传统合金材料的设计规则受限于多以1种或2种主要合金元素为主。作为对这一合金设计限制的突破,含有多种主元素的高熵合金(high entropy alloy,HEA)在最近几年受到广泛的关注[1~4]。最初的高熵合金设计规则为利用多个主元的等原子比实现构型熵的最大化,从而形成稳定的单相固溶体结构。但是,最新研究表明,高熵合金中单相固溶体的形成,对通过等原子比实现最大化的构型熵依赖性较弱[5,6],甚至发现在设计性能优良的多主元高熵合金时,最大构型熵不是最重要的参数[7]。这些研究工作鼓励研究人员放宽了对多个主元素的等原子比以及形成单相固溶体的设计规则,进而提出非等原子比高熵合金的概念[8~10]。在该研究背景下,研究人员设计了具有单相、双相甚至多相结构的非等原子比高熵合金[8~10]。

最近研究[6~8]表明,非等原子比高熵合金的力学性能可以超过等原子比高熵合金。在非等原子比高熵合金中,通过调整原高熵合金体系中的元素组成比例,引入多种形变机制,可协调高熵合金的强韧化[8,11~14]。例如,Guo等[11]设计了非等原子比的Cr10Mn50Fe20Co10Ni10高熵合金,其形变过程中形变微带的激活可同时充当位错源和位错障碍,进而形成位错胞并有效提高其室温力学性能(抗拉强度为(621±8) MPa,延伸率为55%±1%)。非等原子比的V10Cr15Mn5Fe35Co10Ni25高熵合金在低温形变过程中产生的大量形变孪晶,使其呈现出良好的力学性能(抗拉强度1128 MPa,延伸率78.6%)[12]。Li等[8]基于亚稳态工程设计了具有相变诱导塑性(transformation-induced plasticity,TRIP)效应的双相Fe50Mn30Co10Cr10高熵合金,其室温强度超过了800 MPa的同时延伸率超过了70%,强韧化指标远高于普通等原子比的高熵合金体系。

在合金材料中掺入小尺寸间隙原子,如C、B、O和N等,这些间隙原子的存在可引起固溶体的点阵畸变,进而提高合金材料的力学性能。最近,已有研究[15~18]表明,在非等原子比高熵合金中添加间隙原子可作为有效的强韧化方式。例如,将C原子加入到Fe40.4Ni11.3Mn34.8Al7.5Cr6高熵合金中,使其层错能降低,形变机制由波形滑移转变为平面滑移,进而使抗拉强度达到(1174±19) MPa,延伸率为49.5%±0.6%[17]。Lei等[18]将2% (原子分数)的O原子和N原子间隙至难熔Ti0.5Nb0.5HfZrTi高熵合金中,其屈服强度分别达到1138和1362 MPa。其中,O的加入使得合金中生成了有序间隙原子复合体,钉扎位错并促进了交滑移的发生,使其具有良好的延伸率(20.6%)。值得关注的是,间隙原子B在加入非等原子比的高熵合金中研究较少。掺入B间隙原子具有以下两点优势:第一,B原子易在晶界析出,在细化晶粒的基础上可增加晶界的内聚力[19,20],以期同步提高合金的强韧性;第二,B原子的添加会导致局部晶格扭曲以形成显著的间隙固溶强化效应[21]。因此,利用B原子来优化非等原子比高熵合金力学性能的研究工作是十分有意义的。

本工作以一种典型的非等原子比高熵合金(Fe50Mn30Co10Cr10)作为研究对象,掺入B作为间隙原子,利用形变及退火工艺调控该高熵合金的微观组织结构,重点结合电子通道衬度显像(ECCI)技术及电子背散射衍射(EBSD)技术,系统地揭示形变量对形变机制的影响规律,以及退火时间和退火温度对再结晶行为的影响规律,建立Fe50-xMn30Co10Cr10Bx高熵合金的再结晶组织与形变及退火工艺之间的定性关系,以期为进一步调控与优化Fe50-xMn30Co10Cr10Bx高熵合金的强韧化性能奠定理论基础。

1 实验方法

为指导设计Fe50-xMn30Co10Cr10Bx双相高熵合金,首先利用Pandat相图计算软件及自构建的数据库计算Fe50-xMn30Co10Cr10Bx (x=0~5)高熵合金的伪二元相图,并绘制Fe50Mn30Co10Cr10高熵合金和Fe47Mn30Co10-Cr10B3高熵合金相组成随温度变化图。

利用真空非自耗电弧熔炼炉制备Fe47Mn30Co10-Cr10B3和Fe50Mn30Co10Cr10高熵合金。首先,将纯度大于99.5%的金属粉末进行充分混合,并压成直径10 mm、高10 mm的圆柱体。将制备好的圆柱样放置在水冷铜坩埚中,在Ar气氛中进行熔炼。为使合金成分均匀,每个样品至少反复熔炼4次,熔炼完毕待冷却后取出,得到纽扣状的铸态试样。对铸态试样进行1000 ℃、12 h的均匀化处理后,通过电火花线切割加工得到尺寸为10 mm×8 mm×2 mm的块状试样。随后,对Fe47Mn30Co10Cr10B3块状试样进行轧制形变处理,其形变量分别为10% (小形变量)、20% (中等形变量)和50% (大形变量)。最后,对形变10%的样品进行1000 ℃、5 min的退火处理,水淬;对形变50%的样品进行相同温度(1000 ℃)下不同保温时间(1、5和30 min)的退火处理,水淬。对Fe50Mn30Co10Cr10块状试样进行大形变量(50%)轧制处理,随后进行1000 ℃保温5 min退火处理,水淬。

选取板材的RD-TD (轧向-横向)面作为EBSD标定面。先利用砂纸水磨样品(终磨用3000号砂纸),再利用电解抛光制备EBSD试样。电解抛光液的成分为10%高氯酸+90%乙醇(体积分数),抛光温度为-30 ℃。电解抛光时试样接直流稳压电源的阳极,用不锈钢作阴极,抛光电压为20 V,抛光电流稳定在0.3 A左右。制备好的EBSD样品被放入Sigma HD场发射扫描电镜(FEG-SEM)进行表征。利用Channel 5软件进行EBSD数据分析,在晶界图中将两相邻晶粒取向差在3

2 实验结果

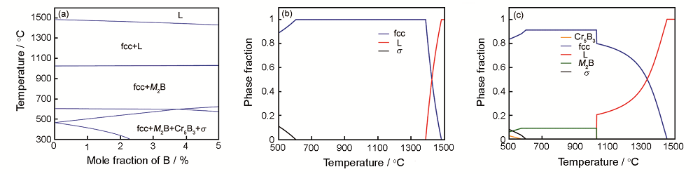

图1a为Fe50-xMn30Co10Cr10Bx (x=0~5) HEA的伪二元相图。可见,随着B含量的增加,高温相区的相结构组成变化不明显,以fcc相为主;而在低温相区,由Cr5B3+fcc+M2B+σ组成的四元相区逐渐扩宽。这表明,随着温度的降低,fcc相首先凝固,存在较宽的固/液共存区(1025~1453 ℃);随后,析出M2B相,形成fcc+M2B的双相结构;随着温度的进一步降低,发生固态相变,形成Cr5B3、σ相。图1b和c分别为x=0和3时相组成随温度的变化图。可见,x=0时,凝固过程中首先形成fcc单相结构(606~1330 ℃),在较低温度下(605 ℃)形成σ相(图1b);当x=3时,合金体系的熔点降低(1027 ℃),同时,析出第二相颗粒(600~1026 ℃),形成fcc+M2B的双相结构(其中M=Cr、Fe、Mn、Co)。此外,B的加入使σ相的形成温度略微降低(600 ℃),且随着温度的降低将进一步形成Cr5B3相(574 ℃)。

图1

图1

Fe50-xMn30Co10Cr10Bx (x=0~5)高熵合金(HEA)的伪二元相图,及x=0和3时高熵合金的相组成随温度的变化图

Color online

Fig.1

Pseudo binary phase diagram of Fe50-xMn30Co10Cr10Bx (x=0~5) high entropy alloy (HEA) (a), and fractions of stable phases as a function of temperature for x=0 (b) and x=3 (c) HEA

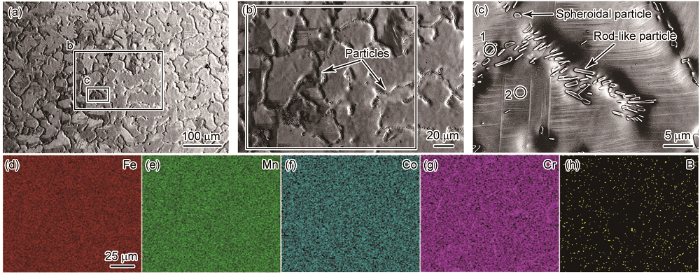

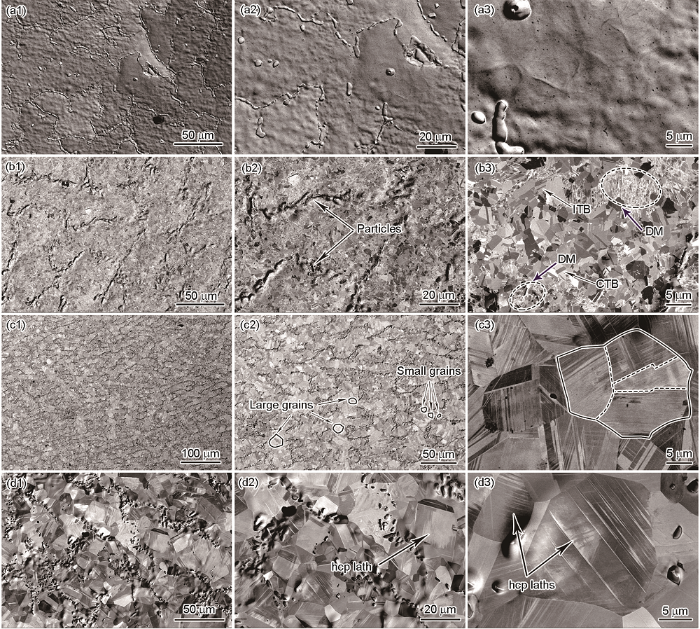

图2a~c为Fe47Mn30Co10Cr10B3 HEA铸态微观组织的SEM像。可见,铸态组织呈枝晶态结构,枝晶臂长度约为100 μm (图2a);第二相颗粒多在晶界析出,尺寸约为3 μm,少量第二相颗粒在晶内析出,尺寸约为1 μm (图2b)。从图2c可观察到第二相颗粒具有2种不同的形态,即长条状和球状结构。图2b方框区域的EDS面扫描结果见图2d~h,表明Fe、Co、Mn元素分布均匀,而Cr和B元素在第二相颗粒的位置存在偏聚现象。表1为对图2c中基体及第二相颗粒的EDS点扫描分析结果。结果表明,基体的元素含量基本符合该合金设计成分,且第二相颗粒可鉴定为CrxB第二相。图3所示为Fe47Mn30Co10Cr10B3HEA铸态样品的XRD谱。可见,铸态样品中存在fcc基体相和Cr5B3第二相。

图2

图2

铸态Fe47Mn30Co10Cr10B3 HEA微观组织的SEM像及EDS元素面扫描图

Color online

Fig.2

SEM images of microstructures of as-cast Fe47Mn30Co10Cr10B3 HEA (a~c), and EDS maps of the square region in Fig.2b (d~h)

表1 图2c中第二相颗粒及基体的EDS分析结果 (atomic fraction / %)

Table 1

| Location | Fe | Mn | Co | Cr | B |

|---|---|---|---|---|---|

| 1 | 17.44 | 24.46 | 1.34 | 47.91 | 8.85 |

| 2 | 47.06 | 27.34 | 9.80 | 10.62 | 5.18 |

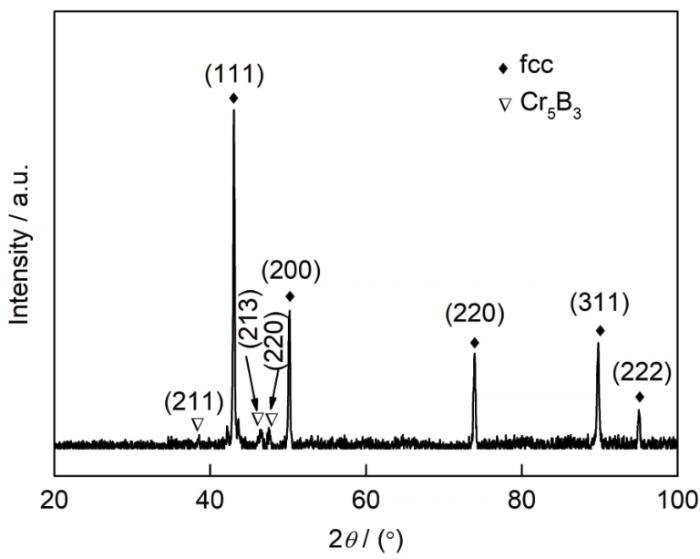

图3

图3

铸态Fe47Mn30Co10Cr10B3 HEA的XRD谱

Fig.3

XRD spectrum of as-cast Fe47Mn30Co10Cr10B3 HEA

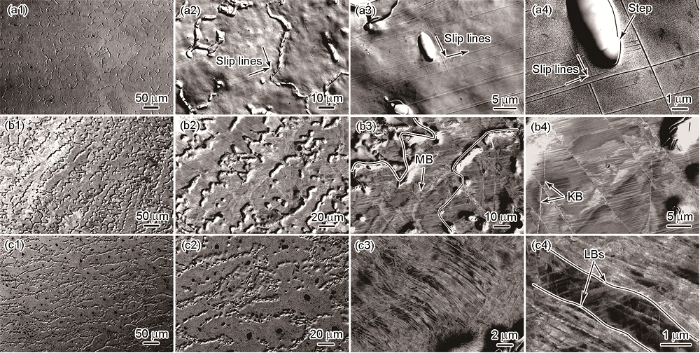

图4为不同形变量下Fe47Mn30Co10Cr10B3 HEA的微观组织演变图。由图可见,在小形变量下(10%),晶粒仍保留枝晶状结构(图4a1);从放大图可见,晶内滑移开动,滑移线切过第二相颗粒,并终止于晶界处(图4a2,其中箭头表示不同方向滑移系);当第二相颗粒被位错切割时,在第二相颗粒两侧各有一个台阶形状(如图4a4所示);另外,在第二相颗粒附近更易激活多系滑移,且可观察到在晶界附近存在多系滑移系(如图4a2~a4箭头所示)。这是由于晶界相邻的晶粒的晶体学取向不同,各个晶粒的形变必须与相邻的晶粒相互协调以维持形变的连续性[22]。因此,为保持形变的连续性,各晶粒协调形变,进而可在晶界附近观察到多滑移系的开动。在中等形变量下(20%),晶粒形态存在被拉长的趋势,第二相颗粒沿晶粒被拉长的方向分布(图4b1和b2);晶粒内各区域开动的滑移系数目不同从而使晶粒“碎化”,“碎化”的各区域由显微带(microband,MB)分隔开(图4b3)。在图4b4中观察到扭折带(kink band,KB)的形变组织。在大形变量下(50%),初始的枝晶态晶粒已经完全转变为扁平的形态,且晶粒和第二相颗粒沿着轧向呈流线形式分布(图4c1和c2);此外,形变量的增加使显微带不断地被细化,并逐渐转化为层带结构(lamellar boundary,LB),且其间距为几百纳米(图4c3和c4)。

图4

图4

不同形变量下Fe47Mn30Co10Cr10B3 HEA的微观组织演变图

Fig.4

Microstructure evolutions of Fe47Mn30Co10Cr10B3 HEA with deformations of 10% (a1~a4), 20% (b1~b4) and 50% (c1~c4) (MB—microband, KB—kink band, LB—lamellar boundary)

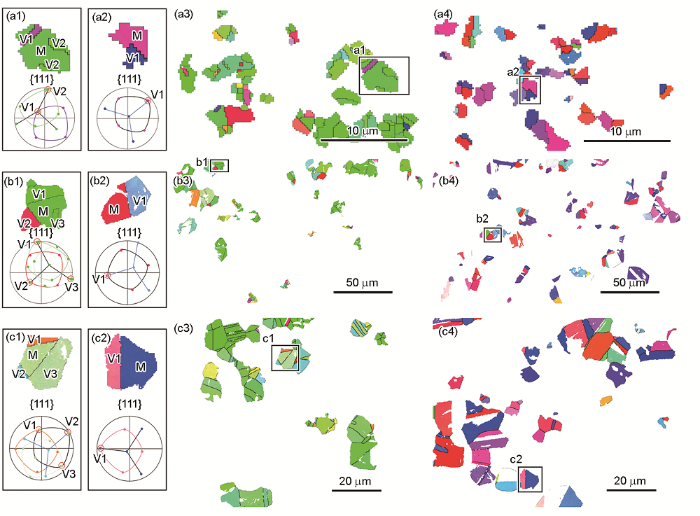

图5为不同形变量Fe47Mn30Co10Cr10B3 HEA的EBSD图。由图可见,小形变量下(10%)的晶粒仍保持初始态的枝晶状(图5a1);呈fcc单相结构(图5a2);第二相颗粒附近及晶界处的KAM值更高,而晶内KAM值较低(图5a3)。这表明位错在第二相颗粒及晶界处的应力分布更为集中。在中等形变量下(20%),出现了条状形态的形变组织(图5b1)。由于形变过程中发生塑性诱导相转变(fcc→hcp),从而形成fcc和hcp的双相组织(含量分别为64.0%和30.7%,体积分数,下同),其中hcp相呈条状(图5b2);在相界处的应力值更高,而相内KAM值较低(图5b3)。这表明位错在相界面处聚集,且相界面处的位错可作为缺陷,为fcc→hcp相变提供驱动力[23,24]。在大形变量下(50%),晶界已经完全扭曲模糊(图5c1),更多的hcp相被激活(76.3%),且hcp相以块状为主(图5c2);KAM值整体偏高,表明该材料的形变量基本上已经达到饱和状态(图5c3),另外,hcp相内观察到大量小角度晶界(图5c1),这表明激活了hcp相内位错滑移。

图5

图5

不同形变量下Fe47Mn30Co10Cr10B3 HEA的EBSD图

Color online

(a1~c1) inverse pole figure (IPF) maps (Black lines represent high angle boundaries, gray lines represent low angle boundaries) (a2~c2) phase maps (a3~c3) Kernel average misorientation (KAM) maps

Fig.5

EBSD maps of Fe47Mn30Co10Cr10B3 HEA with deformations of 10% (a1~a3), 20% (b1~b3) and 50% (c1~c3)

图6为变形态Fe47Mn30Co10Cr10B3 HEA经不同退火处理的微观组织。由图6a1~a3可见,变形10%的Fe47Mn30Co10Cr10B3 HEA经1000 ℃、5 min退火处理后,晶粒形状和尺寸均未发生明显变化,仍为枝晶结构,且晶粒尺寸仍约为100 μm。另外,第二相颗粒分布也未发生变化,大部分仍在晶界处分布。这表明当形变量小时,退火处理没有足够的驱动力改变晶粒的形状及尺寸。而变形50%的Fe47Mn30Co10Cr10B3 HEA经1000 ℃、5 min退火处理后组织中可观察到大量等轴细小的再结晶晶粒(图6c1)。但是,第二相颗粒仍保留形变态中呈流线分布的状态,这表明退火工艺不能改形变态第二相颗粒沿着轧向分布的情况。由图6a1~a3和c1~c3可见,经过大形变量“碎化”的形变组织具备更大的再结晶驱动力[25],在相同退火工艺下可诱发更多的再结晶晶粒。

图6

图6

形变态Fe47Mn30Co10Cr10B3 HEA经不同退火处理后的微观组织

(a1~a3) deformed 10% sample followed by annealing at 1000 ℃ for 5 min(b1~d3) deformed 50% sample followed by annealing at 1000 ℃ for 1 min (b1~b3), 5 min (c1~c3) and 30 min (d1~d3)

Fig.6

Microstructures of deformed Fe47Mn30Co10Cr10B3 HEA after different annealing treatments (DM—deformed microstructure, ITB—incoherent twin boundary, CTB—coherent twin boundary)

图6b1~d3为Fe47Mn30Co10Cr10B3 HEA最大形变量的样品(50%)经过相同温度(1000 ℃)不同保温时间退火处理的微观组织。退火1 min后,第二相颗粒附近形成了大量的微米级细晶(图6b1和b2),细晶内部存在退火孪晶(图6b3),呈共格和非共格2种形态。此外,该退火组织仍保留部分形变组织(图6b3虚线内),为未完全再结晶组织。退火5 min后,形成大量等轴晶粒(图6c1),且相较于退火1 min的细晶,该等轴晶粒尺寸增大。有趣的是,在第二相颗粒密集的区域,晶粒尺寸明显较小(<10 μm),而远离第二相颗粒的晶粒尺寸大(>10 μm,图6c2)。另外,在等轴晶粒内部存在大量不同方向的密集板条,该板条使晶粒内部被划分为几个不同的区域(图6c3)。该板条为热诱导hcp相板条,且激活了不同取向的hcp板条变体。退火30 min后,晶粒尺寸与退火5 min晶粒尺寸相当,并没有发生明显的长大现象;同样在等轴晶内观察到大量密集的hcp板条(图6d2和d3中箭头指出)。

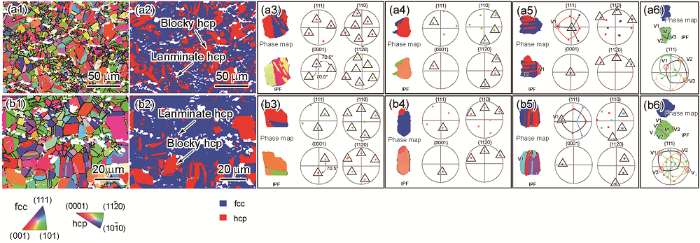

图7a1~d3为形变态Fe47Mn30Co10Cr10B3 HEA经不同退火处理的EBSD图。变形10%的Fe47Mn30Co10-Cr10B3 HEA经1000 ℃、5 min退火后枝晶形态未发生改变(图7a1);呈fcc单相(图7a2);晶内存在少量的退火孪晶(图7a3)。变形50%的Fe47Mn30Co10Cr10B3 HEA经1000 ℃、5 min退火后晶粒呈等轴状(图7c1);呈fcc+hcp双相结构(图7c2),该hcp相为热诱导的hcp相,且其形态呈现块状和条状;晶内出现大量退火孪晶(图7c3)。由图7a1~a3和c1~c3可知,形变量影响退火后hcp相及退火孪晶的形成,即形变量的增加更易诱导形成hcp相和退火孪晶。不掺B的Fe50Mn30Co10Cr10 HEA经轧制变形及1000 ℃、5 min退火处理后,形成粗大的等轴晶(>30 μm,图7e1);呈fcc+hcp双相结构(图7e2);晶内存在大量70.5°/<

图7

图7

形变态Fe47Mn30Co10Cr10B3和Fe50Mn30Co10Cr10 HEA样品经不同退火处理后的EBSD图

Color online

(a1~a3) deformed 10% Fe47Mn30Co10Cr10B3 HEA samples followed by annealing at 1000 ℃ for 5 min(b1~d3) deformed 50% Fe47Mn30Co10Cr10B3 HEA samples followed by annealing at 1000 ℃ for 1 min (b1~b3), 5 min(c1~c3) and 30 min (d1~d3) (e1~e3) deformed 50% Fe50Mn30Co10Cr10 HEA samples followed by annealing at 1000 ℃ for 5 min

Fig.7

IPF maps (a1~e1), phase maps (a2~e2) and grain boundary maps (a3~e3) of Fe47Mn30Co10Cr10B3 (a1~d3) and Fe50Mn30Co10Cr10 (e1~e3) HEA after different annealing treatments

变形50%的Fe47Mn30Co10Cr10B3 HEA在1000 ℃退火1 min后,再结晶晶粒细小(尺寸约为2 μm,图7b1),处于未完全再结晶状态;呈fcc单相(图7b2);fcc相内出现大量退火孪晶(图7b3)。退火5 min样品,再结晶晶粒长大,且呈现出混晶组织,其中小晶粒的尺寸约为4 μm,而大晶粒尺寸约为30 μm (图7c1);相结构为fcc+hcp双相组织 (图7c2)。结合相图和反极图(图7c1和c2),可观察到大尺寸晶粒内存在块状hcp相,而小尺寸晶粒多由fcc相及条状hcp相构成,且小尺寸晶粒多聚集于第二相颗粒附近。由图7c3可见,fcc相内形成大量退火孪晶界,而在hcp相内存在一种特殊取向的晶界,即70.5°/<

为研究Fe47Mn30Co10Cr10B3 HEA晶粒取向与退火孪晶变体之间的关系,在反极图中单独抠出典型晶粒以作详细分析,如图8所示。由图可见,在1000 ℃退火1 min后,某晶粒内部形成了2组孪晶变体(V1和V2,图8a1),另有晶粒内部仅存在单个孪晶变体(V1,图8a2)。而在退火5 min样品中,可观察到具有3个退火孪晶变体的晶粒(V1、V2和V3,图8b1)和单变体的晶粒(V1,图8b2)。另外,退火30 min的样品与退火5 min样品一致,存在3个孪晶变体(V1、V2和V3,图8c1)的晶粒和单孪晶变体(V1,图8c2)的晶粒。因此,将退火态的晶粒分为2类:Ⅰ类是具有多孪晶变体的晶粒(孪晶变体数

图8

图8

变形50%的Fe47Mn30Co10Cr10B3 HEA在不同退火条件下的孪晶变体情况

Color online

(a1~c1) single fcc grain with multiple twinning variants (a2~c2) single fcc grain with single twinning variant (a3~c3) multiple twinning variants in whole fcc grains (a4~c4) single twinning variant in whole fcc grains

Fig.8

Analysis of twinning variants in deformed 50% Fe47Mn30Co10Cr10B3 HEA under annealing at 1000 ℃ for 1 min (a1~a4), 5 min (b1~b4) and 30 min (c1~c4) (Red circles—the activated variant of annealing twins; M—the fcc matrix)

为研究Fe47Mn30Co10Cr10B3 HEA热诱导hcp相的形态和变体情况,从反极图和相图中单独抠出典型晶粒作详细分析,如图9所示。热诱导hcp相结构呈2种形态,即块状和条状(图9a2和b2)。其中,hcp相与fcc相的S-N取向关系,即{0001}hcp//{111}fcc、<11

图9

图9

变形50%的Fe47Mn30Co10Cr10B3 HEA退火样品中热诱导hcp相变体分析

Color online

(a1, b1) IPF maps (a2, b2) phase maps (a3, b3) grains with multiple hcp variants (a4, a5, b4, b5) grains with single hcp variant (a6, b6) grains without hcp variants

Fig.9

Analyses of thermal-induced hcp variants in Fe47Mn30Co10Cr10B3 HEA under annealing at 1000 ℃ for 5 min (a1~a6) and 30 min (b1~b6) (black triangle—the activated variant of hcp; red circle—the activated variant of annealing twins)

3 讨论

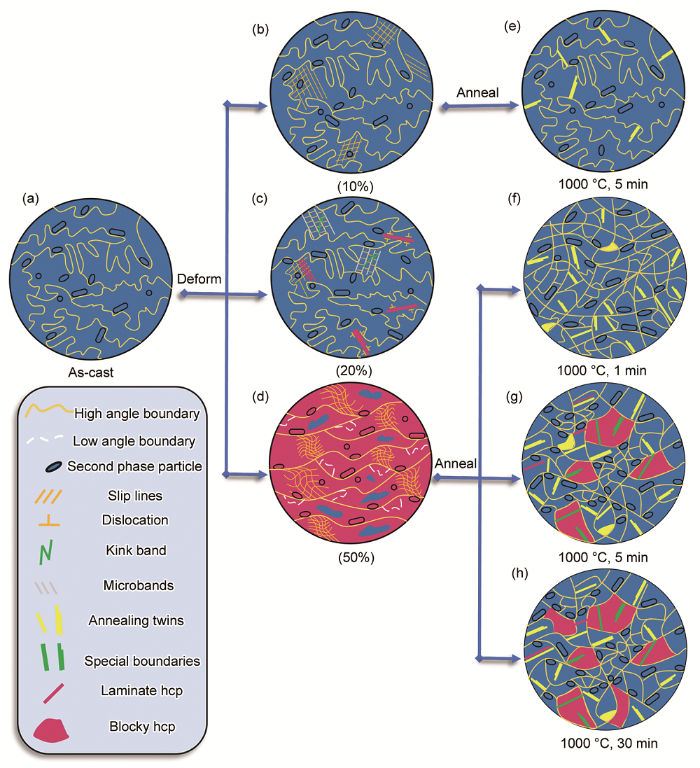

图10为形变及退火工艺处理后Fe47Mn30Co10Cr10B3 HEA微观组织的演变示意图。铸态组织的晶粒尺寸粗大,呈枝晶结构,第二相颗粒在晶界析出(图10a)。图10b~d显示了室温下的不同形变量微观组织结构演变示意图,其形变过程主要分为以下3个阶段。第1阶段,在小形变量下(图10b),晶粒保持枝晶结构,在第二相颗粒及晶界附近激活多个滑移系。该阶段的形变机制以位错滑移为主。在第2阶段,随着形变量增加(图10c),晶粒沿着轧向被拉长,第二相颗粒沿轧向在晶界分布。晶内由显微带(MB)隔开滑移系数目不同的区域。为松弛显微带内的形变应力,形成扭折带(KB)。同时,在位错密集区域形成形变诱导的条状hcp相。此阶段的形变机制由位错滑移和形变诱导塑性共同主导。在第3阶段,形变量达到最大时(图10d),可观察到MB组织不断被细化扭曲呈层带结构(LB),且第二相颗粒沿轧向分布。此时,相组织以形变诱导的块状hcp相为主,存在零星分布的残余fcc相。Fujita和Ueda[24]在研究马氏体相变过程中同样观察到hcp相结构由条状到块状转变这一现象。他们认为在晶界发射的Shockley 不全位错作用下,(111)平面上会形成堆垛层错,这些堆垛层错可为马氏体相变提供形核核心。在外应力作用下,随着(111)面上层错的不断堆垛,层错的宽度增加,进而使hcp相不断变宽[23]。因此,可观察到随着形变量的增加,条状hcp相向块状hcp相的转变,即板条不断地长大融合形成块体。零星分布的残余fcc相表明,在大形变量的条件下,形变诱导塑性的效应已达到饱和。然而为了容纳进一步的塑性形变,块状hcp相内形成了大量小角度晶界,这表明位错运动将作为一种补充形变机制,即位错滑移在hcp相内被激活。

图10

图10

Fe47Mn30Co10Cr10B3 HEA形变和退火过程的微观组织演变示意图

Color online

Fig.10

Schematics showing microstructure evolution of Fe47Mn30Co10Cr10B3 HEA after deformation and annealing (a~h)

对不同形变量的样品进行相同退火工艺(1000 ℃、5 min)处理(图10e和g),在形变10%的退火样品中晶粒保持枝晶结构,晶内形变组织消失,并出现少量退火孪晶,相组织为fcc单相(图10e)。而对于变形50%的退火样品(图10g),其晶粒呈等轴晶状,晶内形成大量退火孪晶。相结构由fcc+hcp双相组成,在hcp相内可观察到70.5°/<11

对变形50%样品进行相同退火温度(1000 ℃)不同退火时间的处理(图10f~h),可观察到退火1~5 min过程中,再结晶晶粒长大现象明显,且相结构由fcc单相转变为fcc+hcp双相;而5~30 min过程中,晶粒尺寸基本相同,且仍呈现混晶的双相组织。这表明在退火再结晶过程中第二相颗粒主要有以下3点作用:(i) 晶界的迁移率受到第二相颗粒的影响[26],而本工作中的第二相颗粒大多数在晶界偏聚,因此降低了晶界的迁移率;(ii) 第二相颗粒对晶界移动具有钉扎作用[26,27],从而抑制再结晶过程中晶粒的长大;(iii) 形变过程中第二相颗粒附近具备更高的密集位错,可为再结晶过程提供更高的驱动力[25,26]。对此,在第二相颗粒附近的晶粒有更大的再结晶驱动力,从而快速完成再结晶过程,且其晶粒尺寸受到第二相颗粒的限制作用,从而形成小尺寸的再结晶晶粒。此外,随着退火时间的增加,有利于更多的亚稳态fcc相向更稳定的hcp相转变,可观察到热诱导hcp相形成(图10g和h)。

4 结论

(1) Fe47Mn30Co10Cr10B3 HEA的形变机制分为3个阶段:fcc相内位错滑移为主导,相变诱导塑性和位错滑移共同主导,hcp相内位错滑移主导。

(2) 在相同退火条件下,形变量影响高熵合金的再结晶行为。形变量的增加使退火再结晶晶粒显著细化,退火孪晶增多,并有利于热诱导hcp相形成。在形变量且退火温度相同的条件下,退火时间影响高熵合金的再结晶行为。1~5 min过程中,再结晶晶粒长大现象明显,且相结构由fcc单相转变为fcc+hcp双相。而5~30 min过程中,晶粒尺寸变化不明显,且呈现双相组织。

(3) 在形变过程中,第二相颗粒可有效阻碍位错运动。而在退火过程中,在晶界处析出的第二相颗粒可有效抑制再结晶晶粒长大,从而形成混晶组织。

(4) fcc晶粒取向影响退火孪晶变体的形成,在<101>取向晶粒内易形成多个孪晶变体,在<111>和<100>取向晶粒内易形成单个孪晶变体。fcc+hcp双相退火组织中,大尺寸fcc晶粒有利于多个hcp变体的形成,小尺寸fcc晶内易形成单个hcp变体。当小尺寸fcc晶粒内无孪晶变体时,有利于块状hcp相形成,含有单个孪晶变体时有利于条状hcp相的形成,而具有多个孪晶变体时将阻碍hcp相的形成。

参考文献

High-entropy alloy: Challenges and prospects

[J].

High-entropy alloys: A critical review

[J].

High-entropy alloys and metallic nanocomposites: Processing challenges, microstructure development and property enhancement

[J].

Science and technology in high-entropy alloys

[J].

Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys

[J].

Strong and ductile non-equiatomic high-entroy alloys: Design, processing, microstructure, and mechanical properties

[J].We present a brief overview on recent developments in the field of strong and ductile non-equiatomic high-entropy alloys (HEAs). The materials reviewed are mainly based on massive transition-metal solute solutions and exhibit a broad spectrum of microstructures and mechanical properties. Three relevant aspects of such non-equiatomic HEAs with excellent strength-ductility combination are addressed in detail, namely phase stability-guided design, controlled and inexpensive bulk metallurgical processing routes for appropriate microstructure and compositional homogeneity, and the resultant microstructure-property relations. In addition to the multiple principal substitutional elements used in these alloys, minor interstitial alloying elements are also considered. We show that various groups of strong and ductile HEAs can be obtained by shifting the alloy design strategy from single-phase equiatomic to dual- or multiphase non-equiatomic compositional configurations with carefully designed phase instability. This design direction provides ample possibilities for joint activation of a number of strengthening and toughening mechanisms. Some potential research efforts which can be conducted in the future are also proposed.

Non-equiatomic high entropy alloys: Approach towards rapid alloy screening and property-oriented design

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].Metals have been mankind's most essential materials for thousands of years; however, their use is affected by ecological and economical concerns. Alloys with higher strength and ductility could alleviate some of these concerns by reducing weight and improving energy efficiency. However, most metallurgical mechanisms for increasing strength lead to ductility loss, an effect referred to as the strength-ductility trade-off. Here we present a metastability-engineering strategy in which we design nanostructured, bulk high-entropy alloys with multiple compositionally equivalent high-entropy phases. High-entropy alloys were originally proposed to benefit from phase stabilization through entropy maximization. Yet here, motivated by recent work that relaxes the strict restrictions on high-entropy alloy compositions by demonstrating the weakness of this connection, the concept is overturned. We decrease phase stability to achieve two key benefits: interface hardening due to a dual-phase microstructure (resulting from reduced thermal stability of the high-temperature phase); and transformation-induced hardening (resulting from the reduced mechanical stability of the room-temperature phase). This combines the best of two worlds: extensive hardening due to the decreased phase stability known from advanced steels and massive solid-solution strengthening of high-entropy alloys. In our transformation-induced plasticity-assisted, dual-phase high-entropy alloy (TRIP-DP-HEA), these two contributions lead respectively to enhanced trans-grain and inter-grain slip resistance, and hence, increased strength. Moreover, the increased strain hardening capacity that is enabled by dislocation hardening of the stable phase and transformation-induced hardening of the metastable phase produces increased ductility. This combined increase in strength and ductility distinguishes the TRIP-DP-HEA alloy from other recently developed structural materials. This metastability-engineering strategy should thus usefully guide design in the near-infinite compositional space of high-entropy alloys.

Phase engineering of high-entropy alloys

[J].

High-entropy alloys with heterogeneous microstructure: Processing and mechanical properties

[J].

Dislocation-induced breakthrough of strength and ductility trade-off in a non-equiatomic high-entropy alloy

[J].

Cryogenic strength improvement by utilizing room-temperature deformation twinning in a partially recrystallized VCrMnFeCoNi high-entropy alloy

[J].

Joint contribution of transformation and twinning to the high strength-ductility combination of a FeMnCoCr high entropy alloy at cryogenic temperatures

[J].

Novel Co-rich high performance twinning-induced plasticity (TWIP) and transformation-induced plasticity (TRIP) high-entropy alloys

[J].

Second phase strengthening in advanced metal materials

[J].i.e., sizes, volume fractions, morphology, etc., could be manipulated by controlling the interface features and mechanical mismatch of the precipitates and matrix, which eventually give rise to much enhanced mechanical performance.]]>

先进金属材料的第二相强化

[J].归纳总结了本课题组近几年来在几种典型的先进金属材料(高性能钢铁材料、高熵合金及块体非晶合金)中应用第二相强化机制的研究工作. 研究发现, 通过调控第二相与基体组织的界面特性和性能匹配, 可以有效调控第二相的尺寸、体积比及形貌等特征, 从而大幅度提高这些材料的综合力学性能.

Deformation behavior and toughening of high-rntropy alloys

[J].A new alloy design concept, high-entropy alloys (HEAs), has attracted increasing attentions and becomes a new research highlight recently. Different from traditional alloy design strategy which usually blends with one or two elements as the principal constituent and other minor elements for the further optimization of properties, HEAs are multicomponent alloys containing several principle elements (usually ≥5) in equiatomic or near equiatomic ratio. Due to their unique atomic structure, HEAs possess a lot of distinguished properties. Since the discovery of HEAs, a variety of HEA systems have been developed and shown unique physical, chemical and thermodynamic properties, especially the promising mechanical properties such as high strength and hardness, abrasion resistance, corrosion resistance and softening resistance. Here in this short review manuscript, starting from the research challenges for understanding the deformation mechanism of HEAs, this work briefly summarized the mechanical properties and deformation behavior of HEAs, reviewed the proposed strengthening-toughening strategies and their corresponding deformation mechanism in HEAs. A brief perspective on the research directions of mechanical behavior of HEAs was also proposed.

高熵合金的变形行为及强韧化

[J].高熵合金是近年来涌现出的一种新型金属材料。不同于传统合金设计以1种或2种元素为主添加其它合金元素为辅的方案,高熵合金由多种元素以等原子比或近等原子比的成分组成,具有独特的原子结构特征,因而呈现出诸多不同于传统合金的独特性能。自高熵合金被首次报道以来,目前已经研发出了一系列的高熵合金体系,在物理、化学、热力学性能方面显示出独有的优势,尤其在力学行为方面显示出高强、高硬、耐磨、耐蚀、抗高温软化等优异的性能,在国际学术界引起了广泛的关注和研究兴趣,已经成为新的研究热点。本文从高熵合金变形机理研究存在的挑战出发,主要综述了高熵合金的力学性能和变形行为特点,已经提出的强韧化方案及相关机理,并对未来高熵合金变形行为的研究进行了简单展望。

The effect of interstitial carbon on the mechanical properties and dislocation substructure evolution in Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys

[J].

Snoek-type damping performance in strong and ductile high-entropy alloys

[J].Noise and mechanical vibrations not only cause damage to devices, but also present major public health hazards. High-damping alloys that eliminate noise and mechanical vibrations are therefore required. Yet, low operating temperatures and insufficient strength/ductility ratios in currently available high-damping alloys limit their applicability. Using the concept of high-entropy alloy (HEA), we present a class of high-damping materials. The design is based on refractory HEAs, solid-solutions doped with either 2.0 atomic % oxygen or nitrogen, (Ta0.5Nb0.5HfZrTi)98O2 and (Ta0.5Nb0.5HfZrTi)98N2. Via Snoek relaxation and ordered interstitial complexes mediated strain hardening, the damping capacity of these HEAs is as high as 0.030, and the damping peak reaches up to 800 K. The model HEAs also exhibit a high tensile yield strength of ~1400 MPa combined with a large ductility of ~20%. The high-temperature damping properties, together with superb mechanical properties make these HEAs attractive for applications where noise and vibrations must be reduced.

Effect of boron on grain-boundaries in Ni3Al

[J].

Grain boundary segregation engineering in metallic alloys: A pathway to the design of interfaces

[J].

Boron doped ultrastrong and ductile high-entropy alloys

[J].

Plastic deformation of metals and alloys

[A]. Laughlin D E, Hono K.Physical Metallurgy II

[M].

A model for the FCC→HCP transformation, its applications, and experimental evidence

[J].

Stacking faults and f.c.c. (γ)→h.c.p. (ε) transformation in 188-type stainless steel

[J].