齿轮是汽车变速与传动系统中至关重要的基础零部件。在传动过程中,由于齿轮与齿面间存在滑动和滚动摩擦,使得齿根在服役过程中需要承受弯曲和冲击应力,这对齿轮的强度、冲击韧性以及疲劳强度提出了严格的要求[1]。同时,随着精密机械制造业的发展,齿轮的生产加工精度要求也越来越高。16MnCrS5齿轮钢是在德国引进的16MnCr5齿轮钢的基础上添加S元素而获得的一类渗碳齿轮钢,其切削性和淬透性显著提高,被广泛应用于制造齿轮和蜗杆等汽车零部件[2~4]。齿轮在生产制造中一般要经历锻造、预备热处理、切削、渗碳、淬火、回火等过程。与其他齿轮钢类似,16MnCrS5齿轮钢存在着淬火变形的问题,这会造成齿面摩擦加剧以及轮齿间无法啮合等问题,严重影响齿轮的寿命与传动稳定性[5]。因此,为了解决16MnCrS5齿轮钢的淬火变形问题,需要对其淬火变形行为进行深入研究,明晰其淬火变形机理,进而为16MnCrS5齿轮钢生产工艺优化提供理论支撑。

渗碳齿轮钢热处理变形的控制是一个复杂的系统工程,覆盖到齿轮生产制造的各个环节[6],涉及材料本身的因素主要有晶粒尺寸、带状组织和淬透性[7]。其中,淬透性对渗碳齿轮钢热变形的影响最为显著,其淬火变形量随着淬透性的增加而增加[8]。研究[9]发现,淬火后齿轮钢芯部硬度低于40 HRC时,齿轮的淬火变形量较小,同时其强度较低,而当芯部硬度超过42 HRC时,齿轮热处理变形加剧,淬火变形量较大,不符合生产要求。因此根据齿轮性能指标要求,其芯部硬度存在一个合理区间,进而对齿轮钢淬透性提出了较高的要求。此外,晶粒尺寸对渗碳齿轮钢淬火变形同样有着显著的影响,研究[10]发现,由于淬火形成的马氏体晶粒尺寸与原奥氏体存在着继承关系,粗大马氏体的生成会诱导产生较大的组织应力,导致粗晶粒齿轮钢的热处理变形明显大于细晶粒齿轮钢。近年来,带状组织对齿轮钢淬火变形的影响引起了广泛关注[11~15],但其影响规律尚不明确[16]。通常情况下,带状组织的出现不利于齿轮钢淬火变形的控制[6]。华公平等[13]发现,带状组织的形成会造成20CrNi2Mo钢渗碳层的组织和硬度分布不均匀,导致试样淬火变形量沿带状组织方向增大。杨超等[17]发现,微观组织带状化的SAE8620H钢在淬火过程中试样膨胀呈现明显各向异性,并且组织带状化程度越高,其淬火变形越显著。

1 实验方法

1.1 C型试样淬火变形实验

实验用16MnCrS5齿轮钢的化学成分(质量分数,%)为:C 0.15~0.19,Si 0.15~0.30,Mn 1.00~1.30,P ≤ 0.025,S 0.020~0.035,Cr 0.80~1.10,Al 0.020~0.050,Fe余量。试样晶粒尺寸和带状组织的调控通过热机械加工实现:以10 ℃/min速率将原始试样加热至1150 ℃,分别保温10和60 min,水冷淬火,获得不同晶粒尺寸的试样;以10 ℃/min速率将原始试样加热至1050 ℃,保温3 min,随后热轧减薄50%,分别以水冷(冷却速率约150 ℃/s)、空冷(冷却速率约4 ℃/s)和炉冷(冷却速率约0.3 ℃/s)方式进行冷却[12],获得不同组织带状化程度的试样。由于淬透性本质上与钢材的化学成分相关,为了研究齿轮钢淬透性对其淬火变形的影响,选取与16MnCrS5齿轮钢微观组织及使用场景相似的TL4227齿轮钢进行淬火变形量对比分析。淬火变形量的测定采用C型缺口试样,如图1所示。首先,将电火花线切割获得的C型缺口试样用800号水磨砂纸进行打磨,去除试样表面锈斑及加工毛刺,之后将试样在无水乙醇中超声清洗,吹干,测量试样原始缺口宽度(w1)。随后将缺口试样以10 ℃/min速率加热至870 ℃奥氏体化温度,保温30 min,水冷淬火,测量其淬火缺口宽度(w2)。w1和w2均取3次测量结果的平均值。根据淬火前后试样缺口尺寸的变化,计算试样淬火变形量d =

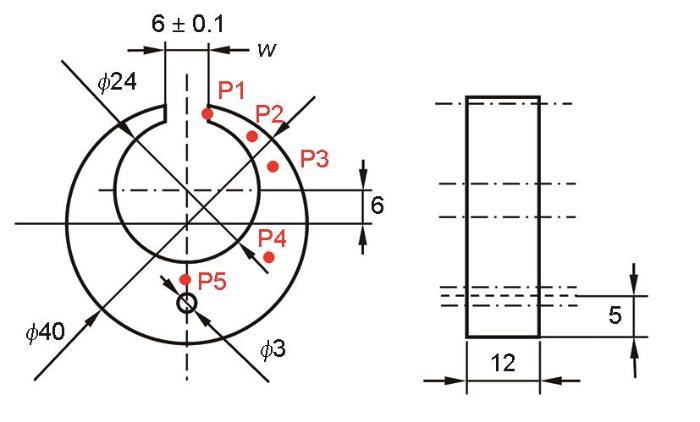

图1

图1

淬火变形测定用C型缺口试样及数值模拟结构模型5个特征位置点

Fig.1

C-notch specimen for the measurement of quenching deformation and 5 characteristic points (P1-P5) of the geometrical model for numerical simulation (unit: mm. w—width)

利用DM4 M型光学显微镜(OM)对试样微观组织进行表征,采用线性截距法(GB/T 6394—2002)统计晶粒尺寸。带状组织的评定采用GB/T 13299—1991《钢的显微组织评定方法》中规定的目视比较法进行[23],共分为0~5级,其中,5级表示试样微观组织带状化程度最高。16MnCrS5与TL4227齿轮钢的淬透性依据GB/T 225—2006《钢淬透性的末端淬火试验方法(Jominy试验)》进行测定,使用HXD-1000TMC型显微硬度计测量试样Vikers硬度,随后将测量得到的Vikers硬度(H,单位HV)由公式

1.2 数值模拟

16MnCrS5齿轮钢热处理变形数值模拟采用有限元模拟软件Deform 11进行,其所涉及的详细数学模型(包括温度场模型、应力应变场模型、相变动力学模型等)参见文献[17]。由于淬火过程中传热属于瞬态传热,假设C型缺口试样沿各方向的导热系数相同,则瞬态温度场偏微分方程为:

式中,λ为导热系数,T为绝对温度,t为时间,ρ为材料密度,c为材料的定压比热容,Q为淬火过程中由相变潜热产生的热流密度。淬火过程中边界条件依据Newton对流边界进行设定,已知C型缺口试样表面温度(Tw)与淬火介质温度(TC),则:

式中,

式中,ϕ为马氏体转变量,α为相变动力学参数,Ms为马氏体转变开始温度。对于扩散型的贝氏体、铁素体及珠光体相变,其相变动力学往往采用Avrami方程[26]描述:

图2

图2

16MnCrS5齿轮钢相变参数测定

Fig.2

Measurements of the phase-transformation parameters of 16MnCrS5 gear steel

(a) time-temperature-transformation (TTT) curves (A, F, P, B, and M denote austenite, ferrite, pearlite, bainite, and martensite, respectively; Ms, Mf, Ac1, and Ac3 are martensite transformation start temperature, martensite transformation finish temperature, start temperature of transformation from pearlite to austenite during heating, and finish temperature of transformation from ferrite to austenite during heating, respectively. 1% and 99% represent the transformation variables of 1% and 99%, respectively)

(b) continuous cooling transformation (CCT) curves

16MnCrS5齿轮钢淬火过程中的变形分为热应力诱导与组织应力诱导,其中,热应力诱导的应变(εth)为:

式中,i表示对应物相组织,Vi 和ei 分别为对应物相i的体积分数与热膨胀系数,ΔT为实时温度与室温(25 ℃)差值。组织应力诱导的应变(εtr)为:

式中,

图3

图3

16MnCrS5齿轮钢室温应力-应变曲线和计算所得500 ℃下流变应力曲线

Fig.3

Tensile true stress-strain curve at ambient temperature (a) and the simulated flow stress curves of the theoretical constituent phases (martensite, bainite, austenite, ferrite, and pearlite) at 500 oC (b) for 16MnCrS5 gear steel with a grain size of 22 μm

在分析晶粒尺寸对16MnCrS5齿轮钢淬火变形影响的数值模拟过程中,通过JMatPro 7.0软件中Deform-HT模块定义试样的晶粒尺寸,在工程应用范围内,建立了不同晶粒尺寸(22、33、75、90和120 μm)相对应的材料参数数据库。渗碳齿轮钢中带状组织由珠光体带和铁素体带组成[28],这导致其通常呈现各向异性。研究[14]表明,尽管有限元软件可以直接模拟铁素体与珠光体的带状结构,但是由于其物性参数难以测定,导致带状组织的精确模拟仍存在困难。鉴于试样组织带状化程度与其各向异性呈正相关,本工作将带状组织模型进行了简化,通过各向异性参数及不同方向上导热系数的改变构建不同等级带状组织结构模型,在不改变试样晶粒尺寸与淬透性的前提下,对5个不同等级带状组织试样的淬火变形过程进行了数值模拟研究。淬透性是钢铁材料重要的基础指标之一,表示钢淬火时获得马氏体组织的能力,决定着材料表面到芯部的硬度变化[18]。在Deform参数设定过程中,通过输入材料的Jominy硬度曲线定义材料的淬透性。在实际生产中,材料淬透性的评定通常采用硬度测量的方法,取距离淬火端9 mm处的硬度(J9)表征材料的淬透性。因此,为了模拟淬透性对齿轮钢淬火变形的影响,本工作定义了6组具有不同淬透性16MnCrS5齿轮钢的Jominy硬度曲线,如图4所示,图中6组试样的J9分别为38.8、36.6、34.4、32.2、29.8和26.4 HRC。从C型缺口试样的中心剖面缺口端至芯部选取5个典型位置,依次标记为P1 (缺口)、P2、P3、P4和P5 (芯部),如图1所示,模拟C型缺口试样在淬火过程中温度场、相场与应力场的变化。

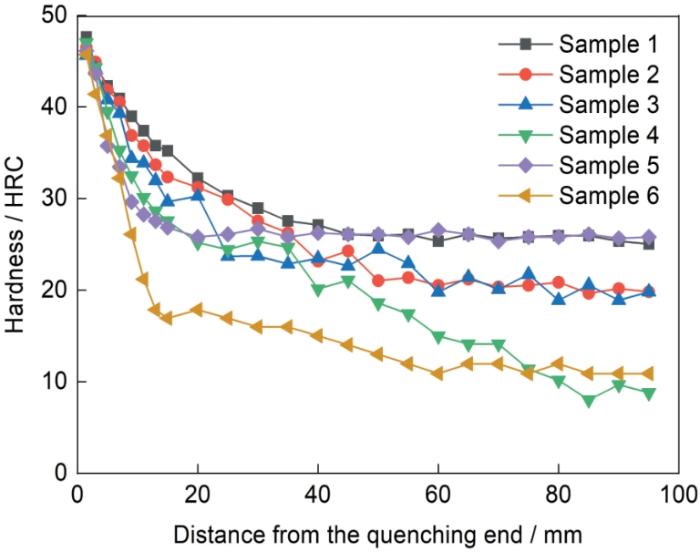

图4

图4

不同淬透性16MnCrS5齿轮钢的Jominy硬度曲线

Fig.4

Jominy hardness curves of the 16MnCrS5 gear steels with different hardenabilities (J9 represents the hardness at 9 mm from the quenching end)

2 结果与分析

2.1 晶粒尺寸对淬火变形的影响

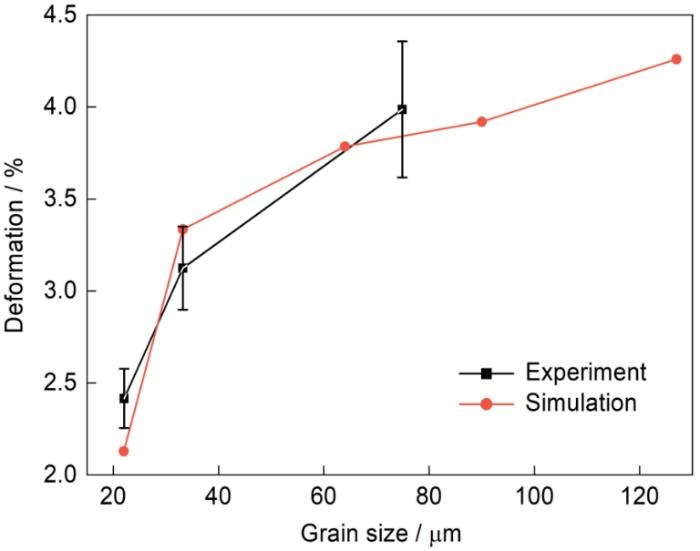

图5所示为16MnCrS5齿轮钢原始试样及不同工艺热处理后试样显微组织的OM像。从图5a可见,原始试样的晶粒尺寸为22 μm。经过1150 ℃退火处理10和60 min后,平均晶粒尺寸分别增加至33和75 μm,如图5b和c所示。图6所示为通过实验测定和数值模拟获得的16MnCrS5齿轮钢C型缺口试样淬火变形量随晶粒尺寸的变化。可以看出,16MnCrS5齿轮钢原始试样及经过1150 ℃退火10和60 min试样,其C型缺口试样淬火变形量分别为2.412%、3.124%和3.987%,随着晶粒尺寸的增加,16MnCrS5齿轮钢C型缺口试样淬火变形量逐渐增加。晶粒尺寸为75 μm的试样在淬火过程中产生的变形量约是晶粒尺寸为22 μm试样的1.7倍,增加近一倍。数值模拟结果显示,当C型缺口试样中晶粒尺寸为120 μm时,其淬火变形量约是晶粒尺寸为22 μm试样的2倍,淬火变形实验结果与数值模拟结果吻合。

图5

图5

16MnCrS5齿轮钢原始试样及不同工艺热处理后试样显微组织的OM像

Fig.5

OM images of the 16MnCrS5 original sample (a) and that after annealing at 1150 oC for 10 min (b) and 60 min (c)

图6

图6

淬火变形实验和数值模拟获得的16MnCrS5齿轮钢C型缺口试样淬火变形量随晶粒尺寸变化

Fig.6

Quenching deformations of the 16MnCrS5 C-notch samples obtained by experiment and simulation as function of grain size

图7a所示为不同晶粒尺寸试样P3位置淬火温度随时间变化的数值模拟结果。可以看出,随着晶粒尺寸的增大,P3位置的冷却速率也相应提高。在金属材料内部,晶粒与晶粒之间的热量传输是通过载热子的散射来实现的,由于晶界处存在晶界热阻,因此晶粒尺寸越小,热导率越低[27],冷却速率越慢。这种由晶粒尺寸差异引起的冷却速率变化会影响16MnCrS5齿轮钢淬火过程中马氏体相变的发生,当冷却速率低于马氏体相变的临界冷却速率时,试样中可能出现贝氏体转变。由于贝氏体转变所引起的体积膨胀较小,因此导致残余应力降低,淬火变形量下降。此外,晶粒尺寸也会影响材料的屈服强度,根据Hall-Petch公式,晶粒尺寸越大,试样屈服强度通常越小。因此,具有较大晶粒尺寸的16MnCrS5齿轮钢试样在淬火过程中容易发生塑性变形。同时,数值模拟结果表明,粗大的马氏体在其形成过程中诱导试样产生较大的组织应力(如图7b所示),而淬火产生的马氏体晶粒尺寸与原奥氏体存在继承关系,因此试样晶粒尺寸越大,淬火过程诱发组织应力越大,试样变形越严重。在工程应用中,可以通过合金成分的调整,如添加微量的Nb、V、Ti等元素抑制齿轮钢晶粒在渗碳过程中的长大[29],实现晶粒尺寸的调控,进而弱化渗碳齿轮钢淬火热变形。

图7

图7

不同晶粒尺寸16MnCrS5齿轮钢在淬火过程中P3位置温度变化与组织应力变化数值模拟结果

Fig.7

Numerical simulated temperature (a) and struc-tural stress (b) change curves as function of time at P3 of samples with different grain sizes during quenching (Inset in Fig.7a is the close-up view of the purple frame region)

2.2 带状组织对淬火变形的影响

16MnCrS5齿轮钢经热轧处理后以水冷、空冷和炉冷方式冷却能够诱导产生不同程度带状化组织,其对应的带状组织等级分别为0级、1级与5级,如图8所示。图9所示为16MnCrS5齿轮钢C型缺口试样淬火变形量随试样带状组织等级变化的实验与数值模拟结果。实验结果表明,带状组织能够显著影响16MnCrS5齿轮钢淬火变形。带状组织等级为0级、1级与5级时,对应试样的淬火变形量分别为0.602%、1.556%和4.341%,即随着试样带状组织等级的增加,其淬火变形量逐渐增大。数值模拟结果同样表明,随着带状组织等级的增加,16MnCrS5齿轮钢沿轧制方向(RD)和横向(TD)的淬火变形量均逐渐增大。并且,试样淬火变形量的增加速率随着带状组织等级的提升而增大,特别是当带状组织等级大于3级后,试样淬火变形量随带状组织等级变化更为显著。带状组织的各向异性使得试样淬火变形量沿RD和TD表现不同,沿TD变形量较大,沿RD变形量较小。

图8

图8

16MnCrS5齿轮钢经热轧处理后以不同方式冷却获得的带状组织形貌的OM像

Fig.8

OM images showing the banded structure morphologies of the 16MnCrS5 samples after hot rolling with water-colling (a), air-cooling (b), and furnace cooling (c)

图9

图9

淬火变形实验和数值模拟获得的16MnCrS5齿轮钢C型缺口试样淬火变形量随带状组织等级变化

Fig.9

Quenching deformations of the 16MnCrS5 C-notch samples obtained by experiment and simulation as function of band structure grade (TD—transverse direction, RD—rolling direction)

低碳钢在热轧过程中通常会诱发带状组织的产生,即珠光体和铁素体呈带状分布的组织结构。然而,由于铁素体含C量较低,其Ms较高[11],致使其在淬火冷却过程中率先发生马氏体相变,导致试样中马氏体相变不均匀分布,进而在试样内部形成了不均匀的应力分布状态,导致具有带状组织的试样淬火变形量增大。并且,由于带状组织的力学性能存在各向异性,沿RD屈服强度高于TD,导致试样在淬火过程中沿TD较易发生塑性变形,致使试样沿TD淬火变形量相较于RD更大。由于带状组织往往在热轧过后的冷却过程中形成,而冷却速率对带状组织的影响最为显著(冷速越慢,带状组织越严重[30]),因此在工业生产中,通过改变冷却介质可以实现16MnCrS5齿轮钢带状组织等级的控制,以弱化其淬火变形。

2.3 淬透性对淬火变形的影响

选用晶粒尺寸与带状组织等级相近的16MnCrS5和TL4227齿轮钢试样进行淬火变形实验。由于2种齿轮钢成分存在差异,导致呈现不同的淬透性。图10所示为16MnCrS5与TL4227齿轮钢末端淬火曲线(Jominy硬度曲线),其J9分别为32.2和34.4 HRC,即TL4227齿轮钢的淬透性高于16MnCrS5齿轮钢。图11a所示为上述16MnCrS5和TL4227齿轮钢试样淬火变形实验结果及不同淬透性16MnCrS5齿轮钢淬火变形量随淬透性变化数值模拟结果。实验结果表明,16MnCrS5齿轮钢试样的平均淬火变形量为2.412%。在晶粒尺寸和组织带状化程度与16MnCrS5齿轮钢基本相同的情况下,具有更高淬透性的TL4227试样,其平均淬火变形量(3.740%)更高。数值模拟结果表明,当J9 > 32.2 HRC时,16MnCrS5齿轮钢试样芯部组织主要为马氏体(如图11b所示),淬透性对其淬火变形量的影响更为显著(淬火变形量对J9的线性斜率更大)。而当 J9 ≤ 32.2 HRC时,虽然16MnCrS5齿轮钢试样芯部仍以马氏体为主,但贝氏体转变开始出现(如图11c所示),此时试样淬火变形量对J9的变化相对不敏感。

图10

图10

16MnCrS5齿轮钢与TL4227齿轮钢Jominy硬度曲线

Fig.10

Jominy hardness curves of the 16MnCrS5 and TL4227 gear steels

图11

图11

16MnCrS5和TL4227齿轮钢淬火变形实验结果以及不同淬透性16MnCrS5齿轮钢淬火变形和淬火组织随淬透性变化数值模拟结果

Fig.11

Quenching deformations of the 16MnCrS5 and TL4227 C-notch samples obtained by experiment and that of the 16MnCrS5 structural models with different hardenabilities calculated by simulation (a), martensite transformation distribution of the sample with J9 = 38.8 HRC (b), and bainite transformation distribution of the sample with J9 = 32.2 HRC (c)

淬透性(J9)反映淬火试样芯部马氏体组织含量,淬透性越大,试样芯部马氏体含量越高,如图12a所示。因此,可以推断在淬火过程中,试样淬透性越大,其芯部发生马氏体相变产生的体积膨胀越大,致使试样产生较大的组织应力,如图12b所示,导致其淬火变形量增大。此外,研究[8]表明,随着齿轮钢淬透性的增加,芯部组织淬火后产生的贝氏体尺寸将越来越小,当其淬透性超过某一临界值时(在本工作中以J9 = 32.2 HRC为标志),芯部将以马氏体为主,且马氏体含量随淬透性的提升而增加。此时,试样淬火变形量对淬透性的变化更为敏感。钢铁材料的淬透性本质上与其化学成分相关,例如,C、Cr、Mn和Mo等元素含量的增加能够有效提高钢的淬透性[31],因此调整化学成分是调控16MnCrS5齿轮钢淬透性最有效的方式。工业生产中,在保证16MnCrS5齿轮钢性能指标的基础上,通过合金成分的微调,优化其淬透性参数,实现淬火热变形的弱化。

图12

图12

不同淬透性试样P5位置马氏体体积分数与组织应力随淬火持续时间变化数值模拟结果

Fig.12

Numerical simulated martensite volume fraction (a) and structural stress (b) change curves as function of time at P4 of the C-notch samples with different hardenabilities during quenching

2.4 淬火变形机理

齿轮钢淬火变形与淬火过程中诱导产生的热应力和组织应力密切相关。16MnCrS5齿轮钢C型缺口试样淬火变形可分为4个阶段(除P1缺口、P5芯部),如图13a所示。在阶段Ⅰ,试样芯部发生马氏体相变之前,其淬火变形由热应力主导。由于试样缺口位置附近冷却速率较快,马氏体转变率先开始,此时试样表面承受压应力,芯部材料承受拉应力。但由于马氏体转变量较少,导致相变诱发体积膨胀产生的张应力不足以抗衡热收缩应力。当热应力与组织应力的差值超过齿轮钢的屈服强度后,塑性变形开始发生,试样缺口的位移量缓慢增加。在阶段Ⅱ,随着试样缺口与芯部之间的温差减小,如图13b所示,热应力随之降低。与此同时,试样表层完全马氏体化且芯部开始出现马氏体相变及少量的贝氏体相变,由相变诱导产生的组织应力超过热应力时,试样缺口位移量开始下降。当试样P4位置马氏体组织占比超过50%时,如图13c所示,试样淬火变形量出现最小值。在阶段Ⅲ,随着试样温度进一步降低,芯部马氏体转变继续进行直至试样完全马氏体化,但由于此时试样表层已经完全马氏体化,限制了芯部马氏体相变所诱发的体积膨胀,导致热应力的影响超过组织应力,致使试样变形回弹。在阶段Ⅳ,随着试样缺口与芯部之间温度差降低到0,试样实现完全马氏体化,缺口位移量趋于稳定。

图13

图13

16MnCrS5齿轮钢的淬火变形分析

Fig.13

Analyses of quenching deformation of 16MnCrS5 gear steel

(a) curves of quenching deformation of the 5 characteristic points with time

(b) temperature difference between notch and core changes over time

(c) variation of martensite proportion with time at P4

图14所示为淬火变形后16MnCrS5齿轮钢微观组织SEM像及EBSD分析。图14a为试样P5位置微观组织,试样经过淬火变形后,芯部出现板条状马氏体和少量的羽毛状及粒状贝氏体,这与图11c数值模拟结果相吻合。图14b所示为试样P5位置马氏体相EBSD晶体取向成像图(反极图),试样在淬火过程中发生了大量的马氏体相变,进而诱导产生较大的组织应力,该组织应力导致马氏体附近晶格畸变较大,衍射花样较差,EBSD无法标定。图14c所示为图14b对应的局部取向差(kernel average misorientation)成像图。可以看出,淬火试样中应力主要集中在相变马氏体及其周围区域,表明试样在淬火过程中产生了较大的组织应力且这种组织应力主要由马氏体相变诱导产生。

图14

图14

淬火变形后16MnCrS5齿轮钢微观组织表征

Fig.14

Microstructure characterizations of the quench-ing deformed 16MnCrS5 gear steel

(a) SEM image

(b) EBSD inverse pole figure (IPF) grain orientation map

(c) corresponding kernel average misorientation (KAM) map

3 结论

(1) 16MnCrS5齿轮钢C型缺口试样的淬火变形量随着晶粒尺寸的增加而增加,晶粒尺寸为75 μm的试样的淬火变形量相较于晶粒尺寸为22 μm的试样增加近一倍。

(2) 16MnCrS5齿轮钢C型缺口试样随着淬透性的增加,芯部马氏体含量增加,淬火变形量随之增大。数值模拟结果表明,当淬透性J9 > 32.2 HRC时,淬火试样芯部组织以马氏体为主,试样淬火变形量对淬透性的变化较为敏感。当淬透性J9 ≤ 32.2 HRC时,淬火试样芯部仍以马氏体为主,但贝氏体转变开始出现,致使试样淬火变形量对淬透性的变化相对不敏感。

(3) 随着带状组织等级的增加,16MnCrS5齿轮钢C型缺口试样的淬火变形量随之增加。数值模拟结果表明,试样垂直于轧制方向的淬火变形量明显小于平行于轧制方向的变形量,且当带状组织等级超过3级时,试样淬火变形量显著增加。因此,为控制16MnCrS5齿轮钢的淬火变形量,应严格控制其带状组织等级在3级以下。

(4) 16MnCrS5齿轮钢的淬火变形主要受热应力和马氏体相变诱导应力相互作用的影响,其中,马氏体相变的不均匀性(时间与空间分布)是导致淬火变形的关键因素。

参考文献

Blending gear shift strategy design and comparison study for a battery electric city bus with AMT

[J].

A review on the production of metal matrix composites through stir casting—Furnace design, properties, challenges, and research opportunities

[J].

Spark erosion machining of miniature gears: A critical review

[J].

Hydrogen embrittlement behavior of a vacuum-carburized gear steel

[J].Carburized gear steel has a high-hardness case layer with excellent wear and fatigue resistance and a low-hardness core with high toughness. Such different microstructures imply different susceptibilities to hydrogen embrittlement (HE). However, a few or no studies have explored the HE behavior of carburized gear steel. Herein, the HE behavior of a vacuum-carburized gear steel 20Cr2Ni4A was investigated via an electrochemical hydrogen-charging and slow strain rate tensile test. For comparison, another group of specimens was prepared by a conventional quenched and tempered (QT) treatment. The volume fraction of retained austenite was significantly higher in the case layer of the carburized specimen (13.8%) than in the core and the QT specimen (4.6%). The retained austenite in the case layer showed a mainly irregular block-type morphology with wide size distribution. The room-temperature diffusible hydrogen content in the hydrogen-charged carburized specimen were almost identical to the QT specimen but the nondiffusible hydrogen content was significantly higher in the former than in the latter. Meanwhile, the hydrogen diffusion coefficient was notably lower in the hydrogen-charged carburized specimen than that in the QT sepcimen because the former retained higher fractions of austenite and cementite. The QT specimen exhibited superior strength and ductility. After hydrogen charging, the strength of the QT specimen remained almost unchanged but the total elongation notably decreased, causing the HE index (HEI), as evidenced using the relative total elongation loss, being 54.3%. Relative to the QT specimen, the carburized specimen achieved a higher tensile strength (increase by 34.6%) but a much lower ductility (total elongation and reduction of area reductions by 66.5% and 92.4%, respectively). The carburized specimen underwent premature brittle fracture before yielding, indicating susceptibility to HE. In fact, the HEI was as high as 90.9%. Mixed intergranular and quasi-cleavage fractures were observed in the surface embrittled region of the hydrogen-charged QT specimen. This region roughly corresponded to the maximum hydrogen diffusion distance. Meanwhile, the hydrogen-charged carburized specimen exhibited an embrittled internal-surface region with a certain width of intergranular fracture, and a long crack had propagated along the circumferential direction near the effective case depth. The microstructure, strength level, and residual stress are thought to mainly explain the abovementioned differences between the carburized and QT specimens.

真空渗碳处理齿轮钢的氢脆敏感性

[J].

Recent development and application products of bulk glassy alloys

[J].

Effect of pre-heat treatment before carburizing on distortion of gear shaft made of 17CrNiMo6 steel

[J].Taking 17CrNiMo6 steel gear shaft as the research object, carburizing with pre-heat and direct carburizing processes of the gear shaft were quantitatively analyzed by finite element software, and the main pre-heat process parameters affecting the heat treatment distortion of the gear shaft were determined.The temperature field and stress field in the two processes were compared and analyzed, and the effect of pre-heat treatment on the heat treatment distortion of gear shaft was studied.The results show that pre-heat treatment at 400℃ for 3 h before carburizing can effectively reduce the heat treatment distortion of the gear shaft.

渗碳前预热处理对17CrNiMo6钢制齿轮轴畸变的影响

[J].以17CrNiMo6钢制齿轮轴为研究对象,用有限元软件对齿轮轴的渗碳预热和直接渗碳过程进行了定量分析,确定了影响畸变的主要预热工艺参数,并对这两种过程中的温度场和应力场进行了对比分析,研究预热处理对齿轮轴热处理畸变的影响。结果表明,在渗碳前进行400℃保温3 h的预热处理,能够有效减小齿轮轴热处理畸变。

Microstructure and distortion of niobium-containing 18CrNiMo7-6 gear steel after high-temperature carburization

[D].

含铌18CrNiMo7-6齿轮钢高温渗碳组织和变形研究

[D].

Study on hardenability, heat treatment distortion and fatigue property of carburized gear steels

[D].

渗碳齿轮钢淬透性及其热处理变形和疲劳性能研究

[D].

Research on abnormal deformation of automobile gear during carburizing and quenching heat treatment

[J].

汽车齿轮渗碳淬火热处理异常变形的研究

[J].

Effect of austenite grain size on heat treatment distortion automotive gear steels

[J].

奥氏体晶粒度对汽车齿轮钢热处理畸变的影响

[J].

Microstructure homogenization of 17CrNiMo6 gear steel

[J].Taking 17CrNiMo6 gear steel as the research object, and the forged specimens were annealed at different temperatures for different time. The formation of the banded structure and its homogenization behavior were studied and quantitatively analyzed by means of optical microscope, scanning electron microscope, energy dispersive spectrometer and data processing software Origin. The results show that the enrichment of C, Cr, Ni, Mn and Mo in the pearlite+bainite region is the root cause of the band structure of the 17CrNiMo6 gear steel. When the heating temperature is 1100℃ with the holding time of 11 h, or the heating temperature is 1250℃ with the holding time being more than 2 h, the banded structure is eliminated, but the non-uniformity of alloy elements is still high. When the heating temperature is 1250℃ and the holding time is 4 h, the segregation coefficients <i>K</i> for C, Cr, Mn, Ni, P, S, Mo are 1.02, 0.98, 1.02, 1.02, 1.01, 0.98, and 0.98, respectively, and the element distribution is also uniform.

17CrNiMo6齿轮钢的组织均匀化

[J].

Research on forming mechanism of banded structure in 60Si2Mn spring flat steel and its influence on mechanical properties

[D].

60Si2Mn弹簧扁钢带状组织形成机理及对性能的影响研究

[D].

Formation and elimination of banded structure of 20CrNi2Mo steel

[J].

20CrNi2Mo钢带状组织的形成与消除

[J].

The relationship between inclusions characteristic parameters and bending fatigue performance of 20Cr2Ni4A gear steel

[J].

Dynamic recrystallisation behaviour and microstructural evolution in a Mn-Cr gear steel

[J].

Research on the hardenability and phase transformation behavior of heavy transmission gear steel

[D].

重载传动齿轮钢淬透性及相变变形规律的研究

[D].

Numerical simulation of banded microstructure on quenching distortion in gear steel based on Deform

[J].

基于Deform的带状组织对齿轮钢淬火变形影响数值模拟

[J].

Quench hardening effect of gray iron brake discs on particulate matter emission

[J].

A study on fabrication, heat-treatments and mechanical properties of V-Nb microalloyed gear steel

[D].

V-Nb微合金化齿轮钢及其热处理工艺和力学性能的研究

[D].

Suppression of austenite grain coarsening by using Nb-Ti microalloying in high temperature carburizing of a gear steel

[J].

Multi-length scale modeling of carburization, martensitic microstructure evolution and fatigue properties of steel gears

[J].Multi-length scale modeling is performed to (i) predict the carburized case depth of SAE8620 steel gears by solving the Fick’s second law of diffusion, (ii) model the martensitic microstructure evolution in a grain inside the carburized case as well as to study the effect of stress cycling on retained austenite (RA) and martensite using a 3D phase-field model, (iii) simulate the effect of carburization and different RA contents on macroscale fatigue behavior of SAE8620 steel spur gear using the finite element method. The diffusion model predicts that the case depth increases with increasing heat treatment time and temperature. The phase-field simulations show that RA can transform to martensite during fatigue loading, where the extent of the transformation will depend on the type of stresses applied, i.e. stresses in a high stress regime or low stress regime of fatigue loading. Reverse transformation of martensite to austenite is also observed in low RA sample under high stress regime. The macroscale simulations show that the carburized case with high RA gives rise to better fatigue life compared to that with low RA.

Mechanism of the microstructural evolution of 18Cr2Ni4WA steel during vacuum low-pressure carburizing heat treatment and its effect on case hardness

[J].

A study on hardenability and band structure of 20CrMoH gear steel

[D].

20CrMoH齿轮钢的淬透性及带状组织研究

[D].

A simple conversion formule of HV and HRC mutual

[J].

一种简单的洛氏C硬度与维氏硬度相互换算数学公式

[J].

A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels

[J].

Stress-phase-transformation interactions—Basic principles, modelling, and calculation of internal stresses

[J].

Flow stress constitutive equation of M50NiL gear steel based on Johnson-Cook model

[J].

基于Johnson-Cook模型构建M50NiL齿轮钢的流变应力本构方程

[J].

Residual stress interaction on gear manufacturing

[J].

Nano- and microhardness distribution in the carburized case of Nb-microalloyed gear steel

[J].The characteristics of in-depth hardness distribution in the high-temperature carburized case of Nb-microalloyed gear steel before and after cryogenic treatment were studied by nano-indentation method and Vickers hardness method. The results showed that there was no significant difference in Vickers hardness of the carburized case before and after cryogenic treatment, while the nano-hardness of the carburized case was increased after cryogenic treatment. The change of nano-hardness could be related to the decrease in retained austenite content. The retained austenite content in the surface of the carburized case was 26%, which was reduced to 18% after cryogenic treatment at - 196 degrees C, with the nano-hardness increased from 11.8 to 12.6 GPa. Nano-indentation can be used to reliably measure the properties of the high-temperature carburized case with fine retained austenite for Nb-microalloyed gear steel.

Effects of heat treatment and hot processing on banded structure characteristics and mechanical properties of PCrNi3MoV steel

[D].

热处理和热加工对PCrNi3MoV钢带状组织及力学性能的影响研究

[D].