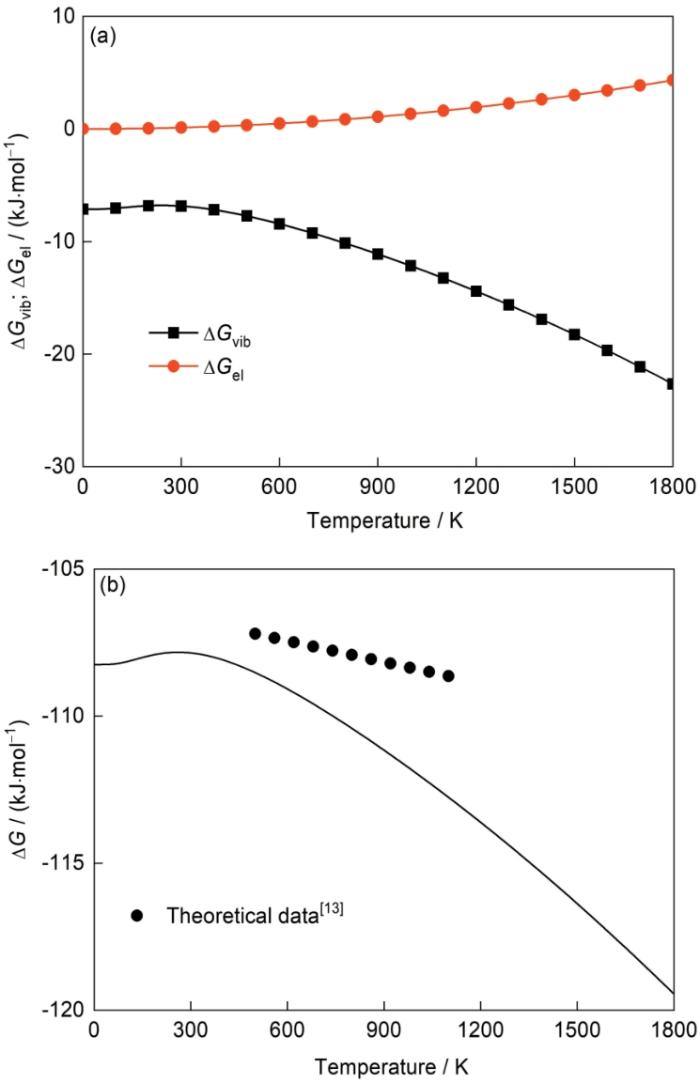

图7

图7

晶格振动和电子引起的自由能改变量及NbC总Gibbs自由能改变量随温度的变化

Fig.7

Change in Gibbs free energies related to lattice vibrations and electrons (ΔGvib,ΔGel) (a) and dependence of change in total Gibbs free energy on temperature for NbC (ΔG) (b)

2.3 平衡态凝固时液析碳化物NbC的析出行为

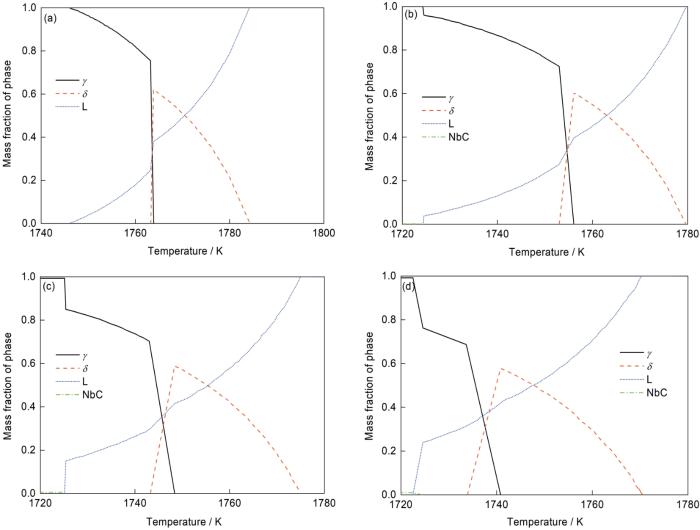

利用Thermo-Calc软件的TCFE12数据库,分析了Nb含量对中碳钢平衡凝固相变的影响,结果如图8所示。

图8

图8

凝固过程Thermo-Calc热力学计算Nb含量对相变的影响

Fig.8

Effect of Nb content on phase transformation during solidification process by Thermo-Calc calculation

(a) 0.1Nb (b) 0.6Nb (c) 1.1Nb (d) 1.6Nb

平衡态下,4种钢在钢液中都没有碳化物生成。温度降低,钢液开始凝固。当Nb含量为0.1%时,平衡凝固相变为L→L + δ→L + δ + γ→L + γ→γ。随着温度降低,δ铁素体首先从液相中析出,出现L和δ两相共存(L→L + δ);当温度降至包晶反应温度时,δ铁素体和残余液相发生包晶反应,生成奥氏体γ,出现L、δ和γ三相共存(L + δ→L + δ + γ);δ铁素体的消失代表包晶反应结束,出现L与γ两相共存(L + δ + γ→L + γ);最终残余液相全部凝固为奥氏体γ (L + γ→γ)。当Nb含量大于0.1%时,平衡凝固相变的路径为L→L + δ→L + δ + γ→L + γ→L + γ + NbC→γ + NbC,在糊状区发生了L→γ + NbC共晶反应,NbC与奥氏体共同结晶,液析碳化物生成。

表4列出了平衡态凝固时三相共存(L + δ + γ)的温度区间(ΔTL + δ + γ )以及液析碳化物开始生成的温度(Tstart)。随着Nb含量的增加,三相共存(L + δ + γ)的温度区间由0.6 K增至7 K。当Nb含量为0.1%时平衡凝固过程中没有液析碳化物,Nb含量的增加导致液析碳化物在平衡凝固过程中生成,液析碳化物开始析出的温度受Nb含量的影响不大。

表4 不同Nb含量中碳钢的三相共存温度区间(ΔTL + δ + γ )和碳化物析出温度(Tstart) (K)

Table 4

| Sample | ΔTL + δ + γ | Tstart |

|---|---|---|

| 0.1Nb | 0.6 | - |

| 0.6Nb | 3 | 1724.6 |

| 1.1Nb | 5 | 1725.5 |

| 1.6Nb | 7 | 1724.7 |

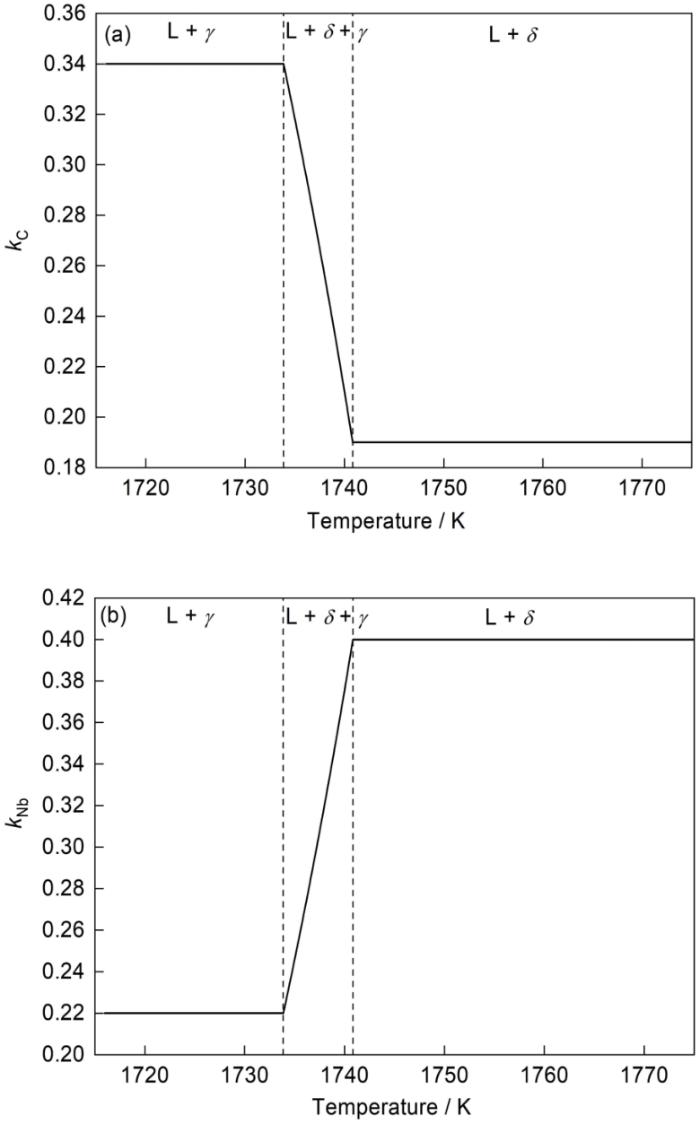

图9

图9

1.6Nb钢的溶质平衡分配系数随温度的变化

Fig.9

Variation of solute equilibrium partition coeffici-ents kC (a) and kNb (b) with temperature for 1.6Nb steel

2.4 非平衡态凝固时液析碳化物NbC的析出行为

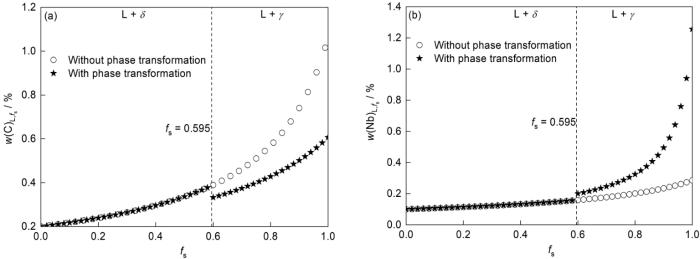

2.4.1 凝固相变对溶质元素微观偏析的影响

图10

图10

L + δ→L + γ相变对0.1Nb钢溶质偏析的影响

Fig.10

Effects of phase transition on solute segregation in 0.1Nb steel (fs is the solid phase volume fraction, w(C)

(a) C (b) Nb

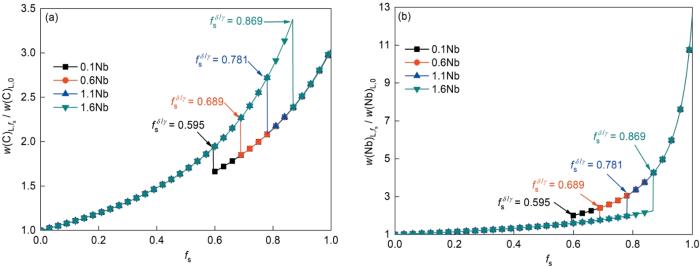

2.4.2 Nb含量对溶质元素微观偏析的影响

凝固前沿的液相中,4种钢溶质元素的偏析比随fs的变化如图11所示。凝固相变发生后,因C元素在γ相的溶解度高于在δ相的溶解度,C的偏析比在相变点处降低;Nb元素在γ相的溶解度低于在δ相的溶解度,所以Nb的偏析比在相变点处升高。

图11

图11

Nb含量对溶质元素偏析比的影响

Fig.11

Effects of Nb content on segregation ratios of C (a) and Nb (b) (

Nb含量不同导致凝固相变点不同。当Nb含量由0.1%增至0.6%、1.1%、1.6%时,L + δ→L + γ相变发生时的固相分数(

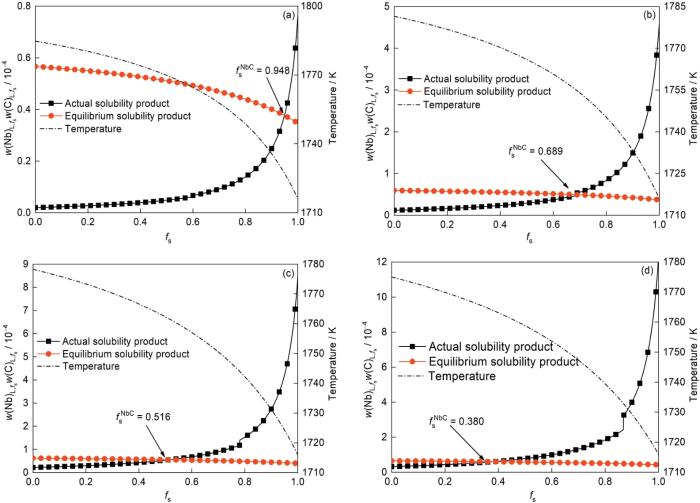

2.4.3 Nb含量对液析碳化物NbC析出的影响

凝固过程中,溶质元素在液相和固相中的溶解度不同,当k < 1时溶质元素逐渐从固相排出到固/液界面,导致凝固前沿溶质元素的富集。图12给出了冷速为10 ℃/s时,根据耦合凝固相变的Voller-Beckermann模型[22,23]得到的4种钢中Nb和C的实际固溶度积随fs的变化情况。当fs = 0.9时,0.1Nb、0.6Nb、1.1Nb和1.6Nb钢凝固前沿钢液中Nb和C的实际浓度积分别为0.25 × 10-4、1.49 × 10-4、2.74 × 10-4和3.99 × 10-4,远高于其初始浓度积0.02 × 10-4、0.06 × 10-4、0.22 × 10-4和0.32 × 10-4。图12中的右坐标轴是不同fs下凝固前沿液相的温度[41],fs随着温度降低而增加。利用文献[42]中Nb和C的平衡浓度积公式并综合考虑溶质元素之间的相互作用,得到固/液界面液相中Nb和C的平衡浓度积

图12

图12

4种实验用钢凝固前沿实际浓度积和平衡浓度积

Fig.12

Curves of actual solubility product and equilibrium solubility product at solidification front against solid fraction (The vertical coordinate on the right represents the temperature of the liquid at the solidification front under different solid fractions;

(a) 0.1Nb (b) 0.6Nb (c) 1.1Nb (d) 1.6Nb

当凝固前沿液相中溶质元素Nb和C的实际浓度积超过其平衡浓度积时,就具备了NbC析出的热力学条件[43]。溶质的初始含量与凝固过程中碳化物的析出时机密切相关。由图12可知,当Nb的初始含量为0.1%时,NbC开始析出时的固相分数(

表5

当

Table 5

| 0.1Nb | 0.6Nb | 1.1Nb | 1.6Nb | 0.1Nb | 0.6Nb | 1.1Nb | 1.6Nb | |

| 0.380 | 0.289 | 0.289 | 0.289 | 0.289 | 0.130 | 0.780 | 1.432 | 2.084 |

| 0.516 | 0.344 | 0.344 | 0.344 | 0.344 | 0.146 | 0.879 | 1.612 | - |

| 0.689 | 0.369 | 0.369 | 0.453 | 0.453 | 0.240 | 1.440 | - | - |

| 0.948 | 0.547 | 0.546 | 0.548 | 0.549 | 0.684 | - | - | - |

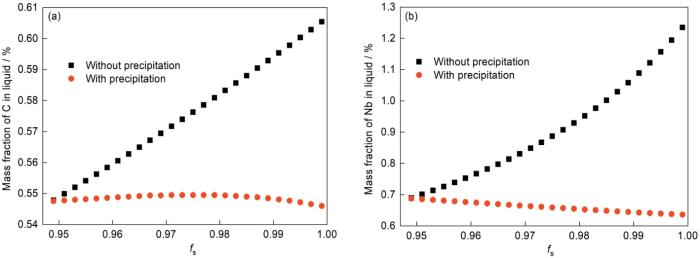

2.4.4 NbC析出对微观偏析的影响

NbC析出前,由微观偏析模型得到固/液界面前沿液相中溶质元素Nb和C的质量分数

图13

图13

NbC析出对0.1Nb钢溶质浓度的影响

Fig.13

Effects of NbC precipitation on solute concentrations of C (a) and Nb (b) for 0.1Nb steel

3 结论

(1) 随着初始Nb含量的增加,液析碳化物NbC的形貌由球形向多面体转变,带状分布的趋势更明显。

(2) 微观偏析模型显示:凝固过程中的L + δ→L + γ相转变,导致溶质元素C的平衡分配系数升高,Nb的平衡分配系数降低,因此固/液界面液相中C的偏析降低,Nb的偏析升高。凝固过程中,较高的初始Nb含量及更低的固相分数,更有利于NbC析出。

(3) 声子谱分析表明NbC满足动力学稳定性,不会向其他相转变。

(4) 利用第一性原理和准谐Debye模型分析发现,不同温度下NbC中电子导致的自由能改变量增加被晶格振动导致的自由能改变量减小所补偿,这说明晶格振动对NbC的稳定性做出了主要贡献。并且,不同温度下NbC的总Gibbs自由能改变量为负,证实了NbC的热力学稳定性。

参考文献

All-optical photodetector based on photothermal effect of MXene Nb2CT x

[D].

基于碳化铌光热效应的全光探测器的研究

[D].

Microstructure control and strengthening mechanism of high strength cold rolled dual phase steels for automobile applications

[J].Steels have been critical in the rapid development of the global automobile industry. Among all automotive steels, dual phase (DP) steels have been extensively used as the mechanical components and outer plates in automobiles, owing to their excellent mechanical properties, desirable weldability and paintability, and low manufacturing cost. DP steels are beneficial in reducing the weight and increasing the safety of automobiles. The optimization of alloy elements and microstructure are essential for the engineering performance of DP steels. Understanding the relationship between their mechanical properties and microstructural features as well as the factors affecting the microstructure is of utmost importance. This study reviews the recent advances in the research on the microstructure evolution and mechanical properties of high strength cold-rolled DP steels for automobile applications. First, the alloy design principles and microstructure tailoring mechanism are summarized. Then, the microstructure evolution during thermal-mechanical processing, which includes rolling, intercritical annealing, subsequent cooling, and over-aging process is discussed. Thereafter, the mechanical properties and failure mechanism of DP steels as well as their relationship with the microstructural features are analyzed. Furthermore, the related challenges and future research directions are discussed and proposed, respectively.

汽车用先进高强度冷轧双相钢的显微组织调控和强韧化机理

[J].汽车用先进高强钢支撑了现代汽车工业的飞速发展。其中双相钢以优异的力学综合性能、良好的焊接和涂装性能及较低的成本,被广泛应用于汽车结构件和车身材料中,实现有效的结构减重并提升汽车的安全性能。合金成分和组织的优化设计是获得高性能双相钢的主要手段,而明确双相钢的组织特性影响因素以及与力学性能之间的关系则是指导双相钢的合金成分和组织优化设计的必然要求。本文围绕汽车用先进高强度冷轧双相钢的显微组织和力学性能研究的最新进展,首先概述了双相钢合金成分设计的准则以及利用合金元素对显微组织进行调控的方法。然后总结了双相钢在热加工过程中的显微组织演变的规律,探讨了轧制、两相区退火、冷却过程以及过时效过程对双相钢显微组织的影响。分析了双相钢力学性能和典型的失效形式,以及与显微组织之间的关系。最后简述了目前汽车用双相钢研究还存在的科学问题和挑战,并展望了未来的研究方向和发展趋势。

Thermodynamic study of carbide and nitride precipitation of niobium in 500 MPa high-strength anti-seismic rebars

[J].

高强抗震钢筋中铌的碳、氮化物析出热力学研究

[J].连铸过程中铌的氮化物、碳化物和碳氮化物在奥氏体晶界的析出对铸坯的质量产生严重的影响。分析了500MPa级高强度抗震钢筋(HRB500E)中铌的氮化物、碳化物和碳氮化物在液相、凝固过程以及奥氏体相等不同阶段的析出热力学,计算了不同温度下NbN和NbC的平衡/实际浓度积,得到NbN和NbC在微合金钢连铸过程中的析出规律。计算结果表明:在HRB500E钢中,NbN、NbC在钢液成分均质状态和凝固过程中难以析出;在奥氏体相中,随着温度的降低,NbC、NbN及NbC0.85N0.15具备析出热力学条件,析出温度分别为1377、1229 和1378K,析出顺序依次为:NbC0.85N0.15、NbC、NbN。

Insight into the effect of Nb microalloying on the microstructure-property relationship of a novel wire rod

[J].The microstructure-property relationship of a novel wire rod was investigated after Nb microalloying. The tensile properties were significantly improved. The impact of Nb on pearlitic transformation, residual stress, residual strain, and microstructure uniformity was discussed in this paper. By changing the alloy phase diagram, Nb microalloying improved the undercooling of the pearlitic transformation, resulting in finer lamellar spacing. Residual stresses and residual strain as different kinds of deformation energy storage satisfied the water-bed effect after Nb microalloying. After hot rolling, the residual stresses of the Nb-bearing wire rod were reduced while the residual strains increased. The increase in deformation between the transverse and longitudinal sections (TS and LS) during hot rolling led to an increase in residual strain and a decrease in residual stress in wire rods. Furthermore, the uniform grains and more random texture observed after Nb microalloying increased the microstructure uniformity of wire rods. This phenomenon was thought to be caused by the precipitation of Nb carbides during hot rolling. (c) 2021 The Authors. Published by Elsevier B.V. This is an open access article under the CC BY-NC-ND license (http://creativecommons.org/licenses/by-nc-nd/4.0/).

In-situ observation for effect of niobium on pearlite transformation in high-carbon steels

[J].

原位观察铌对高碳钢珠光体相变的影响

[J].

Improving mechanical properties in high-carbon pearlitic steels by replacing partial V with Nb

[J].

Element segregation in GH4169 superalloy large-scale ingot and billet manufactured by triple-melting

[J].GH4169 has the advantage of excellent comprehensive mechanical properties, good oxidation and corrosion resistance, etc., which have been widely used in aero engine with the largest consumption. The GH4169 parts include high pressure compressor disk, turbine disk, shaft, gearbox and forged blade, et al. With the development of technology and the requirement of cost reducing, the size of GH4169 ingot and billet increases gradually at home and abroad. However, element segregation becomes more and more severe as the size of GH4169 ingot and billet increases, which will significantly degrade their mechanical properties. In this work, the large-scale GH4169 superalloy ingot (diameter 508 mm) was prepared by triple smelting, vacuum induction melting (VIM)+electro sag remelting (ESR)+vacuum arc remelting (VAR). Then, large-scale GH4169 billet (diameter 240 mm) was obtained from this prepared ingot via two-step high temperature homogenization heat treatment and cogging-forging. The element composition and microstructure at different positions of these large-scale ingot and billet were analyzed by SEM, TEM, EPMA and EDS. The results show that the segregation degree of element Al in GH4169 ingot is small, while those of elements Nb, Ti and Mo are large. Moreover, a lot of secondary phases were precipitated at the interdendritic regions of GH4169 ingot, including MC, Laves and δ phase. In the GH4169 billet prepared in our work, no "freckle" or "white spot" macro segregation was recognized, and the micro-element segregation was eliminated. Furthermore, combined with computational simulation, the chemical composition uniformity and main mechanical properties of GH4169 and Inconel 718 billets were compared. The statistical analysis using sample variance of macro chemical composition shows that the uniformity of chemical composition in GH4169 billet produced by different manufactures is different. The regional element segregation results in some vacillation on the mechanical properties of GH4169 billet. It is proposed that this regional element segregation can be further depressed by elaborately controlling the triple melting process and optimizing the homogenization heat treatment and forging process.

三联熔炼GH4169合金大规格铸锭与棒材元素偏析行为

[J].

Characteristics and generating mechanism of large precipitates in Nb-Ti-microalloyed H13 tool steel

[J].

Thermal fatigue behavior of new type high-Cr cast hot work die steel

[J].

Fractography survey on high cycle fatigue failure: Crack origin characterisation and correlations between mechanical tests and microstructure in Fe-C-Cr-Mo-X alloys

[J].

Stability of (Ti, M)C (M = Nb, V, Mo and W) carbide in steels using first-principles calculations

[J].

Structural, electronic, and magnetic properties of iron carbide Fe7C3 phases from first-principles theory

[J].

Hardness increases due to (Fe, Cr)2C carbide precipitated during natural aging in high chromium cast iron

[J].

Computing solubility products using ab initio methods precipitation of NbC in low alloyed steel

[J].

Ab initio thermodynamic properties of stoichiometric phases in the Ni-Al system

[J].

First-principles thermodynamics from phonon and Debye model: Application to Ni and Ni3Al

[J].

Modeling micro scale phenomena for application in solidification process simulations

[A].

Bemerkungen zur Schichtkristallbildung

[J].

Solute redistribution in dendritic solidification

[J].

Mathematical analysis of solute redistribution during solidification with diffusion in solid phase

[J].

Solute redistribution during solidification with rapid solid state diffusion

[J].

Approximate models of microsegregation with coarsening

[J].

A unified model of microsegregation and coarsening

[J].

New evaluation of the thermodynamics stability for bcc-Fe

[J].

GIBBS2: A new version of the quasi-harmonic model code. I. Robust treatment of the static data

[J].

GIBBS2: A new version of the quasiharmonic model code. II. Models for solid-state thermodynamics, features and implementation

[J].

First-principles theory of short-range order, electronic excitations, and spin polarization in Ni-V and Pd-V alloys

[J].

Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set

[J].

First principles phonon calculation in materials science

[J].

Effect of solute partition coefficient and TiN precipitation on micro-segregation of 22MnB5 steel

[J].

22MnB5钢溶质分配系数及TiN析出对微观偏析的影响

[J].

Simple model of microsegregation during solidification of steels

[J].

Calculation of high temperature solidification characteristics and high temperature physical properties of high strength steel containing niobium

[J].

含Nb高强钢高温凝固特性与物性参数的计算

[J].

The evolution and morphological stability of a particle in a binary alloy melt

[J].

Solid state metathesis routes to transition metal carbides

[J].

Electronic structure, lattice stability, and superconductivity of CrC

[J].

Micro-properties of (Nb, M)C carbide (M = V, Mo, W and Cr) and precipitation behavior of (Nb, V)C in carbide reinforced coating

[J].

Ab initio study of the thermodynamic properties of rare-earth-magnesium intermetallics MgRE (RE = Y, Dy, Pr, Tb)

[J].

Effects of inclusion precipitation, partition coefficient, and phase transition on microsegregation for high-sulfur steel solidification

[J].

Thermodynamics and dynamics of MnS inclusions precipitation during solidification process in heavy rail steels

[J].

重轨钢中MnS析出热力学和动力学分析

[J].采用无水有机溶液电解法分离提取重轨钢中的MnS夹杂物,采用扫描电镜观察铸坯内和钢轨中MnS夹杂物的三维形貌,并结合能谱仪分析其成分。铸坯被轧制成钢轨后,相应的MnS夹杂物都沿着轧制方向被轧制成长条状。基于热力学和动力学模型,分析重轨钢中MnS夹杂物析出行为以及在钢液凝固过程中锰元素和硫元素偏析的程度。热力学分析表明,MnS夹杂物在凝固末期凝固分数为0.94时开始析出,其析出量由初始[w([Mn])]和初始[w([S])]决定,且在凝固过程受到冷却速率的影响,对比发现,热力学的计算析出结果与Thermo-Calc和FactSage6.4的计算结果有较好的一致性;动力学分析表明,在钢液凝固过程增加冷却速率,凝固析出的MnS颗粒尺寸将减小。通过调整钢中[w([Mn])]和[w([S])]以及改变冷却速率,可以控制MnS的析出时机和形态,减小其对钢性能的有害影响。

A coupled mathematical model of microsegregation and inclusion precipitation during solidification of silicon steel

[J].