在钛合金的制备过程中,往往通过热变形及热处理控制初生α相及次生α相的含量、形状及晶粒尺寸,以实现钛合金性能的调控[5~9]。但近年来的研究[10~15]表明,原始β相的晶粒尺寸及取向也会对钛合金的强度、塑性、断裂韧度等关键性能产生影响。其原因在于:一方面,在钛合金β→α的相变过程中,α相的形貌、尺寸及取向直接受β相控制[16,17];另一方面,钛合金在服役状态下仍有残余β相存在,对于近β钛合金来说这种影响尤为明显。作者团队[13]对Ti55531钛合金某自由锻件亮带的组织及取向特征进行探索性研究,发现亮带中的大尺寸{100}取向(垂直锻造方向) β晶粒可使其室温抗拉强度较无织构区域降低约270 MPa,弹性模量降低约25 GPa,延伸率提高约9.6%。由于亮带的尺寸限制,该工作没有系统研究其他取向对宏观力学性能的影响,也没有对大尺寸{100}取向β晶粒的形成原因进行分析。后续研究[18]表明,β相的{100}取向在TC18钛合金锻造及热处理过程中十分稳定。在两相区及单相区压缩变形时都会形成β相的{100}织构,且温度越高、变形量越大,{100}织构越强;在两相区拉伸时,变形温度越高,{100}织构越强;在两相区接近相变点加热时,回复态的{100}取向β晶粒容易利用尺寸优势吞并其他晶粒,这些晶粒即使在单相区接近相变点处被短时间加热也不会被再结晶晶粒吞并[19,20]。

基于上述研究,本工作通过特殊的锻造及热处理工艺制备了包含{100}取向β晶粒(晶粒尺寸大于50 mm × 50 mm × 100 mm)的TC18钛合金试样;通过对不同方向的标准试样进行室温拉伸及室温冲击实验,研究了β相的{100}、{110}、{111}取向对其宏观力学性能的影响;通过光学显微镜(OM)、扫描电子显微镜(SEM)及电子背散射衍射(EBSD)系统观察并分析了制备过程中组织及织构的特征,以期揭示β相对钛合金关键力学性能的影响规律,并为通过控制织构以调整钛合金性能的工艺探索提供理论支撑。

1 实验方法

实验材料为200 mm × 200 mm × 400 mm的TC18钛合金方坯,其名义化学成分(质量分数,%)为Ti-5Al-5Mo-5V-1Cr-1Fe-0.1O,β→α的相转变温度为875 ℃。将方坯在α + β相区(840 ℃)沿长度方向反复镦拔6火次,单火次镦粗变形量为50% (图1a);随后,将坯料进行1火次准β相区锻造[21],即在相转变温度以上15 ℃ (即890 ℃)沿长度方向镦粗30%,获得尺寸约为240 mm × 240 mm × 280 mm的锻坯(图1b)。将锻坯进行高温退火并热处理后,检测坯料不同方向的室温拉伸及室温冲击性能。高温退火工艺为:900 ℃保温12 h、水冷。热处理工艺为:840 ℃保温2 h、炉冷+ 750 ℃保温3 h、空冷+ 610 ℃保温6 h、空冷。

图1

图1

TC18钛合金坯料锻造工艺示意图

Fig.1

Schematics of forging process for TC18 titanium alloy billets (LD—length direction, TD1—transverse direction 1, TD2—transverse direction 2)

(a) forging at α + β region (b) forging at β region

以大尺寸{100}取向β晶粒的<100>方向为基准,分别沿热处理态TC18钛合金的<100>、<110>、<111>方向切取力学性能测试试样。拉伸和冲击试样的工作段长度分别为35和2 mm,切取时确保测试区在大尺寸{100}取向β晶粒的内部,取样位置、方向及试样尺寸如图2所示。采用Instron4507万能试验机进行室温拉伸实验,采用JB30B冲击试验机进行室温冲击实验。

图2

图2

TC18钛合金坯料力学性能测试试样的取样位置示意图及试样尺寸图

Fig.2

Schematics of sampling position (a) and dimensions of tensile (b) and impact (c) specimens for TC18 titanium alloy billet (unit: mm)

分别在第3和6火次坯料的端面、第7火次坯料的端面及中心、高温退火坯料的中心沿垂直变形方向的横截面切取低倍片(厚度为20 mm)。使用60%HNO3 + 40%HF (体积分数,下同)抛光液和13%HNO3 + 16%HF 腐蚀液对第7火次坯料端面和中心的低倍片表面进行抛光和腐蚀,并使用数码相机拍摄其低倍组织。在第3、6、7火次坯料端面低倍片的心部、一半厚度和表面位置、高温退火坯料接近大尺寸β晶粒位置取样,用于组织及织构特征的观察及分析,如图3所示。为避开变形死区,在表面试样距离坯料拔长面约20 mm的位置取样,一半厚度位置试样位于表面试样和心部试样中间。采用OM以及配备EBSD探头的Ultra 55场发射SEM表征显微组织形貌和织构特征,并利用Channel 5取向分析软件分析EBSD数据,根据长度方向(LD)绘制晶粒取向分布图和极图等。

图3

图3

TC18钛合金低倍片中显微组织观测试样的取样位置示意图

Fig.3

Schematic of sampling position for microstructure observation specimens in TC18 titanium alloy for macrostructure test

2 实验结果

2.1 α+ β 两相区锻造3火次后的组织及织构特征

图4

图4

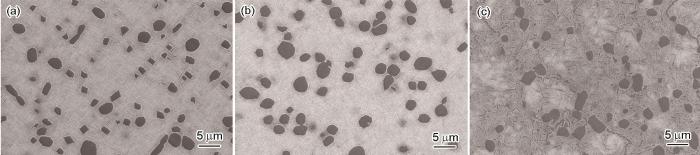

α + β两相区锻造3火次后TC18钛合金坯料各位置横截面的SEM像

Fig.4

Cross-sectional SEM images of the center (a), half thickness layer (b), and surface (c) of TC18 titanium alloy billet after three-pass forging at α + β region

在α + β两相区锻造3火次后,TC18钛合金坯料横截面心部至表面β相的晶粒取向分布图如图5a~c所示,图中空白点为α相或EBSD未能标定的点。由于锻造工序为先镦粗后拔长,因此在坯料心部及一半厚度位置形成了2种具有bcc结构的典型拉伸织构:{100}织构和{110}织构(图5a和b),其中心部{100}取向晶粒完全将{110}取向晶粒包围(图5a);表面位置的应力复杂且应变较小,因此晶粒取向较为随机(图5c)。β相的再结晶晶粒分布如图5d~f所示。在使用Channel 5软件处理数据时,设定亚晶界判定角度(θc)为2°,晶界判定角度(θGB)为10°。即当晶粒中的平均取向差θ0 > 2°时,晶粒被定义为变形晶粒;当晶粒中存在亚晶,每个亚晶中的θ0 < 2°,而亚晶之间的取向差θi > 2°时,晶粒被定义为回复晶粒;其他晶粒定义为再结晶晶粒。可见,锻造后产生的动态再结晶晶粒数量很少(其在心部至表面的占比分别为3.2%、9.8%和14.7%),大部分晶粒处在回复状态(其在心部至表面回复晶粒的占比分别为81.9%、31.8%和0.9%)或变形状态(其在心部至表面变形晶粒的占比分别为14.9%、58.4%和84.4%)。其中,心部及一半厚度位置的{100}取向β相多为回复状态,{110}取向β相多为变形状态(图5d和e);表面位置的β相基本为变形状态(图5f)。β相的{100}及{110}极图如图5g~i所示。心部区域的织构最强,其中{100}织构强度为46.5,一半厚度位置次之(织构强度为17.7),表面没有形成明显的织构(最高织构强度为4.1)。

图5

图5

α + β两相区锻造3火次后TC18钛合金坯料各位置β相的晶粒取向分布图、再结晶变形晶粒分布图和极图

Fig.5

EBSD analyses of β phases at center (a, d, g), half thickness layer (b, e, h), and surface (c, f, i) of TC18 titanium alloy billet after three-pass forging at α + β region

(a-c) grain orientation distribution maps (d-f) recrystallized grain distribution maps (g-i) pole figures

由于坯料心部与表面位置β相的取向特征明显不同,而一半厚度位置为2者过渡,为进一步观察心部及表面位置的微观组织及取向,采用更高放大倍数进行EBSD扫描,α和β相的晶粒取向分布图和极图如图6所示。对比图6a和e,坯料表面位置因变形温度低,其α相面积分数明显高于心部(心部为15.5%,表面为28.9%)。心部仅存在1个{100}取向的β晶粒(图6b),与其内部的α相之间严格遵从{0002}α //{110}β,<11

图6

图6

α + β两相区锻造3火次后TC18钛合金坯料心部和表面α相及β相的晶粒取向分布图和极图

Fig.6

EBSD analyses of α and β phases at center (a-d) and surface (e-h) of TC18 titanium alloy billet after three-pass forging at α + β region

(a, e) grain orientation distribution maps of α phase (b, f) grain orientation distribution maps of β phase (c, g) {0001}α pole figures (d, h) {110}β pole figures

2.2 两相区锻造6火次后的组织及织构特征

在α + β两相区锻造6火次后,TC18钛合金坯料的显微组织与3火次锻造后基本一致,仍由等轴初生α相、未完全破碎的晶界α相、细针状的次生α相及原始β相基体组成,如图7所示。其心部至表面的初生α相平均晶粒尺寸分别为2.01、2.68和2.89 μm。

图7

图7

α + β两相区锻造6火次后TC18钛合金坯料横截面各位置的SEM像

Fig.7

Cross-sectional SEM images of center (a), half thickness layer (b), and surface (c) of TC18 titanium alloy billet after six-pass forging at α + β region

图8为α + β两相区锻造6火次后TC18钛合金坯料心部至表面横截面处β相的晶粒取向分布图、再结晶晶粒分布图及极图。可见,心部与一半厚度位置β相的取向特征趋于一致,晶粒主要由回复状态的大尺寸{100}取向β晶粒及少量变形状态的{110}晶粒组成(图8a、b、d和e);表面存在变形状态的大量{100}取向β晶粒和少部分过渡取向β晶粒(图8c和f)。与3火次锻造试样相比,其动态再结晶晶粒占比下降(心部至表面分别为1.0%、4.2%和13.1%),回复晶粒占比提高(心部至表面分别为96.7%、83.4%和2.3%);心部至表面β相的{100}织构进一步增强(织构强度分别为56.7、51.2、8.3) (图8g~i)。图9为α + β两相区锻造6火次后TC18钛合金坯料表面位置α和β相的晶粒取向分布图和极图。与3火次锻造试样相比,其初生α相的平均晶粒尺寸增大(图6e和9a),β晶粒碎化程度进一步提高并趋于等轴化(图6f和9b),大部分两相晶粒保持Burgers取向关系(图9c和d)。

图8

图8

α + β两相区锻造6火次后TC18钛合金坯料各位置β相的晶粒取向分布图、再结晶晶粒分布图和极图

Fig.8

EBSD analyses of β phases at center (a, d, g), half thickness layer (b, e, h), and surface (c, f, i) of TC18 titanium alloy billet after six-pass forging at α + β region

(a-c) grain orientation distribution maps (d-f) recrystallized grain distribution maps (g-i) pole figures

图9

图9

α + β两相区锻造6火次后TC18钛合金坯料表面α相及β相的晶粒取向分布图和极图

Fig.9

EBSD analyses of α and β phases in TC18 titanium alloy billet's surface after six-pass forging at α + β region

(a) grain orientation distribution map of α phase (b) grain orientation distribution map of β phase (c) {0001}α pole figure (d) {110}β pole figure

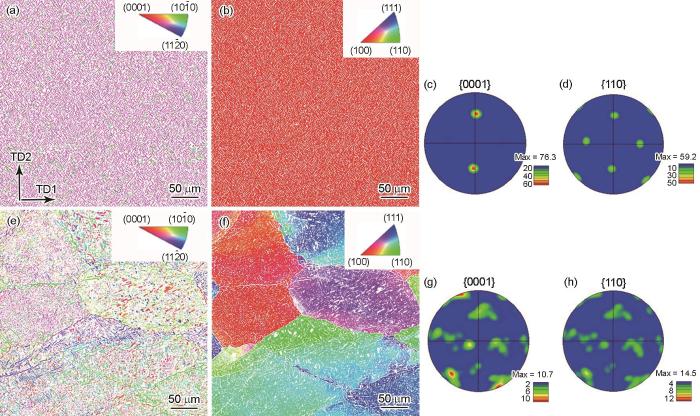

2.3 准 β 锻造后的组织及织构特征

TC18钛合金坯料的第7火次锻造为在准β相区的锻造,锻造完成后坯料端面及中心位置的横截面都出现了明显的亮带组织,其尺寸分别约为80 mm × 80 mm和150 mm × 150 mm,如图10所示。图11分别为准β相区锻造后TC18钛合金坯料心部至表面横截面处β相的晶粒取向分布图、再结晶晶粒分布图及极图。心部及一半厚度位置在扫描区域内均由一个回复态{100}取向β晶粒及少量岛屿状变形及再结晶状态杂取向晶粒构成(图11a、b、d和e),{100}织构的织构强度继续提高(分别为59.0和59.6) (图11g和h)。表面位置β晶粒的取向较为丰富(图11c),取向以{111}为主(最高织构强度为4.4) (图11i),晶粒内部存在较大的取向差。心部至表面均以回复状态晶粒为主,其占比分别为99.3%、99.4%和81.9% (图11d~f)。

图10

图10

准β相区锻造后TC18钛合金坯料端部及中心横截面的低倍组织

Fig.10

Cross-sectional macrostructure morphologies at head face (a) and core (b) of TC18 titanium alloy billet after forging at quasi-β region

图11

图11

准β相区锻造后TC18钛合金坯料各位置β相的晶粒取向分布图、再结晶晶粒分布图和极图

Fig.11

EBSD analyses of β phases at center (a, d, g), half thickness layer (b, e, h), and surface (c, f, i) of TC18 titanium alloy billet after forging at quasi-β region

(a-c) grain orientation distribution maps (d-f) recrystallized grain distribution maps (g-i) pole figures

图12

图12

准β相区锻造后TC18钛合金坯料心部和表面α及β相的EBSD晶粒取向分布图和极图

Fig.12

EBSD analyses of α and β phases at center (a-d) and surface (e-h) of TC18 titanium alloy billet after forging at quasi-β region

(a, e) grain orientation distribution maps of α phase (b, f) grain orientation distribution maps of β phase (c, g) {0001}α pole figures (d, h) {110}β pole figures

2.4 高温退火后的组织及织构特征

高温退火后,通过分区扫描并拼接的方法观察了TC18钛合金坯料横截面大尺寸{100}取向β晶粒及其附近晶粒的取向特征,如图13所示。可见,大尺寸{100}取向β晶粒周围的等轴β晶粒取向随机且尺寸较大,但与{100}取向β晶粒相比仍有数量级的差别;大尺寸{100}取向β晶粒内部也有大量等轴晶粒,其晶粒尺寸更小且均为岛屿状。值得注意的是,{100}取向β晶粒内部的等轴晶粒较准β锻造后数量明显增多,尺寸明显增大。大尺寸{100}取向β晶粒及其周围晶粒的衬度图、晶粒取向分布图和再结晶晶粒分布图如图14所示。大尺寸{100}取向β晶粒内部仍有大量缺陷(图14a和b),未发生再结晶;其周围及内部的等轴晶粒大部分为再结晶态,少部分为回复态(图14c)。大尺寸{100}取向β晶粒内部存在大量亚晶(15a),由于高温退火后的冷却方式为水冷,其内部形成了大量厚度为纳米级的针状α相(图15b)。

图13

图13

高温退火后TC18钛合金坯料横截面β晶粒的晶粒取向分布图

Fig.13

Cross-sectional grain orientation distribution map of β grains in TC18 titanium alloy billet after high-temperature annealing

图14

图14

高温退火后TC18钛合金坯料中大尺寸{100}取向β晶粒及其周围晶粒的衬度图、晶粒取向分布图和再结晶晶粒分布图

Fig.14

Band contrast map (a), grain orientation distribution map (b), and recrystallized grains distribution map (c) of large-sized {100} β grain and its adjacent grains in TC18 titanium alloy billet after high-temperature annealing

图15

图15

高温退火后TC18钛合金坯料中大尺寸{100}取向β晶粒内部的SEM像

Fig.15

Low (a) and high (b) magnified SEM images in large-sized {100} β grain of TC18 titanium alloy billet after high- temperature annealing

2.5 热处理后的组织及性能

表1 TC18钛合金坯料沿不同方向测试的力学性能

Table 1

| Direction | Rm MPa | Rp0.2 MPa | A % | Z % | E GPa | aku J·cm-2 |

|---|---|---|---|---|---|---|

| <100> | 982 | 936 | 14.0 | 36.6 | 96 | 26.25 |

| 979 | 936 | 16.7 | 55.6 | 96 | 31.25 | |

| <110> | 1129 | 1081 | 12.5 | 28.4 | 118 | 52.50 |

| 1145 | 1072 | 10.9 | 27.4 | 115 | 40.00 | |

| <111> | 1328 | 1275 | 11.1 | 56.0 | 125 | 58.75 |

| 1328 | 1276 | 11.7 | 58.3 | 124 | 53.75 | |

| No texture | 1157 | 1136 | 16.5 | 51.6 | 110 | 49.50 |

图16

图16

热处理态TC18钛合金锻坯中<111>织构试样和无织构试样的OM像

Fig.16

OM images of samples with <111> texture (a) and without texture (b) in TC18 titanium alloy billet after heat treatment

3 分析与讨论

3.1 热变形过程中大尺寸{100}取向 β 相晶粒的形成原因

TC18钛合金中β相的大尺寸{100}取向晶粒在坯料横截面心部形成,并随着锻造火次增多逐渐向表面长大。TC18钛合金的导热性较差,坯料心部实际的变形温度及应变明显高于表面,而在热变形过程中{100}取向晶粒占比随两相区热压缩变形温度及变形量的升高而提高[18],因此其心部位置更容易形成β相的强{100}织构(图5)。随着两相区锻造火次增多,即累积变形量逐渐增大,各位置β相的{100}织构均逐渐增强,其主要原因是在两相区的热变形过程中,动态回复是主要的软化机制,如图5和8所示。由于在动态回复过程中,主要通过位错的交滑移和攀移与异号位错相互抵消的方式消耗形变储存能,因此晶粒尺寸越大越能保持其晶体取向的稳定。在准β锻造前的加热过程中,由于回复程度较高且晶粒尺寸过于悬殊,大尺寸{100}取向晶粒不会被新形成的再结晶晶粒吞并;而在随后的变形过程中,动态回复仍然占据主导,心部及厚度一半位置{100}取向的β相晶粒进一步长大,并将其他取向的晶粒包围(图11)。与取向硅钢中的Goss晶粒的二次再结晶长大不同[22,23],这里的晶粒长大并不是通过晶界迁移完成的,而是通过相近取向的晶粒发生亚晶界合并完成的,因此在高温退火后大尺寸的{100}晶粒内部存在大量亚晶的胞状结构,如图15所示。

3.2 β 相取向对钛合金力学性能的影响

根据不同方向室温拉伸及室温冲击的测试结果可知,在完全剔除了成分、组织的影响后,仅改变β相的取向即可极大影响TC18钛合金的关键力学性能。一般认为,α相为硬质相,其含量、形状及晶粒尺寸决定钛合金的性能,但是β相对两相协调变形及滑移穿过机制也有着重要影响[1]。研究[27]表明,当变形量较小且两相无法满足Burgers关系时,滑移将被限制在α相晶粒内无法穿过相界继续滑移。近β钛合金在服役状态下的β相体积分数超过50%,当β相的取向为单一取向时,其对两相协调变形机制的影响更为显著。综上所述,TC18钛合金在<111>方向的强度、弹性模量及冲击韧性大于<110>方向及<100>方向,且<110>方向的力学性能与无织构状态下接近,与bcc金属单晶力学性能具有相同规律[28]。TC18钛合金中大尺寸β相晶粒的<111>方向在基本不损失塑性的情况下,较无织构状态抗拉强度提高约14.8%、屈服强度提高约12.2%、冲击韧性提高约13.6%,为通过织构控制进一步优化钛合金性能提供了可能。

4 结论

(1) 通过6火次α + β两相区锻造、1火次准β相区锻造以及高温退火制备了包含{100}取向β晶粒(尺寸大于50 mm × 50 mm× 100 mm)的TC18钛合金试样。典型方向的室温拉伸及室温冲击测试结果表明,仅改变β相的取向即可极大影响TC18钛合金的关键力学性能,大尺寸β晶粒<111>方向的强度、弹性模量及冲击韧性最高,<100>方向最低,<110>方向介于2者之间且与无织构状态下接近。

(2) 在坯料锻造过程中,TC18钛合金中大尺寸{100}取向β晶粒在横截面心部形成,并随着锻造火次的增多逐渐向表面长大,其中晶粒长大是通过相近取向的晶粒发生亚晶界合并而完成的。

参考文献

Research and application of high-strength titanium alloys used in airplane structure

[J].

航空用高强度结构钛合金的研究及应用

[J].

Development and research status of materials used for landing gear of civil aircraft

[J].

民机起落架用材料的发展与研究现状

[J].

Microstructure controlling technology and mechanical properties relationship of titanium alloys for aviation applications

[J].

航空用钛合金显微组织控制和力学性能关系

[J].钛合金由于具有多样性和复杂性的固态相变特征,其组织性能关系一直都是材料科学工作者研究的热点之一。通过调整钛合金的成分配比、加工工艺以及热处理工艺参数,可以在一定范围内调整钛合金制件的组织类型与组织参数,实现强度、塑性、韧性、疲劳和疲劳裂纹扩展速率等综合性能的最佳匹配。本文在对比钛合金材料的等轴组织、双态组织、网篮组织和片层组织四种典型显微组织特征以及控制技术基础上,以航空用TC21钛合金、TC4-DT钛合金、TC32钛合金以及TB17钛合金为例综述不同显微组织特征与拉伸性能、断裂韧度、疲劳裂纹扩展速率的影响关系,为钛合金选择合适的组织参数、实现最佳的综合性能匹配和稳定批量生产提供参考依据。

Development of quantitative research in titanium alloys

[J].

钛合金的定量研究进展

[J].

Review thermomechanical processing and microstructure of high strength-toughness titanium alloy

[J].

高强韧钛合金热加工技术与显微组织

[J].

Study on microstructure control and mechanical property TA15 alloy large-scale whole frame die forging

[J].

TA15钛合金大型整框模锻件组织控制及性能研究

[J].

Effect of heat treatment on microstructure and mechanical properties of TC18 titanium alloy

[J].

热处理对TC18合金显微组织和力学性能的影响

[J].

Influence of grain size and crystallographic texture on mechanical behavior of TIMETAL-LCB in metastable β-condition

[J].

Effect of β grain size and cooling rate of double aging heat treatment on microstructure and mechanical properties of TB3 titanium alloy

[J].

β晶粒尺寸及双时效炉冷速率对TB3钛合金组织与性能的影响

[J].

β-grain growth and influence of its grain size on damage-tolerance property in titanium alloy

[J].

钛合金β晶粒生长规律及晶粒尺寸对损伤容限性能的影响

[J].

Analysis of bright band formation in Ti-55531 titanium alloy forging

[J].

Ti-55531钛合金自由锻件亮带形成原因分析

[J].

Influence of β grain size on tensile behavior and ductile fracture toughness of titanium alloy Ti-10V-2Fe-3Al

[J].

Anisotropy of mechanical properties of β processed TC17 titanium alloy

[J].

β锻TC17钛合金力学性能各向异性研究

[J].

Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti-6 Al-4V

[J].

The effect of β grain coarsening on variant selection and texture evolution in a near-β Ti alloy

[J].

Effect of hot deformation parameters on the evolution of microstructure and texture of β phase in TC18 titanium alloy

[J].

热变形参数对TC18钛合金β相组织及织构演变规律的影响

[J].利用SEM及EBSD技术,研究热变形参数(变形方式、变形温度、变形量、应变速率、保温时间)对TC18钛合金β相组织及织构演变规律的影响。结果表明,TC18钛合金在热压缩及两相区热拉伸时,β相均以动态回复为主。在热压缩后,主要形成{100}及{111}织构,在热拉伸后,主要形成{110}织构;在单相区压缩时,随着变形温度升高、变形量提高、应变速率降低,{100}织构比例提高、{111}织构比例降低;在两相区压缩时,随着变形温度升高、变形量提高,{100}织构比例提高、{111}织构比例降低;在两相区拉伸时,随着变形量提高,{110}织构比例逐渐提高。

Effect of annealing temperature on microstructure and texture evolution of TC18 titanium alloy

[J].

退火温度对TC18钛合金组织及织构演变规律的影响

[J].

Recovery and recrystallization behavior of large sized β phase grains in TC18 titanium alloy during annealing process

[J].

Quasi-β forging process of titanium alloys

[P].

钛合金准β锻造工艺

[P].

Secondary recrystallization kinetics in GO electrotechnical steels

[J].

Effect of hydrogen content in the final annealing atmosphere on secondary recrystallization of grain-oriented Si steel

[J].

A new route for growing large grains in metals

[J].

Abnormal grain growth induced by cyclic heat treatment

[J].In polycrystalline materials, grain growth occurs at elevated temperatures to reduce the total area of grain boundaries with high energy. The grain growth rate usually slows down with annealing time, making it hard to obtain grains larger than a millimeter in size. We report a crystal growth method that employs only a cyclic heat treatment to obtain a single crystal of more than several centimeters in a copper-based shape-memory alloy. This abnormal grain growth phenomenon results from the formation of a subgrain structure introduced through phase transformation. These findings provide a method of fabricating a single-crystal or large-grain structure important for shape-memory properties, magnetic properties, and creep properties, among others.

Dynamic abnormal grain growth: A new method to produce single crystals

[J].

Quantitative research on micro-plastic deformation mechanism and microstructure evolution of polycrystal-dual phase titanium alloy

[D].

双相多晶钛合金微观塑性变形机理与组织演化的定量研究

[D].