取向硅钢是重要的软磁性材料,主要用于各类变压器的铁芯,其成品具备强Goss ({110}<001>)二次再结晶织构[1~3]。根据铁单晶体的磁化实验,<001>方向为最易磁化方向[4],所以取向硅钢沿轧向磁化时磁性能最优[5,6]。为了获得最优的二次再结晶组织与织构,需要在高温退火前获得足够强的晶粒长大抑制能力以在高温退火初期抑制晶粒正常长大,在高温退火中后期抑制能力丧失时,Goss晶粒发生异常长大[7~10]。常化是高磁感取向硅钢生产过程中的重要工艺环节[11,12],首先加热至高温将抑制剂溶解,在随后的冷却过程中抑制剂重新弥散析出以增强抑制能力[13~18]。目前关于常化对取向硅钢抑制剂析出的影响研究主要集中在常化的冷却段,如李慧等[13]研究指出,一段式常化后沸水淬火较空冷而言抑制剂数量有所减少,但尺寸有所增加;若常化后淬入冷水中,由于冷速过快,许多抑制剂来不及析出,导致抑制剂数量显著减少。Ling等[15]采用二段式常化,冷却时采用冷水淬火、沸水淬火和空冷至相变温度下再沸水淬火的常化工艺,结果显示常化后空冷至相变温度下然后沸水淬火获得了更多纳米级AlN。

在以AlN为主抑制剂的高磁感取向硅钢中,在常化固溶时可形成一定数量的奥氏体[19],通常认为由于N元素在奥氏体中的溶解度要远大于在铁素体中的溶解度[20],所以在常化冷却过程中可通过γ→α相变来促进析出弥散的AlN[13,15,16]。但Wang等[21]指出,由于常化过程中所形成奥氏体数量较少,所以AlN的溶解数量有限,因此对促进AlN析出作用较小。事实上,在工业生产的取向硅钢热轧板中,由表至内存在间距不等、沿轧向延展的碳化物富集的片层区[21~23],而富C片层区之间是铁素体晶粒区,这些区域在常化时并不会发生相变,因此热轧板中这2种截然不同的区域在常化过程中的组织转变将大相径庭,同时其对抑制剂的析出作用也有较大差距,有必要对其进行深入研究。本工作系统研究了高磁感取向硅钢热轧板在常化工序中,其升温速率、固溶温度、相变温度与时间和相变后冷速等工艺参数对组织演变和抑制剂析出的影响,并对常化过程中相变对抑制剂析出的影响进行了分析讨论。

1 实验方法

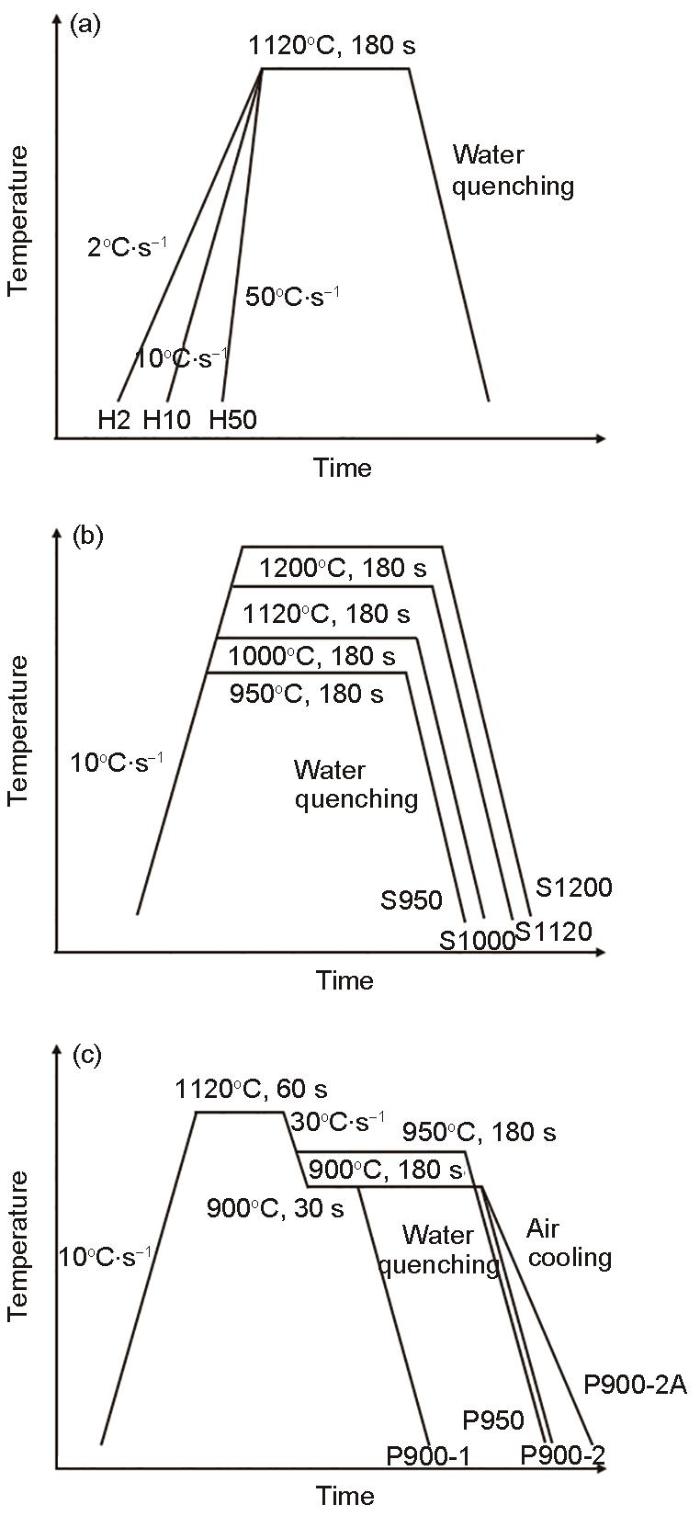

以工业生产的2.4 mm厚低温高磁感取向硅钢热轧板为研究材料,Si含量为3.25% (质量分数,下同),以AlN为主抑制剂,MnS为辅助抑制剂。为了研究常化升温速率、固溶温度、相变温度与时间、相变后冷却速率对抑制剂析出的影响,设计了4组常化工艺,如图1所示。将以2、10和50℃/s升温的常化样品分别记为H2、H10和H50,将固溶温度为950、1000、1120和1200℃的常化样品分别记为S950、S1000、S1120 (同H2)和S1200,在固溶后冷却至不同的相变温度并保温不同时间,包括900℃、30 s,900℃、180 s和950℃、180 s,对应的常化样品分别记为P900-1、P900-2和P950,目的是在此阶段引入奥氏体至铁素体相变以促进抑制剂析出,上述所有样品最后水冷至室温。为比较相变后冷速的影响,另将经900℃、180 s相变保温后空冷至室温的样品,记为P900-2A。图1所示各工艺方案均在Gleeble-3800型热模拟试验机上进行实验,采用喷水冷却方式。利用SDPTOP-MX4R型光学显微镜(OM)、JSM-6701F型冷场发射扫描电子显微镜(SEM)和PHI710型扫描Auger探针仪上配备的EDAX OIM 6.0型电子背散射衍射仪(EBSD)进行组织观察和表征。采用DIL805A/D型热膨胀相变仪原位分析样品在模拟常化工艺时的各相变过程和相变开始转变温度,所采用工艺与图1中类似,但由于设备条件限制,实验时采用100℃/s气冷冷却而非水冷。采用双喷电解和碳膜复型2种制样方法制备透射电镜(TEM)样品,观察析出相(即抑制剂)。由于热轧及常化板表层发生脱碳而为铁素体单相区,故选取接近中心、能发生相变区域进行样品制备。通过JEM-2200FS型场发射TEM对热轧及常化板抑制剂进行观察和分析。利用随机拍摄得到的关于抑制剂的多张TEM图片对抑制剂的平均尺寸及数量密度进行统计,每个样品统计的图片面积都在200 μm2左右。相图计算使用的是Thermo-Calc 2017a商用软件,所用数据库为TCFE9。

图1

图1

高磁感取向硅钢常化工艺示意图

Fig.1

Schematics of normalizing processes of high permeability grain-oriented silicon steel

(a) with the heating rates of 2, 10, and 50oC/s to 1120oC, samples named H2, H10, and H50, respectively

(b) with the different solution temperatures of 950, 1000, 1120, and 1200oC, samples named S950, S1000, S1120, and S1200, respectively

(c) with the additional stage of phase trans-formation at 950oC for 180 s, 900oC for 30 and 180 s, followed by water quenching, samples named P950, P900-1, and P900-2, respec-tively; and 900oC for 180 s followed by air cooling, sample named P900-2A

2 实验结果

2.1 热轧及常化组织

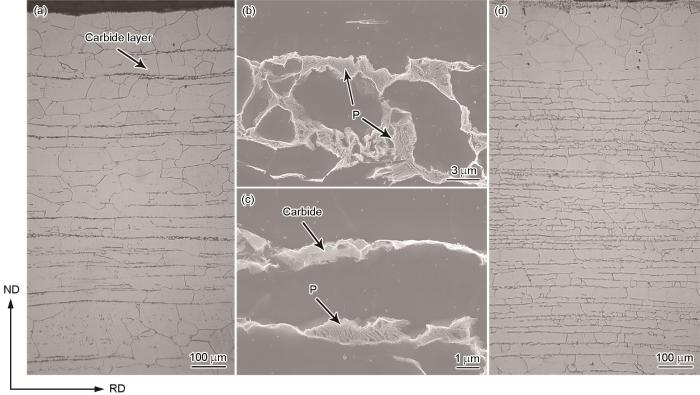

图2

图2

取向硅钢热轧板与常化板的显微组织

Fig.2

OM (a, d) and SEM (b, c) images of hot-rolled (a-c) and H2 normalized (d) grain-oriented silicon steel bands (ND—normal direction, RD—rolling direction, P—pearlite)

图3a~g为不同常化工艺下取向硅钢显微组织的SEM像。常化固溶温度为950℃时,在富C片层区域残留有未溶的珠光体,如图3a所示,且富C组织(珠光体、碳化物)转变成为的奥氏体在淬火中转变为马氏体或以残余奥氏体形式保留下来,后者经EBSD检测确认,形貌多呈三角形或四边形,如图3h所示。在1000℃固溶淬火后,更多的富C片层转变为马氏体,同时仍然可明显观察到众多抑制剂粒子,如图3b所示;1120℃固溶后依然可见这些未溶的碳化物(图3c),但总体上数量较S950和S1000样品减少;而1200℃固溶淬火后碳化物更少,所形成的奥氏体主要转变为马氏体(图3d),且仍然存在残余奥氏体。图3e和f分别为1120℃保温然后分别在900和950℃等温相变后的淬火组织,2者均含有珠光体和马氏体组织,且在P900-2样品中仍然有残余奥氏体,如图3i所示。据作者所知,这是首次在工业取向硅钢的常化组织中观察到残余奥氏体。

图3

图3

不同常化工艺下取向硅钢显微组织的SEM像及残余奥氏体的EBSD质量图和相图叠加图

Fig.3

SEM images of grain-oriented silicon steel after the different normalizing processes (a-g) and EBSD quality map overlapped with phase map of retained austenite (h, i) (M—martensite) (a, h) S950 (b) S1000 (c) S1120 (d) S1200 (e, i) P900-2 (f) P950 (g) P900-2A

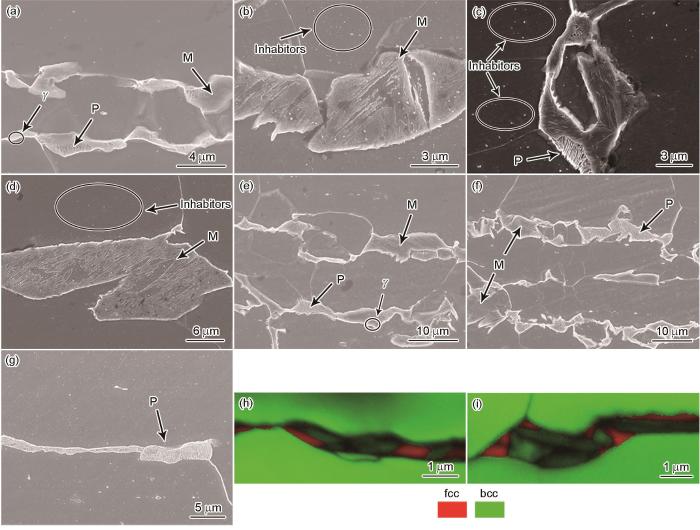

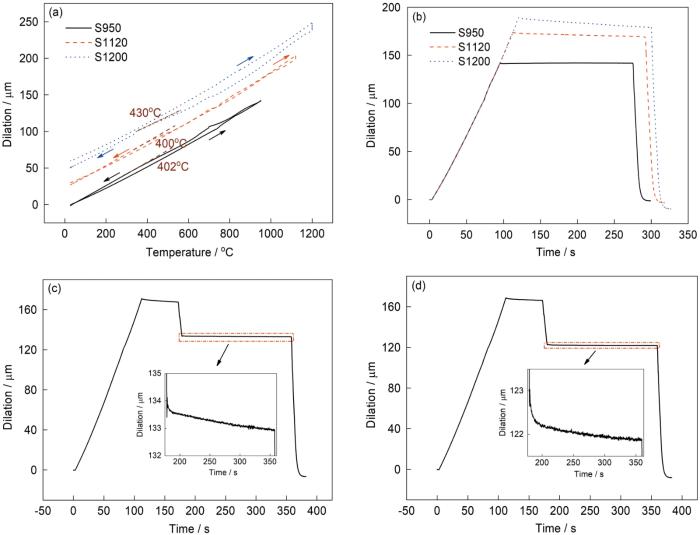

图4a为S950、S1120和S1200样品膨胀量随温度的变化曲线。由于在加热至固溶温度后,最多只能形成约20%的奥氏体[19,21],因此在快冷时马氏体相变膨胀量并不明显,但仍然可以看出1200℃固溶后马氏体相变开始温度(Ms)为430℃,而950~1120℃固溶后Ms降低到约400℃,这是因为在1200℃固溶形成了大量奥氏体,C浓度降低所致。图4b~d为S950、S1120、S1200、P950和P900-2样品膨胀量随时间的变化曲线。由图4b可见,固溶温度越高,固溶期间试样收缩得就越多、越快,意味着更多富C组织更快地转变为奥氏体。同时由图4b还可见,在固溶过程中富C组织的溶解是持续进行的,奥氏体也相应逐渐产生,并且热轧板中富C的片层区域在加热至950~1200℃保温180 s均不能完全溶解。邻近未溶碳化物的奥氏体中C含量高、奥氏体稳定性也高,淬火后也更容易残留下来。

图4

图4

不同常化工艺下取向硅钢的热膨胀曲线

Fig.4

Dilatometric changes of grain-oriented silicon steel measured during the different normalizing processes

(a, b) recorded dilations of S950, S1120, and S1200 samples varying with temperature (a) and time (b)

(c) recorded dilation of P950 sample varying with time (Inset shows the locally enlarged curve)

(d) recorded dilation of P900-2 varying with time (Inset shows the locally enlarged curve)

由图3c可知,在1120℃下固溶180 s后珠光体仍未完全溶解,所以对于P950和P900-2样品在1120℃下保温60 s时珠光体更不可能完全溶解,而当温度降低至950或900℃进行相变阶段保温时,此时未溶解的珠光体将继续溶解而导致膨胀量继续下降,如图4c和d所示。未溶解的珠光体中含C量高,其完全奥氏体化温度低,因此在相变保温温度下(900~950℃)会继续发生奥氏体化形成奥氏体,即发生P→γ相变,而非通常所认为的在相变温度下会发生γ→α相变[13,15,16]。事实上,取向硅钢在相变保温温度下发生γ→α相变是建立在基体中C、Si含量均一的条件下(取向硅钢基体中Si含量高达3.25%,而C含量仅为0.05左右,此时铁素体的平衡相分数高),而实际的组织中存在显著的C偏析现象,见图1a~c。另外,由图3e和f可见,P950和P900-2样品中未溶的珠光体片层间距大,其发生奥氏体相变的孕育期长,故在短时溶解时未能完全转变为奥氏体。在第二阶段保温后空冷样品中发现了较多珠光体,如图3g所示,这部分珠光体是缓冷过程中由奥氏体转变而来。

2.2 常化工艺中抑制剂的演变

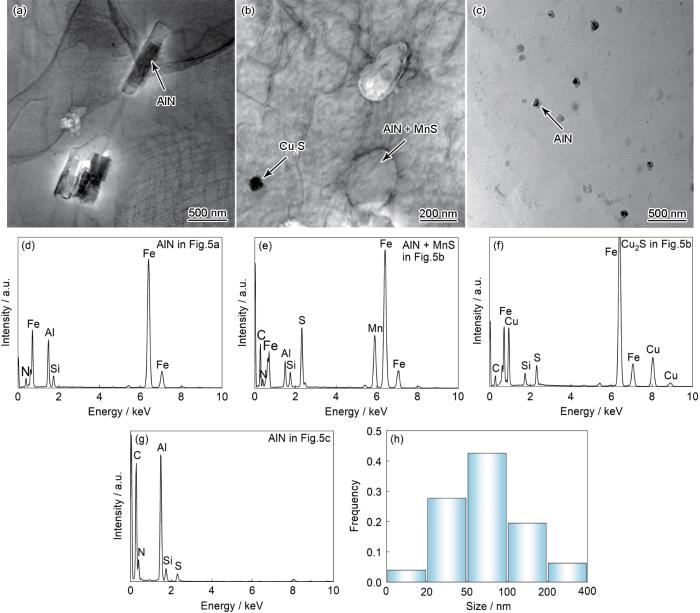

图5a~g给出了取向硅钢热轧板中典型抑制剂的形貌及对应的EDS。可见,在热轧板中抑制剂存在状态主要有3种:(1) 尺寸为400~500 nm的粗大方形AlN,见图5a,相应的EDS见图5d;(2) 圆形或椭圆形的AlN与MnS的复合析出相,尺寸在200 nm左右,见图5b,相应的EDS见图5e;(3) 尺寸为50~150 nm的方形或近似方形的AlN,见图5c,相应的EDS见图5g;除了上述析出相外,热轧板中还有极少量尺寸为50~80 nm的圆形Cu2S,见图5b,相应的EDS见图5f。根据统计结果,热轧板中抑制剂的平均尺寸为103.15 nm,数量密度为6.78 × 105 mm-2。图5h给出了取向硅钢热轧板中抑制剂的尺寸分布。可见,抑制剂尺寸多在20~100 nm区间,超过100 nm的粗大抑制剂为AlN和MnS的复合析出相,也有部分复合析出相含有Cu2S。由于本工作所研究材料为工业生产钢,在炼钢过程中通过废钢、铁合金等会不可避免地带入Cu、Ti等残余元素,由此形成了Cu2S析出物,下文中所观察到的TiN也来源于此。目前普遍认为在常化升温及保温过程中尺寸小于50 nm的细小抑制剂可溶解,而尺寸大于100 nm的粗大抑制剂则难以溶解[16,24]。

图5

图5

取向硅钢热轧板中抑制剂的形貌、成分及尺寸分布

Fig.5

TEM images (a-c), EDS (d-g), and size distributions (h) of inhibitors in hot-rolled grain-oriented silicon steel plate

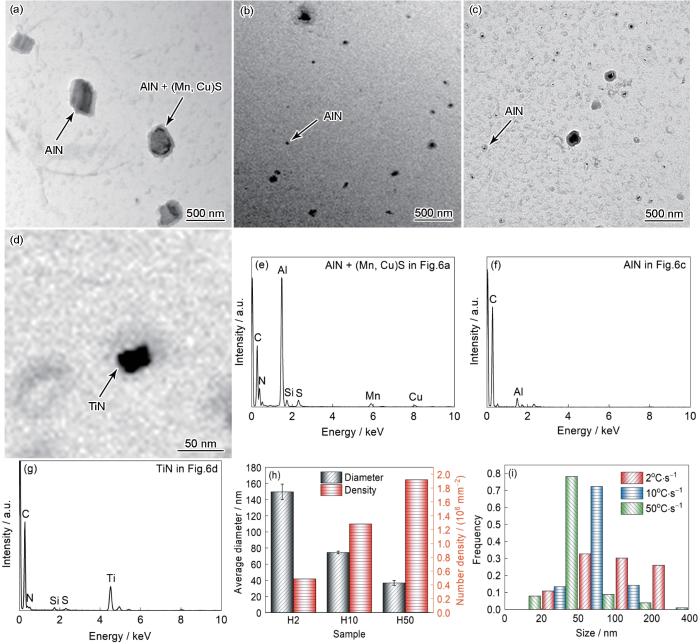

图6为不同升温速率下所得常化板的抑制剂分布与统计结果。可见,以2℃/s升温速率常化后抑制剂发生了明显的粗化(图6a),存在较多尺寸大于100 nm的方形AlN和圆形的AlN与MnS的复合析出相,有的复合析出相中还带有少量Cu2S,复合析出相的EDS见图6e。以10和50℃/s升温速率常化后析出了较多细小抑制剂,见图6b和c,H10样品中主要为50~100 nm的AlN,还存在部分未溶解而保留下来的尺寸为200 nm左右的AlN + MnS的复合析出,以及少量尺寸为20~50 nm的方形AlN和TiN;而H50样品则主要含有尺寸为20~50 nm的方形、细小的AlN与TiN (图6c与d),以及少量200 nm左右未溶解的析出相,图6f和g分别为H50样品中AlN和TiN的EDS分析结果。图6h为不同升温速率下常化板中心层抑制剂平均尺寸与数量密度变化。可见,随着加热速率的升高,抑制剂平均尺寸降低而数量密度增加。图6i为不同升温速率下常化板中抑制剂尺寸的统计分布。可见,H2、H10和H50样品中抑制剂尺寸主要在100~400、50~100和20~50 nm之间,即随加热速率升高,抑制剂粒子显著细化。

图6

图6

取向硅钢常化工艺中不同升温速率下抑制剂的形貌、成分、平均尺寸与数量密度,及尺寸分布

Fig.6

TEM images of inhibitors formed in H2 (a), H10 (b), and H50 (c, d) samples; corresponding EDS (e-g), average size and number density (h) and size distribution (i)

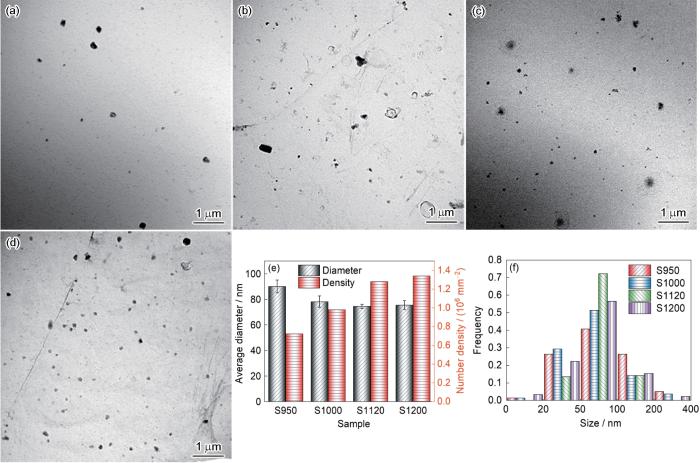

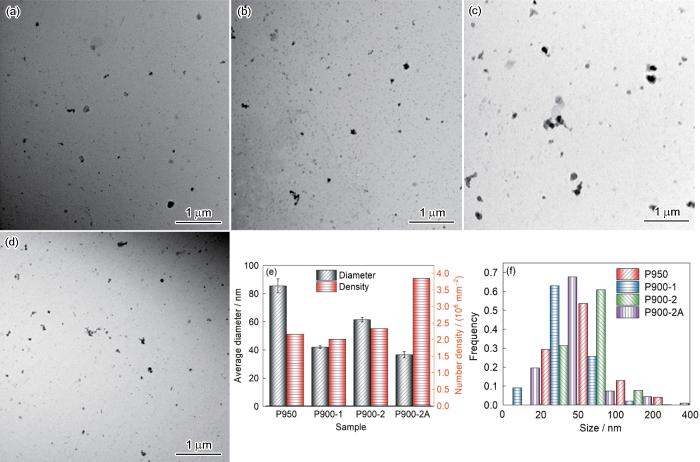

图7为不同固溶温度下所得常化板中抑制剂的分布及其统计结果。从图7a~d可见,当固溶温度从950℃升高至1200℃时,细小抑制剂数量逐渐增加。尺寸大于200 nm的方形或圆形的抑制剂为AlN + (Mn, Cu)S的复合析出物,尺寸为20~100 nm的细小方形抑制剂主要为AlN,也有部分为TiN,尺寸为20~80 nm的细小椭圆形抑制剂为AlN。从图7e可见,抑制剂的平均尺寸随固溶温度升高至1120℃时不断降低且数量密度不断增加,但固溶温度继续增加至1200℃时抑制剂的尺寸和数量均无明显变化。图7f为抑制剂尺寸分布的统计结果。可见,950℃固溶时,未固溶析出相的尺寸超过100 nm的约占1/3,且新析出的细小抑制剂数量较少;而1000℃固溶时,尺寸大于100 nm的析出相数量显著降低,同时细小抑制剂数量也增加。图8a~d为取向硅钢经图1c两阶段常化工艺后的抑制剂分布及统计结果,其形貌、成分特点与上述情形一致。图8e和f为抑制剂平均尺寸、数量密度和尺寸分布统计结果。可见,当相变温度相同时,抑制剂数量和平均尺寸随保温时间延长而增加;当相变保温时间相同时,相变温度越高使得抑制剂尺寸越大而数量密度越低;其后进行空冷的P900-2A样品中,细小抑制剂数量较水冷样品明显增多,说明空冷促进了细小抑制剂的析出。

图7

图7

取向硅钢常化工艺中不同固溶温度下抑制剂的形貌、平均尺寸与数量密度,及尺寸分布

Fig.7

TEM images of inhibitors formed in S950 (a), S1000 (b), S1120 (c), and S1200 (d) samples; corresponding average size and number density (e), and size distributions (f)

图8

图8

取向硅钢常化工艺中不同相变温度、时间和冷速下抑制剂形貌、平均尺寸与数量密度,及尺寸分布

Fig.8

TEM images of inhibitors formed in P900-1 (a), P900-2 (b), P950 (c), and P900-2A (d) samples; corresponding average size and number density (e) and size distributions (f)

3 分析讨论

3.1 常化过程中组织演变

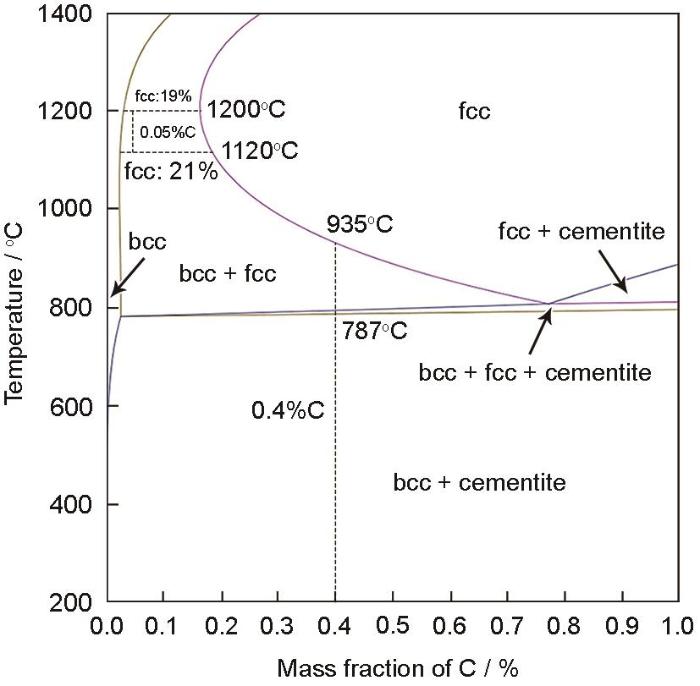

在图2a~c所示的取向硅钢热轧组织中,铁素体区域C含量很低,且基体中含有3.25%Si,因此该区域在常化过程中并不会发生相变,而只在C含量高的富C组织(珠光体、碳化物)片层区域内才会发生相变。在常化的升温及固溶阶段,富C组织向奥氏体转变,且随着固溶温度升高和固溶时间延长将会形成更多奥氏体(图4b)。计算了0.1%Mn-3.25%Si成分体系下工业取向硅钢的Fe-C相图,计算结果如图9所示。在0.05%C含量下,1120和1200℃时的平衡奥氏体体积分数分别为21%和19%,并且在1120℃平衡时能够形成的奥氏体最多。但实际上,在1120℃固溶180 s并不能将富C组织片层完全溶解和奥氏体化(图3c),这说明工业普遍采用的常化工艺的固溶段所能形成的奥氏体不能达到热力学平衡限定的最大值。而在二段式常化中冷却至900~950℃时膨胀量还在持续降低(图4c和d),说明此时继续发生奥氏体化,而不是普遍认为的γ→α相变[13,15,16],因为该相变的发生会使得膨胀量增加,而实验结果却是截然相反的。经统计,取向硅钢热轧板中碳化物片层区域的面积分数约为12.5%,假设碳化物固溶后立刻转变为奥氏体,根据富C片层区域面积分数和钢的C含量可计算出当富C片层全部溶解时所形成的奥氏体C含量约为0.4%,对应的完全奥氏体化温度为935℃,若该区域尚有未溶解的碳化物,则该区域的完全奥氏体化温度就更低。因此,当固溶后冷却至950℃时,富C片层区处于奥氏体单相区,不会发生所认为的γ→α相变;即使冷却至900℃,由于1120℃固溶后富C片层未完全固溶,常化时所形成奥氏体的C含量更低,此时实际上也难以发生铁素体相变,这与上述实验结果是吻合的。若在相变温度下保温后水冷,将得到马氏体和残余奥氏体;若空冷则更多奥氏体转变为珠光体。

图9

图9

Thermo-Calc计算得到的0.1%Mn-3.25%Si取向硅钢的Fe-C相图

Fig.9

Fe-C phase diagram for grain-oriented silicon steel with 0.1%Mn-3.25%Si, calculated by Thermo-Calc software and TCFE9 database

3.2 常化过程中细小抑制剂的来源

以往的研究[13,15,16]认为在常化冷却过程中发生γ→α相变促进了细小弥散抑制剂的析出,但在本工作中并未观察到γ→α相变。由图3b~d和g可见,在铁素体区域就有较多细小抑制剂析出。事实上,AlN在铁素体中的固溶度随温度升高而提高[20],冷却时由于溶解度降低可在铁素体中重新析出细小抑制剂[25],这部分抑制剂的析出量由抑制剂在高温下的溶解量和冷却速率所决定。李慧等[13]将Fe-3.15%Si取向硅钢在1120℃下常化3 min后在室温中水淬也有细小抑制剂析出,但析出量少于空冷或者在沸水中淬火。在本实验中采用的是喷水冷却方式,但观察的位置在2.4 mm厚常化板中心层,冷却速率较表面显著下降,这应是本研究中细小氮化物析出没有被充分抑制的原因。另外,当在900℃以下采用较缓慢的冷却速率如空冷时,由于发生了较多γ→P相变,因而可促进细小AlN在铁素体中析出,这部分抑制剂析出量由缓冷时发生珠光体相变的量所决定。

3.3 常化工艺参数对抑制剂析出的影响

根据Sakai等[24]的研究,常化过程中A类(尺寸10~20 nm)和B类(尺寸20~50 nm)抑制剂可以溶解,而C类(尺寸100~300 nm)抑制剂在常化过程中难以溶解,常化后被保留下来,并在常化冷却过程中析出大量B类抑制剂。蒙肇斌等[26]在Hi-B钢常化过程中的不同时期取样在冰盐水中淬火,采用TEM详细研究了不同常化时期氮化物的存在状态,指出常化升温至950~1000℃时细小氮化物有聚集长大趋势,继续升温至1120℃时各种氮化物开始溶解。在本研究中,由图6a可见,H2样品中抑制剂发生了明显的粗化,这是由于H2样品的升温经过950~1000℃高温区时间长,抑制剂粒子粗化严重,加热至固溶温度(1120℃)时抑制剂尺寸已经足够大而难以溶解。由上文分析可知,对于本工作的常化工艺而言,在冷却过程中并不能发生γ→α相变,所以新析出的抑制剂只能是由于AlN等抑制剂在铁素体中不同温度下的固溶度不同而析出的。抑制剂形成元素在高温下的固溶量决定了能够再析出的抑制剂的量,由于H2样品能够固溶的抑制剂很少,在冷却过程中也难以再有抑制剂析出,析出的尺寸为20~50 nm抑制剂较少,见图6a。而H50样品由于升温速率快,高温段经历时间短,粒子粗化作用较轻,所以在1120℃保温时能够固溶更多的抑制剂,在冷却过程中可以析出大量尺寸为20~50 nm的抑制剂,见图6c。而H10样品的升温速率介于H2和H50之间,析出的抑制剂含量介于2者之间。因此提高加热速率有利于获得细小弥散的抑制剂,并且提高升温速率可以缩短工序时间,提高生产效率。同理,提高常化工艺中的固溶温度可以溶解更多的热轧板中已有的抑制剂,因而在冷却过程中可以析出更多细小氮化物。

Liu等[14]指出,固溶后的第二段相变温度较高时,固溶温度与相变温度差异小,抑制剂析出的驱动力小。并且相变温度较高时,抑制剂形成元素扩散快,抑制剂易粗化。在本实验中,相变温度下无γ→α相变,抑制剂析出的驱动力来源于不同温度下抑制剂形成元素溶解度的差异,与相变温度为950℃时相比,相变温度为900℃时抑制剂析出驱动力更大,可析出更多抑制剂,同时由于950℃保温时元素扩散快,粗化更显著,也使得P950样品中的AlN尺寸较P900-2样品有所增加,见图8b和c。当相变温度为900℃时,延长相变时间可析出更多AlN,并且随着相变时间的延长新析出的AlN会发生长大,所以P900-2样品较P900-1样品所析出AlN数量更多、尺寸更大,见图8a与b。根据图8b与d,相变后空冷较相变后水冷析出了更多细小抑制剂。这是由于空冷时一方面可通过γ→P相变来析出细小抑制剂,另一方面由于冷速较低会使得细小氮化物在铁素体中的析出更充分。

4 结论

(1) 取向硅钢热轧板次表层至中心层区域富C片层与铁素体层交替分布,在常化过程中铁素体层不会发生奥氏体相变,而富C片层逐渐溶解转变为奥氏体。当固溶温度小于1200℃、固溶时间小于180 s时,增加固溶温度和延长固溶时间均可使所形成的奥氏体量增加,但达不到该温度下奥氏体的平衡分数。

(2) 取向硅钢常化过程中加热至1120℃等温3 min并不能将富C片层完全溶解,且此时不同区域内形成的奥氏体C浓度不均匀,此后冷却至900~950℃相变温度保温时将继续发生奥氏体化,即P→γ相变,而非普遍认为的γ→α相变;所形成的奥氏体在水冷后部分转变为马氏体,部分以残余奥氏体的形式保留下来,若在空气中缓冷,奥氏体则主要转变为珠光体。

(3) 提高常化的加热速率和固溶温度,均可以促进抑制剂的溶解,从而在冷却时能够析出细小弥散的抑制剂。固溶后冷却至900℃较950℃更有利于得到细小的氮化物,一方面900℃时抑制剂析出驱动力更大,另一方面温度低可减少新析出抑制剂的粗化。相变后若缓冷,不仅可通过发生γ→P相变促进析出抑制剂,还能促进细小氮化物在铁素体中的沉淀析出。

(4) 取向硅钢常化后细小抑制剂有2个来源:一是铁素体区由于降温导致固溶度下降而析出;二是由于900℃以下空冷时发生γ→P相变时析出。由于铁素体区体积分数大,因此在常化组织中前者的析出更为弥散,而且由于在900~950℃区间等温或快冷时并不能发生预期的γ→α相变,因此铁素体区域内由于不同温度下固溶度差异而析出抑制剂,这是抑制剂析出的主要机制。

参考文献

Recent technology developments in the production of grain-oriented electrical steel

[J].

Developments in the production of grain-oriented electrical steel

[J].

Effect of final annealing atmosphere on secondary recrystallization behavior in thin gauge medium temperature grain oriented silicon steel

[J].The development trend of grain oriented silicon steel is reducing the slab reheating temperature and the thickness of final product. Medium temperature slab reheating grain oriented silicon steel bearing copper was characterized by omitting hot band annealing and larger range of secondary cold rolling reduction which was suitable for the preparation of thin gauge product. But less research were reported about thin gauge grain oriented silicon steel produced by medium temperature reheat technique. It was well known that the sharpness of secondary recrystallization Goss texture is deteriorated by the preparation of 0.18 mm thin gauge grain oriented silicon steel, poor secondary recrystallization and deviated Goss grains occurs by the influence of Goss seeds decreasing and inhibitor decrease. So the key point of producing thin gauge grain oriented silicon steel was controlling the precipitations ageing behavior. In order to improve the sharpness of Goss texture and the magnetic flux density after secondary recrystallization, secondary recrystallization behavior was controlled by annealing atmosphere in this work. The microstructure and texture of interrupted annealing specimens were measured by EBSD system. The results show that the magnetic flux density of 0.18 mm gauge specimen was 1.95 T after final annealing in 90%N2 atmosphere. Due to the coarsening behavior of inhibitors was more strongly influenced by atmosphere in thin gauge silicon steel, the primary recrystallization grain size was smaller and secondary recrystallization duration was longer by improving volume fraction of N2 during final annealing. In this condition, deviated Goss grains were inhibited while Goss grains have enough time for abnormal growth. As a result, sharp Goss texture and stable secondary recrystallization were guaranteed and high magnetic flux density of thin gauge final product was obtained.

高温退火气氛对薄规格中温取向硅钢二次再结晶行为的影响

[J].通过调整最终退火保护气氛来控制0.18 mm厚含Cu中温取向硅钢二次再结晶时抑制剂的熟化和分解行为, 从而达到提高二次再结晶后Goss织构锋锐度和磁性能的目的. 运用EBSD系统观察和分析二次再结晶中断抽出试样的组织和取向. 结果表明: 提高高温退火气氛中的N<sub>2</sub>比例至90%, 最终0.18 mm规格成品磁感达1.95 T. 成品减薄后样品中抑制剂的粗化行为受气氛的影响更为强烈, 表现在提高N<sub>2</sub>比例后初次晶粒尺寸减小, 二次再结晶持续时间延长, 此时Goss取向晶粒拥有足够的时间发生异常长大以获得尺寸优势, 从而抑制偏转Goss取向晶粒的异常长大, 提高了Goss织构的锋锐度和薄规格成品的最终磁性能.

On the magnetic properties of single crystals of iron

[J].

Overview of microstructure and microtexture development in grain-oriented silicon steel

[J].

Recent progress and future trend on grain-oriented silicon steel

[J].

The effect of annealing atmosphere on the evolution behavior of inhibitors in thin-gauge grain-oriented silicon steel

[J].

Effect of decarburisation and nitriding on the carbon content, precipitates, microstructure and texture of Nb-bearing grain-oriented silicon steel

[J].

The role of grain colony on secondary recrystallization in grain-oriented electrical steel: New insights from an original tracking experiment

[J].

Effect of nitriding time on secondary recrystallization behaviors and magnetic properties of grain-oriented electrical steel

[J].

Defining the role of hot band annealing in high-permeability grain-oriented (GO) electrical steel

[J].

Texture change from primary to secondary recrystallization by hot-band normalizing in grain-oriented silicon steels

[J].

Study on microstructure and precipitates at different normalizing in Fe-3.15%Si low temperature oriented silicon steel

[J].<p>The decreasing of slab heating temperature for grain-oriented silicon steel will reduce the amount of precipitates in hot rolled plate, and be disadvantage to the formation of ultimate Goss texture. The aim of normalizing is to control and adjust the amount, size and distribution of precipitates. Microstructures, precipitates and magnetic characteristics of finished products with different normalizing technologies for Fe-3.15%Si low temperature hot rolled grain-oriented silicon steel are researched, and the textures of cold rolled plates which are original hot rolled plate and normalized plate are analyzed by means of OM, TEM, EDS and XRD, respectively. The results show that, normalizing technology with a temperature of 1120 ℃<span>, holding 3 min, and a two-stage cooling is a most advantaged to obtain oriented silicon steel with sharper Goss texture and higher magnetic, owing to the uniform surface microstructures and the obvious inhomogeneity of microstructures along the thickness; the normalizing technology with two-stage cooling is the optimum process, which due to more finer precipitates are dispersively distributed in the matrix, and it is beneficial for finished products to get a higher magnetic; in these two processes, they obtain the same textures which are mainly consist of {111}<110> and {111}<112>, however,comparing with the cold rolled textures without normalizing, the textures</span>density of <em>γ</em> orientation line on cold rolled plate which treated by normalizing are significantly increased.Therefore, it is confirmed that normalizing is helpful for grain--oriented silicon steel to get sharper Goss texture.</p>

Fe-3.15%Si低温取向硅钢不同常化工艺下的组织及析出相研究

[J].

Effect of normalizing annealing temperature on precipitates and texture of Nb-Cr-bearing decarburized grain-oriented silicon steels

[J].The evolution of precipitates and texture was investigated in Nb-Cr-bearing decarburized specimens after normalizing at different temperatures. Enough inhibitors, including Nb(C,N), were obtained, of 20~40 nm in size. Increasing normalizing annealing temperature leads to the number density of the precipitates decreasing and that of mean size increasing. The Goss texture content in the decarburized specimens decreases in different degrees compared with the normalized ones. The minimum Goss texture and maximum ∑9 grain boundaries were obtained in the decarburized specimen normalizing at 950 °C and in this specimen, enough fine dispersed inhibitors, weak but relative stable Goss texture and uniform grain size will be beneficial for Goss grains growth in secondary recrystallization, according to the coincidence site lattice theory.

Effects of normalizing annealing on grain-oriented silicon steel

[J].

Effect of normalization on the microstructure and texture evolution during primary and secondary recrystallization of Hi-B electrical steel

[J].

The quenching effects of hot band annealing on grain-oriented electrical steel

[J].

Effects of temperature and alloying elements on γ phase fraction of grain-oriented silicon steel

[J].

Solubility product of aluminum nitride in 3 percent silicon iron

[J].

Origin of fine equiaxed grains in industrial low-temperature grain-oriented silicon steel normalized sheet and their influence on magnetic properties

[J].

Microstructure and precipitate of low temperature hot rolled HGO silicon steel plate by normalizing

[J].

低温热轧高磁感取向硅钢板常化组织及析出相研究

[J].

High-temperature flow behaviour of grain-oriented and non-grain-oriented electrical steel

[J].Plane strain compression tests were performed on grain-oriented (GO) and non-grain-oriented steel specimens of identical silicon content. Though Arrhenius type constitutive equations showed excellent predictability of the experimental flow stresses, there were clear differences in the flow curves of the respective grades. More specifically, GO steel had higher flow stress and work hardening and showed clear presence of dynamically recrystallized grains. All these were attributed to the higher (0.06 versus 0.003 wt-%) carbon content and corresponding presence of austenite, at elevated temperatures, in the GO steel specimens.

A study on AlN in high permeability grain-oriented silicon steel

[J].We report the results of studies on AlN which precipitates during the γ-α phase transformation in high permeability grain-oriented silicon steel (HI-B). We examined the behavior of AlN in each stage of the process by means of chemical analysis, electron microscope observation and hydrogen hot extraction technique. The AlN observed by the electron microscope in each stage of the HI-B production process can be classified into three types: A type: fine needle-like precipitate; B type: fine plate-like precipitate of irregular shape; C type: larger agglomerate plate-like precipitate. The B type AlN, the most important nitride, precipitates during the γ-α phase transformation which occurs continuously on cooling after hot band annealing. This irregularly-distributed fine AlN is believed to play an important inhibiting role in the secondary recrystallization process.

Nucleation mechanism of precipitate of AlN in ferrite phase of Hi-B steel

[J].

AlN在Hi-B钢铁素体相中析出的形核机制

[J].