高孔隙率钛合金点阵材料具有比强度高、质量轻的特点,在航空、航天、生物医疗等领域具有很大的应用潜力。在过去的十几年里,人们对不同结构类型的钛合金点阵材料进行了实验分析,如立方、十二面体、菱形、G7等点阵材料,旨在设计更轻、更强的点阵材料[1]。但这类结构都是基于桁架结构建立的点阵材料,这种材料应力集中严重且稳定性差,应用受限。近几年,一种新型曲面结构引起了研究人员的关注,这类曲面结构为三周期极小曲面(triply periodic minimal surface,TPMS)结构,该结构是满足一定的约束条件(如边界一定或容纳体积满足一定条件)下表面积最小、可在三维空间上无限延伸的曲面[2,3],如金刚石(diamond,D)、螺旋二十四面体(gyroid,G)、包裹(I-wrapped package,I)、简单(primitive,P) TPMS结构。TPMS做为一种数学方法定义的曲面,在孔隙尺寸、孔隙形状、内通道连通性和体积分数等方面提供了一种高效、简便、准确的设计方法,具有几何连续性和拓扑光滑性的特征,这样的曲面能量稳定、势能最小,与传统的杆连接桁架结构相比,无节点以及不连续点,将应力集中的影响最小化,结构稳定性好[4,5]。TPMS点阵材料有望取代传统桁架结构点阵材料,为多功能应用领域提供更多选择。

近年来,TPMS结构逐渐被引入到生物医疗植入体的设计中。Yánez等[6,7]、Ataee等[8]分析了电子束选区熔化技术(selective electron beam melting,SEBM)成形Ti-6Al-4V骨骼状TPMS点阵材料的力学性能,其弹性模量为59~1060 MPa,抗压强度为21.3~86.6 MPa,比强度最高达到88.6 MPa/(g·cm-3),而骨小梁的弹性模量范围为0.3~3000 MPa,抗压强度为0.88~10.60 MPa[1],TPMS点阵材料很大程度上模拟了骨小梁的拓扑结构、力学特性。Challis等[9]、Yan等[10,11]和Kadkhodapour等[12]通过选区激光熔化(selective laser melting,SLM)技术制备了Ti-6Al-4V骨骼状TPMS点阵材料,弹性模量为120~2809 MPa,抗压强度为4.7~114.7 MPa,最大比强度为91.8 MPa/(g·cm-3),有望成为可用的骨替代品。另外,Bobbert等[13]对SLM成形片状TPMS生物材料的拓扑结构、准静态力学性能进行了表征,其比抗压强度(抗压强度/密度)高达165.2 MPa/(g·cm-3),显著高于骨骼状TPMS点阵材料,阐述了片状TPMS的应用潜力,这将为设计更强、更轻的点阵材料指明方向。

本工作通过SEBM技术成形片状TPMS以及桁架点阵材料,研究SEBM点阵材料的成形质量,对比片状TPMS与传统桁架点阵材料的压缩性能,获得更轻、更强的点阵材料,为航空、航天、生物医疗等应用领域提供潜在候选材料。

1 实验方法

1.1 材料与制备方法

采用粒径为45~105 μm的球形Ti-6Al-4V粉末为原料[17],通过Arcam A2电子束快速成型机结合SEBM技术制备点阵材料。打印层厚为50 μm,束斑直径为200 μm,底板预热温度为730℃。

1.2 结构设计

桁架点阵结构选择典型拉伸主导的桁架结构八面体(octet-truss,O)以及弯曲主导的十四面体(tetrakaidecahedron,T)结构,如图1a和b所示;TPMS结构种类较多,但点阵结构要满足内部连通、曲面连续不间断等结构要求,同时要满足孔隙大、易于出粉等制备要求,因此本工作选择孔隙较大、内部连通且结构各异的D、G、I、P片状TPMS结构,如图1c~f所示。4种TPMS结构都为平滑、连续的曲面结构,较桁架结构无节点以及直角边。4种TPMS结构平均曲率都为0,但是最大曲率半径不同(弯曲程度不同),比表面积(表面积/体积)不同(D、G、I和P比表面积分别为0.48、0.39、0.42和0.29 mm-1),而这些结构差异会带来性能差异。

图1

图1

结构单胞图

(a) octet-truss (O) (b) tetrakaidecahedron (T)

(c) diamond (D) (d) gyroid (G) (e) I-wrapped package (I) (f) primitive (P)

Fig.1

Cells of different structures (O and T are strut-based structures while D, G, I, and P are shell-based triply periodic minimal surface (TPMS) structures)

八面体、十四面体点阵结构通过Solidworks来设计,结构尺寸为50 mm × 50 mm × 50 mm,体积分数范围为0.13~0.35;D、G、I、P TPMS点阵结构分别通过式(

1.3 性能检测

打印完成后,分别测量样品的重量以及体积,并根据下式计算相对密度

式中,m为点阵材料实际质量;v为点阵材料的表观体积;ρ0为Ti-6Al-4V实体的密度,取4.43 g/cm3。

使用JSM-6700扫描电镜(SEM)观察SEBM成形点阵材料的微观结构,根据样品的SEM像测量样品的杆直径、片厚度。使用Axio vert A1 Stemi2000金相显微镜(OM)观察SEBM成形样品的显微组织。

采用WEW-600万能试验机测试试样压缩性能,压缩速率为3 mm/min,压缩过程无引伸计,压缩后获得应力-应变曲线。基于ISO13314-2011标准在应力-应变曲线上获取性能参数,弹性模量取线性段斜率,屈服强度取材料发生0.2%应变时对应的应力;抗压强度对应应力-应变曲线第一个极限应力值;另外,提取应力-应变曲线上第一极限应力值对应的应变为压缩应变,用以表征材料的塑性。

2 实验结果与讨论

2.1 SEBM成形点阵材料成形质量

图2为SEBM成形Ti-6Al-4V点阵材料宏观形貌。可以看出,经SEBM成形的样品孔隙内粉末容易清理,无粉末堵塞现象,点阵材料结构完整。

图2

图2

电子束选区熔化(SEBM)成形Ti-6Al-4V点阵材料的宏观形貌

(a) O (b) T (c) D (d) G (e) I (f) P

Fig.2

Macrostructures of Ti-6Al-4V lattice material manufactured by selective electron beam melting (SEBM)

图3为SEBM成形TPMS样品表面形貌的SEM像(图中箭头为打印方向,标有箭头的样品其表面平行于打印方向,未标箭头的样品其表面垂直于打印方向)。由图可知,经SEBM技术成形的点阵材料整体连续性较好,保留了片状TPMS的曲面特征以及整体形态特征,与计算机辅助设计(CAD)的模型有良好的几何一致性,说明SEBM具有成形曲面结构的能力。另外观察到成形后的样品表面都有明显的台阶纹,这是SEBM成形过程中在样品上进行分层制造而引起的。图3e和f分别为G结构样品的侧面以及底面形貌。可以看出,样品的侧面和底面较粗糙,主要原因是其表面粘附了许多半熔融粉末颗粒。这些半熔融颗粒造成了设计样品与成形样品在尺寸以及相对密度上的偏差,具体数值如表1所示。由表1可知,由于设备打印尺寸精度的原因,每个点阵材料的尺寸都偏离了原始设计,打印前后相对密度范围从0.13~0.40变化到0.14~0.36,范围整体缩小。另外,打印后样品尺寸变化规律与设计尺寸相关,当设计样品的厚度≤ 530 μm时,打印后样品厚度增大,相对密度随之增大,而当设计尺寸> 530 μm时,打印后样品的厚度普遍缩小,相对密度减小。Arcam A2电子束快速成型机成形下限在0.3~0.5 mm之间[18],对于厚度较小的单元结构,设备成形能力的局限性导致试样尺寸均大于设计尺寸;对于厚度较大的单元结构,凝固收缩的影响较大,成形后结构尺寸偏小。总体而言,样品成形尺寸误差≤ 170 μm。

图3

图3

SEBM成形Ti-6Al-4V三周期极小曲面(TPMS)点阵材料表面形貌的SEM像

(a) D (top) (b) G (top) (c) I (top) (d) P (top) (e) G (side) (f) G (bottom)

Fig.3

SEM images of the SEBM manufactured Ti-6Al-4V TPMS lattice material (For arrowed sample, the arrow shows the building direction while for the arrow-free samples, building direction is perpendicular to the image plane)

表1 SEBM成形Ti-6Al-4V点阵材料设计和打印后形态特征参数及压缩性能

Table 1

| Sample | Ralative density | Thickness / μm | Yield strength | σ | E | ε | |||

|---|---|---|---|---|---|---|---|---|---|

| Designed | Printed | Designed | Printed | MPa | MPa | MPa | % | ||

| O1 | 0.13 | 0.16 | 530 | 540 | 27.8 | 32.8 | 1036.8 | 5.1 | |

| O2 | 0.21 | 0.20 | 700 | 680 | 46.5 | 53.3 | 1684.8 | 4.7 | |

| O3 | 0.26 | 0.25 | 800 | 720 | 62.7 | 78.2 | 2234.1 | 4.6 | |

| O4 | 0.35 | 0.30 | 940 | 830 | 96.7 | 117.8 | 3036.6 | 7.6 | |

| T1 | 0.15 | 0.14 | 820 | 760 | 21.2 | 23.4 | 900.0 | 4.1 | |

| T2 | 0.20 | 0.18 | 940 | 890 | 43.6 | 50.2 | 1733.0 | 4.8 | |

| T3 | 0.25 | 0.22 | 1120 | 1060 | 61.2 | 71.4 | 2300.7 | 4.2 | |

| T4 | 0.30 | 0.26 | 1260 | 1180 | 84.3 | 100.1 | 3414.1 | 6.1 | |

| D1 | 0.20 | 0.21 | 440 | 560 | 95.5 | 117.4 | 3329.1 | 10.5 | |

| D2 | 0.25 | 0.22 | 540 | 530 | 103.8 | 122.3 | 3199.0 | 8.9 | |

| D3 | 0.30 | 0.26 | 660 | 650 | 113.0 | 138.7 | 3899.8 | 10.1 | |

| D4 | 0.35 | 0.30 | 820 | 670 | 135.9 | 171.9 | 4461.5 | 8.9 | |

| D5 | 0.40 | 0.36 | 880 | 750 | 194.8 | 234.3 | 4722.9 | 9.3 | |

| G1 | 0.20 | 0.18 | 540 | 520 | 63.4 | 79.0 | 2281.0 | 9.9 | |

| G2 | 0.25 | 0.21 | 660 | 540 | 74.6 | 94.9 | 2745.7 | 10.2 | |

| G3 | 0.30 | 0.26 | 800 | 640 | 97.9 | 127.4 | 3208.0 | 10.6 | |

| G4 | 0.33 | 0.28 | 900 | 740 | 116.5 | 150.3 | 3600.3 | 10.3 | |

| G5 | 0.35 | 0.30 | 940 | 770 | 128.6 | 162.9 | 3920.0 | 10.8 | |

| P1 | 0.13 | 0.14 | 440 | 510 | 71.3 | 80.7 | 3124.2 | 6.2 | |

| P2 | 0.20 | 0.18 | 700 | 680 | 77.8 | 83.4 | 2212.3 | 7.8 | |

| P3 | 0.25 | 0.22 | 880 | 840 | 82.2 | 98.4 | 2624.1 | 8.4 | |

| P4 | 0.30 | 0.26 | 1060 | 940 | 106.0 | 132.0 | 3256.3 | 9.9 | |

| P5 | 0.35 | 0.31 | 1220 | 1050 | 136.3 | 173.4 | 4200.1 | 9.5 | |

| I1 | 0.17 | 0.20 | 440 | 520 | 33.6 | 38.1 | 1232.1 | 7.7 | |

| I2 | 0.20 | 0.22 | 520 | 560 | 56.3 | 64.8 | 1937.2 | 8.4 | |

| I3 | 0.25 | 0.24 | 640 | 610 | 74.8 | 90.1 | 2578.2 | 9.4 | |

| I4 | 0.30 | 0.29 | 820 | 720 | 101.2 | 119.6 | 3443.2 | 8.8 | |

| I5 | 0.35 | 0.33 | 980 | 890 | 121.3 | 156.4 | 3568.3 | 9.8 | |

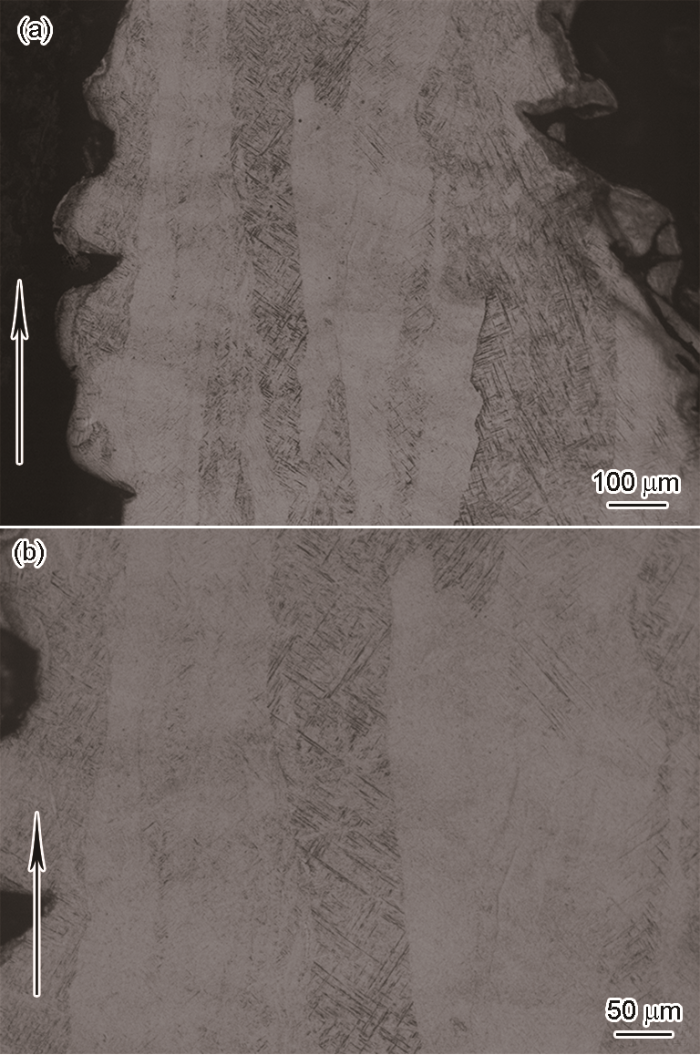

2.2 显微组织

SEBM成形Ti-6Al-4V D型TPMS点阵材料微观组织的OM像如图4所示(图中箭头表示打印方向)。可以看出,SEBM成形点阵材料的微观形貌为平行于打印方向的原始粗大β柱状晶,柱状晶粒中充满了由柱状晶边界产生的非常细小的、正交取向的针状马氏体(α')组织以及细小α + β片组成的魏氏组织。SEBM成形过程中较高的温度梯度使得新晶粒来不及长大便被吞并,且沿着打印方向散热促进了晶粒的外延生长,导致粗大原始β柱状晶组织的形成,而成形过程中较高的冷却速率促进了针状α'组织的形成。

图4

图4

SEBM成形Ti-6Al-4V金刚石(D)型TPMS点阵材料显微组织的OM像

Fig.4

Low (a) and high (b) magnified OM images of SEBM manufactued Ti-6Al-4V type D TPMS lattice material (The arrows show the building directions)

2.3 压缩性能

SEBM成形Ti-6Al-4V D型TPMS点阵材料的应力-应变曲线如图5所示,其他点阵材料的应力-应变曲线与其类似。样品压缩时主要经历了以下几个阶段。弹性阶段:应力-应变曲线以线性响应开始,该阶段线性斜率越大,弹性模量越大;塑性阶段:随着应变增加,应力非线性增加,发生塑性变形,随着应力累积,样品破坏,应力迅速下降;应力波动阶段:压头压到样品的下一层结构时应力又开始非线性增加,但在第2层结构接触到剪切带时,应力下降,以此类推,样品层层压溃,在曲线上表现出波纹线;致密化阶段:最后样品层与层之间相互接触,应力持续上升,样品逐渐致密化,压缩实验停止。

图5

图5

SEBM成形Ti-6Al-4V D型TPMS点阵材料典型压缩应力-应变曲线

Fig.5

Typical stress-strain curve of SEBM manufactured Ti-6Al-4V type D TPMS lattice material

桁架结构存在节点、直角边、杆单元结构特性,受力时在节点、直角边处存在严重的应力集中,在应力集中处过早发生塑性变形;另外,杆单元在承载时易发生屈曲、弯曲变形,破坏了材料的稳定性;因此桁架点阵材料在应力-应变曲线上体现出较差的塑性、较低的强度及弹性模量。而TPMS为连续的曲面结构,无节点、直角、杆单元等结构特点,结构稳定性好,受力均匀,载荷均匀传递,应力集中的影响较小。因此,片状TPMS点阵材料的力学性能高于桁架点阵材料。另外,在4种TPMS点阵材料中,D型TPMS结构比表面积大,弯曲程度较小,压缩时轴向材料利用率较G、I、P点阵材料高,因此D型TPMS点阵材料具有较高的强度。

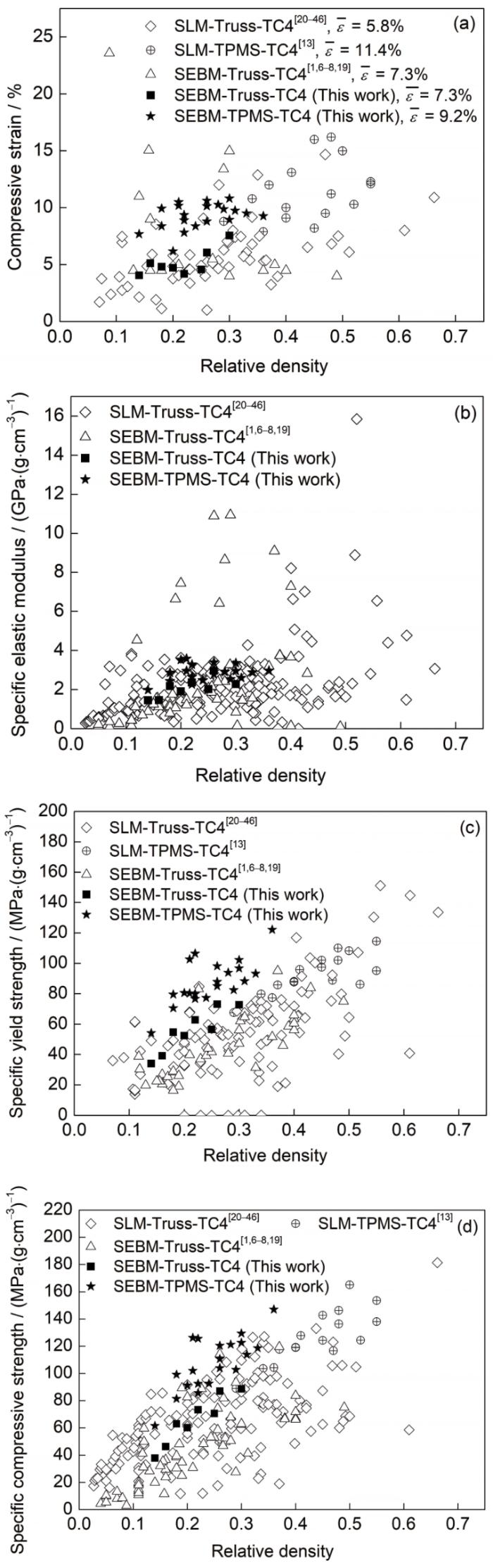

图6

图6

激光选区熔化(SLM)和SEBM成形Ti-6Al-4V点阵材料的力学性能对比

(a) compressive strain (

(b) specific elastic modulus

(c) specific yield strength

(d) specific compressive strength

Fig.6

Comparisons of compressive properties between laser selective melting (SLM) and SEBM manufactured Ti-6Al-4V lattice materials

从图6可以看出,点阵材料的比弹性模量(弹性模量/密度)、比屈服强度(屈服强度/密度)、比抗压强度都随着相对密度的增加而增加。因此,在对比点阵材料的性能时,相对密度须在相同范围之内。

压缩应变是体现材料塑性的重要参数,图6a为SLM和SEBM成形Ti-6Al-4V点阵材料的压缩应变,图中给出了各组压缩应变平均值(

SEBM成形片状D型TPMS点阵材料在相对密度为0.36时(密度为1.595 g/cm3),屈服强度、抗压强度分别为194.8和234.3 MPa (表1),可得其比屈服强度、比抗压强度分别为122.1和146.9 MPa/(g·cm-3),在相同相对密度下,片状D型TPMS点阵材料的比屈服强度、比抗压强度高于目前文献报道及本工作所有SEBM/SLM技术成形Ti-6Al-4V桁架点阵材料的最大比屈服强度95.1 MPa/(g·cm-3)和比抗压强度119.6 MPa/(g·cm-3)。

可见,片状TPMS点阵材料表现出更轻、更强的力学性能,这为航空、航天以及生物医疗等应用提供更多的潜在候选。

3 结论

(1) 通过SEBM技术成功制备了Ti-6Al-4V TPMS点阵材料,成形的点阵材料尺寸误差在束斑直径范围之内,与CAD模型具有良好的几何一致性。

(2) 结合本工作以及文献报道结果显示,SLM/SEBM成形Ti-6Al-4V TPMS点阵材料的力学性能普遍高于桁架点阵材料,证明了片状TPMS点阵材料的力学优越性。

(3) SEBM成形Ti-6Al-4V点阵材料中,片状D型TPMS点阵材料的比抗压强度最高,为146.9 MPa/(g·cm-3),在相同相对密度下,远高于本研究和文献报道的SLM/SEBM成形Ti-6Al-4V点阵材料的最大比抗压强度119.6 MPa/(g·cm-3)。

参考文献

Selective electron beam manufactured Ti-6Al-4V lattice structures for orthopedic implant applications: Current status and outstanding challenges

[J].

Infinite Periodic Minimal Surfaces without Self-Intersections

[M].

A microscopic shell structure with schwarz's D-surface

[J].

Current trends in the design of scaffolds for computer-aided tissue engineering

[J].

Compressive behaviour of gyroid lattice structures for human cancellous bone implant applications

[J].

Gyroid porous titanium structures: A versatile solution to be used as scaffolds in bone defect reconstruction

[J].

Anisotropic Ti-6Al-4V gyroid scaffolds manufactured by electron beam melting (EBM) for bone implant applications

[J].

High specific strength and stiffness structures produced using selective laser melting

[J].

Ti-6Al-4V triply periodic minimal surface structures for bone implants fabricated via selective laser melting

[J]. J

Microstructural and surface modifications and hydroxyapatite coating of Ti-6Al-4V triply periodic minimal surface lattices fabricated by selective laser melting

[J].

The relationships between deformation mechanisms and mechanical properties of additively manufactured porous biomaterials

[J]. J

Additively manufactured metallic porous biomaterials based on minimal surfaces: A unique combination of topological, mechanical, and mass transport properties

[J].

Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing

[M].

Research progress in selective electron beam melting

[J].

电子束选区熔化成形技术研究进展

[J].

Study on biomedical porous Ti-6Al-4V alloy fabricated by electron beam selective melting

[J].

电子束选区熔化制备医用多孔钛合金研究

[J].

Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting

[J].

Flexural properties of Ti6Al4V rhombic dodecahedron open cellular structures fabricated with electron beam melting

[J].

Additive manufacturing of Ti-6Al-4V lattice structures with high structural integrity under large compressive deformation

[J].

Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM)

[J].Adv

Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials

[J]. J

Effect of pore size on bone ingrowth into porous titanium implants fabricated by additive manufacturing: An in vivo experiment

[J].

Effects of build orientation and heat treatment on the microstructure and mechanical properties of selective laser melted Ti6Al4V lattice structures

[J].

Fatigue behavior of porous biomaterials manufactured using selective laser melting

[J].

Selective laser melting-produced porous titanium scaffolds regenerate bone in critical size cortical bone defects

[J].

The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds

[J].

High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints

[J].

Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures

[J].

Bionic mechanical design and 3D printing of novel porous Ti6Al4V implants for biomedical applications

[J]. J

Evaluation of mechanical properties and osteogenesis ability of porous titanium alloy scaffolds manufactured by selective laser melting technique

[J].

基于选区激光熔融技术制备的多孔钛合金支架的力学性能及成骨能力评价

[J].

Trabecular-like Ti-6Al-4V scaffolds for orthopedic: Fabrication by selective laser melting and in vitro biocompatibility

[J].

Bionic design and 3D printing of porous titanium alloy scaffolds for bone tissue repair

[J].

Mechanical properties of porous structures produced by selective laser melting of a Ti6Al4V alloy powder

[J]. J

Tensile and compression properties of variously arranged porous Ti-6Al-4V additively manufactured structures via SLM

[J].

Effect of heat treatment on the microstructure and mechanical properties of Ti6Al4V gradient structures manufactured by selective laser melting

[J].

Mechanical properties and in vitro behavior of additively manufactured and functionally graded Ti6Al4V porous scaffolds

[J].

Mechanical behavior of regular open-cell porous biomaterials made of diamond lattice unit cells

[J]. J

Additively manufactured open-cell porous biomaterials made from six different space-filling unit cells: The mechanical and morphological properties

[J].

Mechanical behavior of additively manufactured porous biomaterials made from truncated cuboctahedron unit cells

[J].

Functionally graded porous scaffolds in multiple patterns: New design method, physical and mechanical properties

[J].

The biomimetic design and 3D printing of customized mechanical properties porous Ti6Al4V scaffold for load-bearing bone reconstruction

[J].

Microstructure and mechanical properties of open-cell porous Ti-6Al-4V fabricated by selective laser melting

[J].

Influence of the unit cell geometrical parameter to the mechanical properties of Ti6Al4V open-porous scaffolds manufactured by selective laser melting

[J].

Failure modes in high strength and stiffness to weight scaffolds produced by Selective Laser Melting

[J].

Continuous compression behaviors of selective laser melting Ti-6Al-4V alloy with cuboctahedron cellular structures

[J].