随着集成电路制程和芯片封装技术的快速进步,电子信息等战略新兴产业对下一代铜合金引线框架材料性能提出抗拉强度不小于800 MPa、导电率不低于50%IACS (IACS—international annealed copper standard)的要求[1~3]。Cu-Ni-Si系合金通过纳米级δ-Ni2Si相的时效析出可获得较高的强度与导电率,是集成电路引线框架用典型材料[4~9]。为满足下一代铜合金引线框架材料更高性能的需求,研究者们通常采用微合金化[10,11]和优化形变热处理工艺等[12,13]方法来促进合金析出相析出、调控析出相的形貌和分布,从而达到提高Cu-Ni-Si系合金的强度和导电率综合性能的目的[12]。

在微合金化研究方面,Chen等[15]通过添加0.2% (质量分数)的Zn促进了Ni2Si相的析出,增强了析出强化效应并改善了钎焊界面性能;Zhang等[16]添加0.03% (质量分数)的P不仅净化了Cu-Ni-Si基体,还能抑制析出相粗化,Ni3P相的析出同时提高了合金导电率和强度;Wang等[17]研究表明适量的Cr元素能与Si元素在时效时形成Cr3Si析出相,与δ-Ni2Si协同强化铜合金的同时提高合金导电率;彭丽军等[18]、Xiao等[19]和冯桄波等[20]研究均发现Co能与Ni、Si形成(Ni, Co)2Si相,并能抑制时效过程中的调幅分解,加速第二相的析出,极大地提高Cu-Ni-Si合金的强度。另一方面,为解决微合金化元素选择和含量确定等难题,本文作者等[21]提供了一种基于机器学习方法的解决思路,开发出机器学习设计系统(machine learning design system,MLDS)并以抗拉强度800 MPa、50%IACS为目标性能设计出了高性能的Cu-3.0Ni-0.6Si-0.16Zn-0.15Cr-0.03P (质量分数,%,下同)合金。

在形变热处理工艺研究方面,形变强化与析出强化相结合可达到协同强化的目的[22~29]。Sun等[30]采用双级液氮冷轧-时效工艺对Cu-1Cr-1Ni-0.6Si合金进行加工,合金抗拉强度(783.6 MPa)与导电率(48.3%IACS)分别比单级室温轧制-时效提高了91.3 MPa和4.9%IACS;Lei等[31]的研究表明,联合时效工艺能使Cu-6.0Ni-1.0Si-0.5Al-0.15Mg-0.1Cr合金获得优异综合性能,合金抗拉强度高达1155.8 MPa,导电率为25.2%IACS;Yang等[32]的研究表明,时效强化型Cu-0.32Cr-0.067Ti-0.032Si合金经过室温冷轧、370℃低温时效可获得比420℃时效更高的力学性能,且能保留较高的位错密度和织构强度。

1 实验方法

选用电解纯Cu (99.99%)、电解纯Ni (99.96%)、高纯Si (99.99%)、纯Cr块(99.96%)、纯Zn块(99.99%)和Cu-14%P中间合金作为熔炼原料,按Cu-3.00Ni-0.60Si-0.16Zn-0.15Cr-0.03P名义成分进行配料,在Ar气保护感应炉中熔炼并浇铸成型,实测成分为Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P。将铸锭切为20 mm × 60 mm × 100 mm坯料并在950℃保温2 h后热轧到10 mm厚;热轧试样在950℃保温4 h后进行淬火处理,然后分别进行总变形量为65%、75%、85%和95%的冷轧变形;将不同变形量后的合金取样,分别在400、450和500℃进行20、30、60、90、120、180、240、300和360 min时效处理,随后测试样品导电率、硬度和抗拉强度并观察合金的析出相形貌。

采用Sigmma2008B涡流导电仪测量导电率,工作频率500 kHz,每个试样测试5次,取均值;采用HXD-1000TM/LCD型显微硬度仪测试硬度,载荷0.05 kg,保持时间15 s,每个试样测试5次,取均值;根据GB/T 228.1—2010标准,采用CTM2500微机控制电子万能试验机进行拉伸实验,试样形状为狗骨状,拉伸速率为0.5 mm/min,相同形变热处理条件下的试样各取3个进行测试,抗拉强度取均值;采用DSC25差示扫描量热仪(DSC)测试不同冷轧变形后的标准样品,温度区间为20~550℃,升温速率10℃/min;在Axio Imager显微镜(OM)上观察显微组织,试样采用传统的机械磨抛制备,腐蚀剂配方为5 g FeCl3 + 15 mL HCl + 100 mL H2O;在Tecnai G2 20型透射电镜(TEM)上进行组织观察以获得TEM像及高分辨TEM (HRTEM)像,操作电压为200 kV,TEM试样经电解双喷减薄,电解液为30%HNO3 + 20%H3PO4 + 50%CH3COOH (体积分数),温度为-30~-10℃,电压为10~15 V,电流为50 mA;采用EDAX 1071型能谱仪(EDS)分析强化相的成分组成。

2 冷轧变形量对合金析出与再结晶工艺窗口的影响

时效温度是Cu-Ni-Si系合金时效工艺中重要的参数。时效温度过低,析出缓慢,生产效率低;时效温度过高,合金易发生再结晶与析出相长大,损害合金性能。一般为了优化合金的时效工艺,需要确定一个合理的时效温度窗口(开始析出温度与开始再结晶温度区间)来尽量避免时效过程中发生再结晶行为。Cu-Ni-Si系合金开始析出温度与开始再结晶温度的DSC测试结果如图1所示。

图1

图1

不同冷轧变形量下Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金的DSC测试结果

Fig.1

DSC test results of the Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P alloy by different cold-rolling deformations (ε)

(a) ε = 0% (b) ε = 65% (c) ε = 75% (d) ε = 85% (e) ε = 95%

(f) precipitation temperatures and recrystallization initial temperatures

图1a为未经过冷轧变形试样的DSC曲线,在测试温度区间内只有一个明显的开始析出温度(348℃),未见再结晶现象,可以推断出合金未变形时,再结晶温度大于550℃;图1b~e分别为冷轧变形量65%、75%、85%和95%的DSC曲线,曲线上有明显的开始析出温度和开始再结晶温度。对比不同变形量下的开始析出和开始再结晶温度可以发现,开始析出温度始终低于开始再结晶温度。开始析出温度和开始再结晶温度随着变形量的增加呈现逐渐降低的趋势:当变形量为65%时,开始析出温度为335℃;当变形量为95%时,开始析出温度降低了26℃,为309℃。与此同时,当变形量为65%时,开始再结晶温度为508℃;当变形量为95%时,开始再结晶温度降低了19℃,为489℃。

特别地,当变形量为85%时,如图1f,合金的开始析出温度下降8℃,开始再结晶温度增加6℃,时效温度窗口增大,说明在此变形量下合金基体中析出相对再结晶发生有明显的阻碍作用。相比于变形量为75%的试样,85%变形试样的形变储能大,由于较高的位错密度能促进溶质原子形核,所以在相同的加热速率下85%变形试样先于75%试样发生时效析出,故前者的开始析出温度较后者低,而析出相又阻碍了晶界的迁移从而使再结晶开始温度提高。同理,95%变形的试样,由于变形的进一步提高,试样基体内位错密度高于85%,开始析出温度同样会降低,但是过高的形变储能和位错密度使试样再结晶快速发生,析出相对晶界迁移的阻碍作用不明显,甚至成为再结晶的形核点加速再结晶,导致开始再结晶温度较85%试样有所降低(具体原因有待进一步明确)。

从以上关于合金在不同冷轧变形程度后DSC测得的开始析出温度与开始再结晶温度的变化趋势与原因分析不难看出,合金的时效析出与再结晶之间互相竞争,相互影响[33]。一方面变形时在合金基体内产生的大量位错成为析出原子的快速通道和形核位置,加快析出相长大,同时也是再结晶的驱动力和形核位置;另一方面时效析出的第二相能钉扎晶界从而影响再结晶的形核和生长,延缓再结晶。很显然,当合金成分一定时,合金开始析出温度取决于冷轧变形程度,而开始再结晶温度不仅与变形程度息息相关,还与析出和再结晶进程的瞬时平衡紧密相关;同时也表明2者之间的交互作用对温度也非常敏感。

DSC的实验结果表明,随着变形量的增加,Cu-Ni-Si-Cr-Zn-P合金时效工艺窗口总体呈减小的趋势。在变形量一定时,应尽量选择工艺窗口温度较高的区间以减少能源消耗。合金经85%冷轧变形后能获得较大的时效工艺窗口。因此,85%冷轧变形合金选择在400~450℃下时效,既可以避免时效热处理时发生再结晶而降低合金力学性能,同时又能保证较强的析出动力,促进析出相的大量析出,使合金保持优良的导电性能。

3 冷轧变形量对时效前合金组织和性能的影响

图2

图2

不同程度冷轧后合金显微组织的OM像

(a) ε = 65% (b) ε = 75% (c) ε = 85% (d) ε = 95%

Fig.2

OM images of microstructures of the alloy after different cold-rolling deformations (RD—rolling direction, ND—normal direction)

Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金试样经固溶处理及不同变形量冷轧后,试样的硬度和导电率测试结果如图3所示。由图可知,固溶处理后合金样品的导电率随着冷轧变形量的增加而缓慢降低,冷轧总变形量为95%时样品的导电率由固溶态下的33.2%IACS降低到28.9%IACS,仅降低了4.3%IACS。与此同时,样品硬度随冷轧变形量的增加而大幅提高,当总变形量为95%时,硬度由固溶态时的122.5 HV提高到175.5 HV,增加了53 HV。另外,冷轧变形量超过75%之后,试样硬度随着变形量的增加速度放缓:当冷轧总变形量为75%时,样品硬度由变形量为65%时的151.5 HV提高到165.2 HV,增加了13.7 HV;当总形变量为85%、95%时硬度分别为170.1和175.5 HV,分别比前次变形增加4.9和5.4 HV。

图3

图3

不同程度冷轧变形对时效前合金导电率和硬度的影响

Fig.3

Effect of cold-rolling deformation reduction on electrical conductivity and hardness of the alloy before aging treatment

4 冷轧变形对时效后合金组织的影响

对比不同冷轧变形量下合金试样在相同温度和保温时间时效后的金相组织能较完整地反映出冷轧变形量对时效组织的影响规律。为此,本工作选取60 min作为典型的保温时间,观察不同冷轧变形后的样品在400、450和500℃下时效60 min的显微组织,如图4所示。图4a~d表明,与冷轧后的合金显微组织相比,经冷轧变形并在400℃下保温60 min后,不同变形量合金试样的显微组织没有明显变化。冷轧变形后的试样在450℃下保温60 min后,如图4e~h所示,合金试样的显微组织发生了明显变化,85%冷轧变形试样(图4g)的原始晶界已经模糊不清但尚能分辨出少量的纤维状原始晶粒,被变形带分割出的亚晶呈鱼鳞状,少量的再结晶晶粒零散地分布在原始晶界处;95%冷轧变形样品原始晶粒已难以分辨(图4h),绝大多数亚晶成为新的细小晶粒分布在原始晶粒和变形带周围。图4i~l为冷轧变形后的合金试样在500℃下保温60 min后的显微组织,此时试样均发生了明显的再结晶,95%冷轧变形样品已经完全再结晶。

图4

图4

不同程度冷轧样品在400、450和500℃下时效60 min的显微组织OM像

(a, e, i) ε = 65% (b, f, j) ε = 75% (c, g, k) ε = 85% (d, h, l) ε = 95%

Fig.4

OM images of microstructures of alloys with different cold-rolling reductions after aging for 60 min at 400oC (a-d), 450oC (e-h), and 500oC (i-l)

综上分析可知,在较低温度下(400℃)合金只发生回复几乎不发生再结晶;而在较高温度(450℃)下样品在局部发生再结晶,其中85%冷轧变形样品较好地保持变形组织形貌;在高温(500℃)下样品几乎都发生了再结晶,除85%冷轧样品外,其他变形量越大的样品再结晶程度越明显。

尽管OM观察的结果也证实了Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金在85%冷轧变形后具有较宽的时效工艺窗口,但DSC测试的开始再结晶温度与金相观察结果有差异,例如:65%冷轧变形后的样品在450和500℃下保温60 min后出现了局部再结晶(如图4e和i),再结晶温度明显低于DSC测量得出的508℃开始再结晶温度。出现这一现象的原因主要有2方面:一方面,在DSC测试时,温度是逐渐增加的(10℃/min),升温过程中试样会发生较为明显的回复,消耗了一部分形变储能降低了再结晶的动力,导致测量出的开始再结晶温度偏高;另一方面,金相试样在不同温度下时效时,在极短的时间内就升温到所设定的温度且进行60 min保温,在升温过程中较少发生回复导致形变储能较大,一旦保温温度超过再结晶临界温度,样品就会再结晶,在时间累积效应下,通过金相就能观察到再结晶现象。

为了进一步明确冷轧变形对Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金时效微观组织的影响机制,本工作以85%冷轧变形后合金在450℃下时效微观组织的演变为主要研究对象,研究冷轧变形对析出组织形貌和分布的影响,以此来理解合金性能提升机制,为制定合理的形变热处理工艺提供依据。选择85%冷轧变形试样作为微观组织研究对象,主要是考虑到85%冷轧变形后合金试样具有较宽的时效工艺窗口,且相比于95%冷轧变形试样具有更好的抗过时效性能,相比于65%和75%冷轧变形的试样具有更高的时效析出动力。

Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金试样经85%冷轧变形在基体内产生大量位错并形成位错缠结和胞壁,如图5a所示,胞壁处位错密度大大高于胞内的密度,会形成较多的溶质原子运动通道,在时效处理时易导致第二相优先在胞壁处析出[37,38];胞内由于位错密度较低,第二相形核率小,从而使胞壁处第二相密度远远大于胞内。图5b所示为冷轧85%的合金试样在450℃下时效20 min时的HRTEM像。可见,在位错附近有大量边长约为4 nm的等边三角形析出相(箭头所指),在位错胞内这样的析出相明显较少。图5c进一步表明析出相与基体是共格关系,且在析出相附近有明显的G.P.区存在[39,40]。图5d为图5c中三角形析出相区域Fourier变换后得到的δ-Ni2Si斑点(正交结构,a = 0.706 nm,b = 0.499 nm,c = 0.372 nm)。上述结果表明:在合金时效前期,位错分布决定着析出形核点的分布,G.P.区与早期析出相共存于基体内,且与基体呈现共格关系。

图5

图5

85%冷轧变形后合金基体内位错与早期析出相

Fig.5

Dislocation and early precipitates in 85% cold rolled alloy matrix

(a) TEM image of dislocation cell

(b) precipitates after aging for 20 min (indicated by arrows)

(c) HRTEM image of G.P. zone and early precipitates

(d) Fourier transform of speckles analysis of early precipitates

图6

图6

85%冷轧变形合金时效中期析出相分布与形态

Fig.6

Distribution and morphologies of precipitates in the middle aging stage of 85% cold rolled wrought copper alloy

(a) 40 min aging (b) partial enlarged detail of Fig.6a and Fourier transform of precipitated phase

(c) 60 min aging (d) 90 min aging

在后续时效中,由于胞壁位错密度大,为附近析出相提供了形核位置和析出驱动力,提高了析出相粗化速率;基体内位错密度的差异使得析出相形核、长大存在差异,导致析出相分布不均匀。与此同时,随着时效时间的延长,基体内部发生回复,由冷轧变形积累的位错逐渐重新排列或形成亚晶结构降低晶体缺陷,造成析出驱动力降低,使析出速率降低;三角形析出相逐渐长大成为球状,与基体之间的共格关系也演变为半共格、非共格关系。

图7

图7

85%冷轧变形合金时效120 min后析出相形貌、EDS及选区电子衍射(SAED)花样

Fig.7

Precipitated phase morphology, EDS, and SAED patterns of 85% cold-rolling deformed alloy after aging for 120 min

(a) bright-field TEM image of precipitated phase

(b) EDS of Cr3Si (c) Cr3Si SAED pattern (d) δ-Ni2Si SAED pattern

5 冷轧变形量对时效后合金性能的影响

不同冷轧变形量的Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P样品在400、450和500℃时效0~360 min后,样品的导电率和硬度结果如图8所示。

图8

图8

冷轧变形+不同温度时效后合金的硬度与导电率

Fig.8

Electrical conductivities (a, c, e) and hardnesses (b, d, f) of the alloy after cold-rolling deformation and aging at different temperatures

(a, b) 400oC (c, d) 450oC (e, f) 500oC

由图8f可知,在500℃时效时,未变形的试样硬度随着保温时间的延长逐渐升高,保温300 min后试样硬度达到158 HV,之后基本保持不变;变形65%的试样硬度在60 min时达到峰值硬度178 HV后也基本保持不变;变形75%的样品在时效20 min时达到峰值硬度185 HV后开始缓慢下降,180 min后硬度开始急剧下降,300 min时硬度仅为145 HV;变形85%的样品在时效40 min后达到峰值201 HV,随后逐渐下降,直到90 min后才开始急剧下降;而变形95%的样品在时效前具有较高的硬度,但在时效期间硬度一直在下降,直到180 min时才保持基本不变,仅维持在130 HV左右。相比于400和450℃,500℃下不同变形量样品的硬度变化较为复杂,其中变形量为95%的样品在时效初期迅速发生再结晶导致硬度迅速下降,析出强化对硬度的贡献远不抵再结晶造成的软化;而变形量85%的样品,20~180 min时效期间硬度和抗过时效能力(稳定性)均高于其他变形量试样;造成这一现象的原因主要是85%变形样品析出动力较65%和75%强,析出相长大发生在再结晶前,粗化的析出相不仅钉轧位错运动,还抑制了晶界的迁移使再结晶延迟。总体而言,变形量65%、75%和85%样品的硬度在达到峰值后逐渐下降,变形量越大,下降速率越快,这是因为在高温时,样品回复时间较短,大量位错形成再结晶核心,形变储存能驱使再结晶迅速发生,以及析出相在高温下迅速长大共同导致合金硬度下降。在500℃时,形变量越大再结晶的时间越早,位错等晶体缺陷的散逸消失越快,导致析出动力减弱,析出相减少,因此样品导电率相比450℃较低。

图8中样品导电率随时效时间的延长持续升高,这表明在时效过程中溶质原子不断析出;在相同时效温度和时效时间下,冷轧变形量越大样品的导电率越高,表明冷轧变形程度越大促进析出的动力越强。样品在未发生再结晶前,在400和450℃时效时,变形量大的样品到达硬度峰值所用的时间短;当时效温度为500℃时,变形量越大的样品越容易发生再结晶。

根据以上实验结果与分析,时效前的冷轧变形不仅可以提高Cu-Ni-Si-Zn-Cr-P合金的力学性能,还几乎不损失导电性能。合理的冷轧变形与时效制度能很好地平衡合金的力学性能与导电性能[33]。当冷轧变形量为85%时,较佳的时效工艺为450℃、60 min;当冷轧变形量为95%时,较佳的时效工艺为400℃、90 min和450℃、60 min。

图9a为Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金试样经过85%冷轧变形后在450℃时效0~360 min的拉伸变形工程应力-应变曲线。时效60 min后达到峰值时效,抗拉强度为(786 ± 12) MPa,延伸率为7.4% ± 0.8%,此时导电率为(47.5 ± 0.9)%IACS。图9b为合金试样经过95%冷轧变形后在400℃时效0~360 min的工程应力-应变曲线,时效90 min后达到峰值时效,抗拉强度为(825 ± 16) MPa,延伸率为10.1% ± 0.7%,此时导电率为(45.3 ± 0.6)%IACS。图9c为合金试样经过95%的冷轧变形后在450℃时效0~360 min的工程应力-应变曲线,时效60 min后达到峰值时效,抗拉强度为(841 ± 10) MPa,延伸率仅为3.4% ± 0.4%,此时导电率为(52.2 ± 0.3)%IACS。

图9

对比上述3种形变-热处理后合金的工程应力-应变曲线可以看出:① 抗拉强度呈现先增加后降低的趋势,延伸率呈现与抗拉强度此消彼长的趋势;② 85%冷轧变形的合金试样虽然峰值抗拉强度稍小于冷轧变形量为95%的合金试样,但是前者比后者具有更优的抗过时效能力,这一点与DSC实验结果相符;③ 95%冷轧变形的试样能在较短的时效时间内达到峰时效状态,但易过时效导致抗拉强度在时效后期急剧下降。

由此可见,以抗拉强度800 MPa、导电率50%IACS为设计目标由MLDS给出的合金成分经过熔炼、均匀化、热轧、固溶后,85%冷轧变形、450℃时效60~180 min后,合金能够获得650~786 MPa的抗拉强度、(47.5~52.4)%IACS的导电率;95%冷轧变形、400~450℃时效60~180 min后,合金能够获得610~841 MPa抗拉强度、(47.7~54.8)%IACS导电率。上述结果表明:通过MLDS方法设计高性能铜合金成分是可行的,且由其设计的合金能通过较宽的工艺范围实现设计性能。

6 冷轧变形量对合金时效动力学的影响

由Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金时效过程中微观组织和性能的变化不难看出,溶质原子在时效过程中源源不断地从Cu基体中析出形成第二相,其中第二相的体积分数、析出相形貌和分布决定着合金的力学性能和导电率。上述形变热处理实验结果说明不同程度的冷轧变形对合金的时效析出促进程度有明显差别。同时,时效热处理过程中析出相体积分数的可预测、模型化对指导生产研发有一定实用价值。定量研究Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金时效前变形量对析出动力学的影响,能为合理安排形变热处理工艺和平衡合金最终力学性能与导电性能提供数据参考。为此,本工作采用传统的Avrami方程来分析不同冷轧变形程度和时效温度对合金的时效动力学的影响规律。

6.1 合金析出相体积分数计算

其中,φ为样品某一时刻的体积分数,V为样品单位体积内在某一时刻析出相的体积,V'为样品最大析出时单位体积内析出相的体积。合金时效足够长时间后导电率不再明显上升时,此时认为合金析出完全,导电率达到最大值ψmax,φ = 1;而未开始时效时,V = 0,导电率为初态导电率ψ0,φ = 0。

合金导电率ψ与φ之间关系密切,体积分数越大,电导率越高。φ与时效时间t之间遵循相变动力学Avrami经验方程[44]:

而当析出终了时,ψ = ψmax,φ = 1,则A = ψmax - ψ0,因此只要测量合金在各个温度下各时刻的导电率就可计算出相应时刻的φ。据此方法并利用实验测得的导电率计算出Cu-3.28Ni-0.60Si-0.22Zn-0.11Cr-0.04P合金新析出相的体积分数。

6.2 析出动力学方程与导电率方程

析出动力学方程常常用Avrami经验方程(

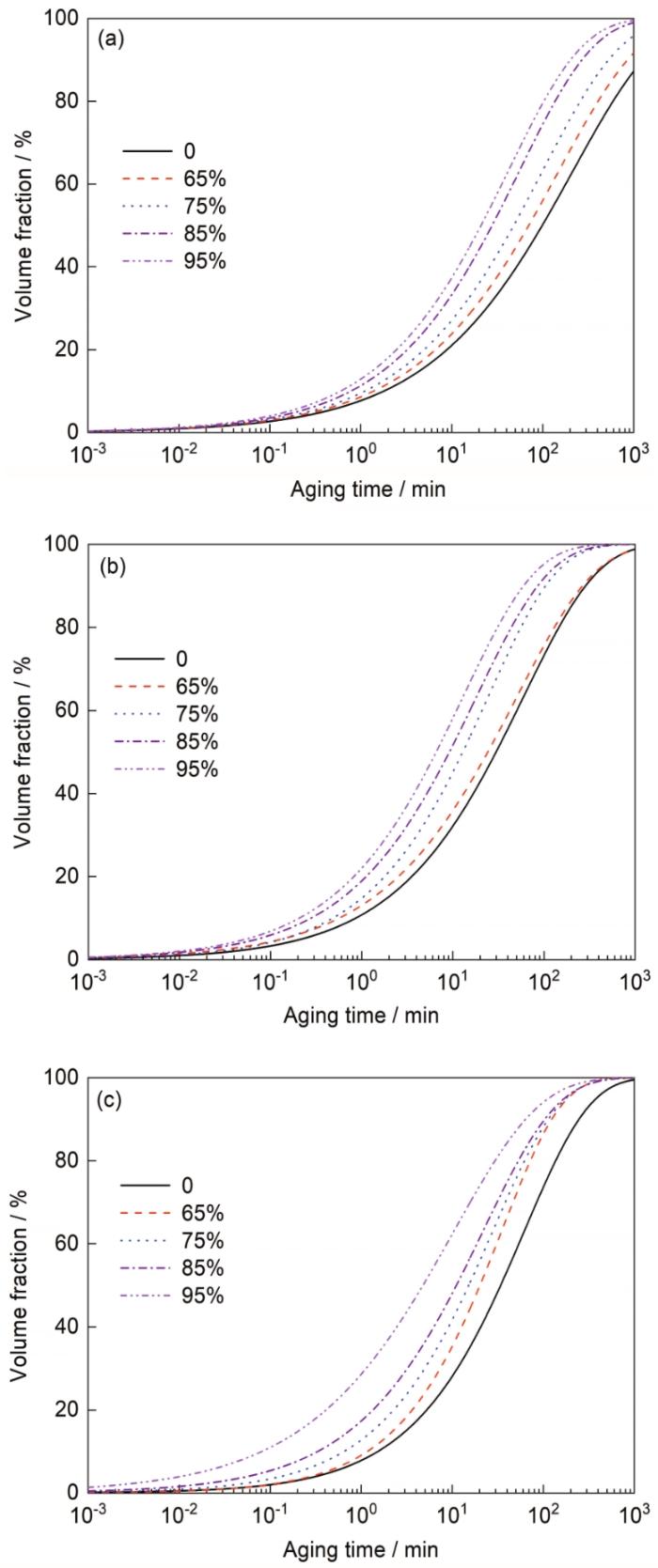

图10

图10

时效时间与析出相体积分数之间的关系

(a) 400oC (b) 450oC (c) 500oC

Fig.10

Relationships between aging time (t) and volume fraction (φ) of precipitated phase

表1 不同时效温度下合金Avrami方程系数n和b的值

Table 1

| Deformation / % | 400oC | 450oC | 500oC | |||

|---|---|---|---|---|---|---|

| n | b | n | b | n | b | |

| 0 | 0.47697 | 0.196816 | 0.53149 | 0.143992 | 0.60633 | 0.093694 |

| 65 | 0.70726 | 0.089045 | 0.50174 | 0.184944 | 0.66154 | 0.075043 |

| 75 | 0.59424 | 0.122617 | 0.57403 | 0.100221 | 0.59698 | 0.116676 |

| 85 | 0.52762 | 0.161306 | 0.53865 | 0.103705 | 0.53706 | 0.170424 |

| 95 | 0.66998 | 0.088510 | 0.54447 | 0.118476 | 0.46226 | 0.283687 |

图11

图11

不同温度时效时合金导电率实验值与计算值

(a) 400oC (b) 450oC (c) 500oC

Fig.11

Experimental and calculated values of electrical conductivity of alloys at different temperatures

6.3 合金析出动力学S曲线

将不同温度下的n和b值代入

图12

图12

冷轧变形量对不同温度下时效析出动力学S曲线的影响

(a) 400oC (b) 450oC (c) 500oC

Fig.12

Influence of cold-rolling deformation on S curve of precipitation kinetics at different temperatures

从图12a中可知,样品在400℃时效时,析出相体积分数达到50%时,变形量为65%、75%、85%和95%的样品用时分别约为70、48、27和20 min,而未变形的样品用时约为100 min。从图12b中可知,样品在450℃时效时,析出相体积分数达到50%时,变形量65%、75%、85%和95%的样品用时分别约为24、14、10和7 min,而未变形的样品用时约为30 min。从图12c中可知,样品在500℃时效时,析出相体积分数达到50%时,变形量65%、75%、85%和95%的样品用时分别约为18、12、9和5 min,而未变形的合金样品用时约为28 min。可以看出:时效温度越高、变形量越大,样品中析出相同体积分数的析出相所需要的时间越短。因此,时效前对合金进行较大程度的冷变形,在相同的时效温度下可以提高析出动力,加速合金析出,有效缩短峰值时效时间;同理,在变形量相同的情况下,时效温度越高合金时效析出动力越强,析出速率越快。

7 结论

(1) 随着冷轧变形量增大,合金开始析出温度和再结晶温度总体呈降低的趋势;仅当变形量为85%时,合金的开始析出温度下降8.5℃,开始再结晶温度反而上升6.6℃,时效窗口增加约15℃。

(2) 85%冷轧变形的样品在450℃时效20 min后,大量边长约为4 nm的等边三角形δ-Ni2Si相在位错附近析出;时效40 min后,δ-Ni2Si析出相与基体之间存在半共格关系;时效120 min后在基体中观察到少量的Cr3Si析出相。

(3) 合金经过85%冷轧变形后在450℃下保温60 min后获得抗拉强度峰值性能为(786 ± 12) MPa,导电率为(47.5 ± 0.9)%IACS;冷轧变形量为95%的试样450℃时效60 min后获得的抗强度峰值(841 ± 10) MPa,导电率为(52.2 ± 0.3)%IACS。

参考文献

Development status and prospects of advanced copper alloy

[J].

先进铜合金材料发展现状与展望

[J].

Phase transformation behaviors and properties of a high strength Cu-Ni-Si alloy

[J].

Strengthening of Cu-Ni-Si alloy using high-pressure torsion and aging

[J].

Dynamic recrystallization behavior and microstructure evolution of high-performance Cu-3.28Ni-0.6Si-0.22Zn-0.11Cr-0.04P during hot compression

[J].

Effect of Ag addition on the microstructure and mechanical properties of Cu-Cr alloy

[J].

Effect of magnesium on microstructure and properties of Cu-Cr alloy

[J].

Effects of microstructure on mechanical properties of CuNiSi alloys

[J].

Composition rule of high hardness and electrical conductivity Cu-Ni-Si alloys

[J].Cu-Ni-Si alloys are among the most widely used electrical conductive (>30%IACS) alloys with quite high strength level (>500 MPa), so they are especially suitable for lead frames and connector joints. However, these two properties are quite composition sensitive, apart from their tight connection with processing. Moreover, their compositions fall within quite broad ranges that poses difficulties for the industries. For instance, typical C7025 alloy has a specified composition (mass fraction, %) range of Ni 2.2~4.2, Si 0.25~1.2, Mg 0.05~0.3, plus less than 0.5 of other impurity elements. Obviously the composition ranges of the elements are far from even their absolute contents. The present work focuses on understanding the composition rule of Cu-Ni-Si via a new structural tool, the cluster-plus-glue-atom model. In this model, any solid solution is described by a nearest neighbor coordination polyhedron plus a one-to-six glue atoms. Specifically for Cu-based alloys, the cluster is cubooctahedron. The composition formula for solute-rich Cu-Ni-Si alloys and pure Cu are established, respectively [(Ni2/3Si1/3)-Cu12]Cu1~6 and [Cu-Cu12]Cu3. A series of Cu-Ni-Si alloys were designed on the basis of the cluster-plus-glue-atom model. In the concentrated solute region with Cu content less than 95%, the alloys were designed using the single cluster model [(Ni2/3Si1/3)-Cu12]Cu1~6. In the dilute solute region where Cu content is larger than or equal to 95%, the alloys were designed using the double cluster model {[(Ni2/3Si1/3)-Cu12]Cu3}A+{[Cu-Cu12]Cu3}B. The alloys were arc-melted into ingots under Ar atmosphere and were subjected to a solution treatment at 950 ℃ for 1 h plus water quenching, and then to an ageing at 450 ℃ for 4 h plus water quenching. The microstructure and properties of the alloys were characterized and tested by XRD, OM, TEM, Vickers hardness tester and digital metal conductivity instrument. The composition rule of the designed Cu-Ni-Si alloy was obtained by experiments.The results shown a special range of Cu content in 95.0%~95.8% as a composition sensitive region, in which, in addition to ageing precipitation strengthening, the alloys also have amplitude modulated decomposition strengthening, resulting in a sudden increase in Vickers hardness and a decrease in electrical conductivity. Vickers hardness and electrical conductivity change with composition variations in an irregular manner. In the concentrated and dilute solute region before and after the composition sensitive region, Vickers hardness (H) is linearly related to the Cu content (CCu) by H=-12.6CCu+1362.7 and H=-26.2CCu+2777.3, and the corresponding electrical conductivity (σ) is also linearly related to the CCu by σ=0.2CCu+28.6 and σ=5.2CCu-466.

高硬导电Cu-Ni-Si合金成分规律

[J].用团簇加连接原子模型设计了系列用于制作引线框架的Cu-Ni-Si合金。在Cu含量小于95%的浓溶质区,采用单团簇模型[(Ni<sub>2/3</sub>Si<sub>1/3</sub>)-Cu<sub>12</sub>]Cu<sub>1~6</sub>设计合金成分;在Cu含量大于或等于95%的稀溶质区,采用双团簇模型{[(Ni<sub>2/3</sub>Si<sub>1/3</sub>)-Cu<sub>12</sub>]Cu<sub>3</sub>}<sub>A</sub>+{[Cu-Cu<sub>12</sub>]Cu<sub>3</sub>}<sub>B</sub>设计合金成分。利用XRD、OM、TEM、Vickers硬度计、电导率测量仪等实验获得Cu-Ni-Si合金的成分规律。结果表明,在Cu-Ni-Si合金的成分范围内存在Cu含量为95.0%~95.8%的成分敏感区,此区间内合金同时存在时效析出强化和调幅分解强化,致使Vickers硬度突然增加,导电率降低,两者变化趋势相反,且与成分之间无规律性依赖关系。成分敏感区前后的浓溶质区和稀溶质区的合金中,不存在调幅分解强化,Vickers硬度(H)随Cu含量(C<sub>Cu</sub>)增加而减少,分别满足H=<sub/>-12.6C<sub>Cu</sub>+1362.7和H=-26.2C<sub>Cu</sub>+2777.3的线性关系;相应的导电率(σ)随C<sub>Cu</sub>的线性增加关系分别为σ=0.2C<sub>Cu</sub>+28.6和σ=5.2C<sub>Cu</sub>-466。

Microstructure and mechanical properties of Cu-Ni-Si alloys

[J].

Simultaneously enhanced hardness and electrical conductivity in a Cu-Ni-Si alloy by addition of Cobalt

[J].

Effects of Cr and Zr additions on microstructure and properties of Cu-Ni-Si alloys

[J].

Research progress of Cu-Ni-Si alloy for lead frame and its preparation and processing technology

[J].

引线框架用Cu-Ni-Si合金及其制备加工工艺的研究进展

[J].

Effect of Ni/Si mass ratio and thermomechanical treatment on the microstructure and properties of Cu-Ni-Si alloys

[J].The effect of the Ni/Si mass ratio and combined thermomechanical treatment on the microstructure and properties of ternary Cu-Ni-Si alloys is discussed systematically. The Cu-Ni-Si alloy with a Ni/Si mass ratio of 4–5 showed good comprehensive properties. Precipitates with disc-like shapes were confirmed as the Ni2Si phase with orthorhombic structure through transmission electron microscopy, high-resolution transmission electron microscopy, and 3D atom probe characterization. After the appropriate thermomechanical treatment, the studied alloy with a Ni/Si mass ratio of 4.2 exhibited excellent mechanical properties: a hardness of 290 HV, tensile strength of 855 MPa, yield strength of 782 MPa, and elongation of 4.5%. Compared with other approaches, the thermomechanical treatment increased the hardness and strength without sacrificing electrical conductivity. Theoretical calculations indicated that the high strength was primarily attributed to the Orowan precipitation strengthening and secondarily ascribed to the work hardening, which were highly consistent with the experimental results. The appropriate Ni/Si mass ratio with a low content of Ni and Si atoms shows high strength and excellent electrical conductivity through combined thermomechanical treatment. This work provides a guideline for the design and preparation of multicomponent Cu-Ni-Si-X alloys with ultrahigh strength and excellent electrical conductivity.

The systems-based design of high-strength, high-conductivity alloys

[J].

Influence of Zinc on coarsening of δ-Ni2Si particles, aging behavior and hardness in a Cu-Ni-Si alloy

[J].

Microstructure and precipitate's characterization of the Cu-Ni-Si-P alloy

[J].

Correlation between microstructures and mechanical properties of cryorolled CuNiSi alloys with Cr and Zr alloying

[J].

Influence of different treatment processes on microstructure and properties of Cu-Ni-Co-Si alloy

[J].

不同处理工艺对Cu-Ni-Co-Si合金组织与性能的影响

[J].

Coarsening behavior of (Ni, Co)2Si particles in Cu-Ni-Co-Si alloy during aging treatment

[J].

Re-aging behaviour and precipitated phase characteristics of high-performance Cu-Ni-Co-Si alloy

[J].

高性能Cu-Ni-Co-Si合金的二次时效行为及析出相特征

[J].

A property-oriented design strategy for high performance copper alloys via machine learning

[J].Traditional strategies for designing new materials with targeted property including methods such as trial and error, and experiences of domain experts, are time and cost consuming. In the present study, we propose a machine learning design system involving three features of machine learning modeling, compositional design and property prediction, which can accelerate the discovery of new materials. We demonstrate better efficiency of on a rapid compositional design of high-performance copper alloys with a targeted ultimate tensile strength of 600–950 MPa and an electrical conductivity of 50.0% international annealed copper standard. There exists a good consistency between the predicted and measured values for three alloys from literatures and two newly made alloys with designed compositions. Our results provide a new recipe to realize the property-oriented compositional design for high-performance complex alloys via machine learning.

Microstructure and properties of Cu-Ni-Si-Zr alloy after thermomechanical treatments

[J].

On the precipitation strengthening of Cu-2.6Ni-0.6Si-0.6Cr bronzes

[J].

Effect of plastic deformation on discontinuous coarsening of spinodally decomposed microstructure in Cu-Ni-Fe alloy

[J].

塑性变形对Cu-Ni-Fe合金失稳分解组织不连续粗化的影响

[J].固溶处理后的塑性变形能促进Cu-Ni-Fe合金时效过程中失稳分解组织的不断连粗化, 塑料变形程度对不连续粗化组织的最终形态有明显的影响.

Thermomechanical processing of Cu-Ni-Si-Cr-Mg alloy

[J].

Improvement in strength and electrical conductivity of Cu-Ni-Si alloys by aging and cold rolling

[J].

Tensile deformation characteristics of a Cu-Ni-Si alloy containing trace elements processed by high-pressure torsion with subsequent aging

[J].

Microstructure and properties of low concentration of Cu-Ni-Si alloy

[J].

低浓度Cu-Ni-Si合金的组织与性能

[J].

Microstructure and properties of Cu-15Ni-8Sn-0.4Si alloy

[J].

Effect of two-step cryorolling and aging on mechanical and electrical properties of a Cu-Cr-Ni-Si alloy for lead frames applications

[J].

Microstructure and mechanical properties of a high strength Cu-Ni-Si alloy treated by combined aging processes

[J].

Influence of low-temperature annealing temperature on the evolution of the microstructure and mechanical properties of Cu-Cr-Ti-Si alloy strips

[J].

Alloy design strategies to increase strength and its trade-offs together

[J].

High strength and high conductivity Cu alloys: A review

[J].

A review of microstructure and texture evolution with nanoscale precipitates for copper alloys

[J].

Enhanced mechanical and electrical properties of a Cu-Ni-Si alloy by thermo-mechanical processing

[J].

Effect of solid solution and aging process on microstructure and properties of Cu-1.4Ni-1.2Co-0.6Si alloy

[J].

固溶时效对Cu-1.4Ni-1.2Co-0.6Si合金组织性能的影响

[J].

Precipitation behavior of Cu-3.0Ni-0.72Si alloy

[J].Cu-Ni-Si alloys have been widely applied in electronic and electrical industries. The precipitation behavior of some of the Cu-Ni-Si alloys is still not well understood. In this study, the precipitation behavior of the Cu-3.0Ni-0.72Si alloy aged at 600 degrees C for different times was investigated by transmission electron microscopy, atom probe tomography and phenomenological theory of precipitation crystallography. A new orientation relationship (OR) between the precipitates and the Cu matrix was found in the over-aged condition and a coarsening mechanism of the metastable precipitates was put forward. The two- and three-dimension invariant line theories were successfully applied in interpreting the evolution of the ORs and the morphologies in the Cu/delta-Ni2Si (Cu/delta) system. At the early stage of aging, the fine metastable delta'-(Cu, Ni)(2)Si precipitates are coherent with the Cu matrix, with a quasi-Bain OR of (110)(Cu)parallel to(100)(delta)', and [001](Cu)parallel to[001]delta', and four pairs of parallel conjugate planes: ((11) over bar1)(Cu)parallel to((3) over bar 01)(delta)', (111)(Cu)parallel to(301)(delta)', ((1) over bar 11)(Cu)parallel to(021)(delta)',, and (1 (11) over bar)(Cu)parallel to(0 (1) over bar1)(delta)'. The precipitates have a delta-Ni2Si structure, with some Ni atoms substituted by Cu atoms. During growth, the core region of the metastable delta'-(Cu,Ni)(2)Si precipitate transforms into stable delta-Ni2Si, with a quasi-NW OR of ((1) over bar 11)(Cu)parallel to(021)delta and [110](Cu)parallel to[100](delta), while a layer of metastable delta'- (Cu, Ni)(2)Si still exists around the core. With prolonging aging time, the delta-Ni2Si precipitates with the OR of ((1) over bar 11)(Cu)parallel to(021)(delta) and [110](Cu)parallel to[100](delta) grow two-dimensionally to form a plate-like shape, while those with the OR of (111)(Cu)parallel to(301)delta and [(1) over bar 10](Cu)parallel to[010](delta) grow one-dimensionally to form a fiber-like shape. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Effects of pre-deformation on precipitation behaviors and properties in Cu-Ni-Si-Cr alloy

[J].

The crystallographic and morphological evolution of the strengthening precipitates in Cu-Ni-Si alloys

[J].

Evaluation of nanoscaled precipitates in a Cu-Ni-Si-Cr alloy during aging

[J].

Thermodynamics and kinetics of discontinuous precipitation in Cu-9Ni-xSn alloy

[J].

Dynamics of phase transformation of Cu-Ni-Si alloy with super-high strength and high conductivity during aging

[J].