镁合金在环保和轻量化技术方面日益受到研究人员的重视,尤其在航空航天领域。然而,镁合金具有hcp晶体结构和较强的基面织构,且其在室温下可开动的滑移系较少,从而使得镁合金的强度和塑性较差,这对镁合金的使用和发展造成了极大的限制[1~5]。目前,大部分镁合金板材的加工都是在高温条件下进行的,能源消耗较大。由于Mg的层错能较低,其在高温变形过程中容易发生动态再结晶和晶粒二次长大,进而导致加工制备镁合金板材的晶粒尺寸难以控制[1]。此外,Mg对O具有较高的亲和力,但凭借氧化反应无法在表面形成保护性氧化膜,故镁合金在高温条件的抗氧化性能较差[6]。众多研究[7~11]表明,在中温变形条件下加工制备镁合金板材,可以有效缓解上述问题。

对商用AZ31镁合金板材的中温轧制变形行为已有大量研究。罗晋如等[7]对AZ31镁合金板材进行了不同温度下的轧制实验,发现只有在超过200 ℃的温度下进行轧制时,才会发生再结晶现象,在低于200 ℃轧制时,不同温度下轧制板材中均会出现二次孪生,其数量随轧制温度的升高而降低。Luo等[8]在150 ℃下对AZ31镁合金进行了温轧实验,发现相较于单轴变形条件,在轧制变形过程中,更容易出现30°和38°的二次孪晶变体。刘子健等[9]研究发现,在200 ℃下对AZ31镁合金进行温轧,可以激活大量的非基面滑移,从而大幅度提升镁合金的塑性变形能力。李彦生等[10]对AZ31镁合金进行了多道次温轧,发现经过五道次轧制后,晶粒尺寸从初始的38 μm细化至2.2 μm。Jia等[11]研究了在233~248 ℃范围内进行多道次温轧后AZ31镁合金板材的微观组织和织构演变,发现在多道次轧制变形后期出现了动态再结晶晶粒,导致平均晶粒尺寸大幅下降。

Tu等[12]通过等径角轧制-连续弯曲-退火工艺(equal channel angular rolling and continuous bending process with subsequent annealing,简称ECAR-CB-A工艺),成功制备出具有双峰分离非基面织构特征的AZ31镁合金板材,显著改善了AZ31镁合金板材在室温下的成形性能,将室温Erichsen值显著提升至7.4 mm。这表明在中温条件下,双峰分离非基面织构AZ31镁合金板材有望获得优于传统基面织构板材的轧制性能。在上述研究中,采用的板材多为常规基面织构AZ31镁合金板材,针对非基面织构板材中温条件下轧制变形行为的研究还鲜见报道。鉴于此,本工作选取基面织构和双峰分离非基面织构AZ31镁合金板材,在中温(200 ℃)下进行多道次轧制实验,研究不同织构AZ31镁合金板材在中温条件下的轧制变形行为。随后,利用光学显微镜(OM)和电子背散射衍射(EBSD)分析轧制板材的微观组织演化规律,进而揭示双峰分离非基面织构板材中温轧制的变形机理。

1 实验方法

实验采用ECAR-CB-A工艺制备双峰分离非基面织构AZ31镁合金板材,其工艺参数和步骤详见参考文献[12]。本工作还使用热轧态的AZ31镁合金板材作为对照样品。用电火花线切割机慢走丝模式切取标准轧制试样,其尺寸为30 mm (横向,TD) × 50 mm (轧向,RD) × 1.10 mm (法向,ND)。分别将具有基面织构和双峰分离非基面织构的AZ31镁合金板材进行200 ℃多道次轧制变形。轧辊直径为170 mm,转速为600 r/min,轧制道次间均加热保温3 min。实验中每道次板材厚度变化如表1所示。当轧制板材出现边裂时停止轧制变形,观察板材开裂时的宏观形貌。随后利用DMI5000M型OM和装有HKL-Nordlys MAX探测器(EBSD探头)的NOVA 400场发射扫描电镜(SEM)对轧制样品的微观组织特征进行观察,观察面为RD-TD面。SEM工作电压20 keV,扫描步长0.35 μm。关于OM和EBSD试样的制备方法详见文献[13]。EBSD数据后处理软件为Channel 5。利用Channel 5软件设定{

表1 不同织构AZ31镁合金板材中温轧制的厚度变化 (mm)

Table1

| Sheet type | As-received | First pass | Second pass | Third pass | Fourth pass | Fifth pass |

|---|---|---|---|---|---|---|

| Basal texture sheet | 1.10 | 1.06 | 0.92 | 0.78 | 0.62 | - |

| Bimodal non-basal texture sheet | 1.10 | 1.06 | 0.89 | 0.82 | 0.72 | 0.57 |

2 实验结果

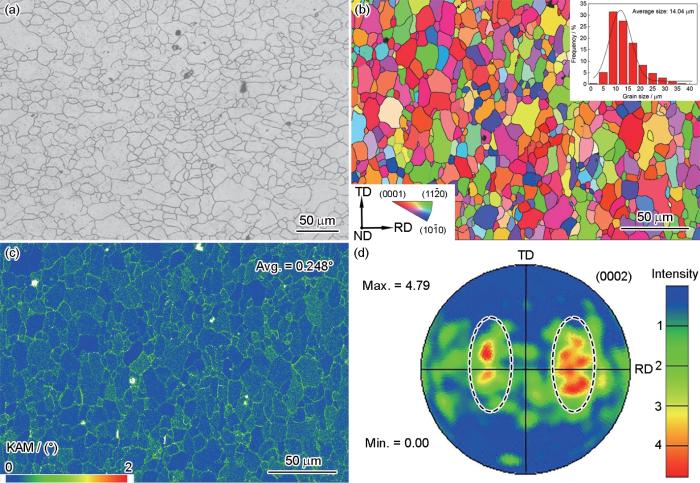

图1为双峰分离非基面织构AZ31镁合金板材的微观组织和织构特征。由OM像(图1a)和反极图(IPF) (图1b)可以看出,该初始板材具有等轴晶结构特征,不含孪晶,平均晶粒尺寸为14.04 μm。从局部取向差(kernel average misorientation,KAM)图(图1c)可知,平均KAM值仅为0.248°。这说明板材中几何必需位错密度(geometrically necessary dislocations,GNDs)较低[14,15],为典型的完全退火态板材。此外,(0002)极图(PF) (图1d)呈现出明显的双峰分离非基面织构特征,基极由ND向RD两侧偏转约40°,最大极点强度仅为4.79。

图1

图1

双峰分离非基面织构AZ31镁合金板材的初始微观组织和织构

Fig.1

Initial microstructure and texture of AZ31 magnesium alloy sheet with bimodal non-basal texture

(a) OM image

(b) inverse pole figure (IPF) and statistical analysis of grain size (inset) (ND—normal direction, TD—transverse direction, RD—rolling direction)

(c) kernel average misorientation (KAM) map

(d) (0002) pole figure (PF)

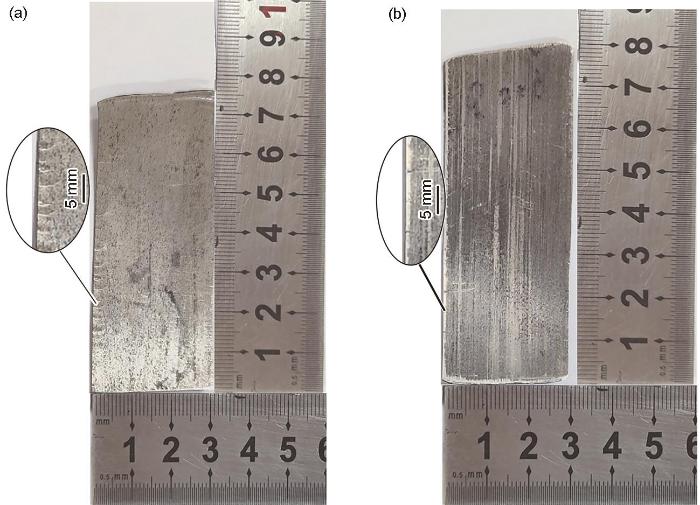

图2为不同织构板材在多道次中温轧制变形过程中出现边裂的宏观照片。双峰分离非基面织构板材在第五道次轧制后出现边裂现象,而基面织构板材在第四道次轧制后出现边裂现象,相应的累积压下量分别为48.0%和43.6%。Han等[16]和陈家明[17]的研究表明,双峰分离非基面织构AZ31镁合金板材在室温多道次轧制变形过程中的累积压下量为39.2%,约为基面织构板材(18.3%)的2.14倍。可见,本工作中双峰分离非基面织构的引入对AZ31镁合金板材在200 ℃中温条件下的轧制成形性能并没有产生显著提升,其累积压下量仅比基面织构板材高出4.4%。为解释这种反常的中温轧制行为,需要对轧制板材的微观组织演化进行进一步研究。

图2

图2

不同织构AZ31镁合金板材在中温制变形过程中出现边裂的宏观照片

Fig.2

Macroscopic photographs showing the occurrence of edge cracks in AZ31 magnesium alloy sheets with different textures during rolling at medium temperature

(a) the fourth pass for basal texture sheet

(b) the fifth pass for bimodal non-basal texture sheet

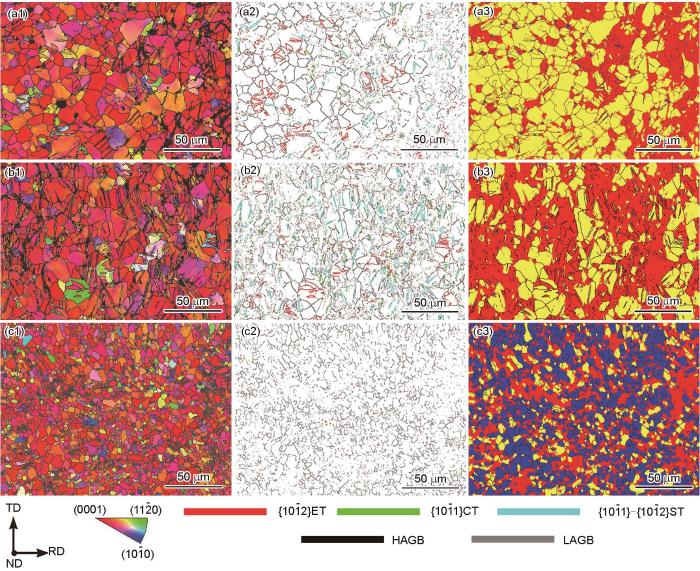

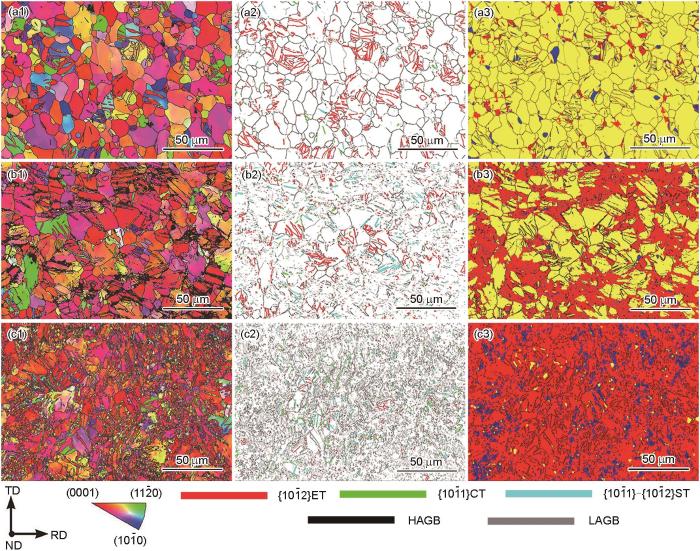

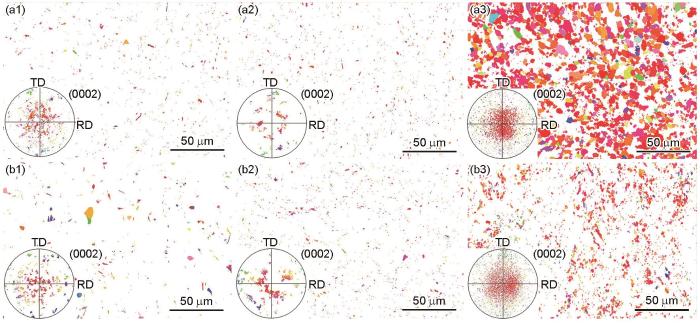

图3和4分别为基面织构和双峰分离非基面织构AZ31镁合金板材在中温轧制变形条件下不同轧制道次微观组织的EBSD表征。从IPF (图3a1~c1和4a1~c1)和晶界(GB)图(图3a2~c2和4a2~c2)可以看出,基面织构和双峰分离非基面织构AZ31镁合金板材在中温轧制过程中出现了多种孪晶类型。对于基面织构AZ31镁合金板材,随着轧制道次增加,{

图3

图3

基面织构AZ31镁合金板材中温轧制样品微观结构特征的EBSD分析

Fig.3

EBSD analyses of microstructural characteristics of AZ31 magnesium alloy sheets with initial basal texture after the first (a1-a3), second (b1-b3), and fourth (c1-c3) passes of rolling at medium temperature (ET—extension twin, CT—compression twin, ST—secondary twin, HAGB—high angle grain boundary, LAGB—low angle grain boundary)

(a1-c1) IPFs (a2-c2) grain boundary (GB) maps (a3-c3) grain orientation spread (GOS) maps

图4

图4

双峰分离非基面织构AZ31镁合金板材中温轧制样品微观结构特征的EBSD分析

Fig.4

EBSD analyses of microstructural characteristics of AZ31 magnesium alloy sheets with initial bimodal non-basal texture after the first (a1-a3), second (b1-b3), and fifth (c1-c3) passes of rolling at medium temperature

(a1-c1) IPFs (a2-c2) GB maps (a3-c3) GOS maps

图5

图5

不同织构AZ31镁合金板材中温轧制变形过程中的再结晶晶粒演化

Fig.5

EBSD images and (0002) PF (insets) showing the evolution of recrystallized grains within AZ31 magnesium alloy sheets with different textures during rolling process at medium temperature

(a1-a3) the first (a1), second (a2), and fourth (a3) passes for basal texture sheets (b1-b3) the first (b1), second (b2), and fifth (b3) passes for bimodal non-basal texture sheets

3 分析与讨论

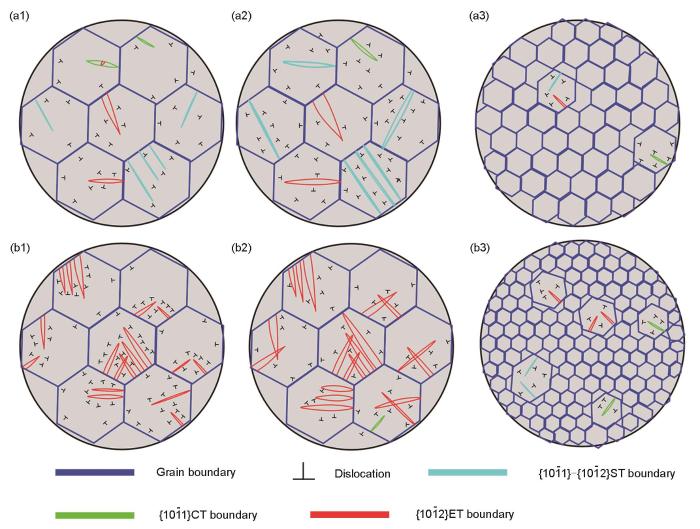

研究[20]表明,变形机制的开启对镁合金塑性变形行为有着重要影响。当温度升高至200 ℃时,非基面滑移的临界分切应力(critical resolved shear stress,CRSS)将显著降低[21~23]。对于基面织构AZ31镁合金板材而言,其中温轧制变形机制如图6a1~a3所示。在轧制变形过程中会激活大量的基面<a>位错和非基面位错(包括柱面<a>位错和锥面<c + a>位错)[9],并伴随产生部分{

图6

图6

不同织构AZ31镁合金板材中温轧制过程中的变形机制示意图

Fig.6

Schematics of deformation mechanisms for AZ31 magnesium alloy sheets with different textures during medium-temperature rolling

(a1-a3) the first (a1), second (a2), and fourth (a3) passes for basal texture sheets (b1-b3) the first (b1), second (b2), and fifth (b3) passes for bimodal non-basal texture sheets

Huang等[27]研究表明,DRX有助于缓解镁合金板材轧制变形过程中晶界位置的应力集中,并消耗晶界附近的塞积位错,进而延缓微裂纹的产生。因此,对于基面织构AZ31镁合金板材而言,尽管初始的基面织构特征不利于轧制变形,但中温轧制变形过程中快速发生的DRX和较高的DRX体积分数确保其具有较好的轧制变形能力(累积压下量为43.6%)。对于双峰分离非基面织构AZ31镁合金板材而言,尽管其初始的双峰分离非基面织构特征有利于轧制变形,但轧制变形过程中{

4 结论

(1) 在中温(200 ℃)多道次轧制实验中,双峰分离非基面织构AZ31镁合金板材经五道次轧制后出现边裂,其累积压下量为48.0%,基面织构板材经四道次轧制后出现边裂,其累积压下量为43.6%。双峰分离非基面织构板材的累积压下量仅比基面织构板材高出4.4%。表明在中温条件下,双峰分离非基面织构对板材轧制性能的提升有限。

(2) 基面织构板材在轧制变形过程中会激活大量的基面<a>位错和非基面位错(包括柱面<a>位错和锥面<c + a>位错),以及少量的{

(3) 在中温条件下,基面织构板材累积压下量43.6%时的DRX体积分数高达47.9%,而双峰分离非基面织构板材累积压下量48.0%时的DRX体积分数仅为11.4%。这种差异显著的DRX行为是导致基面织构板材和双峰分离非基面织构板材轧制性能接近(累积压下量差仅为4.4%)的主要原因。

参考文献

Recent research and developments on wrought magnesium alloys

[J].

Towards magnesium alloys for high-volume automotive applications

[J].

Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications

[J].

Research and application development of advanced magnesium alloys

[J].

高性能镁合金研究及应用的新进展

[J].

Latest research advances on magnesium and magnesium alloys worldwide

[J].

Research progress on the mechanisms controlling high-temperature oxidation resistance of Mg alloys

[J].This paper briefly reviews the progress on high-temperature oxidation mechanisms of pure Mg and Mg alloys, the thermodynamics and kinetics of high-temperature oxidation of Mg alloys, and the antioxidation mechanism of Mg alloys. The potential of applying advanced characterization techniques in studying the high-temperature oxidation of Mg alloys is envisaged. Finally, the development trends of the oxidation-resistant Mg alloy are also summarized. The main viewpoints are as follows: The protection of magnesium alloys at high temperatures is provided by the formation of a continuous, dense oxide scale that is a specific thickness and prevents the outward diffusion of magnesium vapor and the inward diffusion of oxygen; the oxidation resistance of Mg alloys is usually closely related to the thermal stability of the second phases; when the trace alloy elements are not enough to form the corresponding surface oxide scale, the oxidation resistance can be improved by creating a substitutional solid solution and using the reactive element effect; the size of the oxide grain size decreases and then enhances the oxidation resistance once the surface active elements is enriched on the surface of the alloys; the selective oxidation and synergistic effect of alloying elements are critical to the oxidation resistance of Mg alloys; the addition of nano or microparticles into the Mg alloys improve the high-temperature oxidation resistance of the Mg alloy by reducing the size of specific oxidation sensitive regions. In the future, the research on the high-temperature oxidation of Mg alloys can be based on the following aspects: Investigating the processes and nature of the oxidation resistance of Mg alloys using cutting-edge characterization techniques; constructing the underlying connections between the alloying elements and the oxide scale grain size and mechanical properties; designing and optimizing multi-alloying element composition systems.

镁合金抗高温氧化机理研究进展

[J].

Influence of rolling temperature on the {1011}-{1012} twinning in rolled AZ31 magnesium alloy sheets

[J].

轧制温度对AZ31镁合金轧制板材中的{1011}-{1012}双孪生行为的影响

[J].在150-350 ℃温区内不同温度下轧制AZ31镁合金板, 观察了不同温度下轧制变形量为9%的AZ31镁合金板材的显微组织, 研究分析了轧制温度对轧制板材中{1011}-{1012} 双孪晶的含量、类型以及高温轧制过程中双孪晶中的动态再结晶行为的影响, 讨论了板材中的孪晶对其力学性能的影响. 研究结果表明: 在150-300 ℃温区内轧制时,板材组织中均有含量不等的{1011}-{1012} 双孪晶,随着轧制温度的升高, 孪晶含量下降. 250 ℃以上轧制的板材中单片一次孪晶中出现的双孪晶类型较为单一, 仅出现共面型双孪晶.在250 ℃以上轧制板材中的双孪晶晶界处中可以观察到明显的动态再结晶现象, 这些动态再结晶晶粒对孪晶界和孪晶起到消除和吞噬的作用. 350 ℃下轧制的AZ31镁合金板材中未观察到{1011}-{1012双孪晶. 随着轧制温度的升高,镁合金轧制板材的强度减弱而塑性增强.

Twinning behavior of a strongly basal textured AZ31 Mg alloy during warm rolling

[J].

Effects of rolling temperature on edge crack and microstructure of AZ31B magnesium alloy thin strip

[J].

轧制温度对AZ31B镁合金薄带轧制的边裂及显微组织的影响

[J].

Effect of multi-pass warm rolling process on microstructure and properties of AZ31 magnesium alloy

[J].

多道次温轧对AZ31镁合金组织和性能的影响

[J].

Texture evolution of AZ31 magnesium alloy sheets during warm rolling

[J].

Effect of rolling speeds on texture modification and mechanical properties of the AZ31 sheet by a combination of equal channel angular rolling and continuous bending at high temperature

[J].

Influence of bimodal non-basal texture on microstructure characteristics, texture evolution and deformation mechanisms of AZ31 magnesium alloy sheet rolled at liquid-nitrogen temperature

[J].

A procedure to obtain correlation curve between local misorientation and plastic strain

[J].

A round robin EBSD measurement for quantitative assessment of small plastic strain

[J].

Role of unusual double-peak texture in significantly enhancing cold rolling formability of AZ31 magnesium alloy sheet

[J].

Study on cold rolling formability and associated microstructure evolution of AZ31 magnesium alloy sheet with bimodal non-basal texture

[D].

双峰分离非基面织构AZ31镁合金板材冷轧性能及组织演化研究

[D].

Hot pack rolling nearly lamellar Ti-44Al-8Nb-(W, B, Y) alloy with different rolling reductions: Lamellar colonies evolution and tensile properties

[J].

Microstructure evolution in warm rolling of extrude AZ31B magnesium alloy plates

[J].

挤压AZ31B镁合金板材中温轧制变形中的组织变化

[J].

Research progress on plastic deformation mechanism of Mg alloys

[J].Possible slip and twinning systems and their critical resolved shear stresses of Mg alloys with hcp structure were described. Research works on plastic deformation behavior and micro-mechanism of different kinds of Mg alloys were reviewed. Both microstructure and texture evolutions during different thermomechanical processes, both dynamic and static recrystallization mechanisms of Mg alloys were described and discussed. Deformation and strengthening mechanisms of precipitates hardening Mg alloys were also addressed with emphasis on the interaction between precipitates and twinning/slip.

镁合金塑性变形机理研究进展

[J].

Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals

[J].

Effect of temperature and strain rate on the deformation behavior and microstructure of a homogenized AZ31 magnesium alloy

[J].

Deformation mechanisms of AZ31 magnesium alloy

[A].

Static recrystallization induced by twinning in AZ31 magnesium alloy

[J].

孪晶诱发的AZ31镁合金静态再结晶行为

[J].利用电子背散射衍射(EBSD)技术研究了AZ31镁合金单轴压缩变形后产生不同类型的孪晶组织对静态再结晶的晶粒形核及取向变化的影响,样品在室温下进行应变为16%的单轴压缩变形,然后在250℃分别保温3,20min和60min进行退火实验。结果表明:样品在退火3min后只有局部发生再结晶,且再结晶小晶粒优先在{1011}-{1012}二次孪晶内部形核,而{1012}拉伸孪晶不利于再结晶晶粒的形核;退火20min后完成再结晶过程。由孪晶诱发的新形核的再结晶晶粒与基体的取向差在38°两侧随机分布,可明显细化原始晶粒,并弱化变形后的取向。

Mechanical responses and deformation mechanisms of an AZ31 Mg alloy sheet under dynamic and simple shear deformations

[J].

{

Molecular dynamic simulation and transmission electron microscopy (TEM) characterization was employed to investigate the {10 (1) over bar2} twinning mechanism in magnesium. A partial dislocation assisted twinning nucleation mechanism was proposed based on simulation results, in which the twin lattice was reconstructed from parental matrix by two-step sweeping of partial dislocations on different close packed planes from matrix and the subsequently formed twin precursor respectively. A {10 (1) over bar2} twin precursor was observed adjacent to matrix/twin interface by a spherical aberration corrected TEM, which indicated the hexagonal-close-packed (hcp) matrix -> quasi face-centered cubic (fcc) twinning precursor -> h.c.p twin transformation sequence during {10 (1) over bar2} twinning process. (C) 2020 Published by Elsevier B.V. on behalf of Chongqing University.

Influence of strain rate on dynamic recrystallization behavior and hot formability of basal-textured AZ80 magnesium alloy

[J].