电弧熔丝增材制造(WAAM)技术采用电弧作为热源,以丝材作为原材料,相比激光和电子束热源具有热流密度低、加热半径大、成本较低的特点,且成形效率高,成形速率一般为2~10 kg/h[11~14]。现有的WAAM技术所用到的方法主要集中于熔化极气体保护焊(GMAW)和气体钨极氩弧焊(GTAW)。为了提高WAAM结构件的性能,需要对其组织和力学性能的关系有充分的了解。目前,已有许多研究者使用WAAM技术研究了TC4钛合金的组织与力学性能的关系[15~17]。研究表明,电弧熔丝增材制造堆积态的低倍组织均由外延生长的柱状原始β晶粒组成,与锻态TC4钛合金形成的等轴状原始β晶粒具有明显的差异,同时由于电弧熔丝增材制造试块中温度梯度的差异,沿着堆积增高方向形成具有一定周期性的α相高倍组织,导致不同区域的高倍组织具有明显的差异。这些组织上的差异导致电弧熔丝增材制造TC4结构件力学性能具有一些明显的特征,如不同区域力学性能的差异,原始β晶粒的结构和原始β晶粒内α相组织与织构差异是影响力学性能一致性的主要原因[18,19]。

在关于WAAM的研究中,堆积成形的构件容易出现坍塌[20]、扭曲[21]等宏观缺陷,一般可采用成形前基板热处理、正确的路径规划、原位层间冷轧、调节工艺参数的方法减少成形构件的宏观缺陷[11]。已有关于路径优化的工作[12]中,方波扫描路径相对较为简单,但目前的工作集中于对方波扫描路径进行理论分析[22,23],对其成形构件的组织、力学性能分析较少。Hu等[24]对GMAW技术中的多道次搭接成形方式进行了研究,主要对道次间的搭接量进行了理论和实验分析,但由于搭接区具有特殊的温度梯度,搭接区和普通堆积区的组织和织构会具有更明显的差异,从而造成成形结构件不同区域的力学性能具有更明显的差异。目前对于搭接区组织和力学性能一致性的研究尚鲜见报道,搭接方式成形工艺尚未成熟,因此该工艺尚未能大规模应用。

冷金属过渡(cold metal transfer,CMT)是GMAW技术的一种,采用同轴送丝方式[25],相比其它GMAW和GTAW等技术,CMT电弧熔丝增材制造技术具有丝材可达性好、能耗低的优点。本工作采用配备了CMT电源的电弧熔丝增材制造设备,以TC4-DT合金丝材作为原材料,在优化工艺参数的基础上,着重对堆积路径进行优化,采用相对较为简单的方波扫描路径。在前期对所采用的增材制造设备进行调试的过程中发现,为确保成形件的质量,该工艺堆积的最长距离不宜超过30~50 mm,本实验选取30 mm作为最长堆积距离。采用多个道次搭接的方式堆积了4道9层的实验试块,对搭接区的组织和力学性能进行了研究,同时对包含搭接线的拉伸试样的变形行为进行了研究。根据搭接区和普通堆积区组织、取向分布和相应的Schmid因子的差异,讨论了不同区域组织的均匀性和力学性能的差异程度,探究力学性能一致性的影响因素,为后续搭接方式成形工艺的优化奠定基础。

1 实验方法

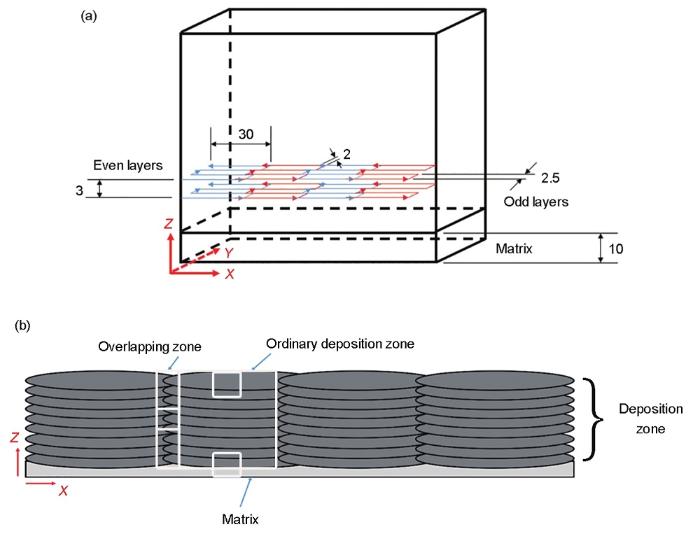

本实验所用电弧熔丝增材制造设备为青岛卓思三维智造技术有限公司研发的JointX X5型金属3D打印机,配备CMT电源,最大成形尺寸为500 mm×500 mm×500 mm。本实验设定送丝速率约为4000 mm/min,焊枪行进速率约为900 mm/min,基材为TC4钛合金轧制板材,在Ar气保护条件下进行堆积。堆积路径如图1a所示,堆积试块为如图1b所示4道9层的直壁墙,为便于描述,将试样堆积增高方向定义为Z向,每层堆积过程中采用方波扫描路径,长路径方向定义为X向,与之垂直的方向定义为Y向,试块每道宽度约为30 mm,层高约为3 mm,每一道次内的区域定义为普通堆积区,2个道次之间重叠的区域定义为搭接区。

图1

图1

堆积路径示意图和试块示意图

Color online

Fig.1

Schematics of the deposition path (unit: mm) (a) and the deposition sample (b)

本实验所用TC4-DT钛合金丝材直径为1.2 mm,采用三次真空自耗熔炼获得合金铸锭,经锻造开坯、轧制、多道次拉拔、扒皮、校直、清洗后形成成品丝材。其化学成分(质量分数,%)为:Al 6.15,V 4.25,Fe<0.05,O 0.13,N 0.005,H 0.003,Ti余量。

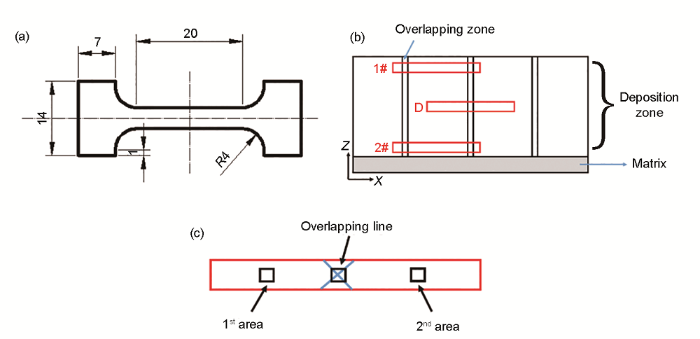

试块经X射线探伤,显示少量缺陷位于堆积体底部与基板交界处,实验中避免在此区域取样以排除缺陷的影响。选取如图1b所示红框内的典型区域进行低倍组织、高倍组织和宏观织构特征分析。低倍组织切片经表面机加工后粗磨、精磨,采用HF∶HNO3∶H2O=1∶2∶20 (体积比)的腐蚀剂进行深度腐蚀,采用Stemi2000-C体视显微镜进行观察;高倍组织切片经过机械预磨、抛光后,采用HF∶HNO3∶H2O=1∶2∶100 (体积比)的腐蚀剂进行腐蚀,采用Axiovert 200MAT光学显微镜(OM)进行观察,采用D8 Discover X射线衍射仪(XRD)测定不同区域的α相宏观织构。搭接区室温拉伸性能采用如图2a所示的小板状拉伸试样,试样厚度为2.5 mm,搭接区位于标距段中心,采用INSTRON 5582材料试验机进行室温拉伸实验。室温拉伸取样位置如图2b所示,1#试样标距段位于普通堆积区顶部,2#试样标距段位于普通堆积区底部,D试样标距段包含搭接区,每个位置取2个平行试样进行室温拉伸实验获取室温力学性能数据。断口及断口侧面观察采用Stemi2000-C体视显微镜和S-3400N扫描电镜(SEM)进行观察。

图2

图2

室温拉伸实验板状拉伸试样、取样位置及拉伸变形行为研究观察选区

Fig.2

The schematic of tensile sample (unit: mm) (a), sampling position (b) and the observation areas of D sample after 1% plastic deformation (c) (D: overlapping zone; 1#: top of the ordinary deposition zone; 2#: bottom of the ordinary deposition zone)

2 实验结果

2.1 组织特征

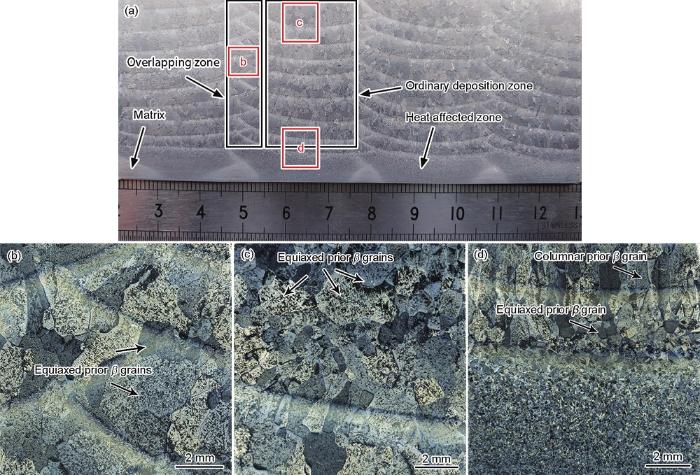

通过CMT工艺打印得到的TC4-DT合金的4道9层试块的低倍组织如图3a所示。自下而上可分为基材原始组织区(matrix)、热影响区(heated affected zone,HAZ)和堆积区(deposition zone),堆积区可分为普通堆积区(ordinary deposition zone)和搭接区(overlapping zone)。热影响区呈弧形,每一道次中心最大深度纵向贯穿了整个基板,约为10 mm;堆积区中,可以清晰地看到层界线及搭接线,普通堆积区中,每层的形状呈弧形,每层的层高约为2~3 mm,每一道次的宽度约为30 mm,层界线两两相交形成的搭接区宽度约为3 mm。截取图3a方框b~d所示的方形试样进行局部组织分析,如图3b~d所示。对比可以看出,搭接区与普通堆积区上部均形成了粗大的等轴状原始β晶粒,而在普通堆积区底部,堆积体与基板交界处形成了细小的等轴状原始β晶粒,普通堆积区第一层形成了宽度较小的柱状原始β晶粒,采用割线法测得普通堆积区底部第一层原始β晶粒的平均宽度约为427 μm,而普通堆积区顶部原始β晶粒的平均宽度约为798 μm。

图3

图3

冷金属过渡(CMT)成形TC4-DT合金试块低倍组织

(a) macrostructure of the integrated sample

(b) local macrostructure of the overlapping zone

(c) local macrostructure of the top of the ordinary deposition zone

(d) local macrostructure of the bottom of the ordinary deposition zone

Fig.3

The macrostructures of the TC4-DT sample deposited by cold metal transfer (CMT)

图4a和b分别为普通堆积区底部和顶部高倍组织,两者未见明显差异,主要为编织状组织,存在少量晶界α相和源于晶界α相的α集束。编织状组织主要由多种取向的长宽比较小的α板条编织而成,其含量约为90%;晶界α相多为连续晶界α相,局部区域存在非连续晶界α相;部分晶界上存在平行排布的α片层,这种α片层在晶界上形核并向晶内生长,具有相近的位相关系。

图4

图4

CMT成形TC4-DT合金试块普通堆积区高倍组织

Fig.4

Microstructures of the top (a) and bottom (b) of the ordinary deposition zone of the TC4-DT sample deposited by CMT

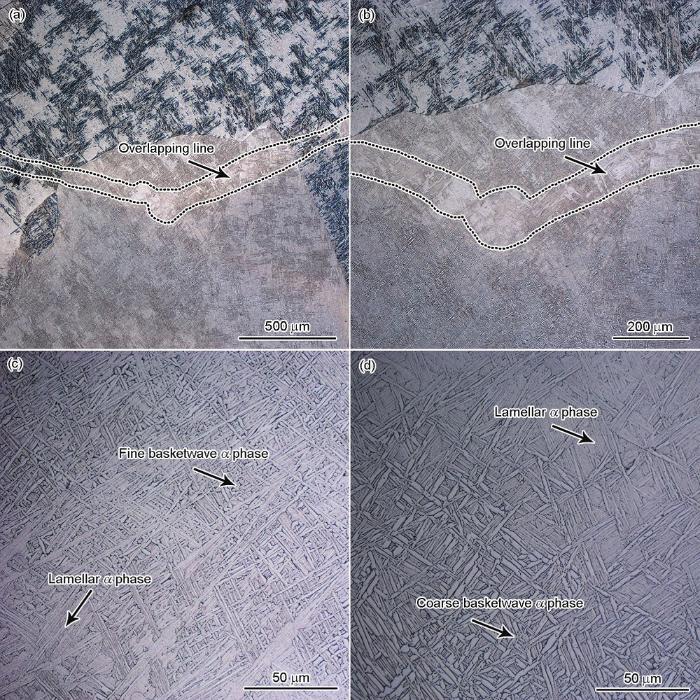

图5

图5

CMT成形TC4-DT合金试块搭接区高倍组织

(a, b) overlapping zone with different magnifications(c, d) microstructures above (c) and below (d) the overlapping line

Fig.5

Microstructures of the overlapping zone of the TC4-DT sample deposited by CMT

2.2 晶体取向特征

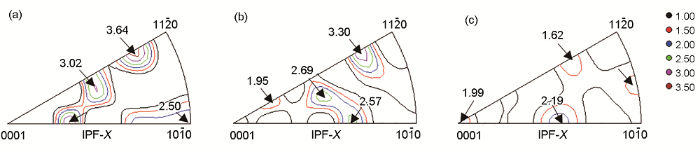

图6为堆积试块不同区域的X方向反极图(IPF-X)。可见,堆积试块不同区域的织构类型和强度存在明显的差异:搭接区主要在与<0001>方向偏离20°~70°处形成较强的集中取向,在<

图6

图6

CMT成形TC4-DT合金试块不同区域的X方向反极图(IPF-X)

Color online

(a) the overlapping zone (b) top of the ordinary deposition zone (c) bottom of the ordinary deposition zone

Fig.6

Inverse pole figures in X-direction (IPF-X) of different zones of the TC4-DT sample deposited by CMT

2.3 室温拉伸性能

表1为堆积试块不同区域的室温拉伸性能。可见,不同区域的屈服强度和拉伸塑性具有较大差异。搭接区试样屈服强度最高,普通堆积区顶部试样屈服强度最低,相差56 MPa;普通堆积区底部试样的屈服强度为762 MPa,比取自顶部试样高33 MPa;普通堆积区顶部试样具有最高的拉伸塑性,平均为14.8%。

表1 不同取样位置室温拉伸性能

Table 1

| Sample | Rp0.2 / MPa | Average / MPa | Rm / MPa | Average / MPa | A / % | Average / % |

|---|---|---|---|---|---|---|

| Overlapping zone, D | 786 | 785 | 854 | 851 | 11.5 | 11.0 |

| 784 | 848 | 10.5 | ||||

| Top of ordinary deposition zone, 1# | 724 | 729 | 834 | 837 | 15.0 | 14.8 |

| 734 | 840 | 14.5 | ||||

| Bottom of ordinary deposition zone, 2# | 771 | 762 | 877 | 864 | 10.5 | 10.5 |

| 753 | 851 | 10.5 |

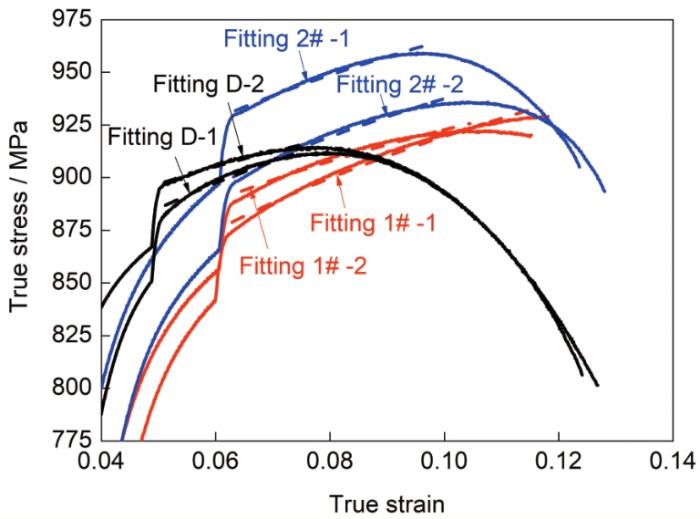

图7为不同区域拉伸试样的真应力-应变曲线,为了得到不同区域的加工硬化系数,使用Hollomon方程分别对每个位置的2个平行试样屈服后的抛物线硬化阶段进行拟合:

图7

图7

不同拉伸试样的真应力-应变曲线

Fig.7

True stress-stain curves of different tensile samples

表2 Hollomon方程拟合结果

Table 2

| Sample | Fitting curve | r2 |

|---|---|---|

| D-1 | S=1106.34ε0.074 | 0.9608 |

| D-2 | S=1044.34ε0.052 | 0.9754 |

| D-average | S=1075.34ε0.063 | |

| 1#-1 | S=1151.01ε0.098 | 0.9869 |

| 1#-2 | S=1092.49ε0.073 | 0.9700 |

| 1#-average | S=1121.75ε0.086 | |

| 2#-1 | S=1153.92ε0.078 | 0.9782 |

| 2#-2 | S=1147.38ε0.088 | 0.9791 |

| 2#-average | S=1150.65ε0.083 |

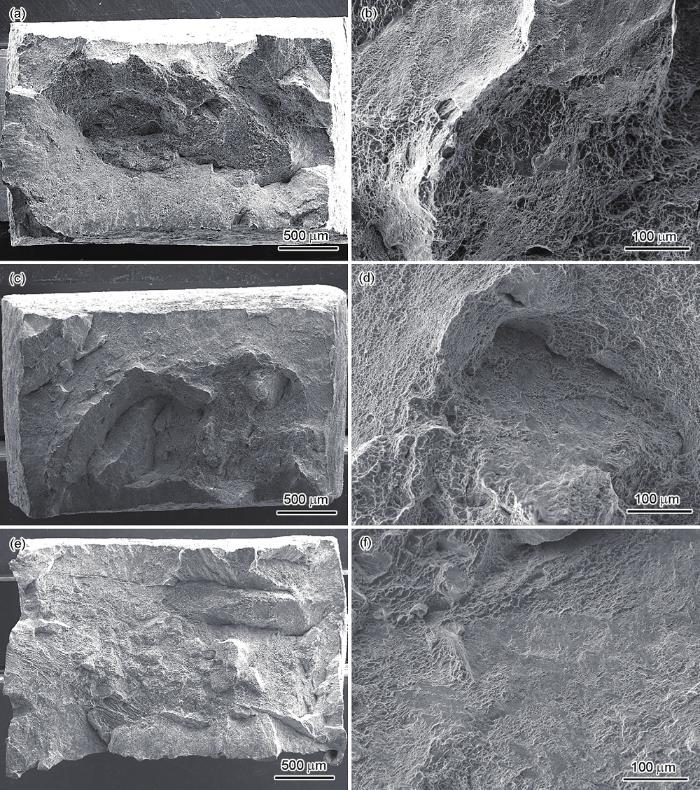

图8

图8

不同取样位置拉伸断口形貌

Fig.8

Fracture morphologies of samples D (a, b), 1# (c, d) and 2# (e, f) with different magnifications

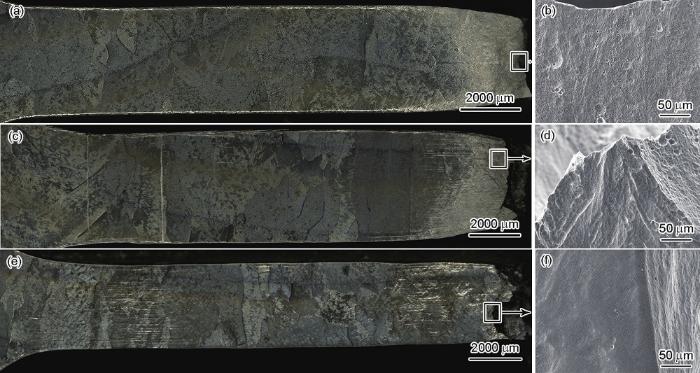

图9

图9

不同取样位置试样断口侧面形貌

Fig.9

Macrostructures (a, c, e) and SEM images of fracture side (b, d, f) of samples D (a, b), 1# (c, d) and 2# (e, f)

2.4 拉伸变形行为

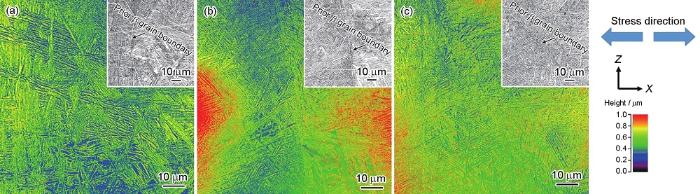

图10

图10

D试样在1%塑性变形后不同选区的激光共聚焦高度图

Color online

(a) overlapping lines (b) 1st area on the ordinary deposition zone (c) 2nd area on the ordinary deposition zone

Fig.10

Height maps of different zones on sample D after 1% plastic deformation (Insets show the prior β grain boundaries)

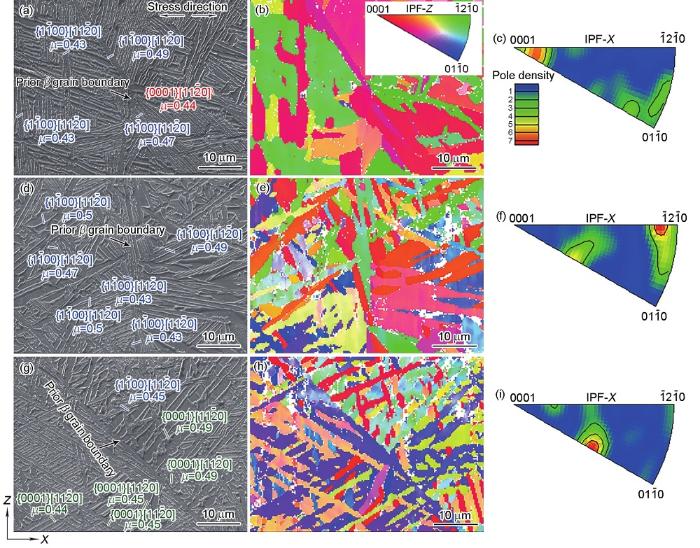

经过1%变形后,搭接区试样不同选区的滑移形貌、EBSD取向图和转变α相反极图如图11所示,蓝线代表柱面滑移,绿线代表基面滑移,红线代表锥面滑移。对于试样整体而言,试样以柱面滑移为主,且Schmid因子均在0.4~0.5之间。激光共聚焦高度图显示搭接线选区变形程度较小,但仍有部分α板条变形程度相对较大,图11a显示搭接线处变形程度较大的α板条开动的滑移系为柱面滑移,EBSD取向图显示搭接线选区存在尺寸较大的取向相同的区域,表明搭接线处平行排列的粗大的α板条具有相同的取向。层带内的滑移形貌表明层带内的变形主要以柱面滑移和基面滑移为主,图11e和i表明层带内主要由取向各异的α板条互相交织而成,形成编织状组织,与高倍组织观察结果一致。

图11

图11

D试样在1%塑性变形后不同选区的滑移形貌、EBSD取向图及转变α相反极图

Color online

(a~c) overlapping lines(d~f) 1st area on the ordinary deposition zone(g~i) 2nd area on the ordinary deposition zone

Fig.11

Slip characteristics (a, d, g), the relative EBSD maps (b, e, h) and IPF-X (c, f, i) for transformed α phase of different areas on sample D after 1% plastic deformation (μ—Schmid factor)

3 分析讨论

3.1 搭接区组织和织构的形成机理

CMT电弧熔丝增材制造得到的TC4-DT试块低倍组织主要为粗大的等轴状原始β晶粒,与TIG、EBRM等技术成形得到的粗大柱状原始β晶粒具有明显的差异[19,26]。本文作者前期研究[28]表明,根据柱状晶-等轴晶转变(CET)模型,低倍组织的形态与堆积过程中的温度梯度(G)和凝固速率(R)有关,而这2个变量与增材制造工艺的输入功率(P)和焊枪行进速率(V)有关,P越大,V越大,组织更利于向等轴状转变。本工作中所采用的CMT电弧熔丝增材制造工艺中,P约为2250 W,V约为900 mm/min,根据CET模型和3D-Rosenthal模型的计算[28],达到了柱状晶向等轴晶转变的临界条件,因此CMT电弧熔丝增材制造工艺更容易形成等轴状的原始β晶粒。

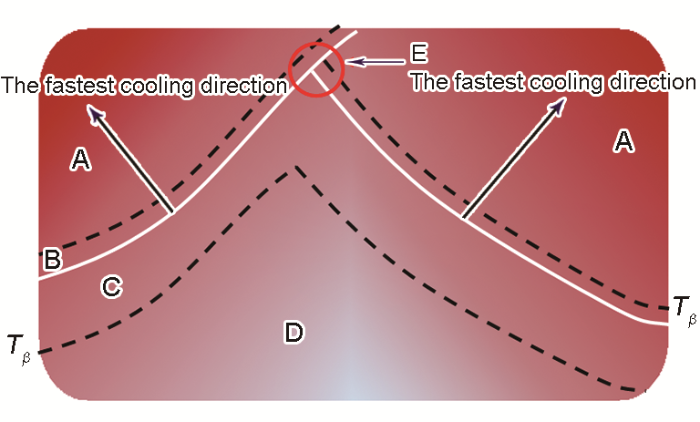

如图5所示的搭接区高倍组织主要为α相,α相的形态与该区域的固态相变有密切联系[26]。堆积过程中搭接区的温度梯度如图12所示。根据组织的不同可分为A、B、C、D和E 5个区域,其中B区为搭接线,不同区域组织的形成过程具有明显的差异。A区远大于β转变温度(Tβ),处于β单相区内,已有的α相完全转变成β相,在后续冷却过程中形成编织状细α板条组织。B区温度略高于Tβ,考虑到相变动力学因素,该区域α相未完全转变成β相,残留的α相具有相同的取向,在高温下长大,冷却后形成如图5c和d所示的较粗的平行排列的α板条。E区为两搭接线相交的区域,该区域在堆积过程中发生了2次长大粗化的过程,因而形成如图5b所示搭接线相交处更加粗大的组织。C区温度略低于Tβ,该区域α相未转变成β相,由于该区域温度较高,所有的α相均发生了长大粗化的过程,最终形成了编织状粗α板条组织。D区温度远低于Tβ,该区域未达到α相长大粗化的动力学条件,因而保留了原有的编织状细α板条组织,与A区组织相同。

图12

图12

搭接区组织分区及最快散热方向示意图

Fig.12

Organization division and the fastest cooling directions of overlapping zone (Tβ—β fransformation temperature)

根据Burgers关系,TC4-DT中α相的织构与原始β晶粒的取向有关,而原始β晶粒的取向与最快散热方向有关[26,27,29]。堆积过程中的最快散热方向如图12所示,最快散热方向与搭接线切线方向垂直,为温度梯度最大的方向。可见搭接线两侧的最快散热方向具有明显的差异,因而搭接线两侧的原始β晶粒具有不同的生长方向,最终导致搭接线两侧的α相织构具有明显的差异;在普通堆积区底部,最快散热方向只有堆积增高方向(Z向),且由于基板温度低,温度梯度较大,而对于普通堆积区顶部,一方面由于下方堆积体温度较高,温度梯度小于堆积区底部,另一方面,该区域与打印室内Ar气接触时间较长,散热方向由单一的Z向变为多个方向。图6a的α相IPF-X反极图中,强度较高的取向数目的关系为:搭接区>普通堆积区顶部>普通堆积区底部,可见不同区域中热传导的复杂性的关系为:搭接区>普通堆积区顶部>普通堆积区底部。

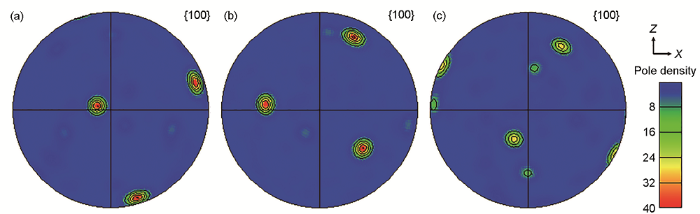

在已有的研究工作中,de Formanoir等[30]在电子束选区熔化(EBM)制备的TC4合金中,发现合金中的原始β晶粒具有较强的{100}β//Z的丝织构,而刘征[26]利用Burgers取向关系,计算得到了在无变体选择的条件下,β相丝织构转变形成的α相织构。计算结果表明,在由{100}β//Z理想丝织构转变而成的α相织构的IPF-X图上,在接近<0001>方向和与<0001>方向呈45°方向均形成较强的集中取向,而在IPF-22.5°反极图上,则在与<0001>呈20°和70°方向分别形成较强的集中取向。在IPF-22.5°、45°和67.5°反极图上,在接近<

由图6可知,普通堆积区和搭接区均包含由{100}β //Z理想丝织构转变而成的α相织构,在普通堆积区底部,织构类型主要为{100}β //Z丝织构转变而成的α相织构,在普通堆积区顶部,部分原始β晶粒取向发生了一定角度的偏转,偏转角约为22.5°,形成{100}β与Z方向呈22.5°的丝织构,最终形成2种转变α相织构的混合织构。在搭接区中,由于该区域热传导的复杂性,不仅有{100}β//Z丝织构的转变α相织构,还包含了{100}β与Z方向呈22.5°~67.5°的丝织构转变而成的α相织构。图13所示为搭接区不同EBSD观察选区内残留β相{100}极图。可见,搭接线处织构类型为{100}β //Z丝织构,搭接区层带内包含有其它取向的织构。普通堆积区顶部和搭接区的织构明显强于普通堆积区底部的织构,主要是由于普通堆积区顶部和搭接区的原始β晶粒尺寸大于普通堆积区底部的原始β晶粒尺寸,导致XRD测量的区域集中在少量的原始β晶粒中,从而使得这2个区域织构强度较高。

图13

图13

D试样1%塑性变形后不同EBSD选区内残留β相{100}极图

Color online

(a) overlapping lines (b) 1st area on the ordinary deposition zone (c) 2nd area on the ordinary deposition zone

Fig.13

{100} pole figures of prior β phase of different areas on sample D after 1% plastic deformation

3.2 力学性能一致性的影响因素

力学性能一致性体现了同一工艺下材料不同位置的力学性能差异,钛合金的力学性能取决于合金的变形行为,而组织形貌和晶体取向是影响变形行为的2个最主要因素。

在钛合金中,组织形貌的差异主要表现为组织类型和晶粒尺寸的差异。对比普通堆积区底部和顶部的低倍组织可知,2个区域原始β晶粒尺寸具有明显的差异,对比图4a和b可以看出,普通堆积区顶部和底部的高倍组织类型没有明显差异,均为编织状组织,且α板条的宽度相当,均为1~1.5 μm,可认为晶内α板条对变形的阻力相同。把一个原始β晶粒视为一个晶粒,以原始β晶粒尺寸(dβ)作为计算基准,根据Hall-Petch公式可得屈服强度(σs)与dβ的关系:

式中,σα反映晶内α板条对变形的阻力;

对于普通堆积区底部:

对于普通堆积区顶部:

由

求得:

Paradkar等[31]在单相β钛合金变形行为的研究中,通过实验求得了粗大原始β晶粒中的晶界对变形的影响系数,系数范围在1.4~3.2 MPa·

宏观织构主要是对原始β晶粒内的α板条的取向进行表征,反映了晶粒内的α板条对变形的影响程度。由图6所示的各个区域的IPF-X图可以看出,从宏观织构上看,各个区域在接近<

由图11可知,搭接线选区和普通堆积区层带内选区的微观织构具有明显的差异。搭接线选区内,IPF-X图显示存在一个较强的织构分布在<0001>方向上,在此处,所有的柱面、基面滑移系的Schmid因子都接近于0,因此可判断该区域的屈服强度较高,同时此搭接线选区内还存在一个靠近<

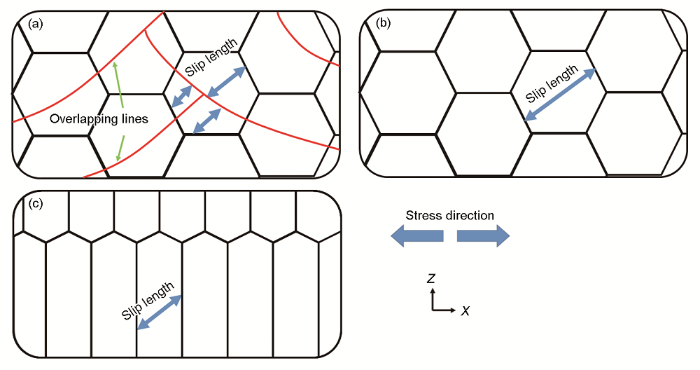

由上述分析可知,屈服强度与原始β晶界、原始β晶粒内的α板条界面和搭接线均有密切联系,这3种影响因素对屈服强度的影响程度排序如下:搭接线>原始β晶界>α板条界面,若忽略α板条对位错滑移的影响,得到如图14所示不同区域中位错滑移程的示意图,各个区域的平均有效位错滑移程关系如下:搭接区<普通堆积区底部<普通堆积区顶部。已有的研究[36]表明,合金中的屈服强度与形变过程中位错的有效滑移程的平方根呈一定比例关系,有效滑移程越短,合金的屈服强度越高,根据平均有效滑移程可推测各个区域的屈服强度应有如下的关系:搭接区>普通堆积区底部>普通堆积区顶部,推测与实际测定结果相符,说明原始β晶界和搭接线是引起CMT电弧熔丝增材制造TC4-DT合金力学性能一致性的主要因素。

图14

图14

CMT成形TC4-DT试块不同区域的滑移程示意图

Fig.14

The schematics of slip length of overlapping zone (a), top of the ordinary deposition zone (b) and bottom of the ordinary deposition zone (c) of the TC4-DT sample deposited by CMT

4 结论

(1) 利用CMT电弧熔丝增材制造技术制备的TC4-DT试块的不同区域的组织具有明显的差异。沿堆积增高方向,低倍组织由尺寸较小的等轴和柱状晶混合组织逐渐转变为粗大的等轴晶粒;普通堆积区高倍组织主要由晶内编织状α相、晶界α相和源于晶界的α集束组成;搭接区高倍组织主要由细编织状、平行排列和粗编织状α相以及界面β相组成,这种组织的形成可由堆积过程中特殊温度梯度合理解释。

(2) 试块不同区域的织构类型和强度具有明显差异。普通堆积区底部以源于{100}β //Z丝织构的α转变织构为主;沿堆积增高方向,原始β晶粒尺寸增大,织构强度明显变强;普通堆积区顶部还出现了源于{100}β与Z方向呈22.5°丝织构的α转变织构;搭接区由于热传导的复杂性,不仅有源于{100}β //Z丝织构的α转变织构,还包含源于{100}β与Z方向呈22.5°~67.5°丝织构的α转变织构。

(3) 室温下,试块不同区域的屈服强度和加工硬化系数具有明显的差异。由Hall-Petch公式计算结果和激光共聚焦显微镜观察结果可知,β晶界对力学性能的影响大于晶粒内α板条对力学性能的影响,搭接线在<0001>方向上存在一个较强的织构,其特点是柱面和基面滑移的Schmid因子均接近0,导致此处强度较高;在原始β晶界和搭接线的影响下,各个区域的平均有效位错滑移程具有以下的关系:搭接区<普通堆积区底部<普通堆积区顶部,因而搭接区具有最大的屈服强度和最小的加工硬化系数。

参考文献

Application state and prospects for titanium alloys

[J].

钛合金的应用现状及发展前景

[J].

Residual stress field and thermal relaxation behavior of shot-peened TC4-DT titanium alloy

[J].

Effect of electron beam welding on the microstructures and mechanical properties of thick TC4-DT alloy

[J].

Effects of β treatments on microstructures and mechanical properties of TC4-DT titanium alloy

[J].

Study on microstructure and tensile properties of TC4-DT titanium alloy forgings

[J].

TC4-DT钛合金锻件组织与拉伸性能研究

[J].

Flow properties and microstructure evolution of TC4-DT alloy at high temperature

[J].

TC4-DT合金的高温流变特性及组织演变

[J].

Development and application of metal additive manufacturing technology

[J].

金属增材制造技术在航空领域的发展与应用

[J].

Additive manufacturing of Ti6Al4V alloy: A review

[J].

Developments of additive manufacturing technology

[J].

增材制造技术的发展

[J].

Current status and perspectives on wire and arc additive manufacturing (WAAM)

[J].

Arc welding processes for additive manufacturing: A review

[A].

Wire+arc additive manufacturing

[J].

Current state and future development of the wire arc additive manufacture technology abroad

[J].

国外电弧增材制造技术的研究现状及展望

[J].

Morphology investigation on direct current pulsed gas tungsten arc welded additive layer manufactured Ti6Al4V alloy

[J].

Study on wire and arc additive manufacturing forming process of TC4 titanium alloy

[D].

TC4钛合金电弧熔丝沉积成形工艺研究

[D].

Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition

[J].

Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment

[J].Plasma arc additive manufacturing (PAM) is a novel additive manufacturing (AM) technology due to its big potential in improving efficiency, convenience and being cost-savings compared to other AM processes of high energy bea\m. In this research, several Ti-6Al-4V thin walls were deposited by optimized weld wire-feed continuous PAM process (CPAM), in which the heat input was gradually decreased layer by layer. The deposited thin wall consisted of various morphologies, which includes epitaxial growth of prior beta grains, horizontal layer bands, martensite and basket weave microstructure, that depends on the heat input, multiple thermal cycles and gradual cooling rate in the deposition process. By gradually reducing heat input of each bead and using continuous current in the PAM process, the average yield strength (YS), ultimate tensile strength (UTS) and elongation reach about 877MPa, 968MPa and 1.5%, respectively, which exceed the standard level of forging. The mechanical property was strengthened and toughened due to weakening the aspect ratio of prior beta grains and separating nano-dispersoids among alpha lamellar. Furthermore, this research demonstrates that the CPAM process has a potential to manufacture or remanufacture in AM components of metallic biomaterials without post-processing heat treatment.

Effect of ultrasonic impact on the properties of arc additive manufacturing of titanium alloy

[D].

超声冲击电弧增材制造钛合金零件的组织性能研究

[D].

Research on mechanisms and controlling methods of macro defects in TC4 alloy fabricated by wire additive manufacturing

[J].

Realisation of a multi-sensor framework for process monitoring of the wire arc additive manufacturing in producing Ti-6Al-4V parts

[J].

Tool-path planning for direction-parallel area milling

[J].

The optimal zigzag direction for filling a two-dimensional region

[J].

Multi-bead overlapping model with varying cross-section profile for robotic GMAW-based additive manufacturing

[J].

Energy input and metal transfer behavior of CMT welding process

[J].

CMT能量输入特点与熔滴过渡行为

[J].为分析CMT焊接方法的工艺特点,采用高速CCD摄像机建立了电弧形态和熔滴过渡视觉传感系统并且通过电流、电压传感器建立了波形采集系统,以此分析其能量输入特点和熔滴过渡行为.结果显示,CMT焊接波形控制呈现典型的直流脉冲特征,焊接时热输入较低;在CMT短路过渡过程中,熔滴尺寸随焊接电流的增加幅度不大,将熔滴尺寸控制在一定范围内可实现稳定的短路过渡.CMT短路过渡通过焊丝回抽,避免了大的电磁力,有效地消除了飞溅.当电流增大到一定值时,其过渡形式将转变为射滴过渡和短路过渡的混合过渡.

The microstructure and tensile behavior of TC4 titanium alloy produced via electron beam rapid manufacturing

[D].

电子束熔丝成形TC4合金的组织和拉伸力学行为研究

[D].

Microstructure and mechanical properties of Ti6Al4V produced by electron beam rapid manufacturing

[D].

电子束快速成形TC4钛合金显微组织及力学性能研究

[D].

Microstructure and its CET prediction of TC4-DT by CMT mode wire and arc additive manufacturing

[J].

CMT成型TC4-DT合金组织及形成机理的CET模型预测

[J].

The crystallographic orientation of α phase in Ti60 alloy

[D].

Ti60合金中α相的晶体取向研究

[D].

Electron beam melted Ti-6Al-4V: Microstructure, texture and mechanical behavior of the as-built and heat-treated material

[J].

On the validity of Hall-Petch equation for single-phase β Ti-Al-Nb alloys undergoing stress-induced martensitic transformation

[J].

The effect of alpha platelet thickness on plastic flow during hot working of TI-6Al-4V with a transformed microstructure

[J].AbstractThe effect of alpha platelet thickness on the plastic flow of Ti–6Al–4V with a transformed microstructure was established by conducting isothermal, hot compression tests at hot working temperatures on samples with identical crystallographic texture and beta grain size. Microstructures containing alpha laths/platelets ranging in thickness from approximately 0.4 to 10 μm were produced by various sequences consisting of hot rolling and heat treatment. Constant-strain-rate and strain-rate-jump compression tests were conducted at subtransus temperatures of 815, 900, and 955°C in the strain rate regime between 10−3 and 10 s−1. The rate-jump tests suggested that plastic flow is controlled by a power-law creep (dislocation glide/climb) mechanism in all cases except the low-strain rate deformation of material with the thinnest alpha laths. All of the constant-strain-rate compression tests yielded flow curves consisting of a peak stress at low strains (≤0.03), extensive flow softening, and a steady-state flow stress at large strains. The peak stress results indicated a significant Hall–Petch dependence on alpha lath/platelet thickness at the two lower test temperatures. The magnitude of this dependence was predicted by the classical Eshelby expression for grain-size strengthening. In addition, a first-order analysis demonstrated that the observed flow softening is of the same magnitude as that which would be associated with the loss of Hall–Petch strengthening (due to alpha–beta interfaces) during hot working.]]>

Analysis of the different slip systems activated by tension in a α/β titanium alloy in relation with local crystallographic orientation

[J].AbstractThe gliding modes of a duplex Ti–6Al–4V titanium alloy were investigated through in situ (scanning electron microscopy) tensile tests. A method based on electron back-scattering diffraction (EBSD) measurements was used to identify activated slip systems. The approach applied to a large number of grains allowed a statistical analysis of the nature (basal, prismatic, pyramidal) and distribution of the slip systems according to the crystallographic texture. A discussion concerning the pertinence of Schmid’s law to explain the occurrence and succession of slip events is then proposed. The domain in favor of each type of slip system is finally presented by using inverse pole figures mapped with Schmid’s factor iso-curves.]]>

Examination of the distribution of the tensile deformation systems in tension and tension-creep of Ti-6Al-4V (wt.%) at 296 K and 728 K

[J].

Crystallography of fatigue crack initiation and growth in fully lamellar Ti-6Al-4V

[J].