镁合金科学与技术

1

2007

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

镁合金科学与技术

1

2007

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Development of the as-cast microstructure in magnesium-aluminum alloys

1

2001

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Microstructure and mechanical properties of Mg-Gd-Dy-Zn alloy with long period stacking ordered structure or stacking faults

1

2011

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Magnesium alloys and applications

1

1994

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Mg合金的最新发展及应用前景

1

2001

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Mg合金的最新发展及应用前景

1

2001

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Microstructure and mechanical properties of multi-directionally forged Mg-Al-Zn alloy

1

2012

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa

1

2001

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

The intrinsic effect of long period stacking ordered phases on mechanical properties in Mg-RE based alloys

1

2016

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

High strength Mg94Zn2.4Y3.6 alloy with long period stacking ordered structure prepared by near-rapid solidification technology

1

679

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Texture evolution, deformation mechanism and mechanical properties of the hot rolled Mg-Gd-Y-Zn-Zr alloy containing LPSO phase

1

731

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

工具转速对搅拌摩擦加工Mg-Zn-Y-Zr耐热镁合金超塑性行为的影响

1

2018

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

工具转速对搅拌摩擦加工Mg-Zn-Y-Zr耐热镁合金超塑性行为的影响

1

2018

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Hot deformation and dynamic recrystallization behaviors of Mg-Gd-Zn alloy with LPSO phases

1

2019

... Mg及镁合金作为最轻的金属结构材料,密度仅为1.74 g/cm3,是钢的23%,Al的64%,具有比强度高、比刚度高、阻尼性能好等优点,在航空航天、民用运输及电子产品等领域具有广阔的应用前景[1,2,3].然而,与传统的钢铁材料、铝合金相比,镁合金室温成形性差、强度低、耐蚀性较差等缺点严重限制了镁合金在工业上的应用[4,5].大量不同的实验方法被用于提高镁合金的综合性能,其中添加稀土元素和制备细晶是具有革新性的方法[6].2001年,Kawamura等[7]通过粉末冶金法制备的含长周期堆垛有序结构(LPSO)相的Mg-Zn-Y合金室温屈服强度超过600 MPa,自此,含LPSO相镁合金的热变形行为开始受到研究者的广泛关注[8,9,10,11,12]. ...

Dislocation structure in rapidly solidified Mg97Zn1Y2 alloy with long period stacking order phase

2

2005

... 近年来,众多研究[13,14,15,16,17,18]表明LPSO相的存在对滑移、孪生、扭折及动态再结晶均存在一定影响.Matsuda等[13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

... [13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

Interaction between long period stacking order phase and deformation twin in rapidly solidified Mg97Zn1Y2 alloy

4

386

... 近年来,众多研究[13,14,15,16,17,18]表明LPSO相的存在对滑移、孪生、扭折及动态再结晶均存在一定影响.Matsuda等[13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

... [14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

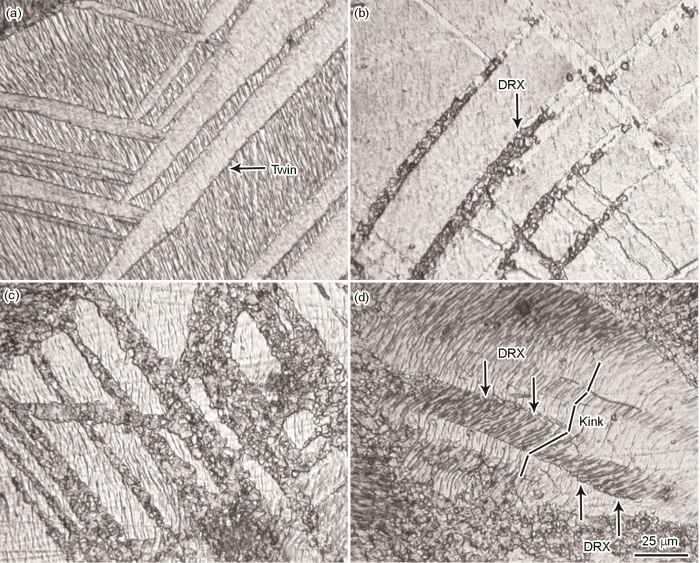

... 合金多向锻造过程中的显微组织演变如图4所示,其中图4b、d、f、h分别为图4a、c、e、g中矩形区域的放大图.1道次变形后,部分晶粒内部出现多个变体同时激发的孪生现象,如图4b中箭头所示.并且单个晶粒内孪晶片层厚度较薄,粗大的孪晶为多个孪晶粗化合并导致.一方面,单道次变形量较小,孪晶厚度较小;另一方面,晶内LPSO相对孪晶长大也存在一定的阻碍作用[14].由于铸态合金中晶体取向较为随机,并且孪生的激发极大地依赖于晶体取向,因此仅有部分晶粒内发生了孪生变形.此外,金相组织中未观察到明显的动态再结晶行为.2、3道次变形后,发生孪生的晶粒数目明显增加,由于载荷方向发生变化,原本不利于孪生的晶粒可能在后续变形中激发孪生,从而导致孪生体积分数显著提高(如图4c与e所示).大量交错或平行的孪晶切割原始粗晶,晶粒细化程度提高.并且,粗晶晶界及内部能够观察到再结晶组织,晶内再结晶组织呈链状或条状的分布特征,如图4f所示.6道次变形后,晶粒内未观察到低道次变形显微组织中的条状孪晶,而是出现大量由再结晶细晶构成的条带状组织,如图4h所示.并且该条带状细晶组织与低道次变形后平行或交叉的孪晶形貌特征极为相似,可以推断孪晶片层在后续变形过程中发生再结晶并逐渐演化为再结晶条带状组织.Xiao等[26]的研究中也报道了孪晶诱发再结晶并形成再结晶条带状组织的现象,与本工作的实验结果相符. ...

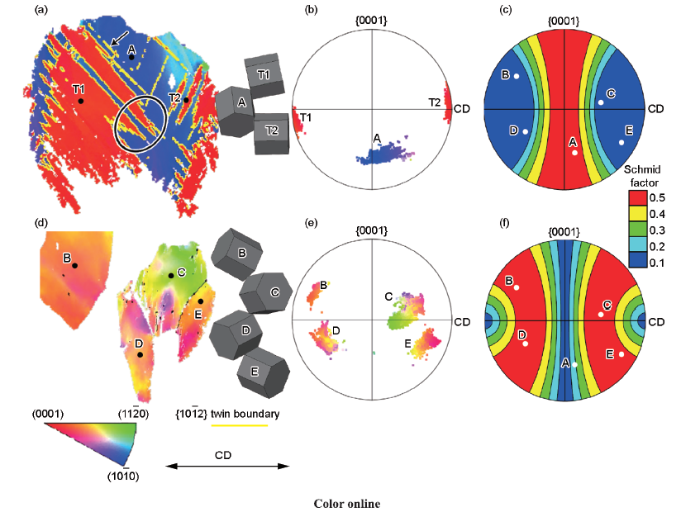

... 为研究锻造过程中{}拉伸孪生变形的晶体取向相关性,对比分析了1道次变形过程中孪生晶粒(记做A)与部分未孪生晶粒(记做B、C、D、E) Schmid因子的差异性.如图9a所示,孪生晶粒内多个变体同时激发({}孪晶界用黄线标识),同一变体通过粗化合并形成粗大的孪晶.然而,构成粗大孪晶中的各小孪晶沿孪生切变方向长度不一,且孪晶尖端终止于晶粒内部,意味着孪晶沿切变方向的长大受到阻碍并导致新的孪晶在晶界处形核,如图中椭圆及箭头所示.研究[14]表明,LPSO相抑制孪晶长大但几乎不影响孪晶形核.类似结论也存在于Mg-Zn合金的孪生现象中,含第二相的样品中孪晶尺寸小而数量多,第二相对孪晶形核影响并不显著[32].虽然本工作中孪晶长大受到LPSO相的抑制,但是孪晶形核未受到明显阻碍,多孪晶形核及长大使晶粒获得较大的孪晶体积分数(约为58.4%),因此孪生依然为该晶粒的主导变形机制. ...

Crystallographic classification of kink bands in an extruded Mg-Zn-Y alloy using intragranular misorientation axis analysis

3

2013

... 近年来,众多研究[13,14,15,16,17,18]表明LPSO相的存在对滑移、孪生、扭折及动态再结晶均存在一定影响.Matsuda等[13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

... [15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

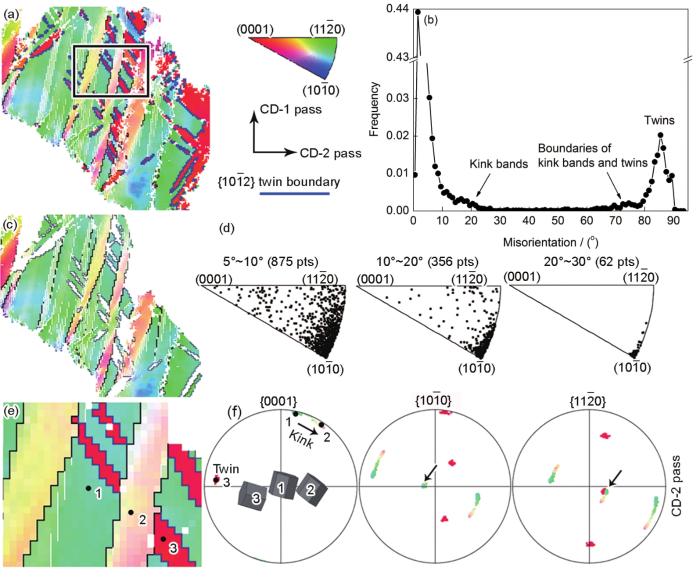

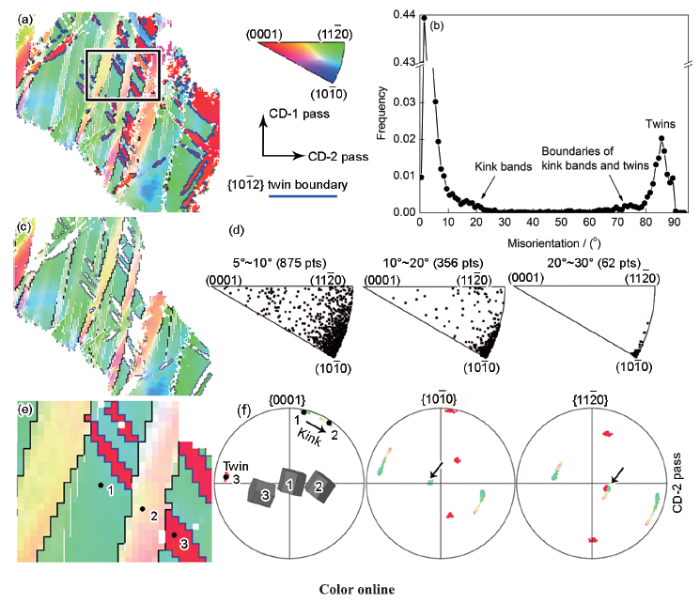

... 除孪生与滑移外,扭折变形也是含LPSO相镁合金塑性变形过程中的一种重要机制,受平行于基面压缩的载荷作用甚至能够替代孪生来协调变形.图10为2道次变形后既发生扭折变形又发生{}拉伸孪生的晶粒及其取向分布特征.晶内取向差角度分布如图10b所示.变形后晶粒出现大量大角度晶界,其数值主要分布在15°~30°及60°~90°范围,前者来源于扭折带与基体的取向差,而后者来源于孪晶与扭折带及孪晶与基体的取向差.为研究扭折带类型及形成机制,仅包含扭折区域的取向成像图及不同取向差角度范围下的晶内取向差转轴(IGMA)分布如图10c和d所示,其中图10c为隐藏孪生区域后的图10a.根据Yamasaki等[15]的研究结果可知,扭折带取向差的增大主要来源于带内位错的增殖与滑移,并且通过对比扭折带的IGMA分布和特定滑移系的Taylor轴[36],能够判定构成扭折带及取向变化的主要滑移机制.当IGMA分布集中在<>时,意味着扭折变形主要通过单一Burgers矢量的基面<a>滑移来进行;当IGMA分布集中在<>时,意味着扭折变形主要通过具有不同Burgers矢量的基面<a>滑移来进行;而当IGMA分布集中在<0001>时,意味着扭折变形主要通过柱面<a>滑移来进行.观察图10d可知,扭折导致的取向差转轴主要集中在<>方向,意味着扭折带的形成和取向演变与基面<a>滑移密切相关,且位错滑移的方向确定,不存在其它方向的变体.扭折带的形成有利于释放应力集中,提高材料塑性成形的能力;同时,不同取向扭折带的出现导致晶体取向分布多样化,有利于多晶体织构的弱化;并且扭折带界面被证实可以诱发动态再结晶,起到细化晶粒的效果[28,29]. ...

Strengthening and toughening mechanisms in Mg-Zn-Y alloy with a long period stacking ordered structure

2

2010

... 近年来,众多研究[13,14,15,16,17,18]表明LPSO相的存在对滑移、孪生、扭折及动态再结晶均存在一定影响.Matsuda等[13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

... [16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

Evolution of LPSO phases and their effect on dynamic recrystallization in a Mg-Gd-Y-Zn-Zr alloy

4

2017

... 近年来,众多研究[13,14,15,16,17,18]表明LPSO相的存在对滑移、孪生、扭折及动态再结晶均存在一定影响.Matsuda等[13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

... [17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

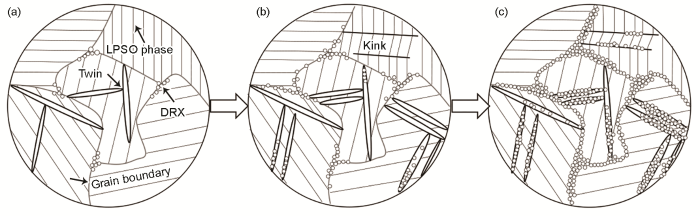

... 综上可知,晶界、孪晶与扭折带均能诱发动态再结晶.图7为合金多向锻造过程中再结晶行为示意图.多向锻造初期,晶界处优先出现动态再结晶晶粒,孪晶内部及界面处无明显动态再结晶.随变形程度的增加,晶界处再结晶体积分数增大,同时孪晶内出现动态再结晶晶粒.并且,发生孪生及扭折的晶粒数目增多,孪晶与扭折带切割细化粗晶.继续增大变形量,晶界与孪晶内再结晶程度增大,孪生区域逐渐演变为条带状细晶组织,同时扭折界面也成为动态再结晶形核点,协同细化晶粒.在孪生与扭折切割晶粒,晶界处动态再结晶,孪生与扭折诱发再结晶多种机制的共同作用下,原始粗大晶粒得到了显著细化.此外,晶内片层状LPSO相对晶粒细化也存在一定的促进作用.根据Zhou等[17]的研究结果,晶内细小层片状的LPSO相对动态再结晶的晶界迁移具有抑制作用,降低了合金动态再结晶体积分数;而晶内块状的LPSO相能够通过PSN (particle stimulated nucleation)机制促进动态再结晶形核,从而提高了合金的再结晶体积分数.本实验初始态合金中的LPSO相尺寸较小且密集分布在晶粒内部(图3).参照Zhou等[17]的研究结果,本工作中的LPSO相对再结晶会产生抑制效果.结合图5及6可知,孪晶内的再结晶及晶界处的再结晶晶粒细小,并且再结晶并未向基体发生明显的扩张,意味着基体中的LPSO相对动态再结晶晶粒的长大及迁移具有一定的抑制作用.同时,如图4h所示,6道次变形后显微组织中仍然能够观察到大量未再结晶的残留基体,也说明LPSO相对合金的动态再结晶具有一定的抑制作用. ...

... [17]的研究结果,本工作中的LPSO相对再结晶会产生抑制效果.结合图5及6可知,孪晶内的再结晶及晶界处的再结晶晶粒细小,并且再结晶并未向基体发生明显的扩张,意味着基体中的LPSO相对动态再结晶晶粒的长大及迁移具有一定的抑制作用.同时,如图4h所示,6道次变形后显微组织中仍然能够观察到大量未再结晶的残留基体,也说明LPSO相对合金的动态再结晶具有一定的抑制作用. ...

Dynamic recrystallization behaviors of Mg-Gd-Y-Zn-Zr alloy with different morphologies and distributions of LPSO phases

2

715

... 近年来,众多研究[13,14,15,16,17,18]表明LPSO相的存在对滑移、孪生、扭折及动态再结晶均存在一定影响.Matsuda等[13]研究发现,LPSO相的存在提升了基面位错启动的临界分切应力(CRSS),抑制了基面滑移的启动,促进了非基面滑移的激活,基面滑移的抑制以及非基面滑移的启动提高了合金的变形抗力和延伸率.同时,还发现在快速凝固Mg-Zn-Y合金中密集分布的LPSO相显著抑制了{}孪晶的长大,{}孪晶仅能沿LPSO相边缘生长[14].随着LPSO相的引入,扭折变形成为稀土镁合金中一种常见的变形机制[15].Shao等[16]的研究表明,LPSO相产生的扭折带可通过限制微裂纹传播来降低合金断裂可能性.此外,LPSO相对镁合金动态再结晶行为存在很大影响:与传统商用AZ/ZK镁合金相比,含LPSO相镁合金热变形中动态再结晶程度往往更低,Zhou等[17]和Zhang等[18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

... [18]认为这是由于晶内层片状LPSO相对位错滑移和动态再结晶的晶界迁移具有阻碍作用造成的.目前,对Mg-Zn-RE合金的研究主要集中在稀土元素对LPSO相结构和对合金力学性能的影响上,镁合金热变形过程中LPSO相对变形机制的影响作用仍待进一步研究.因此,探讨含LPSO相镁合金热变形过程中的变形机制、动态再结晶行为及组织结构的演变规律有着重要科学意义. ...

Multi-directional forging of AZ61Mg alloy under decreasing temperature conditions and improvement of its mechanical properties

1

528

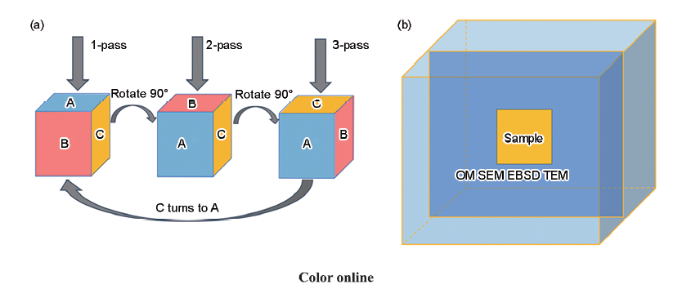

... 在众多镁合金大塑性变形方法中,多向锻造工艺作为一种重要加工方法,被广泛应用于超细晶镁合金的制备[19].恒温多向锻造以及降温多向锻造后的再结晶晶粒尺寸在0.3~0.8 μm[20,21],能够将晶粒细化至微米级别.除了对晶粒细化的显著功效外,多向锻造不断变化的载荷方向及道次变形量等因素也会影响合金的变形机制和显微组织演变.Mehrabi等[22]发现经8道次多向锻造后,Mg-Li-Zn合金获得更高比例的大角度晶界和更为均匀的组织结构;邓丽萍等[23]的研究表明,多向锻造的道次变形量会影响孪晶的激活量和孪晶片层的形貌,从而对显微组织及织构调控产生影响. ...

Microstructure evolution and mechanical properties of Mg-Gd-Y-Ag-Zr alloy fabricated by multidirectional forging and ageing treatment

1

702

... 在众多镁合金大塑性变形方法中,多向锻造工艺作为一种重要加工方法,被广泛应用于超细晶镁合金的制备[19].恒温多向锻造以及降温多向锻造后的再结晶晶粒尺寸在0.3~0.8 μm[20,21],能够将晶粒细化至微米级别.除了对晶粒细化的显著功效外,多向锻造不断变化的载荷方向及道次变形量等因素也会影响合金的变形机制和显微组织演变.Mehrabi等[22]发现经8道次多向锻造后,Mg-Li-Zn合金获得更高比例的大角度晶界和更为均匀的组织结构;邓丽萍等[23]的研究表明,多向锻造的道次变形量会影响孪晶的激活量和孪晶片层的形貌,从而对显微组织及织构调控产生影响. ...

Microstructure and mechanical properties of ZK21 magnesium alloy fabricated by multiple forging at different strain rates

1

556

... 在众多镁合金大塑性变形方法中,多向锻造工艺作为一种重要加工方法,被广泛应用于超细晶镁合金的制备[19].恒温多向锻造以及降温多向锻造后的再结晶晶粒尺寸在0.3~0.8 μm[20,21],能够将晶粒细化至微米级别.除了对晶粒细化的显著功效外,多向锻造不断变化的载荷方向及道次变形量等因素也会影响合金的变形机制和显微组织演变.Mehrabi等[22]发现经8道次多向锻造后,Mg-Li-Zn合金获得更高比例的大角度晶界和更为均匀的组织结构;邓丽萍等[23]的研究表明,多向锻造的道次变形量会影响孪晶的激活量和孪晶片层的形貌,从而对显微组织及织构调控产生影响. ...

Superplasticity in a multi-directionally forged Mg-Li-Zn alloy

1

765

... 在众多镁合金大塑性变形方法中,多向锻造工艺作为一种重要加工方法,被广泛应用于超细晶镁合金的制备[19].恒温多向锻造以及降温多向锻造后的再结晶晶粒尺寸在0.3~0.8 μm[20,21],能够将晶粒细化至微米级别.除了对晶粒细化的显著功效外,多向锻造不断变化的载荷方向及道次变形量等因素也会影响合金的变形机制和显微组织演变.Mehrabi等[22]发现经8道次多向锻造后,Mg-Li-Zn合金获得更高比例的大角度晶界和更为均匀的组织结构;邓丽萍等[23]的研究表明,多向锻造的道次变形量会影响孪晶的激活量和孪晶片层的形貌,从而对显微组织及织构调控产生影响. ...

AZ31镁合金室温多道次压缩过程微观组织和织构演变的研究

2

2019

... 在众多镁合金大塑性变形方法中,多向锻造工艺作为一种重要加工方法,被广泛应用于超细晶镁合金的制备[19].恒温多向锻造以及降温多向锻造后的再结晶晶粒尺寸在0.3~0.8 μm[20,21],能够将晶粒细化至微米级别.除了对晶粒细化的显著功效外,多向锻造不断变化的载荷方向及道次变形量等因素也会影响合金的变形机制和显微组织演变.Mehrabi等[22]发现经8道次多向锻造后,Mg-Li-Zn合金获得更高比例的大角度晶界和更为均匀的组织结构;邓丽萍等[23]的研究表明,多向锻造的道次变形量会影响孪晶的激活量和孪晶片层的形貌,从而对显微组织及织构调控产生影响. ...

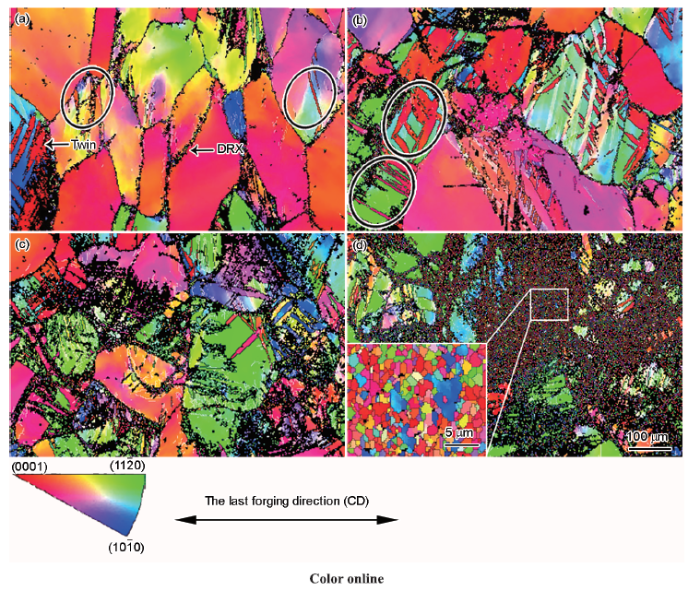

... 为研究合金多向锻造过程中的变形机制,对合金进行EBSD分析,结果如图8所示.其中取向成像图的颜色参照方向为最终锻造压下方向,记作CD,即:红色代表晶粒c轴平行于CD方向,蓝色和绿色分别代表晶粒<>晶向和<>晶向平行于CD方向.大角度晶界(>15°)与小角度晶界(4°~15°)分别用黑线与白线标识.1道次锻造后,c轴垂直于CD方向的晶粒内孪生大量激发,如图8a左侧箭头所示.该孪晶与基体具有86°<>的取向关系,属于{}拉伸孪晶.并且该晶粒取向符合垂直于c轴压缩时易于激发{}拉伸孪晶的规律[23,31].c轴近似平行于CD方向的晶粒内孪生数目明显减少且孪晶尺寸非常小,如图8a中椭圆区域所示.对于未孪生或者少孪生晶粒而言,滑移为合金变形初期的主导变形机制,且滑移不均匀性导致了明显的晶内取向梯度.此外,晶界处能够观察到少量细小的动态再结晶晶粒,与图6a中SEM观测结果具有一致性.2、3道次变形后,发生孪生变形的晶粒数目增多.这是由于1道次变形中不利于孪生激发的晶粒在后续变形过程中可能转到利于孪生激发的取向.如图8b中椭圆标识的晶粒,其c轴垂直于2道次压缩方向,处于{}拉伸孪生的有利取向.6道次变形后,粗晶体积分数大为降低,再结晶体积分数增大,合金变形组织由残留粗晶与再结晶细晶共同构成.图8d中的放大图表明,再结晶晶粒尺寸约为4 μm,晶体取向分布较为随机. ...

AZ31镁合金室温多道次压缩过程微观组织和织构演变的研究

2

2019

... 在众多镁合金大塑性变形方法中,多向锻造工艺作为一种重要加工方法,被广泛应用于超细晶镁合金的制备[19].恒温多向锻造以及降温多向锻造后的再结晶晶粒尺寸在0.3~0.8 μm[20,21],能够将晶粒细化至微米级别.除了对晶粒细化的显著功效外,多向锻造不断变化的载荷方向及道次变形量等因素也会影响合金的变形机制和显微组织演变.Mehrabi等[22]发现经8道次多向锻造后,Mg-Li-Zn合金获得更高比例的大角度晶界和更为均匀的组织结构;邓丽萍等[23]的研究表明,多向锻造的道次变形量会影响孪晶的激活量和孪晶片层的形貌,从而对显微组织及织构调控产生影响. ...

... 为研究合金多向锻造过程中的变形机制,对合金进行EBSD分析,结果如图8所示.其中取向成像图的颜色参照方向为最终锻造压下方向,记作CD,即:红色代表晶粒c轴平行于CD方向,蓝色和绿色分别代表晶粒<>晶向和<>晶向平行于CD方向.大角度晶界(>15°)与小角度晶界(4°~15°)分别用黑线与白线标识.1道次锻造后,c轴垂直于CD方向的晶粒内孪生大量激发,如图8a左侧箭头所示.该孪晶与基体具有86°<>的取向关系,属于{}拉伸孪晶.并且该晶粒取向符合垂直于c轴压缩时易于激发{}拉伸孪晶的规律[23,31].c轴近似平行于CD方向的晶粒内孪生数目明显减少且孪晶尺寸非常小,如图8a中椭圆区域所示.对于未孪生或者少孪生晶粒而言,滑移为合金变形初期的主导变形机制,且滑移不均匀性导致了明显的晶内取向梯度.此外,晶界处能够观察到少量细小的动态再结晶晶粒,与图6a中SEM观测结果具有一致性.2、3道次变形后,发生孪生变形的晶粒数目增多.这是由于1道次变形中不利于孪生激发的晶粒在后续变形过程中可能转到利于孪生激发的取向.如图8b中椭圆标识的晶粒,其c轴垂直于2道次压缩方向,处于{}拉伸孪生的有利取向.6道次变形后,粗晶体积分数大为降低,再结晶体积分数增大,合金变形组织由残留粗晶与再结晶细晶共同构成.图8d中的放大图表明,再结晶晶粒尺寸约为4 μm,晶体取向分布较为随机. ...

Variation of long-period stacking order structures in rapidly solidified Mg97Zn1Y2 alloy

1

393

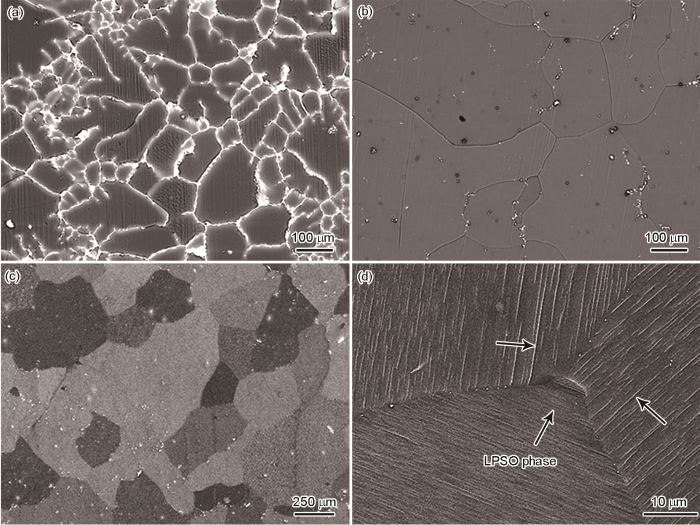

... 为进一步明确热处理后层片状第二相的形貌、尺寸及类型,对合金进行TEM观察.420 ℃下12 h退火态合金STEM像及选区电子衍射(SAED)花样如图3a所示,Mg基体透射斑与(0002)斑点之间出现了13个额外斑点,表明该层片状第二相为14H类型的LPSO相[24].LPSO相在基体内分布并不均匀,尺寸上也存在一定差异.图3b为LPSO相局部放大图,其中亮白色条纹位置为Zn与Gd元素,灰色位置为Mg基体,两者间隔分布,符合Mg-5.6Gd-0.8Zn合金中LPSO相的堆垛特征[25]. ...

Formation of 14H long period stacking ordered structure and profuse stacking faults in Mg-Zn-Gd alloys during isothermal aging at high temperature

1

2007

... 为进一步明确热处理后层片状第二相的形貌、尺寸及类型,对合金进行TEM观察.420 ℃下12 h退火态合金STEM像及选区电子衍射(SAED)花样如图3a所示,Mg基体透射斑与(0002)斑点之间出现了13个额外斑点,表明该层片状第二相为14H类型的LPSO相[24].LPSO相在基体内分布并不均匀,尺寸上也存在一定差异.图3b为LPSO相局部放大图,其中亮白色条纹位置为Zn与Gd元素,灰色位置为Mg基体,两者间隔分布,符合Mg-5.6Gd-0.8Zn合金中LPSO相的堆垛特征[25]. ...

Hot deformation and dynamic recrystallization behaviors of Mg-Gd-Y-Zr alloy

1

2015

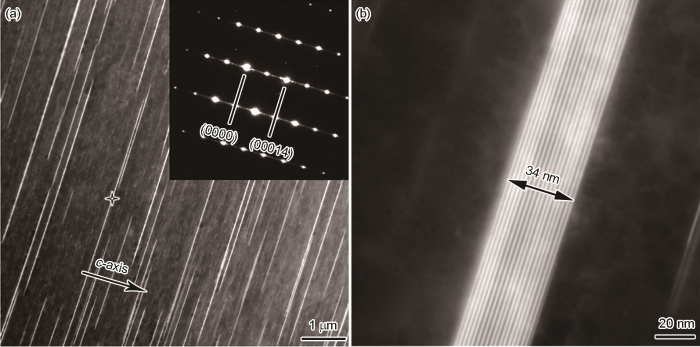

... 合金多向锻造过程中的显微组织演变如图4所示,其中图4b、d、f、h分别为图4a、c、e、g中矩形区域的放大图.1道次变形后,部分晶粒内部出现多个变体同时激发的孪生现象,如图4b中箭头所示.并且单个晶粒内孪晶片层厚度较薄,粗大的孪晶为多个孪晶粗化合并导致.一方面,单道次变形量较小,孪晶厚度较小;另一方面,晶内LPSO相对孪晶长大也存在一定的阻碍作用[14].由于铸态合金中晶体取向较为随机,并且孪生的激发极大地依赖于晶体取向,因此仅有部分晶粒内发生了孪生变形.此外,金相组织中未观察到明显的动态再结晶行为.2、3道次变形后,发生孪生的晶粒数目明显增加,由于载荷方向发生变化,原本不利于孪生的晶粒可能在后续变形中激发孪生,从而导致孪生体积分数显著提高(如图4c与e所示).大量交错或平行的孪晶切割原始粗晶,晶粒细化程度提高.并且,粗晶晶界及内部能够观察到再结晶组织,晶内再结晶组织呈链状或条状的分布特征,如图4f所示.6道次变形后,晶粒内未观察到低道次变形显微组织中的条状孪晶,而是出现大量由再结晶细晶构成的条带状组织,如图4h所示.并且该条带状细晶组织与低道次变形后平行或交叉的孪晶形貌特征极为相似,可以推断孪晶片层在后续变形过程中发生再结晶并逐渐演化为再结晶条带状组织.Xiao等[26]的研究中也报道了孪晶诱发再结晶并形成再结晶条带状组织的现象,与本工作的实验结果相符. ...

Twin recrystallization mechanisms and exceptional contribution to texture evolution during annealing in a magnesium alloy

1

2017

... 为进一步研究合金锻造过程中孪晶诱发再结晶行为及演变过程,对不同锻造道次变形后孪晶及再结晶晶粒形貌特征进行金相显微观察,结果如图5所示.1道次变形后,孪晶条带平直,内部未观察到明显的再结晶晶粒,如图5a所示.2道次变形后,部分孪晶演变为再结晶细晶组织,如图5b中的箭头所示,而剩余的孪晶在后续应力与温度作用下也极有可能演变为再结晶组织.因此,6道次变形后,能够观察到大量的条带状动态再结晶组织,孪晶几乎完全被动态再结晶晶粒占据,如图5c所示.Guan等[27]研究发现,孪晶形成后其内部基体在后续变形过程中的滑移是导致孪晶诱发再结晶的主要原因:一般而言,孪生变形后,孪晶基体处于滑移变形的硬取向,特别是基面滑移,而多向锻造过程中载荷方向不断变化可能利于孪晶内基体的滑移变形,因此能够促进孪晶诱发再结晶并形成条带状细晶组织.除了孪晶诱发再结晶,扭折带诱发再结晶也是含LPSO相镁合金中一种重要的再结晶机制,扭折界面的位错堆积和应力集中均有利于动态再结晶的形核与长大[28].因此,再结晶晶粒会沿扭折界面形核并长大,如图5d中箭头所示.但并非所有的扭折界面均能诱发再结晶.Wu等[29]指出,扭折界面诱发再结晶与扭折界面取向差密切相关,大角度扭折界面的高应变储能更容易促进再结晶形核. ...

Extensive dynamic recrystallized grains at kink boundary of 14H LPSO phase in extruded Mg92Gd3Zn1Li4 alloy

2

... 为进一步研究合金锻造过程中孪晶诱发再结晶行为及演变过程,对不同锻造道次变形后孪晶及再结晶晶粒形貌特征进行金相显微观察,结果如图5所示.1道次变形后,孪晶条带平直,内部未观察到明显的再结晶晶粒,如图5a所示.2道次变形后,部分孪晶演变为再结晶细晶组织,如图5b中的箭头所示,而剩余的孪晶在后续应力与温度作用下也极有可能演变为再结晶组织.因此,6道次变形后,能够观察到大量的条带状动态再结晶组织,孪晶几乎完全被动态再结晶晶粒占据,如图5c所示.Guan等[27]研究发现,孪晶形成后其内部基体在后续变形过程中的滑移是导致孪晶诱发再结晶的主要原因:一般而言,孪生变形后,孪晶基体处于滑移变形的硬取向,特别是基面滑移,而多向锻造过程中载荷方向不断变化可能利于孪晶内基体的滑移变形,因此能够促进孪晶诱发再结晶并形成条带状细晶组织.除了孪晶诱发再结晶,扭折带诱发再结晶也是含LPSO相镁合金中一种重要的再结晶机制,扭折界面的位错堆积和应力集中均有利于动态再结晶的形核与长大[28].因此,再结晶晶粒会沿扭折界面形核并长大,如图5d中箭头所示.但并非所有的扭折界面均能诱发再结晶.Wu等[29]指出,扭折界面诱发再结晶与扭折界面取向差密切相关,大角度扭折界面的高应变储能更容易促进再结晶形核. ...

... 除孪生与滑移外,扭折变形也是含LPSO相镁合金塑性变形过程中的一种重要机制,受平行于基面压缩的载荷作用甚至能够替代孪生来协调变形.图10为2道次变形后既发生扭折变形又发生{}拉伸孪生的晶粒及其取向分布特征.晶内取向差角度分布如图10b所示.变形后晶粒出现大量大角度晶界,其数值主要分布在15°~30°及60°~90°范围,前者来源于扭折带与基体的取向差,而后者来源于孪晶与扭折带及孪晶与基体的取向差.为研究扭折带类型及形成机制,仅包含扭折区域的取向成像图及不同取向差角度范围下的晶内取向差转轴(IGMA)分布如图10c和d所示,其中图10c为隐藏孪生区域后的图10a.根据Yamasaki等[15]的研究结果可知,扭折带取向差的增大主要来源于带内位错的增殖与滑移,并且通过对比扭折带的IGMA分布和特定滑移系的Taylor轴[36],能够判定构成扭折带及取向变化的主要滑移机制.当IGMA分布集中在<>时,意味着扭折变形主要通过单一Burgers矢量的基面<a>滑移来进行;当IGMA分布集中在<>时,意味着扭折变形主要通过具有不同Burgers矢量的基面<a>滑移来进行;而当IGMA分布集中在<0001>时,意味着扭折变形主要通过柱面<a>滑移来进行.观察图10d可知,扭折导致的取向差转轴主要集中在<>方向,意味着扭折带的形成和取向演变与基面<a>滑移密切相关,且位错滑移的方向确定,不存在其它方向的变体.扭折带的形成有利于释放应力集中,提高材料塑性成形的能力;同时,不同取向扭折带的出现导致晶体取向分布多样化,有利于多晶体织构的弱化;并且扭折带界面被证实可以诱发动态再结晶,起到细化晶粒的效果[28,29]. ...

Kink boundaries and their role in dynamic recrystallisation of a Mg-Zn-Y alloy

2

2019

... 为进一步研究合金锻造过程中孪晶诱发再结晶行为及演变过程,对不同锻造道次变形后孪晶及再结晶晶粒形貌特征进行金相显微观察,结果如图5所示.1道次变形后,孪晶条带平直,内部未观察到明显的再结晶晶粒,如图5a所示.2道次变形后,部分孪晶演变为再结晶细晶组织,如图5b中的箭头所示,而剩余的孪晶在后续应力与温度作用下也极有可能演变为再结晶组织.因此,6道次变形后,能够观察到大量的条带状动态再结晶组织,孪晶几乎完全被动态再结晶晶粒占据,如图5c所示.Guan等[27]研究发现,孪晶形成后其内部基体在后续变形过程中的滑移是导致孪晶诱发再结晶的主要原因:一般而言,孪生变形后,孪晶基体处于滑移变形的硬取向,特别是基面滑移,而多向锻造过程中载荷方向不断变化可能利于孪晶内基体的滑移变形,因此能够促进孪晶诱发再结晶并形成条带状细晶组织.除了孪晶诱发再结晶,扭折带诱发再结晶也是含LPSO相镁合金中一种重要的再结晶机制,扭折界面的位错堆积和应力集中均有利于动态再结晶的形核与长大[28].因此,再结晶晶粒会沿扭折界面形核并长大,如图5d中箭头所示.但并非所有的扭折界面均能诱发再结晶.Wu等[29]指出,扭折界面诱发再结晶与扭折界面取向差密切相关,大角度扭折界面的高应变储能更容易促进再结晶形核. ...

... 除孪生与滑移外,扭折变形也是含LPSO相镁合金塑性变形过程中的一种重要机制,受平行于基面压缩的载荷作用甚至能够替代孪生来协调变形.图10为2道次变形后既发生扭折变形又发生{}拉伸孪生的晶粒及其取向分布特征.晶内取向差角度分布如图10b所示.变形后晶粒出现大量大角度晶界,其数值主要分布在15°~30°及60°~90°范围,前者来源于扭折带与基体的取向差,而后者来源于孪晶与扭折带及孪晶与基体的取向差.为研究扭折带类型及形成机制,仅包含扭折区域的取向成像图及不同取向差角度范围下的晶内取向差转轴(IGMA)分布如图10c和d所示,其中图10c为隐藏孪生区域后的图10a.根据Yamasaki等[15]的研究结果可知,扭折带取向差的增大主要来源于带内位错的增殖与滑移,并且通过对比扭折带的IGMA分布和特定滑移系的Taylor轴[36],能够判定构成扭折带及取向变化的主要滑移机制.当IGMA分布集中在<>时,意味着扭折变形主要通过单一Burgers矢量的基面<a>滑移来进行;当IGMA分布集中在<>时,意味着扭折变形主要通过具有不同Burgers矢量的基面<a>滑移来进行;而当IGMA分布集中在<0001>时,意味着扭折变形主要通过柱面<a>滑移来进行.观察图10d可知,扭折导致的取向差转轴主要集中在<>方向,意味着扭折带的形成和取向演变与基面<a>滑移密切相关,且位错滑移的方向确定,不存在其它方向的变体.扭折带的形成有利于释放应力集中,提高材料塑性成形的能力;同时,不同取向扭折带的出现导致晶体取向分布多样化,有利于多晶体织构的弱化;并且扭折带界面被证实可以诱发动态再结晶,起到细化晶粒的效果[28,29]. ...

金属学原理

1

2013

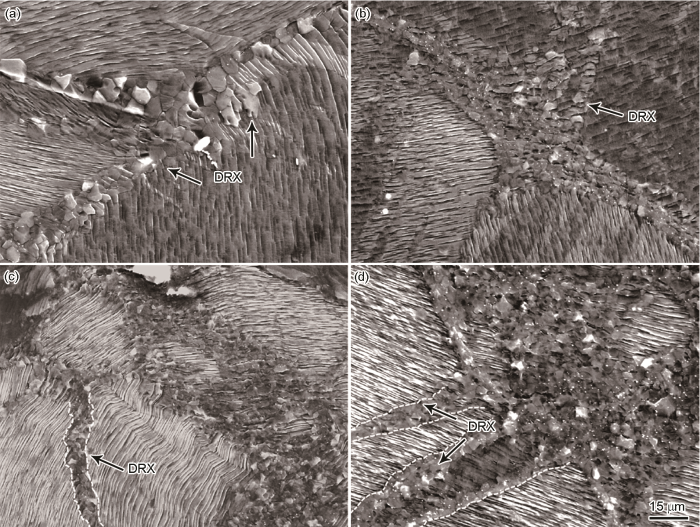

... 为研究合金晶界处的动态再结晶行为,对各锻造态合金晶界处的细晶组织进行SEM表征,结果如图6所示.1道次变形后,晶界处发生动态再结晶,生成细小的再结晶晶粒,晶粒平均尺寸约为4 μm (如图6a中箭头所示).由于晶界处应力集中程度大,为协调变形,多个滑移系启动,造成取向梯度大,位错塞积严重,从而有利于动态再结晶形核[30].2道次变形后,晶界处再结晶晶粒数目增多,且再结晶向粗晶内部扩展,如图6b中箭头所示区域.3道次变形后,晶界处再结晶程度进一步扩大.同时,粗晶内部形成了再结晶晶粒构成的条带状组织,如图6c和d中白色虚线所示,该条带状再结晶组织与图5b、c中的金相组织结果具有一致性. ...

金属学原理

1

2013

... 为研究合金晶界处的动态再结晶行为,对各锻造态合金晶界处的细晶组织进行SEM表征,结果如图6所示.1道次变形后,晶界处发生动态再结晶,生成细小的再结晶晶粒,晶粒平均尺寸约为4 μm (如图6a中箭头所示).由于晶界处应力集中程度大,为协调变形,多个滑移系启动,造成取向梯度大,位错塞积严重,从而有利于动态再结晶形核[30].2道次变形后,晶界处再结晶晶粒数目增多,且再结晶向粗晶内部扩展,如图6b中箭头所示区域.3道次变形后,晶界处再结晶程度进一步扩大.同时,粗晶内部形成了再结晶晶粒构成的条带状组织,如图6c和d中白色虚线所示,该条带状再结晶组织与图5b、c中的金相组织结果具有一致性. ...

{} twin variants selection mechanisms during twinning, re-twinning and detwinning

1

2014

... 为研究合金多向锻造过程中的变形机制,对合金进行EBSD分析,结果如图8所示.其中取向成像图的颜色参照方向为最终锻造压下方向,记作CD,即:红色代表晶粒c轴平行于CD方向,蓝色和绿色分别代表晶粒<>晶向和<>晶向平行于CD方向.大角度晶界(>15°)与小角度晶界(4°~15°)分别用黑线与白线标识.1道次锻造后,c轴垂直于CD方向的晶粒内孪生大量激发,如图8a左侧箭头所示.该孪晶与基体具有86°<>的取向关系,属于{}拉伸孪晶.并且该晶粒取向符合垂直于c轴压缩时易于激发{}拉伸孪晶的规律[23,31].c轴近似平行于CD方向的晶粒内孪生数目明显减少且孪晶尺寸非常小,如图8a中椭圆区域所示.对于未孪生或者少孪生晶粒而言,滑移为合金变形初期的主导变形机制,且滑移不均匀性导致了明显的晶内取向梯度.此外,晶界处能够观察到少量细小的动态再结晶晶粒,与图6a中SEM观测结果具有一致性.2、3道次变形后,发生孪生变形的晶粒数目增多.这是由于1道次变形中不利于孪生激发的晶粒在后续变形过程中可能转到利于孪生激发的取向.如图8b中椭圆标识的晶粒,其c轴垂直于2道次压缩方向,处于{}拉伸孪生的有利取向.6道次变形后,粗晶体积分数大为降低,再结晶体积分数增大,合金变形组织由残留粗晶与再结晶细晶共同构成.图8d中的放大图表明,再结晶晶粒尺寸约为4 μm,晶体取向分布较为随机. ...

Effect of particles on the formation of deformation twins in a magnesium-based alloy

1

2009

... 为研究锻造过程中{}拉伸孪生变形的晶体取向相关性,对比分析了1道次变形过程中孪生晶粒(记做A)与部分未孪生晶粒(记做B、C、D、E) Schmid因子的差异性.如图9a所示,孪生晶粒内多个变体同时激发({}孪晶界用黄线标识),同一变体通过粗化合并形成粗大的孪晶.然而,构成粗大孪晶中的各小孪晶沿孪生切变方向长度不一,且孪晶尖端终止于晶粒内部,意味着孪晶沿切变方向的长大受到阻碍并导致新的孪晶在晶界处形核,如图中椭圆及箭头所示.研究[14]表明,LPSO相抑制孪晶长大但几乎不影响孪晶形核.类似结论也存在于Mg-Zn合金的孪生现象中,含第二相的样品中孪晶尺寸小而数量多,第二相对孪晶形核影响并不显著[32].虽然本工作中孪晶长大受到LPSO相的抑制,但是孪晶形核未受到明显阻碍,多孪晶形核及长大使晶粒获得较大的孪晶体积分数(约为58.4%),因此孪生依然为该晶粒的主导变形机制. ...

Role of {} twinning characteristics in the deformation behavior of a polycrystalline magnesium alloy

2

2010

... hcp结构镁合金具有6个等效的孪生变体,按照位置关系可以将6个变体归为邻位、间位以及对位变体3类,其中对位变体取向非常接近,取向差仅为7.4°[33].该孪生晶粒中激发的孪晶具有非常接近的c轴取向,如图9a中的六棱柱及图9b中的{0001}极图所示,这意味着激发的孪晶为对位变体[34].图9c为c轴取向固定且沿CD方向压缩时,6个变体Schmid因子最大值在极图中的分布特征.参照图9b与c可知,A晶粒处于{}孪生变形非常有利的取向.图9d和e为未孪生晶粒B~E的取向成像图及其c轴在{0001}极图中的取向分布.根据{0001}极图及图9c可知,这部分晶粒最高孪生Schmid因子均低于0.2,取向不利于孪生激发;基面滑移Schmid因子高于0.4,如图9f所示.对于镁合金滑移系而言,基面滑移具有最低的临界分切应力[35],是镁合金塑性变形中最常见的变形机制,因此可以推断基面滑移为这部分晶粒的主导变形机制. ...

... 为研究多向锻造过程中载荷方向变化对合金{}拉伸孪生激发的影响,分析了3道次变形后,含有4种孪晶变体的晶粒在不同载荷下的孪生Schmid因子,如图11所示.为更好地区分基体与孪晶形貌特征,图11a中的取向成像图参考方向设置为视线方向.该晶粒内激发的4种孪生变体标记为T1~T4.相比于形貌较为规则的T2~T4孪晶变体,T1孪晶及附近基体的形貌发生了较大改变,部分孪晶与基体失去了{}孪生取向关系,因此推测该孪晶为2道次(CD-2 pass)激发的孪晶,并且在后续变形中发生塑性变形,从而导致其形貌变化及晶体取向差偏离理论值.而形貌规则的孪晶T2~T4为3道次(CD-3 pass)激发的不同变体.根据孪晶c轴与压缩轴的关系也可验证上述推断.Hong等[33]研究发现,当平行于镁合金基面压缩且孪生变体的激发受Schmid定律控制时,激发的孪晶变体的c轴近似平行于压缩方向.如图11a中六棱柱所示,T1孪晶c轴近似平行于CD-2 pass,而T2~T4孪晶c轴近似平行于CD-3 pass,该结果与上述结论具有一致性.为进一步验证上述猜想,根据T1孪晶附近基体M1的取向,计算了2道次压缩载荷下6个理论变体的Schmid因子,结果如图11c所示.V1与V2 2个对位变体较其它变体具有更高的Schmid因子,而实际激发的孪晶T1的位置与V1与V2位置重合,如图11b与c所示,说明T1极有可能为2道次变形过程中激发的孪晶.在3道次变形中,载荷方向旋转90°,根据T2~T4附近的基体M2的取向计算得到的6个变体的Schmid因子如图11d所示.可以看出,V3与V4的位置与实际孪晶T2重合,而V5与V6的位置与实际孪晶T3和T4重合,如图11b与d所示,并且2组变体均具有较高的Schmid因子,因此3个变体可以同时激发.由此可见,多向锻造各道次变形过程中,不同载荷方向下Schmid因子最高的孪生变体种类及数量存在差异,并且具有更高Schmid因子的变体优先激发.因此,多向锻造过程中载荷不断变化,上道次未能激发孪晶的基体在后续变形过程中可能转为孪生有利取向,从而激发孪晶,最终造成一个粗晶内多孪晶变体同时出现的现象,并且多个孪晶变体的出现更加有利于铸态粗晶细化,如图11e所示. ...

Influence of observation plane on twin variant identification in magnesium via trace and misorientation analysis

1

618

... hcp结构镁合金具有6个等效的孪生变体,按照位置关系可以将6个变体归为邻位、间位以及对位变体3类,其中对位变体取向非常接近,取向差仅为7.4°[33].该孪生晶粒中激发的孪晶具有非常接近的c轴取向,如图9a中的六棱柱及图9b中的{0001}极图所示,这意味着激发的孪晶为对位变体[34].图9c为c轴取向固定且沿CD方向压缩时,6个变体Schmid因子最大值在极图中的分布特征.参照图9b与c可知,A晶粒处于{}孪生变形非常有利的取向.图9d和e为未孪生晶粒B~E的取向成像图及其c轴在{0001}极图中的取向分布.根据{0001}极图及图9c可知,这部分晶粒最高孪生Schmid因子均低于0.2,取向不利于孪生激发;基面滑移Schmid因子高于0.4,如图9f所示.对于镁合金滑移系而言,基面滑移具有最低的临界分切应力[35],是镁合金塑性变形中最常见的变形机制,因此可以推断基面滑移为这部分晶粒的主导变形机制. ...

A Taylor model based description of the proof stress of magnesium AZ31 during hot working

1

2003

... hcp结构镁合金具有6个等效的孪生变体,按照位置关系可以将6个变体归为邻位、间位以及对位变体3类,其中对位变体取向非常接近,取向差仅为7.4°[33].该孪生晶粒中激发的孪晶具有非常接近的c轴取向,如图9a中的六棱柱及图9b中的{0001}极图所示,这意味着激发的孪晶为对位变体[34].图9c为c轴取向固定且沿CD方向压缩时,6个变体Schmid因子最大值在极图中的分布特征.参照图9b与c可知,A晶粒处于{}孪生变形非常有利的取向.图9d和e为未孪生晶粒B~E的取向成像图及其c轴在{0001}极图中的取向分布.根据{0001}极图及图9c可知,这部分晶粒最高孪生Schmid因子均低于0.2,取向不利于孪生激发;基面滑移Schmid因子高于0.4,如图9f所示.对于镁合金滑移系而言,基面滑移具有最低的临界分切应力[35],是镁合金塑性变形中最常见的变形机制,因此可以推断基面滑移为这部分晶粒的主导变形机制. ...

Investigation of prism <a> slip in warm-rolled AZ31 alloy

1

2011

... 除孪生与滑移外,扭折变形也是含LPSO相镁合金塑性变形过程中的一种重要机制,受平行于基面压缩的载荷作用甚至能够替代孪生来协调变形.图10为2道次变形后既发生扭折变形又发生{}拉伸孪生的晶粒及其取向分布特征.晶内取向差角度分布如图10b所示.变形后晶粒出现大量大角度晶界,其数值主要分布在15°~30°及60°~90°范围,前者来源于扭折带与基体的取向差,而后者来源于孪晶与扭折带及孪晶与基体的取向差.为研究扭折带类型及形成机制,仅包含扭折区域的取向成像图及不同取向差角度范围下的晶内取向差转轴(IGMA)分布如图10c和d所示,其中图10c为隐藏孪生区域后的图10a.根据Yamasaki等[15]的研究结果可知,扭折带取向差的增大主要来源于带内位错的增殖与滑移,并且通过对比扭折带的IGMA分布和特定滑移系的Taylor轴[36],能够判定构成扭折带及取向变化的主要滑移机制.当IGMA分布集中在<>时,意味着扭折变形主要通过单一Burgers矢量的基面<a>滑移来进行;当IGMA分布集中在<>时,意味着扭折变形主要通过具有不同Burgers矢量的基面<a>滑移来进行;而当IGMA分布集中在<0001>时,意味着扭折变形主要通过柱面<a>滑移来进行.观察图10d可知,扭折导致的取向差转轴主要集中在<>方向,意味着扭折带的形成和取向演变与基面<a>滑移密切相关,且位错滑移的方向确定,不存在其它方向的变体.扭折带的形成有利于释放应力集中,提高材料塑性成形的能力;同时,不同取向扭折带的出现导致晶体取向分布多样化,有利于多晶体织构的弱化;并且扭折带界面被证实可以诱发动态再结晶,起到细化晶粒的效果[28,29]. ...

Kink formation and concomitant twin nucleation in Mg-Y

1

2016

... 为进一步说明孪生与扭折机制之间的相互作用,对孪晶、扭折带以及基体(图10a中黑框所示区域)的位向关系作进一步的分析,结果如图10e和f所示,其中数字标号1~3分别代表基体、扭折带与孪晶.观察图10e可知,晶粒内部孪晶与扭折带相互交错,孪晶贯穿扭折带之间的基体,并终止于基体与扭折带的界面,扭折带内未发现孪晶,可以推断扭折先于孪生发生,而后孪生在扭折界面形核并在基体内不断长大.反之,如果是孪生先于扭折进行,扭折基面两侧的孪晶应该连续.Wang等[37]在Mg-Y合金原位拉伸实验中发现,扭折先于孪生发生且扭折界面的基面位错能够促进{}孪生形核,并且,大多数孪晶受到扭折界面的阻碍而无法进一步长大,仅能沿扭折带外基体扩展.图10e的实验现象很好地符合了上述扭折与孪生关系的实验结论,即扭折界面为{}孪生提供形核点,同时阻碍孪晶扩展.孪生与扭折导致的基体取向改变如图10f中的极图和六棱柱所示.扭折带的基面相较于周围的基体发生了明显偏转,由于不同扭折带及同一扭折带不同区域基面旋转存在差异性,从而导致{0001}极图中基面法向(c轴)呈现初始位置向CD方向连续分布的特征.如图10f中箭头所示,扭折带与基体的其中一个{}极点重合,意味着扭折带与基体的<>方向重合,这与图10d中取向差转轴为<>的结果相符合.类似地,基体与孪晶取向差转轴为<>,从而导致其中一个{}极点重合.虽然孪生与扭折均导致了原始晶体的取向发生了变化,但是两者导致取向变化的方式截然不同.孪生主要通过原子切变及重组方式,存在固定的取向关系及转轴.而扭折导致的取向变化及转轴不存在确定值,与变形量及启动的位错类型密切相关.在压缩方向平行于基面时,{}孪生与扭折均处于易于激发的晶体取向.因此,整个晶粒右下部分(图10a)孪生大量激发,而对于中部区域,孪生与扭折同时激发.晶内不同区域孪生与扭折的差异原因目前尚不十分清楚,可能与晶粒的局部应力状态及不同区域LPSO相的分布及尺寸差异有关. ...