对于复合制造结合区的组织与性能,已在不同合金体系中开展了研究[8,13~15]。针对1Cr12Ni2WMoVNb钢,Wang等[13]在锻件基材上利用送粉式激光增材制造方法开展复合制造,发现结合区由比基材区更细小的等轴奥氏体晶粒组成,而激光沉积区包含较粗大的柱状奥氏体晶粒和树枝晶结构,该组织特征决定了激光增材区和结合区的显微硬度均高于基材区,拉伸试样的断裂位置位于基材区。Ghoncheh等[14]通过铺粉式激光增材制造将AlSi10Mg粉末沉积在AA2618铝合金铸态基材的顶部形成复合制造零件,结果表明AlSi10Mg/AA2618界面显示出良好的融合性,结合区中合金元素的扩散系数、凝固过程中的溶质分配系数、液相混合焓以及溶解度决定了元素在基体中的扩散趋势,复合试件的强度和断裂应变由性能较弱的AA2618基体决定。对于钛合金,Zhu等[8]研究了复合制造Ti-6.5Al-3.5Mo-1.5Zr-0.3Si (TC11)钛合金的组织与力学性能,发现结合区内形成大量细小的次生相,有效提升了结合区的强度。然而对于目前应用范围最广的钛合金——Ti-6Al-4V (TC4)而言,虽然对其激光增材制造组织已开展了大量研究[16~19],但对其复合制造过程中锻态基材与激光增材之间的结合区组织特征及形成机制仍缺乏研究报道。

复合制造和熔焊技术具有一定的相似性,2者都是通过高能热源形成熔池,熔池凝固后形成良好的冶金结合,同时结合区(热影响区)均受到高温热源的影响。针对Ti-6Al-4V合金,Zhang等[20]对焊接接头附近结合区内的组织演变、元素分布及晶粒取向进行了深入分析,提出热影响区中部的边缘相(Rim-α)和靠近熔化区的阴影结构是由元素扩散不均匀和冷速差异所导致。Wang等[21]研究了电子束焊接Ti-6Al-4V结合区的组织形貌,发现结合区内部的组织存在不均匀性,熔化区内部出现了马氏体和细层片α相组织,这种特殊组织可改善焊接件的拉伸性能和高周循环疲劳性能,但削弱了冲击韧性和低周循环疲劳性能。上述针对TC4焊接结合区的研究虽然对理解复合制造具有一定帮助,但焊接结合区中的组织特征和形成规律与复合制造并不完全等同。焊接过程中结合区仅受到热源的一次或几次影响,而复合制造过程中结合区将经历热源的循环往复受热。这种受热条件的差异可能导致不同的微观组织,并对最终性能产生影响。

1 实验方法

基材选用锻造态Ti-6Al-4V合金,尺寸为100 mm × 45 mm × 55 mm。增材用Ti-6Al-4V合金粉末通过等离子旋转电极方法制备,粉末颗粒直径为80~150 μm,表面光洁度好,卫星球粉数量少。Ti-6Al-4V粉末和锻造基材的化学成分如表1所示。在LSF-VII型激光立体成形设备上完成不同工艺参数下的增材制造,该设备包含6 kW半导体激光器、五轴四联动数控工作台、高精度送粉器、同轴送粉喷嘴、惰性气氛加工室和氧含量实时监测系统等,成形过程中采用高纯Ar气作为保护气体和载粉气体。图1a所示为增材制造过程示意图,扫描方式为循环往复式,成形工艺参数如表2所示。图1b为实验所得不同工艺参数下的整体试件,增材部分尺寸为60 mm × 20 mm × 60 mm。

表 1 锻造态Ti-6Al-4V基材与Ti-6Al-4V合金粉末的化学成分 (mass fraction / %)

Table 1

| Alloy | H | O | N | C | Si | Fe | V | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|

| Substrate | 0.0019 | 0.140 | 0.010 | 0.020 | 0.030 | 0.03 | 4.2 | 6.36 | Bal. |

| Powder | 0.0030 | 0.087 | 0.002 | 0.008 | 0.028 | 0.03 | 4.2 | 6.37 | Bal. |

图1

图1

锻造-增材复合制造实验示意图、复合制造试件、结合区拉伸试样取样位置和拉伸试样尺寸

Fig.1

Schematics of forging-additive hybrid manufactured processing (a), hybrid manufactured samples (substrate size: 100 mm × 45 mm × 55 mm, deposition size: 60 mm × 20 mm × 60 mm) (b), sampling position of tensile specimen in bonding zone (c), and the size of tensile specimen (d)

表2 锻造-增材复合制造工艺参数

Table 2

| Sample | P W | v mm·s-1 | d mm | R0 % | Vf g·min-1 | ΔZ mm | El J·mm-1 |

|---|---|---|---|---|---|---|---|

| 1 | 1500 | 15 | 5 | 50 | 12-13 | 0.7 | 100 |

| 2 | 2000 | 15 | 5 | 50 | 12-13 | 0.7 | 133 |

| 3 | 2000 | 10 | 5 | 50 | 12-13 | 0.7 | 200 |

在试件基材与增材结合部位取组织观测试样,将样品机械磨抛后用Kroll's试剂腐蚀,利用GX71光学显微镜(OM)和TESCAN MAIA3扫描电子显微镜(SEM)观察微观组织及断口形貌,利用SEM配备的能谱仪(EDS)进行成分分析。电子背散射衍射(EBSD)分析采用的加速电压为20 kV,工作距离为17 μm,步长为0.25 μm。力学性能试样的取样位置位于结合区,如图1c所示,增材部分和基材部分各占50%,拉伸试样的尺寸如图1d所示,标距段尺寸为15 mm × 5 mm × 2 mm。在INSTRON电子拉力试验机上参照GB/T228-2002 《金属材料拉伸试验方法》进行室温拉伸性能测试。

2 实验结果与讨论

2.1 复合制造试样组织表征与分析

2.1.1 结合面附近基材区及增材区组织

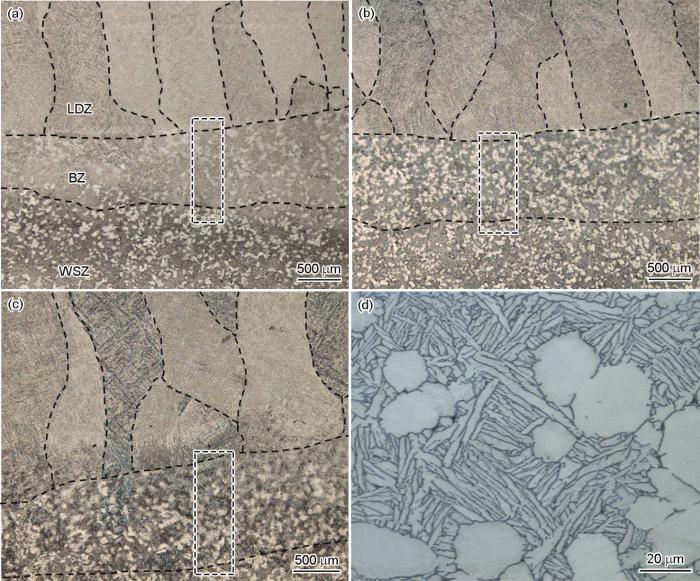

图2为3种不同线能量密度下锻件-增材复合制造Ti-6Al-4V合金增材-基材结合界面附近的微观组织,结果表明从基材区到增材区组织发生显著变化。以线能量密度为100 J/mm的试样(图2a)为例,最下方基材区域(wrought substrate zone,WSZ)组织与初始锻态基材组织相同,均为等轴α相和层片α相形成的双态组织,高倍显微照片如图2d所示,其中等轴α相平均直径约为12.5 μm,片状α相平均宽度约为1.6 μm。最上方的增材区域(laser deposition zone,LDZ)由贯穿多个沉积层的外延生长柱状β晶粒组成,β晶粒内部包含细小的层片α相,这与以往研究中[16,18]观测到的钛合金增材区组织相同。在基材区与增材区中间的结合区(bonding zone,BZ),由于受到激光热源的影响,初始双态组织发生了从下到上的非均匀变化,该区域的组织将在下文进行详细分析。

图2

图2

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金的结合部位及基材的显微组织

Fig.2

Microstructures of the bonding zone in forging-additive hybrid manufactured Ti-6Al-4V alloy under linear energy densities of 100 J/mm (a), 133 J/mm (b), and 200 J/mm (c), and high magnified image of WSZ in Fig.2a (d) (WSZ—wrought substrate zone, LDZ—laser deposition zone, BZ—bonding zone)

图3

图3

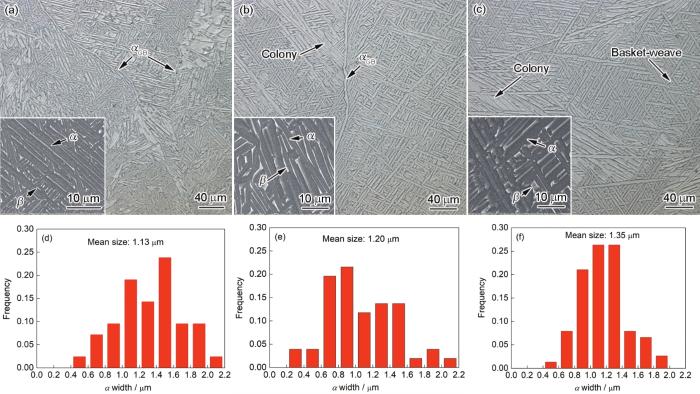

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金增材区的微观组织及其特征尺寸

Fig.3

Microstructures (a-c) and feature sizes (d-f) of α phase of the laser deposition zone in forging-additive hybrid manufactured Ti-6Al-4V alloy under linear energy densities of 100 J/mm (a, d), 133 J/mm (b, e), and 200 J/mm (c, f) (Insets in Figs.3a-c show the enlarged views. α: dark area, β: bright bar, αGB—grain boundary α phase)

2.1.2 结合区组织特征

图4

图4

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金结合区的显微组织

(a1, a2, a3) 100 J/mm (b1, b2, b3) 133 J/mm (c1, c2, c3) 200 J/mm

Fig.4

Microstructures of the bonding zones in forging-additive hybrid manufactured Ti-6Al-4V alloy corresponding to the square areas in Figs.2a (a), 2b (b), and 2c (c), and locally magnified images of bottom-BZ (a1, b1, c1), mid-BZ (a2, b2, c2), and up-BZ (a3, b3, c3) (The dashed lines in Figs.4a, b, and c show the interfaces between the up-BZ and LDZ. The dotted lines in Figs.4a3, b3, and c3 show the morphologies of equiaxed β grains formed during heating)

图5

图5

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金结合区中不同组织的尺寸

(a) width of lamellar α phase in bottom-BZ

(b) diameter of equiaxed α phase in bottom-BZ

(c) width of lamellar α phase in up-BZ

(d) diameter of equiaxed β phase in up-BZ

Fig.5

The sizes of different microstructures of the bonding zone under different linear energy densities in forging-additive hybrid manufactured Ti-6Al-4V alloy

如图4a2、b2和c2所示,结合区中部仍由等轴α相和层片α相组成,但相比于结合区下部,此处等轴α相直径和层片α相宽度均有所减小,α层片之间不再是连续的β相,因而OM下层片组织不再如基材中清晰。在钛合金的升温过程中,α相溶解起始温度约为650℃,α相完全溶解温度(β相转变温度)约为980℃[18]。结合区中部区域受到激光热源的影响,温度上升,其峰值温度位于α相起始溶解温度和完全溶解温度之间(650~980℃),等轴α相和层片α相发生部分溶解,使得最终残余的等轴α相直径和层片α相宽度减小。此区域SEM像如图6所示。可以看出,在层片α相之间的β相中形成了次生α相(αs),且随线能量密度的增大,次生α相体积分数增大。

图6

图6

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金结合区中部的显微组织

Fig.6

Microstructures of the middle of bonding zone in forging-additive hybrid manufactured Ti-6Al-4V alloy under linear energy densities of 100 J/mm (a), 133 J/mm (b), and 200 J/mm (c) (αs—secondary α)

如图4a3、b3和c3所示,结合区上部呈现出魏氏体组织,晶界α相勾勒出等轴β晶粒形貌,β晶粒内包含由α层片以及一些白色的区域。白色区域的高倍SEM像如图7a~c所示(在SEM中呈现灰色)。可以看到,该区域同样由许多α层片构成,其尺寸随着线能量密度的增大而减小。Pederson等[24]在研究Ti-6Al-4V合金焊接接头的热影响区中发现过类似组织,并将其命名为阴影结构(Ghost structure)。EDS线扫描发现,阴影结构区域成分和周围区域存在差异,如图7d所示,其中阴影区域Al元素含量高于周围层片区,而V元素含量低于周围区域,因此呈现出不同的衬度。上部区域β晶粒内α层片尺寸及等轴β晶粒尺寸的统计结果分别如图5c和d所示。可以看出,随着线能量密度的增大,α层片尺寸以及等轴β晶粒的直径均增大,该区域的α层片是基材组织达到β相转变温度以后发生β→α相转变形成的。

图7

图7

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金结合区上部的显微组织以及阴影结构的元素含量变化

Fig.7

Microstructures of the up of bonding zone in forging-additive hybrid manufactured Ti-6Al-4V alloy under linear energy densities of 100 J/mm (a), 133 J/mm (b), 200 J/mm (c), and element content changes in ghost structure along line in Fig.7b (d)

2.1.3 结合区非均匀组织形成机制

增材制造过程中基材要经历循环往复受热。开始时刻,激光热源直接照射在基材上,热源经过基材表面任意一点A时,A点下方基材温度急剧上升,当热源移动之后,A点下方基材开始降温,当沉积下一道或下一层时,热源再次靠近A点时,A点下方温度再次升高。初始阶段,基材温度在一个较高数值的区间内震荡。随着沉积层数的增高,热源逐渐远离基材,基材温度下降。基材从上至下不同部位由于距热源的距离不同,受到热源的影响程度不同,导致其相变过程不同,最终形成不同的微观组织。

结合区下部由于距离熔池较远,升温所能达到的峰值温度远低于β相转变温度,故该处无相变发生,初始的等轴α相、层片α相仅仅发生一定的粗化(图5)。随着线能量密度的增大,同一竖直高度处的基材温度升高,溶质扩散加剧,粗化更为显著。因而结合区下部的等轴α相、层片α相的尺寸随能量密度升高而增大。

结合区上部最靠近热源,其升温过程的峰值温度超过β相转变温度,初生α相全部转变为β相。在初次降温过程中,由于初始等轴α相转变成的β相内Al含量较多,优先形核形成α'马氏体相(阴影区内的层片α相),在晶界处形核的α'相以片层状的形式向晶内生长,在随后的热循环过程中α'马氏体相分解,最后形成包含晶界α相和层片α相的魏氏组织[19]。通过晶界α相可以观察到初始升温形成的等轴β晶粒形貌(图4a3、b3和c3中虚线所示)。随着线能量密度的增大,该区域在β相转变温度以上停留时间较长,等轴β晶粒尺寸增大,同时晶内层片α相的宽度增大(图7a~c和图5d所示)。在升/降温过程中,初始等轴α相中的Al与V元素没有足够时间扩散达到平衡,因而形成阴影结构[16,24] (图4和7a~c所示)。阴影结构的尺寸随着线能量密度的增大而减小,这主要与升降温过程中元素扩散有关,相比于线能量密度为100 J/mm时的情形,线能量密度为200 J/mm时,Al和V元素的扩散更充分,所以阴影结构尺寸减小。

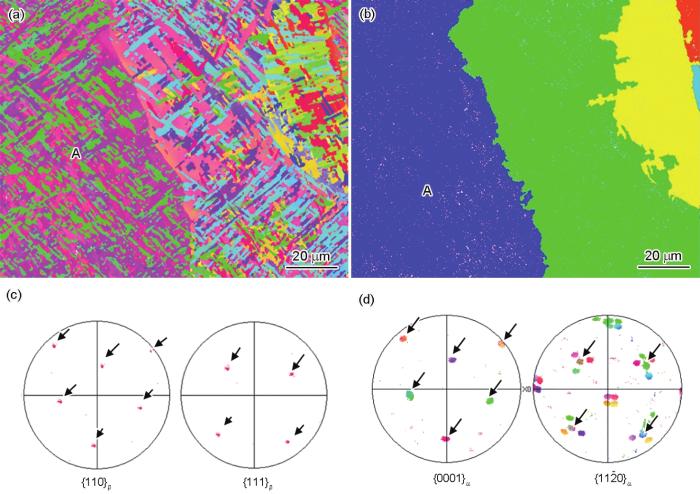

等轴α相是基材在前期热机械处理过程中由层片α相发生再结晶转变而形成的一种组织形态,是基材中α相的一种初始组织,并非在激光沉积成形过程中形成。层片状α是α相从母相β相析出时由于弹性应变能导致的特殊形态。β→α转变过程中遵循Burgers取向关系:<110>β //<0001>α,<111>β //<

图8

图8

锻件-增材复合制造Ti-6Al-4V试样增材区的EBSD测试结果以及A晶粒的散点极图

Fig.8

EBSD of the deposition zone (a), the reconstruction of β grain in Fig.8a (b), and scatter pole figures of α phase (c) and β phase (d) of A grain in forging-additive hybrid manufactured Ti-6Al-4V alloy (A grain represents β grain in Fig.8a, arrows in Figs.8c and d show the pole positions)

图9

图9

增材区中α相和β相的TEM像以及电子衍射斑点

Fig.9

TEM images of α and β phases (a), corresponding electron diffraction patterns of β phase (b) and α phase (c) in the deposition zone

2.2 力学性能

2.2.1 拉伸性能

图10

图10

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金结合区试样的应力-应变曲线

Fig.10

Stress-strain curves of the bonding zone samples in forging-additive hybrid manufactured Ti-6Al-4V alloy under different linear energy densities

表3 不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金的力学性能

Table 3

| Sample | UTS / MPa | YS / MPa | EL / % |

|---|---|---|---|

| 1 | 954.64 ± 0.4 | 861.74 ± 3.2 | 12.48 ± 2.25 |

| 2 | 918.00 ± 8.1 | 815.60 ± 5.5 | 12.80 ± 0.24 |

| 3 | 915.86 ± 10.5 | 828.23 ± 7.8 | 15.43 ± 0.45 |

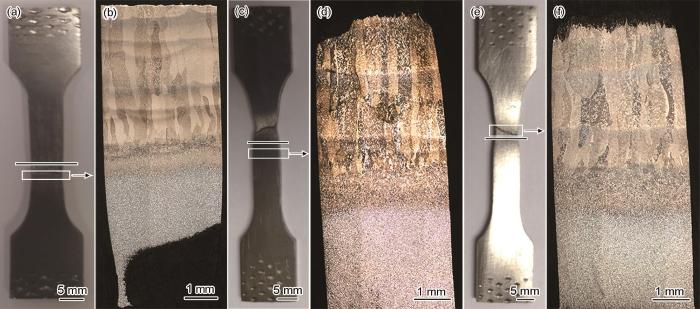

不同线能量密度下结合区试样的断裂位置如图11所示。线能量密度为100 J/mm时,断裂部位位于基材区,而线能量密度为133和200 J/mm时,断裂部位均位于增材区。3种线能量密度下断裂部位均远离结合区,表明增材区与基材区的结合良好,结合区的强度超过基材区和增材区。在本实验中,3种线能量密度下,基材均为双态组织,当线能量密度为100 J/mm时,增材区以及结合区内部的典型组织尺寸均较小(图3和5),增材区的屈服强度大于基材区,拉伸过程中应变主要集中在性能较弱的基材区,并在该区域发生断裂;当线能量密度为133和200 J/mm时,增材区以及结合区内部的典型组织尺寸增大,由Hall-Petch效应可知,增材区的屈服强度下降,所以拉伸过程中,断裂位置位于增材区。这与Liu等[32]发现拉伸应变倾向于集中在非均匀样品的较弱区域上,并导致在该区域发生断裂是一致的。

图11

图11

不同线能量密度下结合区锻造-增材复合制造Ti-6Al-4V合金试样的断裂位置

Fig.11

Low (a, c, e) and locally high (b, d, f) magnified images showing fracture positions of the bonding zone samples in forging-additive hybrid manufactured Ti-6Al-4V alloy under line energy densities of 100 J/mm (a, b), 133 J/mm (c, d), and 200 J/mm (e, f)

由图10可知,与线能量密度为133和200 J/mm相比时,线能量密度为100 J/mm时,结合区试样的抗拉强度和屈服强度最大,原因是线能量密度为100 J/mm时,单位时间激光能量输入小,热累积程度低、冷速较大,因此等轴α相粗化程度较小,析出的层片α相宽度较小。对于钛合金而言,层片α相厚度及等轴α相尺寸是决定屈服强度的主要因素,材料的屈服强度随这些组织特征尺寸的减小而增大。因此,能量密度为100 J/mm时,相对细小的层片α相和等轴α相导致其屈服强度较高。

2.2.2 断口形貌

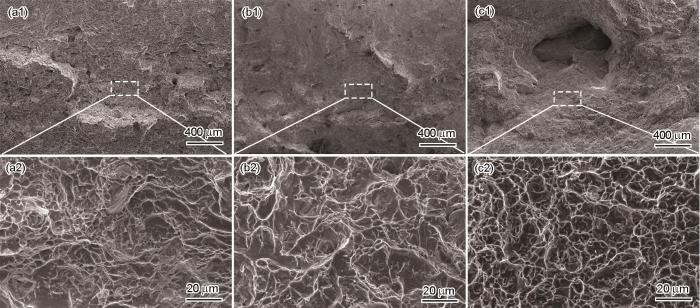

图12

图12

不同线能量密度下锻造-增材复合制造Ti-6Al-4V合金结合区的断口形貌

Fig.12

Low (a1-c1) and locally high (a2-c2) magnified fracture morphologies of bonding zone in forging-additive hybrid manufactured Ti-6Al-4V alloy under linear energy densities of 100 J/mm (a1, a2), 133 J/mm (b1, b2), and 200 J/mm (c1, c2)

3 结论

(1) 锻造-增材复合制造Ti-6Al-4V试样结合区受热源的影响形成非均匀组织。其中下部为双态组织,中部由等轴α相、层片α相以及高温时效保温形成的次生α相组成,上部为层片α相形成的魏氏体组织,并伴随着由于元素扩散不充分而形成的阴影结构。

(2) 随线能量密度的增大,锻造-增材复合制造Ti-6Al-4V试样结合区下部等轴α相和层片α相发生一定程度的粗化;结合区中部次生α相的体积分数增大;结合区上部层片α相宽度增大,阴影结构的尺寸减小。此外,增材区柱状β晶粒尺寸以及层片α相的宽度随线能量密度的增加而变大。

(3) 本工作采用的3种能量密度下,结合区强度均大于基材区和增材区。线能量密度为100 J/mm时,增材区的强度大于基材区,断裂位置位于基材区;线能量密度为133和200 J/mm时,增材区的强度小于基材区,断裂位置位于增材区。随线能量密度的增大,锻造-增材复合制造Ti-6Al-4V试样的屈服强度和抗拉强度减小,延伸率增加。

参考文献

3D printing of high-strength aluminium alloys

[J].

Additive manufacturing of metals

[J].

Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys

[J].

Additive manufacturing of metallic components—Process, structure and properties

[J].

Additive manufacturing of ultrafine-grained high-strength titanium alloys

[J].

Customized exposure strategies for manufacturing hybrid parts by combining laser beam melting and sheet metal forming

[J]. J.

Advanced manufacturing approach via the combination of selective laser melting and laser metal deposition

[J]. J.

Microstructure and mechanical properties of hybrid fabricated Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy by laser additive manufacturing

[J].

Influence of the spatial variation of Poisson's ratio upon the elastic field in nonhomogeneous axisymmetric bodies

[J].

Microstructural investigation and mechanical behavior of a two-material component fabricated through selective laser melting of AlSi10Mg on an Al-Cu-Ni-Fe-Mg cast alloy substrate

[J].

Metallurgical and mechanical assessment of hybrid additively-manufactured maraging tool steels via selective laser melting

[J].

Diffusion-induced stress in inhomogeneous materials: Concentration-dependent elastic modulus

[J].

Microstructure and mechanical properties of hybrid fabricated 1Cr12Ni2WMoVNb steel by laser melting deposition

[J].

On the solidification characteristics, deformation, and functionally graded interfaces in additively manufactured hybrid aluminum alloys

[J].

Additive manufactured new hybrid high entropy alloys derived from the AlCoFeNiSmTiVZr system

[J].

Texture and microstructure characterization in laser additive manufactured Ti-6Al-2Zr-2Sn-3Mo-1.5Cr-2Nb titanium alloy

[J].

A study of the microstructural evolution during selective laser melting of Ti-6Al-4V

[J].

Microstructure evolution and layer bands of laser melting deposition Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy

[J]. J.

Texture evolution during laser direct metal deposition of Ti-6Al-4V

[J].

Temperature-gradient induced microstructure evolution in heat-affected zone of electron beam welded Ti-6Al-4V titanium alloy

[J].

Tensile and fatigue behavior of electron beam welded dissimilar joints of Ti-6Al-4V and IMI834 titanium alloys

[J].

Densification and microstructure of TiCx /Ti nanocomposites prepared by selective laser melting

[J].

选区激光熔化制备TiCx /Ti纳米复合材料的致密化及显微组织

[J].

Research progress of microstructure and fatigue behavior in additive manufacturing Ti-6Al-4V alloy

[J].

增材制造Ti-6Al-4V合金组织及疲劳性能研究进展

[J].

Microstructure and mechanical properties of friction- and electron-beam welded Ti-6Al-4V and Ti-6Al-2Sn-4Zr-6Mo

[J].

Influence of alloying elements partitioning behaviors on the microstructure and mechanical properties in α+β titanium alloy

[J].

α + β两相钛合金元素再分配行为及其对显微组织和力学性能的影响

[J].

Laser welding of electron beam melted Ti-6Al-4V to wrought Ti-6Al-4V: Effect of welding angle on microstructure and mechanical properties

[J]. J.

Effect of electron beam welding on the microstructures and mechanical properties of thick TC4-DT alloy

[J].

Crystallographic variant selection in α-β brass

[J].

Crystallographic and morphological relationships between β phase and the Widmanstätten and allotriomorphic α phase at special β grain boundaries in an α/β titanium alloy

[J].

Influences of deformation strain, strain rate and cooling rate on the Burgers orientation relationship and variants morphology during β→α phase transformation in a near α titanium alloy

[J].

Predicting equilibrium shape of precipitates as function of coherency state

[J].

Strain rate dependent deformation and failure behavior of laser welded DP780 steel joint under dynamic tensile loading

[J].

Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition

[J].

Effects of deposition strategies on macro/microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V

[J].