AerMet100高强钢是一种对回火温度很敏感的二次硬化钢,在不同回火温度处理可获得不同的微观结构。当回火温度低于452℃时,主要由马氏体板条及其边界上的渗碳体构成;当回火温度在452℃时,马氏体板条之间的渗碳体分解,马氏体板条中针状纳米析出相开始形核;随着回火温度进一步升高,马氏体板条内的针状纳米析出相逐渐长大,并与马氏体基体保持共格关系;当回火温度在482℃时,在马氏体板条之间出现逆转奥氏体薄膜,部分针状纳米析出相粗化并与马氏体基体失去共格关系;随着温度继续升高,逆转奥氏体薄膜含量逐渐增加[5,6]。通常认为AerMet100钢的高韧性主要来源于逆转奥氏体薄膜,但当回火温度高于某一温度时,虽然逆转奥氏体膜含量增加,其韧性却急剧下降,因此必然存在影响其韧性的另一个因素[5]。通过分析AerMet100钢的高分辨透射电镜图像,Duan等[6]在基体中发现了大量的有序畴结构,且其含量随回火温度升高而增加,并基于有序畴和逆转奥氏体膜的综合作用,对AerMet100钢断裂韧性随回火温度的变化进行了解释。AerMet100钢的高强度则主要来源于高密度位错马氏体板条和针状纳米析出相。随着回火温度上升,高密度位错马氏体板条变化不明显,但M2C析出相会逐渐长大,并最终失去与马氏体基体的共格关系,使得AerMet100高强钢的整体强度降低[7,8]。虽然针状纳米析出相是AerMet100高强钢强度的主要来源,但由于AerMet100高强钢中的纳米析出相与马氏体基体共格且尺寸很小(长度约为10 nm,宽度为2~3 nm),无法通过萃取方式从AerMet100高强钢中提取,因此无法利用选区电子衍射(SAED)原位或离位确定其晶体结构;另外,其体积分数较低,利用X射线衍射仪(XRD)也无法获得钢中纳米析出相的结构信息。因此对AerMet100高强钢针状纳米析出相结构、体积分数和化学成分的确定一直存在挑战。

小角中子散射(SANS)是一种通过倒空间散射曲线的分析拟合来表征实空间纳米结构的实验技术,可以提供材料在1~100 nm尺度上的化学成分、密度和磁矩矢量不均匀分布区的形貌、尺寸分布和含量信息,被广泛应用于工程材料领域。在合金材料领域,SANS常被用于对合金中的GP区、团簇、析出相和纳米晶进行表征[9]。利用中子的高穿透性,在原位变温条件下可以实现对合金材料时效时通过Spinodal分解和形核-长大过程进行的相分离过程及微结构动态演化过程的原位实时观测[10,11]。其中,一个重要应用范例是研究马氏体时效钢中的析出行为[12,13]。在前期的研究工作[14]中,分别采用透射电镜(TEM)、原子探针层析成像(APT)技术和SANS对3种氧化物弥散强化(ODS)钢中的纳米团簇和氧化物析出相的尺寸及分布展开了研究,结果表明3种技术获得的纳米相的尺寸基本一致。相对于另外2种技术,SANS可直接对块体样品的结构进行分析,因此样品制备更为便捷,所得到的结构数据统计性和可靠性也最高,不足之处在于无法获得纳米析出相的化学成分信息。此外,中子具有自旋,可以与磁矩发生磁偶极相互作用,因此SANS也常被用于研究合金中纳米磁畴随外场加载的演变[15,16]。例如,马氏体钢基体具有较强的铁磁性,而碳化物相是顺磁性/非磁性的,其中子的磁散射长度密度(SLD)可假设为零,在饱和磁场下可看作是在铁磁介质中存在的“磁洞”[17]。这种磁性的差别为小角中子磁散射提供了强烈的磁衬度,而纳米析出相的核散射和磁散射长度密度均与其化学元素组成具有对应关系。在一定条件下,通过对比核散射和磁散射长度密度,可以推断合金中纳米析出相的化学成分信息[18]。

本工作采用SANS技术对分别在454、482、486和498℃回火5 h的AerMet100合金钢展开研究。通过在SANS实验时施加1.1 T横向磁场,实现了对散射数据的核、磁散射分离。结合TEM观测,通过2种散射数据的模型拟合结果定量表征分析了合金钢中M2C型针状析出相的尺寸、分布和含量。并针对SANS核磁散射比值的2个峰值,对碳化物和基体相中子核散射和磁散射长度密度进行计算对比,对碳化物的可能化学组成进行了推断。本工作旨为铁磁性合金中纳米相形貌和化学成分的中子散射无损定量表征提供示范。

1 实验方法

1.1 材料及中子散射实验方法

SANS实验在中国散裂中子源的小角中子散射线站上开展,实验用AerMet100钢样品尺寸为20 mm × 20 mm × 1 mm,通过能谱仪测量该钢的化学成分(原子分数,%)为:C 0.2,Co 13.5,Ni 10.3,Cr 3.9,Mo 4.1,Fe 68.0[6]。实验所用入射中子波长为0.1~0.9 nm,束斑直径为6.5 mm。由于析出相尺寸较小,设置的样品-探测器距离为2 m,散射数据由120根He-3管组成的二维位置灵敏的探测器阵列收集,有效探测面积为1 m × 1 m,从而使得所能覆盖的散射矢量值(Q)范围达到0.08~14 nm-1[19]。分别对在454℃ (CoNi_454)、482℃ (CoNi_482)、486℃ (CoNi_486)和498℃ (CoNi_498)回火5 h处理的样品进行散射和透过率测试,并将测试的空束散射数据作为谱仪本底扣除。采用SANS@CSNS线站配备的电磁铁装置对上述样品施加横向的磁场,分别在无磁场(此时电磁铁退磁场约为5 mT)、50 mT、0.1 T和1.1 T饱和磁场强度下测试样品的SANS散射数据。

1.2 数据处理方法

对测得的SANS实验数据进行积分和归一化处理,并采用样品的透过率数据进行校正,以消除不同厚度样品对不同中子吸收效应的影响。图1a给出了不同波长下CoNi_454样品的透过率曲线。可见在入射中子波长为0.21和0.42 nm处出现了明显的Bragg边。这是由于合金晶格的衍射效应使得部分中子被衍射出去而使得透过率显著下降。该现象常见于铁基、铜基和镍基晶态合金材料中,会导致SANS测到的样品透过率在某些波长前后出现波动而无法用于对数据进行校正。根据国际通用的处理方法,本工作采用波长0.43~1.09 nm的中子波长(图1a中虚线所示区域为该波长范围样品的中子透过率)进行SANS数据积分和规约处理。为了排除核散射与磁散射的相互影响,分别沿0° (平行磁场)和90° (垂直磁场)方向,对1.1 T近饱和磁场下的二维散射花样按照10°空间角宽度进行积分和规约处理(图1b),从而得到分别沿平行和垂直磁场方向散射数据的积分强度

图1

图1

CoNi_454样品透过率曲线的Bragg边,及沿0°和90°方向按10°角进行积分和规约

Fig.1

Transmission curve and Bragg-edge feature of CoNi_454 sample (a), integration and normalization within 10° azimuth angle along the 0° and 90° orientations (b) (Qx, Qy —scattering vector moduli in x and y axes, repectively)

1.3 XRD和TEM实验方法

采用线切割截取尺寸为10 mm × 10 mm × 1 mm的片状试样,依次使用320、800、1000和1500号水砂纸进行研磨,最后用2.5 μm的金刚石研磨膏抛光。利用D/MAX-2500型高能XRD对抛光后的试样进行物相分析(Cu靶,扫描速率6°/min,电压40 kV,电流200 mA)。

抛光后的试样经过冲片、电解双喷制备TEM样品。实验设备为RL-I电解双喷仪,实验条件为:温度-15℃,10% (体积分数)高氯酸无水乙醇溶液,恒定电流200 mA,电解液流量和穿孔尺寸控制参数均设置为50。采用2100F场发射TEM观察样品微观组织。

2 实验结果及分析

2.1 电子显微成像结果

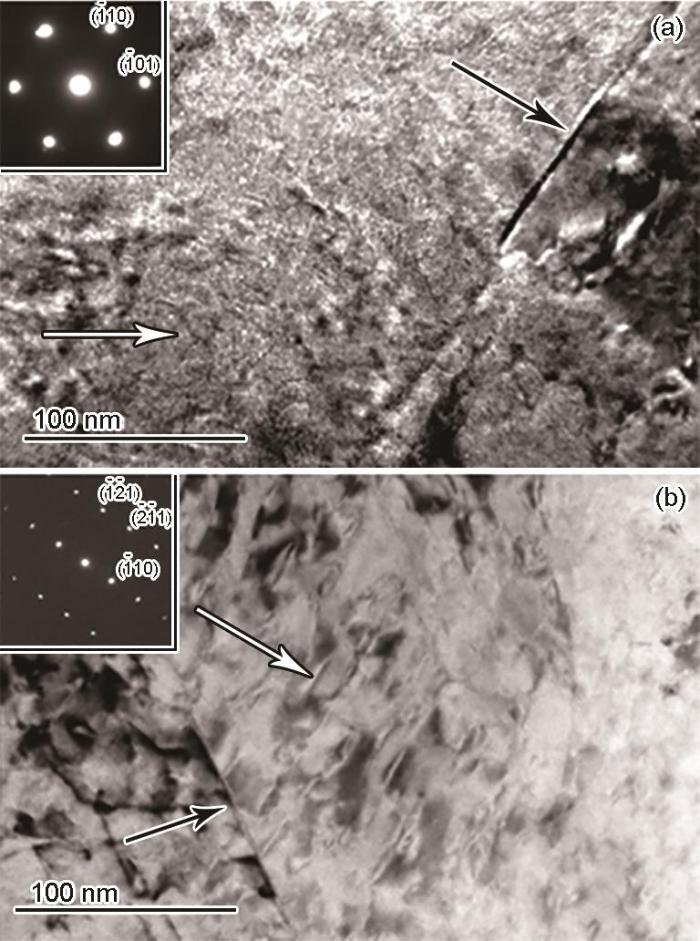

图2是AerMet100钢经过回火处理后的显微组织TEM像及SAED花样。在马氏体基体中可以发现大量的针状析出相(白色箭头所示),在马氏体板条边界出现逆转奥氏体薄膜(黑色箭头所示)。当回火温度为486℃时,马氏体板条间存在厚度为2.5 nm的不连续的逆转奥氏体薄膜;当回火温度提高至498℃时,板条间的逆转奥氏体薄膜发生明显的长大,厚度达到3 nm,同时逆转奥氏体形成连续的薄膜。

图2

图2

486和498℃回火5 h的AerMet100钢显微组织的TEM像及选区电子衍射(SAED)花样

Fig.2

TEM images and SAED patterns (insets) of AerMet100 steel samples tempered at 486oC (a) and 498oC (b) for 5 h (White and black arrows indicate precipitates and reverted austenite films (RAFs), respectively)

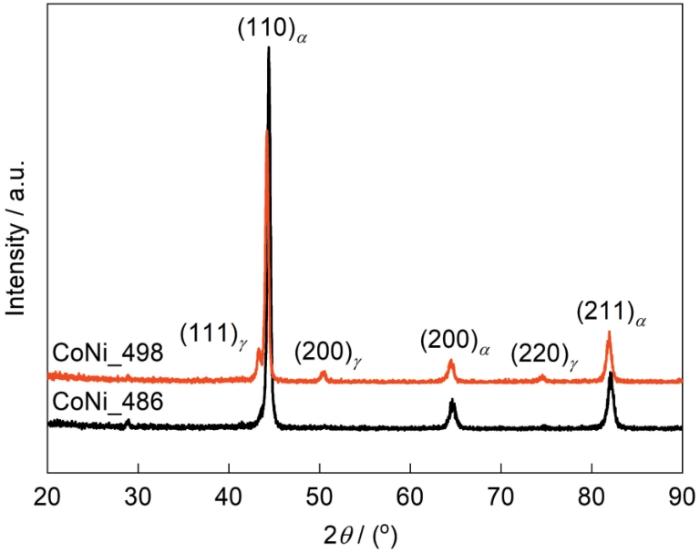

图3为AerMet100钢回火处理后的XRD谱。经486℃回火处理后,衍射峰主要由(110) α 、(200) α 和(211) α 3个马氏体衍射峰组成,未发现额外的碳化物或奥氏体衍射峰。然而,经498℃回火处理后,XRD谱中出现了额外的(111) γ 、(200) γ 和(220) γ 奥氏体衍射峰。对比2种热处理状态(110) α 衍射峰位置可以看出,回火温度不同可导致(110) α 衍射峰出现位移。相较于486℃回火试样,498℃回火试样的(110) α 衍射峰向左移动了0.05°,对应的(100)晶面间距大约相差0.0004 nm。

图3

图3

AerMet100回火钢的XRD谱

Fig.3

XRD spectra of the AerMet100 steel tempered at different temperatures

图4

图4

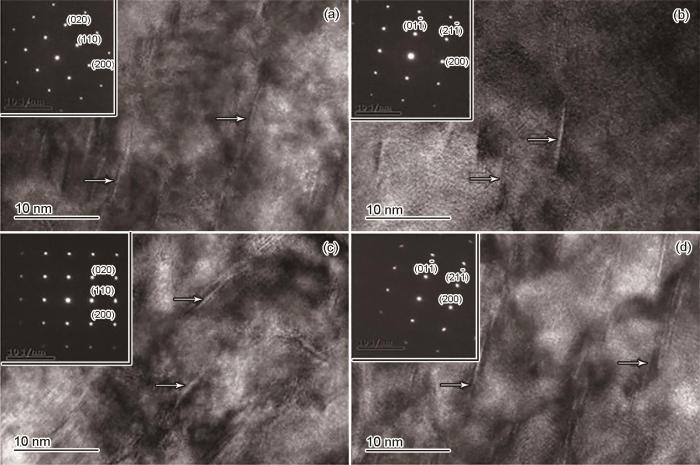

AerMet100钢回火处理后沿基体不同晶体学取向的针状M2C析出相形貌的TEM像及SAED花样

Fig.4

TEM images and SAED patterns (insets) of the needle-like M2C precipitates in tempered AerMet100 steel along different crystallographic orientations of the matrix phase (White arrows indicate the needle-like precipitates)

(a) 486oC, [001] α (b) 486oC, [011] α (c) 498oC, [001] α (d) 498oC, [011] α

2.2 SANS数据及拟合策略分析

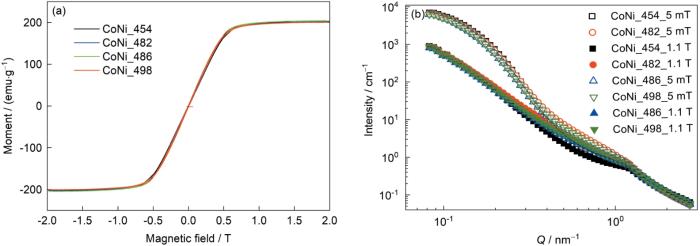

为了进一步分析AERMET100钢中析出相的尺寸分布及其随时效温度的演化,分别对454、482、486及498℃回火5 h的样品开展了SANS实验观测,实验结果如图5所示。由图5a中4种回火状态AERMET100钢的磁滞回线可以看出,施加1.1 T磁场,样品基本处于饱和磁化状态,随着磁矩的转动,0.2 nm-1处所探测的磁畴结构被消除。从图5b可以看出,在Q为0.2和1.5 nm-1处,散射曲线均存在明显的“隆起”特征,表明合金中存在尺寸不同的纳米结构。其中,1.5 nm-1处的散射特征在5 mT和1.1 T磁场下均存在,且随磁场变化很小,表明其主要结构来源为析出相的核散射。然而,在0.2 nm-1处散射曲线仅在5 mT磁场下存在明显“隆起”特征,随着加载至1.1 T磁场,所有样品在该处的散射特征均消失,说明该处的结构来源为合金中的磁不均匀结构。

图5

图5

不同温度回火处理AerMet100钢的磁滞回线,及无磁场(电磁铁5 mT剩磁)和1.1 T磁场条件下AerMet100钢小角中子散射(SANS)一维散射曲线

Fig.5

Magnetic hysteresis curves (a) and the 1D SANS scattering curves measured under no field application (5 mT remanence) and 1.1 T magnetic field of AerMet100 steel tempered at different temperatures (b) (SANS—small-angle neutron scattering; Q—scattering vector modulus)

在采用中子散射技术观测材料微观结构时,主要需要考虑2个方面的因素:结构的尺度和结构的中子散射衬度。根据TEM结果可知,在AERMET100钢的组成相中,马氏体板条尺寸粗大(300 nm~3 μm),不在SANS的探测尺度范围(1~100 nm)。而低温回火产生的Fe3Mo3C (尺寸约50 nm)和高温时效的(Cr, Mo)2C析出相(尺寸为1~20 nm)均在SANS探测范围内。表1所示为对合金组成相的中子散射长度密度的计算结果,其中,ρN和ρM分别为AERMET100钢组成相的中子核散射长度密度和磁散射长度密度。Fe3Mo3C低温相以及逆转奥氏体薄膜与基体马氏体板条之间的衬度,即中子散射长度密度差的平方

表1 AerMet100钢组成相的成分、密度及中子散射长度密度

Table 1

| Phase | Chemical composition | Density / (g·cm-3) | ρN / (1010 cm-2) | ρM / (1010 cm-2) |

|---|---|---|---|---|

| Martensite lath matrix | Fe70.92Co13.4Ni11.1Cr3.1Mo1.2C0.23Ti0.05 | 7.62 | 6.84 | 4.43 |

| Reverse austenite film | Fe70.92Co13.4Ni11.1Cr3.1Mo1.2C0.23Ti0.05 | 7.59 | 6.74 | 0 |

| Needle-like carbide | (Cr x Mo y )C | Unknown | 5.21 | 0 |

| Tempered particle | Fe3Mo3C | 9.17 | 6.52 | - |

Note: ρN—nuclear neutron scattering length density, ρM—magnetic neutron scattering length density; the chemical composition and density of nano-scale needle-like carbide is to be determined in this study

其中,携带析出相的形状和尺寸分布等形貌信息的圆柱模型形状因子(form factor,F)表述如下[24]:

采用对数正态分布函数来进行描述析出相的尺寸分布f(R)[23]:

代表针状纳米相之间相对位置干涉对散射曲线的调制作用的结构因子(structure factor,S)表述如下[20]:

式中,

2.3 核磁散射分离及散射曲线拟合分析

2.3.1 不同磁场下SANS二维散射花样

图6

图6

不同磁场加载下498℃回火AerMet100钢的二维SANS散射花样

Fig.6

2D SANS patterns of 498oC-tempered AerMet100 steel under different magnetic field strengths (I—integral intensity)

(a) no field application (5 mT) (b) 50 mT (c) 0.1 T (d) 1.1 T

2.3.2 饱和磁场下SANS核磁散射比值

图7

图7

1.1 T磁场加载下AerMet100回火钢的SANS实验观测结果,核散射和拟合曲线,磁散射和拟合曲线,以及核磁散射比值曲线

Fig.7

SANS results of AerMet100 tempered steel under magnetic field application

(a) total SANS 1D scattering data

(b, c) experimental and fitted nuclear (b) and magnetic (c) SANS results

(d) observed ratio between SANS nuclear scattering intensity (IN) and magnetic scattering intensity (IM)

根据分离出的SANS实验核磁散射强度可以计算出2者的核散射衬度平均值为

通过查询各元素的中子散射长度

这种通过纳米异质相与基体之间理论核、磁散射衬度比值与实验核、磁散射强度比值测得的散射衬度对比计算的方法可以对纳米异质相的化学成分进行推测。对于磁矩和成分与基体合金存在差别的纳米异质相,采用该方法推断其化学组成具有通用性。然而,所获得的纳米相的化学成分可能与其实际成分存在一定的偏差,除了受SANS数据统计误差影响外,其可能的影响因素还包括:(1) 由于在热处理过程中的元素扩散,基体相的成分可能发生变化;(2) 当合金中存在多种纳米析出相,不同组成的纳米相体积分数也可能出现相对变化[28],使得根据原有单一基体相成分计算的核磁散射长度密度与实际值存在偏差;(3) 当纳米异质相含有“杂质”时,例如空位,也会使得推测的纳米相成分存在偏差[29]。尽管如此,SANS核磁散射分离为细小纳米相成分的确定提供了新思路,该技术可以弥补传统SANS仅能测试形貌尺寸的不足。

2.3.3 SANS核散射与磁散射拟合结果

表2 AerMet100钢SANS核散射拟合结果

Table 2

| Sample | D / nm | L / nm | RHS / nm | fV / % |

|---|---|---|---|---|

| CoNi_454 | 1.15 ± 0.76 | 6.00 ± 1.27 | 5.95 ± 1.05 | 0.54 ± 0.15 |

| CoNi_482 | 2.02 ± 1.04 | 9.63 ± 0.87 | 6.68 ± 0.92 | 2.47 ± 0.34 |

| CoNi_486 | 2.37 ± 0.75 | 10.6 ± 1.72 | 6.75 ± 0.78 | 3.25 ± 0.38 |

| CoNi_498 | 2.48 ± 0.99 | 15.9 ± 2.94 | 7.07 ± 0.93 | 5.19 ± 0.68 |

Note: D—diameter of needle-like carbide, L—length of needle-like carbide, RHS—radius of hard sphere model, fV—volume fraction of needle-like carbide

表3 AerMet100钢SANS磁散射拟合结果 (nm)

Table 3

| Sample | D | L | RHS | t |

|---|---|---|---|---|

| CoNi_454 | 1.80 ± 0.74 | 6.51 ± 0.42 | 5.01 ± 0.47 | 0 |

| CoNi_482 | 2.46 ± 0.75 | 13.70 ± 1.24 | 18.50 ± 0.41 | 2.59 ± 0.47 |

| CoNi_486 | 2.60 ± 0.86 | 13.40 ± 1.50 | 18.00 ± 0.35 | 5.56 ± 1.60 |

| CoNi_498 | 2.62 ± 0.40 | 19.07 ± 1.61 | 18.57 ± 0.46 | 5.57 ± 1.56 |

Note: t—thickness of the reverse austenite

由本工作的示范性研究可以看出:与TEM技术的微观形貌分析特点相比,结合核-磁散射分离的SANS技术能够对较大块体样品(探测体积范围mm3~cm3)中纳米析出相的形貌、尺寸和成分进行定量分析。通过统计平均获得的结构参数可靠性更高,也更能代表整块样品的结构和成分特征。此外,中子的穿透性也使得人们能够在复杂外场环境下对材料的纳米结构进行原位观测,更易于实现对制备加工和服役条件下样品微观结构演化的原位观测。然而,SANS技术的观测结果不如TEM成像直观和易于解读,散射数据的解析依赖于模型拟合,相对更为复杂,这也是该技术未来发展需要重点突破的研究方向。

3 结论

(1) TEM和SANS实验结果均显示回火处理后AerMet100合金钢中针状析出相平均长度为6~16 nm,平均直径为1~2 nm。SANS测定合金中针状碳化物相的体积分数随回火温度升高,由0.54%逐渐提高至5.19%。

(2) 随着磁场的加载,SANS散射花样逐渐由各向同性演变成各向异性的倒“8”字特征。磁散射拟合得到的碳化物直径均大于核散射结果,说明在碳化物与马氏体基体相界面处存在自旋错排的纳米磁畴区。

(3) 饱和磁化状态下,纳米析出相SANS核磁散射的比值存在2个峰值。通过对碳化物和基体相中子核磁散射长度密度的对比计算,推断出针状碳化物的可能化学组成及密度分别为:(Cr0.40Mo1.60)C和8.55 g/cm3。

参考文献

Transmission electron microscopy examination of hardening and toughening phenomena in AerMet 100

[J].

Hydrogen transport and embrittlement in 300 M and AerMet100 ultra high strength steels

[J].

Room temperature creep and the initiation of stress corrosion cracking in AerMet 100

[J].

An advanced alloy for landing gear and aircraft structural applications—Aerometr® 100 Alloy

[R].

Study on the microstructure and mechanical properties of Aermet 100 steel at the tempering temperature around 482°C

[J].

Effect of ordered domains on the fracture toughness of high Co-Ni secondary hardening steel

[J].

Effect of tempering temperature on the microstructure and properties of ultrahigh-strength stainless steel

[J].The microstructure, precipitation and mechanical properties of Ferrium S53 steel, a secondary hardening ultrahigh-strength stainless steel with 10% Cr developed by QuesTek Innovations LLC, upon tempering were studied by scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and tensile and impact tests. Based on these results, the influence of the tempering temperature on the microstructure and properties was discussed. The results show that decomposition occurred when the retained austenite was tempered above 440 °C and that the hardening peak at 482 °C was caused by the joint strengthening of the precipitates and martensite transformation. Due to the high Cr content, the trigonal M7C3 carbide precipitated when the steel was tempered at 400 °C, and M7C3 and M2C (5-10 nm in size) coexisted when it was tempered at 482 °C. When the steel was tempered at 630 °C, M2C and M23C6 carbides precipitated, and the sizes were greater than 50 nm and 500 nm, respectively, but no M7C3 carbide formed. When the tempering temperature was above 540 °C, austenitization and large-size precipitates were the main factors affecting the strength and toughness.

Microstructure and mechanical properties in isothermal tempering of high Co-Ni secondary hardening ultrahigh strength steel

[J].

Achieving highest Young's modulus in Al-Li by tracing the size and bonding evolution of Li-rich precipitates

[J].For decades, it has been well accepted that every 1 wt.% Li addition to Al will reduce Al alloy's density by 3% and increase its Young's modulus by 6%. However, the fundamental mechanism of modulus improvements stays controversial though all studies agreed that the contribution of such a substantial boosting comes from Li-rich clusters either in solid solution or precipitations. In this study, we experimentally produce nano-sized Li-rich clusters by non-equilibrium solidification using centrifugal casting and trace their evolutions as a function of subsequent heat treatments. High-resolution transmission electron microscopy (HRTEM) reveals a further decrease in the lattice constants of Li-rich regions from the as-cast (0.406 nm), solid solution (0.405 nm) to the aged state (0.401 nm), while Young's modulus of the Al-Li alloy reaches 89.16 GPa. Small-angle neutron scattering (SANS) experiments and first-principle calculations based on density functional theory have shown both the bond strength around precipitates and the size of those Li-rich region dominate Young's modulus. At the beginning, it is volumetric compression due to Li addition that increases modulus, tightening the Al-Al potential curves. In the end, it is the Al-Al and Al-Li valence bonds in Al<sub>3</sub>Li at large size and high-volume fraction which increase its second derivative of internal energy and thus Young's modulus.

In situ determination of aging precipitation in deformed Fe-Cu and Fe-Cu-B-N alloys by time-resolved small-angle neutron scattering

[J].

Spinodal decomposition coupled with a continuous crystal ordering in a titanium alloy

[J].

Small-angle neutron scattering analysis of the precipitation behaviour in a maraging steel

[J].

In situ characterization of 17-4PH stainless steel by small-angle neutron scattering

[J].

Study of precipitates in oxide dispersion-strengthened steels by SANS, TEM, and APT

[J].

Nanostructure, mechanical properties, and corrosion resistance of super duplex stainless steel 2507 aged at 500oC

[J].

Evolution of medium-range order and its correlation with magnetic nanodomains in Fe-Dy-B-Nb bulk metallic glasses

[J].Fe-based metallic glasses are promising functional materials for advanced magnetism and sensor fields. Tailoring magnetic performance in amorphous materials requires a thorough knowledge of the correlation between structural disorder and magnetic order, which remains ambiguous. Two practical difficulties remain: the first is directly observing subtle magnetic structural changes on multiple scales, and the second is precisely regulating the various amorphous states. Here we propose a novel approach to tailor the amorphous structure through the liquid-liquid phase transition. In-situ synchrotron diffraction has unraveled a medium-range ordering process dominated by edge-sharing cluster connectivity during the liquid-liquid phase transition. Moreover, nanodomains with topological order have been found to exist in composition with liquid-liquid phase transition, manifesting as hexagonal patterns in small-angle neutron scattering profiles. The liquid-liquid phase transition can induce the nanodomains to be more locally ordered, generating stronger exchange interactions due to the reduced Fe-Fe bond length and the enhanced structural order, leading to the increment of saturation magnetization. Furthermore, the increased local heterogeneity at the medium-range scale enhances the magnetic anisotropy, promoting the permeability response under applied stress and leading to a better stress-impedance effect. These experimental results pave the way to tailor the magnetic structure and performance through the liquid-liquid phase transition.

The kinetics of precipitation from supersaturated solid solutions

[J].

Dependence of the ratio between magnetic and nuclear small angle neutron scattering on the size of the heterogeneities

[J].

The time-of-flight small-angle neutron spectrometer at China spallation neutron source

[J].

Analytical scattering function of a polydisperse Percus-Yevick fluid with Schulz- (Γ-) distributed diameters

[J].

Approximations leading to a unified exponential/power-law approach to small-angle scattering

[J].

Small-angle scattering from polymeric mass fractals of arbitrary mass-fractal dimension

[J].

Analysis of small-angle scattering data from colloids and polymer solutions: modeling and least-squares fitting

[J].

Micromagnetism-microstructure relations and the hysteresis Loop

[A].

Toward understanding complex spin textures in nanoparticles by magnetic neutron scattering

[J].

Magnetic small-angle neutron scattering

[J].

Analysis of the precipitation behaviour in a high-speed steel by means of small-angle neutron scattering

[J].

Characterization of nano-sized oxides in Fe-12Cr oxide-dispersion-strengthened ferritic steel using small-angle neutron scattering

[J].