含Ag不锈钢最早由Yokota等[9]在不锈钢的基础上通过控制成分以及连铸工艺,研发出2种含Ag抗菌不锈钢。随着技术的发展,关于Ag含量对奥氏体不锈钢抗菌性能、力学性能和耐蚀性能影响的研究已有较系统的研究报道[10,11]。然而,对含Ag奥氏体不锈钢的微观组织,特别是富Ag相的存在形式和分布,尚缺乏深入的研究报道。Xuan等[12]在304不锈钢中添加0.27% (质量分数)的Ag,确定纳米尺度的富Ag相为从基体中析出的析出相,Ag析出相与奥氏体在相界处存在

本工作通过在奥氏体不锈钢中添加不同含量的Ag,利用光学显微镜(OM)、扫描电镜(SEM)、二次离子质谱仪(SIMS)及电子背散射衍射(EBSD)测试等手段,初步探索了Ag在奥氏体不锈钢中的存在形式以及Ag对奥氏体不锈钢组织、织构和力学性能的影响规律,旨在更多地了解含Ag奥氏体不锈钢的微观组织,揭示Ag对奥氏体不锈钢力学性能的影响机制。

1 实验方法

实验所用材料为不同Ag含量的304奥氏体不锈钢。采用中频感应炉熔炼,浇铸成235 mm × 235 mm的方锭,铸锭经1180℃保温8 h后锻造成80 mm × 260 mm × 3600 mm的板材;在1250℃保温1.5 h后进行热轧,开轧温度1240℃,终轧温度1150℃,终轧厚度为3.8 mm;最后冷轧成3 mm厚的奥氏体不锈钢板。冷轧钢板经1150℃固溶处理10 min,水冷,以保证完全奥氏体化。不锈钢具体化学成分见表1。

表1 不同Ag含量不锈钢的化学成分 (mass fraction / %)

Table 1

| Sample | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | Ag | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 304 | 0.056 | 0.404 | 1.14 | 0.0383 | 0.0094 | 17.47 | 8.09 | 0.0289 | 0.001 | Bal. | |

| 304Ag-1 | 0.039 | 0.179 | 1.23 | 0.0200 | 0.0100 | 18.26 | 9.37 | 0.0198 | 0.009 | 0.034 | Bal. |

| 304Ag-2 | 0.039 | 0.179 | 1.33 | 0.0198 | 0.0074 | 18.06 | 9.59 | 0.0199 | 0.004 | 0.062 | Bal. |

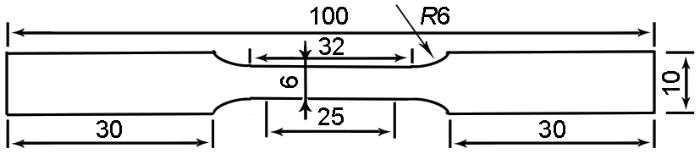

采用D8 Advance型X射线衍射仪(XRD)对不锈钢进行物相分析,测量角度2

图1

2 实验结果及讨论

2.1 Ag对304不锈钢微观组织的影响

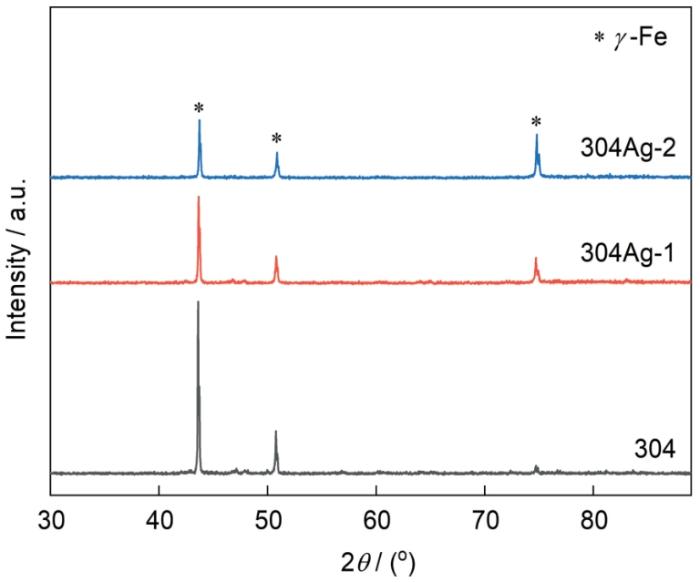

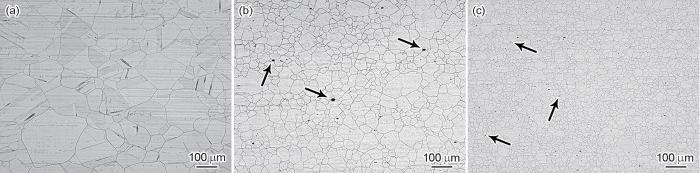

由图2可知,不同Ag含量不锈钢的XRD谱只呈现出奥氏体的衍射峰,说明合金经固溶处理后已完全奥氏体化。图3为不同Ag含量不锈钢的OM像。可见黑色小颗粒主要分布在奥氏体晶界(如图3箭头所示),少量分布于晶粒内部。随着Ag含量的增加,含Ag奥氏体不锈钢再结晶晶粒尺寸逐渐减小。经测量,未添加Ag的304不锈钢试样的平均晶粒尺寸为(126 ± 3) μm,显微晶粒度为3.0,304Ag-1和304Ag-2不锈钢试样的平均晶粒尺寸分别为(61 ± 3)和(47 ± 4) μm,显微晶粒度分别为5.0和6.0,结果表明含Ag奥氏体不锈钢的晶粒尺寸随着Ag含量的增加而减小,这与文献[15,17]研究结果一致。

图2

图2

不同Ag含量不锈钢的XRD谱

Fig.2

XRD spectra of stainless steels with different Ag contents

图3

图3

不同Ag含量不锈钢的OM像

Fig.3

OM images of 304 (a), 304Ag-1 (b), and 304Ag-2 (c) stainless steels (Arrows show spherical particles)

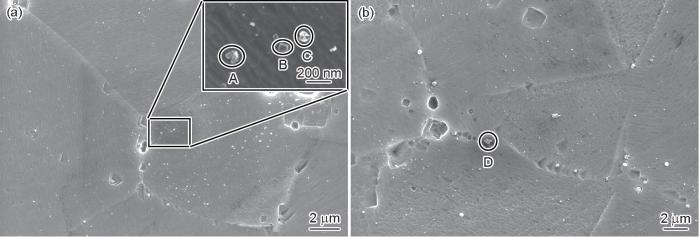

图4为304Ag-1和304Ag-2不锈钢试样的SEM像。可见304Ag-1和304Ag-2不锈钢试样的晶粒内部以及晶界上分布有亮色的颗粒。通过EDS分析(表2),颗粒A、C和D为含Ag的团簇状颗粒,颗粒B为不含Ag的方形颗粒。根据Ag-Fe二元合金相图[18,19],可知Ag的固溶度随温度的降低有所减小,故含Ag奥氏体不锈钢在固溶处理时会发生脱溶转变。Xuan等[12]确定了在含Ag的304不锈钢中Ag相与基体存在一定的取向关系,且Ag的点阵常数为0.40857 nm,奥氏体点阵常数为0.36468 nm[20],计算得出错配度为10.7%,所以含Ag相与基体两相之间是共格或半共格相界。因此,含Ag相趋于形成球形粒子,以取得最小界面面积,即其界面能最小。

图4

图4

304Ag-1和304Ag-2不锈钢的SEM像

Fig.4

SEM images of 304Ag-1 (a) and 304Ag-2 (b) stainless steels (Inset shows the high magnified image)

表2 图4中颗粒A~D的EDS结果 (mass fraction / %)

Table 2

| Point | C | Si | Ti | Cr | Mn | Fe | Ni | Ag |

|---|---|---|---|---|---|---|---|---|

| A | 7.59 | 0.30 | 0.19 | 17.57 | 1.37 | 57.36 | 10.08 | 5.54 |

| B | 5.56 | 0.30 | 1.77 | 18.59 | 1.46 | 61.35 | 10.97 | - |

| C | 7.61 | 0.32 | 0.30 | 17.60 | 1.27 | 56.24 | 10.04 | 6.62 |

| D | 7.59 | 0.17 | 0.52 | 16.22 | 1.11 | 54.72 | 7.97 | 11.70 |

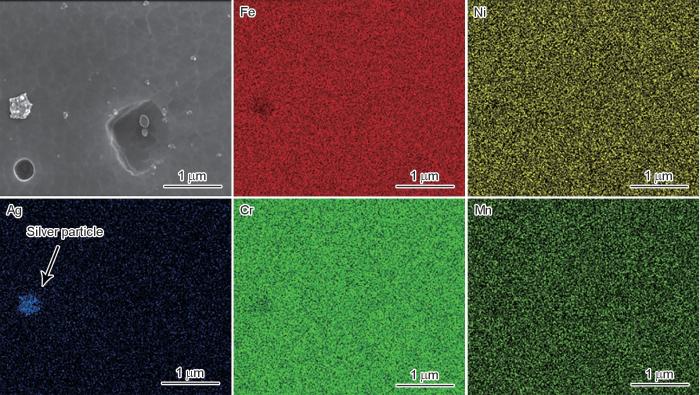

图5

图5

304Ag-2不锈钢的SEM像和EDS面扫描结果

Fig.5

SEM image and corresponding EDS mappings of 304Ag-2 stainless steel

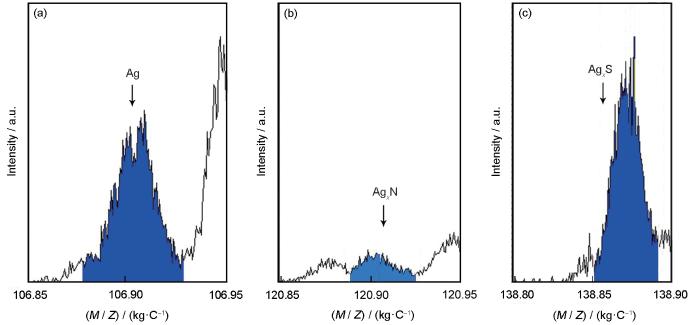

图6

图6

304Ag-2不锈钢含Ag颗粒成分二次离子质谱(SIMS)

Fig.6

Secondary ion mass spectrometry (SIMS) of Ag (a), Ag x N (b), and Ag x S (c) particles in 304Ag-2 stainless steel (M / Z—mass-to-charge ratio)

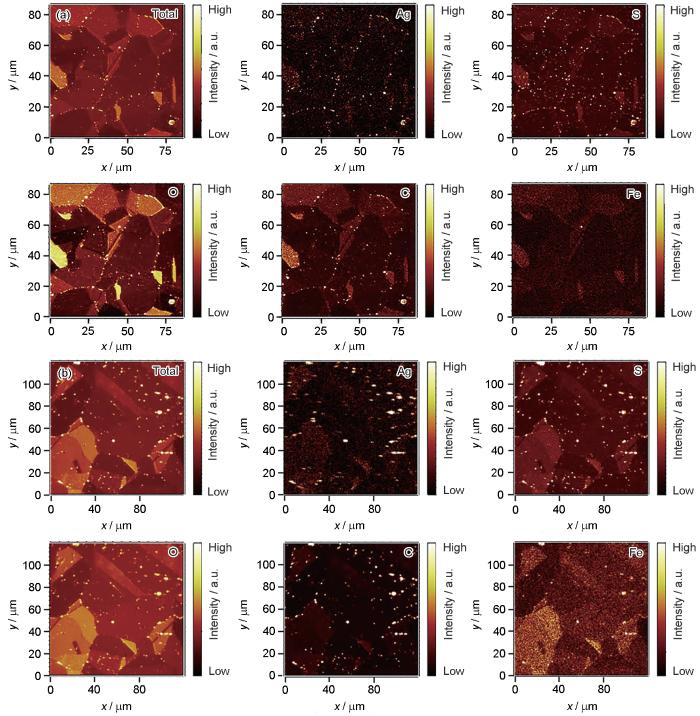

图7

图7

304Ag-1和304Ag-2不锈钢表面SIMS二维元素分布图

Fig.7

Two-dimensional element distributions in SIMS of 304Ag-1 (a) and 304Ag-2 (b) stainless steels

式中,N为单位体积内满足第二相粒子尺寸d ≥ λc的形核点数。随着Ag含量的增加,由于PSN效应形成的N增多,相应的Drec减小,所以奥氏体不锈钢晶粒尺寸明显减小(图3)。同时,d < λc的第二相粒子,对于再结晶晶粒长大具有一定的阻碍作用,最终使得合金再结晶晶粒细小均匀。

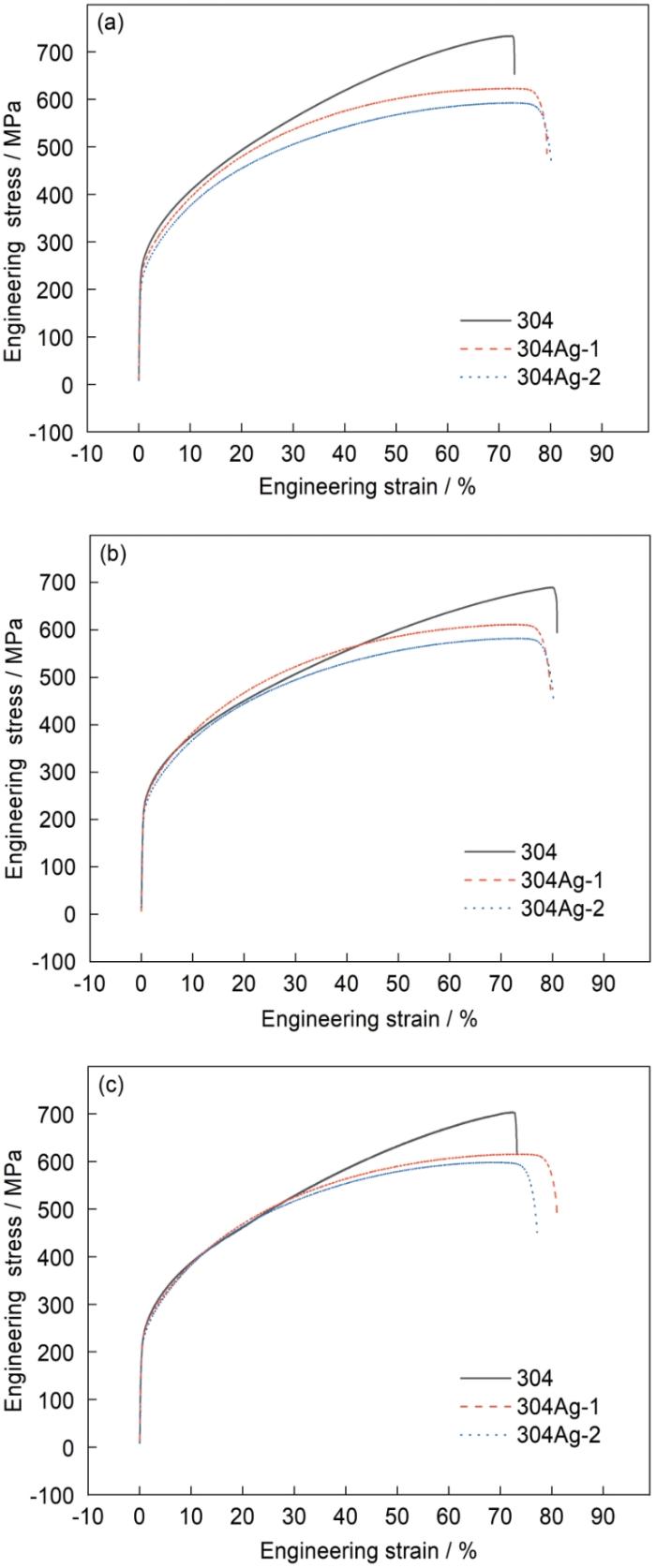

2.2 Ag对304不锈钢力学性能的影响

图8为不同Ag含量不锈钢沿3个方向拉伸的工程应力-应变曲线。表3为304、304Ag-1和304Ag-2不锈钢沿3个方向拉伸的力学性能。可以看出,随着Ag含量从0增加至0.062%,不锈钢沿3个方向的抗拉强度和屈服强度均不断降低。前述中Ag含量增加导致晶粒细化,根据Hall-Petch公式[26],晶粒尺寸的减小有助于强度的提高,但又有研究[16]表明,Ag的软化作用可以降低不锈钢的抗拉强度和屈服强度。说明含Ag不锈钢试样中细晶强化作用对强度的贡献小于Ag的软化作用,软化作用占主导地位,使含Ag不锈钢试样的强度随Ag含量的增加而下降。此外,随着Ag含量的增加,不锈钢的延伸率增大,这一结果与Morrison[15]和Gu等[27]的研究一致。这是由于Ag的添加可以通过晶粒细化来改善延伸性[28],且Ag单质和Ag x S及Ag x N等化合物颗粒相对于基体属于软韧相,材料受到一定的外力时,会与基体协同产生塑性变形,提高延伸率[20]。

图8

图8

不同Ag含量不锈钢沿不同方向的工程应力-应变曲线

Fig.8

Engineering stress-strain curves of stainless steels with different Ag contents in different directions

(a) 0°, rolling direction (RD)

(b) 45°

(c) 90°, transeverse direction (TD)

表3 不同Ag含量不锈钢在不同拉伸方向的力学性能

Table 3

| Direction | Material | Rm / MPa | Rp0.2 / MPa | A / % |

|---|---|---|---|---|

| 0° (RD) | 304 | 733 | 241 | 77 |

| 304Ag-1 | 623 | 233 | 80 | |

| 304Ag-2 | 592 | 221 | 81 | |

| 45° | 304 | 690 | 223 | 73 |

| 304Ag-1 | 611 | 223 | 80 | |

| 304Ag-2 | 585 | 219 | 81 | |

| 90° (TD) | 304 | 703 | 235 | 80 |

| 304Ag-1 | 615 | 230 | 81 | |

| 304Ag-2 | 598 | 223 | 81 |

2.3 Ag对304不锈钢织构的影响

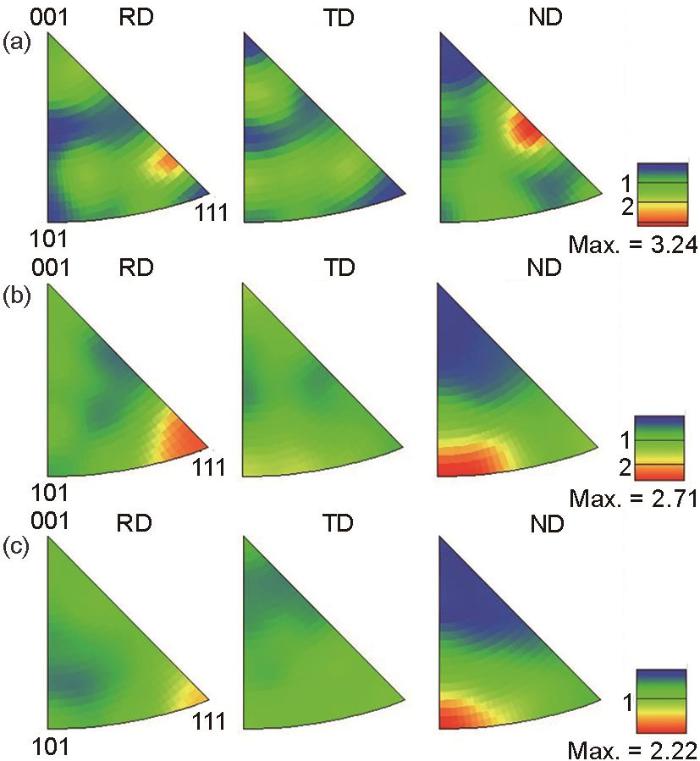

图9

图9

不同Ag含量不锈钢轧向(RD)、横向(TD)和法向(ND)的反极图

Fig.9

Inverse pole figures of RD, TD, and ND of 304 (a), 304Ag-1 (b), and 304Ag-2 (c) stainless steels (ND—normal direction)

此外,由于不同取向的晶粒滑移系开动的难易程度不同,织构较弱的试样有多种不同取向的晶粒,因此有多种位错滑移的可能。每种取向的晶粒协调变形的能力不同,在综合作用下表现为:织构较弱的试样协调变形的能力稍微增强,因此随着Ag含量的增加,织构减弱,不锈钢试样协调变形的能力增强,晶粒取向易发生变形,材料的强度逐渐降低。

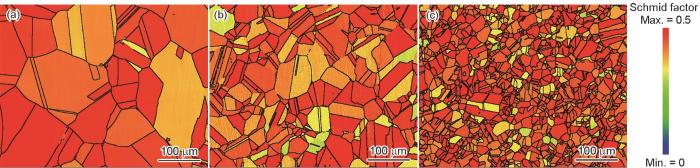

图10

图10

不同Ag含量不锈钢在{111}〈110〉滑移系下的晶粒Schmid因子分布

Fig.10

Schmid factor distributions of grains in 304 (a), 304Ag-1 (b), and 304Ag-2 (c) stainless steels with different Ag contents under {111}〈110〉 slip systems

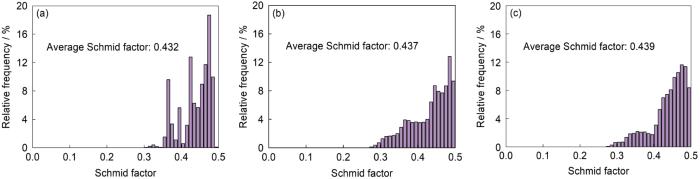

图11

图11

不同Ag含量不锈钢在{111}〈110〉滑移系下晶粒Schmid因子频率分布直方图

Fig.11

Frequency distribution histograms of Schmid factor of grains in 304 (a), 304Ag-1 (b), and 304Ag-2 (c) stainless steels with different Ag contents under {111}〈110〉slip systems

根据晶粒Schmid因子频率分布直方图统计出,304、304Ag-1和304Ag-2不锈钢试样在{111}〈110〉滑移系下晶粒Schmid因子平均值均不低于0.43 (图11),这表明3种奥氏体不锈钢试样均具有良好的变形能力,且随着Ag含量的增加,晶粒的平均Schmid因子也逐渐增大,说明304Ag-2不锈钢试样中处于“软取向”的晶粒占绝大多数。根据Schmid定律可知,当作用在晶粒滑移面上沿滑移方向的分切应力达到某一临界值时,晶粒便开始滑移,对多晶体而言即发生屈服现象。含Ag奥氏体不锈钢试样的平均Schmid因子越大,在{111}滑移面上分切应力越大,晶粒内部的滑移系开动所需的外加应力越小,不锈钢试样表现出来的宏观强度也就越小。这与之前从织构角度分析得到的结论以及宏观的应力-应变曲线吻合。

3 结论

(1) 随着Ag含量的增加,304奥氏体不锈钢的平均晶粒尺寸减小,304、304Ag-1和304Ag-2不锈钢试样的平均晶粒尺寸分别为(126 ± 3)、(61 ± 3)和(47 ± 4) μm。

(2) Ag在奥氏体不锈钢中主要以Ag单质、Ag x S和Ag x N等化合物的形式存在,主要分布于晶界处,少量分布于晶内;固溶处理后,未固溶的Ag单质和Ag x S及Ag x N等化合物粗大颗粒(d ≥ λc)会刺激再结晶形核(PSN效应),而细小的Ag单质和Ag x S及Ag x N等化合物颗粒(d < λc)则阻碍再结晶晶粒长大,进一步细化晶粒。

(3) 随着Ag含量的增加,含Ag 304不锈钢的强度降低,而延伸率则略微增加,且含Ag 304不锈钢与轧向呈0°、45°和90°方向的强度和延伸率一致性优于304不锈钢。

(4) 随着Ag含量的增加,“软取向”的晶粒占比增多,在给定加载应力下,含Ag奥氏体不锈钢更易发生形变。

参考文献

Recent developments in stainless steels

[J].

Current status of research on anti-bacterial stainless steels

[J].

抗菌不锈钢研究现状

[J].

Development situation and application prospect of antibacterial stainless steels

[J].

抗菌不锈钢的发展研究现状及展望

[J].

Copper precipitation behavior and mechanical properties of Cu-bearing 316L austenitic stainless steel: A comprehensive cross-correlation study

[J].

Study of the processing map and hot deformation behavior of a Cu-bearing 317LN austenitic stainless steel

[J].

Enhancement of strength and ductility by Cu-rich precipitation in Cu-bearing 304L austenitic stainless steel

[J].

Antibacterial ability of a novel Cu-bearing 2205 duplex stainless steel against Pseudomonas aeruginosa biofilm in artificial seawater

[J].

Antibacterial performance of a Cu-bearing stainless steel against microorganisms in tap water

[J].Tap water is one of the most commonly used water resources in our daily life. However, the increasing water contamination and the health risk caused by pathogenic bacteria, such as <em>Staphylococcus aureus</em> and <em>Escherichia coli</em> have attracted more attention. The mutualism of different pathogenic bacteria may diminish antibacterial effect of antibacterial agents. It was found that materials used for making pipe and tap played one of the most important roles in promoting bacterial growth. This paper is to report the performance of an innovative type 304 Cu-bearing stainless steel (304CuSS) against microbes in tap water. The investigation methodologies involved were means of heterotrophic plate count, contact angle measurements, scanning electron microscopy for observing the cell and subtract surface morphology, atomic absorption spectrometry for copper ions release study, and confocal laser scanning microscopy used for examining live/dead bacteria on normal 304 stainless steel and 304CuSS. It was found that the surface free energy varied after being immersed in tap water with polar component and Cu ions release. The results showed 304CuSS could effectively kill most of the planktonic bacteria (max 95.9% antibacterial rate), and consequently inhibit bacterial biofilms formation on the surface, contributing to the reduction of pathogenic risk to the surrounding environments.

Silver dispersed stainless steel with antibacterial property

[J].

Effect of silver on microstructure and antibacterial property of 2205 duplex stainless steel

[J].

Effect of silver on antibacterial properties of stainless steel

[J].

Antibacterial property and precipitation behavior of Ag-added 304 austenitic stainless steel

[J].

Effects of Ag on microstructure and properties and its precipitation behavior in antibacterial stainless steel

[J].

Ag对抗菌不锈钢组织性能的影响及其析出行为

[J].

Development of silver-containing austenite antibacterial stainless steels for biomedical applications Part I: Microstructure characteristics, mechanical properties and antibacterial mechanisms

[J].

Influence of silver on structure and properties of low-carbon steel

[J]

Influence of silver additions to type 316 stainless steels on bacterial inhibition, mechanical properties, and corrosion resistance

[J].

Selective laser melting of Zn-Ag alloys for bone repair: Microstructure, mechanical properties and degradation behaviour

[J].

The Ag-Fe (silver-iron) system

[J].

Effect of particles on texture banding in an aluminium alloy

[J].

Effect of precipitation on the evolution of cube recrystallisation texture

[J].

Influence of particles with different sizes on microstructure, texture and mechanical properties of Al-Mg-Si-Cu series alloys

[J].

不同尺寸粒子对Al-Mg-Si-Cu系合金组织、织构和力学性能的影响

[J].通过拉伸实验, OM, SEM, TEM观察以及EBSD测试等手段研究了不同尺寸粒子对Al-Mg-Si-Cu系合金板材力学性能、组织和织构的影响规律. 结果表明, 随着溶质元素浓度的增加, 合金屈服强度和抗拉强度均不断增加, 但是延伸率却略有降低, 且3个方向存在一定差异. 此外, 合金的平均塑性应变比 r - 也随溶质元素浓度增加而增加. 3种合金基体内的不同尺寸粒子主要为Mg2Si, Al15Mn3Si2和α-Al(Fe, Mn)Si富铁相, 这些粒子尺寸和浓度搭配合理不仅可以诱发粒子刺激形核效应(particle stimulated nucleation, 简称PSN), 而且可有效抑制晶粒长大, 最终使得合金固溶时形成大量细小再结晶晶粒, 而织构组分以旋转立方织构CubeND18, Goss织构{011}<100>, P{011}<122>和Cu{112}<111>为主. 此外, 根据合金成分、热加工工艺以及显微组织间的定量关系提出了不同尺寸粒子影响再结晶形核和长大过程的模型示意图。

The Hall-Petch relationship

[J].

晶粒度与合金强度关系

[J].

Tensile properties of chromium alloyed with silver

[J].

Effects of trace elements on properties and microstructure of electronic aluminum foil billet

[J].

微量合金元素对电子铝箔坯料组织与性能的影响

[J].

The room temperature creep behavior of Ti-6Al-4V alloy and its effect on subsequent mechanical properties were investigated. The results show that all these factors, such as macro-texture, creep stress level and pre-plastic-strain, have a significant impact on the room temperature creep behavior of Ti-6Al-4V. With the increase of the <0001> peak pole density along the loading direction, the work hardening exponent increases, and the creep exponent becomes smaller, resulting in the better room temperature creep property of Ti-6Al-4V. Enough high stress is the prerequisite for room temperature creep. The obvious room temperature creep behavior can be observed only when the creep stress is not lower than 0.85σy, and the room temperature strain increases with the creep stress level. Pre-plastic-strain can suppress the subsequent room temperature creep of Ti-6Al-4V, no matter the pre-plastic-strain comes from the monotonic loading or from the creep behavior. The pre-plastic-strain can deteriorate the fatigue property of the alloy, although it can reduce subsequent creep strain.

Texture and mechanical properties of API X100 steel manufactured under various thermomechanical cycles

[J].