为满足日益增长的工程应用需求,金属结构材料在要求具备高强度的同时还需要有良好的塑性。然而,材料中存在的高强度与良好塑性难以匹配的问题一直制约着先进结构材料的发展[1]。传统金属材料的设计理念通常是选取1种或2种主要的金属做主元素,在此基础上添加少量其他元素,例如钢铁、铝合金和镍基合金等。通过调控局部的应力场与位错行为,达到优化材料综合力学性能的目的。近年来,高熵合金(HEA)——一种具有等原子比或近等原子比的多主元合金设计思路被提出,并受到广泛关注与研究[2,3]。理论上,随着主元数目的增加,合金倾向于形成硬且脆的金属间化合物以及复杂的结构相,这2者都会恶化合金的力学性能。但高熵合金较高的构型熵降低了系统的Gibbs自由能,使合金形成稳定的单相固溶体,包括fcc、bcc以及hcp晶体结构,而非金属间化合物和复杂的结构相[4,5]。高熵合金展现出许多独特的性质和非凡的性能,在低温、航空航天、储氢、抗辐照等领域展现出极大的应用潜力[6,7]。在高熵合金体系中,fcc高熵合金由于其良好的综合力学性能、极端条件下优越的断裂韧性和抗腐蚀性能受到广泛关注[8~11]。但是受制于fcc晶体自身的屈服强度较低[12],亟待开发具有高屈服和抗拉强度的fcc结构高熵合金。

轧制作为金属材料热机械处理的重要工艺,不仅可以在宏观上改变块体材料的尺寸和形状,还能在微观上拉长甚至破碎晶粒,再结合后续的再结晶退火处理,可达到细化晶粒和提升材料力学性能的目的[13,14]。其中,根据轧制时采用温度的差异,可将轧制方式分为液氮轧制(liquid nitrogen rolling,LNR)、室温冷轧(cold rolling,CR)以及温轧(warm rolling,WR)。3种轧制温度导致材料的层错能存在差异[15,16],轧制后形成的微观组织也不尽相同。根据相关文献[12,15,17,18]报道,随着层错能降低,fcc金属的塑性变形机制会由位错滑移转变为位错滑移加形变孪生,再到位错滑移、形变孪生与马氏体相变。

Sun等[19,20]在77 K下通过对合金进行拉伸预变形引入了应变诱导的孪晶,且随着拉伸变形量的增加,孪晶的体积分数不断增大。这些孪晶通过细化微观组织、降低位错的平均自由程,在后续拉伸过程中有效地阻碍了位错滑移,提高了材料的屈服强度。Moon等[21]在此基础上结合低温退火处理,使合金中应变诱导孪晶被保留[22]的同时,部分位错发生回复。这不仅提高了材料的屈服强度,也增加了其加工硬化能力。然而,变形结合低温退火所保留的形变孪晶虽然有效地提高了材料的屈服强度,但变形量的增加会大幅度降低材料的塑性。例如压下量为50%的冷轧态样品经历500 ℃退火后,其屈服强度高达1284 MPa,但均匀延伸率仅为1%。

基于此,本工作采用不同温度下的轧制变形,在铁基fcc高熵合金中引入不同的微观组织,并结合低温退火保留形变孪晶以及回复部分位错的方法,即通过调控合金的微观组织,达到优化材料综合力学性能的目的。并分析不同轧制温度结合退火制备材料的变形机制及其对材料力学性能的影响,旨在为改善fcc高熵合金的性能提供新思路。

1 实验方法

实验用高熵合金的名义化学成分为Fe50Mn29-Co10Cr10Cu1 (原子分数,%)。采用纯度大于99.9% (质量分数)的纯金属,在充满Ar气的真空感应炉中熔铸合金,随后在1200 ℃下进行锻造处理及900 ℃下的多道次热轧(累积压下量为50%)。在1200 ℃下对热轧合金进行保温2 h的均匀化处理,然后水淬。均匀化处理后合金的平均晶粒尺寸约为500 μm。将热轧板分为3块,分别在液氮温度(-196 ℃)、室温(25 ℃)和300 ℃进行累积压下量为40%的多道次轧制,并将其依次标记为LNR、CR和WR样品,随后将轧制态合金分别在500和800 ℃的马弗炉中退火(AN) 1 h,然后水淬。将经不同轧制温度和不同退火温度的样品进行编号,分别记为LNR40% + AN500 ℃、CR40% + AN500 ℃、WR40% + AN500 ℃、LNR40% + AN800 ℃、CR40% + AN800 ℃和WR40% + AN800 ℃。

采用电火花放电加工法从合金板材上切割出横截面尺寸为3 mm × 2 mm、标距长度13 mm的扁平狗骨状拉伸试样。用砂纸进行机械抛光去除试样表面的氧化物与缺陷,随后在AG-X100KN型万能试验机上沿轧制方向对各样品进行室温下的单轴拉伸测试,应变速率为1 × 10-3 s-1。

使用Smartlab X射线衍射仪(XRD)分析单轴拉伸测试前后样品的晶体结构和相组成(波长λ = 0.154056 nm,CuKα1),测试电压和电流分别为40 kV和200 mA。采用步进式扫描,衍射角度范围40°~100°,步长0.04°。使用Jade软件对XRD数据进行处理与分析。为分析不同退火温度下是否发生了再结晶、再结晶的比例以及再结晶的晶粒尺寸,使用JSM-7001F扫描电子显微镜(SEM)对样品的微观组织进行表征,每个样品至少选取3个区域进行观察,从而获得具有统计意义的结果。首先对样品进行机械抛光使其表面达到镜面光泽,然后用6.25%HClO4 + 93.75%C2H5OH (体积分数)的混合溶液对样品进行电化学抛光处理以去除应变层。使用配备有HKL电子背散射衍射(EBSD)系统的JSM-7001F SEM进一步表征样品的变形程度、晶界分布、相组成、几何必需位错密度和晶体学取向,扫描步长为80 nm;所有样品由电化学抛光处理制备,并使用Channel 5软件进行数据后处理。

使用2100F透射电子显微镜(TEM)对拉伸前后的LNR40% + AN500 ℃、CR40% + AN500 ℃和WR40% + AN500 ℃样品进行微观组织表征,电压200 kV。将TEM样品制备成半径3 mm、厚度50 μm的薄片,在-25 ℃下使用10%HClO4 + 90%C2H5OH (体积分数)的混合溶液进行电解双喷处理。所有样品的坐标系由3个正交的坐标轴定义,即轧板的轧向(RD)、横向(TD)和法线方向(ND)。样品的XRD和TEM测试与表征在合金的轧面(即RD-TD平面)上进行,SEM和EBSD样品在合金的侧轧面(即RD-ND平面)。

2 实验结果

2.1 相组成

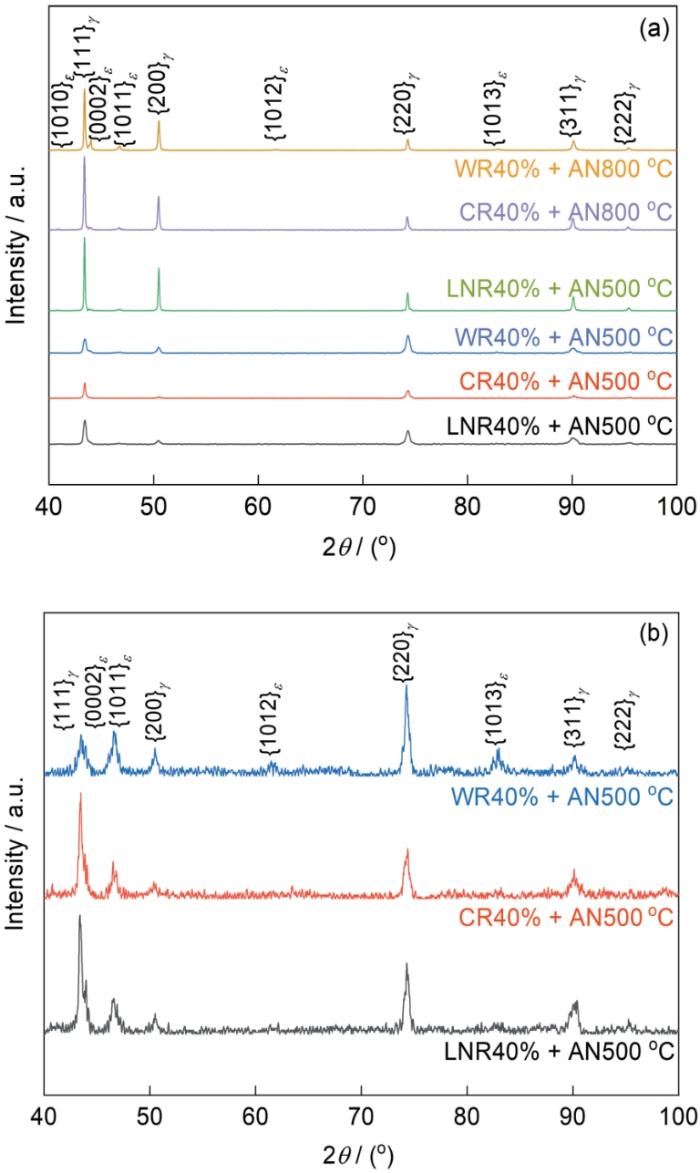

图1给出了各样品在拉伸变形前后的XRD谱。由图可见,样品均由γ-奥氏体(fcc)和ε-马氏体(hcp) 2相构成。合金中fcc相的晶格常数约为0.36 nm,与Cantor合金相接近[3],且拉伸断裂后各样品中无新的衍射峰出现。fcc相的衍射角2θ = 43.4°、50.4°、74.3°、90.1°和95.5°,晶面指数分别为{111}、{200}、{220}、{311}和{222};hcp相的2θ = 41.0°、43.9°、46.7°、61.6°、82.8°,晶面指数分别为{1010}、{0002}、{1011}、{1012}和{1013}。经计算,各样品在拉伸前后2相所占比例(体积分数)列于表1。拉伸前,经3种温度轧制并结合500 ℃退火得到的样品中,马氏体的体积分数均小于10%。随着退火温度升高至800 ℃,经液氮轧制结合退火制备的样品中马氏体基本消失(约2.5%),经室温冷轧结合退火的样品中马氏体含量降低至6.0%,而温轧结合退火的样品中马氏体含量较500 ℃退火有所增加(达到14.5%)。拉伸变形后,LNR40% + AN500 ℃样品中的hcp马氏体含量由9.5%增加至14.2%,CR40% + AN500 ℃样品中的马氏体含量由7.7%增加至12.0%,WR40% + AN500 ℃样品中的马氏体含量由8.4%增加至12.3%。

图1

图1

经轧制结合退火制备的样品拉伸前后的XRD谱

Fig.1

XRD spectra of samples prepared by rolling and annealing before (a) and after (b) tensile tests (LNR—liquid nitrogen rolling, CR—cold rolling at room temperature, WR—warm rolling, AN—annealing)

表1 经轧制结合退火制备的样品在拉伸前后的相组成 (volume fraction / %)

Table 1

| Sample | Tensile test | fcc | hcp |

|---|---|---|---|

| LNR40% + AN500 oC | Before | 90.5 | 9.5 |

| After | 85.8 | 14.2 | |

| CR40% + AN500 oC | Before | 92.3 | 7.7 |

| After | 88.0 | 12.0 | |

| WR40% + AN500 oC | Before | 91.6 | 8.4 |

| After | 87.7 | 12.3 | |

| LNR40% + AN800 oC | Before | 97.5 | 2.5 |

| CR40% + AN800 oC | Before | 94.0 | 6.0 |

| WR40% + AN800 oC | Before | 85.5 | 14.5 |

2.2 微观结构

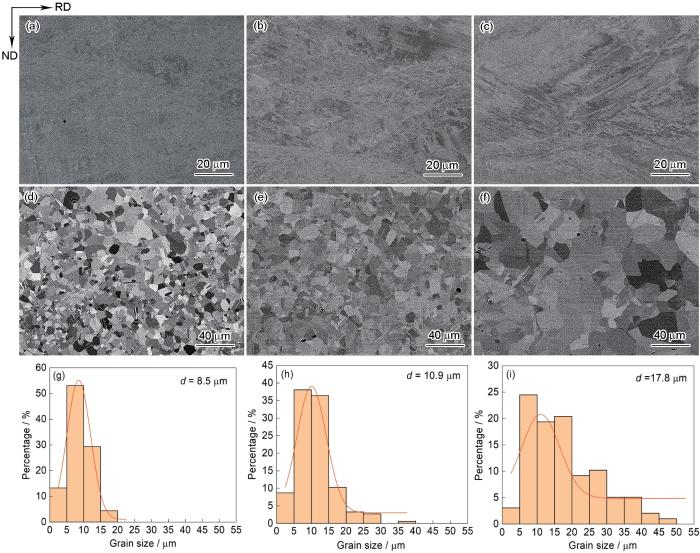

图2

图2

经不同工艺制备的样品的SEM像及晶粒尺寸分布图

Fig.2

SEM images (a-f) and grain size distribution maps (g-i) of the samples prepared by different processing routes (d—average grain size, RD—rolling direction, ND—normal direction )

(a) LNR40% + AN500 oC (b) CR40% + AN500 oC (c) WR40% + AN500 oC (d, g) LNR40% + AN800 oC (e, h) CR40% + AN800 oC (f, i) WR40% + AN800 oC

图3为经轧制变形结合500 ℃退火制备的各样品在RD-ND平面上的EBSD分析。图3a1~c1为Kikuchi带衬度(band contrast,BC)图。可以明显看出,LNR40% + AN500 ℃样品中存在大量缺陷,表现出较高的局部应变;CR40% + AN500 ℃样品中的缺陷和应变有所下降;相比之下,WR40% + AN500 ℃样品中的缺陷最少,应变水平也最低。在各样品相分布图中只观察到了fcc相(图中红色区域),这与EBSD的分辨率有限、无法识别淬火时形成的尺寸较小的热诱导hcp马氏体有关。大角度晶界(取向差大于10°)、小角度晶界(取向差位于3°~10°)和Σ3孪晶界分别用粗黑实线、细黑实线和白色实线标记,如图3a2~c2所示。图3a3~c3为局部取向差(kernel average misorientation,KAM)图。LNR40% + AN500 ℃和CR40% + AN500 ℃样品具有较高的平均KAM值(分别为0.89°和0.77°),而WR40% + AN500 ℃样品的平均KAM值相对较低(0.61°)。沿RD方向的取向分布图(反极图,IPF)如图3a4~c4所示。可以看出,各样品中晶体学取向呈随机分布,织构很弱。

图3

图3

经轧制结合500 ℃退火制备样品的EBSD像

Fig.3

EBSD maps of LNR40% + AN500 oC (a1-a4), CR40% + AN500 oC (b1-b4), and WR40% + AN500 oC (c1-c4) samples

(a1-c1) band contrast maps (a2-c2) phase distribution maps (High-angle boundaries with misorientation angles larger than 10° are indicated by black solid lines, low-angle boundaries with misorientation angles between 3° and 10° are indicated by thin black solid lines, and Σ3 twin boundaries in the fcc phase are indicated by white solid lines) (a3-c3) kernel average misorientation maps (a4-c4) inverse pole figures parallel to the tensile axis

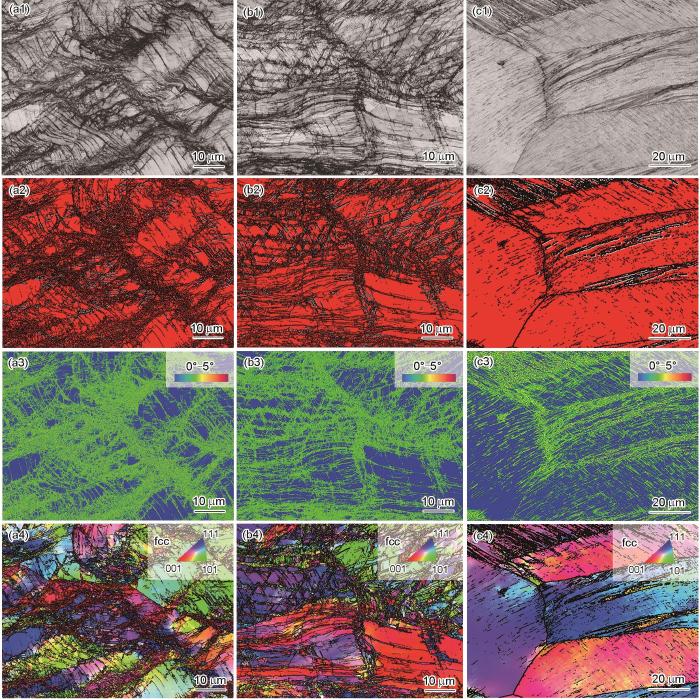

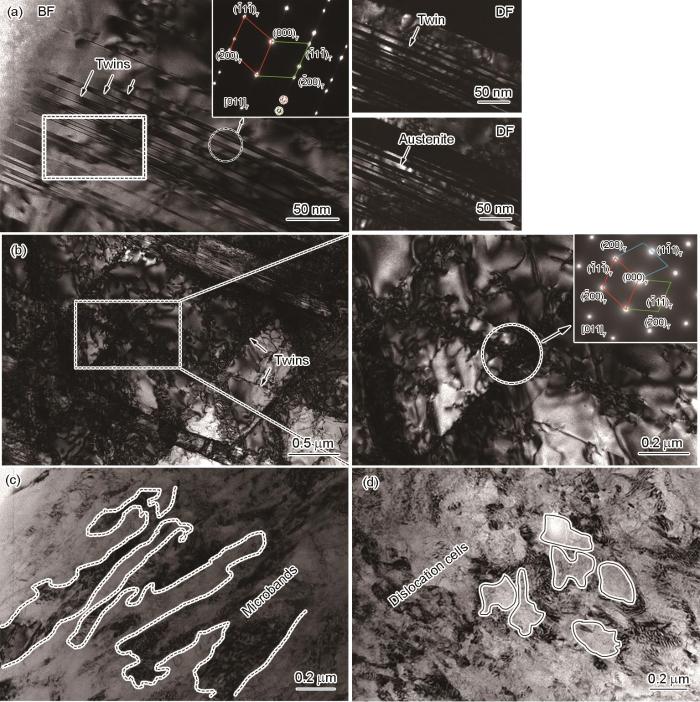

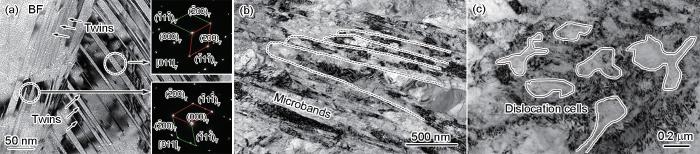

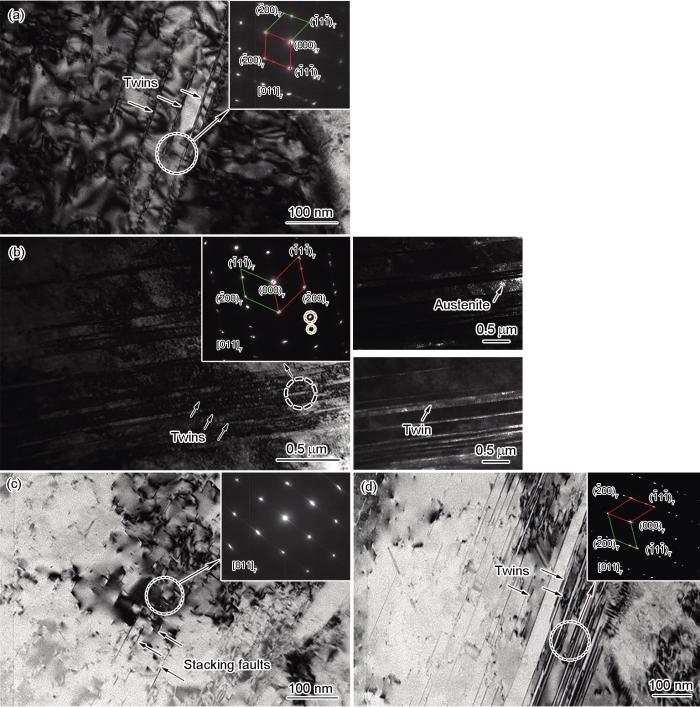

为了揭示各样品的微观变形机制,对拉伸前LNR40% + AN500 ℃、CR40% + AN500 ℃和WR40% + AN500 ℃样品的微观结构进行了表征,结果如图4~6所示。图4a为LNR40% + AN500 ℃样品的TEM明场像、对应的选区电子衍射(SAED)花样以及白色虚线方框区域的暗场像。可见,样品中存在纳米孪晶片层。在样品中也观察到了孪晶交叉,如图4b中箭头所示。经过对多个不同区域进行统计可知,孪晶片层的平均宽度与平均间距分别为6和8 nm。值得注意的是,在样品中并未观察到深低温轧制导致的马氏体板条。除大量形变孪晶,还观察到一定量的微带与位错胞状结构,如图4c和d所示。图5a给出了CR40% + AN500 ℃样品中交叉孪晶的TEM明场像和对应的SAED花样(其中,右上和右下的SAED花样分别对应于右侧和左侧的孪晶)。与液氮轧结合退火制备的样品相比,冷轧结合退火制备样品中孪晶的数量有所减少,其平均孪晶宽度与间距分别增长至7和13 nm。同时,还观察到微带与位错胞状结构,如图5b和c所示。图6为WR40% + AN500 ℃样品拉伸前的微观结构。样品呈大量密集的位错胞状结构,胞壁处位错密集堆积(图6a)。观察到极少量的形变孪晶形貌及相应SAED花样(图6b)。此外,TEM和高分辨TEM (HRTEM)观察表明,样品中存在大量堆垛层错,如图6c和d所示。可以看出,该样品的形变孪晶数量非常少,堆垛层错和大量缠结的位错是其主要结构特征。

图4

图4

LNR40% + AN500 ℃样品的TEM像及选区电子衍射(SAED)花样

Fig.4

TEM images and the selected area electron diffraction (SAED) patterns (insets) of the LNR40% + AN500 oC sample showing deformation twins (a), twin intersection (b), microbands (c), and dislocation cells (d) (T—twin, BF—bright field, DF—dark field)

图5

图5

CR40% + AN500 ℃样品的TEM像及SAED花样

Fig.5

TEM images and the SAED patterns (insets) of the CR40% + AN500 oC sample showing deformation twins with different directions (a), microbands (b), and dislocation cells (c)

图6

图6

WR40% + AN500 ℃样品的TEM像及SAED花样

Fig.6

TEM images and the SAED patterns (insets) of the WR40% + AN500 oC sample showing dislocation cells (a), deformation twins (b), and stacking faults (c); high-resolution TEM (HRTEM) image and fast Fourier transform (FFT) (inset) pattern of stacking faults (d)

2.3 拉伸力学性能

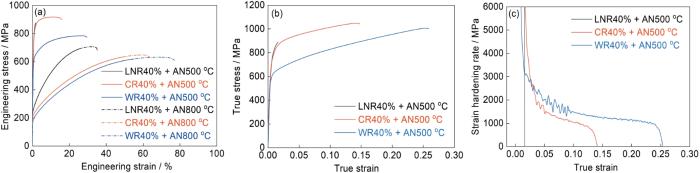

图7a为经轧制变形结合退火处理后各样品的工程应力-应变曲线。结果表明,同一退火温度下,随着轧制温度升高,材料的屈服强度持续降低,塑性升高。以轧制变形结合500 ℃退火样品为例,LNR40% + AN500 ℃样品的屈服强度为792 MPa,抗拉强度为875 MPa,均匀延伸率为1.7%;CR40% + AN500 ℃样品的屈服强度为752 MPa,抗拉强度为917 MPa,均匀延伸率为11.2%;WR40% + AN500 ℃样品的屈服强度为604 MPa,抗拉强度为784 MPa,均匀延伸率为26.2%。值得注意的是,LNR40% + AN500 ℃样品在屈服后快速断裂,这可能与液氮温度轧制时形成的微裂纹以及退火后未发生再结晶有关。考虑到由液氮轧和冷轧结合退火制备样品的马氏体含量差异不大(不超过2%),且2者均未发生再结晶,因此把前者的断裂归因于其内部由几何必需位错(GND)引起的局部应变较高所致(见3.3节讨论)。此外,在同一轧制温度下,随着退火温度升高,材料强度持续降低,塑性升高。例如,CR40% + AN800 ℃样品的屈服强度为215 MPa,抗拉强度为648 MPa,均匀延伸率为59.5%。在所研究的材料中,CR40% + AN500 ℃与WR40% + AN500 ℃样品的综合力学性能最优,2者在具有较高强度的同时,仍然保留了一定的塑性。为揭示轧制变形结合500 ℃退火处理得到的各样品在拉伸变形过程中的应变硬化行为以及可能存在的变形机制,对其真应力-真应变曲线和应变硬化率曲线进行了绘制,分别如图7b和c所示。随应变增加,LNR40% + AN500 ℃样品的应变硬化率急剧下降,而CR40% + AN500 ℃与WR40% + AN500 ℃样品的加工硬化行为多出2个阶段,即真应变分别达到约0.001和0.03时,材料应变硬化率的降幅开始降低并趋于平缓,以及最后应变硬化率再次降低直至断裂。同时,对比CR40% + AN500 ℃与WR40% + AN500 ℃样品的应变硬化率曲线发现,前者在变形初期具有较高的应变硬化率,但当真应变达到约0.034后,后者表现出更高的加工硬化能力。

图7

图7

不同工艺制备的样品工程应力-应变曲线、真应力-应变曲线和应变硬化率曲线

Fig.7

Engineering stress-strain curves (a), true stress-strain curves (b), and strain hardening rate curves (c) of the samples prepared by different processing routes

3 分析与讨论

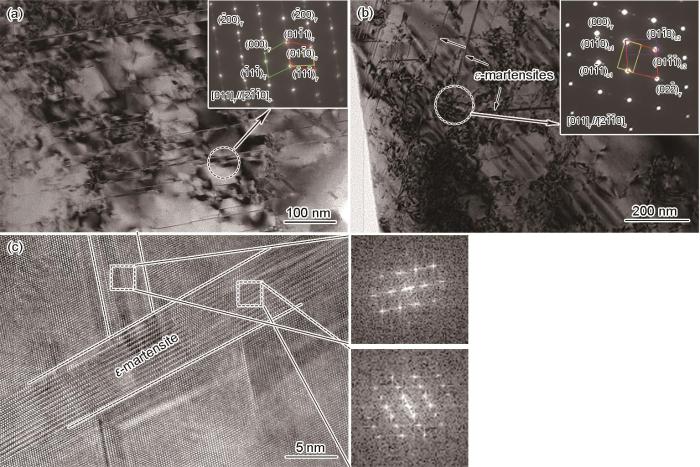

3.1 轧制结合退火工艺制备各样品的相组成

图8给出了经室温冷轧后样品的微观结构。可以看出,轧制变形后,除了密集的位错和形变孪晶(图8a),合金中还存在大量形变诱导的马氏体,如图8b所观察到的同一晶粒内开动了不同方向的马氏体,图8c为图8b中不同方向马氏体的HRTEM像及快速Fourier变换(FFT)。根据变形温度、层错能和fcc金属塑性变形机制的关系[12,15~18],可以推断更低温度下轧制制备的LNR40%样品中也应存在大量形变诱导的马氏体和形变孪晶。然而,轧制变形结合500 ℃退火制备的各样品中却均未发现非热马氏体,这说明轧制过程中生成的马氏体在后续退火过程中发生了逆转变,同时也表明XRD谱中所检测到的hcp马氏体为淬火时形成的热马氏体,而非轧制时形成的形变诱导马氏体。值得注意的是,与500 ℃退火处理各样品中hcp马氏体的含量均小于10%不同,经800 ℃退火制备的各样品中hcp马氏体含量有较大差异。具体为,LNR40% + AN800 ℃样品马氏体含量约为2.5%,CR40% + AN800 ℃样品中马氏体含量约为6.0%,而WR40% + AN800 ℃样品中马氏体含量高达14.5%。由于液氮轧制向合金中引入的形变储能最大,缺陷与形核位点最多,故其再结晶过程中形成的平均晶粒尺寸最小(约8.5 μm)。由于晶粒尺寸越小越不容易形成热马氏体[23,24],因此LNR40% + AN800 ℃样品中仅有少量马氏体形成,而晶粒尺寸最大的WR40% + AN800 ℃样品(约17.8 μm)中则具有较高的马氏体含量。

图8

图8

冷轧样品的TEM像及SAED花样

Fig.8

TEM images and the SAED patterns (insets) of the samples prepared by cold rolling showing deformation twins and martensite (a), martensite with different directions in one grain (b), and HRTEM image and FFT of martensite in Fig.8b (c)

3.2 强化机制

轧制结合500及800 ℃退火制备得到的各样品屈服强度(σ0.2)由固溶强化(σS,此处指室温下由于Cu原子固溶引起的强化和晶格摩擦阻力之和)、位错强化(σD)和界面强化(σB)组成,即σ0.2 = σS + σD + σB。值得注意的是,界面不仅包括大角度晶界和小角度晶界,还包括孪晶界以及马氏体逆转变后的奥氏体晶界。

σD可以通过下式进行计算[30]:

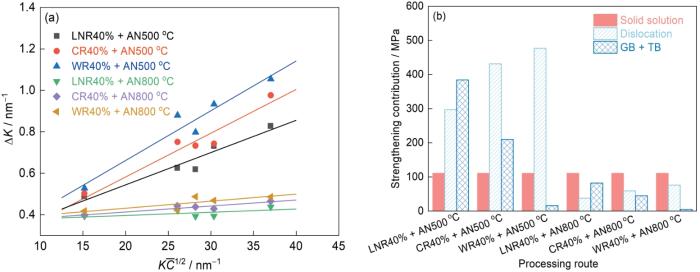

通过修正的Williamson-Hall (MWH)法,对轧制结合退火制备样品在拉伸前的总位错密度进行了计算。MWH法的原理是通过分析与比较衍射峰宽化的情况,定量评估材料中的总位错密度等信息,MWH等式[33]为:

式中,

具体地,通过测量材料中{111}、{200}、{220}、{311}和{222}晶面对应的衍射角和半高宽,结合fcc单晶弹性系数(C11 = 258.4 GPa,C12 = 137.6 GPa,C44 = 205.0 GPa)[34],以及利用Ungár等[35]提出的方法,可计算出上述晶面对应的

图9

图9

由轧制结合500和800 ℃退火制备的各样品修正Williamson-Hall (MWH)图及屈服强度贡献柱状图

Fig.9

Modified Williamson-Hall (MWH) plots (a), and strengthening contributions to yield strength (b) of samples prepared by rolling and 500 and 800 oC annealing (GB—grain boundary, TB—twin boundary; K =

理论上,通过Hall-Petch关系、Fullman体积统计分析等方法[36]可以分别计算材料中晶粒尺寸、孪晶以及马氏体对强度的贡献。但考虑到轧制变形结合500 ℃退火制备的样品处于非再结晶态,总体呈现组织严重破碎,晶界与孪晶界相互交织,且马氏体逆转变为奥氏体的复杂微观结构,无法单独计算3者的强度贡献,故用各样品的实测屈服强度减去σS和σD来获得总的界面强化,即σB = σ0.2 - σS - σD。经计算,对应于液氮轧、冷轧和温轧3种轧制工艺,经500 ℃退火制备的各样品的σB分别为384、210和16 MPa,800 ℃退火制备的各样品的σB分别为82、45和5 MPa。

对比几种样品的屈服强度贡献(图9b)可以看出,LNR40% + AN500 ℃的界面强化非常突出,800 ℃退火制备样品的界面强化较低。因此,接下来重点讨论500 ℃退火制备样品的界面强化。相比于冷轧与温轧条件,液氮轧结合退火制备样品中的KAM值较高的区域更为显著(图3a3~c3),因此其内部晶粒破碎的程度更大,界面对位错的阻碍作用更强。孪晶在3种样品中也有明显不同。与温轧相比,液氮轧和冷轧制备的样品内形成了更多的形变孪晶,同时500 ℃退火后形变孪晶仍得以保留,这使得在后续拉伸过程中轧制所产生的形变孪晶可有效阻碍位错滑移,提高了材料的屈服强度。此外,马氏体逆相变对界面强化也有一定的贡献。根据相关文献[37,38]报道,发生逆转变的马氏体虽然晶体结构发生了改变,由hcp马氏体转变为fcc奥氏体,但其微观形貌被保留。该板条结构可有效地阻碍位错滑移,形成大量的位错缠结与堆垛层错,进而提高材料的强度。总的来说,与800 ℃退火制备的样品相比,500 ℃退火得到的样品屈服强度源于非再结晶区保留下来的微观组织与位错。在500 ℃退火制备的样品中,液氮轧条件下的界面强化更突出,冷轧制备样品界面强化的贡献约为位错的一半,温轧条件下位错强化占主导。

3.3 位错密度的演化

一般来说,金属材料在塑性变形过程中会产生2种位错,即由于晶格几何约束而在应变梯度场中产生的GND以及塑性变形过程中随机捕获而演化的统计存储位错(statistically stored dislocation,SSD)[39,40]。然而,随着应变增加,材料中2种位错密度的变化趋势有可能不同。例如,Zhu等[41]研究了多晶纯Ni在等静态压缩下2种位错的演化规律,发现较小应变下晶界及三叉晶界处形成了大量GND以协调不同取向的晶粒发生均匀塑性变形。随着应变增加,GND将晶粒分割成取向不同的亚结构,在此过程中,晶粒内部尤其是亚结构中会产生大量SSD。当应变超过临界应变时,SSD密度便超过GND。Yan等[42]研究了NiTi形状记忆合金在压缩变形中SSD与GND的变化趋势。结果表明,随着应变增加SSD的密度不断增大,但GND密度持续下降。前者是因为变形过程中更多的滑移系开动,后者则源于材料在变形中塑性应变梯度的减小。类似的随应变增加SSD与GND的密度呈现不同变化趋势的现象在单轴拉伸变形中也有报道[43]。

通过分析轧制结合500 ℃退火制备各样品的EBSD数据可以发现,液氮轧条件下样品的GND密度最高(约1.53 × 1014 m-2),而冷轧与温轧条件下的GND密度依次递减,分别为1.32 × 1014和1.05 × 1014 m-2。结合总位错密度,可得到对应于液氮轧、冷轧和温轧3种轧制工艺结合500 ℃退火制备的各样品的SSD密度,分别为7.77 × 1014、1.66 × 1015和1.95 × 1015 m-2。由此分析,对本实验材料而言,温轧制备的样品中SSD密度高于较低温度轧制得到的样品。此外,GND和SSD虽然均有助于提高材料的强度[44,45],但2者的强化方式有所差异。即,SSD主要贡献于林位错强化,而GND则是通过在软域内引起背应力而强化材料[46]。Huang等[39,47,48]通过温轧制备出了具有超高强度与良好塑性匹配的淬火配分钢,其屈服强度主要源自林位错硬化。根据Taylor硬化定律计算得知,2.05 GPa的屈服强度中林位错硬化贡献了1.6 GPa,这也间接表明其温轧样品具有较高的SSD密度。

3.4 韧化机制

分析轧制结合退火处理各样品的应力-应变曲线(图7)可以发现,CR40% + AN500 ℃与WR40% + AN500 ℃样品在具有较高强度的同时,还保留了较好的均匀延伸率,分别为11.2%和26.2%。众所周知,金属材料的强度提升往往以塑性损失作为代价,即高强度与高塑性难以匹配。然而,相变诱导塑性(TRIP)与孪生诱导塑性(TWIP)效应为同时提高材料的强度与塑性提供了可能。TRIP与TWIP效应也已被广泛引入高熵合金[4,6,49]。Li等[50]研发了fcc + hcp双相Fe50Mn30Co10Cr10亚稳态高熵合金,当平均晶粒尺寸为4.5 μm时,屈服强度与抗拉强度分别为340和870 MPa,同时均匀延伸率仍高达60%。合金良好的强塑性匹配来源于TRIP与TWIP效应的协同作用。

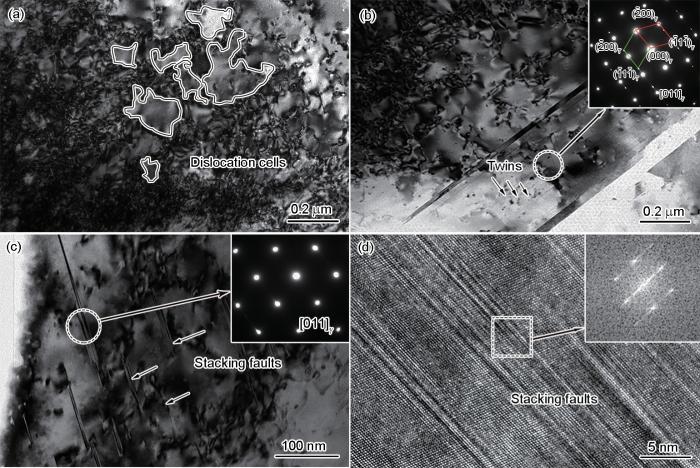

为了揭示本工作中轧制结合500 ℃退火制备各样品的塑性来源,首先观察单轴拉伸断裂后的CR40% + AN500 ℃和WR40% + AN500 ℃样品XRD谱(图1b),发现拉伸变形后2种样品中的hcp相均有所增加。拉伸断裂后材料的微观结构表征显示(图10),在CR40% + AN500 ℃和WR40% + AN500 ℃样品中均观察到了显著的形变孪晶。这些材料在拉伸变形前存在大量缺陷,包括位错和层错等,有利于形变孪晶的开动[51~53]。然而,在拉伸断裂后的上述材料中并未识别到形变诱发马氏体,这可能是由于马氏体含量有限及合金较低的层错能(约9.9 mJ/m2)导致其在TEM样品制备过程中发生了马氏体逆相变[54,55]所致。因此,温轧结合退火制备样品的良好的塑性主要源于其内部形变孪晶的开动。孪晶通过减小位错的平均自由程(即动态Hall-Petch效应)[56],促进位错的积累,从而提高了材料的应变硬化能力并改善了塑性。

图10

图10

经轧制结合500 ℃退火制备的各样品在拉伸变形后的TEM像及SAED花样

Fig.10

TEM images and the SAED patterns (insets) of the samples after tensile test

(a, b) deformation twins in the CR40% + AN500 oC sample (The right figures in Fig.10b are the corresponding dark-field TEM images) (c, d) stacking faults (c) and deformation twins (d) in the WR40% + AN500 oC sample and corresponding SAED patterns (insets)

4 结论

(1) 与轧制结合800 ℃退火制备的样品相比,轧制结合500 ℃退火制备的各样品具有更高的屈服强度与抗拉强度,但塑性有一定损失。材料较高的屈服强度来源于500 ℃退火保留下来的包括形变孪晶、马氏体逆相变而来的奥氏体和位错在内的非再结晶组织。

(2) 不同轧制温度导致各材料在拉伸测试前的微观结构存在差异。LNR40% + AN500 ℃和CR40% + AN500 ℃样品内以形变孪晶为主,而WR40% + AN500 ℃样品内则以位错滑移、堆垛层错、位错缠结和位错胞为主。

(3) CR40% + AN500 ℃和WR40% + AN500 ℃样品在具备较高屈服强度的同时还保留了一定的均匀延伸率,良好的塑性主要源于拉伸过程中大量形变孪晶的开动。孪晶界减小了位错运动的平均自由程,从而提高了材料的应变硬化能力。

参考文献

Evading the strength-ductility trade-off dilemma in steel through gradient hierarchical nanotwins

[J].The strength-ductility trade-off has been a long-standing dilemma in materials science. This has limited the potential of many structural materials, steels in particular. Here we report a way of enhancing the strength of twinning-induced plasticity steel at no ductility trade-off. After applying torsion to cylindrical twinning-induced plasticity steel samples to generate a gradient nanotwinned structure along the radial direction, we find that the yielding strength of the material can be doubled at no reduction in ductility. It is shown that this evasion of strength-ductility trade-off is due to the formation of a gradient hierarchical nanotwinned structure during pre-torsion and subsequent tensile deformation. A series of finite element simulations based on crystal plasticity are performed to understand why the gradient twin structure can cause strengthening and ductility retention, and how sequential torsion and tension lead to the observed hierarchical nanotwinned structure through activation of different twinning systems.

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Microstructural development in equiatomic multicomponent alloys

[J].

Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering

[J].

Effect of elemental combination on friction stress and Hall-Petch relationship in face-centered cubic high/medium entropy alloys

[J].In this study, we report the effect of elemental combinations on the friction stress and Hall-Petch relationship in medium entropy alloys (MEAs) and high entropy alloys (HEAs) which are defined as the alloys composed of four or less and five or more principal elements, respectively, with (near-) equiatomic concentrations. The MEAs (CoCrFeNi, CoCrNi, etc.), which are subsystems of equi-atomic CoCr-FeMnNi HEA, were highly deformed by high-pressure torsion (HPT) and subsequently annealed at different temperatures. The specimens with fully-recrystallized microstructures of FCC single-phase with various mean grain sizes down to sub-micrometer scale were obtained. Subsequently, tensile tests were performed at room temperature to obtain precise Hall-Petch relationships and friction stresses of the materials. Co-20(CrNi)(80) was successfully predicted as the alloy showing the highest strength among the MEAs by the modified Labusch model (so-called mean field Labusch model) for solution hardening. Experimental values of the friction stresses were found to fit with the model very well, indicating that the strength of the alloys was closely related to entirely distorted crystal lattice acting as high-density obstacles for dislocation motion in the alloys. At the same time, values of the average lattice distortion in the alloys were found comparable to those in some dilute alloys, although "severe"" lattice distortion had been believed as a reason for the higher strength than dilute systems. Finally, a strengthening mechanism by element-element interaction was proposed as an additional mechanism to enhance the strength in FCC HEAs and MEAs. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy

[J].

Hydrogen storage properties of multi-principal-component CoFeMnTix Vy Zrz alloys

[J].

Impact of W alloying on microstructure, mechanical property and corrosion resistance of face-centered cubic high entropy alloys: A review

[J].

A review on pitting corrosion and environmentally assisted cracking on duplex stainless steel

[J].

Fatigue behavior of CoCrFeMnNi high-entropy alloy under fully reversed cyclic deformation

[J].Bulk ultrafine-grained (UFG) CoCrFeMnNi high-entropy alloy (HEA) with fully recrystallized microstructure was processed by cold rolling and annealing treatment. The high-cycle fatigue behaviors of the UFG HEA and a coarse-grained (CG) counterpart were investigated under fully reversed cyclic deformation. The fatigue strength of the UFG HEA can be significantly enhanced by refining the grain size. However, no grain coarsening was observed in the UFG HEA during fatigue tests. Mechanisms for the superior mechanical properties of the UFG HEA were explored.

Novel casting CoCrNiAl eutectic high entropy alloys with high strength and good ductility

[J].

A fracture-resistant high-entropy alloy for cryogenic applications

[J].High-entropy alloys are equiatomic, multi-element systems that can crystallize as a single phase, despite containing multiple elements with different crystal structures. A rationale for this is that the configurational entropy contribution to the total free energy in alloys with five or more major elements may stabilize the solid-solution state relative to multiphase microstructures. We examined a five-element high-entropy alloy, CrMnFeCoNi, which forms a single-phase face-centered cubic solid solution, and found it to have exceptional damage tolerance with tensile strengths above 1 GPa and fracture toughness values exceeding 200 MPa·m(1/2). Furthermore, its mechanical properties actually improve at cryogenic temperatures; we attribute this to a transition from planar-slip dislocation activity at room temperature to deformation by mechanical nanotwinning with decreasing temperature, which results in continuous steady strain hardening. Copyright © 2014, American Association for the Advancement of Science.

Enhanced strength-ductility-toughness synergy in an HSLA steel with multi-gradient ultrafine grained structure by adopting a two-stage rolling coupling inter-pass ultra-fast cooling process

[J].

Enhanced mechanical properties of a carbon and nitrogen Co-doped interstitial high-entropy alloy via tuning ultrafine-grained microstructures

[J].C-N co-doped interstitial high entropy alloy (iHEA) was reported to have high strength and ductility. However, iHEA with fully recrystallized ultrafine grains (UFGs) and underlying thermally activated processes associated with dislocation slip, twinning, and solute drag have not been reported yet. In this work, a C-N co-doped iHEA with nominal composition Fe<sub>48.5</sub>Mn<sub>30</sub>Co<sub>10</sub>Cr<sub>10</sub>C<sub>0.5</sub>N<sub>1.0</sub> (at.%) was prepared, and the microstructures were tuned by cold-rolling and annealing treatments to improve mechanical properties. Upon cold-rolling with a strain of 1.74, the main microstructures in the iHEA are composed of nano-grains, nano-twins, HCP laminates, and high density of dislocations, leading to ultrahigh hardness of 466.7 HV and tensile strength of 1730 MPa at the expense of ductility (2.44%). Both the nanostructures and the high hardness of the iHEA can be maintained up to an annealing temperature of 600 °C (462.5 HV). After annealing at 650 °C for 1 h, the UFG microstructures are obtained in the iHEA, containing recrystallized grains with an average grain size of 0.91 µm and nanoprecipitates with an average diameter of 90.8 nm. The combined strengthening and hardening effects of UFGs, nanoprecipitates, twinning, and solutes contribute to high strain hardening (<em>n</em> = 0.81), gigapascal yield strength (984 MPa), and good ductility (20%). The C-N co-doping leads to a strong drag effect on dislocation slip, resulting in a nano-scale mean free path of dislocation slip λ¯ (1.44 nm) and much small apparent activation volume V* (15.8<em>b<sup>3</sup></em>) of the UFG iHEA.

Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy

[J].

Temperature-dependent stacking fault energy, deformation behavior, and tensile properties of a new high-entropy alloy

[J].

Lattice Distortions in the FeCoNiCrMn high entropy alloy studied by theory and experiment

[J].

Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy

[J].

Modulating the prestrain history to optimize strength and ductility in CoCrFeMnNi high-entropy alloy

[J].

Revisiting the role of prestrain history in the mechanical properties of ultrafine-grained CoCrFe-MnNi high-entropy alloy

[J].

Twinning engineering of a CoCrFeMnNi high-entropy alloy

[J].

Nanostructured steel with high work-hardening by the exploitation of the thermal stability of mechanically induced twins

[J].

Effect of grain and twin boundaries on the hardening mechanisms of twinning-induced plasticity steels

[J].

Microscopic deformation and strengthening-toughening of FeMnCoCr-based high-entropy alloys

[D].

FeMnCoCr系高熵合金的微观形变与强韧化研究

[D].

Tuning deformation mechanisms of face-centered-cubic high-entropy alloys via boron doping

[J].

Interstitial atoms enable joint twinning and transformation induced plasticity in strong and ductile high-entropy alloys

[J].High-entropy alloys (HEAs) consisting of multiple principle elements provide an avenue for realizing exceptional mechanical, physical and chemical properties. We report a novel strategy for designing a new class of HEAs incorporating the additional interstitial element carbon. This results in joint activation of twinning-and transformation-induced plasticity (TWIP and TRIP) by tuning the matrix phase's instability in a metastable TRIP-assisted dual-phase HEA. Besides TWIP and TRIP, such alloys benefit from massive substitutional and interstitial solid solution strengthening as well as from the composite effect associated with its dual-phase structure. Nanosize particle formation and grain size reduction are also utilized. The new interstitial TWIP-TRIP-HEA thus unifies all metallic strengthening mechanisms in one material, leading to twice the tensile strength compared to a single-phase HEA with similar composition, yet, at identical ductility.

Multi-heterostructure and mechanical properties of N-doped FeMnCoCr high entropy alloy

[J].

Interstitial-driven local chemical order enables ultrastrong face-centered cubic multicomponent alloys

[J].

Micromechanical behavior of multilayered Ti/Nb composites processed by accumulative roll bonding: An in-situ synchrotron X-ray diffraction investigation

[J].

Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy

[J].

Ultrahigh cryogenic strength and exceptional ductility in ultrafine-grained CoCrFeMnNi high-entropy alloy with fully recrystallized structure

[J].

Crystallite size distribution and dislocation structure determined by diffraction profile analysis: Principles and practical application to cubic and hexagonal crystals

[J].

First-principles investigation of the micromechanical properties of fcc-hcp polymorphic high-entropy alloys

[J].High-entropy alloys offer a promising alternative in several high-technology applications concerning functional, safety and health aspects. Many of these new alloys compete with traditional structural materials in terms of mechanical characteristics. Understanding and controlling their properties are of the outmost importance in order to find the best single-or multiphase solutions for specific uses. Here, we employ first-principles alloy theory to address the micro-mechanical properties of five polymorphic high-entropy alloys in their face-centered cubic (fcc) and hexagonal close-packed (hcp) phases. Using the calculated elastic parameters, we analyze the mechanical stability, elastic anisotropy, and reveal a strong correlation between the polycrystalline moduli and the average valence electron concentration. We investigate the ideal shear strength of two selected alloys under shear loading and show that the hcp phase possesses more than two times larger intrinsic strength than that of the fcc phase. The derived half-width of the dislocation core predicts a smaller Peierls barrier in the fcc phase confirming its increased ductility compared to the hcp one. The present theoretical findings explain a series of important observations made on dual-phase alloys and provide an atomic-level knowledge for an intelligent design of further high-entropy materials.

The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice

[J].

The enhanced static recrystallization kinetics of a non-equiatomichigh entropy alloy through the reverse transformation of strain induced martensite

[J].

Amount of retained austenite at room temperature after reverse transformation of martensite to austenite in an Fe-13%Cr-7%Ni-3%Si martensitic stainless steel

[J].

Improving tensile properties of room-temperature quenching and partitioning steel by dislocation engineering

[J].

Geometrically necessary dislocations favor the Taylor uniform deformation mode in ultra-fine-grained polycrystals

[J].

Dislocation-type evolution in quasi-statically compressed polycrystalline nickel

[J].

Crystal plasticity finite element simulation of NiTi shape memory alloy under canning compression based on constitutive model containing dislocation density

[J].

Investigations of dislocation-type evolution and strain hardening during mechanical twinning in Fe-22Mn-0.6C twinning-induced plasticity steel

[J].

A dislocation density based strain gradient model

[J].

On the measurement of dislocations and dislocation substructures using EBSD and HRSD techniques

[J].

Gradients of strain to increase strength and ductility of magnesium alloys

[J].

Alloy design by dislocation engineering

[J].<p>Ultra-high strength alloys with good ductility are ideal materials for lightweight structural application in various industries. However, improving the strength of alloys frequently results in a reduction in ductility, which is known as the strength-ductility trade-off in metallic materials. Current alloy design strategies for improving the ductility of ultra-high strength alloys mainly focus on the selection of alloy composition (atomic length scale) or manipulating ultra-fine and nano-grained microstructure (grain length scale). The intermediate length scale between atomic and grain scales is the dislocation length scale. A new alloy design concept based on such dislocation length scale, namely dislocation engineering, is illustrated in the present work. This dislocation engineering concept has been successfully substantiated by the design and fabrication of a deformed and partitioned (D&P) steel with a yield strength of 2.2 GPa and an uniform elongation of 16%. In this D&P steel, high dislocation density can not only increase strength but also improve ductility. High dislocation density is mainly responsible for the improved yield strength through dislocation forest hardening, whilst the improved ductility is achieved by the glide of intensive mobile dislocations and well-controlled transformation-induced plasticity (TRIP) effect, both of which are governed by the high dislocation density resulting from warm rolling and martensitic transformation during cold rolling. In addition, the present work proposes for the first time to apply such dislocation engineering concept to the quenching and partitioning (Q&P) steel by incorporating a warm rolling process prior to the quenching step, with an aim to improve simultaneously the strength and ductility of the Q&P steel. It is believed that dislocation engineering provides a new promising alloy design strategy for producing novel strong and ductile alloys.</p>

High dislocation density-induced large ductility in deformed and partitioned steels

[J].A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium manganese steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D and P) process produced dislocation hardening but retained high ductility, both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D and P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for the development of high-strength, high-ductility materials.Copyright © 2017 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Design of a twinning-induced plasticity high entropy alloy

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

In-situ SEM observation of phase transformation and twinning mechanisms in an interstitial high-entropy alloy

[J].

Molecular dynamic simulations of deformation mechanisms for FeMnCoCrNi high-entropy alloy bicrystal micropillars

[J].High-entropy alloys (HEAs) have attracted considerable research attention in the material field because of their outstanding mechanical properties. For metallic materials, grain boundary plays a crucial role in the mechanical behavior and plastic deformation mechanisms. To show the effect of grain boundary on deformation mechanisms in HEAs, the mechanical behavior and evolution of deformation systems in the equiatomic FeMnCoCrNi HEA bicrystals with various orientation combinations during uniaxial tension are investigated using molecular dynamic simulations, and the effect of the orientation relationship between the grain boundary and tensile direction on mechanical behavior is demonstrated. The findings reveal that for all models studied, dislocations nucleate preferentially at the grain boundary and slip into the grains on both sides. Grain boundaries are widened and curved during deformation. Necking tends to occur at the grain boundary when the grain boundary is perpendicular to the tensile direction, which decreases flow stress with increasing loading. For the model with a grain boundary parallel to the deformation direction, the model's flow stress remains at a level above 1 GPa during the whole plastic deformation. The bicrystal with a combination of [111] and [110] orientations shows the most significant fluctuation of flow stress and the highest work hardening ability compared with other models. The decrease in stress with deformation is due to the slip of numerous dislocations, while the high strain hardening ability is caused by the formation of ε-martensite, stacking faults, and twins. Furthermore, the deformation behavior of FeMnCoCrNi, FeCuCoCrNi HEAs, and pure Cu are compared. Compared with Cu, the larger lattice distortion in FeMnCoCrNi and FeCuCoCrNi HEAs makes the grain boundaries coarser, which makes dislocations easy to nucleate under loading, and the formation of ε-martensite is the most outstanding in FeMnCoCrNi HEA with a lower stacking fault energy. The results of this study can guide the design of microstructures and orientations in high-performance HEAs with micron- and nanoscaled grains.

FeMnCoCrNi高熵合金双晶微柱变形机制的分子动力学模拟

[J].为了揭示高熵合金中晶界对塑性变形机制的影响,利用分子动力学模拟方法研究了具有不同初始取向组合的等主元FeMnCoCrNi高熵合金双晶在单轴拉伸变形中的力学性能与变形系统演化,并揭示了晶界与拉伸方向的位向关系对高熵合金力学行为的影响。结果表明,对研究的所有双晶模型而言,位错优先在晶界处形核并向两侧的晶粒内滑移。在变形过程中,晶界发生了不同程度的宽化和弯曲。当晶界与拉伸方向垂直时,颈缩易于在晶界处发生,这导致双晶的流变应力随外加载荷增大而降低。而当晶界平行于拉伸方向时,在整个塑性变形过程中模型保持1 GPa以上的流变应力。相对于其他双晶而言,[111]与[110]取向组合的双晶流变应力波动幅度最大,同时呈现出最强的加工硬化能力。其中应力的下降归因于大量的位错发生了滑移,而高的硬化能力则是由较多的ε-马氏体、层错以及孪晶形成所致。此外,还对比了FeMnCoCrNi、FeCuCoCrNi和纯Cu 3种材料的变形行为。与Cu相比,FeMnCoCrNi和FeCuCoCrNi高熵合金中的晶格畸变使晶界更加粗糙,这使得外加载荷作用下位错易于形核,且层错能较低的FeMnCoCrNi中形成的ε-马氏体最多。

Chemical short-range order dependence of micromechanical behavior in CoCrNi medium-entropy alloy studied by atomic simulations

[J].

Bidirectional transformation enables hierarchical nanolaminate dual-phase HEAs

[J].

Cu alloying enables superior strength-ductility combination and high corrosion resistance of FeMnCoCr high entropy alloy

[J].

Deformation twinning in nanocrystalline materials

[J].