在过去30年里,改善阳极材料的方法主要集中在纳米结构水平上设计和合成新的材料[7,8,9,10]。从某种程度上来说,传统的Ni-YSZ (钇稳定氧化锆)金属陶瓷阳极中无序的孔洞结构不利于燃料的快速扩散和燃料产物的快速排出,因为这会导致反应速率的降低。Nelson等[11]通过液晶模板电镀法(liquid crystal templating electrodeposition route)成功制备出一种六边形结构排布的纳米蜂窝镍(nickel nano-honeycombs,NNHC)金属薄膜[11]。这种材料拥有更多孔洞及更高的比表面积,能加快反应速率,并且其有序的结构有利于燃料产物从电极表面脱离;另外它是一种单晶结构,电子移动时没有了晶界的阻碍,从而进一步提高了导电性,减少能量损失[12],因此非常有潜力作为SOFC的阳极材料。

Song等[22]使用CNT作为功能性添加剂来改善用于可充电碱性Ni电池的贴片Ni泡沫电极的电化学性能,发现与没有添加CNT的电极相比,添加3% CNT (质量分数)的电极表现出更高的充电效率,更大的比放电容量,更高的放电电压,更好的高倍率性能和出色的循环稳定性。Jiang等[23]在不锈钢基体上合成了CNT/Ni混合纳米结构阵列,并发现由于该复合材料具有独特的互连混合结构,又兼具CNT网良好导电性的优点,可用作电化学电容器(ECs)的高性能电极材料。Jang等[24]在Ni薄膜电极里添加质量分数为1%~5%的CNT来延缓导电Ni薄膜的致密化,以匹配可能的共烧陶瓷层,同时使Ni薄膜的电阻率最小化。结果显示在1100 ℃时,CNT对致密化的阻滞效果很明显,但电阻率并没有因为添加CNT而显著降低。这表明CNT/Ni复合膜作为一种共烧电极,极具应用前景。大多数关于CNT/Ni复合材料的实验研究致力于开发和改进制造工艺以改善机械性能或将其用作功能材料[25]。另外CNT/Ni复合材料还可以用作葡萄糖生物传感器[26,27]、氢气传感器[28]、乙醇生物传感器[34]等。

1 模型与方法

为研究NNHC以及CRNNHC沿径向(radial) Y轴方向和沿轴向(axial) Z轴方向的力学性能,本工作选取一个代表性体积单元(representative volume element,RVE)。分子动力学模拟的元胞大小为14.08 nm×14.08 nm ×14.08 nm,如图1所示。X、Y、Z轴分别对应[010]、[100]、[001]晶向。元胞中存在过中心和4个顶角的沿[001]方向为旋转轴的圆柱孔,孔半径R=3.696 nm (图1)。相对密度为0.567,原子数为146320。为了研究CNT的添加对NNHC力学性能的影响,在Ni基质中添加CNT,如图1c所示,CNT沿Z轴贯穿且均匀地分布在基质中。CNT的手性均为(4, 4),质量分数为5.22‰,计算公式参照文献[38]。

图1

图1

本工作所用分子动力学(MD)模型

Fig.1

Molecular dynamics (MD) model in this work (R—radius of pore, CNT—carbon nanotube, NNHC-nickel nano-honeycombs, CRNNHC—CNT-reinforced NNHC)

(a) the model of CRNNHC

(b) the size distribution of CRNNHC

(c) the internal distribution of CNT in the CRNNHC

NNHC和CRNNHC中Ni原子间的相互作用通过原子嵌入势(EAM)[40]描述,CRNNHC中碳纳米管中C原子间的相互作用通过AIREBO势[41]描述,C-Ni之间相互作用以及长程C原子相互作用通过Lennard-Jones (LJ)[42]势描述,εNi-C和σNi-C通过Lorentz-Berthelot (LB)[43]混合准则确定,其中εNi-C为C-Ni间势阱深度参数,σNi-C为C-Ni间相互作用的势能正好为零时的C-Ni距离参数。εNi-C通过εNi和εC的几何平均值计算εNi-C=

所有试样在X、Y、Z轴方向均采用周期性边界条件。在变形前所有模型都在等温等压(NPT)系综中0 Pa下弛豫100 ps,以达到最小能量,模拟中分析步长选为0.5 fs[47]。

以CNT质量分数为5.22‰的CRNNHC为代表,研究温度对NNHC和CRNNHC力学性能的影响。温度跨度从300 K到900 K共7组,每组相差100 K,变形时应变速率为5×109 s-1。

2 结果分析

2.1 不同温度下径向拉伸

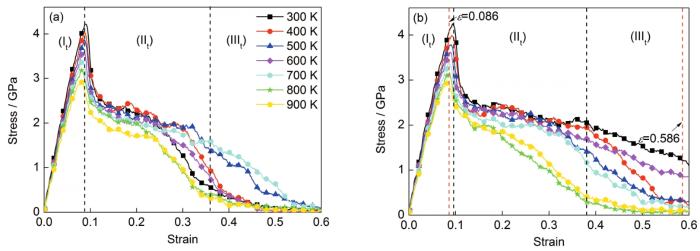

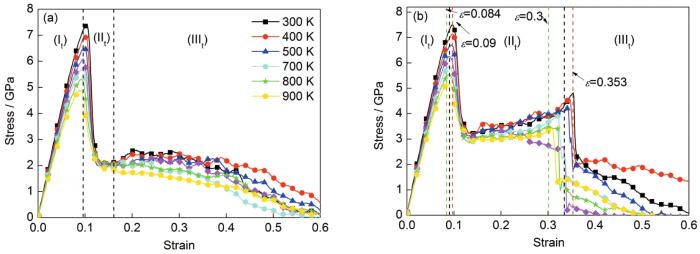

图2a和b分别给出了不同温度下,NNHC和CRNNHC试样沿径向拉伸的应力-应变曲线。曲线分为3个阶段:(It) 线弹性阶段,(IIt) 迅速软化,(IIIt) 断裂阶段。阶段It的E及σu均随着温度的升高而降低;进入阶段IIt后,应力迅速下降,温度高的试样在阶段IIt末期已达到一个相对低的应力;进入阶段IIIt后,试样应力大小随温度变化未见明显规律性。

图2

图2

不同温度下NNHC和CRNNHC沿径向拉伸的应力-应变曲线

Fig.2

The radial tensile stress-strain curves of NNHC (a) and CRNNHC (b) with different temperatures (ε—strain)

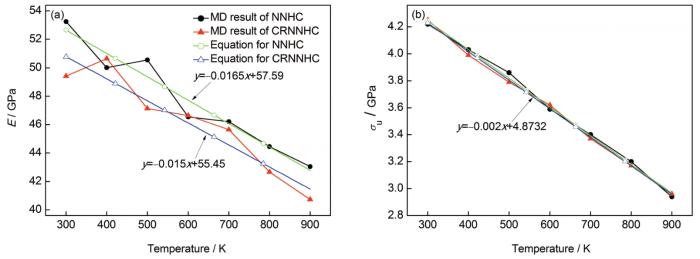

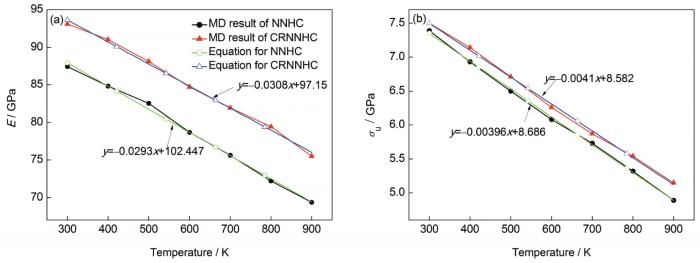

图3a和b分别给出了不同温度下,NNHC与CRNNHC试样沿径向拉伸的E和σu。本工作中,任一温度下NNHC与CRNNHC的弹性模量百分比差通过公式(ECRNNHC-ENNHC)/ENNHC计算,其中,ENNHC和ECRNNHC分别是该温度下NNHC和CRNNHC的弹性模量;该温度下NNHC与CRNNHC的最终应力百分比差通过公式(σuCRNNHC-σuNNHC)/σuNNHC计算,其中,σuNNHC和σuCRNNHC分别为该温度下NNHC和CRNNHC的最终应力。图中曲线通过多项式拟合得到,具体方法参见文献[50]。由图3a可以看出,无论是NNHC还是CRNNHC,弹性模量随温度升高皆呈近似线性下降。在温度为300 K时百分比差最大,百分比差绝对值为7.2%,可以看出CNT减弱作用最强。由于CNT与镍基质界面的弱结合以及CNT径向拉伸或压缩性能较差[48,51],所以CNT的添加可能导致径向拉伸或压缩性能变差。在400 K时,CNT增强作用幅值仅为1.3%。由图3b可以看出,在温度为500 K时,NNHC与CRNNHC的最终应力数值差与百分比差均最大,数值差为0.07 GPa,百分比差为1.8%。无论是NNHC还是CRNNHC,其σu随温度升高均快速线性下降。

图3

图3

不同温度下NNHC和CRNNHC沿径向拉伸的力学性能

Fig.3

The radial tensile E (a) and σu (b) of NNHC and CRNNHC with different temperatures (E—elastic modulus,

以上分析表明,CRNNHC在径向拉伸变形时,CNT增强效果不明显,甚至起到减弱作用。

2.2 不同温度下径向压缩

图4

图4

不同温度下NNHC和CRNNHC沿径向压缩的应力-应变曲线

Fig.4

The radial compression stress-strain curves of NNHC (a) and CRNNHC (b) with different temperatures

图5

图5

不同温度下NNHC和CRNNHC沿径向压缩的力学性能

Fig.5

The radial compressive E (a) and σu (b) of NNHC and CRNNHC with different temperatures

模拟结果表明,CRNNHC在径向压缩变形时,CNT增强效果不明显,甚至起到减弱作用。

2.3 不同温度下轴向拉伸

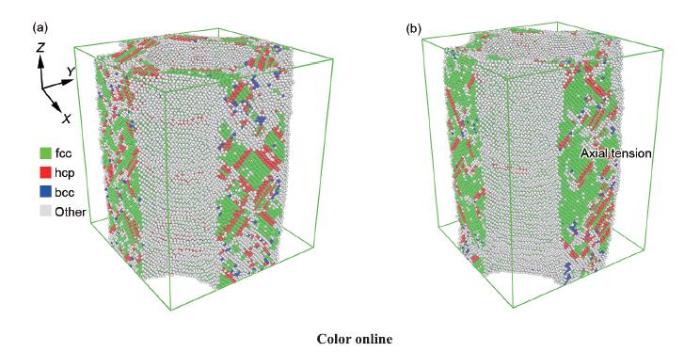

图6a和b分别给出了不同温度下NNHC和CRNNHC沿轴向拉伸的应力-应变曲线。图7为900 K时CRNNHC沿轴向拉伸原子分布图。对于NNHC而言,与径向拉伸一样,沿轴向拉伸的应力-应变曲线也可分为如2.1节中所描述的3个阶段。但是对于CRNNHC而言,由于CNT的存在,导致CRNNHC的轴向拉伸曲线在阶段IIt和IIIt之间多一个应力平台期。无论是NNHC还是CRNNHC,它们在阶段It的E和σu都随着温度的升高而降低,试样进入阶段IIt后,应力迅速下降。但是,它们数值特征上与径向拉伸不同,对于轴向拉伸试样,无论温度高低,试样会在阶段IIt末期达到一个比较相近的应力。NNHC试样进入阶段IIIt后,试样的应力随温度变化未见明显规律性;而CRNNHC需要再经过一个平台期后才开始断裂。如图7所示,当应变达到0.084时,CRNNHC试样开始从弹性变形进入塑性变形,一些区域出现了大量层错堆积,由于纳米孔的存在,位错产生后会快速从孔界面滑出。由于CNT承载了大量载荷,CRNNHC的应力-应变曲线出现较长的应力平台阶段,如图6b中的应力平台。当应变达到0.3时,随着位错滑移以及原子迁移,空位增加,对应于图6b中应力-应变曲线急速下降。

图6

图6

不同温度下NNHC和CRNNHC沿轴向拉伸的应力-应变曲线

Fig.6

The axial tension stress-strain curves of NNHC (a) and CRNNHC (b) with different temperatures

图7

图7

温度为900 K时CRNNHC沿轴向拉伸原子分布图

Fig.7

Atomic snapshots of CRNNHC under axial tension at the temperature of 900 K with ε=0.084 (a) and ε=0.3 (b)

图8

图8

不同温度下NNHC和CRNNHC沿轴向拉伸的力学性能

Fig.8

The axial tensile E (a) and σu (b) of NNHC and CRNNHC at different temperatures

以上分析表明,CNT的添加对NNHC对轴向拉伸力学性能起到了良好的增强作用。

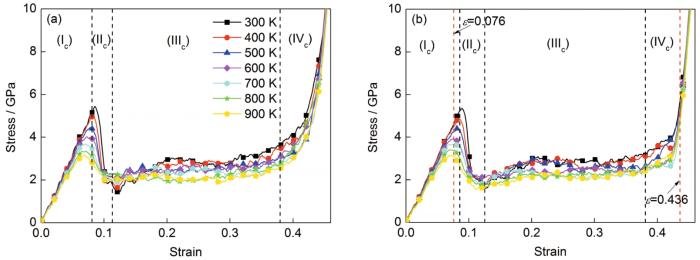

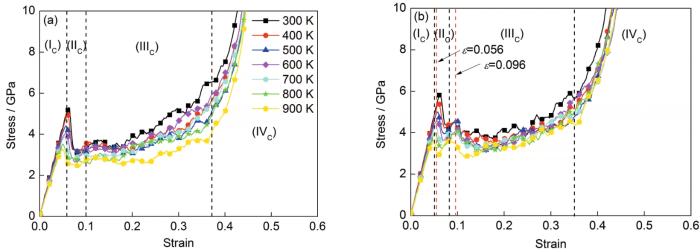

2.4 不同温度下轴向压缩

图9a和b分别给出了不同温度下NNHC和CRNNHC沿轴向压缩的应力-应变曲线。可以看出,与径向压缩一样,无论是NNHC还是CRNNHC,其沿径向压缩的应力-应变曲线都可分为如2.2节中所描述的4个阶段。阶段Ic末期的σu随温度的升高而降低;阶段IIc末期孔洞塌陷的应力随温度升高而降低;阶段IIIc应力平台期对应的整体应力水平随温度升高皆呈下降趋势;阶段IVc中εd随着温度升高而升高,但升高幅度不大。

图9

图9

不同温度下轴向压缩应力-应变曲线

Fig.9

The axial compression stress-strain curves of NNHC (a) and CRNNHC (b) with different temperatures

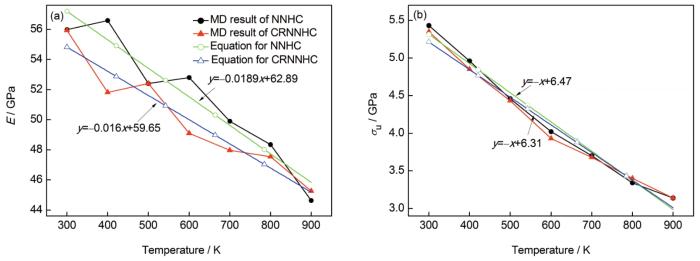

图10

图10

不同温度下NNHC和CRNNHC沿轴向压缩的力学性能

Fig.10

The axial compressive E (a) and σu (b) of NNHC and CRNNHC at different temperatures

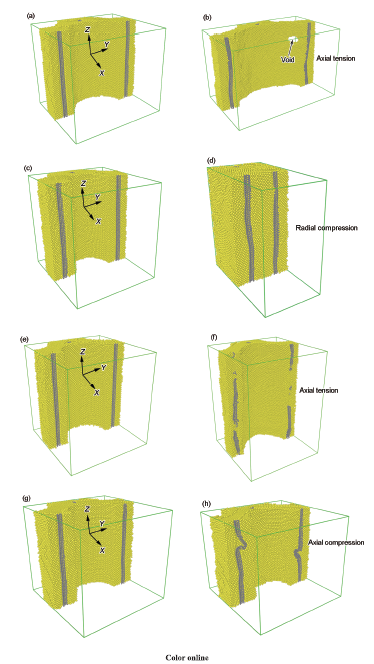

图11给出了CNT质量分数为5.22‰的CRNNHC试样在4种变形情况下的原子分布图。可以看出,CNT的所受应力与变形方向有关。与径向加载相比,轴向加载的CRNNHC试样中CNT能承载更多的载荷,故在轴向方向CNT能起到一个良好的额外加强效果。而CNT与镍基质间界面的弱结合,导致载荷不能在径向方向有效传递,从而形成界面缺陷,这一点与CNT金属玻璃复合材料相似[51]。因此,径向方向CRNNHC的力学性能与NNHC相似,甚至会出现下降的情况。CNT/Ni界面的弱作用是径向轴向加强作用差异的主要原因。从图10a还可以看出,CNT虽然发生了位移,但是形变量极小。图11c是径向压缩过程中CNT的原子分布图,与径向拉伸相似,虽然CNT发生了位移,但主要是以扭曲为主,因此对CRNNHC的应力贡献几乎为零,直至被压实后原子间挤压剧烈才受到一点力。

图11

图11

温度为600 K时CRNNHC在径向拉伸、径向压缩、轴向拉伸和轴向压缩变形下的原子分布图

Fig.11

Atomic snapshots of CRNNHC along different deformation directions of radial tension (a, b), radial compression (c, d), axial tension (e, f) and axial compression (g, h) under the temperature of 600 K

(a) εu=0.086 (b) εu=0.586 (c) εu=0.076 (d) εu=0.436

(e) εu=0.090 (f) εu=0.353 (g) εu=0.056 (h) εu=0.096

3 结论

(1) 就弹性模量而言,无论是NNHC还是CRNNHC,径向拉伸、径向压缩、轴向拉伸和轴向压缩4种变形下都对温度极为敏感,随着温度的升高而线性下降,尤其轴向线性下降更明显。轴向试样的弹性模量的最大最小值之差要大于径向,相比于径向,轴向方向弹性模量对温度更为敏感,表明CNT的添加起到了较为显著的增强作用。最大增强8.54 GPa,最大增强百分比高达12%。NNHC与CRNNHC不同温度下的E都可以用函数y=kx+b估算。

(2) 最终应力方面,无论是NNHC还是CRNNHC,4种变形情况下随着温度的升高而降低,并且4种变形情况都呈现出较好的线性关系。另外最终应力对应的应变εu随着温度的升高也在相应减小。CNT的添加对纳米蜂窝镍的径向弹性模量和最终应力起到了减弱作用,径向拉伸下试样的σu的最大最小值之差比其余3种情况的低,说明径向拉伸的σu对温度的敏感性比其它3种情况低,但是变化不大。CNT的添加对纳米蜂窝镍的轴向弹性模量和最终应力起到了增强作用,其中轴向压缩增强作用最为明显,百分比差最高达14%。NNHC与CRNNHC不同温度下σu都可以用函数y=kx+b估算。

(3) 对比CRNNHC拉伸与压缩原子分布图发现,压缩情形时εu小于拉伸情形。表明压缩变形时CRNNHC将更易破坏,这表明破坏前吸收的能量相对较小。研究还发现,CNT的添加对纳米蜂窝镍径向拉伸或压缩性能起到了弱化作用,而对轴向拉伸或压缩性能起到了增强作用,从而提高了韧性。所以CRNNHC轴向变形的力学性能普遍要优于沿径向变形的力学性能。

参考文献

Materials and technologies for SOFC-components

[J].

Solid oxide fuel cell interconnect design optimization considering the thermal stresses

[J].The mechanical failure of solid oxide fuel cell (SOFC) components may cause cracks with consequences such as gas leakage, structure instability and reduction of cell lifetime. A comprehensive 3D model of the thermal stresses of an anode-supported planar SOFC is presented in this work. The main objective of this paper is to get an interconnect optimized design by evaluating the thermal stresses of an anode-supported SOFC for different designs, which would be a new criterion for interconnect design. The model incorporates the momentum, mass, heat, ion and electron transport, as well as steady-state mechanics. Heat from methane steam reforming and water-gas shift reaction were considered in our model. The results examine the relationship between the interconnect structures and thermal stresses in SOFC at certain mechanical properties. A wider interconnect of the anode side lowers the stress obviously. The simulation results also indicate that thermal stress of coflow design is smaller than that of counterflow, corresponding to the temperature distribution. This study shows that it is possible to design interconnects for an optimum thermal stress performance of the cell.

Mechanical properties of tape cast nickel-based anode materials for solid oxide fuel cells before and after reduction in hydrogen

[J].AbstractThe processing of solid oxide fuel cells (SOFCs) often involves co-sintering of multi-layered stacks. In the case of SOFCs incorporating Ni-based anodes, hydrogen reduction of the anode usually takes place during the first service cycle of operation or conditioning. Initial reduction causes changes in the chemistry, microstructure and properties of the Ni-based anode material, which in turn induce mechanical stresses in the cell. In this study the elastic moduli, biaxial strength and fracture toughness of unreduced (NiO-YSZ) and reduced (Ni-YSZ) anode were determined as functions of porosity. Elastic properties were determined by impulse excitation at ambient temperature. Biaxial strength and fracture toughness were determined at ambient temperature by the ring-on-ring and double torsion test methods, respectively. It was found that the mechanical properties of unreduced and reduced Ni-based anode materials depend strongly on porosity. Property–porosity trends were found to be in good agreement with prediction of the minimum solid area model. Results presented in this study show that the elastic moduli and biaxial strength of the Ni-based anode material decreases after reduction in hydrogen while fracture toughness increases after reduction due to formation of ductile Ni-metal phase.]]>

Optimization of the strength of SOFC anode supports

[J].

Microstructural effects on the electrical and mechanical properties of Ni-YSZ cermet for SOFC anode

[J].

Solid oxide fuel cell anode materials for direct hydrocarbon utilization

[J].Direct utilization of hydrocarbon and other renewable fuels is one of the most important issues concerning solid oxide fuel cells (SOFCs). Mixed ionic and electronic conductors (MIECs) have been explored as anode materials for direct hydrocarbon-type SOFCs. However, electrical conductivity of the most often reported MIEC oxide electrodes is still not satisfactory. As a result, mixed-conducting oxides with high electrical conductivity and catalytic activity are attracting considerable interest as an alternative anode material for noncoke depositing anodes. In this study, we examine the oxide composite Ce(Mn,Fe)O(2)-La(Sr)Fe(Mn)O(3) for use as an oxide anode in direct hydrocarbon-type SOFCs. High performance was demonstrated for this composite oxide anode in direct hydrocarbon-type SOFCs, showing high maximum power density of approximately 1 W cm(-2) at 1073 K when propane and butane were used as fuel. The high power density of the cell results from the high electrical conductivity of the composite oxide in hydrocarbon and the high surface activity in relation to direct hydrocarbon oxidation.

Nanostructured YSZ thin film for application as electrolyte in an electrode supported SOFC

[J].

Nanostructured functional layers for solid oxide fuel cells

[J].

Scalable nanostructured membranes for solid-oxide fuel cells

[J].The use of oxide fuel cells and other solid-state ionic devices in energy applications is limited by their requirement for elevated operating temperatures, typically above 800°C (ref. 1). Thin-film membranes allow low-temperature operation by reducing the ohmic resistance of the electrolytes. However, although proof-of-concept thin-film devices have been demonstrated, scaling up remains a significant challenge because large-area membranes less than ~ 100 nm thick are susceptible to mechanical failure. Here, we report that nanoscale yttria-stabilized zirconia membranes with lateral dimensions on the scale of millimetres or centimetres can be made thermomechanically stable by depositing metallic grids on them to function as mechanical supports. We combine such a membrane with a nanostructured dense oxide cathode to make a thin-film solid-oxide fuel cell that can achieve a power density of 155 mW cm⁻² at 510 °C. We also report a total power output of more than 20 mW from a single fuel-cell chip. Our large-area membranes could also be relevant to electrochemical energy applications such as gas separation, hydrogen production and permeation membranes.

Thin-film solid oxide fuel cells on porous nickel substrates with multistage nanohole array

[J]. J

Mesoporous nickel/nickel oxide—A nanoarchitectured electrode

[J].

A High-performance supercapacitor/battery hybrid incorporating templated mesoporous electrodes

[J]. J

Exceptionally high Young's modulus observed for individual carbon nanotubes

[J].

Electrical conductivity of individual carbon nanotubes

[J].

Unusually high thermal conductivity of carbon nanotubes

[J].Combining equilibrium and nonequilibrium molecular dynamics simulations with accurate carbon potentials, we determine the thermal conductivity lambda of carbon nanotubes and its dependence on temperature. Our results suggest an unusually high value, lambda approximately 6600 W/m K, for an isolated (10,10) nanotube at room temperature, comparable to the thermal conductivity of a hypothetical isolated graphene monolayer or diamond. Our results suggest that these high values of lambda are associated with the large phonon mean free paths in these systems; substantially lower values are predicted and observed for the basal plane of bulk graphite.

Carbon nanotube/polyaniline composite as anode material for microbial fuel cells

[J].-3 to 4.2 W·m-3; meanwhile, during the chronoamperometric experiment with a charge-discharge time of 60-60 min, the cumulative charge of the composite bioanode was 18,865.8 C·m-2, which is much higher than that of the NCNT/S anode (3625.3 C·m-2). High-throughput sequencing technology revealed that the ternary composite bioanode had good biocompatibility and high diversity. Therefore, this synthesized ternary composite is a promising candidate as a capacitive and biocompatible anode material in MFC.]]>

A review on the status of anode materials for solid oxide fuel cells

[J].

Three-dimensional carbon nanotube-textile anode for high-performance microbial fuel cells

[J].Microbial fuel cells (MFCs) harness the metabolism of microorganisms, converting chemical energy into electrical energy. Anode performance is an important factor limiting the power density of MFCs for practical application. Improving the anode design is thus important for enhancing the MFC performance, but only a little development has been reported. Here, we describe a biocompatible, highly conductive, two-scale porous anode fabricated from a carbon nanotube-textile (CNT-textile) composite for high-performance MFCs. The macroscale porous structure of the intertwined CNT-textile fibers creates an open 3D space for efficient substrate transport and internal colonization by a diverse microflora, resulting in a 10-fold-larger anolyte-biofilm-anode interfacial area than the projective surface area of the CNT-textile. The conformally coated microscale porous CNT layer displays strong interaction with the microbial biofilm, facilitating electron transfer from exoelectrogens to the CNT-textile anode. An MFC equipped with a CNT-textile anode has a 10-fold-lower charge-transfer resistance and achieves considerably better performance than one equipped with a traditional carbon cloth anode: the maximum current density is 157% higher, the maximum power density is 68% higher, and the energy recovery is 141% greater.

Carbon nanotubes in novel ceramic matrix nanocomposites

[J].The extraordinary mechanical, thermal and electrical properties of carbon nanotubes have prompted intense research into a wide range of applications in structural materials, electronics, chemical processing and energy management. Attempts have been made to develop advanced engineering materials with improved or novel properties through the incorporation of carbon nanotubes in selected matrices (polymers, metals and ceramics). But the use of carbon nanotubes to reinforce ceramic composites has not been very successful; for example, in alumina-based systems only a 24% increase in toughness has been obtained so far. Here we demonstrate their potential use in reinforcing nanocrystalline ceramics. We have fabricated fully dense nanocomposites of single-wall carbon nanotubes with nanocrystalline alumina (Al2O3) matrix at sintering temperatures as low as 1,150 degrees C by spark-plasma sintering. A fracture toughness of 9.7 MPa m 1/2, nearly three times that of pure nanocrystalline alumina, can be achieved.

Load transfer and deformation mechanisms in carbon nanotube-polystyrene composites

[J].This paper demonstrates the viability of in-situ transmission electron microscopy for studying the deformation mechanisms of polymer nano-composites. In-situ straining studies are performed on carbon multiwalled nanotube (MWNT)-polystyrene composite films. The experiments show that load transfer across the nanotube-polystyrene interface is operative well into the plastic deformation regime of the composite film. The MWNTs are observed to bridge cracks propagating through the polystyrene, providing closure stresses across the crack wake. Although some MWNTs fracture by either a sword-in-sheath mechanism or transverse shear fracture, most of the MWNTs eventually debond at the MWNT-polymer interface and subsequently pull out of the matrix.

CNT-reinforced ceramics and metals

[J].

Performance improvement of pasted nickel electrodes with multi-wall carbon nanotubes for rechargeable nickel batteries

[J].

CNT/Ni hybrid nanostructured arrays: synjournal and application as high-performance electrode materials for pseudocapacitors

[J].

Densification behavior and electrical properties of carbon nanotube-Ni nanocomposite films for co-fireable microcircuit electrodes

[J].

Bioavailability of nickel in single-wall carbon nanotubes

[J].

Arrayed CNT-Ni nanocomposites grown directly on Si substrate for amperometric detection of ethanol

[J].A novel amperometric biosensor utilizing carbon nanotube (CNT)-Ni nanoparticle hybrid arrays for ethanol detection has been developed. The sensor was fabricated by e-beam deposition of thin Ni film on arrayed multi-walled carbon nanotubes grown directly on Si substrate. As the Ni film thickness is ≤ 200nm, high-resolution SEM and TEM images showed well-dispersed and strongly adhered crystalline Ni nanoparticles uniformly populated on the sidewalls of CNTs, and the sensitivity of the resultant CNT-Ni sensor generally increased with increasing nickel thickness. The best sensor showed a wide response range of 50-600 μM, a response time of <10s, and a sensitivity of 14.81 μA μM(-1)cm(-2) which is ∼380% higher in comparison with the nanostructured Ni/Pt/Ti electrodes.

Synjournal of carbon nanotube-nickel nanocomposites using atomic layer deposition for high-performance non-enzymatic glucose sensing

[J].A useful strategy has been developed to fabricate carbon-nanotube-nickel (CNT-Ni) nanocomposites through atomic layer deposition (ALD) of Ni and chemical vapor deposition (CVD) of functionalized CNTs. Various techniques, including scanning electron microscopy (SEM), transmission electron microscopy (TEM), and X-ray photoelectron spectroscopy (XPS), were used to characterize the morphology and the structure of as-prepared samples. It was confirmed that the products possess uniform Ni nanoparticles that are constructed by finely controlled deposition of Ni onto oxygen or bromine functionalized CNT surface. Electrochemical studies indicate that the CNT-Ni nanocomposites exhibit high electrocatalytic activity for glucose oxidation in alkaline solutions, which enables the products to be used in enzyme-free electrochemical sensors for glucose determination. It was demonstrated that the CNT-Ni nanocomposite-based glucose biosensor offers a variety of merits, such as a wide linear response window for glucose concentrations of 5 μM-2 mM, short response time (3 s), a low detection limit (2 μM), high sensitivity (1384.1 μA mM(-1) cm(-2)), and good selectivity and repeatability.

Palladium nanoparticles modified carbon nanotube/nickel composite rods (Pd/CNT/Ni) for hydrogen sensing

[J].

Molecular dynamics of single wall carbon nanotube growth on nickel surface

[J].Several first-principles surface and bulk electronic structure calculations relating to the nucleation and growth of single-wall carbon nanotubes are described. Density-functional theory in various forms is used throughout. In the surface-related calculations, a 38-atom Ni cluster and several low-index Ni surfaces are investigated using pseudopotentials and plane-wave expansions. The energetic ordering of the sites for C atom adsorption is found to be the same, with the Ni(100) facet favored. The bulk diffusion coefficient of C in Ni as a function of cluster size and temperature is calculated from various molecular dynamics approaches. In another group of bulk-related calculations, Gaussian orbital basis sets are used to study a cluster or "flake" containing 14 C atoms. The flake is a segment of three hexagons from an "unrolled" carbon nanotube, with an armchair termination. The binding energies of C, Ni, Co, Fe, Cu, and Au atoms to it were calculated in an effort to gain insight into the mechanism for the high catalytic activity of Ni, Co, and Fe and the lack of it in Cu and Au. The binding energies of Cu and Au are about 1 eV less than those of the three catalytic elements. Similar methods are used to study the initial stages of nanotube growth within the context of classical nucleation theory. Finally, issues relating to the establishment of a fundamental catalytic mechanism are addressed.

A molecular dynamics study of the effect of a substrate on catalytic metal clusters in nucleation process of single-walled carbon nanotubes

[J].

Ab initio molecular dynamics simulation of the dissociation of ethanol on a nickel cluster: Understanding the initial stage of metal-catalyzed growth of carbon nanotubes

[J]. J

Conformation and catalytic activity of nickel-carbon cluster for ethanol dissociation in carbon nanotube synjournal: Ab initio molecular dynamics simulation

[J].

Influence of nickel coating on the interfacial bonding characteristics of carbon nanotube-aluminum composites

[J].

Mechanical properties of nickel-coated single-walled carbon nanotubes and their embedded gold matrix composites

[J].

Molecular dynamics simulation for mechanical properties of magnesium matrix composites reinforced with nickel-coated single-walled carbon nanotubes

[J].

Enhanced interfacial strength of carbon nanotube/copper nanocomposites via Ni-coating: Molecular-dynamics insights

[J].To investigate the amount of systemic oxidative stress-related DNA damage and serum total antioxidant status of patients with normal-tension glaucoma compared with healthy controls.

Exploring plastic deformation mechanism of multilayered Cu/Ti composites by using molecular dynamics modeling

[J].

Cu/Ti纳米层状复合体塑性变形机制的分子动力学模拟研究

[J].

Study on lightweight and strengthening effect of carbon nanotube in highly ordered nanoporous nickel: A molecular dynamics study

[J].

Advanced anodes for high-temperature fuel cells

[J].Fuel cells will undoubtedly find widespread use in this new millennium in the conversion of chemical to electrical energy, as they offer very high efficiencies and have unique scalability in electricity-generation applications. The solid-oxide fuel cell (SOFC) is one of the most exciting of these energy technologies; it is an all-ceramic device that operates at temperatures in the range 500-1,000 degrees C. The SOFC offers certain advantages over lower temperature fuel cells, notably its ability to use carbon monoxide as a fuel rather than being poisoned by it, and the availability of high-grade exhaust heat for combined heat and power, or combined cycle gas-turbine applications. Although cost is clearly the most important barrier to widespread SOFC implementation, perhaps the most important technical barriers currently being addressed relate to the electrodes, particularly the fuel electrode or anode. In terms of mitigating global warming, the ability of the SOFC to use commonly available fuels at high efficiency, promises an effective and early reduction in carbon dioxide emissions, and hence is one of the lead new technologies for improving the environment. Here, we discuss recent developments of SOFC fuel electrodes that will enable the better use of readily available fuels.

Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys

[J].

A reactive potential for hydrocarbons with intermolecular interactions

[J].

The effects of deviations from Lorentz-Berthelot rules on the properties of a simple mixture

[J].

Transient deformation regime in bending of single-walled carbon nanotubes

[J].Pure bending of single-walled carbon nanotubes between (5,5) and (50,50) is studied using molecular dynamics based on the reactive bond order potential. Unlike smaller nanotubes, bending of (15,15) and larger ones exhibits an intermediate deformation in the transition between the buckled and fully kinked configurations. This transient bending regime is characterized by a gradual and controllable flattening of the nanotube cross section at the buckling site. Unbending of a kinked nanotube bypasses the transient bending regime, exhibiting a hysteresis due to van der Waals attraction between the tube walls at the kinked site.

A cohesive law for carbon nanotube/polymer interfaces based on the van der Waals force

[J].

Molecular dynamics studies of CNT-reinforced aluminum composites under uniaxial tensile loading

[J].

Giant energy absorption capacity of graphene-based carbon honeycombs

[J].

In-plane compressive behavior of graphene-coated aluminum nano-honeycombs

[J].

Molecular dynamics study of the mechanical behavior of nickel nanowire: Strain rate effects

[J].

Size-dependent effects on equilibrium stress and strain in nickel nanowires

[J].

Mechanical characteristics of CNT-reinforced metallic glass nanocomposites by molecular dynamics simulations

[J].