针对AlSi10Mg多孔结构力学响应的研究,初期通过静态加载条件,确定了AlSi10Mg多孔结构在低应变率下的力学行为及宏观损伤模式[13~16],主要包括低应变率下的应力-应变关系、承载强度、宏观结构损伤裂纹等。随着分离式Hopkinson压杆实验技术的发展和普及[17~20],明确了AlSi10Mg多孔结构在高应变率下的力学性能、宏观/细观结构损伤模式等[21~23],主要表现为高应变率下的承载状态、吸能模式、变形破坏形式等,为反向设计满足高应变率下的AlSi10Mg多孔结构提供了一定的参考依据。目前,国内外学者对AlSi10Mg多孔结构力学行为的研究虽已经取得了显著的进展[24~27],但研究手段较为单一,研究的应变率范围也具有一定的局限性,整体仍处于不断发展和完善的阶段,特别是AlSi10Mg多孔结构在全应变率加载条件下(低应变率、中应变率和高应变率)的力学行为及损伤模式,以及通过高精度数值模拟技术协同阐明AlSi10Mg多孔结构损伤模式及损伤机制方面。而在AlSi10Mg多孔结构服役环境中又常面临这些问题,因此,迫切需要对其在不同加载应变率下的损伤模式及响应机制展开研究。

本工作通过低应变率、中应变率和高应变率加载装置开展实验研究,探明AlSi10Mg多孔结构在不同加载应变率下的力学响应、破坏形式、吸能特性及影响因素。构建高精度数值模拟,进一步探明加载应变率对AlSi10Mg多孔结构力学行为的影响模式及破坏机理。

1 实验和数值模拟方法

1.1 实验材料及试件

实验用AlSi10Mg粉末的主要成分(质量分数,%)为:Si 9.50~10.50,Mg 0.25~0.50,Fe ≤ 0.60,Mn ≤ 0.50,Zn ≤ 0.15,Cu ≤ 0.06,Al余量。利用Sigma 300 system场发射扫描电镜(SEM)观察AlSi10Mg合金粉末形貌,电子束的加速电压(EHT)为15 kV,探测器类型为SE2,工作距离为10.4 mm。

三维周期极小曲面(triply periodic minimal surface,TPMS)是一种在Cartesian正交坐标系下呈现周期性的曲面,表面任意点处切线斜率为零,即表面光滑过渡。通过调整TPMS单元表达式内相关参数,分别可以实现对TPMS单元曲面的内外偏移、结构孔隙率的调节及单元周期大小的改变。TPMS不仅被认为是描述人体骨骼生物形态的理想几何形状,也被用于航天飞行器关键部件保护结构中优先考虑的几何形状。面对防护结构在特殊服役环境中的轻量化、强吸能和抗冲击特性需求,基于TPMS的Schoen Gyroid函数曲面[28~30]构造本研究中的AlSi10Mg多孔结构,其表达形式如下:

式中,a为晶胞单元长度,参数t控制Schoen Gyroid函数曲面体积。

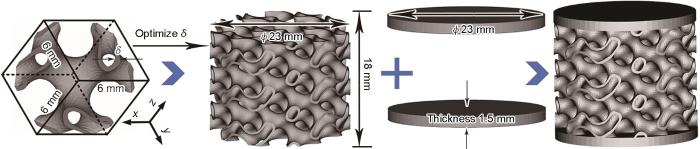

图1为AlSi10Mg多孔结构优化及设计的主要成形模式示意图。对标AlSi10Mg多孔结构轻量化、抗冲击及吸能特性,优化出较为合理的壁厚(δ)为0.23 mm,结构体积分数约为9.43%。试件优化及设计过程主要步骤:首先构建合适的晶胞,然后再根据所要设计的结构尺寸进行阵列,最后,设计试件两端的封皮。本工作中,AlSi10Mg多孔结构晶胞尺寸为6 mm × 6 mm × 6 mm,试件尺寸为直径23 mm、厚21 mm (中间多孔结构18 mm,上下蒙皮各1.5 mm)。

图1

图1

AlSi10Mg多孔结构优化及设计的主要成形模式示意图

Fig.1

Schematics of main forming modes for optimization and design of AlSi10Mg porous structure (δ—wall thickness)

试件由SLM技术制造完成,在制造之前,对SLM工艺参数进行优化,优化后的具体加工工艺参数为:激光功率400 W,激光扫描速率1300 mm/s,扫描间距170 μm,粉末层厚度30 μm。

1.2 实验装置和原理

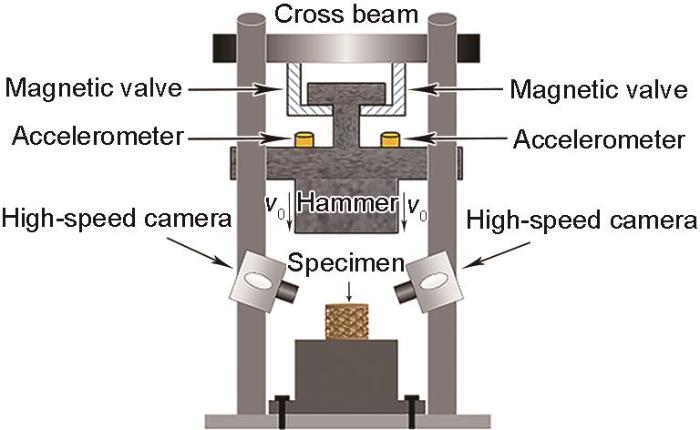

低应变率实验(0.009 s-1)应用SHIMADZU万能试验机对AlSi10Mg多孔结构进行准静态加载。为全面了解AlSi10Mg多孔结构在加载过程中的损伤、变形和破坏模式,利用3台Manta G-917B摄像机从3个不同方位同步监测试件的变形和破坏方式。中应变率(50 s-1)实验采用落锤试验机对试件进行加载,其实验装置示意图如图2所示。实验研究中,2个加速度传感器同步探测加载过程中的加速度信号,2台高速相机同步监测AlSi10Mg多孔结构在加载过程的损伤模式。

图2

图2

中应变率加载实验装置示意图

Fig.2

Schematic of medium strain rate loading experimental device (v0—speed in the loading direction)

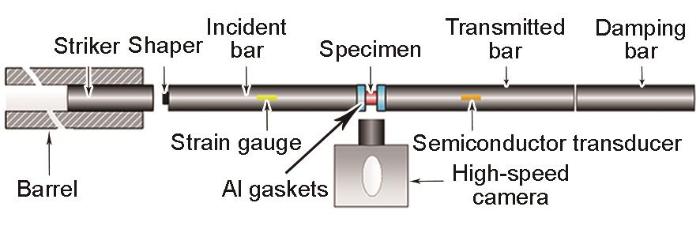

高应变率(378~1639 s-1)实验采用改进的分离式Hopkinson压杆(split Hopkinson pressure bar,SHPB)进行加载,图3为改进的SHPB实验装置示意图。图中,撞击杆、入射杆、透射杆以及吸收杆均为直径37 mm的圆柱体,所用材料均为Al,长度分别为500、2500、2500和1000 mm。通过调整气舱压力,进而控制撞击杆速率,使得撞击杆以不同速率撞击入射杆,从而实现不同高应变率加载。在入射杆的撞击端中心位置安装Cu片脉冲整形器,其尺寸为直径10 mm、厚1 mm。在入射杆的中间位置安装应变计,测试入射信号和反射信号。为防止强动载荷破坏入射杆和透射杆,在试件的两端均加了Al垫片。由于多孔结构透射信号较为微弱,将半导体应变计安装在透射杆中间,其灵敏度高,抗干扰性强。吸收杆与透射杆相连,用于吸收透射信号,避免重复加载试件。高速相机监测试件在整个加载过程的变形破坏形式。

图3

图3

改进的分离式Hopkinson压杆(SHPB)实验装置示意图

Fig.3

Schematic of improved split Hopkinson pressure bar (SHPB) experimental device

式中,c0为压杆的弹性波速;εi和εr分别为应变片测试到的入射脉冲应变信号和反射脉冲应变信号;τ为应变。由

试件两端的压力F1和F2可以表示为:

因此,试件中的平均应力(σ)、ε和应变率(

联立式(

1.3 有限元模型及相关参数

式中,M为屈服强度参数;B为模型参数;n为硬化指数;C为应变率敏感参数;m为温度软化参数;σe为等效流动应力;εp为等效塑性应变;

表1 Johnson-Cook本构模型和断裂准则相关参数

Table 1

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Yield strength parameter | M | 331.17 | MPa |

| Model parameter | B | 576.65 | MPa |

| Strain rate sensitive parameter | C | 0.032 | |

| Hardening index | n | 0.99 | |

| Temperature softening parameter | m | 0.945 | |

| Reference strain rate | 1 | s-1 | |

| Reference temperature | Tr | 298 | K |

| Melting point temperature | Tm | 843 | K |

| Material model parameter | D1 | 0.04704 | |

| D2 | 1.155 | ||

| D3 | -0.841 | ||

| D4 | -0.042 | ||

| D5 | 0 | ||

| Material density | ρ | 2700 | kg·m-3 |

| Elastic modulus | E | 75 | GPa |

| Poisson's ratio | ν | 0.3 |

式中,εf为断裂应变;σ*为应力三轴度,σ*=σm / σMises (其中,σm为静水压力,σMises为等效应力);D1~D5为材料模型参数,相关参数具体数值如表1所示。

2 结果与讨论

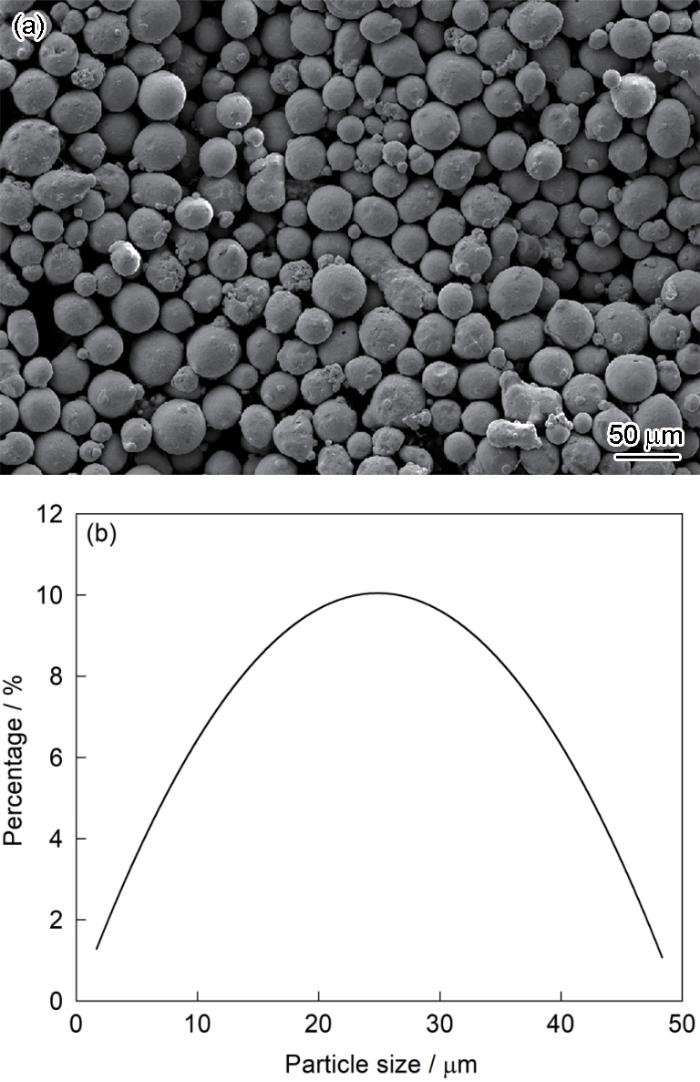

2.1 AlSi10Mg合金粉末表征

图4为AlSi10Mg合金粉末的形貌及粒度分布。由图可知,AlSi10Mg合金粉末球形度良好,其粒度尺寸主要分布在3~48 μm,平均尺寸约为24.8 μm。

图4

图4

AlSi10Mg合金粉末形貌及粒度分布

Fig.4

SEM image (a) and particle size distribution (b) of the AlSi10Mg alloy powders

2.2 力学性能及宏观结构损伤模式

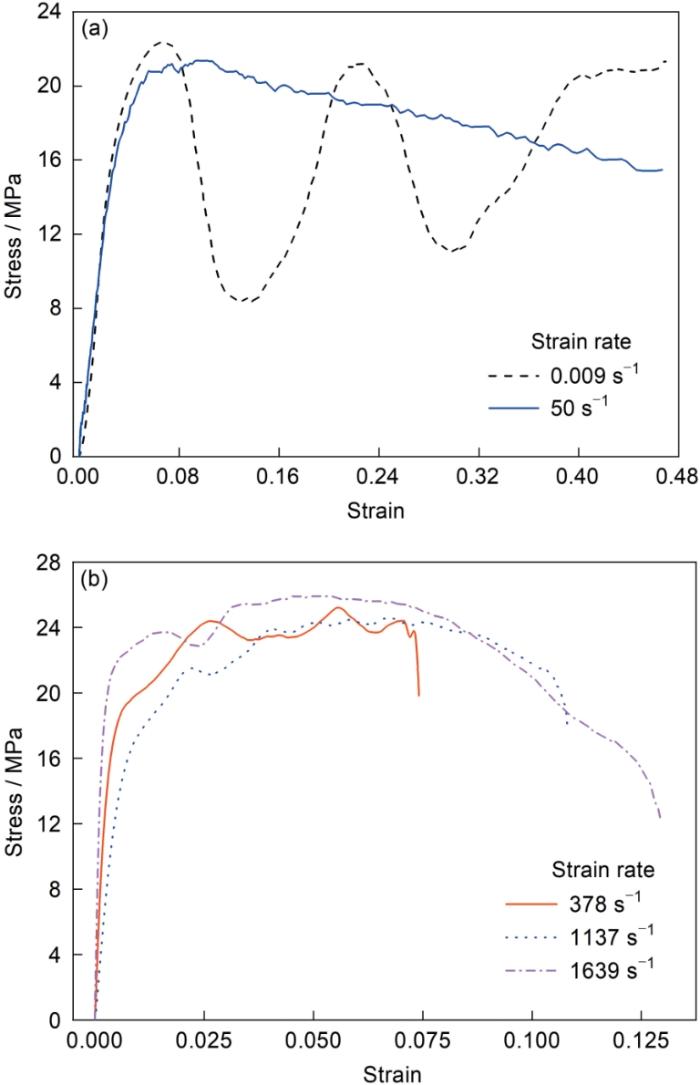

为全面认识AlSi10Mg多孔结构在不同加载应变率下的力学行为,对其在低应变率、中应变率和高应变率下的力学响应展开了一系列实验研究,获得的应力-应变曲线如图5所示。由图可知,AlSi10Mg多孔结构在不同加载应变率下的应力-应变关系具有高度非线性,且无明显的应变率效应。在低应变率(0.009 s-1)和中应变率(50 s-1)加载条件下,AlSi10Mg多孔结构承载强度分别约为22.35和21.33 MPa。而在不同高应变率下(378~1639 s-1)的应力峰值约为(25.23 ± 1.227) MPa,显然AlSi10Mg多孔结构在不同高应变率加载条件下对应变率效应不敏感。分析可知,从低应变率、中应变率再到高应变率加载条件下,AlSi10Mg多孔结构力学行为对应变率敏感性无明显特性,但均具有明显的应变硬化效应。

图5

图5

AlSi10Mg多孔结构在不同加载应变率下的应力-应变曲线

Fig.5

Stress-strain curves of AlSi10Mg porous struc-ture under different strain rates

(a) low and medium strain rates

(b) high strain rates

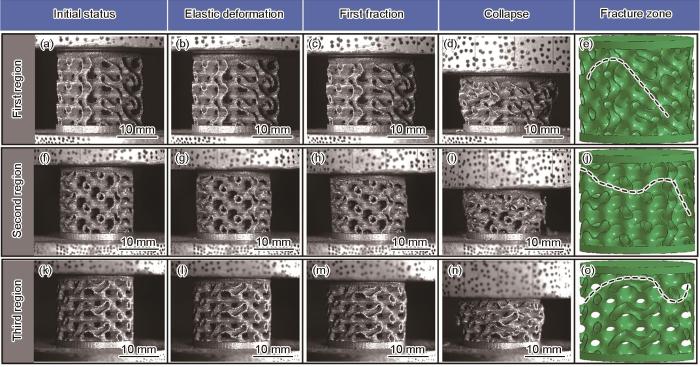

通过对AlSi10Mg多孔结构在低应变率下的应力-应变曲线(图5a)分析可知,该结构在整个加载阶段的力学行为主要表现为弹性变形阶段、塑性变形阶段、剪切破坏阶段及压溃阶段。图6为AlSi10Mg多孔结构在低应变率(0.009 s-1)加载条件下的变形破坏模式及破坏位置示意图。当AlSi10Mg多孔结构应变小于2%时,其力学响应模式主要表现为弹性变形。当应变增加至6.7%时,该多孔结构达到最大承载能力,充足的加载能量使得试件沿斜截面相对错动而破坏,开始出现损伤裂纹,并沿应力薄弱路径不断扩展,这一扩展过程,形成了第一个剪切带,试件3个不同部位的剪切带构型各有差异,如图6e、g和o中虚线所示。继续加载,充足的载荷能量致使AlSi10Mg多孔结构产生了新的断裂带,并不断沿应力薄弱路径继续扩张,形成了新的断裂区域,断裂继续加剧,此时AlSi10Mg多孔结构承载能力已大幅下降,其已基本被压溃。

图6

图6

AlSi10Mg多孔结构在低应变率(0.009 s-1)下的变形破坏模式及破坏位置示意图

Fig.6

Deformation failure mode (a-d, f-i, k-n) and schematics of damage location (dash lines) (e, j, o) at the first region (a-e), the second region (f-j), and the third region (k-o) of AlSi10Mg porous structure at low strain rates (0.009 s-1) (elastic deformation, the strain ε ≈ 2%; first fracture, ε ≈ 6.7%; collapse, ε ≈ 30%)

图7

图7

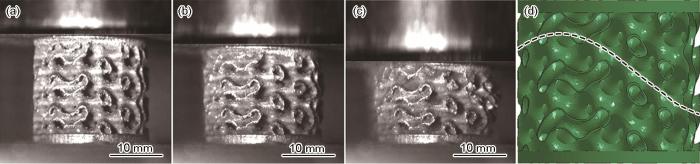

AlSi10Mg多孔结构在中应变率(50 s-1)加载条件下的变形破坏模式及破坏位置示意图

Fig.7

Deformation failure mode (a-c) and schematic of damage location (dash line) (d) of AlSi10Mg porous structure under medium strain rate loading (50 s-1)

(a) initial status (b) first fracture (ε ≈ 8.7%) (c) serious damage (ε ≈ 25%)

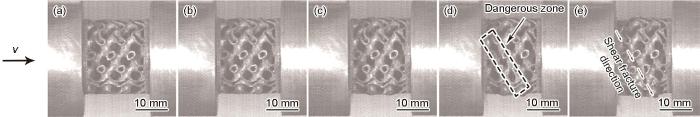

在不同高应变率下AlSi10Mg多孔结构弹性阶段应力-应变曲线高度重合(图5b),可见其在不同高应变率下的动态弹性模量相同,表明其在弹性阶段力学行为不受加载应变率影响。AlSi10Mg多孔结构产生部分塑性变形后,不同高应变率下的应力-应变曲线略有波动,这一波动与加载应力波大小紧密相关,不同的加载应力波在结构内部传递过程中,内部产生反射的应力波会有小幅度的差异,震荡的应力波也会有微小的差异。图8为高速相机拍摄到的AlSi10Mg多孔结构在1137 s-1加载应变率下的变形及破坏模式实验结果。由图8a~c可知,随着加载的进行,AlSi10Mg多孔结构径向先产生均匀变形,这一过程包含了弹塑性变形,随着加载应力波的继续作用,结构内部产生了损伤,出现了应力危险区域,如图8d所示。随着损伤继续演化,结构出现了剪切破坏现象,在试件斜截面上可明显观测到一剪切带(图8e),这一剪切带与轴向加载方向之间的夹角约为50° ± 2.5°。由文献[36~39]可知,铝合金在轴向压缩时其断面与轴向加载方向大致成45°~55°,AlSi10Mg多孔结构破坏模式与铝合金受到轴向压缩载荷作用时沿斜截面破坏形式基本一致。

图8

图8

高速相机拍摄到的AlSi10Mg多孔结构在1137 s-1高应变率加载条件下的变形及破坏模式

Fig.8

Deformation and failure modes of AlSi10Mg porous structure under high strain rate loading of 1137 s-1 captured by high-speed camera for 0 μs (a), 50 μs (b), 100 μs (c), 150 μs (d), and 200 μs (e) (v—impact velocity of the striker)

2.3 破坏机理

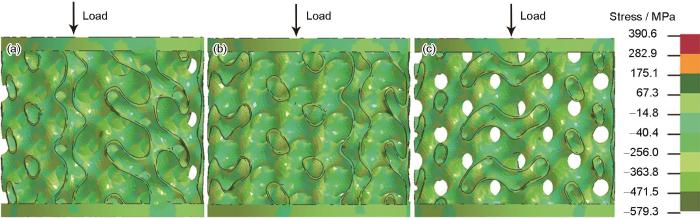

图9

图9

AlSi10Mg多孔结构在低应变率(0.009 s-1)加载条件下,应变约为2%时的承载状态数值模拟结果

Fig.9

Numerical simulation results of the load-bearing state of the AlSi10Mg porous structure at low strain rate (0.009 s-1) as the strain is 2%

(a) the first region (b) the second region (c) the third region

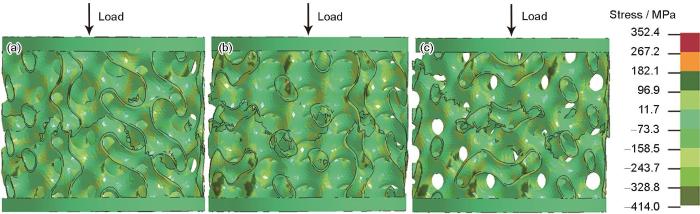

图10

图10

AlSi10Mg多孔结构在低应变率(0.009 s-1)加载条件下,应变约为7.7%时的破坏模式数值模拟结果

Fig.10

Numerical simulation results of failure modes of AlSi10Mg porous structure under low strain rate (0.009 s-1) as the strain is 7.7%

(a) the first region (b) the second region (c) the third region

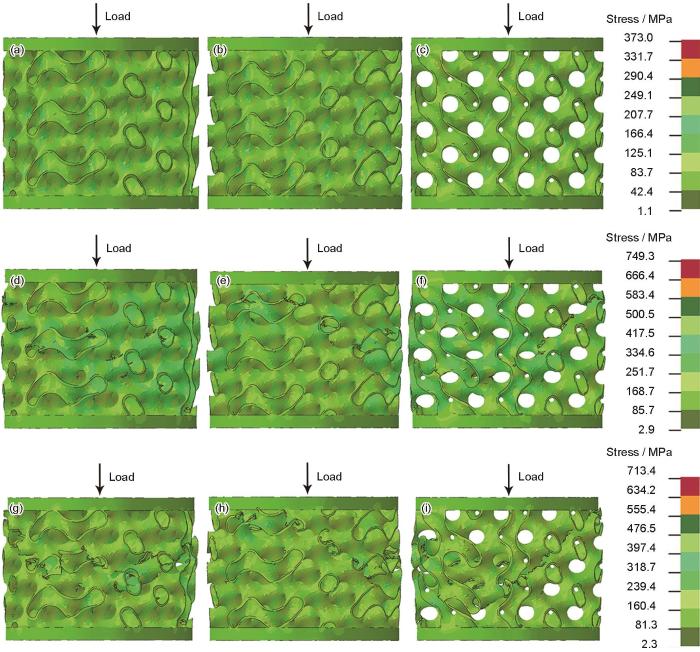

图11为AlSi10Mg多孔结构在中应变率(50 s-1)加载条件下的承载状态及变形破坏模式数值模拟结果。加载初始阶段(应变约为1%),AlSi10Mg多孔结构处于弹性阶段,由第1~3区域(图11a~c)分析可知,该结构应力状态分布均匀,且无明显应力集中现象。随着加载的继续,当冲击载荷大于结构承载强度或剪切强度时,AlSi10Mg多孔结构开始表现出相应的损伤形式。当应变约为8.7%时,由AlSi10Mg多孔结构第1~3区域(图11d~f)分析可知,该结构开始出现明显的损伤裂纹。随着冲击载荷继续加载,当应变约为25%时,损伤裂纹沿应力薄弱路径急剧扩展,同时其他部位也产生剪切失效,从而出现了多个剪切带,如AlSi10Mg多孔结构第1~3区域(图11g~i)所示。

图11

图11

AlSi10Mg多孔结构在中应变率(50 s-1)加载条件下的承载状态及变形破坏模式数值模拟结果

Fig.11

Numerical simulation results of bearing state and deformation failure mode of AlSi10Mg porous structure under medium strain rate (50 s-1) at strains of 1% (a-c), 8.7% (d-f), and 25% (g-i) (a, d, g) the first regions (b, e, h) the second regions (c, f, i) the third regions

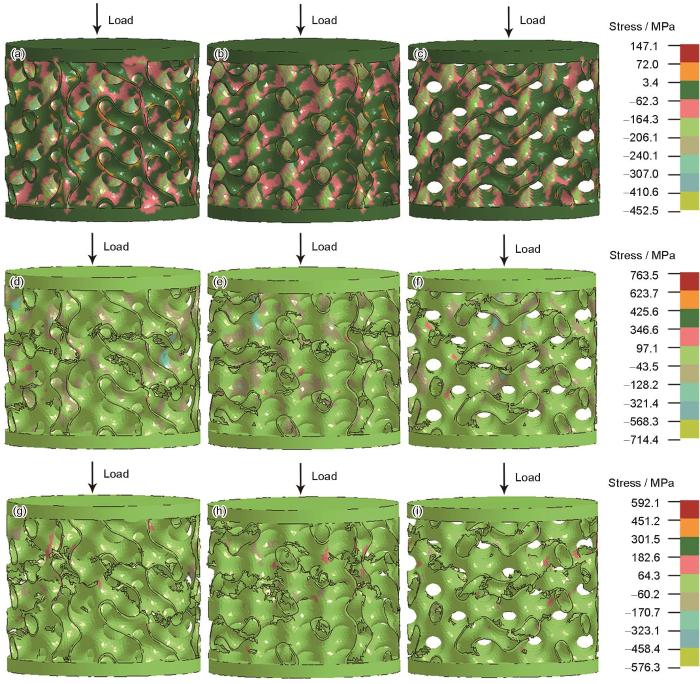

基于改进的SHPB技术,将实验中的动态压缩载荷入射脉冲(入射脉冲时间约为200 μs)输入到入射杆进行数值模拟仿真分析,研究发现,该AlSi10Mg多孔结构在高冲击下的破坏形式与低应变率和中应变率加载方式下不同。图12为AlSi10Mg多孔结构在高应变率(1137 s-1)加载条件下的变形及破坏模式数值模拟结果。在150 μs之前,试件没有出现明显损伤断裂特征(图12a~c),这一现象也与实验研究相一致。当加载脉冲时间为165 μs时,试件产生损伤断裂形貌(图12d~f);继续加载至200 μs,试件断裂形貌损伤程度明显加剧,出现了破坏较为严重的剪切断裂带(图12g~i)。该AlSi10Mg多孔结构试件在其他不同高应变率下的仿真破坏形式也基本与1137 s-1加载应变率下的相似,这与本实验研究中发现的该AlSi10Mg多孔结构对加载应变率不敏感性相吻合。

图12

图12

AlSi10Mg多孔结构在高应变率(1137 s-1)加载条件下的变形及破坏模式数值模拟结果

Fig.12

Numerical simulation results of deformation and failure modes of AlSi10Mg porous structure under high strain rate (1137 s-1) when the loading time is 150 μs (a-c), 165 μs (d-f), and 200 μs (g-i) (a, d, g) the first regions (b, e, h) the second regions (c, f, i) the third regions

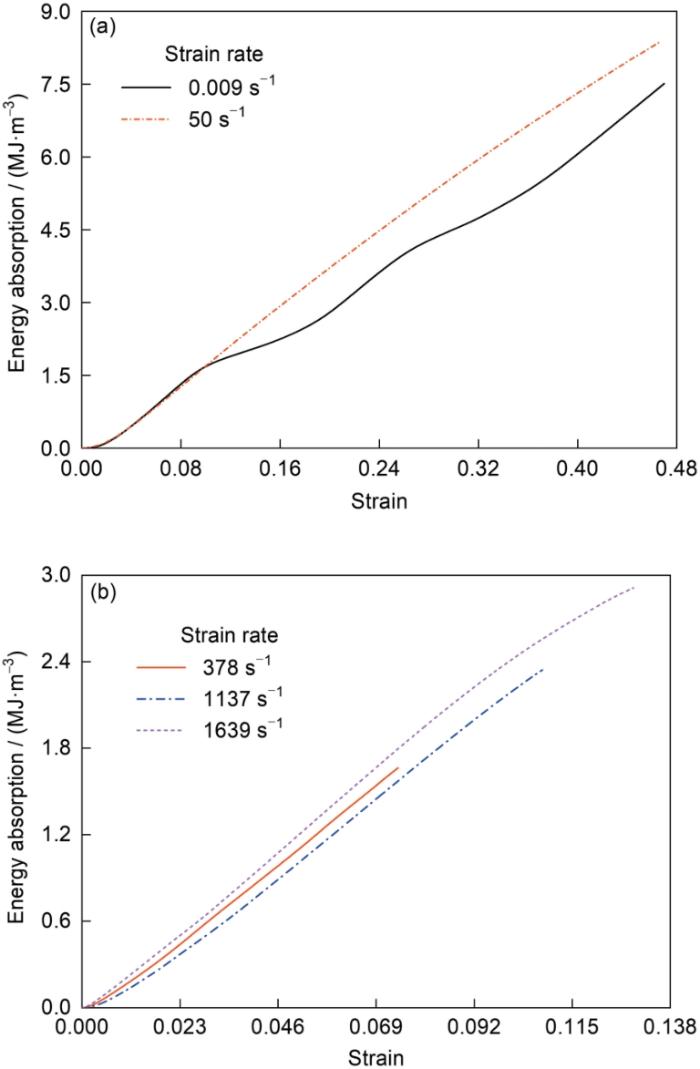

2.4 能量吸收特性

图13

图13

AlSi10Mg多孔结构在不同加载应变率下的能量吸收特性

Fig.13

Energy absorption characteristics of AlSi10Mg porous structure under low and medium strain rates (a), and different high strain rates (b)

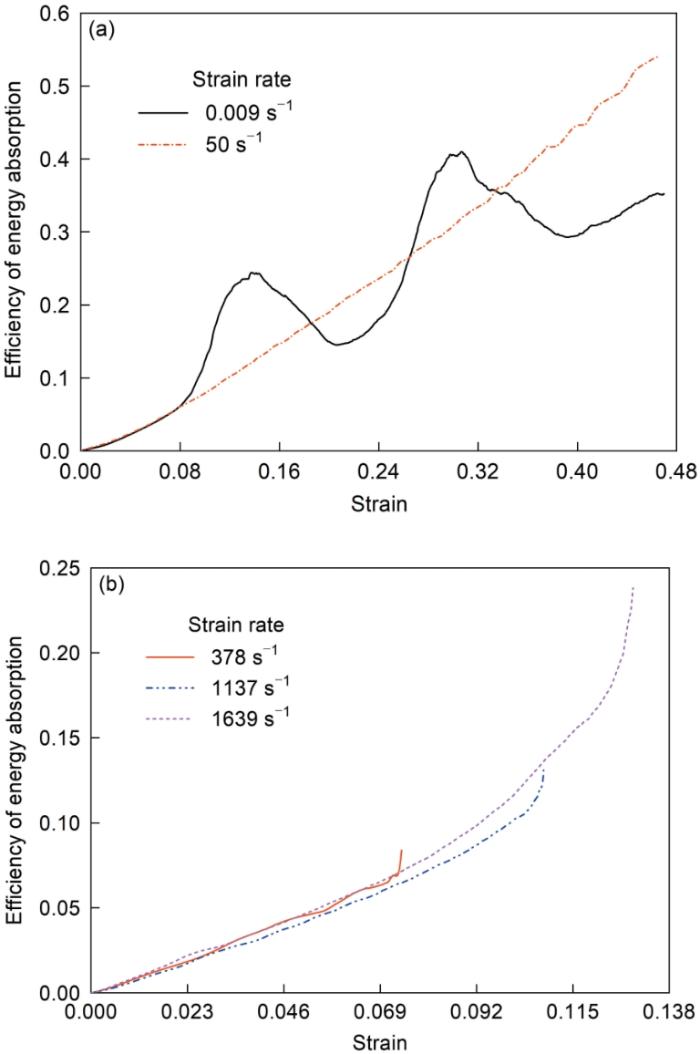

图14

图14

AlSi10Mg多孔结构在不同加载应变率下的能量吸收效率

Fig.14

Efficiency of energy absorptions of AlSi10Mg porous structure under low and medium strain rates (a), and different high strain rates (b)

3 结论

(1) AlSi10Mg多孔结构力学行为对加载应变率效应不敏感,但具有明显的应变硬化效应。AlSi10Mg多孔结构损伤破坏模式主要表现为损伤断裂、剪切破坏,且破坏断面与轴向加载方向夹角主要分布在45°~55°之间。

(2) 数值模拟研究表明,在压缩载荷作用下AlSi10Mg多孔结构沿斜截面相对错动而发生剪切失效,产生多处剪切带,是导致其结构破坏的主要原因。同时发现AlSi10Mg多孔结构的破坏模式及破坏机理对加载应变率不敏感。

(3)多孔结构单位体积所吸收的能量和能量吸收效率研究表明, AlSi10Mg多孔结构具有较好的吸能特性。当结构应变小于10%时,其在低应变率(0.009 s-1)和中应变率(50 s-1)下的吸能特性相同,当结构应变大于10%时,其在中应变率下的单位体积能量吸收量比低应变率下略微增大,最大差异值约为1.34 MJ/m3;而其在低应变率和中应变率下的能量吸收效率优势交错进行,应变约为0.138时,低应变率下的能量吸收效率比中应变率下的大12.1%,而当应变约为0.459时,中应变率下的能量吸收效率却比低应变率下的大18.5%。而在不同高应变率(378~1639 s-1)加载条件下,AlSi10Mg多孔结构吸能特性十分接近。

参考文献

Investigation of porosity, microstructure and mechanical properties of additively manufactured graphene reinforced AlSi10Mg composite

[J].

Mechanical properties of AlSi10Mg lattice structures fabricated by selective laser melting

[J].

Laser powder bed fusion of AlSi10Mg: Influence of energy intensities on spatter and porosity evolution, microstructure and mechanical properties

[J].

The mechanical behavior and microstructure of additively manufactured AlSi10Mg for different material states and loading conditions

[J].

Investigation for macro mechanical behavior explicitly for thin-walled parts of AlSi10Mg alloy using selective laser melting technique

[J].

Effect of construction angles on microstructure and mechanical properties of AlSi10Mg alloy fabricated by selective laser melting

[J].

Hybridisation of AlSi10Mg lattice structures for engineered mechanical performance

[J].

Effects of processing parameters and heat treatment on thermal conductivity of additively manufactured AlSi10Mg by selective laser melting

[J].

Investigation on mechanical properties and energy absorption capabilities of AlSi10Mg triply periodic minimal surface sheet structures fabricated via selective laser melting

[J].

Analysis of the interdependent relationship between porosity, deformation, and crack growth during compression loading of LPBF AlSi10Mg

[J].

Laser powder bed fusion of oxidized microscale SiC-particle-reinforced AlSi10Mg matrix composites: Microstructure, porosity, and mechanical properties

[J].

Effects of different mechanical and chemical surface post-treatments on mechanical and surface properties of as-built laser powder bed fusion AlSi10Mg

[J].

Effect of internal pores on fatigue properties in selective laser melted AlSi10Mg alloy

[J].

Data on mechanical pro-perties of open-cell AlSi10Mg materials and open-cell AlSi10Mg-SiC composites with different pore sizes and strain rates

[J].

Effect of microstructure and porosity of AlSi10Mg alloy produced by selective laser melting on the corrosion properties of plasma electrolytic oxidation coatings

[J].

Tensile behavior of AlSi10Mg overhanging structures fabricated by laser powder bed fusion: Effects of support structures and build orientation

[J].

Structure and mechani-cal properties of an advanced aluminium alloy AlSi10MgCu(Ce, Zr) produced by selective laser melting

[J].

Structural integrity of additively manufactured aluminum alloys: Effects of build orientation on microstructure, porosity, and fatigue behavior

[J].

Effect of input powder attributes on optimized processing and as-built tensile properties in laser powder bed fusion of AlSi10Mg alloy

[J].

Thermal expansion behavior and elevated temperature elastic properties of an interpenetrating metal/ceramic composite

[J].

Dimensional changes of selectively laser-melted AlSi10Mg alloy induced by heat treatment

[J].

Microstructures and hardening mechanisms of a 316L stainless steel/Inconel 718 interface additively manufactured by multi-material selective laser melting

[J].

Promoting the densification and grain refinement with assistance of static magnetic field in laser powder bed fusion

[J].

Mechanical properties of high Mg-content Al-Mg-Sc-Zr alloy fabricated by selective laser melting

[J].

Additive manufacturing of aluminum metal matrix composites: Mechanical alloying of composite powders and single track consolidation with laser powder bed fusion

[J].

Laser incidence angle influence on energy density variations, surface roughness, and porosity of additively manufactured parts

[J].

A machine learning framework to predict local strain distribution and the evolution of plastic anisotropy & fracture in additively manufactured alloys

[J].

Laser powder-bed-fusion of Si3N4 reinforced AlSi10Mg composites: Processing, mechanical properties and strengthening mechanisms

[J].

Modification of residual stresses in laser additive manufactured AlSi10Mg specimens using an ultrasonic peening technique

[J].

Split Hopkinson pressure bar tests for investigating dynamic properties of additively manufactured AlSi10Mg alloy by selective laser melting

[J].

Dynamic response of AlSi10Mg alloy fabricated by selective laser melting

[J].

Constitutive models for the dynamic behaviour of direct metal laser sintered AlSi10Mg_200C under high strain rate shock loading

[J].

Dynamic loading of direct metal laser sintered AlSi10Mg alloy: Strengthening behavior in different building directions

[J].

Dynamic compressive response of additively manufactured AlSi10Mg alloy hierarchical honeycomb structures

[J].

Numerical and experimental investigations of built orientation dependent Johnson-Cook model for selective laser melting manufactured AlSi10Mg

[J].

Effect of heat treatment patterns on porosity, microstructure, and mechanical properties of selective laser melted TiB2/Al-Si-Mg composite

[J].

3D printed self-similar AlSi10Mg alloy hierarchical honeycomb architectures under in-plane large deformation

[J].

Experimental investigation on shear strength of laser powder bed fusion AlSi10Mg under quasi-static and dynamic loads

[J].

Plasticity and fracture of cast and SLM AlSi10Mg: High-throughput testing and modeling

[J].

Advancements in the additive manufacturing of magnesium and aluminum alloys through laser-based approach

[J].

TEM study of the microstructure of an alumina/Al composite prepared by gas-pressure infiltration

[J].

Design and performance of a novel neutron shielding composite materials based on AlSi10Mg porous structure fabricated by laser powder bed fusion

[J].

Compressive failure modes and energy absorption in additively manufactured double gyroid lattices

[J].

A novel T6 rapid heat treatment for AlSi10Mg alloy produced by laser-based powder bed fusion: Comparison with T5 and conventional T6 heat treatments

[J].

Influence of processing parameters on AlSi10Mg lattice structure during selective laser melting: Manufacturing defects, thermal behavior and compression properties

[J].

Selective laser melting of TiN nanoparticle-reinforced AlSi10Mg composite: Microstructural, interfacial, and mechanical properties

[J].

The interplay of geometric defects and porosity on the mechanical behavior of additively manufactured components

[J].

Effect of direct aging and annealing on the microstructure and mechanical properties of AlSi10Mg fabricated by selective laser melting

[J].

Laser-based additively manufactured bio-inspired crashworthy structure: Energy absorption and collapse behaviour under static and dynamic loadings

[J].

Effects of graphene on the mechanical properties of AlSi10Mg melted by SLM

[J].