钛合金具有优异的比强度,可以满足航空航天产品对材料轻质高强的需求,广泛用于航空发动机转动件及飞机结构等零部件[1~3]。在零部件的生产过程中,焊接是一种常用的成形方式,主要包括熔焊和固相焊。其中,熔焊是依靠焊丝或合金熔化后实现连接,采用熔焊会导致接头处的组织与基体母材部分的组织存在较大差异。固相焊包括钎焊、摩擦焊、自蔓延高温合成反应焊以及扩散焊等方式。钎焊需要钎料作为中间层材料,会引入一些其他元素,在接头处形成金属间化合物,导致接头处性能下降[4]。自蔓延高温合成反应焊技术控制复杂,对设备的要求较高[5]。摩擦焊无法对中空结构和复杂形状的构件进行连接[6]。扩散连接是通过界面间原子层元素扩散实现冶金结合,不会引入其他元素,避免了因母材熔化而导致接头性能恶化[7];该工艺可以实现复杂形状和结构的连接,被应用于航空航天等领域,为钛合金复杂结构、梯度结构等零部件制造提供了新思路[7,8]。

国内外研究人员在扩散连接方面开展了大量相关研究工作。Ferguson和Ramulu[9]构建扩散和蠕变方程模型,研究了扩散连接时界面孔洞间相互作用的影响,并通过实验对模型结果进行检验,获得了表面几何形状对连接性能的影响。高云鹏等[10]研究了不同热压温度下TC11钛合金扩散连接区的组织及性能,发现扩散连接界面两侧的晶体取向差异使得疲劳裂纹易在界面处萌生,影响了接头的疲劳性能。Ma等[11]对TC4合金进行了热压扩散连接,建立了扩散键合过程中孔洞闭合的动力学模型,分析发现幂律蠕变是扩散连接孔洞收缩的主要机制。邹军涛等[12]采用热压扩散连接技术制备了Cu/Al双金属,发现随着焊接温度的升高和保温时间的延长,界面层厚度逐渐增加。Sharma和Dwivedi[13]研究了“预摩擦”的表面处理方法和参数对结构钢热压扩散连接接头组织及性能的影响,结果表明,接头的抗拉强度随着焊接时间的增加而增加,热处理后在连接界面处出现了再结晶晶粒。现有研究中,所采用的热压扩散连接方法多为施加单轴方向的结合力,致使焊件在垂直力的方向上产生不同程度的变形。而在实际工程应用中,一些航空零部件的结构和性能对变形的要求较为严苛,例如钛合金空心结构叶片,其宏观变形程度需控制在5%以内[7]。另一方面,变形后的组织取向差异导致母材性能变化,也限制了该方法的应用。通过施加各向均衡的静压力,可以使焊件在连接过程中各向受力均匀,不发生宏观形变,内部孔隙等缺陷收缩愈合,获得性能质量较好的连接材料[14~16],目前该扩散连接方法少见报道。

1 实验方法

本工作所用材料为TC4钛合金锻造棒材,其合金化学成分(质量分数,%)为:Al 6.49,V 4.26,Fe 0.04,H 0.0026,C 0.021,N 0.0043,O 0.17,Ti余量。通过连续升温金相法测得棒材的β转变温度为(997

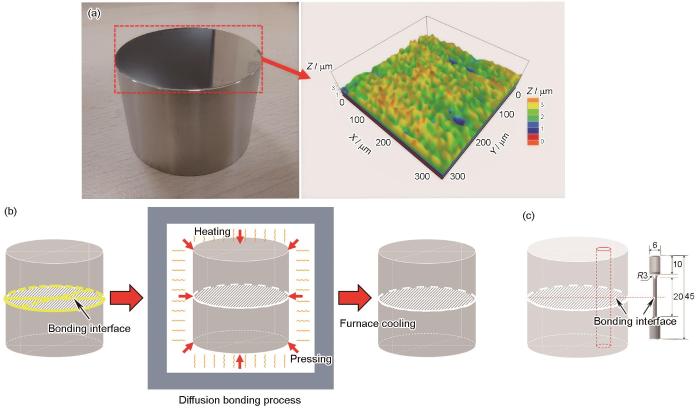

图1

图1

钛合金扩散连接面形貌、扩散连接过程示意图及拉伸实验取样示意图

Fig.1

Morphology of titanium alloy diffusion joint surface and schematics of diffusion bonding process

(a) photo and three-dimensional morphology of diffusion joint surface

(b) schematic of the bar hot pressing diffusion bonding process

(c) schematic of sampling positions for microstructure and tensile tests (unit: mm)

在棒材1/2半径处按照图1c所示的取样方式切取显微组织和力学性能测试试样,扩散连接界面位于试样的中心位置。采用AXIOVERT 200 MAT金相显微镜(OM)和配备了Ultim MaxN硅漂移型能谱仪(EDS)的MIRA 3场发射扫描电子显微镜(SEM)观察热压扩散接头的显微组织及断口形貌。采用Nano Measurer 1.2软件对不同热压扩散接头处的微观组织尺寸进行测量统计。参照GB/T 228.1—2010 《金属材料拉伸试验 第1部分:室温试验方法》,在TSE504D型万能试验机上进行室温拉伸性能测试,每组测试3支试样,取平均值。

2 实验结果与讨论

2.1 热压温度对扩散连接区显微组织的影响

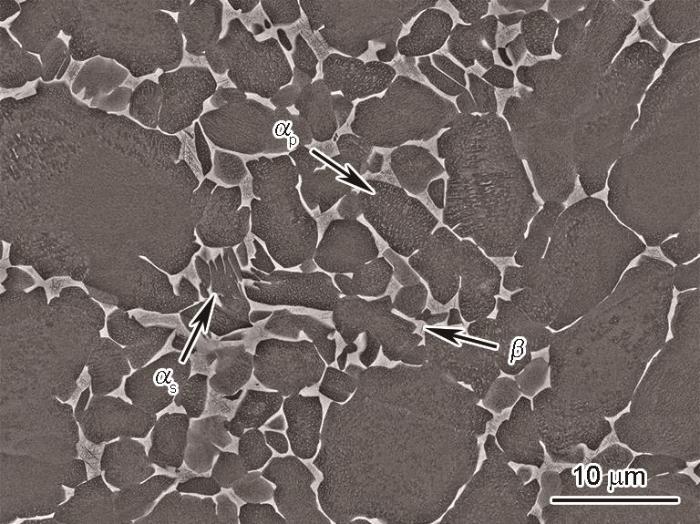

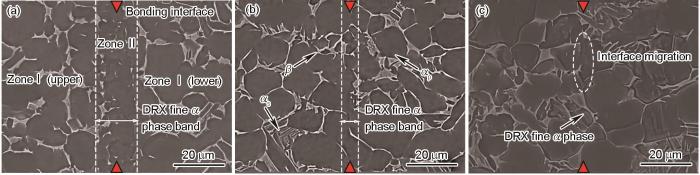

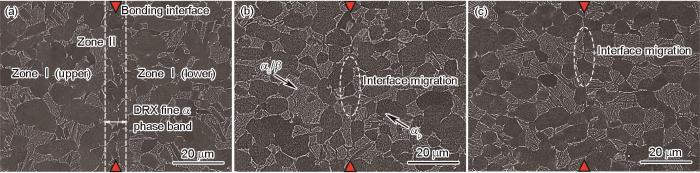

TC4钛合金锻造棒材的显微组织如图2所示。其组织由等轴状初生α (αp)相、针状次生α (αs)相及少量的β相构成。不同热压温度处理后TC4钛合金扩散连接区的显微组织如图3所示。热压后的TC4钛合金内部组织可以分为母材区(区域Ⅰ,图3中双虚线两侧区域)和界面扩散区(区域Ⅱ,图3中双虚线中间区域)。热压后合金棒材界面处实现了冶金结合,扩散区域未见孔隙及未焊合区域。由于本工作选用的热压温度均低于合金的相变点温度,扩散连接后母材区的组织由等轴状αp相、β相及αs相组成,与原始合金的组织接近。从图3界面处组织分析可见,扩散界面处组织出现一定程度的细化。热压过程中合金界面处会发生一定的塑性变形,在高温下该区域合金发生动态再结晶形成细小的α相[20],其尺寸显著低于母材中α相的尺寸(如图3a和b中区域II)。这种显著差异现象称为晶体学失配(crystallographic mismatch)[21]。Xiong等[21]将晶体学失配归结为2种类型,一种为靠近连接界面区域(即界面区)与远离连接界面区域(即母材区)的晶粒尺寸差异较大;另一种为通过中间夹层扩散结合时,连接界面与母材之间的晶格结构差异,常出现在单晶材料的扩散连接中。本工作中,连接界面处形成的晶体学失配现象与Xiong等[21]研究中提到的第一种类型相符合。随着热压温度的改变,界面处细小α相的尺寸和数量也存在一定的差异。930和950 ℃热压处理后界面扩散区(区域Ⅱ)可以观察到细小α相带的存在(如图3a和b所示)。分别测量图3a和b中区域Ⅱ形成的细小α相的尺寸,其中,930 ℃处理后区域Ⅱ处的细小α相带较宽,α相数量较多,尺寸为3~7 μm。当温度达到950 ℃后,区域Ⅱ处的细小α相带宽度减小,α相数量减少,尺寸为8~13 μm。温度升高到970 ℃后,区域Ⅱ处仅存在零星分布的细小α相(图3c中箭头处所示),连接界面处出现了曲折的阶梯状α/α或α/β/α界面,跨越了原始界面,并取代其成为新的连接界面(图3c中圆圈处),这表明该温度下界面处发生了局部晶界迁移。

图2

图2

TC4钛合金棒材的显微组织

Fig.2

Microstructure of TC4 titanium alloy bar (αp—primary α phase, αs—secondary α phase)

图3

图3

不同热压温度下扩散连接接头显微组织的SEM像

Fig.3

SEM images of microstructures of joints diffusion bonded at different temperatures (DRX—dynamic recrystallization)

(a) sample 1# (930 oC) (b) sample 2# (950 oC) (c) sample 3# (970 oC)

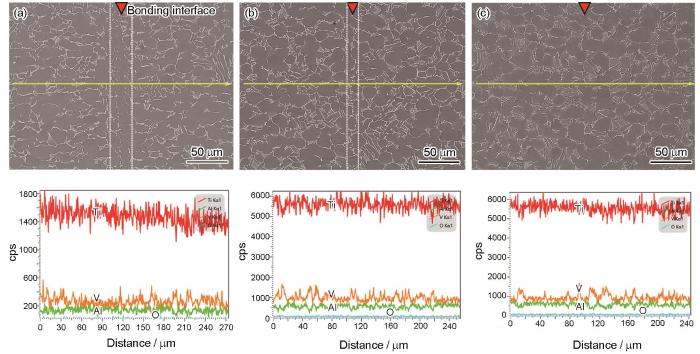

大多数固态微观结构的变化,如晶粒长大、再结晶以及相变等,通常都会受到晶界迁移(grain boundary migration)的支配[21]。扩散连接界面迁移和再结晶的驱动力主要源于元素扩散和应力诱导[22~24]。对不同温度热压后连接界面及其邻近基体母材区域的元素分布进行EDS检测,结果如图4所示。从图4可以看出,连接界面处元素的衍射峰均没有明显高于基体母材中,整体合金元素分布均匀。在本工作连接温度范围内,Ti、Al、V元素的扩散系数随着温度的升高而升高,并且Ti的扩散系数最大,V的扩散系数次之,Al的扩散系数最小[25]。合金中的原子扩散系数(D)和温度(T)之间满足Arrhenius定律,即:D = D0exp[Q / (RT)],其中,

图4

图4

不同热压温度下扩散连接区的SEM像和元素分布情况

Fig.4

SEM images and element distributions of diffusion bonding region at different hot pressing temperatures

(a) sample 1# (b) sample 2# (c) sample 3#

2.2 热压温度对界面组织演变的影响

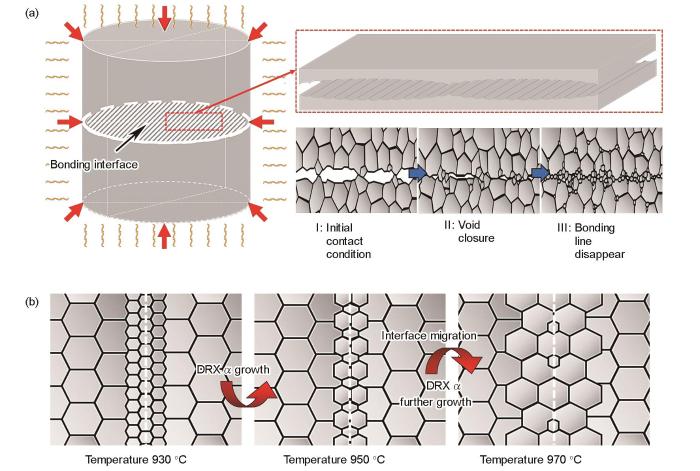

TC4钛合金棒材热压扩散连接过程可以划分为3个阶段。如图5a所示,第一个阶段为物理接触阶段,合金连接界面间以表面沟壑状的凹凸脊点接触为主,在压力作用下,上述接触点部位发生塑性形变,在压力的持续作用下,连接界面间的接触面积不断增大,开始发生动态再结晶,萌生出细小的α相。第二个阶段为界面孔隙闭合阶段,界面孔隙闭合主要受扩散作用以及幂律蠕变影响[9]。随着保温保压时间的增加,连接界面的接触点面积逐渐增大,界面间的孔隙逐渐缩小,界面连接区(结合区)面积进一步增大,此时界面接近闭合临界状态[27],再结晶形成的细小α相数量进一步增加。第三阶段为界面连接线消失阶段,在高温高压的持续作用下,界面处合金元素充分扩散后,界面处的孔隙完全愈合,再结晶区域进一步增加,连接界面处的成分趋于平衡,合金棒材在界面处实现冶金结合[19]。

图5

图5

钛合金棒材热压扩散过程组织演化规律示意图

Fig.5

Microstructure evolution schematics of titanium alloy bar during hot pressing diffusion process

(a) jointing process of the bar diffusion bonding interface

(b) effect of hot pressing temperature on the evolution of bonding interface

在扩散连接过程中,热压温度对连接界面处析出相的形貌变化以及晶界迁移程度有显著影响。如图5b所示,界面处再结晶形成的细小α相会经历从萌生到长大的过程,这一过程会随着热压温度的升高而加快。当热压温度为930 ℃时,界面在达到图5a中第三阶段之后,再结晶形成的细小α相还未长大,数量较多,尺寸较小(图3a和4a);随着温度提升至950 ℃,元素扩散速率提升,再结晶形成的细小α相从萌生到长大的过程加快,因此,在相同的保温时间下,界面处再结晶的细小α相尺寸有一定程度增大,数量相对减少(图3b和4b);当热压温度进一步提升至970 ℃时,元素扩散速率进一步提升,界面处的再结晶细小α相的生长进程进一步加快,界面处的晶界迁移程度增加(图3c和4c)。

2.3 热压温度对界面力学性能的影响

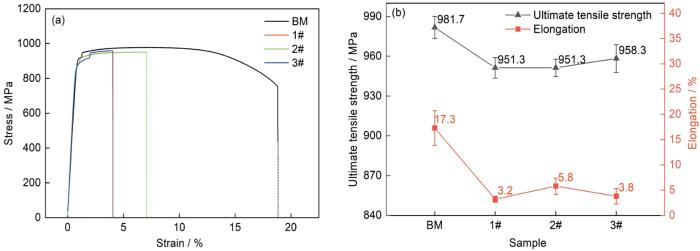

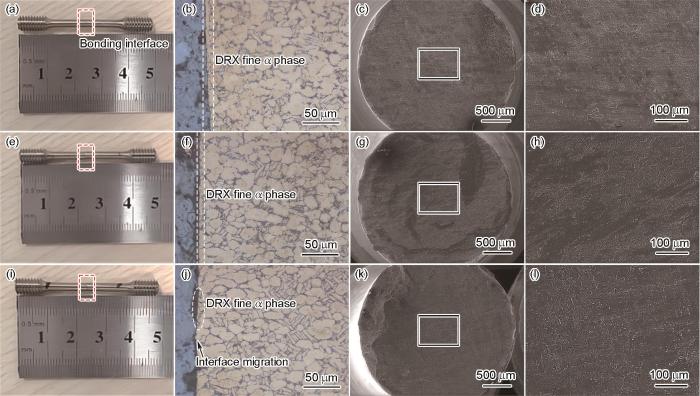

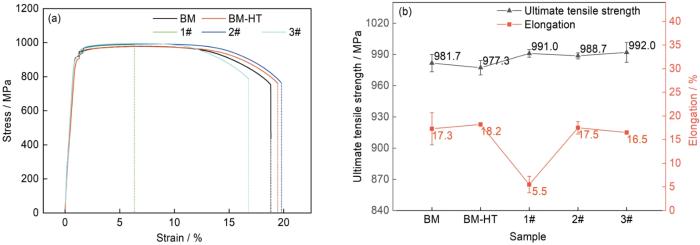

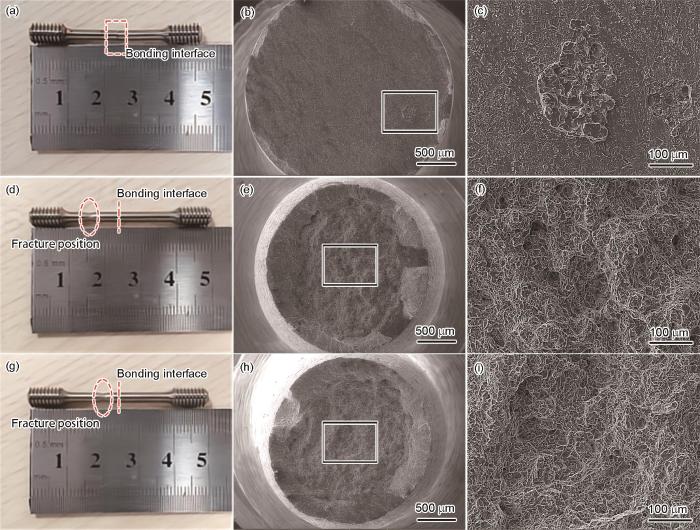

图6为不同温度热压后合金的应力-应变曲线与拉伸性能。与原始棒材相比,热压后棒材的强度有一定程度的降低,同时延伸率也大幅度降低。由于热压后合金的显微组织与母材基本接近(图2和3),力学性能的差异主要受扩散区性能影响(图5)。采用不同温度热压后试样的拉伸断口形貌如图7所示,试样的断裂位置均发生在连接界面处(图7a、e和i)。从不同断口横截面形貌可以看出,断口表面均较为平整,未见拉伸断裂产生的韧窝现象(图7c、g和k),属于典型的脆性断裂。在平坦的断面附近可以明显地观察到细小α相(如图7b、f及j中的虚线部位所示),在断口的边部未发现明显的塑性形变以及颈缩现象。这些特征与图6中延伸率显著降低的现象相一致。

图6

图6

不同热压温度下扩散连接钛合金的力学性能

Fig.6

Stress-strain curves (a) and tensile properties (b) of diffusion bonding titanium alloys at different hot pressing temperatures (BM—base material)

图7

图7

不同热压温度下扩散连接钛合金的拉伸断口形貌

Fig.7

Tensile fracture morphologies of diffusion bonding titanium alloys of sample 1# (a-d), sample 2# (e-h), and sample 3# (i-l)

(a, e, i) tensile sample photos (b, f, j) microstructures of vertical sections (c, g, k) macromorphologies of cross sections (d, h, l) corresponding magnified views of the boxed areas in Figs.7c, g, and k, respectively

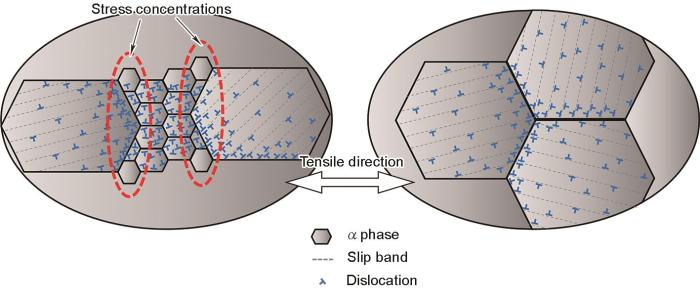

扩散连接区的性能受连接界面处形成的晶体学失配现象以及晶界迁移程度的影响。一方面,界面处再结晶形成的细小α相与母材α相之间存在较大的尺寸差异,根据Hall-Petch关系式[28]可知,界面处晶体学失配导致了界面与母材之间的屈服强度差异。在拉伸加载时,界面处形成的密集细小α相区域形成加工“硬区”,在界面细小的α相与母材α相的边界处会产生应力集中,致使裂纹易在该区域萌生[21];另一方面,晶体材料的塑性变形受位错的滑动影响[29]。晶界对位错的传播起到阻碍作用,晶界迁移形成的梯度台阶可以阻碍位错的传播速率[29~31],随着晶界对位错运动的阻碍,位错在晶界附近堆积,致使尺寸粗大的α相中,位错密度的分布呈现由中心向晶界递增的梯度差异。而在细小的α相中,由于较小尺寸的限制,这种梯度差异并不明显,因此会形成相对较高密度的位错。界面与母材的晶体学失配致使界面处无法协调变形,位错在细小α相与母材α相的边界处塞集,导致应力集中(图8)。细小α相与母材α相间脆弱的界面处积累了大量位错,也为裂纹的扩展提供了快速有效的途径,裂纹传递扩展的速率较快,因此,在界面处发生沿晶脆性断裂(如图7b、f和j所示)。从图6还可以看出,晶体学失配现象对抗拉强度的影响较小,而延伸率对这种微观结构特征则表现出较高的敏感性,热压扩散成形合金的延伸率显著降低,这也与晶体学失配影响界面协调变形的研究论证[21]相一致。

图8

图8

拉伸过程中位错在不同尺寸α相中的分布示意图

Fig.8

Schematic of dislocation distributions in α phases with various sizes during tensile testing

2.4 热处理对连接界面组织和性能的影响

合金加工后通常采用热处理对合金进行处理,从而实现合金组织与性能的调控[32]。图9为热处理调控(970 ℃、2 h、空冷)后连接界面处的显微组织。可以看出,热处理后的组织由等轴状αp、针状αs和β相组成。热处理对扩散连接组织结构的演化调控主要包括2方面:由于采用的热处理温度(970 ℃)与合金的β相转变温度(997 ℃)接近,母材区中部分尺寸较大的等轴状αp相向β相进行转变,这部分转化的β相在较快的冷却过程中析出针状的αs相,从而使得母材区中的αp相尺寸一定程度细化;另一方面,热压扩散界面处形成的再结晶细小α相在热处理的高温作用下会发生合并、长大粗化,数量显著降低。当连接温度处于930~950 ℃之间时,热处理后的界面扩散区仍存在一定程度的再结晶细小α相,在该连接温度范围内,热处理可以在一定程度上改善界面扩散区形成的晶体学失配现象,但并不能完全消除。当连接温度超过950 ℃时,热处理后界面处的细小α相消失,晶体学失配现象得到完全改善,界面处阶梯状的晶界数量增加,元素扩散更加充分,界面处的晶界迁移程度增加。

图9

图9

扩散连接区经热处理后显微组织的SEM像

Fig.9

SEM images of diffusion bonding regions after heat treatment (970 oC, 2 h, air cooling)

(a) sample 1# (b) sample 2# (c) sample 3#

热处理后扩散连接棒材的力学性能如图10所示。可以看出,热处理后合金的抗拉强度与母材的抗拉强度相当,延伸率有了显著提升。1#样品经热处理后延伸率由3.2%提升至5.5%,2#和3#的样品延伸率均达到16%以上,与原始棒材的延伸率相当。采用热处理调整扩散连接界面处的显微组织,可以实现热压扩散连接合金性能的调控。一方面,钛合金在进行拉伸变形时,等轴态的αp相可以有效阻碍位错与滑移[33],热处理后组织中析出的针状αs相与β相形成的αs/β层状结构使位错分布更加均匀,避免由于应力集中导致的裂纹早期萌生[34]。另一方面,热处理可以消除界面处的晶体学失配现象,有效改善界面处组织不均匀程度,越来越多的阶梯状界面取代原始界面,界面迁移程度进一步增加,延伸率随之提升[35]。

图10

图10

扩散连接钛合金经热处理后的力学性能

Fig.10

Stress-strain curves (a) and tensile properties (b) of diffusion bonding titanium alloys after heat treatment (BM-HT—base material after heat treatment)

图11

图11

热处理后扩散连接钛合金拉伸断口形貌

Fig.11

Tensile fracture morphologies of diffusion bonding titanium alloys after heat treatment of sample 1# (a-c), sample 2# (d-f), and sample 3# (g-i)

(a, d, g) tensile sample photos (b, e, h) macromorphologies of cross sections (c, f, i) corresponding magnified views of the boxed areas in Figs.12b, e, and h, respectively

3 结论

(1) 在β相转变温度以下,分别采用930、950和970 ℃ 3种热压温度进行了扩散连接实验,均实现了TC4钛合金棒材扩散连接界面冶金结合。

(2) 热压扩散连接过程中,界面处的合金发生动态再结晶现象,界面处形成了细小α相,随热压温度的升高,细小α相的尺寸增大、数量减少。

(3) 热压扩散连接合金界面处形成的α相与基体合金的α相尺寸存在差异,这种晶体学失配现象是影响合金延伸率的主要因素。

(4) 通过热处理可以调控界面处的α相尺寸,弱化晶体学失配的影响,大幅度提升合金的延伸率,热处理后合金的性能与基体相当。

参考文献

Toughening high strength titanium alloys through fine tuning phase composition and refining microstructure

[J].Titanium alloys are key materials for applications in major engineering areas, such as aerospace and marine equipment. Studies on structural titanium alloys focus on strengthening and toughening the alloys, especially the latter. The mainstream structural titanium alloys comprise both α and β phases. The optimization of the strength and toughness balance relies on the control of the compositions, volume fractions, and morphologies of both phases. In this study, some recent advances along the above line are reviewed, focusing on studies on the composition design, plastic-deformation mechanism, and microstructure tuning. Rational design of the compositions of both phases improved the deformation coordination within the α phase and across the α/β interface, suppressed the precipitation of brittle ω and α2 phases, and resulted in improved plasticity and toughness through the α-deformation twin and β-deformation-triggered phase transformation. The multiscale microstructure enhanced the strength and toughness of the titanium alloy. Using the abovementioned approaches, a series of titanium alloys with an improved strength-toughness combination were developed and fabricated. Finally, an attempt was made to predict the prospect of technology development in the field of high-strength and high-toughness titanium alloys for various applications.

高强韧钛合金组成相成分和形态的精细调控

[J].

Influence of alloying elements partitioning behaviors on the microstructure and mechanical properties in α + β titanium alloy

[J].

α + β两相钛合金元素再分配行为及其对显微组织和力学性能的影响

[J].研究了两相区固溶温度及固溶后冷速对Ti-6Al-4V (TC4)合金元素再分配行为的影响,利用EPMA技术表征了初生α相(α<sub>p</sub>)以及β转变区域(β<sub>t</sub>)的元素浓度,考察了β<sub>t</sub>显微组织尺寸随固溶温度及元素浓度的变化。结果表明:随着固溶温度升高,β<sub>t</sub>区域元素浓度变化显著,表现为Al含量升高、V含量降低,而α<sub>p</sub>晶粒中元素浓度变化较小,导致两区域元素浓度差异减小;同一固溶温度下,以不同冷却方式(水冷、空冷及炉冷)冷却的显微组织及元素分布显示,冷却速率越低,α<sub>p</sub>比例越高,α<sub>p</sub>与β<sub>t</sub>之间元素浓度差异越明显。合金经固溶水冷、空冷后,β<sub>t</sub>分别为淬火马氏体、次生α相(α<sub>s</sub>)+残余β相,2种冷速下β<sub>t</sub>的显微组织尺寸均与高温β相内的元素浓度水平有关,即β<sub>t</sub>内部显微组织尺寸受固溶温度的显著影响。利用纳米压痕技术表征了不同固溶温度下微区域(α<sub>p</sub>、β<sub>t</sub>)的力学特征,结果表明,密排六方(hcp)晶格α<sub>p</sub>本身呈现的力学行为的各向异性对其纳米压痕性能起决定性作用,而β<sub>t</sub>的弹性模量及硬度主要受α<sub>s</sub>片层尺寸的影响。最后讨论了“固溶温度-微区元素浓度-微区显微组织-微区力学性能”之间的关系。

Effect of cold rotary-swaging deformation on microstructure and tensile properties of TB9 titanium alloy

[J].<p>TB9 titanium alloy has been widely used for aerospace due to it's superior low stiffness, corrosion resistance and workability. It has been reported that cold deformation can improve the comprehensive mechanical properties of titanium alloys. At the same time, the cold rotary-swaging deformation facilitates the production of small batches and the acquisition of special shape and size bars. However, current studies on the microstructure and properties of cold rotary-swaged titanium alloys are not systematic. So, the effects of cold deformation rate on the microstructure, texture evolution and mechanical property of TB9 alloy during cold rotary-swaging were investigated using OM, EBSD, XRD, TEM and tensile test. The results showed that the grain size of TB9 titanium was refined with the increase in diameter reduction. Meanwhile, with the deformation increases, the grains rotation along the swaging axis occurs, forming a preferred orientation, the textures change from initial {001}<110> and {001}<100> to <i>α</i>-fiber and <i>γ</i>-fiber {001}<110>, {112}<110> and {111}<110>. All of grains refinement, texture components and substructures contributed to the enhancement of strength after cold rotary-swaging. And the ductile kept on a high level after 70% cold working, which means the TB9 titanium has a great cold deformation ability.</p>

冷旋锻变形对TB9钛合金显微组织和拉伸性能的影响

[J].采用冷旋锻对TB9钛合金棒材进行多道次冷变形,利用OM、EBSD、XRD、TEM以及拉伸等实验研究了不同冷变形量TB9钛合金棒材的显微组织、织构和拉伸性能及其规律。结果表明,TB9钛合金棒材的晶粒尺寸随冷旋锻变形量的增大而减小,部分晶粒尺寸达到纳米级。同时,晶粒随变形量的增加沿旋锻轴向转动,形成择优取向,由初始{001}和{001}织构转变为取向的α-fiber和γ-fiber {001}、{112}和{111}织构。在亚结构、小尺寸晶粒以及织构的共同作用下,TB9钛合金的强度随变形量的增大而增加,延伸率和面缩率在70%冷变形后仍保持在一个较高的水平,具有优异的冷变形能力。

Research progress of titanium alloys and their diffusion bonding fatigue characteristics

[J].This paper concentrates on the research progress of titanium alloys and their diffusion bonding fatigue characteristics, and summarizes the laws of fatigue crack initiation and growth of titanium alloys with/without welding. The chemical composition, classification, and common welding method of titanium alloys are stated, with emphasis on the features and advantages of diffusion bonding. The phenomena of slip band formation and dislocation movement under cyclic loading are described, and the mechanism of fatigue crack initiation is clarified. The selection of microstructures is a common method to optimize mechanical properties of titanium alloys. Previous studies suggested that the laminated structure is an important mode to realize the low fatigue crack growth rate of titanium alloys. Improper parameters of the welding process can cause joint defects, and further heat treatment can reduce joint defects while improving the fatigue life and strength. Finally, the multilayer and heterogeneous laminates of titanium alloys produced by diffusion bonding are briefly described to realize the possibility of high damage tolerance.

钛合金及其扩散焊疲劳特性研究进展

[J].本文主要对钛合金及其扩散焊疲劳特性研究进展进行了综述,总结了钛合金及其焊接后疲劳裂纹萌生和扩展的规律。概述了钛合金的化学成分和分类,以及常用焊接方法,重点介绍扩散焊的特点和优势。描述了循环载荷作用下滑移带形成和位错的运动现象,阐明疲劳裂纹萌生的机制。钛合金微观组织的选择是优化力学性能的常见方法,现有研究表明,制备层合结构是降低钛合金疲劳裂纹扩展速率的一种重要调控手段。不合适的焊接工艺参数会导致接头缺陷的形成,后续热处理能够降低接头缺陷,并提高焊接构件的疲劳寿命和疲劳强度。最后,简述了扩散焊制备多层和异种钛合金层合结构来实现构件高损伤容限的可行性。

Advances in TiAl intermetallics and its joining technology (Part Ⅱ)

[J].

TiAl金属间化合物及其连接技术的研究进展

[J].

Microstructure evolution and super-diffusion mechanism of weld zone of dissimilar titanium alloys after linear friction welding

[J].

异种钛合金线性摩擦焊组织演变及超扩散机理(英文)

[J].

Study on microstructure and impact toughness of TC4 titanium alloy diffusion bonding joint

[J].

An investigation on adaptively machining the leading and tailing edges of an SPF/DB titanium hollow blade using free-form deformation

[J].

Surface tracking of diffusion bonding void closure and its application to titanium alloys

[J].Diffusion bonding is a process by which two flat, usually metallic, surfaces are welded together at a high temperature and moderate pressure. Bonding occurs due to a combination of diffusion and power law creep that close the voids formed by microscopic differences between the mating surfaces. While the different process parameters are well understood the effects of surface condition and void shapes during bonding has not been thoroughly researched. In this paper we use measured surface profiles, discretize them, and apply the diffusion and creep equations numerically to the profiles in order to provide insight into the effects of surface geometry on bonding. Using this method the voids can interact with each other and the effects of nearby voids can be computed. Experimental tests are performed to confirm the model and theoretical tests were created to determine what the effects of different surface geometries are on bonding performance. While in most cases the bonding was dominated by power law creep the most optimal void shape was one where the voids had completed the creep stage and were controlled by diffusive processes. It was also found that concentrating the overlap area also increases bonding performance.

Microstructure and mechanical properties of diffusion bonded TC11 alloy joint

[J].

TC11钛合金扩散连接接头组织及力学性能研究

[J].

Modeling of void closure in diffusion bonding process based on dynamic conditions

[J].

Interfacial microstructure and shear strength of Cu/Al bimetal fabricated by diffusion welding

[J].

扩散连接制备Cu/Al双金属及其界面组织与剪切强度(英文)

[J].

Diffusion bonding of pre-friction treated structural steel with reversion of deformation induced grains

[J].

Effects of hot isostatic pressure on microdefects and stress rupture life of second-generation nickel-based single crystal superalloy in as-cast and as-solid-solution states

[J].Due to the excellent high temperature comprehensive performance and cost effective, the second-generation nickel-based single crystal superalloy has been widely used in the high-pressure turbine blades of advanced aero-engines. Microdefects such as micropores and interdendritic eutectic are seriously harmful to the high temperature mechanical properties of nickel-based single crystal superalloys. Hot isostatic pressure (HIP) technology, which has been widely used in powder and casting superalloys, can effectively reduce the micropores, interdendritic eutectic and other structural defects formed in the turbine blades during manufacturing, and improve the service reliability of turbine blades. However, the effect of HIP process on the high temperature stress rupture life of nickel-based single crystal superalloys is still controversial, especially with regard to the initial microstructure state of the nickel-based single crystal superalloys, i.e. the as-cast microstructure state or the as-solid-solution state. In this work, a kind of second-generation nickel-based single crystal superalloy with as-cast state or as-solid-solution state was selected as the research object. Through two-stage heat/booster type heat treatment process, in combination with microdefects quantitative analysis, quantitative characterization of alloying element segregation and high temperature stress rupture tests at 980 ℃ and 250 MPa, the effects of HIP process on the microdefects and high temperature stress rupture life of the used superalloy with different initial microstructures were studied. The results indicated that the solid-solution treatment can significantly promote the diffusion of alloying elements, such as Re, W, Al, and Ta, reduce the area fraction of interdendritic eutectic, but significantly increase the average area fraction and size of micropores in the used alloy with as-cast state. While, HIP process can effectively reduce the average area fraction and size of microspores in the used alloy with as-cast state or as-solid-solution state, but cannot eliminate the interdendritic eutectic as remarkable as the solid-solution treatment. By HIP process of the used alloy with as-solid-solution state, the area fraction of micropores is reduced to 0.005%, the eutectic structure is basically eliminated, and the dendrite segregation of Re, W, Al, Ta and other elements is significantly alleviated, resulting in the higher stress ruputure life of the used alloy, about 40% over that of the used alloy with the standard heat treatment state. Performing HIP process on nickel-based single crystal superalloy alloy with as-solid-solution state is of benefit to the high temperature stress rupture life due to the reduction of microdefects and the homogenization of alloying elements, in comparison with performing HIP process directly on the alloy with as-cast sate.

热等静压对铸态及固溶态第二代镍基单晶高温合金显微缺陷及持久性能的影响

[J].以初始组织分别为铸态组织和固溶态组织的第二代镍基单晶高温合金为研究对象,通过进行1300 ℃、30 MPa、2 h+1300 ℃、100 MPa、3 h两阶段的热等静压处理,对比热等静压前后显微缺陷及微观组织的变化,并在980 ℃、250 MPa条件下进行高温持久性能实验,明确了热等静压处理对不同初始组织状态下镍基单晶合金组织状态及持久性能改善的影响机制。结果表明:固溶处理显著促进Re、W、Al、Ta等合金元素的扩散,降低铸态组织共晶面积分数但显著提高显微孔洞平均面积分数及平均尺寸。热等静压处理可以显著降低显微孔洞平均面积分数及平均尺寸且对固溶态组织的作用更为显著,但热等静压对共晶组织的消除作用不如固溶处理明显。固溶态组织经热等静压处理后,显微孔洞面积分数降低至0.005%;共晶组织基本消除;Re、W、Al、Ta等元素枝晶偏析程度显著缓解;其980 ℃、250 MPa高温持久寿命相比未经热等静压处理的标准热处理态合金提高了40%左右。对固溶态组织进行热等静压处理的工序安排有利于提高显微孔洞闭合作用,促进成分均匀化并显著提高合金高温持久寿命。

Effect of thermal induced porosity on high-cycle fatigue and very high-cycle fatigue behaviors of hot-isostatic-pressed Ti-6Al-4V powder components

[J].The present work reports the effect of thermal induced porosity (TIP) on the high-cycle fatigue (HCF) and very high-cycle fatigue (VHCF) behaviors of hot-isostatic-pressed (HIPed) Ti-6Al-4V alloy from gas-atomized powder. The results show that the residual pores in the as-HIPed powder compacts present no obvious effect on the HCF life. The regrowth of the residual pores can be observed after solution heat treatment. The pore location ranks the most harmful for the fatigue life compared with the other initiating defects. The maximum stress intensity factors were calculated. The plastic zone size of fine granular area (FGA) is much less than the characteristic size of the microstructure, and the crucial size of the internal pores in this study is about 40 μm. The failure types of fatigue specimens in the VHCF regime were classified, and the competition of different failure types was described based on the modified Poisson distribution.

Effect of hot isostatic pressing procedure on performance of Ti6Al4V: Surface qualities, microstructure and mechanical properties

[J].

Atomistic investigation of the effects of temperature and surface roughness on diffusion bonding between Cu and Al

[J].

Effect of bonding temperature and holding time on properties of hollow structure diffusion bonded joints of TC4 alloy

[J].

Microstructure evolution and mechanical properties of γ-TiAl honeycomb structure fabricated by isothermal forging and pulse current assisted diffusion bonding

[J].

Particle deformation and microstructure evolution during cold spray of individual Al-Cu alloy powder particles

[J].

Common mechanical properties of diffusion bonded joints and their corresponding microstructure features

[J].

Direct imaging of atomistic grain boundary migration

[J].Grain boundary (GB) migration plays an important role in modifying the microstructures and the related properties of polycrystalline materials, and is governed by the atomistic mechanism by which the atoms are displaced from one grain to another. Although such an atomistic mechanism has been intensively investigated, it is still experimentally unclear as to how the GB migration proceeds at the atomic scale. With the aid of high-energy electron-beam irradiation in atomic-resolution scanning transmission electron microscopy, we controllably triggered the GB migration in α-AlO and directly visualized the atomistic GB migration as a stop motion movie. It was revealed that the GB migration proceeds by the cooperative shuffling of atoms on GB ledges along specific routes, passing through several different stable and metastable GB structures with low energies. We demonstrated that GB migration could be facilitated by the GB structural transformations between these low-energy structures.

A study on the diffusion-induced grain boundary migration ahead of stress corrosion cracking crack tips through advanced characterization

[J].

Interdiffusion along grain boundaries—Diffusion induced grain boundary migration, low temperature homogenization and reactions in nanostructured thin films

[J].

Molecular dynamics simulation of Ti-6Al-4V diffusion bonding behavior under different process parameters

[J].

Molecular dynamics simulation of TC4 aging phase transition and diffusion bonding

[J].

TC4时效相变及扩散连接的分子动力学模拟

[J].

Effects of surface roughness on interface bonding performance for 316H stainless steel in hot-compression bonding

[J].

Transition of dominant deformation mode in bulk polycrystalline pure Mg by ultra-grain refinement down to sub-micrometer

[J].

Direct observation of individual dislocation interaction processes with grain boundaries

[J].

Effect of strain rate on plastic deformation bonding behavior of Ni-based superalloys

[J].Plastic deformation bonding (PDB) has emerged as a promising solid state bonding technique with limited risk of phase transformations and residual thermal stresses in the joint. In this study, the PDB behavior of IN718 superalloy was systematically investigated by performing a series of isothermal compression tests at various processing conditions. It was revealed that, with increasing PDB strain rate at 1000 °C, different extents of dynamic recrystallization (DRX) occur in the bonding area of IN718 joints. The extent of DRX, average size of DRXed grains, and a newly proposed “interfacial bonding ratio (ΨBonding)” parameter (to quantify the bond quality) were initially reduced with increase in the strain rate up to 0.1 s-1 and later increased at further higher strain rates. Electron backscattered diffraction (EBSD) and transmission electron microscopy (TEM) based interfacial microstructure analyses indicated that the quality of the bonded joints is closely related with the development of fine DRXed grains at the bonding interface with the increasing strain, which promotes adiabatic temperature rise. It was revealed that the initial bulging and subsequent migration of the original interfacial grain boundary (IGB) were the main mechanisms promoting DRX in the well bonded IN718 superalloy joints. Moreover, the mechanical properties of the bonded joints were not only controlled by the recrystallized microstructure but also depended upon the Bonding parameter of the joints.

In situ atomistic observation of disconnection-mediated grain boundary migration

[J].

Effect of solution aging treatment on microstructure and properties of 7A52 aluminum alloy CMT + P welded joint

[J].

固溶时效处理对7A52铝合金CMT + P焊接接头组织及性能的影响

[J].

Effects of solid solution, cooling rates and aging treatments on microstructure and mechanical properties of TC4-DT alloy

[J].

固溶-冷速-时效对TC4-DT合金显微组织和力学性能的影响

[J].

Influence of α/β interface phase on the tensile properties of laser cladding deposited Ti-6Al-4V titanium alloy

[J].

Effect of grain boundary migration on impact toughness of 316L diffusion bonding joints

[J].