金属增材制造(additive manufacturing,AM)技术近年来得到了迅速发展,其中选区激光熔化(selective laser melting,SLM)技术由于其具备低孔隙率和高精度制备的能力,被广泛用于航空航天、能源装备等复杂结构部件的制造[1,2]。然而,随着产品小型化的趋势以及对表面质量和几何精度要求的提高,SLM已不能满足成形精度要求。因此,微米级选区激光熔化(micro-selective laser melting,M-SLM)技术孕育而生。相比SLM的光斑尺寸(50~90 µm)[3]和成形精度(约200 μm)[4],M-SLM技术具有光斑直径小(< 20 µm)、成形精度高(20~50 µm),表面粗糙度(Ra)可达1 μm的部件制备优势,在通信电子、生物医疗等领域有巨大的推广应用潜力。

基于传统SLM制备的316L不锈钢已有广泛报道[5~12],如:Yang等[10]探讨了不同SLM工艺下316L不锈钢试样的凝固组织和气孔特征,指出在相同的激光能量密度下,协同改变激光功率和扫描速率可以得到不同的凝固熔池形貌。同时,孔隙的发展也取决于熔池的尺寸。随着孔隙率和孔隙尺寸的降低,强度变化不明显,但对延展性有显著影响。Yang等[11]对SLM制备316L不锈钢的成形过程进行了理论研究,认为激光熔池在表面张力作用下形成了具有不同对流模式的Marangoni对流,促进了条状、胞状等亚晶粒结构的形成。Shin等[12]进一步研究表明,热处理后的SLM试样孔隙率降低,胞状组织消失,晶粒尺寸略有增大。在力学性能方面,SLM制备316L不锈钢的抗拉强度和延伸率与常规316L相近,这得益于分层的激光增材微观结构,包括晶粒结构、凝固胞状结构和位错等[13~15]。目前,针对以上传统SLM制备316L不锈钢的工艺、组织、力学性能调控等方面研究已经较为系统和充分。而伴随着M-SLM技术的出现,粒径细小的316L粉末能在激光能量密度更集中、熔池尺寸更小(宽25~30 μm),冷却速率更高(107~108 K/s)的条件下成形特征尺寸小(极限可达50 μm)、精度高且结构复杂的部件,这些部件内部几何、微观结构和力学性能与传统SLM成形316L部件截然不同,典型的拉伸强化机制也尚不明晰。目前,M-SLM技术除相关综述文献[16]有所提及外,尚鲜有技术文献报道。为此,本工作采用M-SLM制备316L不锈钢,并研究其增材试样的拉伸力学性能和强化机制,这将有助于深入理解M-SLM成形机理,并对进一步调控增材制造316L不锈钢的微观组织和力学性能具有重要的研究意义。

1 实验方法

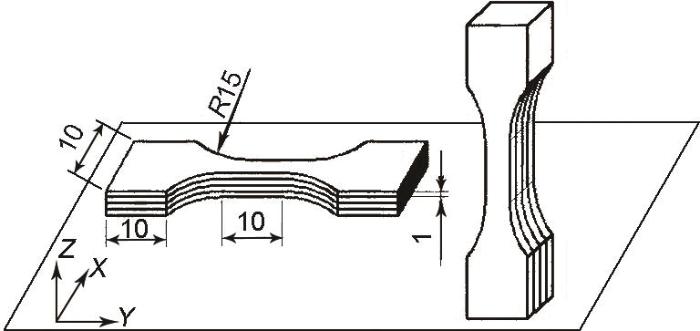

本实验选用的316L不锈钢粉末,球形度> 97%,其化学成分(质量分数,%)为:C 0.02,Si 0.22,Mn 1.58,S < 0.006,P < 0.008,Cr 18.02,Ni 13.82,N 0.078,O < 0.015,Fe余量。M-SLM设备是中国机械科学研究总院集团有限公司联合德国弗朗恩霍夫激光技术研究所(LIT)共同研发,型号为Aixway Precision 100,搭载额定功率100 W、波长980~1020 nm的单模光纤激光器,激光光斑直径15~20 μm,成型仓极限成形尺寸为直径100 mm、高100 mm。在成形前,通过对成型仓反复进行抽真空-充Ar气处理,至富氩仓室氧含量在(500~600) × 10-6之间。按照图1所示尺寸建模、文件切片并导入微机后,开始M-SLM制备横向拉伸试样(拉伸方向平行于Y轴)和纵向拉伸试样(拉伸方向平行于Z轴)。M-SLM成形过程如下:(1) 用2000号砂纸打磨去除成形基板表面污渍和氧化层;(2) 安装基板并调整与刮刀的间距约10 μm;(3) 刮刀利用谐振辅助铺粉专利技术在成形基板上预制首层316L不锈钢粉末薄层;(4) 激光束采用直线面扫描模式,依据切片后的指定路径选择性熔化该层316L不锈钢粉体;(5) 成形基板下降一个粉层厚度(约16 μm),在刮刀铺粉后,层间激光扫描相对变换角度113°后,再次进行选区激光熔化直至拉伸部件最终成形。M-SLM激光束的体能量密度(ρ)可由下式计算[17]:

图1

图1

微米级选区激光熔化(M-SLM)制备拉伸试样尺寸示意图

Fig.1

Schematic of tensile sample using micro-selective laser melting (M-SLM) (unit: mm)

式中,P为激光功率,hs为激光扫描间距,t为铺粉厚度,v为扫描速率。最终计算得到ρ = 87.5 J/mm3。

拉伸实验共开展6组(横向拉伸试样3组,纵向拉伸试样3组,结果分别取平均值),均采用Instron LDW-2型拉伸试验机,在室温下设置拉伸位移速率为0.01 mm/s,通过先期试样标定,并使用动态视频引伸计监控拉伸过程的应变直至试样断裂。使用GeminiSEM 500型扫描电子显微镜(SEM)对M-SLM成形试样未变形区进行微观组织形貌表征。利用D8型X射线衍射仪(XRD)分析未变形区的相组成。切取断口附近塑性变形区进行电化学抛光,在配有电子背散射衍射(EBSD)功能的S-3400N型SEM上完成Kikuchi花样的标定,扫描区域25 μm × 25 μm,扫描步长0.05 μm,并使用HKL Nordlys Channel 5软件对晶粒取向信息进行自动处理,进而得到晶粒取向信息,重构晶界特征分布形貌等;根据Brandon[18]提出的Δθ ≤ 15°Σ -1/2 (Δθ为重合位置点阵模型准则取向差θ的最大偏离量,Σ为重合位置密度)作为判据确定重位点阵晶界,其中Σ3特殊晶界分别按<111>/60°标定,标定率> 92%。

2 实验结果

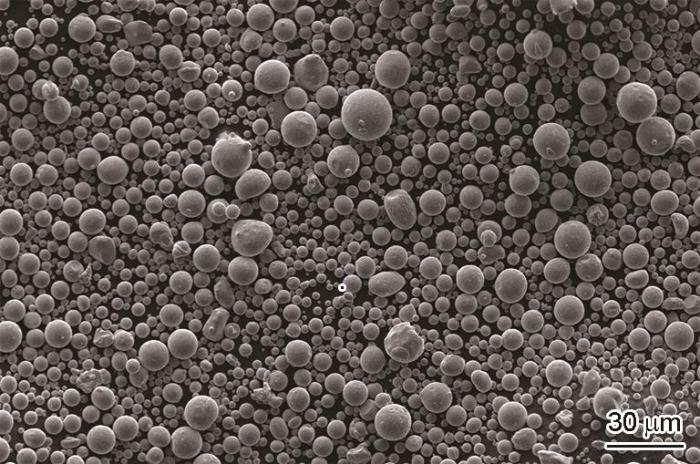

2.1 316L粉体形貌

用于M-SLM成形316L不锈钢粉体的SEM像如图2所示。可见,粉末颗粒球形度良好,异形粉末较少,粉末表面光滑致密,无孔洞缺陷,平均粒径约11 μm。

图2

2.2 M-SLM制备316L不锈钢的物相和微观组织

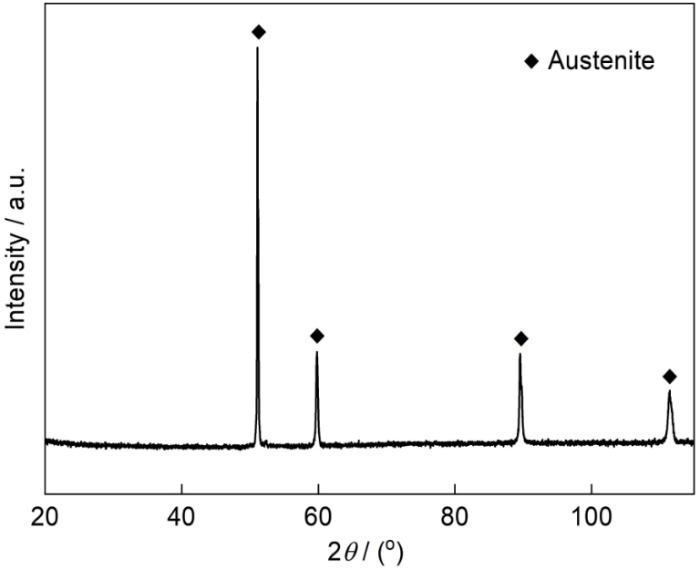

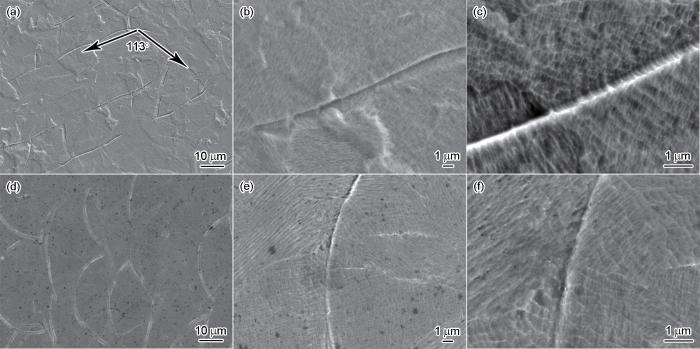

M-SLM制备316L不锈钢的XRD谱如图3所示。成形后的316L不锈钢中仅存在单一奥氏体相,致密度> 99.8%。低Cr/Ni比的不锈钢合金凝固时以奥氏体为初生相[19],同时M-SLM的凝固过程使316L不锈钢激光熔池具有超常凝固速率和极大的过冷度,使316L不锈钢形成了如图4所示的微纳米级胞状结构组织。图4a和d分别为M-SLM制备的316L不锈钢横向和纵向拉伸样品的SEM像。由于使用层间113°旋转扫描策略,在图4a中可以清晰观察到不同层间熔化道呈现113°夹角相互搭接。图4d~f所示纵向样品组织形貌整体呈现为典型增材制造鱼鳞状形貌。现有研究[20]表明,传统SLM成形过程中激光熔池的冷却速率高达约106℃/s,激光高速移动过程中,固/液界面前沿具有较大的过冷度。而M-SLM由于激光能量密度更高(约高出SLM能量密度1个量级),光斑尺寸更小,在这种极快的熔凝过程中,在理论上激光熔池的固/液界面实际相变温度将低于传统SLM制备过程的相变温度。这种凝固过程导致的极大的热过冷和成分过冷可进一步促进316L不锈钢胞状组织结构在M-SLM过程中的微纳米化。

图3

图4

图4

M-SLM成形316L不锈钢横向和纵向显微组织的SEM像

Fig.4

SEM images of M-SLMed transverse direction (a-c) and longitudinal direction (d-f) 316L stainless steel specimens with different magnifications

2.3 M-SLM制备316L不锈钢的拉伸性能

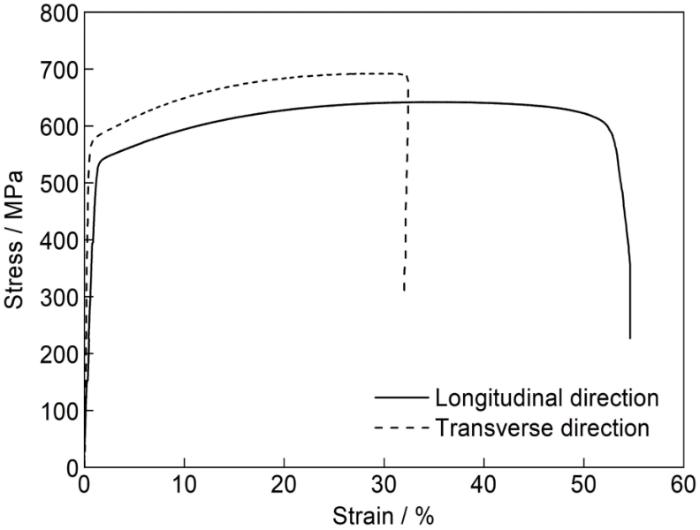

图5

图5

M-SLM成形316L不锈钢工程应力-应变曲线

Fig.5

Tensile engineering stress-strain curves of 316L stainless steel fabricated by M-SLM

表1 M-SLM成形316L不锈钢不同增材方向的拉伸性能

Table 1

| Direction | Rm / MPa | δ / % | UT / (J·cm-3) |

|---|---|---|---|

| Transverse | 692.1 | 32.0 | 210.6 |

| Longitudinal | 642.3 | 54.6 | 331.9 |

静力韧度(static toughness)[21]指在静拉伸实验时,单位体积材料从变形到断裂阶段所消耗的能量,可用于综合评价材料的强度和韧性,通常用静拉伸应力-应变曲线与横坐标轴包围的面积来计算[22]。纵向拉伸试样和横向拉伸试样静力韧度分别为331.9和210.6 J/cm3。显然,M-SLM制备316L不锈钢的拉伸力学性能呈现典型的各向异性。相比于传统铸锻手段成形的316L不锈钢,选区激光熔化316L不锈钢组织由凝固单元、低角度和高角度晶界、位错和氧化物夹杂等构成[23],这些不同层次的组织结构在长度尺度上涉及宏观-介观-微观上多达6个数量级的跨尺度效应,增材制造工艺所独有的特点导致了材料力学性能和塑性变形机制的不同。

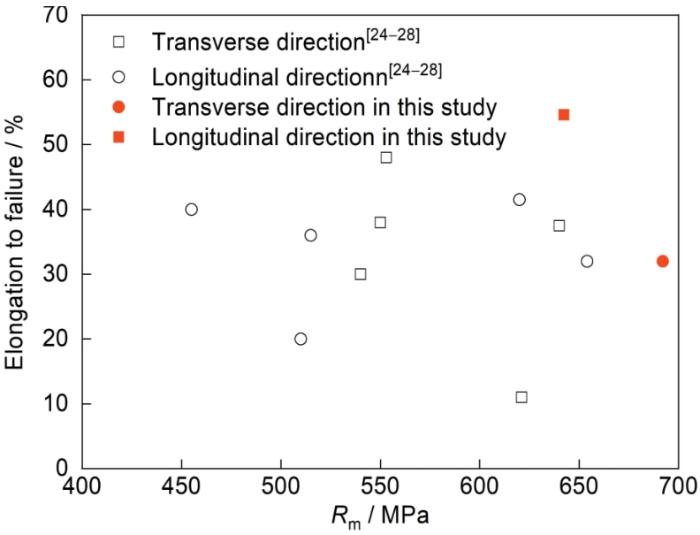

图6

图6

M-SLM和传统SLM成形316L不锈钢拉伸力学性能比较

Fig.6

Comparisons of tensile properties of M-SLMed 316L stainless steel and fabricated by traditional SLM

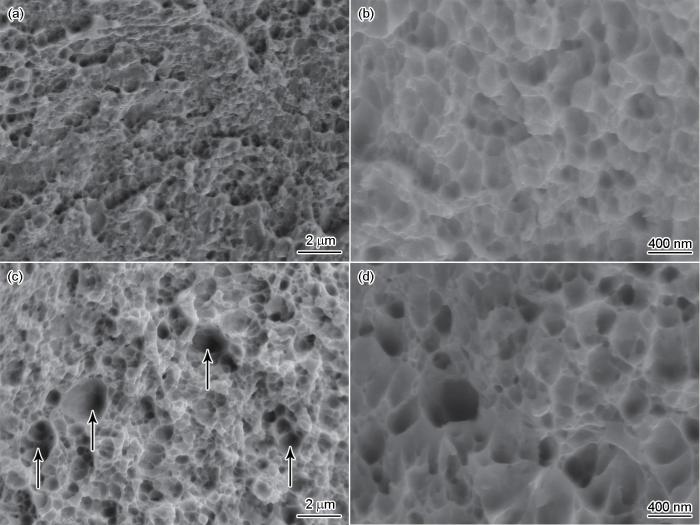

2.4 M-SLM制备316L不锈钢的断口形貌

M-SLM制备不同方向316L不锈钢拉伸断口形貌的SEM像见图7所示。从低倍断口形貌(图7a和c)可见横向和纵向断口均呈韧窝形貌,表现出优良的宏观塑性断裂行为。对比2者高倍断口形貌,图7d中可见大景深韧窝,说明M-SLM制备的316L不锈钢纵向样品比横向样品具有更优异的塑性变形能力,窝口直径在80~500 nm范围内大量分布。韧窝是典型的韧性断裂特征,随着材料拉伸变形的增大,内部的微孔开始在夹杂物、第二相粒子附近形核,伴随应变增加而长大、聚集,最终形成断裂后的蜂巢状窝口形貌,窝口的尺寸和深度在一定程度上反应了拉伸过程中窝口区应力集中而导致变形流变的剧烈程度。从图7c不难看出,断口表面呈现了一定量的大景深韧窝(图中箭头所示),分析认为:本工作所用M-SLM设备的微激光光斑直径15~20 μm,所形成的瞬态激光熔池宽度35~45 μm,在与直径5~20 μm尺度的316L粉体发生瞬态能量交互作用后,制备工艺不当可能导致多种熔凝缺陷的形成,主要体现为层间的未熔合缺陷和高速搅拌的熔池形成的冶金缺陷[30]。本工作采用的M-SLM工艺参数制备的316L不锈钢试样组织致密,在拉伸过程中表现了优异的延伸率,断口呈现的此类大景深韧窝形貌呈球形或椭球形,这可能是微熔池超常快速搅拌与凝固条件下形成的气孔或匙孔等微缺陷。虽然在超常熔凝过程中M-SLM制备的316L不锈钢可能出现微气孔和匙孔等缺陷的概率高于传统SLM,但由于超常冷却环境下气孔不易聚集长大,分散性强,对力学性能的影响比传统SLM更小。

图7

图7

M-SLM成形不同方向316L不锈钢拉伸断口形貌的SEM像

Fig.7

Low (a, c) and high (b, d) magnified SEM images showing the tensile fracture surfaces of transverse direction (a, b) and longitudinal direction (c, d) M-SLMed 316L stainless steel samples (Arrows in Fig.7c show the dimples formed by defects such as pores or keyholes)

3 分析讨论

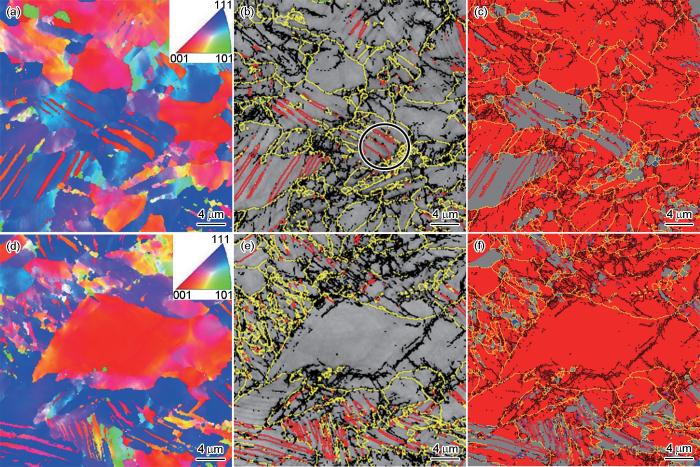

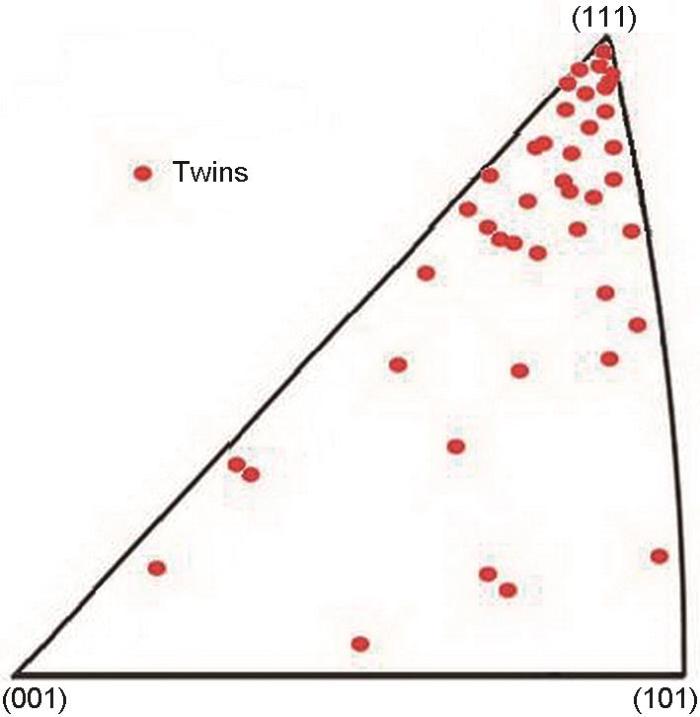

本工作采用87.5 J/mm3的激光能量密度,通过M-SLM制备的316L不锈钢拉伸断口韧窝尺寸多小于1 μm (图7),可见,晶粒尺寸显著细化对316L不锈钢的强度有显著贡献,其中微纳米化的胞状结构也促进了加工硬化过程中的材料均匀变形行为,使得最终的断后延伸率显著提升。图8给出了M-SLM制备316L不锈钢横向与纵向拉伸断裂后变形区微观组织的EBSD反极图、特殊晶界分布图和变形金属分布图。从图8b和e可见,横向和纵向试样在断裂口变形区均可见变形孪晶(红色迹线,按Σ3晶界的(60° ± 3°) <111>的转轴关系标记),且纵向拉伸试样内变形孪晶的密度更高,可以明显观察到变形孪晶对大角度晶界(≥ 15°,黄色迹线)的阻隔作用。316L不锈钢中的fcc结构孪晶界与基体间满足60°<111>转轴关系[31],其产生是由于316L不锈钢在拉伸过程中大角度晶界阻隔位错运动,致使晶界区域产生应力集中,促进了孪晶的优先形核并观察到向晶粒内部扩展,贯穿整个内部晶粒。通过图8a和d所示M-SLM制备的横向和纵向316L试样的取向分布可见,取向接近{001}方向的晶粒内部在图8b和e中并未标记出明显的Σ3孪晶界,说明晶粒取向对Σ3孪晶界有显著影响。通过图9建立的316L不锈钢纵向M-SLM增材拉伸试样变形区孪晶晶粒标准取向三角图可知,当晶粒的拉伸方向接近于<111>晶向时,晶粒内易产生孪晶。相关研究也通过对Schmid因子分析认为,当316L不锈钢中的fcc结构晶粒取向接近<110>-<111>时,晶粒优先通过孪生发生变形[32],而孪生应力(σT)与Schmid因子(m)、Burgers矢量模(b)、孪生Hall-Petch常数(kT)、晶粒尺寸(d)和层错能(γ)之间呈现如下关系[33]:

图8

图8

M-SLM成形316L不锈钢横向和纵向试样拉伸断裂区微观组织EBSD分析

(a, d) inverse pole figures (IPFs)

(b, e) special grain boundary distribution maps

(c, f) deformed metal distribution maps

Fig.8

EBSD analyses of microstructures in tensile fracture zone of 316L stainless steel transverse (a-c) and longitudinal (d-f) specimens prepared by M-SLM

图9

图9

M-SLM成形316L不锈钢纵向试样拉伸断裂区孪晶晶粒标准取向三角图

Fig.9

Twin grains standard orientation triangular map in tensile fracture zone of 316L stainless steel longitudinal specimen prepared by M-SLM

式中,316L不锈钢的γ较低,约14 mJ/m2 [34]。根据交滑移理论,层错能越低,位错的交滑移越困难,进而促进孪晶的产生。但σT还随晶粒尺寸的减小而增大,M-SLM可以获得比传统SLM制备方法更细小的316L不锈钢晶粒,这意味着促使孪生发生变形需要更大的驱动力。由于材料的变形均需要一定的临界分切应力才能发生,且材料滑移临界分切应力远低于孪生变形所需的临界应力,因此,M-SLM制备的超细晶316L不锈钢在拉伸过程中趋向于优先发生位错滑移,见图8c和f中红色所示金属变形区域,之后随应变的增大,开始伴生<111>晶向孪生变形为辅的联动模式,因此进一步提升了M-SLM制备316L不锈钢的拉伸力学性能,如图5所示。

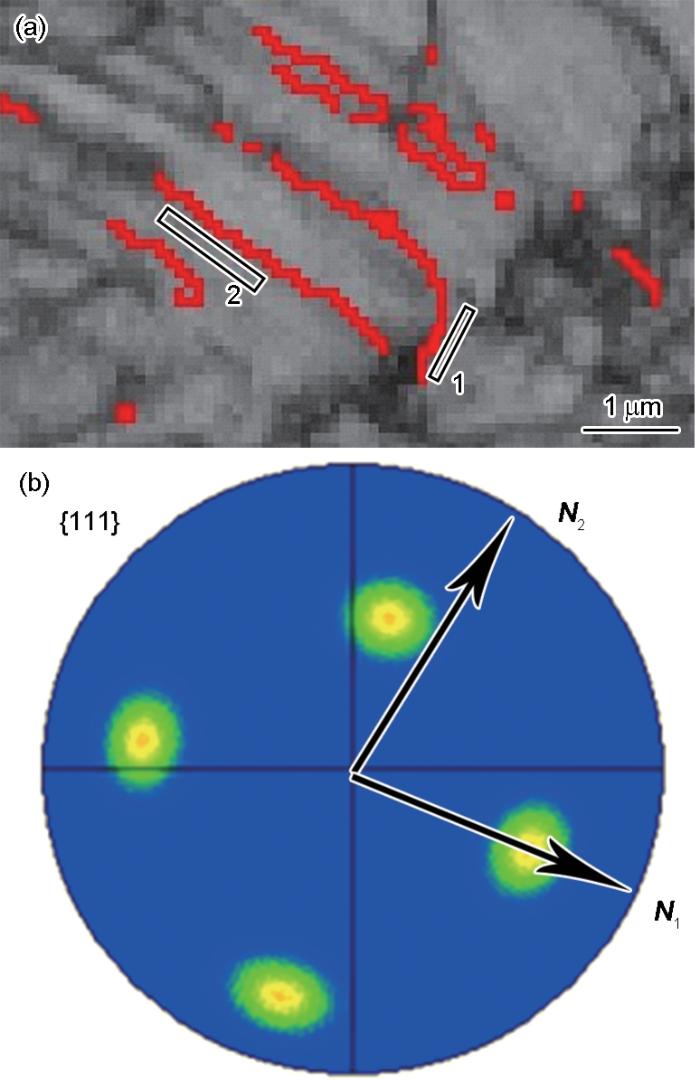

通过传统SLM制备316L不锈钢的组织原位观察[13]发现,当应变从3%增大至12%的过程中,变形机制从位错滑移为主逐渐演变到孪生变形占主导地位;当应变增至36%后,Σ3孪晶界的数量急剧增大。以图8b中圆圈区域为例,对Σ3晶界进行了共格/非共格的判定(图10),参照设置微矩形1和微矩形2分别靠近临近的Σ3晶界,故矩形的短边一定与Σ3晶界的法向方向平行。将短边指向方向复制在{111}极图中,记为法线 N1和 N2,可以看出 N1刚好通过{111}极图的重合点,故将矩形1邻近的晶界判定为共格Σ3 (Σ3c)晶界;而 N2在角度公差±3°范围内均未能与{111}极图点重合,故判定矩形2邻近晶界为非共格Σ3 (Σ3ic)晶界。按此方法,对图8b和e中各随机选取约30条Σ3晶界进行统计分析,分析结果如表2所示。从表中数据定性统计得出,横向试样近断口区的Σ3c和Σ3ic晶界数量百分比分别约为43%和57%,而纵向试样近断口区的Σ3c晶界数量百分比却提高至约70%。

图10

图10

微矩形截面法判定

(a) Σ3 grain boundary

(b) pole figure of {111} crystal form

Fig.10

Schematic of Σ3 grain boundary determination on the circle area in Fig.8b using micro rectangular section method ( N1 and N2 represent normal directions adjacent to grain boundaries of rectangle 1 and rectangle 2, respectively)

表2

Table 2

| No. | φ / (o) | Type | No. | φ / (o) | Type |

|---|---|---|---|---|---|

| 8b-1 | +4 | IC | 8e-1 | +8 | IC |

| 8b-2 | -2 | C | 8e-2 | -1 | C |

| 8b-3 | +6 | IC | 8e-3 | -2 | C |

| 8b-4 | +2 | C | 8e-4 | 0 | C |

| 8b-5 | 0 | C | 8e-5 | -2 | C |

| 8b-6 | -6 | IC | 8e-6 | +4 | IC |

| 8b-7 | +4 | IC | 8e-7 | -3 | C |

| 8b-8 | -1 | C | 8e-8 | +3 | C |

| 8b-9 | +7 | IC | 8e-9 | -9 | IC |

| 8b-10 | -3 | C | 8e-10 | -2 | C |

| 8b-11 | -5 | IC | 8e-11 | -7 | IC |

| 8b-12 | +3 | C | 8e-12 | -2 | C |

| 8b-13 | -7 | IC | 8e-13 | +1 | C |

| 8b-14 | +2 | C | 8e-14 | -4 | IC |

| 8b-15 | -6 | IC | 8e-15 | +7 | IC |

| 8b-16 | -3 | C | 8e-16 | +1 | C |

| 8b-17 | +9 | IC | 8e-17 | -2 | C |

| 8b-18 | -6 | IC | 8e-18 | +5 | IC |

| 8b-19 | +3 | C | 8e-19 | +1 | C |

| 8b-20 | +4 | IC | 8e-20 | -2 | C |

| 8b-21 | +1 | C | 8e-21 | -3 | C |

| 8b-22 | -5 | IC | 8e-22 | +5 | IC |

| 8b-23 | +6 | IC | 8e-23 | +1 | C |

| 8b-24 | -4 | IC | 8e-24 | 0 | C |

| 8b-25 | -1 | C | 8e-25 | -1 | C |

| 8b-26 | 0 | C | 8e-26 | +2 | C |

| 8b-27 | +7 | IC | 8e-27 | -2 | C |

| 8b-28 | -5 | IC | 8e-28 | +3 | C |

| 8b-29 | -6 | IC | 8e-29 | +1 | C |

| 8b-30 | -2 | C | 8e-30 | +4 | IC |

基于界面能理论,晶界处的能量主要包括2部分:弹性畸变能和化学交互能。其中,弹性畸变能的大小取决于失配度的大小。对于共格晶界来说,由于界面上原子保持着匹配关系,因此界面上原子结合键数目不变,此时应变能是主要的。而对于非共格晶界,由于界面上原子的化学键数目和强度与晶内相比发生了很大变化,故其界面能以化学能为主,而总界面能较高。M-SLM增材制备316L不锈钢纵向拉伸断口区亚结构中Σ3c孪晶界的比例显著提升,即在材料内部平衡状态下,Σ3c孪晶界的增加使得总晶界能同比减小,这就很好地解释了M-SLM增材制备316L不锈钢横向拉伸强度普遍高于纵向拉伸强度的原因。这与余晨帆等[31]通过传统SLM制备316L不锈钢得出的拉伸结果相吻合。此外,晶界能还取决于晶界的面积。M-SLM增材制造单相奥氏体316L不锈钢的晶粒细化程度会显著优于传统SLM,且绝大部分细小微纳级晶粒间均形成以大角度晶界为代表的特殊晶界,其总界面能将显著优于传统SLM制备的同种材料。

4 结论

(1) 微米级选区激光熔化成形316L不锈钢的晶粒内部存在尺寸为100~300 nm的胞状组织结构,拉伸断口呈韧窝状,窝口直径80~500 nm,这使得316L不锈钢的横向抗拉强度达692.1 MPa,纵向断后延伸率达54.6%,明显优于传统SLM技术制备的316L不锈钢。

(2) 微米级选区激光熔化成形316L不锈钢在拉伸过程中奥氏体Σ3孪晶界在取向接近<111>的晶粒中较易出现,并阻断了特殊晶界网络的连通性,其横向拉伸试样近断口区的Σ3c和Σ3ic晶界数量百分比分别约为43%和57%,而纵向拉伸试样近断口区的Σ3c晶界数量百分比提高至约70%。Σ3c孪晶界的增加使得总晶界能降低,是导致M-SLM制备316L不锈钢纵向拉伸强度普遍低于横向拉伸强度的原因。

参考文献

Micro- and nanoscale 3D printing

[J].

微纳尺度3D打印

[J].

Additive manufacturing of structural materials

[J].

Metallic materials fabrication by selective laser melting: A review

[J].

A review on surface roughness of metals parts fabricated by selective laser melting

[J].

选区激光熔化成形金属零件表面粗糙度研究进展

[J].

Simulation and experimental studies on process parameters, microstructure and mechanical properties of selective laser melting of stainless steel 316L

[J].

Selective laser melting (SLM) of AISI 316L——Impact of laser power, layer thickness, and hatch spacing on roughness, density, and microhardness at constant input energy density

[J].In selective laser melting (SLM) the variation of process parameters significantly impacts the resulting workpiece characteristics. In this study, AISI 316L was manufactured by SLM with varying laser power, layer thickness, and hatch spacing. Contrary to most studies, the input energy density was kept constant for all variations by adjusting the scanning speed. The varied parameters were evaluated at two different input energy densities. The investigations reveal that a constant energy density with varying laser parameters results into considerable differences of the workpieces’ roughness, density, and microhardness. The density and the microhardness of the manufactured components can be improved by selecting appropriate parameters of the laser power, the layer thickness, and the hatch spacing. For this reason, the input energy density alone is no indicator for the resulting workpiece characteristics, but rather the ratio of scanning speed, layer thickness, or hatch spacing to laser power. Furthermore, it was found that the microhardness of an additively manufactured material correlates with its relative density. In the parameter study presented in this paper, relative densities of the additively manufactured workpieces of up to 99.9% were achieved.

Impact of a process interruption on tensile properties of SS 316L parts and hybrid parts produced with selective laser melting

[J].

Influence of heat treatment temperature on the microstructural, mechanical, and wear behavior of 316L stainless steel fabricated by laser powder bed additive manufacturing

[J].

Enhanced mechanical properties and formability of 316L stainless steel materials 3D-printed using selective laser melting

[J].

Influence of porosity on mechanical and corrosion properties of SLM 316L stainless steel

[J].

Subgrain microstructures and tensile properties of 316L stainless steel manufactured by selective laser melting

[J].

Heat treatment effect on the microstructure, mechanical properties, and wear behaviors of stainless steel 316L prepared via selective laser melting

[J].

Additively manufactured hierarchical stainless steels with high strength and ductility

[J].Many traditional approaches for strengthening steels typically come at the expense of useful ductility, a dilemma known as strength-ductility trade-off. New metallurgical processing might offer the possibility of overcoming this. Here we report that austenitic 316L stainless steels additively manufactured via a laser powder-bed-fusion technique exhibit a combination of yield strength and tensile ductility that surpasses that of conventional 316L steels. High strength is attributed to solidification-enabled cellular structures, low-angle grain boundaries, and dislocations formed during manufacturing, while high uniform elongation correlates to a steady and progressive work-hardening mechanism regulated by a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude. In addition, solute segregation along cellular walls and low-angle grain boundaries can enhance dislocation pinning and promote twinning. This work demonstrates the potential of additive manufacturing to create alloys with unique microstructures and high performance for structural applications.

High strength and ductility of additively manufactured 316L stainless steel explained

[J].

About metastable cellular structure in additively manufactured austenitic stainless steels

[J].

Development of micro selective laser melting: The state of the art and future perspectives

[J].

On the limitations of volumetric energy density as a design parameter for selective laser melting

[J].

The structure of high-angle grain boundaries

[J].

Microstructural development during solidification of stainless steel alloys

[J].

Effects of bulk laser energy density on anisotropy of selective laser sintered 316L stainless steel

[J].

体激光能量密度对选区激光熔化316L不锈钢各向异性的影响

[J].

Relationship between tension toughness and fracture toughness of low carbon low alloy steel

[J].

低碳低合金钢的静力韧度与断裂韧度

[J].

Selective laser melting of high strength and toughness stainless steel parts: The roles of laser hatch style and part placement strategy

[J].

Material-structure-performance integrated laser-metal additive manufacturing

[J].\n Laser-based additive manufacturing has the potential to revolutionize how components are designed. Gu\n et al.\n suggest moving away from a strategy that designs and builds components in a serial manner for a more wholistic method of optimization for metal parts. The authors summarize several key developments in laser powder bed fusion and directed energy deposition and outline a number of issues that still need to be overcome. A more integrated approach will help to reduce the number of steps required for fabrication and expand the types of structures available for end-use components.\n

Study on overlap ratio of pulse laser selective melting forming

[J].

脉冲式激光选区熔化成形搭接率的研究

[J].

Effect of scanning speed on forming defects and properties of selective laser melted 316L stainless steel powder

[J].

扫描速度对选区激光熔化316L不锈钢粉末成形缺陷及性能的影响

[J].

Experimental study on surface quality and process of selective laser melting forming 316L

[J].

选区激光熔化成形316L表面质量及工艺试验研究

[J].

Effects of manufacturing parameters and mechanical post-processing on stainless steel 316L processed by laser powder bed fusion

[J].

Fatigue strength of additively manufactured 316L austenitic stainless steel

[J].

Synchronous-hammer-forging-assisted laser directed energy deposition additive manufacturing of high-performance 316L samples

[J].

Denudation of metal powder layers in laser powder bed fusion processes

[J].

Tensile properties of selective laser melted 316L stainless steel

[J].Selective laser melting (SLM), as the most common additive manufacturing (AM) method, is capable of manufacturing metallic components with complex shape layer by layer. Compared with conventional manufacturing technologies such as casting or forging, the SLM technology has the advantages of high degree accuracy, high material utilization rate and environmentally friendly, and has attracted great attention in the fields of aerospace, nuclear power and medicine. The 316L austenitic stainless steel is widely used in the industrial field because of the excellent corrosion resistance and plasticity. It is also one of the commonly used material systems for SLM. In this work, the tensile properties and fracture mechanism of 316L stainless steel fabricated via SLM technology were investigated. The microstructure of the SLMed 316L specimens after tensile fracture was characterized and analyzed. The results show that the SLMed 316L stainless steel has a relatively desirable combination of strength and ductility, and its tensile performance is obviously better than that of 316L stainless steel prepared by traditional methods. The nanometer-scale cell structure inside the grain contributes to the improvement of strength. Deformation twins were observed in the SLMed 316L stainless steel after tensile test. The appearance of twins is oriented-dependent, and it is easy to occur in the grain with the direction near <110>-<111>.

选区激光熔化316L不锈钢的拉伸性能

[J].对选区激光熔化(selective laser melting,SLM) 316L不锈钢的拉伸性能及断裂机制进行了研究,并对拉伸断裂后的试样进行显微组织表征与分析,探究了拉伸变形过程中微观组织的演化规律。结果表明:采用选区激光熔化技术制备的316L不锈钢具有较好的强塑性匹配,其中晶粒内部纳米尺度胞状结构有助于强度的提升;其拉伸性能明显优于传统手段制备的316L不锈钢。选区激光熔化316L不锈钢在拉伸过程中奥氏体晶粒内部产生形变孪晶,并且形变孪晶的出现存在取向相关,在取向接近<001>的晶粒中不易出现,而在取向接近<110>-<111>的晶粒中较易出现。

The effect of grain size and grain orientation on deformation twinning in a Fe-22wt.%Mn-0.6wt.%C TWIP steel

[J].

Transition of twinning behavior in CoCrFeMnNi high entropy alloy with grain refinement

[J].