根据凝固理论可知,温度梯度(G)和凝固速率(R)共同对金属凝固组织起调控作用,晶粒尺寸主要受控于G × R (冷却速率),而结晶形式和晶粒形貌(柱状树枝晶、平面晶、等轴晶及胞状晶)则主要受控于比值G / R。SLM具有冷却速率极快(高达105~107 K/s)、残余应力大以及温度梯度高等特殊的凝固条件,因此导致了特殊组织结构的产生。在金属3D打印研究领域,为了阐明打印过程中温度梯度与凝固速率对材料微观组织和性能的影响,往往通过改变打印设计获得不同凝固过程,改变打印工艺参数或调整样品几何尺寸是常用的研究手段。EI Cheikh等[14]对单道次不同层厚激光直接沉积316L不锈钢的研究表明,沿着打印构建方向G逐渐增大、R减小,G / R值增加,晶粒组织发生柱状晶向等轴晶的转变。Antonysamy等[15]通过改变钛合金薄壁样品的厚度获得具有不同形貌和晶粒尺寸的选区电子束熔化样品,并借助Rosenthal仿真模型进行了预测与实验验证,随着壁厚增加,熔池内部温度降低,导致G降低((3~5) × 103 K/cm)和R增加(范围为10~30 cm/s),进而发生晶粒长大和粗化。由此可以推测,在固定工艺参数条件下,通过改变几何形状和尺寸影响微观凝固过程,进而会对材料的组织结构和性能产生影响。然而,目前针对SLM成形过程中几何形状变化对凝固过程影响的研究还非常有限,已有研究[19~21]通常采用调整打印工艺参数或同时改变工艺参数和打印策略来获得不同凝固效果,而关于几何形状尺寸对微观组织和材料性能的影响还缺乏针对性的研究,尚未形成系统的理论认识。Wang等[16]虽然在SLM不锈钢研究中提出,随层厚增加,晶粒组织由柱状晶向等轴晶的转变主要是由于凝固速率降低导致的,但也缺乏专门设计不同尺寸效应样品来进行系统研究。

扫描道次和打印层数作为重要尺寸因素,不仅决定了3D打印的加工效率,还会因尺寸和几何形状的变化而对凝固行为产生影响。系统研究扫描道次和打印层数对SLM凝固行为的影响,澄清几何形状尺寸与微观组织和材料性能之间的影响规律及机理,对深入认识SLM技术具有重要意义。本工作通过对扫描道次和打印层数进行系统设计,采用优化后的固定工艺参数制备不同尺寸的SLM 304L不锈钢样品,建立尺寸效应与微观组织和材料性能之间的影响关系。并采用ANASYS ADDITIVE对SLM凝固过程进行仿真模拟分析,阐明尺寸效应通过影响微凝固过程进而影响材料组织和性能的机理。

1 实验方法

1.1 样品制备

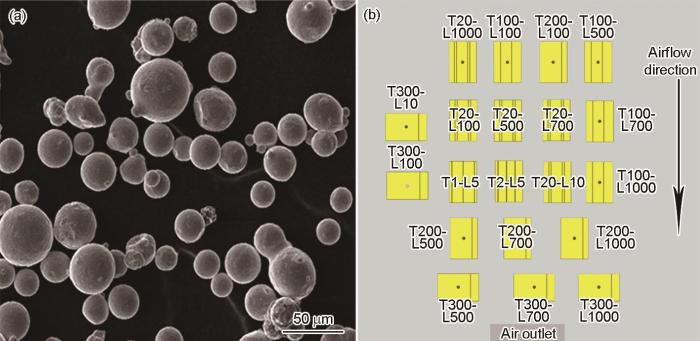

使用粒径分布为15~53 μm的气雾化商用304L不锈钢粉末为原材料,粉末形貌如图1a所示,化学成分如表1所示。样品制备在EOS M280金属3D打印设备上完成,打印过程使用Ar气保护。采用优化后的固化工艺参数进行样品制备(激光功率220 W,扫描速率1060 mm/s,扫描间距0.08 mm,扫描层厚40 μm)。金属基板成形尺寸为250 mm × 250 mm,样品在基板上的排布示意图如图1b所示。改变扫描道次(记为T)和打印层数(记为L)获得具有不同尺寸效应的样品:T设为1、2、10、100、200、300,L设为5、10、100、500、700、1000,试样编号及说明如表2所示。在打印设计时充分考虑样品排布位置,最大程度减少摆放位置或循环气流对样品微观组织可能产生的影响。样品排布尽量靠近基板中心位置,避开循环气流风场可能产生影响的区域。

图1

图1

选区激光熔化(SLM)用304L不锈钢粉末形貌及不同尺寸效应样品在成形基板的排布示意图

Fig.1

Morphology of the gas-atomized powders-304L for selective laser melting (SLM) (a) and schematic of printing composing (b) (T represents scanning track, L represents depositing layer)

表1 原始粉末及SLM 304L不锈钢化学成分 (mass fraction / %)

Table 1

| Sample | C | N | P | S | Cr | Cu | Mn | Ni | O | Si | Mo | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Powder | 0.006 | 0.013 | 0.027 | 0.001 | 18.95 | 0.033 | 0.016 | 9.48 | 0.029 | 0.056 | 0.87 | Bal. |

| SLMed | 0.015 | 0.013 | 0.027 | 0.003 | 19.70 | 0.032 | 0.054 | 9.62 | 0.031 | 0.065 | 0.83 | Bal. |

表2 不同扫描道次(T)与打印层数(L)组合的尺寸效应样品及编号方法

Table 2

| L | T | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 20 | 100 | 200 | 300 | |

| 5 | T1-L5 | T2-L5 | - | - | - | - |

| 10 | - | - | T20-L10 | - | - | T300-L10 |

| 100 | - | - | T20-L100 | T100-L100 | T200-L100 | T300-L100 |

| 500 | - | - | T20-L500 | T100-L500 | T200-L500 | T300-L500 |

| 700 | - | - | T20-L700 | T100-L700 | T200-L700 | T300-L700 |

| 1000 | - | - | T20-L1000 | T100-L1000 | T200-L1000 | T300-L1000 |

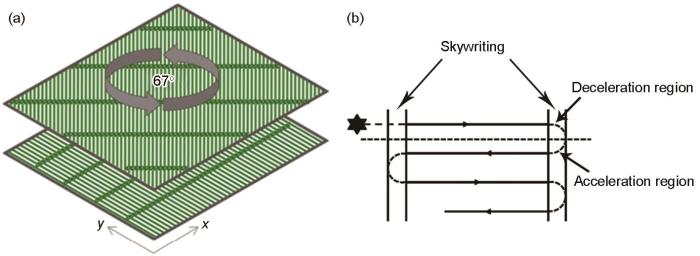

为了避免局部热输入过大导致的残余应力累积和打印变形,并且保证样品的均匀性和打印质量,成形过程中沉积层与层之间采用激光路径旋转67°的扫描方式,如图2a所示,获得致密度高达99.95%的优质样品。成形后块体的化学成分如表1所示。此外,为了排除激光扫描路径在长度方向的干扰,采用了如图2b所示skywriting的扫描方式,该方式在预定的扫描路线开始前和结束后预留了减速区域与加速区域,使激光器在设定的扫描路径上始终保持恒定的扫描速率以避免扫描速率不均匀(如激光弯折处)导致的不同区域热积累差异。为方便取样观察,首先在基板上打印方块样品作为底座,待方块样品完全冷却后再在其上进行打印扫描,获得不同尺寸效应的样品。随后将样品连同打印方块从基板上线切割分离,进行后续观察。

图2

图2

沉积层与层之间旋转67°成形及扫描路径采用“skywriting”扫描策略示意图

Fig.2

Scanning strategies of rotation angle of 67° between adjacent layers (a) and “skywriting” scan mode along the set scanning path (b)

1.2 微观组织表征

将SLM 304L不锈钢样品用SiC砂纸逐级湿磨至3000号,SiO2悬浮液抛光至镜面。选择30%NaOH溶液对样品表面进行电化学腐蚀,反复清洗吹干后,使用DM-i8倒置光学显微镜(OM)进行金相观察,使用Image-J软件统计晶粒尺寸。为了保证对比样品之间的一致性,在金相样品制备和观察过程中,尽可能保证相同的实验条件和处理时间。

选择T300-L100和T300-L1000 2个较大尺寸样品,使用SU7000扫描电镜(SEM)配备的EDAX高速电子背散射衍射(EBSD)系统对其进行相分析,对经SiC砂纸逐级打磨的样品进行电解抛光,采用体积分数4%HClO4 + 96%C2H5OH电解液,电压45 V,时间2 min。选取合适区域进行EBSD扫描,扫描步长为0.1 μm,扫描区域约为320 μm × 320 μm。使用Orientation Image Microscope (OIM) 8.1图像处理软件进行分析,得到晶粒取向和尺寸分布图。

利用D8 Advance X射线衍射仪(XRD)进行物相分析,扫描角度2θ = 20°~90°,扫描速率为0.6°/min。

1.3 力学性能测试

图3

图3

拉伸测试样品尺寸及SLM制备过程示意图

Fig.3

Tensile test specimen (unit: mm) (a) and schematic of SLM (b)

2 实验结果

2.1 显微组织

图4

图4

SLM 304L不锈钢沿打印构建方向显微组织的OM像

Fig.4

Low (a, c) and high (b, d) magnified OM images of SLM 304L ‘fish scale’ morphology (a) and columnar grains (b) with melt pool boundary on longitudinal plane, and laser exposure traces (c) and equiaxed grains (d) on horizontal plane

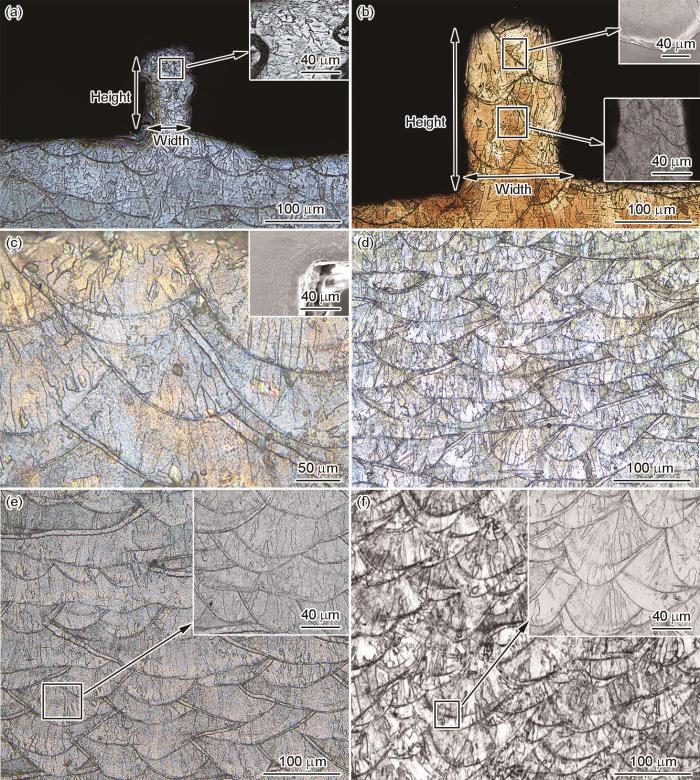

首先对不同T × L组合的样品进行金相观察,图5所示为最小尺寸样品到较大尺寸样品的显微组织形貌。图5a和b分别为单道次(T1-L5)和两道次(T2-L5)小尺寸样品的显微组织,从宏观整体形貌中扫描道次可分辨,T1-L5和T2-L5样品宽度分别为76.23与151.6 μm,与单道次80 μm和两道次160 μm的设计宽度保持较高一致性,证明了实验过程中SLM成形精度高、尺寸变形小。样品高度测量结果分别为167和198 μm,与设计高度200 μm (5层 × 40 μm)之间存在的偏差,主要是由于样品预磨过程中的磨损造成的。对局部区域进行高倍观察,如图5a和b中箭头所示区域,沿打印构建方向主要形成柱状晶组织,T1-L5内部晶粒组织以极细小“米粒形”柱状晶为主,用Image-J软件统计后,晶粒尺寸约为4 μm。T2-L5样品中,柱状晶晶粒尺寸有所长大,靠近基板的底部仍以“米粒形”柱状晶为主,随构建层厚增加,逐渐转变为“短窄形”柱状晶,平均晶粒尺寸约为9 μm。图5c~f分别为T20时,L10、L100、L700和L1000不同层厚样品的显微组织。可知,随打印层厚的增加,样品具有相似的熔池大小和形貌。局部放大形貌表明,随尺寸增大,晶粒内部柱状晶有长大趋势,主要以“长条形”柱状晶存在。通过对比可知,扫描道次相同时,随着L的增大,其内部柱状晶逐渐向更大长径比的“长条形”转变,少部分残留“米粒形”柱状晶主要分布在熔池线附近,如图5e和f的局部放大图所示。对柱状晶尺寸进行统计分析,结果表明,T1-L5和T2-L5样品晶粒尺寸为(4 ± 1)和(9 ± 2) μm,T20-L10、L100、L700和L1000样品内部晶粒尺寸依次为(9 ± 2)、(11 ± 3)、(15 ± 2)和(17 ± 1) μm。由此可见,随层厚增加,柱状晶尺寸呈略微长大趋势。

图5

图5

不同尺寸效应SLM 304L样品沿打印构建方向显微组织的OM像

Fig.5

OM images of SLM 304L stainless steel samples with different T × L sizes along the building direction

(a) T1-L5 (b) T2-L5 (c) T20-L10 (d) T20-L100 (e) T20-L700 (f) T20-L1000

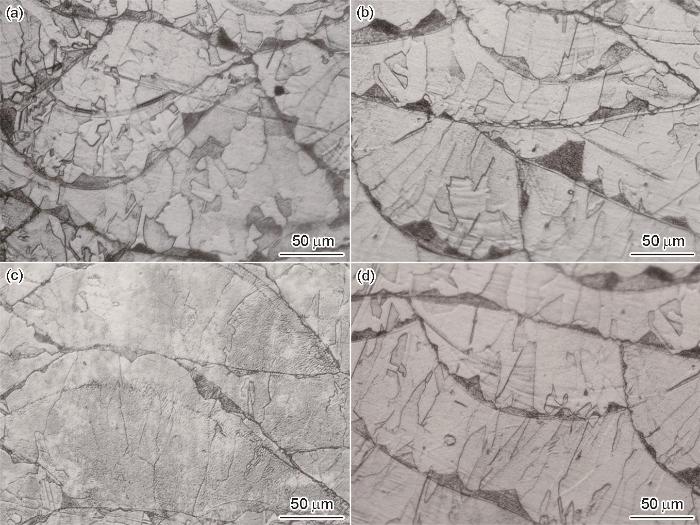

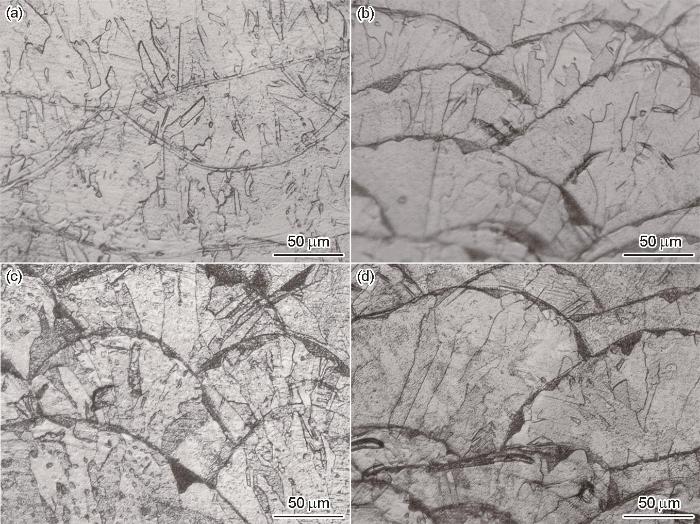

为进一步研究尺寸效应对微观组织的影响,对T100、T200和T300系列的大尺寸样品的柱状晶尺寸及分布进行了分析。图6为T100系列不同打印层数样品沿构建方向的显微组织形貌。图6a T100-L100样品中熔池内部沿打印构建方向生成小尺寸柱状晶,主要为短长径比的“米粒形”和近等轴的“短窄形”柱状晶。与T100-L100相比,T100-500、T100-L700和T100-L1000样品中,随着打印层数增加,熔池内部晶粒组织粗化明显,柱状晶长径比变大,逐渐以“长条形”柱状晶为主。在每个样品中选取3张金相照片,统计100~150个清晰可见的柱状晶组织,依据YB/T 5148—1993金相法统计晶粒尺寸的方法,将晶粒组织所占面积作为判断依据对柱状晶尺寸进行统计分析。根据统计分析,结合柱状晶长径比和面积的统计结果,分别以0~50 μm2、51~150 μm2和≥151 μm2作为门槛值,定义“米粒形”、“短窄形”和“长条形”柱状晶。分别统计“米粒形”、“短窄形”和“长条形”3种形貌柱状晶所占比例与平均晶粒尺寸,结果如表3所示。随着打印层数的增加,晶粒组织粗化明显,柱状晶平均晶粒尺寸由13 μm增加至20 μm;与T100-L100、T100-L500和T100-700相比,T100-L1000样品内部长径比较小的“米粒形”与“短窄形”柱状晶所占比例明显下降,长径比大的“长条形”柱状晶所占比例明显上升,由此可判断样品内部的晶粒尺寸增大的主要原因为“长条形”柱状晶所占的比例上升。

图6

图6

SLM 304L不锈钢T100系列样品显微组织的OM像

Fig.6

OM images of microstructures of T100 series samples in SLM 304L stainless steel

(a) T100-L100 (b) T100-L500 (c) T100-700 (d) T100-L1000

表3 T100系列样品内部晶粒尺寸与柱状晶分布统计结果

Table 3

| Sample | Grain size / μm | Rice-shaped columnar | Narrow-short columnar | Strip columnar |

|---|---|---|---|---|

| (0-50 μm2) / % | (51-150 μm2) / % | (≥ 151 μm2) / % | ||

| T100-L100 | 13 ± 2 | 25.2 | 50.7 | 24.1 |

| T100-L500 | 16 ± 2 | 21.3 | 45.6 | 33.1 |

| T100-L700 | 18 ± 1 | 18.7 | 42.3 | 38.0 |

| T100-L1000 | 20 ± 2 | 17.6 | 45.0 | 47.4 |

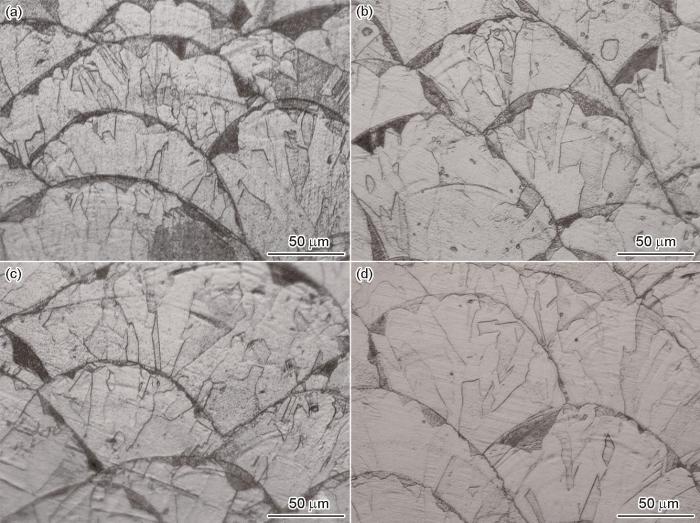

图7

图7

SLM 304L不锈钢T200系列样品显微组织的OM像

Fig.7

OM images of microstructures of T200 series samples in SLM 304L stainless steel

(a) T200-L100 (b) T200-L500 (c) T200-700 (d) T200-L1000

表4 T200样品晶粒尺寸与柱状晶分布统计结果

Table 4

| Sample | Grain size / μm | Rice-shaped columnar | Narrow-short columna | Strip columnar |

|---|---|---|---|---|

| (0-50 μm2) / % | (51-150 μm2) / % | (≥ 151 μm2) / % | ||

| T200-L100 | 15 ± 2 | 20.9 | 46.2 | 32.9 |

| T200-L500 | 19 ± 2 | 18.7 | 44.3 | 37.0 |

| T200-L700 | 20 ± 2 | 17.3 | 45.1 | 37.6 |

| T200-L1000 | 22 ± 1 | 16.1 | 42.4 | 41.5 |

图8

图8

SLM 304L不锈钢T300系列样品显微组织的OM像

Fig.8

OM images of microstructures of T300 series samples in SLM 304L stainless steel

(a) T300-L100 (b) T300-L500 (c) T300-700 (d) T300-L1000

表5 T300系列样品晶粒尺寸与柱状晶分布统计结果

Table 5

| Sample | Grain size / μm | Rice-shaped columnar | Narrow-short columnar | Strip columnar |

|---|---|---|---|---|

| (0-50 μm2) / % | (51-150 μm2) / % | (≥ 151 μm2) / % | ||

| T300-L100 | 18 ± 2 | 12.0 | 37.0 | 51.0 |

| T300-L500 | 20 ± 2 | 11.7 | 32.0 | 56.3 |

| T300-L700 | 23 ± 2 | 10.5 | 30.0 | 59.5 |

| T300-L1000 | 25 ± 1 | 9.7 | 23.1 | 67.2 |

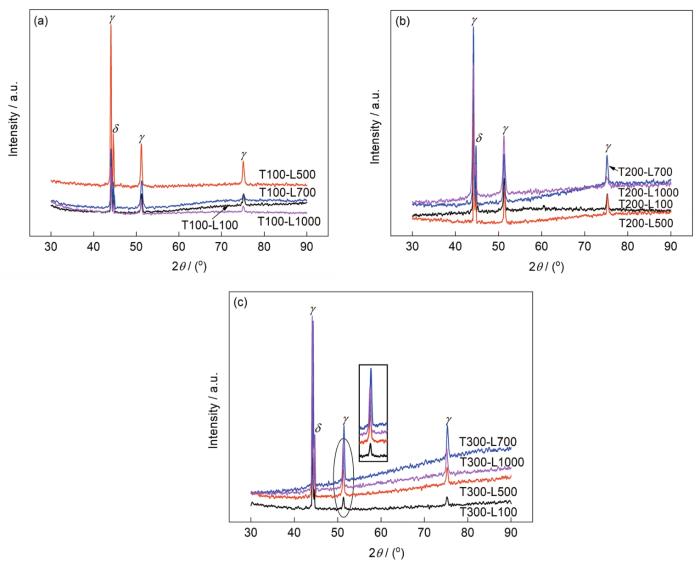

2.2 物相分析

图9为T100、T200和T300系列样品的XRD谱,不同尺寸样品的基体组织均为γ-奥氏体相,主衍射峰位置出现在44°、52°以及75°,在44°主峰附近存在弱峰,对应δ-铁素体的(110)衍射峰。不同尺寸样品的衍射峰位置相同,说明尺寸效应对物相组成的影响较小。此外,随样品尺寸增大,52°与75°附近的γ-奥氏体相衍射峰整体右移,结合显微组织分析结果,推测造成这种现象的原因是大尺寸样品中残余应力增大导致的晶格畸变,柱状晶尺寸变大也会导致残余应力的增加。

图9

图9

T100、T200和T300系列样品XRD谱

Fig.9

XRD spectra of T100 (a), T200 (b), and T300 (c) series samples with different sizes

为进一步研究SLM 304L不锈钢的物相结构和相含量及分布,选取T300-L100与T300-L1000 2个样品进行EBSD析出相面积比分析,如图10所示。在SLM 304L不锈钢中,除奥氏体基体外,还存在δ-铁素体和σ相(FeCrMo化合物)。在2种样品中,析出相的形貌和分布均相似。δ-铁素体面积占比约为1.2%,呈块状分布,与传统铸造/锻造成形所形成的针状δ-铁素体形貌不同,其主要原因是SLM成形过程的超快冷速造成奥氏体不锈钢凝固过程中生成的铁素体无法完全向奥氏体发生相变,最终形成奥氏体包围的残留块状铁素体组织,文献[24]中对此现象进行了详细阐述。σ相含量约为1.0%,沿晶界或熔池界线呈弥散分布,但由于σ相尺寸太小,标定误差较大,因此σ析出相的统计结果仅供参考。EBSD析出相分析进一步验证了XRD的相分析结果,并且在不同尺寸的样品中,析出相的形貌和含量未见明显差异。

图10

图10

T300-L100和T300-L1000样品析出相的EBSD分析

Fig.10

Phase distribution images by EBSD in SLM 304L stainless steel of T300-L100 (a) and T300-L1000 (b)

Color online

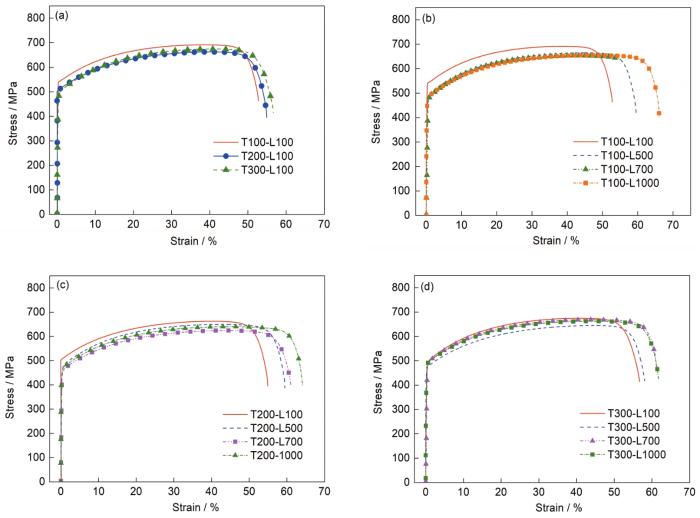

2.3 力学性能

对不同尺寸效应的样品进行室温拉伸力学性能测试,获得应力-应变曲线及拉伸力学性能测试结果,如图11和表6所示。SLM制备的304L不锈钢普遍表现出高强度高塑性的特性,不同尺寸效应的样品中,屈服强度分布范围为460~540 MPa,抗拉强度分布范围为650~690 MPa,塑性延伸率在52%~69%之间。在前期研究[15]中对SLM 304L不锈钢同时获得高强度和高塑性的机理进行了详细阐述,主要原因是SLM过程中极快的冷却速率和高的温度梯度产生了大量亚微米级胞状亚晶,平均胞晶尺寸0.5 μm,对材料起到了细晶强化和提高塑性的作用。图11a和b分别对比了相同层数(L = 100)条件下道次增加(T100、T200和T300),和相同道次(T = 100)条件下层数增加(L100、L500、L700和L1000)对力学性能的影响,随层数和道次单变量增加,均表现出材料强度下降而塑性增加的趋势。但当尺寸增大到一定程度时,力学性能变化趋于平缓。图11c和d为T200和T300 2种较大尺寸样品力学性能随打印层数增加的变化。样品表现出整体屈服强度和抗拉强度下降,塑性延伸率上升。表6综合对比了不同尺寸效应样品的拉伸力学性能测量结果,扫描道次和打印层数的增加都会导致强度下降和塑性延伸率提高,当尺寸增大到一定程度后,力学性能的变化趋势趋于平缓。力学性能测试结果验证了尺寸效应的影响作用,尤其在较小尺寸样品中,尺寸效应的影响作用更加明显。

图11

图11

不同尺寸效应样品的室温拉伸应力-应变曲线

Fig.11

Stress-strain curves of L100 (a), T100 (b), T200 (c), and T300 (d) series samples

表6 SLM 304L不锈钢不同尺寸效应样品室温拉伸强度与塑性

Table 6

| Sample | Yield strength | Ultimate tensile | Elongation |

|---|---|---|---|

| MPa | strength / MPa | % | |

| T100-L100 | 541.5 ± 17 | 691.6 ± 14 | 52.7 ± 0.6 |

| T100-L500 | 478.7 ± 13 | 667.0 ± 16 | 61.0 ± 0.2 |

| T100-L700 | 475.7 ± 15 | 654.7 ± 20 | 60.1 ± 0.9 |

| T100-L1000 | 477.8 ± 9 | 665.9 ± 23 | 66.6 ± 0.3 |

| T200-L100 | 504.6 ± 15 | 682.8 ± 17 | 54.9 ± 0.7 |

| T200-L500 | 476.6 ± 8 | 656.1 ± 19 | 59.9 ± 0.9 |

| T200-L700 | 470.2 ± 11 | 649.1 ± 22 | 63.3 ± 0.4 |

| T200-L1000 | 464.2 ± 15 | 646.3 ± 14 | 67.0 ± 0.5 |

| T300-L100 | 486.8 ± 13 | 674.6 ± 24 | 56.6 ± 0.8 |

| T300-L500 | 470.9 ± 18 | 669.2 ± 18 | 59.3 ± 0.9 |

| T300-L700 | 472.9 ± 8 | 667.8 ± 16 | 63.0 ± 1.0 |

| T300-L1000 | 459.8 ± 12 | 662.7 ± 16 | 63.1 ± 1.2 |

3 分析讨论

3.1 尺寸效应对凝固过程的影响

随着G / R值降低,材料倾向于形成连续性更好的柱状晶组织,而G × R的值越大表明晶粒细化程度越高[23~25]。Geng等[25]针对凝固过程中G和R对显微组织的影响作用和机理进行了系统研究,控制G和R可以控制凝固组织的尺寸和形貌,随着G / R值的增大,凝固组织由等轴晶向柱状晶转变,而随着G × R值的增大,晶粒尺寸呈现逐渐变小的趋势。为了澄清不同尺寸效应样品在SLM成形过程中的凝固行为,采用ANSYS ADDITIVE模块对SLM打印过程中的凝固特征进行仿真模拟,阐明尺寸效应对G和R的影响作用。设计3种尺寸效应的样品,通过仿真模拟获得凝固过程特征,结果如表7所示。随打印层数增加和样品尺寸增大,SLM过程中冷却速率G × R由1.57 × 106 K/s降低至1.47 × 106 K/s,温度梯度G由5.1 × 106 K/m下降至4.7 × 106 K/m,G / R值由1.66 × 107 K·s/m2下降至1.55 × 107 K·s/m2,即样品尺寸增加会导致G × R和G / R同时下降。根据形核理论与过冷度理论可知,尺寸增大会导致成形区过冷度下降,随着过冷度的下降,成核所需驱动力降低,形核生长时间增加,形核临界半径增加,晶粒粗化明显,因此打印尺寸越大,柱状晶的平均晶粒尺寸越大,柱状晶的生长连续性越好。此结论与上述凝固学原理一致,即G × R和G / R的下降会导致尺寸更大、连续性更好的柱状晶生成。

表7 SLM成形过程中凝固速率(R)和温度梯度(G)的模拟结果

Table 7

| X | Y | Z | G | R | G × R | G / R |

|---|---|---|---|---|---|---|

| mm | mm | mm | K·m-1 | m·s-1 | K·s-1 | K·s·m-2 |

| 5 | 1 | 1 | 5116897 | 0.3075 | 1573810 | 16640315 |

| 5 | 1 | 2 | 5143065 | 0.3010 | 1548151 | 17086594 |

| 5 | 1 | 5 | 4789272 | 0.3078 | 1474094 | 15559688 |

模拟仿真结果与实验结果也保持了较好的一致性,如图6~8和表3~5结果,随着打印尺寸增大,熔池内部柱状晶由“米粒形”向“短窄形”进而向“长条形”过渡,“米粒形”和“短窄形”柱状晶的比例分别由25.2%、50.7%下降至9.7%、23.1%,“长条形”柱状晶比例由24.1%上升至67.2%。平均晶粒尺寸由4 μm增加至25 μm。图12所示为根据金相显微照片绘制的T100-L100、T200-L100和T300-L1000 3种尺寸样品的柱状晶分布示意图。表明随着样品尺寸增大,SLM 304L不锈钢样品内部沿打印构建方向倾向于形成尺寸更大、连续性更好的柱状晶组织。在SLM工艺参数和能量输入确定的情况下,随着打印尺寸的增加,过冷度下降,导致沿最大温度梯度(散热方向)方向上的凝固速率下降,形核率下降,促进了晶粒沿散热方向的择优生长,晶粒形貌逐渐由低长径比的近等轴晶组织向高长径比的柱状晶组织发生转变,这与Leicht等[26]在打印尺寸对SLM 316L不锈钢组织演变影响的研究结果基本吻合。

图12

图12

SLM 304L不锈钢样品中沿打印构建方向柱状晶形貌及分布随尺寸效应演变示意图

Fig.12

Schematics showing the change of columnar crystal morphology and proportion with the different build geometries

(a) T100-L100

(b) T200-L100

(c) T300-L1000

3.2 尺寸效应对力学性能的影响作用

式中,

另一方面,随着打印尺寸的增加,打印过程中产生的残余应力不断累加,样品内部的残余应力增加,对材料起到应变硬化提高强度的作用。但同时大尺寸样品经历的循环受热在一定程度上起到对材料进行退火处理消除残余应力的作用,因此随样品尺寸增大,在残余应力累加和循环受热2种竞争影响机制下,残余应力并未表现出线性增加。

综上所述,晶粒尺寸和残余应力对力学性能起相反的影响作用,其中晶界强化作为主要影响机制,对拉伸强度和塑性延伸率产生正向影响,但当样品尺寸增大到某个临界值之后,晶粒度增长不明显、残余应力与循环受热的竞争机制达到平衡,残余应力达到较大值,屈服和抗拉强度将不再下降,反而表现出上升趋势。

4 结论

(1) 通过设计不同T × L尺寸效应的样品,可获得不同的凝固速率与温度梯度。随着样品尺寸的增加,SLM 304L不锈钢内部倾向于形成连续性更好、尺寸更大的柱状晶组织。

(2) 随着打印尺寸的增加,样品内部低长径比的近等轴晶组织所占比例下降,高长径比的柱状晶组织所占比例增加。尺寸效应对SLM 304L不锈钢物相组成无明显影响。

(3) 随着样品尺寸的增加,SLM 304L不锈钢室温拉伸强度下降,塑性增加。尺寸效应影响力学性能的主要机制是晶粒尺寸的变化,晶界强化起主导作用。

参考文献

Processing of titanium net shapes by SLS/HIP

[J].

On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance

[J].

Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing

[J].

Magnesium: Properties-applications-potential

[J].

The history of biodegradable magnesium implants: A review

[J].Today, more than 200years after the first production of metallic magnesium by Sir Humphry Davy in 1808, biodegradable magnesium-based metal implants are currently breaking the paradigm in biomaterial science to develop only highly corrosion resistant metals. This groundbreaking approach to temporary metallic implants is one of the latest developments in biomaterials science that is being rediscovered. It is a challenging topic, and several secrets still remain that might revolutionize various biomedical implants currently in clinical use. Magnesium alloys were investigated as implant materials long ago. A very early clinical report was given in 1878 by the physician Edward C. Huse. He used magnesium wires as ligature for bleeding vessels. Magnesium alloys for clinical use were explored during the last two centuries mainly by surgeons with various clinical backgrounds, such as cardiovascular, musculoskeletal and general surgery. Nearly all patients benefited from the treatment with magnesium implants. Although most patients experienced subcutaneous gas cavities caused by rapid implant corrosion, most patients had no pain and almost no infections were observed during the postoperative follow-up. This review critically summarizes the in vitro and in vivo knowledge and experience that has been reported on the use of magnesium and its alloys to advance the field of biodegradable metals.Copyright (c) 2010 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Laser rapid solidification improves corrosion behavior of Mg-Zn-Zr alloy

[J].

NEET-AMM final technical report on laser direct manufacturing (LDM) for nuclear power components

[R].

Inconel-steel functionally bimetal materials by hybrid directed energy deposition and thermal milling: Microstructure and mechanical properties

[J].

Additively manufactured hierarchical stainless steels with high strength and ductility

[J].Many traditional approaches for strengthening steels typically come at the expense of useful ductility, a dilemma known as strength-ductility trade-off. New metallurgical processing might offer the possibility of overcoming this. Here we report that austenitic 316L stainless steels additively manufactured via a laser powder-bed-fusion technique exhibit a combination of yield strength and tensile ductility that surpasses that of conventional 316L steels. High strength is attributed to solidification-enabled cellular structures, low-angle grain boundaries, and dislocations formed during manufacturing, while high uniform elongation correlates to a steady and progressive work-hardening mechanism regulated by a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude. In addition, solute segregation along cellular walls and low-angle grain boundaries can enhance dislocation pinning and promote twinning. This work demonstrates the potential of additive manufacturing to create alloys with unique microstructures and high performance for structural applications.

Additive manufacturing of titanium alloys in the biomedical field: Processes, properties and applications

[J].

Microstructure, tensile properties and mechanical anisotropy of selective laser melted 304L stainless steel

[J].The microstructure and mechanical properties of 304 L stainless steel fabricated by selective laser melting are investigated in this study. With the optimized laser processing parameters, a relative density of 99.9% is achieved with fine austenite grains and nanoscale cellular subgrains in size of approximately 0.5 μm. The presence of δ-ferrite and σ phase precipitates is identified by the x-ray diffraction and transmission electron microscopy. Moreover, the microstructure is identified as an austenite matrix with about 4% δ ferrite and a trace amount of σ phase by using electron backscattered diffraction analysis. These small σ phase particles are mainly distributed along austenite grain boundaries. Furthermore, the presence of nanoscale cellular subgrains contributes to the good tensile strength and ductility of the selective laser melted 304 L, along with precipitate strengthening and strain hardening. Tensile property anisotropy is also identified in this 304 L, which is attributed to the microstructure difference on vertical and horizontal planes.

Powder bed charging during electron-beam additive manufacturing

[J].

Surface microstructure and properties of 3Cr13 martensitic stainless steel after high current pulsed electron beam bombardment

[J].

强流脉冲电子束轰击作用下3Cr13不锈钢的微观结构及性能

[J].

Direct Laser Fabrication process with coaxial powder projection of 316L steel. Geometrical characteristics and microstructure characterization of wall structures

[J].

Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti-6Al-4V by selective electron beam melting

[J].

Study on energy input and its influences on single-track, multi-track, and multi-layer in SLM

[J].

Multi-physics modelling of molten pool development and track formation in multi-track, multi-layer and multi-material selective laser melting

[J].

Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting

[J].

Relation of thermal behavior and microstructure evolution during multi-track laser melting deposition of Ni-based material

[J].

Optimization of laser energy density and scanning strategy on the forming quality of 24CrNiMo low alloy steel manufactured by SLM

[J].

Effect of scanning strategies on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting

[J].

Fusion boundary microstructure evolution and mechanical properties of cold metal transfer welded dissimilar A5754 and A5083 joint

[J].

Behavior of weld pool convection and columnar-to-equiaxed grain transition in gas tungsten arc welds of ferritic stainless steels with different aluminum contents

[J].

Effect of heat treatment on microstructure and mechanical property of 304L stainless steel prepared by selective laser melting

[J].

热处理对选区激光熔化304L不锈钢组织和力学性能的影响

[J].

Heat transfer and fluid flow and their effects on the solidification microstructure in full-penetration laser welding of aluminum sheet

[J].Understanding the behaviors of heat transfer and fluid flow in weld pool and their effects on the solidification microstructure are significant for performance improvement of laser welds. This paper develops a three-dimensional numerical model to understand the multi-physical processes such as heat transfer, melt convection and solidification behavior in full-penetration laser welding of thin 5083 aluminum sheet. Solidification parameters including temperature gradient G and solidification rate R, and their combined forms are evaluated to interpret solidification microstructure. The predicted weld dimensions and the microstructure morphology and scale agree well with experiments. Results indicate that heat conduction is the dominant mechanism of heat transfer in weld pool, and melt convection plays a critical role in microstructure scale. The mushy zone shape/size and solidification parameters can be modulated by changing process parameters. Dendritic structures form because of the low G/R value. The scale of dendritic structures can be reduced by increasing GR via decreasing heat input. The columnar to equiaxed transition is predicted quantitatively via the process related G3/R. These findings illustrate how heat transfer and fluid flow affect the solidification parameters and hence the microstructure, and show how to improve microstructure by optimizing the process.

Effect of build geometry on the microstructural development of 316L parts produced by additive manufacturing

[J].

Yielding nature and Hall-Petch relationships in Ti-6Al-4V alloy with fully equiaxed and bimodal microstructures

[J].

Microstructure, mechanical property and Hall-Petch relationship of a light-weight refractory Al0.1CrNbVMo high entropy alloy fabricated by powder metallurgical process

[J].

Effect of cooling rate on microstructure evolution and mechanical properties of Ti-V-Mo complex microalloyed steel

[J].Nanoscale co-precipitation strengthening in steels has attracted increasing attention in recent years and has become a new cornerstone for the development of advanced high performance steels with superior combination of strength and ductility. Rolling process, finishing temperature, cooling rate and coiling temperature are the main factors which affect the mechanical properties of microalloyed steels by changing the volume fraction and particle size of precipitates. Nevertheless, the influence of cooling rate on microstructure evolution, precipitates and mechanical properties of complex microalloyed ferritic Ti-V-Mo steel has been rarely reported. In this work, the precipitation law of (Ti, V, Mo)C carbides at different cooling rates and its effect on microstructue evolution and mechanical properties of Ti-V-Mo complex miroalloyed steel were studied by OM, EBSD, HRTEM and Vickers-hardness test. The results indicated that the hardness first increased quickly and then increased slowly as the cooling rate increased (lower than 20 ℃/s); the mean size of (Ti, V, Mo)C particles decreased from 13.2 nm to 6.9 nm and the average size of ferrite grain reduced from 5.06 μm to 2.97 μm; the hardness of Ti-V-Mo steel was improved by the means of grain refinement hardening and precipitation hardening. However, when the cooling rate increased from 20 ℃/s to 30 ℃/s, its effects on grain refinement hardening and precipitation hardening has become saturated, so the hardness was kept flat and achieved a maximum vlaue of 410 HV, and the yield strength reached as high as 1090 MPa. The hardness y of Ti-V-Mo microalloyed steel and cooling rates x accord with a exponential decay relationship: y=-229exp(-x/5)+412.

冷却速率对Ti-V-Mo复合微合金钢组织转变及力学性能的影响

[J].

Effect of cooling rate on boride and room temperature tensile properties of β-solidifying γ-TiAl alloys

[J].

冷却速率对β凝固γ-TiAl合金硼化物和室温拉伸性能的影响

[J].