综上所述,高强度铁基激光熔覆涂层制备的裂纹问题和非平衡凝固晶间脆化相会导致熔覆层过早失效,使得激光熔覆传统铁基涂层组织结构不能满足高载荷摩擦磨损零部件的服役要求。因此,对激光熔覆高强韧铁基合金涂层成分设计、精细组织调控,降低激光熔覆铁基涂层的裂纹敏感性,以及抑制其服役过程中晶间裂纹萌生和扩展,对推广激光熔覆高强韧铁基涂层应用具有重要意义。

针对高强韧铁基涂层激光熔覆制备瓶颈,李铸国团队围绕高强韧铁基涂层材料设计、精细组织调控、性能评价等方面开展了一系列研究,先后自主研发了纳米贝氏体涂层、超细共晶增强铁基涂层、颗粒增强马氏体涂层、高硬非晶铁基涂层等具有高强高韧且适合于激光熔覆制备的涂层体系。本文就以上4种铁基涂层的设计思路、组织结构调控与性能评价等方面的问题展开讨论和展望。

1 纳米贝氏体铁基涂层

1.1 设计思路

纳米贝氏体钢中的高C含量保证了低温下纳米级贝氏体铁素体转变和未转变残余奥氏体的稳定性。但超长的贝氏体相转变时间(高C成分合金的贝氏体相变时间可达数百小时)是阻碍这一新型高强钢应用的主要障碍。有学者尝试采用多步热处理[43]以及预先发生马氏体相变的方法[44]成功加速了纳米贝氏体的相转变时间,但是其工艺过程往往比较复杂。此外,学者们还尝试通过细化初始奥氏体晶粒,以及添加Co或者Al元素的方法加速相变过程[45]。作者团队尝试通过激光熔覆熔凝及随即等温处理的方法,可快速有效获得具有纳米贝氏体组织的铁基涂层[46]。激光熔覆快速熔凝所得到的细化初始奥氏体晶粒可大大缩短整个贝氏体相变时间[47]。因此,激光熔覆和随即等温热处理是一种简单快速制备高强韧铁基纳米贝氏体涂层的有效方法,这也为激光增材制造铁基高强韧构件提供了一种可行的思路。

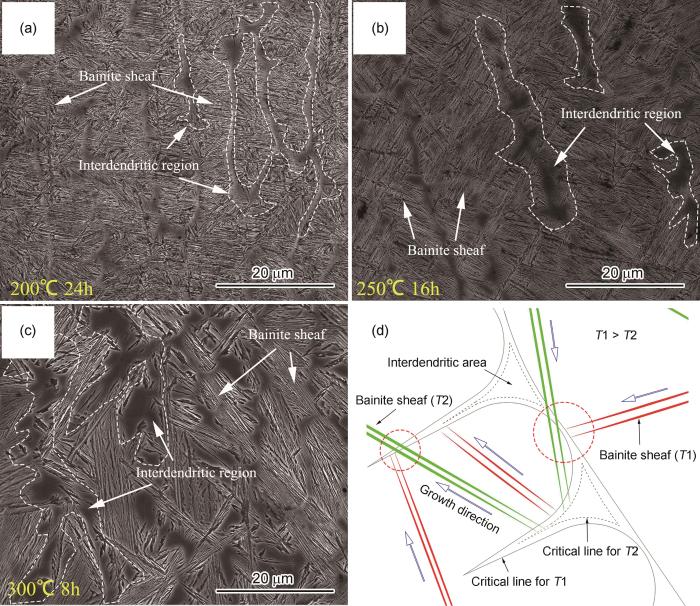

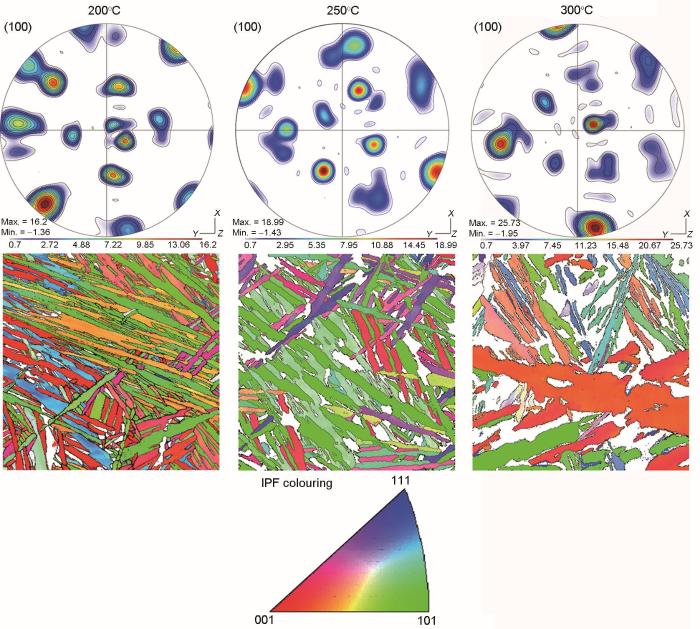

1.2 纳米贝氏体涂层的组织结构

图1

图2

图3

图4

图4

激光熔覆及不同等温温度下所得到的纳米贝氏体相转变动力学曲线

Fig.4

Kinetic curves of nano bainitic transformation under different isothermal temperatures

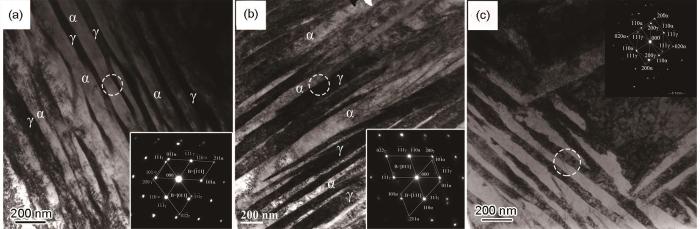

1.3 纳米贝氏体涂层的力学性能

图5

图5

激光熔覆及不同等温温度下所得到的纳米贝氏体涂层的Vickers硬度和拉伸强度

Fig.5

The mechanical properties of the laser cladded nano bainitic coatings under different isothermal temperatures (HAZ—heat affected zone)

(a) Vickers hardness (b) tensile strength

近年来,Jiang等[52]在作者团队研究方法基础上采用激光沉积和热处理的办法,成功制备出强度可达1300 MPa左右的低C含量无碳化物贝氏体涂层。并讨论了制备的后续处理工艺与组织、力学性能的关系。当等温热处理温度高于Ms时,沉积涂层中的残余奥氏体含量会明显增加,相对应的强度和延伸率也高于等温温度低于Ms的沉积涂层。

综上可知,激光熔覆和随即热处理的办法可方便、快捷地制备出高强韧的铁基纳米贝氏体涂层。高强韧铁基纳米贝氏体的激光熔覆工艺为采用激光增材制造制备诸如航空航天、海洋装备等领域的超高强韧部件提供了一种新的思路和方案。

2 超细共晶增强铁基涂层

2.1 设计思路

M3C作为一种白口铸铁中常见的碳化物,与MC和M2C相比具有较高的韧性。最近有研究表明,在Fe3C中掺杂少量的Cr元素可以提高其韧性[53],并且由高韧性(Cr, Fe)3C增强的白口铸铁表现出更好的耐磨性能,其磨损失效机制由碳化物的开裂及剥落变为微切削[54,55]。除此以外,由于M3C具有较好的韧性,因此由M3C增强的铁基涂层在熔覆过程中表现出更低的裂纹敏感性。然而,M3C是一个亚稳态相,在一定条件下会发生分解,限制了其在铁基涂层中作为主要强化相的应用[56]。研究[57]发现,通过在 M3C中掺杂B元素可以显著地降低其形成能,从而生成稳定的M3(C, B)碳硼化物。而碳硼化物的类型一般与B / (B + C)的原子比有关,如果B / (B + C)比在0.5~0.65,则涂层中增强相主要为M3(C, B),而当B / (B + C)的比值超过0.65时涂层中出现脆性M2B硼化物[58]。

2.2 超细共晶增强铁基涂层的组织结构

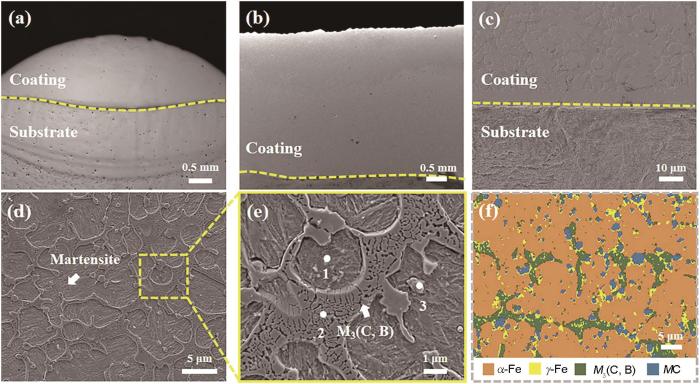

如图6a和b[60]所示,无论是单道熔覆涂层还是多层多道熔覆涂层中都没有出现裂纹。此外,涂层与基体的界面为冶金结合,且涂层的稀释率低于5%。在涂层的底部显微形貌主要为平面晶(图6c[60]),而在涂层内部的显微形貌主要以树枝晶及等轴晶为主(图6d[60])。且涂层的显微组织主要为马氏体基体加网状的析出相。析出相的形貌如图6e[60]所示,可以看出,析出相和基体形成了共晶组织。通过电子背散射衍射(EBSD)获得涂层的相分布(图6f[60])表明,涂层中的主要增强体为M3(C, B)碳硼化物,在晶粒中析出少量MC。电子探针显微分析(EPMA)测试结果表明,B元素主要富集在晶界处的M3(C, B)碳硼化物中,基体和MC中几乎没有B元素。Cr、V和W元素主要富集在晶界上的M3(C, B)中,而在MC碳化物中主要富集Nb和V。

图6

图7

图7

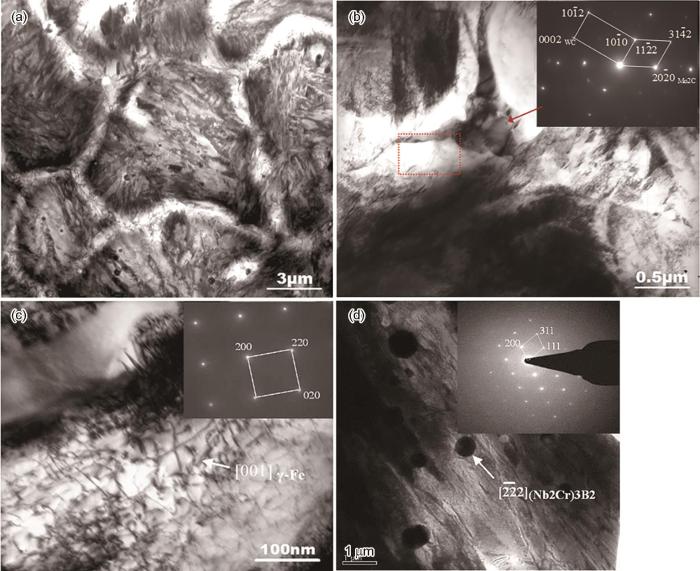

超细共晶增强铁基涂层的TEM像和SAED花样[60]

Fig.7

TEM images of the different position of coating[60]

(a) bright-field image and corresponding SAED pattern of matrix in the coating (b, c) bright-field image of eutectic in the coating (b) and corresponding SAED pattern of γ-Fe (c) (d) magnification of Fig.7a (e) magnification of Fig.7b (f) SAED pattern of M3(C, B)

基于涂层的差示扫描量热法(DSC)曲线可以推测出涂层凝固过程[60]。首先,1408℃时γ-Fe在液相中析出,C和Cr、W等合金元素固溶于γ-Fe中。然后,当温度降至1344℃左右时,MC碳化物在残余液相中或γ-Fe旁边沉淀。由于V和Nb为强MC碳化物形成元素[61],因此这些元素主要富集在MC碳化物中。由于涂层中含有B元素,因此在1178℃发生了由M3(C, B)和γ-Fe组成的共晶反应。这主要是由于B与C的相互作用系数

2.3 超细共晶增强铁基涂层的力学性能

图8

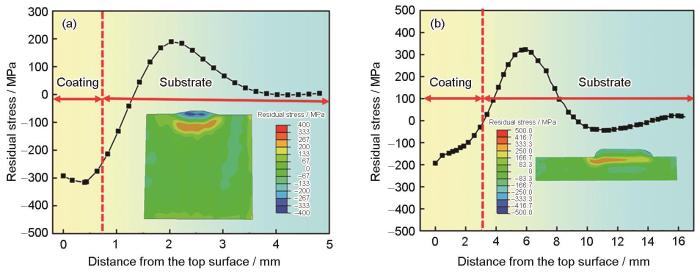

结合涂层凝固机制对残余应力分布特征进行阐述:由于该涂层的液相线温度为1408℃,而马氏体转变结束温度为295℃,低于传统的高速钢涂层,较低的液相线温度和马氏体转变结束温度可以有效降低涂层的冷却范围,从而降低马氏体转变前后冷却过程中产生的热应力。而涂层的相变应力则来自于马氏体相变。涂层中的基体都是马氏体,因此在凝固过程中会发生马氏体相变,而马氏体相变是一个体积膨胀的过程,热应力和相变应力的协同作用使涂层表现出残余压应力。由于基体中马氏体含量较低,有限的相变应力导致涂层与基体界面处产生了残余拉应力。

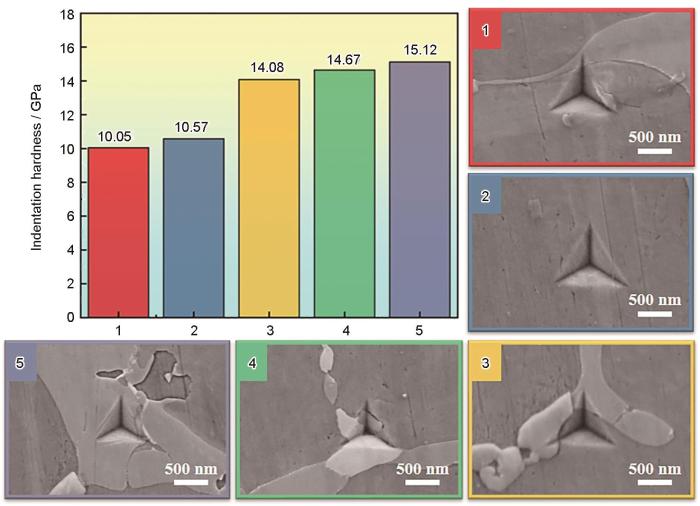

如图9[60]所示,超细共晶增强铁基涂层的硬度分布均匀,平均硬度大于850 HV。涂层的高硬度主要是由于含有大量M3(C, B)增强相。增强相与位错相互作用,阻碍位错的运动,起到弥散强化作用。增强相M3(C, B)的纳米压痕硬度超过14 GPa (图10[60]),比传统Fe3C的硬度高了55%[64]。但在M3(C, B)碳硼化物周围没有出现裂纹,表明M3(C, B)具有良好的韧性。此外,涂层中基体也表现出超高的硬度,约为10 GPa,是淬火态马氏体((0.1%~0.5%)C)的1.41倍[65]。基体的超高硬度可能与马氏体中的纳米孪晶有关。马氏体中存在大量厚度小于10 nm的纳米孪晶,这些纳米孪晶被认为是阻碍位错运动的有效屏障,对提高基体的硬度起着至关重要的作用[66,67]。因此,由于存在大量的M3(C, B)碳硼化物及纳米孪晶增强的亚微米马氏体基体,导致超细共晶增强铁基涂层呈现出高的硬度。

图9

图10

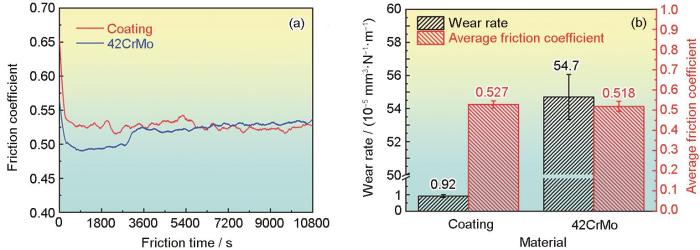

涂层的摩擦系数与基体相似,约为0.52 (图11a[60])。涂层具有较好的耐磨性,磨损率仅为0.92 × 10-5 mm3/(N·m),而基体的耐磨性则较差,磨损率为54.7 × 10-5 mm3/(N·m),是涂层的59.4倍(图11b[60])。传统工具钢涂层的硬度和耐磨性如表1[68]所示。虽然传统工具钢的硬度通常较高,但其耐磨性不如本文作者团队研发的涂层。M4涂层在传统工具钢中表现出最好的耐磨性,磨损率为2.1 × 10-5 mm3/(N·m)[68],是超细共晶增强铁基涂层磨损率的2.3倍。涂层优异的耐磨性主要是由于涂层中具有纳米孪晶的马氏体和M3(C, B)碳硼化物强化导致涂层具有较高的显微硬度。同时M3(C, B)碳硼化物具有较高的硬度和韧性,在磨损过程中不易断裂和剥落,可以有效保护基体不被直接铲掉,提高涂层的耐磨性。此外,研究[69,70]表明,残余压应力对耐磨性有积极影响。残余压应力可能会延迟增强相的剥离以及磨损载荷引起的磨损表面上微裂纹的形成[71]。因此,作者研发的超细共晶增强铁基涂层的磨损性能优于传统工具钢[71]。

图11

表1 传统工具钢涂层和本研究涂层的硬度和耐磨性[68]

Table 1

| Compound | Hardness / HV | Wear rate |

|---|---|---|

| 10-5 mm3·N-1·m-1 | ||

| Present | 850 | 0.92 |

| M4 | 953 | 2.1 |

| HS-30 | 925 | 2.3 |

| M2 | 928 | 3.1 |

| HS-23 | 853 | 3.9 |

| WR6 | 864 | 4.4 |

| WR6 + VC | 949 | 5.1 |

| AISI 420 | 715 | 8.5 |

| H13 | 697 | 12.9 |

| AISI 431 | 729 | 20.6 |

3 颗粒增强马氏体涂层

3.1 设计思路

激光熔覆颗粒增强马氏体涂层的设计目标是确保获得马氏体、残余奥氏体、颗粒增强相的复合相结构。为了实现组织设计的目标,考虑针对铁基合金激光熔覆过程中裂纹形成机制,通过选择过包晶相区间来抑制铁基合金凝固裂纹的产生,并基于“余氏”固体与分子经验电子理论(EET)[72],分别对组织控制和强化元素的相结构因子、界面结合因子进行计算,结合材料热力学计算选择原位生成颗粒相元素,确定颗粒增强马氏体铁基涂层的合金系成分。综合考虑形成颗粒相消耗C含量影响、晶粒细化和净化、以及现有合金元素的合金化成果和经济性,选择铁基熔覆合金涂层的合金系为Fe-C-Cr-Ni-Mo(W)-V(Ti、V、Nb、CeO):(0.6%~0.8%)C,(6%~7%)Cr,(3%~4%)Ni,(1%~2%)Mo、(1%~2%)W、(0.5%~1.0%)V、(0.2%~0.4%)Nb、(0.3%~0.6%)Ti、(0.4%~0.6%)CeO,Fe余量[73,74]。

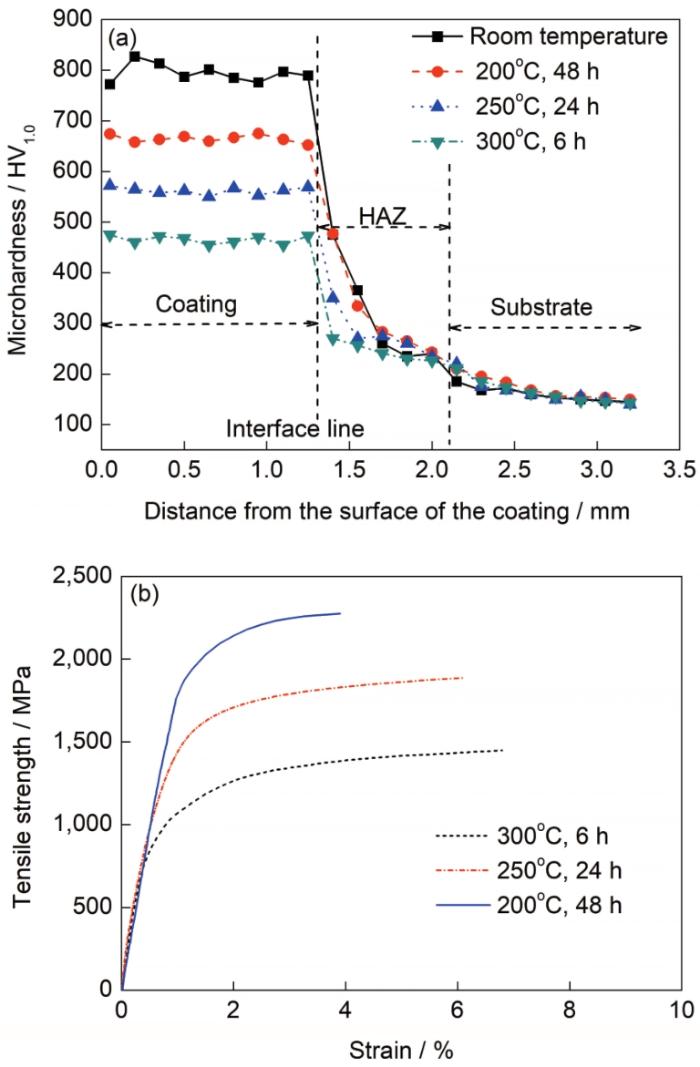

3.2 颗粒增强马氏体涂层的组织结构

作者团队[73]对熔覆层组织特征进行了表征,发现激光熔池内的液态金属优先在基体材料的交界面处形核并外延生长,随后沿热流方向向熔区心部凝固长大,最终呈现为一定方向性的细小枝晶组织(图12a~c[73])。熔覆层和基底的熔合区形成了良好的冶金结合(图12a[73]),在熔合区上部的熔覆金属呈平面晶、胞状晶形态生长。随后胞状枝晶发生转变向柱状树枝晶形态生长,在熔覆层的上部,柱状树枝晶向等轴树枝晶形态生长。在整个熔覆层内,大量的颗粒相呈弥散状态分布(图12d[73])。涂层相构成主要为过饱和α-Fe、γ-Fe、(Fe, Cr)7C3碳化物以及FeCr、FeNi固溶体(图12e[73]),其中马氏体的衍射峰强最高,即马氏体为含量最高的相。马氏体和奥氏体晶面衍射峰向左小角度偏移了1°左右,也即衍射角减小,α-Fe、γ-Fe的晶格常数增加,这是由于在激光熔覆快速凝固过程中发生了溶质截留现象,α-Fe、γ-Fe中溶有较高含量的合金元素。

图12

图13

图13

颗粒增强马氏体涂层熔覆层的显微组织[73]

Fig.13

Microstructures of cladding layer[73]

(a) TEM image

(b) TEM image in the interdendritic region (Inset shows the SAED pattern of blocky carbide)

(c) magnification of the region plotted by the rectangular mark in Fig.13b (Inset shows the SAED pattern of retained austenite)

(d) local magnification of Fig.13a

3.3 颗粒增强马氏体涂层的力学性能

图14

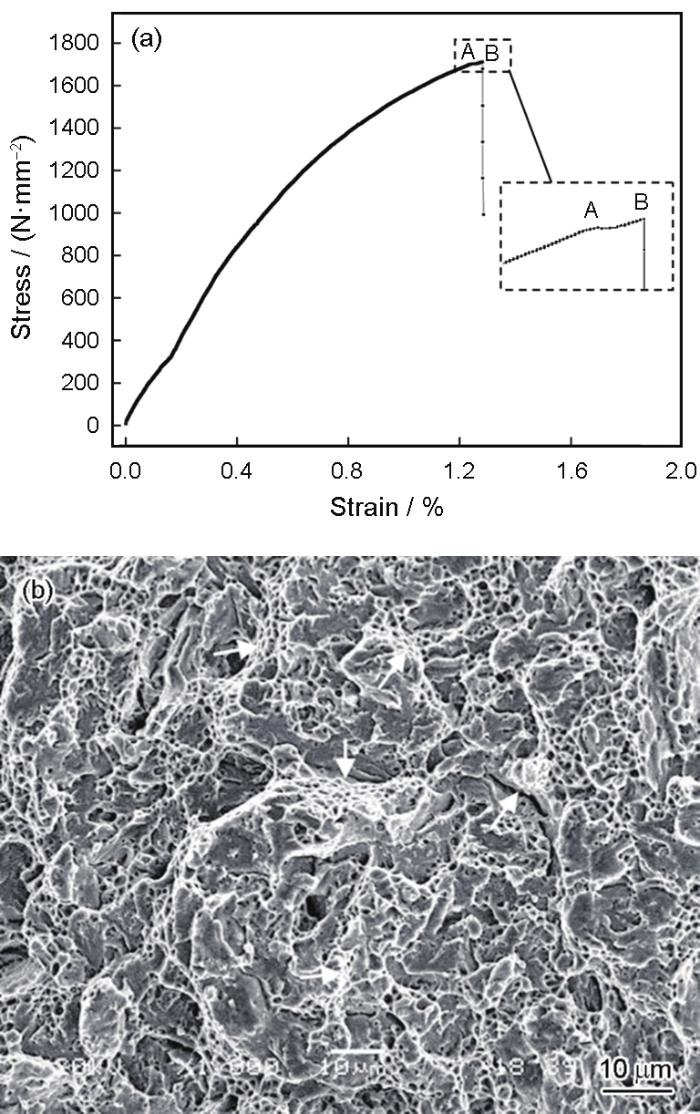

颗粒增强马氏体涂层的应力-应变曲线如图15a[74]所示。其抗拉强度、屈服强度和延伸率分别为1711 N/mm2、1444 N/mm2和1.29%。在涂层中,屈服点A后应力略有下降。屈服点A后,涂层经历应变硬化期,在此期间,应力随着应变的增加而再次增加,直到达到B点的极限强度。图15b[74]显示了颗粒增强马氏体涂层的拉伸断裂形貌特征。涂层的断裂模式为脆性解理、沿晶区准解理断裂,以及枝晶间和附近晶粒中的韧性韧窝或韧带边界区域,如箭头所示。韧性韧窝或韧带呈网状,这归因于枝晶间和附近晶粒边界区域的网状残余奥氏体。A点之前的曲线为线性曲线,但之后,应力达到断裂破坏点B之前出现延性行为。这可能是由于涂层中沿枝晶分布的残余奥氏体中的颗粒和位错相互作用造成的。

图15

4 高硬非晶铁基涂层

4.1 设计思路

由于大块非晶的尺寸、形状、制备方法的局限性,大大限制了非晶材料在各个领域的广泛应用,因此采用激光熔覆技术在基体表面获得非晶材料受到广泛关注。具有较高非晶形成能力的合金体系通常含有贵金属元素,如Zr、Pd、Pt等。这些金属一方面价格昂贵,另一方面在熔覆过程中易氧化,因此大多数激光熔覆非晶时需要惰性气体保护仓或者二次重熔等手段,其工艺较为复杂,阻碍了非晶涂层的应用和发展,因此通过简单工艺制备廉价的铁基非晶合金涂层具有重要的实际应用价值。

4.2 高硬非晶铁基涂层的组织结构

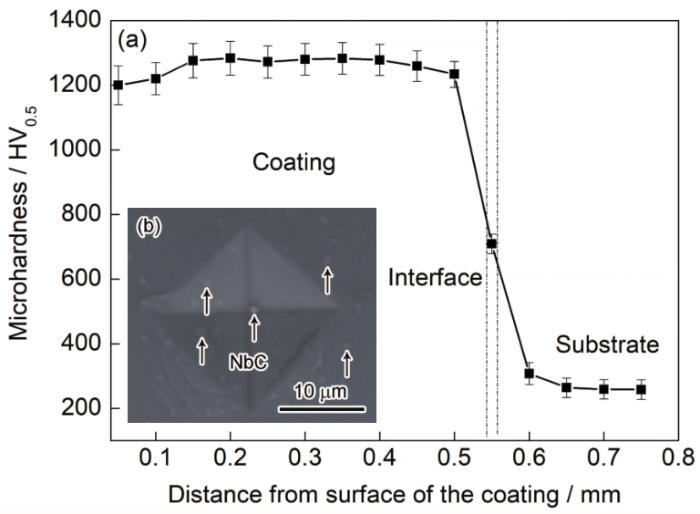

图16

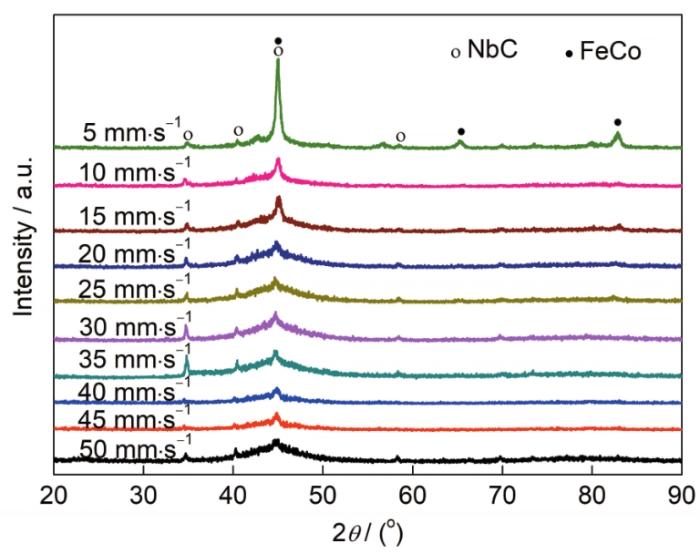

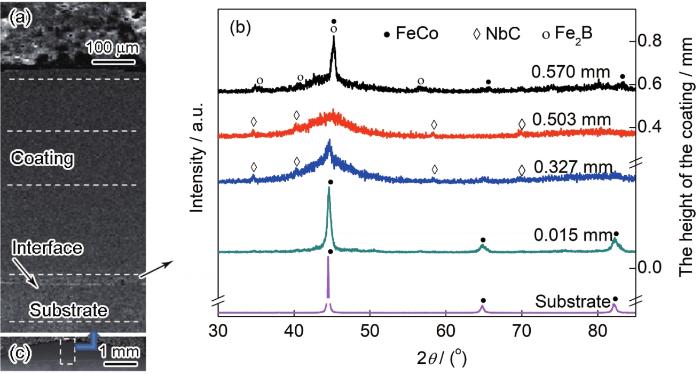

对上述不同激光扫描速率下熔覆层的中部表面的XRD峰位拟合结果表明,当熔覆速率大于10 mm/s时,其熔覆层内的非晶含量迅速增多,当熔覆速率大于45 mm/s时,熔覆层内的非晶含量在90%左右。将筛选出的9组样品进行镶嵌、抛光和王水腐蚀,每个样品的横截面形貌如图17a[76]所示。对10个不同扫描速率的样品用图像分析软件进行分析,如图17b[76]所示。分析发现,随着激光扫描速率的增加,熔覆层中非晶相的含量逐渐增加。当扫描速率为10 mm/s时,其熔覆层中的非晶含量已经接近50%;当扫描速率为30 mm/s时,其熔覆层中的非晶含量跃增到了74%;当速率为45 mm/s以上时,熔覆层中的非晶含量达到90%左右。

图17

图18

表2 熔覆层中不同区域非晶相含量与晶体相的晶粒尺寸[76]

Table 2

| Distance to fusion line / mm | Phases composition | Amorphous percentage / % | Grain size / nm |

|---|---|---|---|

| 0.570 | Fe2B, FeCo | 76.8 | ~19.9 |

| 0.503 | Amorphous, NbC | 96.2 | 29.9-32.0 |

| 0.327 | Amorphous, NbC | 95.7 | 29.5-31.0 |

| 0.015 | FeCo | 11.9 | ~6.4 |

| Substrate | Fe | 0 | ~22.6 |

4.3 高硬非晶铁基涂层的力学性能

图19

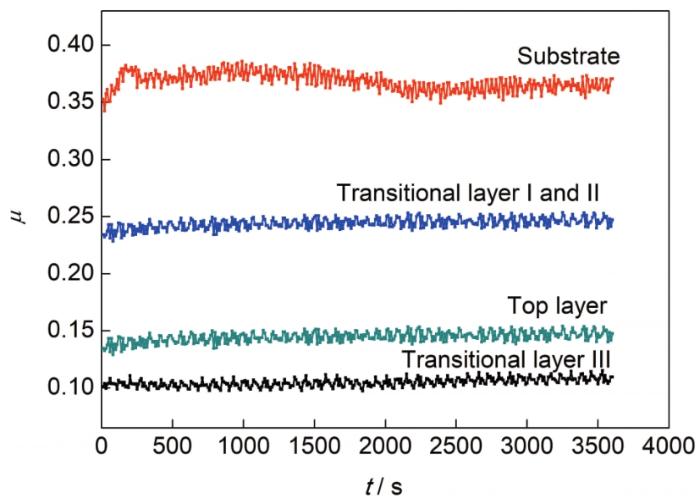

图20[76]是在200 N、60 r/min干摩擦条件下得到的高硬非晶铁基涂层不同区域的摩擦系数和时间的关系曲线。熔覆层中非晶和NbC颗粒相区域(Transitional layer III)的摩擦系数约为0.1,明显小于船体用结构钢CCS-A基体(Substrate)。等轴树枝晶和柱状树枝晶区域(Transitional layer I and II)摩擦系数约为0.24,是非晶和颗粒相区域的将近3倍,而且熔覆层的这2部分区域的摩擦系数随着时间的延长波动幅度较小。摩擦力、磨损失重和摩擦系数见表3[76],可见非晶相区(Layer III)的失重最小,等轴树枝晶和柱状树枝晶区域(Transitional layer I and II)次之,说明非晶相区的耐磨损性能较好。

图20

表3 摩擦力、磨损失重和摩擦系数的数据统计[76]

Table 3

| Region | Average friction force / N | Wear mass loss / g | Friction coefficient | ||

|---|---|---|---|---|---|

| Range | Average | Relative wear | |||

| Layer III | 206.47 | 0.003 | 0.0974-0.1151 | 0.10486 | 0.28 |

| Layer I and II | 206.56 | 0.011 | 0.2285-0.2536 | 0.24412 | 0.66 |

| Substrate | 204.21 | 0.055 | 0.3424-0.3857 | 0.36816 | 1 |

5 展望

激光熔覆铁基合金涂层因其高强度、高硬度、易于与钢铁基体实现冶金结合和低成本等优点而在工程领域有广阔的应用前景。近几十年来,学者们和工程技术人员也在铁基合金激光熔覆领域展开了广泛研究,并取得了一定的成果。但铁基激光熔覆层的裂纹和脆化问题一直是高强铁基合金激光熔覆技术推广应用的主要问题。本团队目前围绕降低铁基激光熔覆层的裂纹敏感性、抑制晶间裂纹萌生扩展提高韧性,从熔覆合金体系设计、精细组织调控机理等方向展开研究,开展了纳米贝氏体涂层、超细共晶增强铁基涂层、颗粒增强马氏体涂层、高硬非晶铁基涂层等具有高强高韧且适合于激光熔覆制备的涂层体系的设计与开发。通过本文研究结果可知,多类型析出强化和在铁素体/马氏体基体上引入塑/韧性相阻碍裂纹扩展这一思路,将有助于进一步提升激光熔覆涂层的强韧性极限,获得超高强度和优良韧塑性的更佳匹配。因此,未来激光熔覆铁基涂层的强韧化发展需要从高通量材料计算和实验相结合,从以下几个方面继续开展超高强韧化铁基激光熔覆合金的研究:(1) 开展基于精细组织调控的高强韧熔覆专用材料开发。通过成分和组织调控实现熔覆基体相结构的纳米化、亚微米化,获得超细强化相和韧化相均匀分布的有序组织结构。(2) 开展基于位错强化和第二相析出强化的理论研究。通过超强韧原位生成或添加纳米颗粒相实现韧性铁基基体相的增强,获得韧性基体相和高密度位错缠节/纳米析出相的均匀强化铁基激光熔覆组织。(3) 开展新型铁基激光熔覆多组元合金的研究与开发。多组元非晶铁基合金可获得超高强度的铁基非晶和具有一定强韧性的晶体相复相组织,可同时提高铁基合金涂层的强度和韧性,并具有一定耐腐蚀性。对不同类型析出相的耦合强化机制、马氏体/铁素体基体与塑性相组成的复合组织强韧化机理等科学规律进行研究是必要的,积累相关数据和经验,并通过材料计算和实验研究,最终可望开发出满足各种服役条件所需的超高强韧激光熔覆铁基合金体系。

参考文献

Wear behavior of sintered hexagonal boron nitride under atmosphere and water vapor ambiences

[J].

Influence of Cr content on tribological properties of Ni3Al matrix high temperature self-lubricating composites

[J].

Microstructure and wear resistance of TaC reinforced Ni-based coating by laser cladding

[J].

A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition

[J].

Recent trends in laser cladding and surface alloying

[J].

Recent research and development status of laser cladding: A review

[J].

Laser cladding technique for erosive wear applications: A review

[J].

Study on the laser cladding of FeCrNi coating

[J].

Effect of Nb content on microstructure and properties of laser cladding FeNiCoCrTi0.5Nb x high-entropy alloy coating

[J].

Research progress of laser cladding stainless steel coating on Fe-based substrate

[J].

铁基材料表面激光熔覆不锈钢涂层的研究进展

[J].

Effect of laser process parameters on the microstructure and properties of TiC reinforced Co-based alloy laser cladding layer

[J].

激光工艺参数对TiC增强钴基合金激光熔覆层组织及性能的影响

[J].

Research on laser repair process of Ni-based superalloy

[J].

镍基高温合金激光修复工艺研究

[J].

Microstructure and wear properties of TiC/FeCrBSi surface composite coating prepared by laser cladding

[J].

Stress-induced selective nano-crystallization in laser-processed amorphous Fe-Si-B alloys

[J].

Microstructure and wear resistance of laser clad Fe-Cr3C2 composite coating on 35CrMo steel

[J].

Microstructure and mechanical properties of laser clad and post-cladding tempered AISI H13 tool steel

[J].

Microstructure and properties of Fe-based composite coating by laser cladding Fe-Ti-V-Cr-C-CeO2 powder

[J].

Characteration of laser cladded Fe-Mn-Cr alloy coatings modified by plasma nitriding

[J].

An investigation on the applying fundamentals of powder feeding laser cladding

[D].

送粉激光熔覆应用基础理论的研究

[D].

Modeling and numerical simulation on laser remelting and cladding

[D].

激光熔凝和激光熔覆的数学模型及数值分析

[D].

Nonequilibrium microstructures and their evolution in a Fe-Cr-W-Ni-C laser clad coating

[J].

The influences of processing parameters on forming characterizations during laser rapid forming

[J].

Fe-based thick amorphous-alloy coating by laser cladding

[J].

Laser cladding of Fe-based corrosion and wear-resistant alloy: Genetic design, microstructure, and properties

[J],

Development of the effect of high energy laser on the rapid solidification structure and properties of the material surface

[J].

高能激光束对材料表层快速凝固组织及性能影响的研究进展

[J].

Mechanism of crack generation in carbide surface layer of laser-clad iron alloys

[J].

Investigation on microstructure and cracking susceptibility of laser-clad Fe-based alloy coatings

[J].

铁基合金激光熔覆层组织分布及开裂敏感性研究

[J].

Research on formation causes and elimination methods of the laser cladding cracks

[J].

激光熔覆裂纹的产生原因及消除方法探究

[J].

Discussion on crack in laser-clad case

[J].

关于激光熔覆层开裂问题的探讨

[J].

Effect of nano-CeO2 on cobalt-based alloy laser coatings

[J].

Effect of a small increase in the Ni content on the properties of a laser surface clad Fe-based alloy

[J].

The mechanism of strengthening and toughening of crack-free Fe-based alloy with high hardness for laser cladding

[J].

高硬度激光熔覆专用Fe基合金强韧化机理

[J].

Effect of carbon content on the microstructure and the cracking susceptibility of Fe-based laser-clad layer

[J].

Design of a new nanostructured, high-Si bainitic steel with lower cost production

[J].

Composition design of nanocrystalline bainitic steels by diffusionless solid reaction

[J].

Quantitative assessment of carbon allocation anomalies in low temperature bainite

[J].

Design of cold rolled and continuous annealed carbide-free bainitic steels for automotive application

[J].

Tensile behaviour of a nanocrystalline bainitic steel containing 3 wt% silicon

[J].

Mechanical properties of low-temperature bainite

[J].

Structure-mechanical property relationship in a high strength low carbon alloy steel processed by two-step intercritical annealing and intercritical tempering

[J].

Effect of prior martensite on bainite transformation in nanobainite steel

[J].

Acceleration of low-temperature bainite

[J].

Microstructure evolution of Fe-based nanostructured bainite coating by laser cladding

[J].

Effects of isothermal heat treatment on nanostructured bainite morphology and microstructures in laser cladded coatings

[J].

Effect of chemical segregation on nanobainitic transformation in laser cladded coatings

[J].

Effect of isothermal temperature on growth behavior of nanostructured bainite in laser cladded coatings

[J].

Characterization of local mechanical properties of laser-cladding H13-TiC composite coatings using nanoindentation and finite element analysis

[J].

The effects of micro-segregation on isothermal transformed nano bainitic microstructure and mechanical properties in laser cladded coatings

[J].

Microstructure and properties of an as-deposited and post treated high strength carbide-free bainite steel fabricated via laser powder deposition

[J].

A comparative study of Cr7C3, Fe3C and Fe2B in cast iron both from ab initio calculations and experiments

[J].

Three-body abrasive wear behavior of cementite with different chromium concentrations

[J].

Effect of chromium content on cementite-pearlite interaction of white cast iron during three-body abrasive wear

[J].

Standard enthalpies of formation of some 3d transition metal carbides by high temperature reaction calorimetry

[J]. J.

Electronic and structural properties of cementite-type M3 X (M = Fe, Co, Ni; X = C or B) by first principles calculations

[J].

Supersolidus liquid-phase sintering of ultrahigh-boron high-carbon steels for wear-protection applications

[J].

Microstructures and wear properties of various clad layers of the Fe-W-C-B-Cr system

[J].

Residual stress distribution and wear behavior in multi-pass laser cladded Fe-based coating reinforced by M3(C, B)

[J].

Solidification of high-speed tool steels

[J].

New Fe-Cr-Mo-Ga-C composites with high compressive strength and large plasticity

[J].

Wear protection by Fe-B-C hard phases

[J].

Microstructures and hardness of as-quenched martensites (0.1-0.5%C)

[J].

Stabilizing nanostructures in metals using grain and twin boundary architectures

[J].

Plastic anisotropy and associated deformation mechanisms in nanotwinned metals

[J].

Microstructural and abrasion wear characteristics of laser-clad tool steel coatings

[J].

Effect of residual stress on the wear resistance of thermal spray coatings

[J].

Effect of the microstructure and residual stress on tribological behavior of induction hardened GCr15 steel

[J].

Effect of varying load on wear resistance of carbon steel under unlubricated conditions

[J].

Study on alloy design, microstructure characteristics, and strength and toughness of Fe-based laser cladding layer

[D].

铁基激光熔覆涂层的合金系设计、组织特征及强韧性研究

[D].

Toughening of Fe-based laser-clad alloy coating

[J].

High-temperature erosion resistance of FeBSiNb amorphous coatings deposited by arc spraying for boiler applications

[J].

Study on FeCo-based amorphous coating using diode laser cladding processing

[D].

半导体激光熔覆铁钴基非晶层的研究

[D].

High power diode laser cladding of Fe-Co-B-Si-C-Nb amorphous coating: Layered microstructure and properties

[J].

A study of high velocity oxy-fuel thermally sprayed tungsten carbide based coatings. Part 1: Microstructures

[J].

Microstructure and property of Fe-Co-B-Si-C-Nb amorphous composite coating fabricated by laser cladding process

[J].

Superhigh strength and good soft-magnetic properties of (Fe, Co)-B-Si-Nb bulk glassy alloys with high glass-forming ability

[J].