形状记忆合金(shape memory alloys,SMAs)是一类承受外力产生变形后,通过施加一定的外部激励(如热场、磁场等),能够回复到其原始形状的功能合金[1,2]。NiTi SMAs具有良好的形状记忆效应、超弹性和生物相容性等功能特性,是目前工程领域应用最广泛的一类功能金属材料,被广泛应用于航空航天和医疗器械等领域[3,4]。然而,由于NiTi SMAs具有高反应敏感性和低热导率等物性,导致其初步成形件的后续加工十分困难[5,6]。目前,传统工艺(如铸造、轧制和锻造等)制备的NiTi构件几何形状比较简单,如丝材、板材和棒材等[5,7]。然而,传统制备工艺囿于模具和减材制造,难以获得复杂几何形状的NiTi构件(如多孔[8]、负Poisson比[9]和层状结构[10]等),无法满足其个性化服役需求,限制了其更广泛的应用。选区激光熔化(selective laser melting,SLM)是一种基于三维计算机辅助设计模型,利用激光束层层熔化金属粉末,直接成型出几何形状复杂可控且具有良好冶金结合金属构件的技术[11,12]。目前,已有研究[5,9,10]通过SLM工艺制备出高致密度的NiTi构件,这表明SLM工艺能够成功应用于NiTi SMAs,大幅减少其后续加工流程,提高生产效率,扩展应用场景。本文聚焦于SLM 制备NiTi SMAs的研究进展,总结了现有的研究成果,旨在为一体化研究SLM NiTi SMAs的工艺参数、微观结构与热机械性能提供参考。最后,本文展望了SLM NiTi SMAs未来的重点研究方向与发展趋势。

1 SLM NiTi SMAs的研究概况

为制备出具有复杂几何形状和优异功能特性的NiTi SMAs,进一步扩大NiTi SMAs的应用,大量研究[8~10]采用SLM工艺制备了NiTi SMAs并对其进行了系统研究。主要是基于优化的工艺参数,开展后续的微观结构、相转变行为和热机械性能研究。对于NiTi SMAs而言,其成形难度大,影响成形的因素多,这主要是因为NiTi SMAs与其他易SLM成形的合金(如Ti6Al4V、镍基高温合金和不锈钢等)存在显著差异:第一,由于NiTi SMAs的成分会显著影响其功能特性,例如相转变温度、形状记忆效应实现温度和超弹性获得温度范围等,这些功能特性对NiTi SMAs的应用至关重要,是决定其服役环境和服役可能性的基础[13],因此,工艺参数对SLM NiTi SMAs成分的影响是必须要考虑的重要因素;第二,NiTi SMAs中存在多种金属间化合物,热导率相对较低,在SLM成形过程中,会形成相对较大的残余热应力,影响其成形性,通过工艺参数优化,减少SLM NiTi SMAs成形过程中的缺陷,是获得质量良好的NiTi SMAs的重要前提条件[14];第三,NiTi SMAs的功能特性与其基体的晶粒尺寸和分布、沉淀相析出行为以及位错密度等因素密切关联,SLM过程中的复杂热历史会对SLM NiTi SMAs的功能特性产生显著影响,工艺参数的调控是控制这种热历史的最重要途径[15,16]。因此,大多研究者从工艺参数优化出发,研究工艺参数对SLM NiTi SMAs成形性、微观结构、相转变行为和热机械性能的影响[17~20]。图1给出了当前基于SLM NiTi SMAs开展的整体研究内容与路径。

图1

图1

选区激光熔化(SLM) NiTi形状记忆合金(SMAs)的整体研究内容与路径

Fig.1

Research content and outline of selective laser melting (SLM) NiTi shape memory alloys (SMAs)

2 SLM NiTi SMAs的粉末原材料和成形性

原材料粉末的制备是SLM制备NiTi SMAs的第一步。对于SLM NiTi SMAs而言,原材料粉末分为2类,一类是混合粉末(图2a[21]、2b[21]),另一类是预合金粉末(图2c[22])。此外,对于NiTi预合金粉末的改性也是近年来的研究热点(图2d[23]、2e[23]、2f[24])。研究[17~24]表明,采用NiTi预合金粉末制备的NiTi SMAs的组织均匀性和综合性能优于采用混合粉末制备的NiTi SMAs。由于Ni原子在SLM过程中的损失以及Ni含量对NiTi SMAs相转变温度的影响,研究人员基于粉末改性、原位生成等理念,通过在原始NiTi合金粉末中添加一定量的Ni元素粉末,进而补充Ni元素在SLM过程中的损失,同时精确调控SLM NiTi SMAs的相转变温度。

图2

图2

SLM制备NiTi SMAs的粉末原材料[21~24]

Fig.2

Feedstock powders to fabricate NiTi SMAs by SLM

(a, b) pre-mixed Ni and Ti powders[21]

(c) pre-alloyed Ni50.2Ti49.8 powder[22] (d-f) NiTi powders modified by Ni particles[23,24] (Inset in Fig.2d is particle size distribution of modified powders, and D50 is the average size of modified powders)

良好的成形质量是实现SLM NiTi SMAs应用的首要条件。Haberland等[25]研究发现,高激光能量密度能够有效提高SLM NiTi SMAs的致密度。同时,高激光能量密度也会增加SLM NiTi SMAs的杂质(C、N和O等)含量,当激光能量密度超过300 J/mm3时,SLM NiTi SMAs中的N含量和O含量显著增加[25]。根据ASTM F2063—2018和GB 24627—2009标准(医疗器械和外科植入物用镍-钛形状记忆合金加工材),为保证SLM NiTi SMAs能够用于医疗器械和外科植入物,其C含量需要小于500 × 10-6,N和O的总含量也要小于500 × 10-6,这对SLM制备NiTi SMAs的环境条件和粉末原材料的质量控制提出了严格要求。

对SLM NiTi SMAs而言,其工艺参数的优化要保证其具有高的致密度和低的杂质含量。高致密度是其后续功能特性研究的基础,而低杂质含量则是保证SLM NiTi SMAs能够用于医疗领域的基础。SLM制备NiTi SMAs的主要工艺参数包括:功率(P)、扫描速率(v)、扫描间距(h)和铺粉厚度(t)等,能量密度E = P / (vht)。这些参数的单一优化和整体优化是获得高致密度NiTi SMAs的关键因素,目前研究结果[8,9,23,24,26~52]表明,获得高致密度(˃ 99%) NiTi SMAs的SLM工艺参数具有如下特征:第一类是低功率结合低扫描速率(P < 150 W,v < 700 mm/s);第二类是高功率结合高扫描速率(P ˃ 200 W,v ˃ 800 mm/s) (表1[8,9,23,24,26~57]总结了目前常用的SLM制备NiTi SMAs的工艺参数)。Li等[9]基于低功率和低扫描速率,通过改变并优化SLM工艺参数,获得了无缺陷的SLM NiTi SMAs (图3a[9]),同时,基于较为理想的SLM工艺参数,成功得到了具有负Poisson比特性的NiTi结构。Gu等[26]通过高功率和高扫描速率,基于仿生学考虑,成功制备了高致密度的NiTi SMAs,压缩强度超过3 GPa,断裂伸长率40% (图3b[26])。Xue等[19,20]采用2种不同成分的NiTi合金粉末,即近等原子NiTi (Ni50.1Ti49.9)和富Ni的NiTi (Ni50.8Ti49.2)合金粉末,基于Eagar-Tsai模型将SLM工艺参数与成型质量结合起来,如图3c和d[19]所示,对2种粉末而言,均存在4个区域,即球化区、匙孔形成区、未完全熔化区和成形质量良好区。通过优化工艺参数能够制备出具有良好延展性、形状记忆效应和超弹性的NiTi SMAs。不难发现,基于优化模型获得的SLM工艺参数可以大大减少工艺试错与实验的成本;Eagar-Tsai模型是基于熔池尺寸的预测,计算成本较低,适合进行工业化应用。Xue等[19,20]的结果也表明,不同成分的NiTi合金粉末的成形质量良好区均包含低功率结合低扫描速率区域和高功率结合高扫描速率区域,这也与表1[8,9,23,24,26~57]中的统计结果一致。

表1 常用的SLM制备NiTi SMAs的工艺参数[8,9,23,24,26~57]

Table 1

| Process parameter | P / W | v / (mm·s-1) | h / mm | t / μm | E / (J·mm-3) | Ref. |

|---|---|---|---|---|---|---|

| characteristic | ||||||

| High P with high v | 200-375 | 1000-1400 | 60 | 30 | 79-208 | [26] |

| 250 | 1250 | 120 | 30 | 55.5 | [27-34] | |

| 200 | 1500 | 40-80 | 40 | 42-83 | [35] | |

| 250 | 900-1100 | 60-75 | 30 | 123-126 | [36] | |

| 250 | 1100 | 120 | 30 | 63 | [37] | |

| Low P with low v | 50-120 | 100-300 | 45-150 | 20 | 55-675 | [9] |

| 70 | 105 | 100 | 30 | 222 | [23] | |

| 120 | 250 | 50 | 40 | 240 | [24] | |

| 40 | 160-280 | 50 | 30 | 95-111 | [36] | |

| 60-120 | 150-600 | 75 | 30 | 44-267 | [8,38] | |

| 90 | 600 | 90 | 30 | 56 | [39] | |

| 120 | 500 | 80 | 30 | 110 | [40-43] | |

| 90 | 414 | 120 | 30 | 61 | [44] | |

| 70 | 80-300 | 100 | 30 | 78-292 | [45-47] | |

| 50 | 200-300 | 120 | 30 | 46-69 | [48] | |

| 60 | 300-480 | 110 | 25 | 46-73 | [49,50] | |

| 50, 100 | 125 | 40-240 | 30 | 56-667 | [51] | |

| 110, 120 | 150-350 | 50 | 30 | 210-533 | [52] | |

| Other | 120 | 800 | 110 | 30 | 46 | [53] |

| 50-250 | 250-1250 | 80-120 | 30 | 40-125 | [54] | |

| 75-200 | 400-1200 | 80-120 | 20-40 | 47-87 | [55,56] | |

| 60-240 | 500 | 80 | 30 | 50-200 | [57] |

图3

图3

低功率和低扫描速率条件下能量密度与NiTi SMAs的成形性关系图[9];高功率和高扫描速率条件下得到的NiTi SMAs[26];Eagar-Tsai模型预测的工艺参数与对应的成形质量图[19]

Fig.3

Variation of formability in SLM NiTi SMAs with different energy densities (low power and low scanning speed) (a)[9], SLM NiTi SMAs with different energy densities (high power and high scanning speed) (b)[26], diagrams between the process parameters of SLM Ni50.8Ti49.2 (c)[19] and Ni50.1Ti49.9 (d)[19] SMAs and formability predicted by Eagle-Tsai model (Pentagram shape in orange is SLM NiTi SMAs fabricated with low power and low scanning speed, pentagram shape in red is SLM NiTi SMAs fabricated with high power and high scanning speed)

与传统制备NiTi SMAs工艺不同的是,在SLM制备NiTi SMAs过程中,一方面可能会出现成形缺陷,如球化、匙孔和未完全熔合等微缺陷,以及分层、裂纹和翘曲等宏观缺陷[9,22,54,55];另一方面由于常用激光的能量密度呈Gaussian分布,形成熔池时,温度场分布不均匀,会导致熔融粉末元素损失不均匀,进而导致基体元素分布不均匀,这会显著影响SLM NiTi SMAs的相转变行为[24,57~59]。图4a~d[19]给出了SLM NiTi SMAs中通常出现的几种缺陷,图4a[19]表明,P = 200 W、v = 0.83 m/s条件下,熔池轨迹稳定,无明显缺陷,是较为理想的成形条件;图4b[19]表明,P = 240 W、v = 0.08 m/s条件下,由于扫描速率较小,激光能量密度过高,导致熔化过程中元素挥发相对严重,形成蒸气,快速凝固的金属液体使得部分元素蒸气无法逸出,进而形成了匙孔;图4c[19]表明,P = 160 W、v = 1.33 m/s条件下,由于能量密度过小,导致金属粉末熔化不完全,出现熔池轨迹断续的现象;图4d[19]表明,P = 200 W、v = 2.08 m/s条件下,熔池轨迹出现球化现象,这主要是由于该工艺参数条件下,形成的熔池与接触的基板之间的润湿性较差导致的。此外,Lu等[22]指出在SLM制备NiTi SMAs过程中,高的激光能量密度并不能完全保证获得高致密的NiTi SMAs。图4e~h[22]表明,在激光能量密度为208和190 J/mm3时,SLM NiTi SMAs上表面形成了许多孔洞,然而,当能量密度较低时(194和156 J/mm3),上表面没有孔洞形成。因此,在SLM制备NiTi SMAs的过程中需要考虑工艺参数优化,避免成形缺陷的产生,同时需要指出的是,一定的后处理(热处理、热等静压等)是改善SLM NiTi SMAs功能稳定性的有效方法[29,35]。总体说来,SLM制备NiTi合金的工艺参数探索仍旧是目前的研究热点,目前的研究结果并没有得到单一的最优工艺参数,工艺参数呈现出2种趋势,即低功率结合低扫描速率和高功率结合高扫描速率,这一现象的出现可能与采用的成形设备有关,此外,这2类工艺参数条件下熔池的相对稳定可能是成型质量良好的主要原因,后续需要基于大量的熔池模拟研究进一步分析。

图4

3 SLM NiTi SMAs的相转变行为

相转变行为直接决定了NiTi SMAs的服役温度和工作状态。Wang等[10]和Speirs等[60]采用Ni50.6Ti49.4 SMA粉末,在铺粉厚度(30 μm)和能量密度(100 J/mm3)大体相同的前提下,改变功率、扫描速率和扫描间距,研究了相转变行为与SLM工艺参数的关系,结果发现相转变温度随着SLM工艺参数的变化而发生显著变化,这为调控SLM NiTi合金的相转变温度提供了一种有效途径。进一步地,Wang等[10]的研究也发现固溶处理(1000℃、2 h)可以减小所有SLM Ni50.6Ti49.4的相转变温度间隔(Af~As和Ms~Mf,其中Af为奥氏体转变结束温度,As为奥氏体转变开始温度,Ms为马氏体转变开始温度,Mf为马氏体转变结束温度),但马氏体相转变峰值温度(Mp)基本不受固溶处理的影响(图5a和b[10])。基于此,认为SLM NiTi合金相转变温度的变化可能不是由于合金中沉淀物或残余内应力的存在引起的,而是由基体中Ni / Ti原子比的改变引起的,导致基体中Ni / Ti原子比变化的原因有Ni原子蒸发和杂质O原子的引入,前者会降低Ni / Ti原子比,后者会导致形成Ti4Ni2O x,使得Ni / Ti原子比增加。Wang等[15]也研究了功率单调变化对SLM Ni50.6Ti49.4合金相转变行为的影响,结果表明,随着功率增加,相转变峰值温度增加,Ms保持不变,相转变峰变得更加尖锐(图5c[15])。Cao等[35]研究了扫描间距和热处理对SLM Ni51.4Ti48.6合金相变温度的影响(图5d~f[35])。结果表明,打印态和固溶处理Ni51.4Ti48.6合金的相转变温度随着扫描间距增加而显著降低,在冷却和加热过程中都表现出一步相转变。固溶处理后Ni51.4Ti48.6合金的相转变温度间隔(Af~As和Ms~Mf)更窄,相变峰更加尖锐。时效处理后,Ni51.4Ti48.6合金在冷却过程中表现出了两步相转变行为,在加热过程中则表现出一步相转变,热处理过程中基体析出的Ni4Ti3沉淀相是其冷却过程中出现两步相转变行为的原因。对于时效处理Ni51.4Ti48.6合金,扫描间距变化时,Af保持不变。

图5

图5

相同能量密度(100 J/mm3)下SLM Ni50.6Ti49.4合金的制备态及其在1000℃固溶处理2 h后的DSC曲线[10];功率变化时SLM Ni50.6Ti49.4合金的DSC曲线[15];不同扫描间距下打印态、固溶处理态和时效态Ni51.4Ti48.6合金的DSC曲线[35]

Fig.5

DSC curves of SLM Ni50.6Ti49.4 with same energy density for as-fabricated (a)[10] and solution treated at 1000oC for 2 h (b)[10]; DSC curves of SLM Ni50.6Ti49.4 with altered laser power (c)[15]; DSC curves of as-fabricated (d)[35], solution treated (e)[35], and aged (f)[35] Ni51.4Ti48.6 fabricated with different hatches

从上述研究结果可知,导致SLM NiTi SMAs相转变温度变化的因素有很多,包括不同工艺参数导致的基体中Ni / Ti原子比的变化、杂质O元素的引入、基体中的残余应力、沉淀相的析出等,同时,后续热处理也是一个调控SLM NiTi SMAs相转变温度的高效方法,这些研究结果为更加多元、更加可控的SLM NiTi SMAs的制备提供了可能。

4 SLM NiTi SMAs的微观结构与性能

4.1 SLM NiTi SMAs的微观结构

SLM NiTi SMAs的微观结构直接影响其功能特性。由于SLM成形过程中,存在着局部区域的快速升温熔化与凝固,随后的逐道次、逐层成形过程也会导致复杂热历史的存在,这都会导致SLM工艺制备的NiTi SMAs的微观结构与传统工艺制备的NiTi SMAs存在明显区别。光学显微镜(OM)研究结果[35]表明,采用不同扫描间距(40~80 μm)制备的Ni51.4Ti48.6合金中没有明显孔隙,相对致密度高(˃ 99%)。在SLM Ni51.4Ti48.6合金的侧面观察到大量柱状晶,这是由于在SLM逐层熔化凝固的过程中,存在层与层之间的部分重熔现象,熔池内部晶粒的定向生长和“外延生长”共同作用导致的。同时,这也表明扫描间距变化对SLM NiTi SMAs的微观结构存在显著影响。进一步地,Saedi等[61]研究了不同扫描速率、不同功率条件下SLM Ni50.8Ti49.2合金的微观结构变化,结果发现SLM工艺参数直接影响晶粒的尺寸和形态,不同功率和扫描速率的组合会获得完全不同的晶粒形貌[61]。

SLM过程中,柱状晶的定向生长和“外延生长”,以及B2母相在凝固过程中[100]B2的择优生长,会导致SLM NiTi SMAs中普遍存在织构。Saedi等[61]通过X射线衍射(XRD)表征了不同工艺参数下SLM Ni50.8Ti49.2合金的织构强度,从结果可知SLM Ni50.8Ti49.2合金在[001]方向上都具有较强的织构,在低功率和低速率下(100 W和125 mm/s) NiTi合金的织构强度为4.3,而高功率和高速率下(250 W和1500 mm/s)的织构强度为2.8。可见,工艺参数显著影响SLM NiTi SMAs的织构强度。进一步地,Shayesteh Moghaddam等[62]在高功率和高速率(250 W和1500 mm/s)条件下,通过改变扫描间距实现了对SLM Ni50.8Ti49.2合金织构强度的有效调控,制备的Ni50.8Ti49.2合金在较低的扫描间距下(80 μm)会获得更好的超弹性。采用80 µm扫描间距制备的Ni50.8Ti49.2合金表现出良好的超弹性响应,在第一次循环压缩中回复应变为5.62%,回复率为98%;在10 cyc循环压缩结束后,其稳定的回复应变为5.2%。研究结果也证实改变扫描间距可以有效调控晶粒尺寸、形状和取向,从而调整SLM NiTi SMAs的超弹性。同时,由于透射电镜(TEM)分析表明基体中不存在Ni4Ti3沉淀相,因此在80 µm扫描间距条件下获得的强[001]织构是使SLM Ni50.8Ti49.2合金具有良好超弹性的主要原因[62]。

从上述结果可以发现,SLM NiTi SMAs中织构的存在是导致其性能提高的一个重要因素,同时也有大量的研究表明NiTi SMAs基体中存在的位错和沉淀相等也是其性能变化的影响因素。图6[16]显示了采用TEM获得的不同扫描间距下SLM Ni50.9Ti49.1合金在熔池不同区域的亚结构、沉淀相和位错。在晶粒内部存在大量尺寸为200~400 nm的亚结构,其边界分布着大量的纳米级Ti2Ni沉淀物,尺寸为10~30 nm。图6b、d和f[16]是旋转晶带轴后得到的能够显示位错的TEM像。可以发现,35 μm扫描间距制备的Ni50.9Ti49.1合金位错密度远低于120 μm扫描间距制备的Ni50.9Ti49.1合金的位错密度。相对小的扫描间距意味着NiTi SMAs要经受更多的加热和重熔循环,导致基体位错密度的降低。120 μm扫描间距制备的Ni50.9Ti49.1合金熔池边缘的位错密度也略低于中心样品,这是由于在熔池的边缘区域发生了重熔,导致位错密度有所降低。除上述亚结构、沉淀相和位错外,还观察到了另外一种尺寸< 5 nm的沉淀物,这种更加细小的纳米沉淀物在2种不同扫描间距制备的Ni50.9Ti49.1合金中均大量存在,由于亚结构的边界处存在大量的Ti2Ni沉淀相,推测这些更加细小的纳米沉淀物是富Ni成分,很可能是Ni4Ti3,但这一结果仍有待进一步证实。

图6

图6

不同扫描间距下SLM Ni50.9Ti49.1合金在熔池不同区域的亚结构、沉淀相和位错的TEM像[16]

Fig.6

TEM images of SLM Ni50.9Ti49.1 fabricated at different hatches showing subgrain structure and nanoprecipitates (a, c, e) and dislocations (b, d, f)[16]

(a, b) center of the laser track at 35 µm hatch

(c, d) center of the laser track at 120 µm hatch

(e, f) edge of the laser track at 120 µm hatch

从物理冶金学过程上来说,SLM是一个有序构建过程,其中金属粉末颗粒快速熔化,随后逐道次、逐层快速凝固获得具有特定设计构型的金属构件。Lu等[23]指出这些有序熔池和循环热历史的存在通常会导致在3个相邻熔池之间形成3个特征区:热影响区(heat-affected zone,HAZ)、过渡区(transition zone,TZ)和细小胞状晶区(cellular-grain zone,CGZ)[23],3个区域定义成组成基体的一个基本单元,称为功能基元。具体而言,Lu等[23]基于纳米镍粒子改性的Ni50.6Ti49.4合金粉末,采用SLM工艺获得了具有有序功能基元的Ni50.6Ti49.4合金。结果表明,HAZ、TZ 和 CGZ这3个区域具有不同的晶粒尺寸和沉淀相的不均匀分布。这3个特征区的协同作用导致SLM Ni50.6Ti49.4合金在循环压缩过程中获得了相对稳定的回复应变和较小的滞后区域面积。这些结果为通过原始粉末改性调控SLM NiTi合金的超弹性功能特性提供了新的可能途径,也可以为SLM工艺调控NiTi合金的微观结构提供一种新的策略。

后续热处理也是调控SLM NiTi SMAs微观结构和功能特性的重要途径。富Ni的NiTi合金在时效过程中通常会析出Ni4Ti3沉淀相,且其析出位置、尺寸等对相转变行为和功能特性等存在显著影响。Lu等[47]对SLM Ni50.4Ti49.6合金进行固溶和不同温度的时效处理后,发现球状和透镜状的Ni4Ti3纳米沉淀相在基体中形成(图7a~d[47]),球状Ni4Ti3纳米沉淀相的尺寸约为10 nm,透镜状Ni4Ti3纳米沉淀相的长度则大于100 nm,这些纳米Ni4Ti3沉淀相周围会形成一定的应力/应变场,对SLM Ni50.4Ti49.6合金的超弹性行为产生不同的影响。Cao等[35]对固溶时效处理的Ni51.4Ti48.6合金进行了扫描透射电镜(STEM)观察,获得的高角度环形暗场扫描TEM像表明透镜状Ni4Ti3纳米沉淀相均匀分散在基体中,这些Ni4Ti3沉淀相的尺寸小于80 nm (图7e[35])。Xue等[19]通过STEM和选区电子衍射(SAED)分析了经过时效处理的SLM NiTi合金的微观结构和沉淀相析出情况(图7f~h[19]),与Cao等[35]观察到的结果不同的是,Xue等[19]在打印态NiTi合金中观察到了尺寸较大的纳米氧化物颗粒(Ti4Ni2O x ),时效处理后,基体中存在R相和尺寸范围为25~35 nm的Ni4Ti3沉淀相。

图7

图7

热处理后SLM NiTi SMAs的TEM像、STEM像和SAED花样[19,35,47]

Fig.7

TEM images, STEM images, and selected area electron diffraction pattern of SLM NiTi alloys after heat treatment

(a-d) TEM images of SLM Ni50.4Ti49.6 after solution treatment (at 1000oC for 1 h) and ageing (at 350oC/450oC for 1 h)[47]

(e) STEM-HAADF image of SLM Ni51.4Ti48.6 after solution treatment (at 950oC for 12 h) and ageing (at 450oC for 5 h)[35]

(f-h) STEM-HAADF image and selected area electron diffraction pattern of SLM Ni51.1Ti48.9 after ageing (at 400oC for 1 h)[19]

从上述可以得到,SLM制备的NiTi SMAs具有特殊的微观结构(柱状晶、织构、亚结构等),这些微观结构的形成与SLM工艺过程中高的升温速率、快的冷却速率和复杂的热历史有关,其形成的具体的原因有待进一步研究。同时,研究也证实后续热处理能够在SLM制备的NiTi SMAs基体中引入纳米尺度的沉淀相,进而提高其功能特性,这为后续研究指明了一个新的方向。

4.2 SLM NiTi SMAs的力学性能

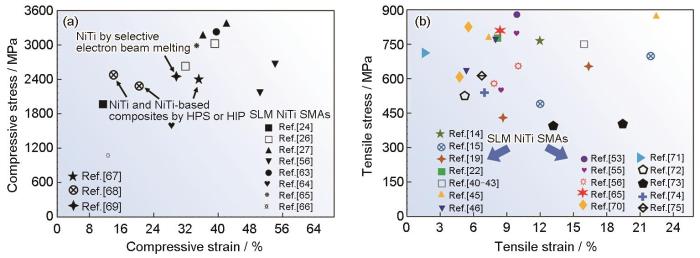

图8

图8

压缩条件和拉伸条件下NiTi SMAs的力学性能总结[14,15,19,24,26,27,40~43,45,46,53,55,56,63~75]

Fig.8

Summaries of mechanical properties of NiTi SMAs

(a) NiTi SMAs by SLM[24,26,27,56,63-66], NiTi and NiTi-based composites by hot pressed sintering (HPS) and hot isostatic pressing (HIP)[67,68], and NiTi SMAs by selective electron beam melting[69] under compression

(b) NiTi SMAs by SLM under tension[14,15,19,22,40-43,45,46,53,55,56,65,70-75]

4.3 SLM NiTi SMAs的热机械性能

Saedi等[61]比较了功率和扫描速率不同、能量密度相同(55.5 J/mm3)时,Ni50.8Ti49.2合金的压缩超弹性行为(图9a[61]),结果表明Ni50.8Ti49.2合金发生应力诱导马氏体相变的临界应力、相变平台和应力-应变曲线围成的面积表现出不同的特征。就SLM NiTi SMAs的微观结构和机械响应而言,相同的能量水平不一定会制备出性能相同的零件,因此找到最佳的制备NiTi合金的工艺窗口,需要关注工艺参数的组合。为探究单一工艺参数对SLM NiTi SMAs压缩超弹性行为的影响,Shayesteh Moghaddam等[62]通过改变扫描间距(80~180 μm),探究了其对压缩超弹性行为的影响,研究发现随着扫描间距的增加,压缩超弹性回复应变和回复率逐渐降低,当扫描间距为160 µm 时,压缩超弹性回复应变和回复率分别降低至4.35%和83%;在扫描间距为80 μm时,Ni50.8Ti49.2合金表现出最好的压缩超弹性回复应变和回复率,分别为5.62%和98% (图9b[62])。此外,在扫描间距范围为80~160 µm时,应力诱导马氏体相转变的临界应力没有显著差异;在扫描间距达到180 µm时,SLM Ni50.8Ti49.2合金的应力诱导马氏体相转变的临界应力明显降低,这是由于在此扫描间距条件下相邻的激光轨迹没有完全熔合,形成了孔隙,导致应力诱导马氏体相转变临界应力降低。针对SLM Ni50.8Ti49.2合金的循环压缩超弹性行为,Saedi等[61]比较了低功率结合低速率和高功率结合高速率2类工艺参数对其的影响,发现低功率结合低速率条件下获得的压缩超弹性回复应变和回复率远高于高功率结合高速率制备的NiTi合金(图9c~f[62])。

图9

图9

相同能量密度[61]和不同扫描间距[62]条件下打印态SLM Ni50.8Ti49.2合金的压缩超弹性行为;不同功率和速率下打印态SLM Ni50.8Ti49.2合金的循环压缩超弹性行为[62]

Fig.9

Compression superelastic behaviors and cyclic superelastic behaviers of as-fabricated SLM NiTi SMAs

(a) compression superelastic behaviors of Ni50.8Ti49.2 under the same energy density (55.5 J/mm3)[61] (Af—austenite transformation finish temperature)

(b) compression superelastic behaviors of Ni50.8Ti49.2 under different laser scanning hatches[62] (c-f) cyclic superelastic behaviors of Ni50.8Ti49.2 under different laser powers and scanning speeds[62]

Saedi等[29]研究了不同状态SLM Ni50.8Ti49.2合金的压缩超弹性行为,研究结果显示固溶处理可以提高超弹性回复应变和回复率,同时固溶和350℃不同时间(5、10和18 h)时效处理后,在首次加载到1000 MPa时,卸载之后应变完全回复,表明时效态样品中应力诱导马氏体相转变在第一次加载过程中是完全可逆的,这一良好的超弹性与时效过程中析出的沉淀相有关;当时效温度达到450℃时,超弹性回复应变和回复率相对350℃时效显著降低,这与450℃时效处理时,Ni50.8Ti49.2合金基体中的沉淀相快速长大,导致对基体的增强作用减少有关(图10a[29])。除此之外,Saedi等[79]考虑到SLM NiTi SMAs的生物应用可能性,对打印态的SLM Ni50.8Ti49.2合金直接进行350℃时效处理1 h,在人体温度条件下(37℃)对其进行超弹性表征,发现直接时效处理可以有效提高SLM Ni50.8Ti49.2合金的超弹性回复应变和回复率,回复应变达到4% (图10b[79])。这些研究结果都表明热处理可有效调控SLM NiTi SMAs的形状记忆效应和超弹性。Cao等[35]研究了SLM Ni51.4Ti48.6合金的压缩超弹性性能(图10c~f[35])。对于打印态和固溶处理态Ni51.4Ti48.6合金,应变不能完全回复,存在明显残余应变,时效处理表现出完美的超弹性回复,回复应变为4.6%。循环压缩超弹性测试表明,对于打印态和固溶处理态Ni51.4Ti48.6合金,残余应变积累量随着循环次数的增加而减小,最后逐步稳定(图10f[35])。时效态Ni51.4Ti48.6合金在10 cyc循环压缩超弹性测试期间表现出稳定的超弹性响应和完全的回复应变,应力诱导马氏体相转变的临界应力和应力滞后在循环过程中也没有变化,在循环过程中应力滞后稳定在140 MPa,这一低的应力滞后有利于获得高的能量转换效率和良好的功能稳定性。

图10

图10

SLM NiTi SMAs的压缩超弹性[29,35,79]

Fig.10

Compressive superelasticity of SLM NiTi SMAs

(a) Ni50.8Ti49.2 in as-fabricated and different heat-treated states[29]

(b) superelasticity of Ni50.8Ti49.2 in heat-treated at 350oC for 1 h[79]

(c) single superelasticity of Ni51.4Ti48.6 in as-fabricated, solid solution, and ageing states[35] (σ—stress, ε—strain) (d-f) superelasticities of Ni51.4Ti48.6 in as-fabricated, solid solution, and ageing states during 10 cyc[35]

不难发现,上述结果都是基于压缩过程对SLM NiTi SMAs的功能和性能进行评估,这是因为SLM NiTi SMAs的拉伸性能对其内部的缺陷(微裂纹、孔洞等)十分敏感,因此得到拉伸性能良好的SLM NiTi SMAs存在一定的困难,近年来部分研究者对SLM NiTi SMAs的拉伸性能进行了探索。Shayesteh Moghaddam等[75]通过不同扫描策略和不同加载方向,评估了SLM Ni50.1Ti49.9合金的拉伸性能各向异性。结果表明,建造方向和扫描策略会显著影响SLM Ni50.1Ti49.9合金的微观结构,从而影响其断裂应力、塑性、形状记忆效应和功能稳定性等。研究者采用与x轴成± 90°的交替扫描策略在水平方向上制备的Ni50.1Ti49.9合金具有最高的抗拉强度(606 MPa)和伸长率(6.8%),同时,其在4次形状记忆效应循环后的回复应变为3.54%。Wang等[15]研究了不同功率条件下SLM Ni50.6Ti49.4合金的单向拉伸性能,室温下基体以奥氏体相为主,获得了良好的力学性能(断裂伸长率> 10%,断裂强度> 550 MPa,图11a[15])。Wang等[15]的研究也表明,SLM工艺可以作为一种有效改变NiTi SMAs基体中Ni / Ti原子比的方法,NiTi SMAs的马氏体相转变温度随着扫描速率、扫描间距或功率的单调变化而单调变化,成分分析结果表明,不同SLM工艺条件导致的Ni损失量不同是导致其相转变温度变化的主要原因。Xiong等[43]通过优化层间扫描长度和层间扫描方向,成功制备出了室温下马氏体相为主的、具有非定向柱状晶粒的无缺陷Ni50.4Ti49.6合金,其拉伸断裂应变达到15.6%,强度超过700 MPa (图11b[43])。这些研究结果为通过调控SLM的工艺参数进而调控NiTi合金的相转变温度和力学性能提供了依据。同时,从上述工作可以看出,SLM NiTi SMAs的单向拉伸性能相对传统工艺制备的NiTi SMAs有待进一步提高。

图11

图11

SLM NiTi SMAs的单向拉伸力学性能和拉伸超弹性[15,19,43,47,80]

Fig.11

Uniaxial tensile mechanical properties and tensile superelasticity of SLM NiTi SMAs

(a) uniaxial tensile mechanical properties of SLM Ni50.6Ti49.4 (at austenite state) at different laser powers[15]

(b) uniaxial tensile mechanical properties of SLM Ni50.4Ti49.6 at martensite state[43] (c, d) tensile driving behaviors at different laser scanning hatches[80] (εact—actuation strain, εirr—irrecoverable strain) (e, f) cyclic tensile superelasticities of SLM Ni50.8Ti49.2 with and without heat treatment[19] (T—temperature) (g, h) cyclic tensile superelasticities of SLM Ni50.4Ti49.6 with different heat treatments[47]

Sam等[80]表征了不同扫描间距条件下,SLM Ni50.9Ti49.1 SMAs的拉伸形状记忆驱动行为,获得的最大驱动应变约为4.5%,此时对应的驱动力为200 MPa,不可回复应变约为1% (图11c和d[80])。Xue等[19]研究了SLM Ni50.8Ti49.2合金在热处理前后的拉伸超弹性行为及其差异(图11e和f[19])。在400℃时效1 h后,其超弹性回复应变优于打印态Ni50.8Ti49.2合金,但没有表现出完美的拉伸超弹性,这可能与基体中形成的Ni4Ti3的尺寸、数量和分布情况有关。对相同热处理条件下、相同成分的块体Ni50.8Ti49.2合金进行拉伸超弹性实验,发现合金表现出近乎完美的超弹性回复应变,回复应变高达7%。Lu等[47]通过不同时效处理,在SLM Ni50.4Ti49.6合金中获得了不同的超弹性回复应变和回复率,在10 cyc循环拉伸加载和卸载后,回复应变为2.25%~2.31% (图11g和h[47])。

表2[23,24,26,29,35,51,61,62,70,79,82,83]和3[14,19,20,47,49,56,72]分别总结了近年来压缩和拉伸条件下SLM NiTi SMAs的超弹性回复应变。可知,目前大量研究是基于压缩变形来研究SLM NiTi SMAs的超弹性回复应变的,回复应变大多集中在3%~5%,最高回复应变可达9.4%[24];拉伸条件下SLM NiTi SMAs的超弹性研究表明回复应变集中在2%~4%。相对传统轧制+时效NiTi合金在加载卸载后接近100%回复率和超过6%的回复应变[81]而言,可以发现SLM NiTi SMAs在加载卸载后的回复率和回复应变相对较低,有待进一步提高,因此探索得到提高SLM NiTi SMAs的回复应变和形状回复稳定性的途径是实现其应用的重要条件。

表2 压缩条件下SLM NiTi SMAs的超弹性回复应变总结[23,24,26,29,35,51,61,62,70,79,82,83]

Table 2

| NiTi (atomic | Feedstock | Equipment type | Compressive | Recovery | Cycle | Ref. |

|---|---|---|---|---|---|---|

| fraction / %) | stress | strain | number | |||

| MPa | % | |||||

| Ni49.4Ti50.6 + Ni nanoparticles | Pre-alloyed powder | Concept Laser M2 Cusing | 800 | 3.52-3.54 | 13 | [23] |

| Ni53Ti47 | Pre-alloyed NiTi powder (15-53 μm) + | Eplus-M100T | 700-1800 | 4.0-9.4 | 4 | [24] |

| coated Ni powder (1.5 μm) | ||||||

| Ni50.6Ti49.4 | Pre-alloyed powder (15-53 μm) | An in-house SLM | 800 | 5.6-6.7 | 10 | [26] |

| machine (SLM-150) | ||||||

| Ni50.8Ti49.2 | Pre-alloyed powder (25-75 μm) | 3D Systems Phenix | 1000 | 2.64-4.20 | 10 | [29] |

| Ni51.4Ti48.6 | Pre-alloyed powder (30-45 μm) | SLM-YZ250 | 600-850 | 2.2-4.6 | 10 | [35] |

| Ni50.8Ti49.2 | Pre-alloyed powder (D50 = 50 µm) | 3D Systems Phenix PXM | 800 | 2.23-4.56 | 10 | [51] |

| Ni50.8Ti49.2 | Pre-alloyed powder (25-75 μm) | 3D Systems Phenix | 800 | 2.29-5.50 | 10 | [61] |

| Ni50.8Ti49.2 | Pre-alloyed powder (25-75 μm) | 3D Systems Phenix | 600 | 3.40-5.20 | 10 | [62] |

| Ni50.7Ti49.3 | Pre-alloyed powder (D50 = 37 μm) | Solutions 280 | 700 | 3.7-7.4 | 10 | [70] |

| Ni50.8Ti49.2 | Pre-alloyed powder (D50 = 50 μm) | 3D Systems Phenix | 280-1750 | 1.5-5.5 | 4 | [79] |

| Ni50.8Ti49.2 | Pre-alloyed powder | Renishaw AM400 | 500/900 | 5.5/6 | 1 | [82] |

| Ni50.8Ti49.2 | Pre-alloyed powder (25-75 μm) | 3D Systems Phenix PXM | 300 | 3.0-3.4 | 1 | [83] |

表3 拉伸条件下SLM NiTi SMAs的超弹性回复应变总结[14,19,20,47,49,56,72]

Table 3

| NiTi (atomic | Feedstock | Equipment type | Tensile | Recovery | Cycle number | Ref. |

|---|---|---|---|---|---|---|

| fraction / %) | stress | strain | ||||

| MPa | % | |||||

| NiTi | Pre-alloyed powder | Eplus-M100T | 500-700 | 1.41-2.14 | 10 | [14] |

| (15-53 μm) | ||||||

| Ni51.1Ti48.9 and | Pre-alloyed powder | 3D Systems ProX DMP 200 | 300-550 | 1.0-4.5 | 1 and incremental loading | [19] |

| Ni50.3Ti49.7 | (D50 = 29 μm) | |||||

| Ni51.2Ti48.8 | Pre-alloyed powder | 3D Systems ProX DMP 200 | 300-400 | 1-6 | Incremental loading | [20] |

| Ni50.4Ti49.6 | Pre-alloyed powder | Concept Laser M2 Cusing | 450 | 0.77-2.31 | 20 | [47] |

| (D50 = 37 μm) | ||||||

| Ni50.92Ti49.08 | Pre-alloyed powder | Concept Laser Mlab-R | 100-500 | 0.26-2.25 | Incremental loading | [49] |

| (D50 = 40.6 μm) | ||||||

| Ni50.8Ti49.2 | Pre-alloyed powder | BLT S210 | 400/500 | 2/4 | 1 | [56] |

| (15-53 μm) | ||||||

| Ni50-51Ti49-50 | Pre-alloyed powder | Renishaw AM400 | 300-550 | 2-4 | 8 | [72] |

可以发现,具有相同理论Ni含量、相同热处理状态的SLM NiTi合金和传统工艺制备的NiTi合金的超弹性行为存在明显差异,具体原因如下:(1) 对于打印态SLM NiTi合金而言,其晶粒尺寸多为微米级,相对传统工艺制备的纳米晶NiTi合金,晶粒尺寸显著增大,严重减弱了其功能特性的稳定性;(2) 打印态SLM NiTi合金的晶粒尺寸存在不均匀的分布,基体存在热应力和元素分布不均匀的现象,在循环加载过程中,部分区域容易形成微裂纹等缺陷,削弱功能稳定性;(3) 尽管SLM NiTi合金和传统工艺制备的NiTi合金理论上具有相同的Ni含量,但是SLM过程中Ni元素蒸发导致其基体中Ni原子含量有所减少,进而导致其基体中不能形成与块状NiTi合金基体中相当的Ni4Ti3沉淀相,以增强基体,提高超弹性回复应变。在SLM过程中,已经凝固的相邻道次和底层会被重新加热,类似一个快速热处理过程。通过降低扫描间距,可以实现更长时间的时效热处理,延长形成Ni4Ti3沉淀相的过程[23]。然而,降低扫描间距也会导致能量密度增加,熔池温度升高,更多的Ni原子会蒸发。因此,为了获得更好的超弹性,需要使用具有高的Ni / Ti原子比的NiTi合金粉末,以保证能够在样品中形成足够数量的Ni4Ti3沉淀相。总体而言,目前大量的研究聚焦于SLM工艺参数对NiTi合金压缩性能的影响,也尝试通过热处理提高NiTi合金的压缩功能特性,同时,对SLM NiTi合金的拉伸性能进行了初步研究。整体来说,目前SLM NiTi合金的功能特性相对传统工艺制备的NiTi合金仍有待提高。

5 SLM多孔NiTi SMAs及其生物相容性探索

鉴于其优良的生物相容性和耐腐蚀性,加之独特的热机械性能(超弹性和形状记忆效应),NiTi SMAs也是一种理想的生物医用材料[86]。NiTi SMAs介入支架可通过很小的输送装置进入狭窄的人体病变部位,撤除输送装置后,支架将自动恢复到预定的形状而支撑病变部位。图12a给出了不锈钢、NiTi SMAs、人体骨骼与肌腱的性能对比图。可以发现,人体骨骼在加载条件下的响应情况与NiTi SMAs的超弹性响应十分类似,这为NiTi SMAs作为人体骨骼植入件提供了基础条件。致密NiTi SMAs的弹性模量范围为20~60 GPa,低于传统的生物医用金属(CP-Ti、Ti6Al4V和β型钛合金等)的弹性模量(80~120 GPa[87]),但仍高于人体硬组织/骨骼的弹性模量(3.2~20 GPa[88]),实体NiTi SMAs植入后仍可能会导致“应力屏蔽”现象的出现。多孔结构的出现为进一步降低植入件的弹性模量提供了可能,多孔NiTi合金具有与人体骨骼相当的弹性模量,生物相容性良好,孔洞有利于人体体液营养成分传输,使得植入后愈合效果更好。另外,多孔NiTi SMAs具有质量轻、比表面积大等优点,是骨科植入物的理想原材料,被广泛关注与研究[30,89]。本节总结了SLM多孔NiTi SMAs及其生物相容性探索的最新研究结果。

图12

图12

NiTi、不锈钢和人体组织的性能对比图;多孔结构的模型图以及SLM制备的多孔NiTi SMAs[37,38,63,90]

Fig.12

Comparisons of mechanical properties of NiTi SMAs, stainless steel, and human tissues (a), isometric view of the CAD model and image of SLM porous Ni45.2Ti54.8 (b)[38], CAD models with three different pore sizes and image of SLM porous Ni50.4Ti49.6 (c)[63], cellular lattice structure and image of SLM porous Ni50.6Ti49.4 (d)[90], and CAD models and image of the SLM Ni50.3Ti49.7 gyroid cellular structure (e) (U-GCS: uniform gyroid cellular structure, Y-GCS: graded gyroid structure with the density gradient along y-axis, Z-GCS: graded gyroid structure with density along gradient z-axis)[37]

图12b~e[37,38,63,90]为不同多孔结构的模型图和SLM制备的多孔NiTi SMAs形貌图。Tan等[38]基于相同的多孔模型,采用不同的工艺参数制备得到多个多孔NiTi SMAs (图12b[38]),通过成型质量、缺陷形成、几何精度、微观结构和杂质含量等的综合分析,得到了较为合适的制备多孔NiTi SMAs的工艺参数(能量密度60~90 J/mm3,激光功率60~75 W);Lu等[63]基于相同的多孔CAD模型,通过调节孔隙和孔径的尺寸,通过SLM工艺制备出不同孔隙率的NiTi SMAs (图12c[63]);Yang等[90]通过调整多孔的杆径(0.6、0.4和0.2 mm),得到了具有不同超弹性行为的多孔NiTi结构(图12d[90])。Chen等[37]通过设计得到3种不同多孔结构(均匀孔隙、沿Y轴梯度孔隙、沿Z轴梯度孔隙),通过SLM工艺制备得到了整体质量良好的3种多孔NiTi结构(图12e[37])。这些结果都表明,SLM多孔NiTi结构的多样性包括孔型设计多样性、孔隙率多样性、制备工艺参数的多样性等,这为SLM多孔NiTi结构提供了很大的自由设计度、为其个性化定制提供了可能。然而,多孔NiTi结构的弹性模量和性能需要与骨组织相匹配,为了实现SLM多孔NiTi植入物的临床应用,需要根据临床需求来设计植入物,通过结构设计和制造工艺来优化植入物性能,并对其性能进行准确评估。

需要指出的是,不同的SLM多孔 NiTi SMAs会表现出显著不同的力学性能和功能特性。图13a[63]是图12c[63]中不同多孔NiTi SMAs在室温下的单向压缩应力-应变曲线。可以看到,900和835 μm孔径的多孔NiTi的压缩断裂强度和断裂应变比较接近,而618 μm孔径多孔 NiTi表现出最低的抗压强度,为262 MPa,这是由于其杆径最小,对塑性变形的发生和随后断裂的抵抗力最低导致的。图13a[63]中3种不同孔径多孔 NiTi的压缩断裂强度均大于人体骨骼的最大强度(< 200 MPa),可以满足人体植入件的强度要求。图13b~d[37]是3种不同多孔结构的压缩应力-应变曲线,压缩曲线表明相同结构的多孔NiTi SMAs的力学性能稳定,证实了SLM工艺制备多孔NiTi SMAs的质量稳定性,3种多孔NiTi的屈服强度在15.8~21.6 MPa之间,弹性模量在5.2~6.1 GPa之间,符合人体小梁骨的机械性能要求。图13e和f[63]是多孔NiTi支架的形状记忆性能曲线,900和618 μm孔径的多孔NiTi中的可回复应变和形状回复率分别为5.10%和91.4%、4.29%和65.2%。加载过程中,不同孔径NiTi支架应力分布状态的差异是导致回复应变和形状回复率差异的主要原因[91]。对于具有相同杆径的多孔结构,回复应变随着扫描速率的增加而减小,然后随着扫描速率的进一步增加而增大(图13g和h[90])。在以200 mm/s扫描速率制备的支柱厚度为0.2 mm的多孔结构中,获得了10%的最大回复应变。

图13

图13

不同多孔NiTi SMAs的力学性能与功能特性[37,63,90]

Fig.13

Mechanical properties of porous NiTi SMAs with different pore sizes (a)[63], mechanical properties of porous NiTi SMAs with different structures (b-d)[37], shape memory effect of porous NiTi SMAs with different pore sizes (εrec—recoverable strain) (e, f)[63], and superelasticities of porous NiTi SMAs with different strut thicknesses (g, h)[90]

为探究孔径对细胞黏附和生长的影响,Lu等[63]对MC3T3-E1细胞与NiTi合金之间的相互作用进行了研究。图14a[63]是MC3T3-E1细胞在多孔NiTi上经过1 d培养后的荧光图像。可以发现,体外培养1 d后,MC3T3-E1细胞均存活并且增殖,这表明SLM制备的多孔NiTi具有良好的生物相容性。同时,如图14a[63]中的虚线圆圈所示,可以看到MC3T3-E1细胞的生长桥接了多孔NiTi的孔隙,图14a中插图[63]是MC3T3-E1细胞桥接孔的形态。此外,可以发现MC3T3-E1细胞在培养开始时主要沿着孔的边缘进行生长,这是因为孔内的α-MEM培养基可以为细胞生长提供养分,而孔的边缘则提供了细胞黏附的位置。因此,在细胞培养开始时(1 d),MC3T3-E1细胞沿着孔的边缘进行生长。图14b和c[63]是MC3T3-E1细胞在多孔NiTi结构上培养7 d后的SEM像。可以发现,在多孔NiTi支架的外表面上存在大量的细胞。与图14a[63]相比,由于培养时间的延长,多孔结构边缘的MC3T3-E1细胞逐步向远离多孔边缘的位置生长。因此,在培养7 d后,在外表面观察到相对均匀分布的MC3T3-E1细胞。SLM制备的多孔NiTi支架内表面的细胞形态如图14c[63]所示。飞溅粉末/液滴与熔池形成的冶金结合,导致大量的球形表面在多孔NiTi支架内表面形成,这些球形表面增大了内表面的表面积,可以有效促进细胞的黏附和生长,如图14中红色箭头所示,观察到了大量细胞。这些结果表明SLM多孔NiTi支架和实体NiTi合金具有很好的生物相容性,SLM制备的NiTi合金具有作为生物医学植入物的前景。

图14

图14

SLM多孔NiTi SMAs的生物相容性[63]

Fig.14

Biocompatibility of SLM porous NiTi SMAs[63]

(a) fluorescence images of live cell viability of MC3T3-E1 cells seeded on NiTi samples after being cultured for 1 d (The dotted circle and arrows indicate that MC3T3-E1 cells bridged the pores) (b, c) SEM images of MC3T3-E1 cells on outer (b) and inner (c) surfaces of the porous NiTi scaffolds after being cultured for 7 d in a humid environment at 37oC (The arrows indicate MC3T3-E1 cells)

6 总结与展望

目前,针对SLM NiTi SMAs已经得到了较为系统的研究,关于SLM NiTi SMAs成形性的研究表明,低功率结合低速率以及高功率结合高速率是目前普遍采用的工艺参数;SLM NiTi SMAs相转变行为的调控则主要归因于基体中Ni原子含量的变化和热处理过程中沉淀相的析出与分布等,同时,成形过程中残余热应力的存在以及基体中元素分布不均匀的现象也会影响SLM NiTi SMAs的相转变行为;对于SLM NiTi SMAs的微观结构而言,大量柱状晶以及不均匀结构的存在会导致SLM NiTi SMAs功能各向异性的出现,后续热处理工艺能够有效消除这种各向异性并改善其功能特性;SLM NiTi SMAs的生物相容性正逐步成为研究热点,多孔结构设计的多样性、表面改性处理的可控性等为其在生物医用领域的应用提供了更多可能。根据国内外研究现状和发展趋势,为进一步促进SLM NiTi SMAs的发展,需要从以下几方面重点突破。

(1) SLM NiTi SMAs的拉伸超弹性研究。SLM NiTi SMAs中结构缺陷(如微裂纹、孔隙等)的存在导致目前研究以压缩变形为主,对SLM NiTi SMAs的拉伸超弹性研究相对较少,而NiTi SMAs在服役过程中普遍存在拉伸变形,因此SLM NiTi SMAs的拉伸超弹性有待深入研究。同时,对比也可以发现SLM NiTi SMAs相对传统轧制+时效NiTi SMAs的超弹性有待进一步提高,因此探索提高SLM NiTi SMAs的回复应变和形状回复稳定性的途径是实现其工业化应用的必要条件。

(2) SLM NiTi SMAs的双程形状记忆效应研究。双程形状记忆效应不是NiTi SMAs的固有属性,需要经过适当的冷变形(马氏体或奥氏体状态的过量变形)、热机械循环训练和约束时效等途径获得。从工程应用的角度讲,理想的双程形状记忆效应训练工艺应该具有应变大、稳定性好和相变温度变化小等特点。研究如何在SLM NiTi SMAs中获得稳定的双程形状记忆效应,实现其在智能机器人、复杂驱动装置与执行元器件等领域对复杂驱动元件的创新应用,是拓展复杂SLM NiTi构件应用的重要发展方向。

(3) SLM NiTi SMAs结构疲劳和功能疲劳的性能评价。目前关于SLM NiTi SMAs结构疲劳和功能疲劳的性能评价研究尚存在较大空白。在循环拉伸或压缩过程中,SLM NiTi SMAs会逐步出现结构疲劳和功能疲劳,2者存在紧密联系,也表现出显著区别。结构疲劳或者功能疲劳出现时,会破坏SLM NiTi SMAs的服役效果。SLM NiTi SMAs在循环拉伸或压缩过程中,基体位错的产生与积累、微裂纹的形成与扩展等会逐步导致其结构疲劳的出现;同时,在循环拉伸或压缩过程中,或者升温降温过程中,SLM NiTi SMAs在发生相转变的过程中,由于界面的不兼容性,会在马氏体与奥氏体的界面处形成少量的位错,这些位错的逐步积累会导致马氏体相变温度、相变滞后等功能特性发生衰减,最终导致功能疲劳的出现。在结构疲劳出现的过程中,会导致功能疲劳;功能疲劳形成的过程中,也会导致结构疲劳。如何使得结构疲劳和功能疲劳达到均衡状态,是SLM NiTi SMAs面临和亟需解决的关键问题之一。

(4) 各向同性的SLM NiTi SMAs的制备与研究。由于SLM过程中的快速熔化与凝固、复杂热历史等,SLM NiTi SMAs的微观结构与传统工艺得到的NiTi合金存在明显区别。SLM过程中,方向性的散热与凝固,会促进柱状晶定向生长和“外延生长”,导致大量柱状晶的形成和[100]B2织构的形成。如何有效避免大量柱状晶的形成,制备得到具有等轴晶结构、性能各向同性,同时提高其功能特性的SLM NiTi SMAs,是当前的研究热点。当前,国内外研究结合熔池凝固过程中的温度场分布、晶粒形核长大的理论等,通过外加磁场、基板预热和调控工艺策略等方法影响熔池凝固行为,获得了具有特定微观结构的SLM NiTi SMAs,在一定程度上减少了柱状晶的形成。同时,后续热处理也是有效获得各向同性SLM NiTi SMAs的有效方法。

(5) SLM多孔NiTi SMAs的生物力学性能与表面改性研究。SLM多孔NiTi SMAs相对传统多孔NiTi具有孔隙孔径可控、可设计度高、可个性化定制等优点。SLM多孔NiTi SMAs的研究目前主要涉及制备精度、微观结构、压缩性能、形状记忆性能、超弹性和体外生物相容性等,对于生物力学性能,如人体温度、人体体液下的强度、形状记忆性能、超弹性等,却没有涉及。后续研究需要对SLM多孔NiTi的生物力学性能开展大量研究,为其作为骨科植入物打下坚实基础。功能化表面改性处理是实现NiTi SMAs生物相容性进一步提高、减少Ni原子释放的关键步骤。通过抛光、表面合金化和涂层等表面技术,可大幅改善多孔NiTi SMAs的生物行为。此外,这些表面处理还可改善其促成骨、抗菌、抗炎等生物功能。

(6) SLM多孔NiTi SMAs的植入实验与性能评估。尽管多孔NiTi SMAs在椎间融合器等骨科植入物方面已经取得了显著的临床应用效果,但SLM多孔NiTi植入物的临床应用尚未实现。开展SLM多孔NiTi SMAs的植入实验与性能评估是实现其临床应用的必要前提。通过多孔结构设计与优化,制备得到满足不同植入需求的多孔NiTi植入物;通过动物植入实验,评估其生物相容性,检测其植入需求完成度,并对其综合性能进行准确评估,得到SLM多孔NiTi植入物的综合评估数据库,能够为实现个性化的多孔NiTi植入物在骨缺损治疗、骨缺损自填充等方面的临床创新应用奠定基础。整体而言,SLM多孔NiTi植入物临床应用的实现是一个充满挑战的跨学科难题,需要材料、机械、生物、医学等多学科共同来完成。

参考文献

High temperature shape memory alloys

[J].

A review of shape memory alloy research, applications and opportunities

[J].

Research progress in elastocaloric cooling effect basing on shape memory alloy

[J].

形状记忆合金弹热制冷效应的研究现状

[J].

Manufacturing and processing of NiTi implants: A review

[J].

Welding and joining of NiTi shape memory alloys: A review

[J].

Stress-induced nanoscale phase transition in superelastic NiTi by in situ X-ray diffraction

[J].

Additive manufacturing of bio-inspired multi-scale hierarchically strengthened lattice structures

[J].

The development of TiNi-based negative Poisson's ratio structure using selective laser melting

[J].

Selective laser melting produced layer-structured NiTi shape memory alloys with high damping properties and Elinvar effect

[J].

Recent advances on high-entropy alloys for 3D printing

[J].

Influence of laser scanning speed on phase transformation and superelasticity of 4D-printed Ti-Ni shape memory alloys

[J].By adjusting laser scanning speed during 4D printing, Ti-Ni shape memory alloys (SMAs) with different phase transformation temperatures and microstructures are manufactured. The influences of laser scanning speed on phase component, phase transformation temperature, microstructure and superelasticity of 4D-printed Ti-Ni SMAs are analyzed by various methods of XRD, DSC, SEM and cyclic compression experiment. The results show that the volume fraction of martensite (B19’) in 4D-printed TiNi SMAs decreases together with the gradually increased volume fraction of austenite (B2) when the laser scanning speed increases from 80 mm/s to 150 mm/s. Meanwhile, the martensite transformation start temperature (<i>M</i><sub>s</sub>) and the austenite transformation finish temperature (<i>A</i><sub>f</sub>) decrease with the increase of laser scanning speed. At the laser scanning speed of 80 mm/s, the cyclic compression experiments under austenite state (B2) show that the 4D-printed Ti-Ni SMAs have good superelasticity, exhibiting the stable recovery strain of 4.99% after ten times cyclic compression. It’s much higher than the recovery strain of 2.64%, which have been reported. With the increased laser scanning speed to 150 mm/s, the recovery strain remains at 4.55% after three cycle compressions.

激光扫描速度对4D打印钛镍形状记忆合金相转变和超弹性的影响

[J].通过调控激光扫描速度,运用4D打印技术制备出具有不同相转变温度和微观结构的钛镍形状记忆合金。结合XRD、DSC、SEM和循环压缩等分析方法研究了不同扫描速度对4D打印钛镍合金相组成、相转变、微观结构和超弹性的影响。结果表明,当激光扫描速度从80 mm/s到150 mm/s时,4D打印钛镍合金中马氏体相(B19')含量减少,奥氏体相(B2)含量增加;马氏体转变开始温度(M<sub>s</sub>)和奥氏体转变结束温度(A<sub>f</sub>)随激光扫描速度增加而降低。奥氏体状态下循环压缩试验结果表明:激光扫描速度为80 mm/s时,4D打印钛镍合金具有良好的超弹性,10次循环压缩后稳定的可回复应变达到4.99%,高于目前文献报道的回复应变2.64%;激光扫描速度为150 mm/s时,在3次循环压缩后回复应变几乎保持在4.55%不变。

Influence of Ni on martensitic phase transformations in NiTi shape memory alloys

[J].

The interaction effect of process parameters on the phase transformation behavior and tensile properties in additive manufacturing of Ni-rich NiTi alloy

[J].

Effect of process parameters on the phase transformation behavior and tensile properties of NiTi shape memory alloys fabricated by selective laser melting

[J].

A sensory material approach for reducing variability in additively manufactured metal parts

[J].Despite the recent growth in interest for metal additive manufacturing (AM) in the biomedical and aerospace industries, variability in the performance, composition, and microstructure of AM parts remains a major impediment to its widespread adoption. The underlying physical mechanisms, which cause variability, as well as the scale and nature of variability are not well understood, and current methods are ineffective at capturing these details. Here, a Nickel-Titanium alloy is used as a sensory material in order to quantitatively, and rather rapidly, observe compositional and/or microstructural variability in selective laser melting manufactured parts; thereby providing a means to evaluate the role of process parameters on the variability. We perform detailed microstructural investigations using transmission electron microscopy at various locations to reveal the origins of microstructural variability in this sensory material. This approach helped reveal how reducing the distance between adjacent laser scans below a critical value greatly reduces both the in-sample and sample-to-sample variability. Microstructural investigations revealed that when the laser scan distance is wide, there is an inhomogeneity in subgrain size, precipitate distribution, and dislocation density in the microstructure, responsible for the observed variability. These results provide an important first step towards understanding the nature of variability in additively manufactured parts.

Microstructure and transformation behavior of in-situ shape memory alloys by selective laser melting Ti-Ni mixed powder

[J].

Microstructure of selective laser melted nickel-titanium

[J].

Controlling martensitic transformation characteristics in defect-free NiTi shape memory alloys fabricated using laser powder bed fusion and a process optimization framework

[J].

Laser powder bed fusion of defect-free NiTi shape memory alloy parts with superior tensile superelasticity

[J].

Additive manufacturing of NiTi shape memory alloys using pre-mixed powders

[J].

Altered phase transformation behaviors and enhanced bending shape memory property of NiTi shape memory alloy via selective laser melting

[J].

Constructing function domains in NiTi shape memory alloys by additive manufacturing

[J].

Selective laser melted high Ni content TiNi alloy with superior superelasticity and hardwearing

[J].TiNi alloys with high content Ni (52-55 at.%) are perfectly suitable for preparing wear- and corrosion-resistant parts that service on the space station, spacecraft, and submarine, because of their superior superelasticity, high strength, and hardwearing. However, the fabrication of complicated Ni-rich TiNi parts by the traditional machining method often faces problems of poor precision, low efficiency, and high cost. In this work, we succeed in preparing an excellent Ti47Ni53 alloy by selective laser melting (SLM), and thus, open a new way for the efficient and precise formation of complicated Ni-rich TiNi parts with superelasticity and hardwearing. An optimized processing window for compact parts without defects is reported. The elaborately fabricated Ti47Ni53 alloy exhibited a breaking strain of 11%, a breaking stress of 2.0 GPa, a superelastic strain of 9%, and a better hardwearing than that of casting and quenched Ti47Ni53 alloy. Besides, the microstructure, phase transformation, and deformation, as well as their influence mechanisms are investigated by in situ transmission electron microscope (TEM) and high-energy X-ray diffraction (HE-XRD). The results obtained are of significance for both fundamental research and technological applications of SLM-fabricated high Ni content TiNi alloys.

On the development of high quality NiTi shape memory and pseudoelastic parts by additive manufacturing

[J].

Additively manufacturing-enabled hierarchical NiTi-based shape memory alloys with high strength and toughness

[J].

Structural and functional properties of NiTi shape memory alloys produced by selective laser melting

[A].

Selective laser melting of NiTi shape memory components

[A].

The influence of heat treatment on the thermomechanical response of Ni-rich NiTi alloys manufactured by selective laser melting

[J].

Mechanical and shape memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting

[J].

On the effects of geometry, defects, and material asymmetry on the mechanical response of shape memory alloy cellular lattice structures

[J].

Multi-scale shape memory effect recovery in NiTi alloys additive manufactured by selective laser melting and laser directed energy deposition

[J].

Study on variations of microstructure and metallurgical properties in various heat-affected zones of SLM fabricated nickel-titanium alloy

[J].

Mechanical and shape memory properties of triply periodic minimal surface (TPMS) NiTi structures fabricated by selective laser melting

[J].

Large tunable elastocaloric effect in additively manufactured Ni-Ti shape memory alloys

[J].

Effect of SLM parameters on transformation temperatures of shape memory nickel titanium parts

[J].

Compression behavior of graded NiTi gyroid-structures fabricated by laser powder bed fusion additive manufacturing under monotonic and cyclic loading

[J].

Laser powder bed fusion of Ti-rich Ti-Ni lattice structures: Process optimisation, geometrical integrity, and phase transformations

[J].

Engineering the elastic modulus of NiTi cellular structures fabricated by selective laser melting

[J].

3D-printing damage-tolerant architected metallic materials with shape recoverability via special deformation design of constituent material

[J].

The microstructure of a selective laser melting (SLM)-fabricated NiTi shape memory alloy with superior tensile property and shape memory recoverability

[J].

Study on corrosion behavior of the selective laser melted NiTi alloy with superior tensile property and shape memory effect

[J].

Selective laser melting of NiTi alloy with superior tensile property and shape memory effect

[J].It is a challenge to develop complex-shaped NiTi shape memory alloy parts by traditional processing methods, due to the poor machinability of NiTi alloy. It is reported that selective laser melting (SLM) of additive manufacturing could overcome this problem. However, the reported SLM-produced NiTi exhibits poor tensile ductility due to the inner defects and adverse unidirectional columnar grains from SLM process. In this work, the defect-less SLM-NiTi with nondirective columnar grains was fabricated by optimizing the intraformational laser scanning length and interformational laser scanning direction. The obtained lath-shaped SLM-NiTi sample exhibits tensile strain of 15.6%, more than twice of the reported maximum result ($\widetilde{7}$%). Besides, the SLM-NiTi part with complex geometry displays a shape memory recovery of 99% under compressive deformation of 50%.

Analysis of microstructure, mechanical properties, wear characteristics and corrosion behavior of SLM-NiTi under different process parameters

[J].

Simultaneous enhancement of mechanical and shape memory properties by heat-treatment homogenization of Ti2Ni precipitates in TiNi shape memory alloy fabricated by selective laser melting

[J].

Ultrahigh-performance TiNi shape memory alloy by 4D printing

[J].

Stable tensile recovery strain induced by a Ni4Ti3 nanoprecipitate in a Ni50.4Ti49.6 shape memory alloy fabricated via selective laser melting

[J].

Effects of printing volumetric energy densities and post-processing treatments on the microstructural properties, phase transformation temperatures and hardness of near-equiatomic NiTinol parts fabricated by a laser powder bed fusion technique

[J].

Evolution of functional properties realized by increasing laser scanning speed for the selective laser melting fabricated NiTi alloy

[J].

Functionally graded NiTi alloy with exceptional strain-hardening effect fabricated by SLM method

[J].

Effect of hatch spacing and laser power on microstructure, texture, and thermomechanical properties of laser powder bed fusion (L-PBF) additively manufactured NiTi

[J].

In-situ formation of Ni4Ti3 precipitate and its effect on pseudoelasticity in selective laser melting additive manufactured NiTi-based composites

[J].

Study on the junction zone of NiTi shape memory alloy produced by selective laser melting via a stripe scanning strategy

[J].

New insights on the laser powder bed fusion processing of a NiTi alloy and the role of dynamic restoration mechanisms

[J].

Study on properties of SLM-NiTi shape memory alloy under the same energy density

[J].

Prediction of SLM-NiTi transition temperatures based on improved Levenberg-Marquardt algorithm

[J].

Ni-loss compensation and thermomechanical property recovery of 3D printed NiTi alloys by pre-coating Ni on NiTi powder

[J].

Effects of laser processing on the transformation characteristics of NiTi: A contribute to additive manufacturing

[J].

Modeling of heat transfer, fluid flow and solidification microstructure of nickel-base superalloy fabricated by laser powder bed fusion

[J].

On the transformation behavior of NiTi shape-memory alloy produced by SLM

[J].

On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi

[J].

Achieving superelasticity in additively manufactured NiTi in compression without post-process heat treatment

[J].Shape memory alloys (SMAs), such as Nitinol (i.e., NiTi), are of great importance in biomedical and engineering applications due to their unique superelasticity and shape memory properties. In recent years, additive manufacturing (AM) processes have been used to produce complex NiTi components, which provide the ability to tailor microstructure and thus the critical properties of the alloys, such as the superelastic behavior and transformation temperatures (TTs), by selection of processing parameters. In biomedical applications, superelasticity in implants play a critical role since it gives the implants bone-like behavior. In this study, a methodology of improving superelasticity in Ni-rich NiTi components without the need for any kind of post-process heat treatments will be revealed. It will be shown that superelasticity with 5.62% strain recovery and 98% recovery ratio can be observed in Ni-rich NiTi after the sample is processed with 250 W laser power, 1250 mm/s scanning speed, and 80 µm hatch spacing without, any post-process heat treatments. This superelasticity in as-fabricated Ni-rich SLM NiTi was not previously possible in the absence of post-process heat treatments. The findings of this study promise the fast, reliable and inexpensive fabrication of complex shaped superelastic NiTi components for many envisioned applications such as patient-specific biomedical implants.

Microstructure, shape memory properties, and in vitro biocompatibility of porous NiTi scaffolds fabricated via selective laser melting

[J].

Achieving biocompatible stiffness in NiTi through additive manufacturing

[J].

Effect of laser energy density on the evolution of Ni4Ti3 precipitate and property of NiTi shape memory alloys prepared by selective laser melting

[J].

Graded functionality obtained in NiTi shape memory alloy via a repetitive laser processing strategy

[J].

The higher compressive strength (TiB + La2O3)/Ti-Ni shape memory alloy composite with the larger recoverable strain

[J].

Compressive behavior of NiTi-based composites reinforced with alumina nanoparticles

[J].

Selective electron beam melting of NiTi: Microstructure, phase transformation and mechanical properties

[J].

Effect of a constant laser energy density on the evolution of microstructure and mechanical properties of NiTi shape memory alloy fabricated by laser powder bed fusion

[J].

Properties of a superelastic NiTi shape memory alloy using laser powder bed fusion and adaptive scanning strategies

[J].

Controlled shape-morphing metallic components for deployable structures

[J].

Fabrication of multi-functional Ni-Ti alloys by laser powder bed fusion

[J].

Laser beam energy dependence of martensitic transformation in SLM fabricated NiTi shape memory alloy

[J].

Anisotropic tensile and actuation properties of NiTi fabricated with selective laser melting

[J].

Effect of ageing treatment on the deformation behaviour of Ti-50.9at.%Ni

[J].

Effects of several factors on the ductility of the Ti-Ni alloy

[J].

Effect of severe plastic deformation on the behavior of Ti-Ni shape memory alloys

[J].

Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys

[J].

Tensile actuation response of additively manufactured nickel-titanium shape memory alloys

[J].

Effects of grain size on the rate-dependent thermomechanical responses of nanostructured superelastic NiTi

[J].

Selective laser melting of Ni-Ti shape memory alloy: Processability, microstructure, and superelasticity

[J].

Thermomechanical characterization of Ni-rich NiTi fabricated by selective laser melting

[J].

Process development and characterization of additively manufactured nickel-titanium shape memory parts

[J].

Texture and anisotropy in selective laser melting of NiTi alloy

[J].

My experience with Ti-Ni-based and Ti-based shape memory alloys

[J].

A review on biomedical titanium Alloys: Recent progress and prospect

[J].

Young's modulus of trabecular and cortical bone material: Ultrasonic and microtensile measurements

[J].An ultrasonic technique and microtensile testing were used to determine the Young's modulus of individual trabeculae and micro-specimens of cortical bone cut to similar size as individual trabeculae. The average trabecular Young's modulus measured ultrasonically and mechanically was 14.8 GPa (S.D. 1.4) and 10.4 (S.D. 3.5) and the average Young's modulus of microspecimens of cortical bone measured ultrasonically and mechanically was 20.7 GPa (S.D. 1.9) and 18.6 GPa (S.D. 3.5). With either testing technique the mean trabecular Young's modulus was found to be significantly less than that of cortical bone (p < 0.0001). However, the specimens were dried before microtensile testing so Young's modulus values may have been greater than those of trabeculae in vivo. Using Young's modulus measurements obtained from 450 cubes of cancellous bone and 256 cubes of cortical bone, Wolff's hypothesis that cortical bone is simply dense cancellous bone was tested. A multiple regression analysis that controlled for group membership showed that Young's modulus of cortical bone cannot be extrapolated from the Young's modulus vs density relationship for cancellous bone, yet the Young's modulus of trabeculae can be predicted by extrapolation from the relationship between Young's modulus vs density of the cancellous bone. These results suggest that when considered mechanically, cortical and trabecular bone are not the same material.

Printing of NiTinol parts with characteristics respecting the general microstructural, compositional and mechanical requirements of bone replacement implants

[J].

Compression and superelasticity behaviors of NiTi porous structures with tiny strut fabricated by selective laser melting

[J].

In-situ dual-deoxidation design of advanced titanium matrix composites by pressureless sintering

[J].