航空发动机主轴轴承是航空发动机的核心部件,需要在高温、高速、重载的苛刻环境下服役,这要求制造主轴轴承的材料必须具有优异的高温硬度、高尺寸稳定性和高耐磨性。M50钢是从高速钢发展而来的第二代高温轴承钢,具有优异的高温性能及疲劳性能,是制造航空发动机主轴轴承的主要材料[1]。众多研究[2,3]表明,影响M50钢服役性能的主要因素是钢中的夹杂物和大尺寸碳化物。近年来,随着稀土纯净化技术[4,5]和双真空冶炼技术[6] (真空感应熔炼+真空自耗重熔)逐渐应用于高纯净度轴承钢制备,夹杂物导致的疲劳失效问题得到控制[7]。但是随着航空技术的发展和轴承服役环境的严苛,轴承钢均质性问题日渐凸显,特别是M50钢中存在的大尺寸一次碳化物在轴承失效过程中的作用越来越明显,已成为影响轴承钢服役寿命的重要因素[8~12]。大尺寸一次碳化物的细化与均质化技术是进一步提高M50钢疲劳寿命的关键。

目前,M2C碳化物的研究主要集中于其在高温下的分解机制。Fredriksson等[17]的研究表明,高速钢中的M2C碳化物在高温下通过M2C + γ-基体→M6C + MC形成MC和M6C 2种碳化物。Lee等[18]的研究进一步证实,M2C碳化物的分解过程可以分为2个步骤,首先Fe元素向M2C内部的扩散导致M2C与基体的界面处形成M6C,之后MC碳化物在M6C内部或界面处形成。Liu等[19]认为M2C碳化物可以分为片层状M2C与棒状M2C碳化物,并分别讨论了2种类型M2C碳化物的分解机制。Zhou等[20]认为,短棒状M2C热稳定性低于层片状,加热更易分解。有研究[21]表明过高的高温保温温度会导致M2C分解产物MC碳化物的异常长大并形成超大尺寸的MC碳化物,严重恶化M50钢的服役性能,所以M2C分解产物的尺寸控制也是决定M50钢中碳化物尺寸的重要因素。目前M2C碳化物分解机制的研究主要集中在M2等高速钢,相比于M2钢,M50钢中的Mo、W、V等合金元素更少,合金成分的变化必然导致一次碳化物的形态、化学成分差异以及热稳定性的不同。因此,有必要对M50钢中一次碳化物的分解行为做进一步研究。此外,M2C碳化物中的Fe、Mo、V合金元素含量在较大范围内波动,第一性原理计算结果表明,化学成分的差异会导致M2C碳化物热稳定性以及界面稳定性的差异[22~24],这导致化学成分不同的M2C碳化物在保温过程中经历不同的组织转变。化学成分差异导致的碳化物热稳定性不同为M2C碳化物的调控提供了新的思路,但目前少有文献报道M50钢中M2C碳化物的化学成分差异及对其分解机制与相变机制的影响。

基于上述分析,本工作系统研究了M2C碳化物在1160~1250℃温度区间的高温分解机制,确定了MC碳化物快速长大的临界温度,基于M2C碳化物的化学成分差异及形态差异,揭示了合金元素对M2C碳化物相变机制与分解机制的影响,为M50钢的碳化物尺寸、形态调控及服役性能提升奠定理论基础。

1 实验方法

实验材料为双真空冶炼(真空熔炼+真空自耗)的M50钢自耗锭,直径约为200 mm,其主要化学成分(质量分数,%)为:C 0.80~0.83,Cr 4.05~4.11,Mo 4.06~4.16,V 0.98~1.01,Mn 0.19~0.21,Si 0.20,Fe余量。自耗锭的高温扩散实验在箱式电阻炉中进行,钢锭随炉升温,分别加热至1160、1180、1210和1250℃并保温20 h,随后随炉冷却到室温。高温扩散后的钢锭进行锻造加工,钢锭随炉缓慢升温至锻造温度,保温10 h后出炉锻造,锻造成尺寸为直径75 mm的圆棒,锻后样品空冷至600℃以下后进行球化退火。

用线切割在自耗锭及棒材的R / 2 (其中R为棒材直径)位置分别切取金相试样(10 mm × 10 mm × 11 mm),金相样品分别用100、200、400、1000及2000号砂纸研磨,之后进行粗抛及细抛处理,以保证抛光结束后样品表面无划痕,之后进行微观组织检测,检测面分别为平行于自耗锭高度方向及棒材长度方向的平面。通过MIRA3场发射扫描电子显微镜(SEM)及其配置的背散射电子(BSE)探头表征一次碳化物的类型及分布,测试电压为15 kV;通过SEM配置的电子背散射衍射(EBSD)探头收集一次碳化物的Kikuchi花样,并以此确定碳化物的晶体结构;通过SEM附带的ULTIM MAX型X射线能谱仪(EDS)以及JXA-8530F PLUS电子探针(EPMA)确定碳化物的化学成分及元素分布。通过JEM ARM 200F型球差校正透射电子显微镜(TEM)表征碳化物界面结构,通过TEM高角度环形暗场(HAADF)像表征界面处的原子排布,通过TEM配置的超大固体角0.97sr高分辨JED-2300T能谱仪表征碳化物界面的合金元素分布。TEM样品通过聚焦离子束(FIB)方式制备,实验过程中TEM电压为200 kV,图像分辨率约为0.078 nm。

2 实验结果

2.1 铸态 M2C一次碳化物的化学成分差异

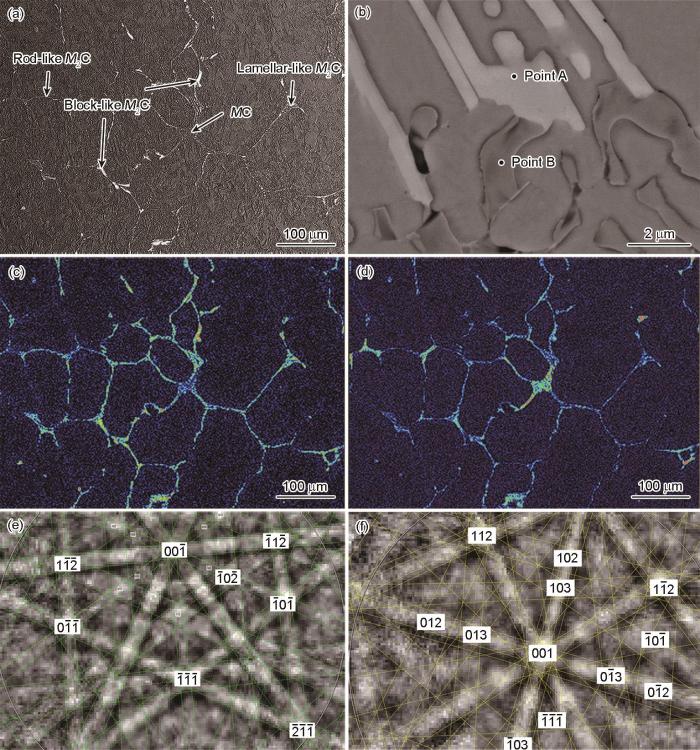

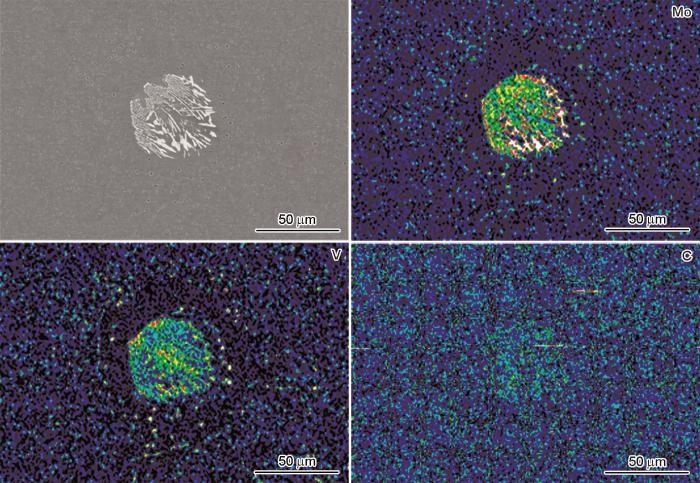

图1为M50钢铸态组织的SEM-BSE像、元素的EPMA面分布图以及碳化物的Kikuchi衍射花样。由图1a可见,一次碳化物沿晶界呈网状分布。存在M2C与MC 2种类型的一次碳化物[25,26],其形貌如图1b所示。图1c和d分别为Mo、V元素的EPMA面分布图,可以看出一次碳化物富含较多的Mo和V元素,并且不同类型的一次碳化物中的合金元素含量存在明显差别。MC碳化物中V元素含量相对较高,M2C碳化物中Mo元素含量相对较高。图1e和f分别为一次碳化物的Kikuchi衍射花样,根据衍射花样可以判断:M2C碳化物为hcp结构,包含较多的Mo元素,在SEM-BSE模式下衬度较亮[27];MC碳化物为fcc结构,V元素含量较高,在SEM-BSE模式下衬度较暗[27]。

图1

图1

M50钢铸态组织SEM-BSE像、元素的EPMA面分布图以及一次碳化物Kikuchi衍射花样

Fig.1

SEM-BSE images of the as-cast M50 steel, EPMA mappings of elements, and Kikuchi diffraction patterns of primary carbide (a, b) SEM-BSE images of the as-cast M50 steel (a), and M2C and MC primary carbides (b) (c, d) EPMA distribution maps of Mo (c) and V (d) elements (e, f) Kikuchi diffraction patterns of M2C (Point A in Fig.1b) (e) and MC (Point B in Fig.1b) (f)

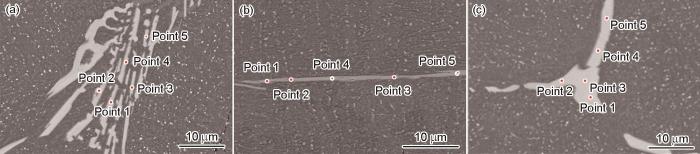

受凝固顺序及偏析程度的影响,M50钢铸态组织中的M2C一次碳化物的形态及化学成分存在明显差别。从二维形貌来看(图1a),三叉晶界处的一次碳化物主要为片层状,沿晶界分布的碳化物主要为棒状,三叉晶界位置存在部分尺寸较大、形状不规则的一次碳化物,其微观形态与片层状M2C碳化物存在明显区别,定义为块状一次碳化物。块状M2C一次碳化物形成过程没有明显的择优取向,M2C晶核形成后向四周生长,而片层状M2C主要沿片层长度方向生长,具有明显的择优取向,是典型的小平面相生长方式[28]。M2C碳化物的化学成分并不固定,其合金元素主要包括Fe、Cr、Mo、V等,凝固顺序及偏析程度的不同也导致不同形态的M2C碳化物中的合金元素存在较大差别。图2为典型的3种不同形态M2C一次碳化物的SEM像,其EDS结果如表1~3所示。可见,3种不同形态的M2C一次碳化物中C元素含量(质量分数,下同)在8%~12%范围内,在碳化物的晶体结构中,C元素一般存在于合金原子组成的晶体结构的间隙中[29],3种不同形态的C元素含量差别不大,说明其晶体结构一致。此外,3种不同形态的M2C碳化物中Cr和V元素含量同样差别不大,Cr和V元素的含量在10%~12%之间。3种M2C碳化物的化学成分差异主要体现在Fe和Mo元素,块状M2C中的Fe和Mo元素含量相对稳定,Fe元素含量一般小于10%,Mo元素含量约为55%;片层状M2C与棒状M2C碳化物的化学成分波动较大。大量数据显示,棒状M2C与片层状M2C碳化物中Fe元素含量在6%~27%之间波动,Mo元素含量在40%~60%之间波动。但从铸态组织的合金元素面分布图(图1c和d)来看,片层状M2C碳化物中的Mo元素含量一般要高于棒状碳化物。总体来看,块状M2C碳化物中Mo元素含量最高,片层状碳化物次之,棒状碳化物Mo元素含量最低。Fe元素的含量则与Mo元素含量相反。

图2

图2

3种不同形态M2C一次碳化物的SEM像

Fig.2

SEM images of M2C primary carbides

(a) lamellar-like carbide (b) rod-like carbide (c) block-like carbide

表1 图2a中片层状一次碳化物的EDS结果 (mass fraction / %)

Table 1

| Point | Fe | Cr | Mo | V | C |

|---|---|---|---|---|---|

| 1 | 26.19 | 12.19 | 40.49 | 9.71 | 11.42 |

| 2 | 22.82 | 10.18 | 45.05 | 10.15 | 11.80 |

| 3 | 17.17 | 11.32 | 47.99 | 11.37 | 12.15 |

| 4 | 22.41 | 10.96 | 44.75 | 10.30 | 11.58 |

| 5 | 21.41 | 11.71 | 44.40 | 11.16 | 11.32 |

表2 图2b中棒状一次碳化物的EDS结果 (mass fraction / %)

Table 2

| Point | Fe | Cr | Mo | V | C |

|---|---|---|---|---|---|

| 1 | 26.06 | 14.12 | 41.12 | 9.17 | 9.41 |

| 2 | 34.51 | 10.07 | 38.97 | 8.23 | 8.23 |

| 3 | 33.48 | 9.38 | 39.61 | 7.99 | 9.32 |

| 4 | 36.25 | 9.73 | 38.17 | 7.70 | 8.15 |

| 5 | 22.93 | 10.34 | 45.77 | 11.22 | 8.64 |

表3 图2c中块状一次碳化物的EDS结果 (mass fraction / %)

Table 3

| Point | Fe | Cr | Mo | V | C |

|---|---|---|---|---|---|

| 1 | 8.02 | 11.75 | 55.09 | 12.62 | 12.52 |

| 2 | 8.73 | 11.76 | 54.51 | 12.59 | 12.41 |

| 3 | 6.29 | 12.71 | 56.14 | 12.46 | 12.40 |

| 4 | 9.04 | 12.03 | 54.35 | 12.47 | 12.11 |

| 5 | 10.28 | 12.47 | 53.46 | 11.61 | 12.18 |

2.2 高温扩散过程中 M2C碳化物组织演变

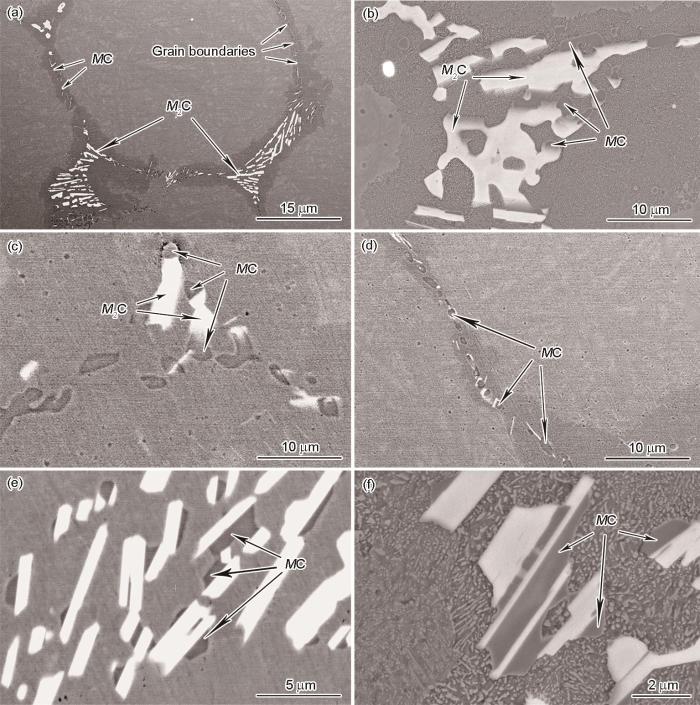

经1160℃保温20 h后,铸态组织中的一次碳化物发生了明显变化,3种不同形态的M2C碳化物的转变过程也存在明显不同。沿晶界分布的棒状M2C碳化物基本消失,取而代之的是沿晶界分布的不规则形状的MC型碳化物(新生MC碳化物),如图3a所示。这与Zhou等[20]的研究结果相符,即短棒状M2C碳化物的热稳定性较低,加热过程中更容易分解。在高温加热过程中,棒状M2C碳化物在薄弱位置分解断开,以“颈缩”的方式形成多段小尺寸M2C,如图3c所示。断开后的小尺寸M2C随后发生相变,MC晶核在M2C碳化物的尖端位置形成,并逐渐向M2C碳化物内部长大。MC碳化物长大的过程中伴随着碳化物的球化,新形成的MC碳化物一般呈不规则颗粒状,见图3d。

图3

图3

经1160℃保温20 h高温扩散处理后M50钢微观组织的SEM-BSE像

Fig.3

SEM-BSE images of the microstructure of M50 steel after heat-treating at 1160oC for 20 h

(a) macroscopic morphology of the microstructure (b) block-like carbide

(c, d) rod-like carbides (e, f) lamellar-like carbides

三叉晶界处残留的M2C碳化物数量较多,主要为块状M2C碳化物与部分片层状M2C碳化物。块状M2C碳化物在1160℃下保温时,仅尖角位置的碳化物分解并溶解到基体中,并未发现碳化物的熔断现象,所以高温扩散处理对块状M2C碳化物的细化效果有限。1160℃保温20 h后,部分块状M2C碳化物已发生相变,相变产物为MC。MC通常形成于块状M2C与基体的界面处,之后向M2C内部长大,如图3b所示。高温处理后,片层状M2C碳化物的数量明显减少,并且多数片层分解断开,形成多段小尺寸M2C,如图3e所示,这表明高温扩散处理对片层状M2C碳化物的细化效果较好。在片层状M2C碳化物中,新生MC碳化物可以在M2C与基体的界面处形核,也可以在M2C内部形成,界面处形成的新生MC主要向基体内生长,如图3e中箭头所示。M2C内部形成的MC晶核呈细小的片层状,2者之间的界面始终保持平直状态,说明M2C内部MC晶核是沿特定晶面形成的,如图3f所示。

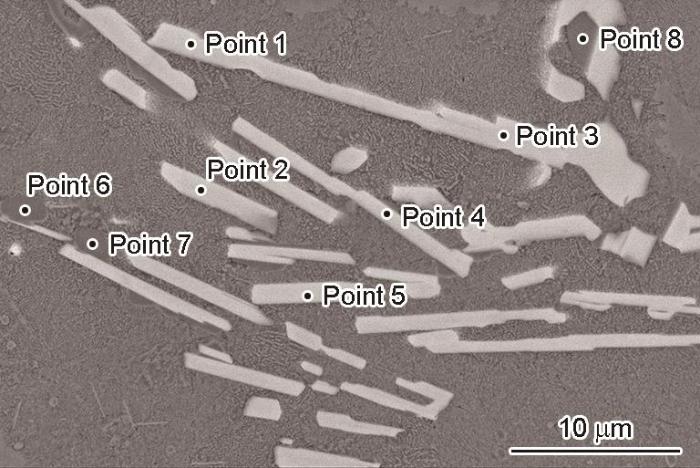

图4为经1160℃保温20 h高温扩散处理后M50钢中残留M2C碳化物及新生MC碳化物的SEM像,2种碳化物的EDS结果如表4所示,其中1~5点为M2C碳化物的化学成分,6~8点为新生MC碳化物的化学成分。大量统计结果显示,经高温扩散处理后残留M2C碳化物中, Fe元素含量均小于10%,一般仅为5%~8%;Mo元素含量较高,一般高于55%;V元素含量同样相对较高,约为14%。图4中6~8点为MC碳化物,根据其形态及所处位置,可以判定是由M2C转变而来的新生MC碳化物。新生MC虽依附于残留M2C生长,但是其Mo、V元素含量发生明显变化,新生MC碳化物中V元素含量一般超过30%,Mo元素含量则明显下降,一般低于40%。此外,新生MC碳化物中,Fe、Cr、C元素的含量也发生一定程度的变化,Fe、Cr元素含量降低,C元素含量升高。M2C与新生MC之间的化学成分差异也证明了M2C的相变过程是由合金元素的扩散控制的,合金元素扩散速率的提高可以加快M2C碳化物的相变进程。

图4

图4

经1160℃保温20 h高温扩散处理后M50钢中残留M2C碳化物以及新生MC碳化物的形貌

Fig.4

Morphologies of retained M2C carbide and newborn MC carbide in M50 steel after heat-treating at 1160oC for 20 h

表4 图4中M2C与MC碳化物的EDS结果 (mass fraction / %)

Table 4

| Carbide | Point | Fe | Cr | Mo | V | C |

|---|---|---|---|---|---|---|

| M2C | 1 | 5.61 | 9.07 | 58.87 | 14.72 | 11.73 |

| 2 | 6.68 | 9.49 | 55.82 | 14.54 | 13.47 | |

| 3 | 5.90 | 10.52 | 57.07 | 13.57 | 12.94 | |

| 4 | 6.87 | 9.53 | 56.20 | 14.60 | 12.80 | |

| 5 | 5.84 | 8.96 | 57.77 | 14.10 | 13.33 | |

| MC | 6 | 3.03 | 5.56 | 38.34 | 33.54 | 19.53 |

| 7 | 2.79 | 5.61 | 38.34 | 37.49 | 15.77 | |

| 8 | 5.27 | 5.50 | 35.33 | 38.32 | 15.58 |

图5

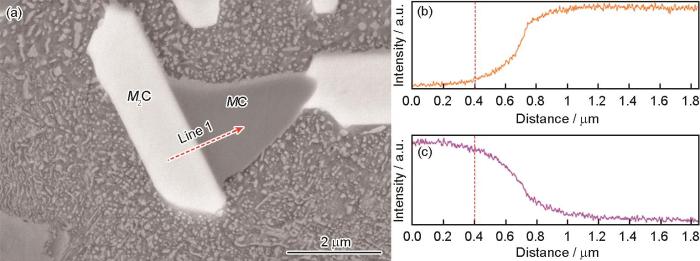

图5

经1160℃保温20 h高温扩散处理后M50钢中片层状M2C碳化物与新生MC碳化物界面结构及V、Mo元素EDS线扫描图

Fig.5

Interface of M2C primary carbide and new-born MC carbide in M50 steel after heat-treating at 1160oC for 20 h (a), and EDS line scanning of V (b) and Mo (c) elements along line 1 in Fig.5a (Dash lines in Figs.5b and c show the interface)

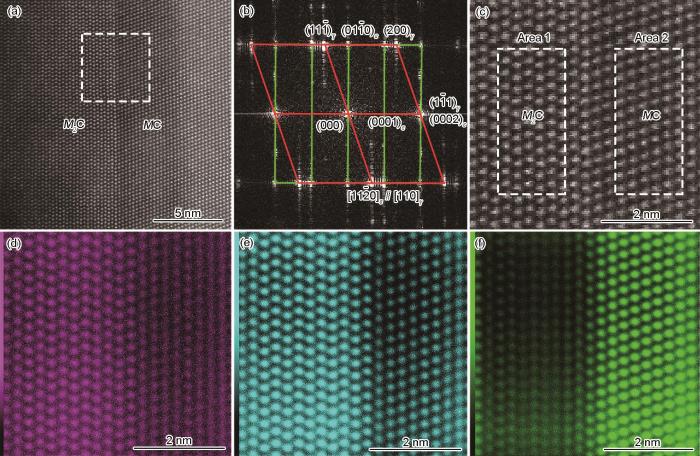

图6为M2C碳化物与新生MC碳化物界面结构的高角度环形暗场扫描透射电子显微镜(HAADF-STEM)像、快速Fourier变换(FFT)及EDS面分布图,图6a界面左侧为M2C碳化物,右侧为MC碳化物。对图6a中矩形区域内的组织进行FFT得到界面结构的衍射斑点,如图6b所示。图中共存在2套衍射斑,红色斑点为MC碳化物,绿色斑点为M2C碳化物。2种碳化物在相变过程中遵循特定的取向关系,MC碳化物的(111)晶面与M2C碳化物的(0001)晶面平行,MC碳化物的[110]晶带轴平行于M2C碳化物的[11

图6

图6

M2C碳化物与新生MC碳化物界面结构的高角度环形暗场扫描透射电子显微镜(HAADF-STEM)像、快速Fourier变换(FFT)及EDS面分布图

Fig.6

Low-magnification high-angle annular dark-field scanning transmission electron microscopy (HAADF-STEM) image of the interface of M2C and MC (a); fast Fourier transform (FFT) patterns of the microstructure in the rectangle of Fig.6a (b); atomic-resolution HAADF-STEM image of the interface of M2C and MC (c); EDS mappings of Fe (d), Mo (e), and V (f)

表5 图6c中M2C与MC的EDS结果 (mass fraction / %)

Table 5

| Area | C | V | Cr | Fe | Mo |

|---|---|---|---|---|---|

| 1 | 3.95 | 17.20 | 5.66 | 3.77 | 69.42 |

| 2 | 6.39 | 39.74 | 4.16 | 2.07 | 47.64 |

图7

图7

经1180℃保温20 h高温扩散处理后M50钢微观组织的SEM-BSE像

Fig.7

SEM-BSE images of the microstructure of M50 steel after heat-treating at 1180oC for 20 h

(a) macroscopic morphology of the microstructure (b) retained M2C carbide

(c, d) high magnified images of positions 1 (c) and 2 (d) in Fig.7b (Arrows in Fig.7d show newborn MC carbides transformed from M2C)

经1210℃保温20 h后,大部分一次碳化物溶解到基体中,同时发现基体组织中形成大量孔洞缺陷,如图8a所示。残留的碳化物发生明显的球化与长大,形成尺寸较大的球形MC碳化物,见图8b~d。MC碳化物的快速长大需要足够的Mo、V等合金元素,因此新的MC碳化物主要在一次碳化物聚集的三叉晶界等位置形成。1210℃保温时,合金元素的扩散速率明显加快,这也导致M2C碳化物的溶解速率以及MC碳化物的长大速率加快。M2C碳化物的快速溶解导致基体中Mo、V元素含量升高,这为MC的快速长大提供了基础。一旦新生MC晶核形成,基体中的Mo、V元素快速向MC内部扩散,导致MC快速长大。MC长大过程中会逐渐取代残留的M2C碳化物(图8d),当MC碳化物长大到一定程度后,多个MC碳化物相互连接,形成尺寸更大的MC碳化物,如图8c所示。

图8

图8

经1210℃保温20 h高温扩散处理后M50钢微观组织的SEM-BSE像

Fig.8

SEM-BSE images of the microstructure of M50 steel after heat-treating at 1210oC for 20 h

(a) macroscopic morphology of the microstructure

(b, c) large sized MC carbides

(d) the growth of MC carbide

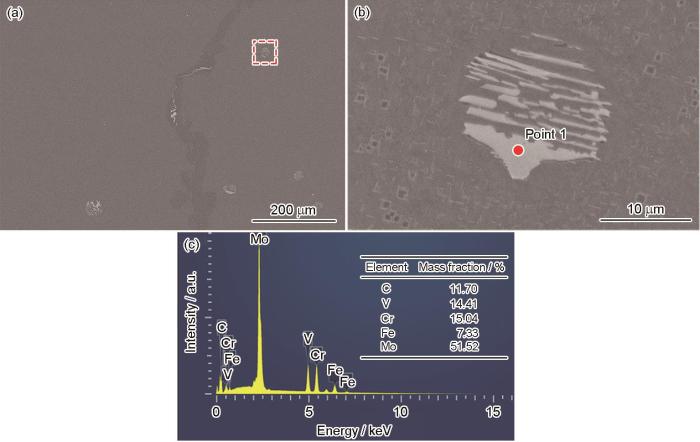

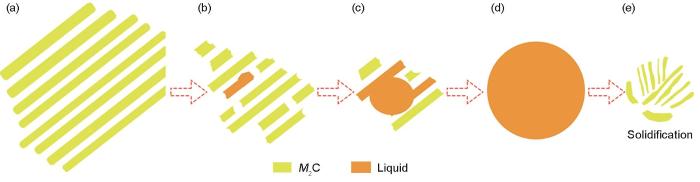

经1250℃保温20 h后,铸态组织中的一次碳化物几乎全部溶解,未发现尺寸较大的MC碳化物,但组织中存在大量呈球形分布的碳化物,如图9a所示。放大后可以发现(图9b),球形碳化物主要由片层状碳化物组成,碳化物在SEM-BSE模式下衬度较亮,结合EDS分析(图9c)可以判断,球形组织中的碳化物是富Mo的M2C型碳化物。球形组织中的新生M2C碳化物与铸态一次碳化物形态存在明显差别,其片层结构更细,并且铸态组织中并未发现呈球形分布的一次碳化物,这证明球形组织是在高温保温过程中形成。图10为M2C碳化物及周围基体组织的EDS合金元素面分布图。可见,碳化物中Mo、V元素偏聚较明显,而碳化物周围的基体组织产生明显的贫Mo、贫V区,这表明在球形组织形成过程中,周围基体组织中的合金元素会向球形组织内部扩散,进而形成M2C碳化物。根据Thermo-Calc计算结果,M50钢的液相线温度约为1447℃,通常状态下,M50钢在1250℃保温时不会产生局部熔化现象,但是M50钢中添加了大量的Cr、Mo、V等合金元素,极易形成元素偏析,合金元素的富集会导致M50钢的熔点下降。杜宁宇[3]的研究表明,M50钢加热至1201℃时,一次碳化物及晶界周围即产生局部熔化现象;Liu等[21]通过激光共聚焦显微镜原位观察发现,M50钢在加热至1200℃时,基体组织会产生局部熔化现象,并形成球形液态组织。根据以上结果可以判断,球形组织的形成是由于M50钢在1250℃保温时局部组织熔化形成液态组织,合金元素向液态组织中扩散导致液态组织中合金元素富集,达到甚至超过共晶点化学成分,形成液析碳化物。新生M2C本质上是片层状M2C碳化物,但由于新生M2C是从球形液态组织中析出,整体呈球形分布。

图9

图9

经1250℃保温20 h高温扩散处理后M50钢微观组织的SEM-BSE像及EDS分析

Fig.9

Low (a) and high (b) magnified SEM-BSE images of the microstructure of M50 steel after heat-treating at 1250oC for 20 h, and EDS analysis of point 1 in Fig.9b (c)

图10

图10

1250℃保温20 h后新生M2C碳化物的SEM-BSE像及EDS面分布图

Fig.10

SEM-BSE image of the newly-formed primary M2C carbide after heat-treating at 1250oC for 20 h; and the EDS mappings of Mo, V, and C elements

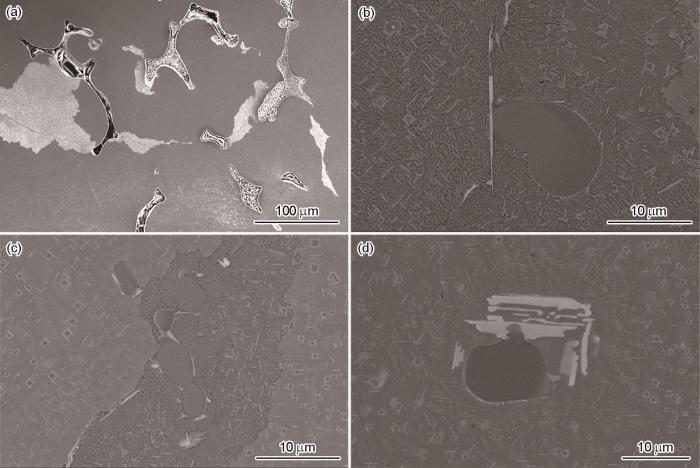

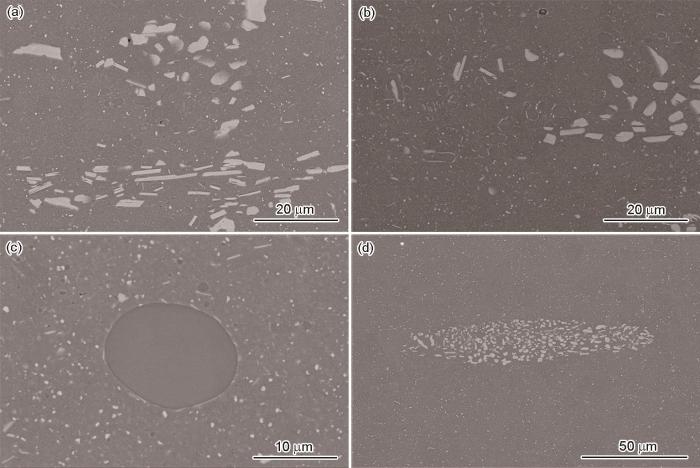

2.3 锻后棒材中碳化物形态与分布

为了研究高温扩散对锻后棒材中碳化物形态及分布的影响,将1160~1250℃保温20 h高温扩散处理后的坯料进行锻造加工,锻后棒材中碳化物分布如图11所示。在锻造加工后,1160℃高温扩散处理的坯料中的碳化物破碎明显,其中块状M2C碳化物破碎后形成不规则形状的小尺寸M2C碳化物,片层状M2C碳化物基本垂直于片层长度方向断开,形成多段小尺寸短棒状碳化物(图11a)。锻后棒材中的MC碳化物为椭球状,尺寸较小,与高温扩散后坯料中的MC碳化物形貌、尺寸基本一致,说明高温保温过程中形成的MC碳化物在热变形过程中不易破碎。经1180℃高温扩散处理的棒材中M2C碳化物的数量明显减少,MC碳化物所占比例增加,并且残留的M2C碳化物主要为不规则形状的M2C碳化物,短棒状的M2C碳化物数量较少(图11b)。MC碳化物所占比例增加的同时,其尺寸及形状没有发生明显变化,说明在1180℃保温时,M2C向MC的转变速率加快,但MC的长大速率较慢。经1210℃高温扩散处理的棒材中M2C碳化物基本全部溶解到基体中,锻后棒材中基本不存在M2C碳化物。而高温保温过程中形成的大尺寸MC碳化物在热变形过程中基本不发生破碎,锻后组织中MC碳化物仍保持椭球型并且尺寸未发生变化(图11c)。经1250℃高温扩散处理的棒材中,保温过程中形成的新生M2C碳化物被完全破碎并沿锻造方向拉长,形成平行分布的条带状M2C碳化物,破碎后的碳化物单个尺寸较小,但呈团簇分布,分布较密集(图11d)。

图11

图11

经不同温度高温扩散处理20 h的M50钢锻造棒材中大尺寸碳化物的SEM-BSE像

Fig.11

SEM-BSE images of the large-scaled carbides in forging M50 steel bars after heat-treating at different temperatures for 20 h

(a) 1160oC (b) 1180oC (c) 1210oC (d) 1250oC

3 分析讨论

3.1 合金成分对 M2C碳化物组织转变的影响

由前述分析可知,在1160℃进行高温扩散处理时,M2C碳化物受化学成分等因素的影响会发生不同的组织转变,部分M2C碳化物快速分解并溶解到基体中,部分M2C碳化物转变为MC碳化物,部分M2C碳化物热稳定性较高,高温处理过程中不发生转变。碳化物在高温保温过程中不同的组织转变过程是调控碳化物尺寸及形态的基础。郑勇[22]通过第一性原理计算发现,合金元素的变化会导致M2C碳化物热稳定性的不同,Cr、Fe元素含量的增加会导致M2C的热稳定性降低。所以,化学成分是导致M2C碳化物发生不同组织转变的重要因素。从M2C碳化物化学成分的总体特征来看,块状M2C碳化物中的Mo元素含量最高,片层状碳化物次之,棒状M2C碳化物中的Mo元素含量最低,Fe元素则与Mo元素含量相反。3种类型的M2C碳化物在高温保温过程中不同的组织转变可在一定程度上反应其热稳定性的变化。

由图3和4可知,棒状M2C在高温保温过程中最先分解,而棒状M2C中的Fe元素含量最高,Mo元素含量最低,这与第一性原理的计算结果相符[22],即Fe元素含量增加、Mo元素含量降低导致M2C碳化物的热稳定性降低。这也进一步解释了Zhou等[20]的研究结果,即短棒状M2C碳化物的热稳定性降低是由于其含有更多的Fe元素。片层状M2C碳化物的化学成分波动较大,1160℃保温20 h后仍残留大量的片层状M2C碳化物。残留的片层状M2C碳化物中, Fe元素含量仅为6%~8%,而Mo元素含量均高于55%,说明Fe元素含量较高的片层状M2C碳化物经1160℃保温20 h后完全分解并溶解到基体中,而Mo、V元素含量较高的片层状M2C碳化物热稳定性相对较高,不易分解。块状M2C碳化物的化学成分较稳定,Mo元素含量较高,Fe元素含量较低,所以块状M2C碳化物的热稳定性最高,1160℃保温20 h后几乎未发生分解。

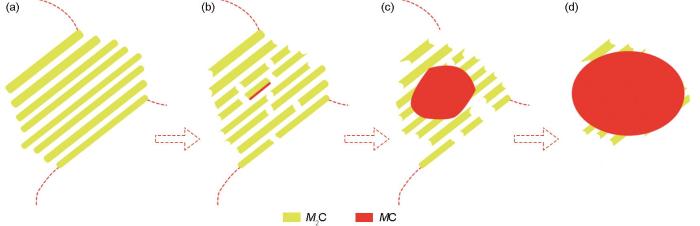

3.2 M2C碳化物的高温分解机制

M2C碳化物在高温保温过程中的组织转变很大程度上决定了锻后棒材组织中的碳化物类型及尺寸,并最终影响材料的服役性能。图12为M2C碳化物在1160~1180℃保温时的组织转变过程示意图,在此温度范围内,部分M2C碳化物快速分解并溶解到基体中,部分M2C碳化物发生相变,形成MC碳化物。保温过程中,棒状M2C碳化物最先分解,分解过程中碳化物内部的Mo、V等合金元素向基体中扩散,基体中的Fe元素向碳化物内部扩散,Fe元素含量较高的碳化物优先分解,导致棒状碳化物逐渐断开,形成如图12a2所示的颗粒状M2C碳化物(黄色碳化物)。之后新生MC碳化物在颗粒状M2C碳化物的尖端形成并逐渐长大(图12a3),最终吞并M2C碳化物并形成如图12a4所示的颗粒状MC碳化物。

图12

图12

M2C碳化物在1160~1180℃时的分解与转变机制示意图

Fig.12

Schematics of the decomposition and transition mechanism of M2C primary carbide when heat-treating at 1160-1180oC (a1-a4) rod-like M2C primary carbides (b1-b4) lamellar-like M2C primary carbides (c1-c3) block-like M2C primary carbides

图12c1~c3所示是块状M2C碳化物在1160~1180℃时的组织转变过程示意图。块状M2C碳化物含有较高的Mo、V等合金元素,并且Fe元素含量一般在10%以下,这导致块状M2C碳化物在此温度下保温时不发生溶解,本工作仅讨论块状M2C碳化物的相变过程。在块状M2C中,MC晶核通常形成于M2C与基体的界面,之后向M2C内部生长,最终吞并整个块状M2C碳化物。界面处形成的MC晶核很难向基体中长大,推测与M2C碳化物较难溶解导致基体中Mo、V等合金元素含量较低有关。

图13

图13

M2C碳化物在1210℃时的分解与转变机制示意图

Fig.13

Schematics of the decomposition and transition mechanism of M2C primary carbide when heat-treating at 1210oC (a-d)

图14

图14

M2C碳化物在1250℃时的分解与转变机制示意图

Fig.14

Schematics of the decomposition and transition mechanism of M2C primary carbide when heat-treating at 1250oC (a-e)

4 结论

(1) M50钢中棒状、片层状与块状M2C碳化物的合金成分存在明显差异,3种碳化物中Fe元素含量依次降低,Mo元素含量依次升高。

(2) M2C碳化物的高温细化机制受合金成分影响,Fe元素含量增加、Mo元素含量减少,会降低M2C碳化物的热稳定性并导致其优先分解。

(3) M2C碳化物向MC碳化物转变遵循特定的取向关系,MC碳化物的[110]晶带轴平行于M2C碳化物的[11

(4) M2C碳化物的细化机制受温度影响,1160~1180℃保温时,M2C碳化物分解并形成小尺寸球形MC碳化物;1210℃保温时M2C碳化物几乎完全分解,MC碳化物快速长大,形成大尺寸MC碳化物;1250℃保温时共晶碳化物全部溶解,但基体组织局部熔化并重新凝固形成球形分布的新生M2C碳化物。

参考文献

Current status of metallurgical quality and fatigue performance of rolling bearing steel and development direction of high-end bearing steel

[J].This paper reviewed the development history of the first generation bearing steel GCr15, the second generation bearing steels M50 and M50NiL, and the third generation bearing steels Cronidur30 and CSS-42L. The fourth generation bearing alloy characterized by light weight is put forward. Based on the analysis of metallurgical quality and fatigue properties of traditional bearing steel, the direction of metallurgical quality control of bearing steel with fine quality and homogenization of large particle inclusions and carbide was proposed, and the contact fatigue control mechanism of bearing steel and two different anti-fatigue mechanisms of carbide control were revealed. According to the latest development of quality control technology and quantitative characterization technology for traditional bearing steel GCr15, the development direction of quality control for high-end bearing steel is proposed. Through the research on the overall heat treatment technology and surface carburizing technology of superfine matrix and carbide of bearing steel GCr15 and CSS-42L steel, the double heat treatment and surface superhardening heat treatment are innovatively developed, which can increase the contact fatigue life of bearing steel GCr15 at room temperature to 5 times and more than 10 times, respectively. Finally, it is pointed out that the application of quantitative inspection and testing technology is an important guarantee for high-performance bearing steel with good metallurgical quality and high performance.

滚动轴承钢冶金质量与疲劳性能现状及高端轴承钢发展方向

[J].

Relationship of inclusions and rolling contact fatigue life for ultra-clean bearing steel

[J].The cleanliness of bearing steels produced in China has been greatly improved due to the significant progress in the steelmaking technologies in the past decade, leading to their total oxygen (T.O.) contents lowered to no more than 6×10-6. Under such a high cleanliness, it is then expected that the influence of non-metallic inclusions on fatigue property should be different from the previous knowledge, because both the size and quantity of inclusions are reduced greatly. Therefore, both inclusions and fatigue properties for three ultra-clean GCr15 (100Cr6) bearing steels containing T.O. around 6×10-6, which were manufactured via different industrial production processes, were studied for this purpose. First, inclusions were characterized by ASPEX SEM and then statically analyzed by the statistics of extreme values (SEV) and the generalized Pareto distribution (GPD). Next, their rolling contact fatigue lives (RCF) L10 and L50 were measured by flat washer tests. Only the largest inclusion in each sample is required for predicting the characteristic sizes of maximum inclusion (CSMI) for the three steels using the SEV method. The calculated CSMIs, however, are not consistent with the variation of either L10 or L50, indicating they are not relevant. In contrast, the types of inclusions above threshold (u) size can be classified and their number density of inclusions quantified when the GPD method is employed. In particularly, the CSMIs of different types of inclusions can be determined. In this case, it has been found that the CSMI of TiN inclusion, which is the most dangerous for initiating cracking, is in a good agreement with the low probability rolling fatigue life (L10), suggesting that they are very correlated. This, however, cannot explain the variation of high-probability fatigue life (L50). Instead, the density of total inclusions also played an important role on the L50 of ultra-clean bearing steels in addition to the CSMI of TiN inclusions. This is reasonable because cracking shall be initiated at not only the most dangerous TiN inclusion during the early failure but also some other highly dense inclusions particularly during the late failure. Therefore, it is then concluded that the L10 is much more related to the CSMI of most dangerous TiN inclusion; whilst the L50 is strongly affected by the number density of total inclusions.

超洁净轴承钢中夹杂物与滚动接触疲劳寿命的关系

[J].以3种不同工艺工业生产的总O含量均≤6×10<sup>-6</sup>的超洁净GCr15轴承钢为研究对象,通过推力片实验测试这3种钢的滚动接触疲劳寿命并获得额定寿命(L<sub>10</sub>)和中值寿命(L<sub>50</sub>),通过ASPEX扫描电镜获得各工艺下的夹杂物样本数据并进行统计分析,使用极值法(SEV)和广义Pareto分布法(GPD)估算出样品中最大夹杂物特征尺(CSMI),然后将其与实测L<sub>10</sub>和L<sub>50</sub>进行对比和分析。结果表明,SEV法仅检测每个样品的最大夹杂物,无法通过其获得的CSMI来合理解释3种钢L<sub>10</sub>和L<sub>50</sub>的变化,2者之间相关性较差;而GPD法分析夹杂物时,需要对阈值尺寸以上的所有夹杂物进行表征和统计分析,可以获得夹杂物的数量密度以及不同类型夹杂物的CSMI,GPD法所预测出的最危险类型TiN夹杂物的CSMI可以合理解释L<sub>10</sub>的变化,2者之间有较好相关性,但无法据此解释L<sub>50</sub>的变化;但将总的夹杂物数量密度与TiN夹杂物最大特征尺寸相结合,能合理解释3种钢的L<sub>50</sub>差异,这是因为当更多样品失效时,裂纹萌生位置将不再仅仅局限于最危险类型夹杂物。因此,最危险类型夹杂物的CSMI与超纯净轴承钢中的早期疲劳失效的L<sub>10</sub>相关性最强,而夹杂物的数量密度对高概率的中值疲劳寿命L<sub>50</sub>也有重要影响。

Research on carbide control and fatigue properties of M50 bearing steel

[D].

M50轴承钢碳化物调控与疲劳性能研究

[D].

Low-oxygen rare earth steels

[J].Rare earth (RE) addition to steels to produce RE steels has been widely applied when aiming to improve steel properties. However, RE steels have exhibited extremely variable mechanical performances, which has become a bottleneck in the past few decades for their production, utilization and related study. Here in this work, we discovered that the property variation of RE steels stems from the presence of oxygen-based inclusions. We proposed a dual low-oxygen technology, and keeping low levels of oxygen content in steel melts and particularly in the raw RE materials, which have long been ignored, to achieve impressively stable and favourable RE effects. The fatigue life is greatly improved by only parts-per-million-level RE addition, with a 40-fold improvement for the tension-compression fatigue life and a 40% enhancement of the rolling contact fatigue life. We find that RE appears to act by lowering the carbon diffusion rate and by retarding ferrite nucleation at the austenite grain boundaries. Our study reveals that only under very low-oxygen conditions can RE perform a vital role in purifying, modifying and micro-alloying steels, to improve the performance of RE steels.© 2022. The Author(s), under exclusive licence to Springer Nature Limited.

Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel

[J].High-carbon chromium bearing steels with different rare earth (RE) contents were prepared to investigate the effects of RE on inclusions and impact toughness by different techniques. The results showed that RE addition could modify irregular Al2O3 and MnS into regular RE inclusions. With the increase of RE content, the reaction sequence of RE and potential inclusion forming elements should be O, S, As, P and C successively. RE inclusions containing C might precipitate in molten steel and solid state, but the precipitation temperature was significantly higher than that of carbides in high-carbon chromium bearing steel. For experimental bearing steels, the volume fraction of inclusions increased steadily with the increase of RE content, but smaller and more dispersed inclusions could be obtained by 0.018% RE content compared with bearing steel without RE, whereas the continuous increase of RE content led to an increasing trend for inclusion size and a gradual deterioration for inclusion distribution. RE addition could improve the transverse impact toughness and isotropy of bearing steel, and for modified high-carbon chromium bearing steel by RE alloying, the increase of RE content continuously increased both transverse and longitudinal impact toughness until excessive RE addition.

Changes of cleanliness and carbide during vacuum preparation of stainless bearing steel

[J].

不锈轴承钢真空制备过程洁净度及碳化物变化

[J].为了提高G102Cr18Mo高碳不锈轴承钢的洁净度、细化碳化物组织,采用真空感应熔炼、两次真空自耗重熔、大锻压比锻造的工艺路线,研究了真空处理及大锻压比锻造对化学成分、气体含量、夹杂物分布、二次枝晶间距及碳化物颗粒度的影响。研究结果表明,真空感应熔炼过程(VIM)中,随着铝含量的增加,碳的脱氧能力大幅降低,即使铝质量分数为0.003%也对碳的脱氧能力有明显的阻碍作用;真空自耗重熔过程(VAR)由于高的真空度、高的重熔温度等热力学条件以及反应动力学条件的改善,氧含量显著降低,第一次自耗重熔后氧质量分数从0.001 49%降低至0.000 57%,降低了61.7%,第二次自耗重熔后氧质量分数降低至0.000 50%。真空感应熔炼、真空自耗重熔过程,夹杂物的成分变化不大,主要以Al-Si夹杂为主,其次为Al<sub>2</sub>O<sub>3</sub>夹杂,再次为MnS夹杂、Mg-Al-Ca、Mg/Ca-Al夹杂。双真空冶炼后,钢中夹杂物主要为0~5 μm的细小夹杂物,未发现大于20 μm的夹杂,含有少量10~20 μm的夹杂,钢的洁净度大幅度提高。在真空自耗锭横断面上,从边部向芯部二次枝晶的形貌变化不大,二次枝晶间距逐渐增大,但是变化趋势缓慢,二次枝晶间距为85~95 μm,这主要得益于低的自耗重熔速度。对真空自耗锭进行大变形处理,最终锻造成40 mm的圆棒,碳化物颗粒的最大尺寸不大于20 μm,平均尺寸为15 μm,且没有碳化物聚集的现象。低的自耗重熔速度和大锻压比锻造是碳化物细化的关键。

Effect of cooling rate on the precipitation mechanism of primary carbide during solidification in high carbon-chromium bearing steel

[J].Bearing is one of the most technologically important engineering components in machines. With the development of several advanced steel-refining technologies to suppress the detrimental effect of nonmetallic inclusions on the mechanical properties of materials, the impact of carbides on the service life of bearings has gradually highlighted. The carbides have become a key factor in determining the performance of a bearing, particularly for primary carbides formed during the solidification of high carbon-chromium bearing steel. Therefore, exploring the formation mechanism of primary carbides and their control strategies is vital to improve the manufacturing process of bearing steel as well as the service life and reliability of bearings. To clarify the formation mechanism of primary carbides and the effects of the processing technique, as well as the addition of rare earth elements, a modified type of GCr15 high carbon-chromium bearing steel with and without rare earth elements was remelted and solidified at different cooling rates. After solidification, the quantity, area, average size, and chemical composition of the primary carbide in the as-cast bearing steel were characterized and analyzed via OM, EPMA, SEM, and XRD. The results show that the type of carbide in GCr15 series bearing steel is M3C cementite with high Cr content (more than 15%, mass fraction). The nucleation rate of M3C cementite increased with the increase in the cooling rate; thus, the number of carbides increased considerably. However, at very high cooling rates, the primary austenite was refined and the diffusion time of C and Cr elements required to form carbides declined; therefore, the size of carbides was reduced significantly, resulting in more uniform dispersion of the carbides. Moreover, the addition of rare earth elements could refine the primary austenite, and subsequently, refine the carbide to some extent. Considering the properties of the primary carbides at different cooling rates, the kinetic formation mechanism for the primary carbide in high carbon-chromium bearing steel during solidification is proposed.

冷速对高碳铬轴承钢液析碳化物凝固析出机制的影响

[J].为明确液析碳化物的形成与工艺的关系和产生机制,以及受添加稀土元素的影响,对添加稀土元素和未添加稀土元素的GCr15系连铸高碳铬轴承钢进行了不同冷却速率下的重熔凝固实验。试样凝固完毕后,采用OM、EPMA、SEM和XRD等表征和分析了铸态轴承钢中的液析碳化物的数量、面积、平均尺寸和化学成分等与冷却速率的关系,以及添加稀土元素的影响效果。结果表明,GCr15系轴承钢液析碳化物的类型为M<sub>3</sub>C型渗碳体,Cr含量较高,可达15% (质量分数)以上,并且随冷速增加,其数量明显增加。但是,当冷却速率较快时,初生奥氏体细化,同时因形成碳化物所需的C、Cr元素扩散时间减少,碳化物尺寸显著减小,且分布更加弥散均匀。通过对比分析添加稀土元素对凝固组织的影响,发现稀土元素有细化奥氏体进而细化液析碳化物的作用。根据不同冷速下液析碳化物的特点,提出了高碳铬轴承钢凝固过程一次碳化物形成的动力学机制。

Damage evolution around primary carbides under rolling contact fatigue in VIM-VAR M50

[J].

Formation mechanism and influence of white etching area on contact fatigue spalling of M50 bearing steel

[J].

The role of primary carbides in fatigue crack propagation in aeroengine bearing steels

[J].

Fatigue crack nucleation and propagation at clustered metallic carbides in M50 bearing steel

[J].

Crack initiation mechanism of M50 bearing steel under high cycle fatigue

[J].

Formation mechanism of MC and M2C primary carbides in as-cast M50 bearing steel

[J].

Formation and evolution mechanism of voids in M50 bearing steel during thermal deformation

[J].M50 bearing steel is widely used in the manufacture of aeroengine spindle bearings. The voids generated by the thermal processing of bearing steel can easily initiate fatigue cracks and lead to fatigue failure of the bearings. Thus, it is essential to understand the steel production conditions, void distribution in the steel, and effect of the subsequent treatment on the healing process of voids to improve the thermal processing and mechanical properties of the steel. In this work, the thermal deformation of the M50 bearing steel was conducted using a thermal simulation machine. The effects of the strain rate (0.001-1 s-1), deformation temperature (1000-1150oC) and strain (10%-50%) on the formation of voids and void healing during the subsequent thermal treatment were systematically studied using OM, SEM, EBSD, and in situ scanning methods. The results show that the formation of voids between the carbide and matrix is attributed to the different hardness values between the matrix and primary M2C and MC carbides. In addition, the carbide fractures can promote the formation of internal voids. The quantitative analysis of the voids indicated that most voids are generated under the following conditions: a high strain rate of 1 s-1, low deformation temperature of 1000oC, and medium deformation of 30%. Applying a heat treatment after deformation can significantly promote the void healing process, and the Cr element is enriched in the healing zone due to its rapid diffusion in γ-Fe.

M50轴承钢热变形过程中孔洞形成及演化机制

[J].M50轴承钢广泛应用于航空发动机主轴轴承的制造,轴承钢热加工产生的孔洞极易作为疲劳裂纹的萌生源导致轴承的疲劳破坏。本工作通过热模拟实验和OM、SEM、EBSD、原位扫描等方法系统研究了不同应变速率(0.001~1 s<sup>-1</sup>)、变形温度(1000~1150℃)和应变(10%~50%)对M50轴承钢内部孔洞产生行为的影响,以及后续保温处理过程中孔洞的愈合机制。结果表明,轴承钢内部一次碳化物M<sub>2</sub>C和MC与基体硬度的差异导致非协调变形,从而在碳化物与基体交界处产生孔洞,此外碳化物的破碎也会促使孔洞在其内部形成。通过对不同条件下孔洞的产生情况进行定量分析发现,在高应变速率(1 s<sup>-1</sup>)、低变形温度(1000℃)、中等变形量(30%)的条件下,M50轴承钢内部产生的孔洞最多。变形后的保温处理可显著促进孔洞的愈合,其中保温处理后孔洞愈合区域富集Cr元素。

On origin of delta eutectoid carbide in M2 high-speed steel and its behaviour at high temperature

[J].

Phase transformation refinement of coarse primary carbides in M2 high speed steel

[J].

Decomposition of the M2C carbide in high speed steel

[J].

Solidification microstructure and M2C carbide decomposition in a spray-formed high-speed steel

[J].

Transformation behavior of primary MC and M2C carbides in Cr4Mo4V steel

[J].

Morphology, microstructure and decomposition behavior of M2C carbides in high speed steel

[J].

Characteristics and transformation of primary carbides during austenitization in Cr4Mo4V bearing steel

[J].

First-principles study of stability and mechanical property of MC and M2C in high speed steel

[D].

高速钢中MC和M2C的稳定性和力学性能的第一性原理研究

[D].

Stability of eutectic carbide in Fe-Cr-Mo-W-V-C alloy by first-principles calculation

[J].

Thermodynamic stability and mechanical properties of (V, M)C (M = W, Mo and Cr) multicomponent carbides: A combined theoretical and experimental study

[J].

Macrostructure, microstructure and mechanical properties evolution during 8Cr4Mo4V steel roller bearing inner ring forging process

[J].

In situ investigation of the fracture of primary carbides and its mechanism in M50 steel

[J].

Effect of nitriding on the transformation of alloy carbides (VC and Mo2C) in 8Cr4Mo4V steel

[J].

Microstructure evolution and growth behaviors of faceted phase in directionally solidified Al-Y alloys II. Microstructure evolution of directionally solidified Al-53%Y peritectic alloy

[J].

定向凝固Al-Y合金组织演化规律及小平面相生长Ⅱ. Al-53%Y包晶合金组织演化规律

[J].

Research progress of Fe-Mn-Al-C system austenitic low density steel

[J].

Fe-Mn-Al-C系奥氏体基低密度钢的研究进展

[J].轻量化且高强韧化已成为汽车用钢的主要发展方向。在不同类型的轻质钢中,Fe-Mn-Al-C系奥氏体基低密度钢因具有更高的比强度和良好的塑韧性备受研究者们青睐。从成分体系与力学性能、多种强韧化机制、不同变形机制及工艺调控等方面总结了Fe-Mn-Al-C系奥氏体基低密度钢的研究进展,重点阐述了奥氏体基低密度钢中特有的B2相以及κ-碳化物、MC碳化物等析出相的析出行为对强韧性机制的影响。最后,结合目前国内外学者对Fe-Mn-Al-C系奥氏体基低密度钢的最新研究成果,对奥氏体基低密度钢进行了展望。

Primary carbide refinement in AISI M50 steel by dislocation engineering via pre-deformation treatment

[J].

Controlling of morphology evolution of eutectic carbide in M2 high speed steel by directional solidification

[J].

定向凝固法控制M2高速钢中共晶碳化物形貌演变行为

[J].

Influence of the nitrogen content on the carbide transformation of AISI M42 high-speed steels during annealing

[J].