合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键。合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径。枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法。弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法。PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难。尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法。CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] 。

在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题。在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长。由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍。

鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类。上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟。因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的。

借鉴相场弥散界面模型相场变量梯度能项的处理思路,本工作将表征元胞状态的场变量及其梯度项引入CA模型,构造场变量梯度泛函推导其扩散方程,以此对枝晶生长动力学进行修正,建立了场变量扩散元胞自动机(field variable diffusion cellular automaton,FCA)模型。以Mg-6%Al (质量分数,下同)合金六重对称的枝晶生长过程为对象,模拟计算不同条件下镁合金的枝晶形貌及演化特征,考察场变量扩散CA生长模型弱化各向异性的能力,对模型计算结果的准确性和适用性进行验证。

1 场变量梯度扩散方程推导

1.1 CA 模型场变量引入的背景和思路

在相场模型中,相场变量用于描述变量在空间中的分布及特征,系统会自发地从场变量非均匀分布状态(非平衡态)向均匀分布状态(平衡态)转变,状态分布的空间变化速率和特征可以用场变量的梯度描述。与热量、质量和动量的扩散行为类似,相场变量同样是在梯度方向的变化速率最大,沿其梯度减小的方向扩散,使系统向梯度趋于零的状态发展。因此,尽管在相场模型中无捕获环节,但扩散界面梯度能项的界面能驱动着相场变量的扩散,主导枝晶生长动力学和形貌演化,在很大程度上避免了各向异性的影响。受此启发,在枝晶生长CA模型中,表征元胞固、液状态的固相分数(f S ) 在0~1内连续变化,因此,尝试考虑在CA模型中引入该场变量的梯度项,弱化枝晶生长的各向异性和网格依赖性。

1.2 二维场变量扩散CA 模型推导

首先,根据元胞的固相分数定义一个场变量u ( x , y ) 式(1)所示。为简化数值计算流程和运算量,对场变量做二值化处理,使用u f S

u ( x , y ) = 0 ( f S < 1 ) 1 ( f S ≥ 1 ) (1)

然后,构造二维计算域S 中场变量u ( x , y ) E (u ),如 式(2)所示。

E ( u ) = D p ∬ S ∇ u p d x d y = D p ∬ S F ( u x , u y ) d x d y (2)

式中,∇ u u ( x , y ) ∇ u = ( u x , u y ) D 为常系数;参数1 ≤ p ≤ 2 ∇ u = ( u x ) 2 + ( u y ) 2 ∇ u F u x , u y = ∇ u p u ( x , y ) ∇ u p E (u )不断减小。

采用梯度下降法[27 ] 求解 式(2),E ( u ) u ( x , y )

∂ u ∂ τ = - g r a d ( E ( u ) ) (3)

式中,τ g r a d ( E ( u ) ) E ( u ) 式(4)所示。

g r a d ( E ( u ) ) = ∂ F ∂ u - d d x ( ∂ F ∂ u x ) - d d y ( ∂ F ∂ u y ) (4)

联立式(2)~(4),得到场变量u ( x , y ) 式(5)所示。

∂ u ∂ τ = D d i v ( ∇ u p - 2 ∇ u ) (5)

当p 式(5)可简化为各向同性线性扩散方程,如 式(6)所示。

∂ u ∂ τ = D ∇ ⋅ ( ∇ u ) = D ( u x x + u y y ) (6)

采用显示差分格式对场变量扩散方程进行离散,为了提高差分格式的精度,运用九点差分格式离散二维场变量扩散方程,如 式(7):

u i , j N = ( 1 - 4 F 0 ) u i , j I + 2 3 F 0 ( u i - 1 , j I + u i + 1 , j I + u i , j - 1 I +

u i , j + 1 I ) + 1 3 F 0 ( u i + 1 , j + 1 I + u i + 1 , j - 1 I + u i - 1 , j - 1 I +

u i - 1 , j + 1 I ) (7)

式中,i 、j 分别为直角坐标系中x 、y 坐标轴方向的元胞索引;F 0 = D Δ t / ( Δ x ) 2 Δ t Δ x F 0 N I u u I

以上即为二维场变量扩散CA模型的推导过程及解析表达式。u N u I u N u N u N u N

1.3 各向异性算例与结果讨论

生长动力学计算是所有相变数值计算模型的核心,CA模型生长动力学和各向异性主要有2方面影响因素:固相元胞捕获规则、界面元胞固相分数的增长。在本工作中,引入场变量扩散项u i , j N

建立具有固定生长速率v s e t f S f S f S ≥ 1 f S Δ f S ) 为:

Δ f S = v s e t (8)

采用 式(7)中的场变量扩散项对界面元胞的固相分数增量进行修正:

Δ f S = v s e t ⋅ u i , j N (9)

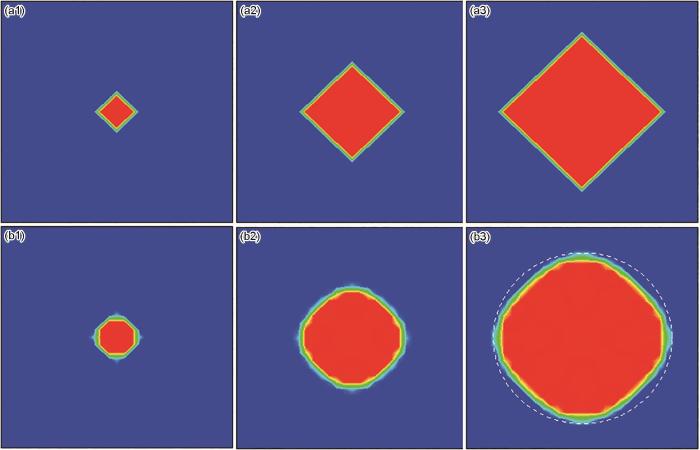

图1 和2 分别为采用Von Neumann型和Moore型邻胞,二维CA模型在不同迭代次数下得到的演化形貌,图中的白色虚线圆为参考曲线,元胞数目251 × 251。其中,图1a1~a3和图2a1~a3 为原始的CA模型的模拟结果,迭代次数分别为20、60和100次;图1b1~b3和图2b1~b3 为FCA模型模拟结果,迭代次数分别为120、260和400次。可以看出,与原始的二维CA模型相比,引入场变量扩散项可以得到近似圆形的演化形貌,且Moore型邻胞的模拟结果优于Von Neumann型邻胞。

图1

图1

Von Neumann型邻胞2种模型模拟结果

Fig.1

Morphologies simulated by two cellular automaton (CA) models using Von Neumann neighborhood

(a1-a3) original CA model with 20 iterations (a1), 60 iterations (a2), and 100 iterations (a3) (b1-b3) field variable diffusion (FCA) model with 120 iterations (b1), 260 iterations (b2), and 400 iterations (b3)

图2

图2

Moore型邻胞2种模型模拟结果

Fig.2

Morphologies simulated by the two CA models using Moore neighborhood

(a1-a3) original CA model with 20 iterations (a1), 60 iterations (a2), and 100 iterations (a3) (b1-b3) FCA model with 120 iterations (b1), 260 iterations (b2), and 400 iterations (b3)

FCA模型显著弱化了原始CA模型中的各向异性,近似实现了各向同性的界面演化。值得一提的是,引入场变量扩散项虽然增加了计算量,但计算流程简洁,可以通过算法优化及并行计算加快计算速率,也易于扩展至三维模型。

2 场变量扩散二元合金枝晶生长CA 模型

基于推导的场变量扩散方程,建立了溶质传输驱动的二元合金枝晶生长CA模型。模型包括场变量扩散、溶质传输、生长动力学计算、元胞状态转变、捕获规则等模块。采用“浓度势法”处理溶质扩散和再分配,利用杠杆定律处理界面凝固/重熔的生长动力学,并将场变量扩散项引入CA模型对界面胞的生长速率进行修正。模型的基本假设如下:(1) 热量传输速率比溶质传输速率高3~4个数量级,因此忽略枝晶生长中的传热;(2) 不考虑熔体流动;(3) 忽略动力学过冷,不考虑固相线斜率、液相线斜率及平衡分配系数(k )随温度和生长速率的变化;(4) 凝固过程中,局部固-液界面达到平衡状态,即在局部固-液界面处,液相平衡溶质浓度(C L * ) 与固相平衡浓度(C S * ) 满足:k = C S * C L *

2.1 溶质控制方程

不考虑液体中的自然对流和强迫对流,液体和固体中扩散的控制方程可以描述为:

∂ C m ∂ t = ∇ ⋅ ( D m ∇ C m ) (10)

式中,t 为时间,s;C D m 2 /s;下标m

因此,采用浓度势[28 ] 的方法进行计算,定义浓度势(P ) :液相元胞P = C L P = C S / k P = C L 式(10)可以改写为 式(11):

∂ C e ∂ τ = ∇ ⋅ ( D ¯ ∇ P ) (11)

式中,C e C e f S C S + ( 1 - f S ) C L D ¯ α 和β ,则D ¯

D ¯ = f S α D S + ( 1 - f S α ) D L + f S β D S + ( 1 - f S β ) D L 2 (12)

式中,f S α f S β α 和β 的

2.2 固- 液界面曲率及界面能各向异性计算

凝固过程中固-液界面处始终维持局部平衡状态:k = C S * C L * C L *

C L * = C 0 + T - T L m L + Γ ⋅ K ⋅ f ( φ , θ ) m L (13)

式中,T T L C 0 m L Γ K m - 1 φ θ f φ , θ K [29 ] 、φ f φ , θ 14)~(16)。

K = 2 ∂ f S ∂ x ∂ f S ∂ y ∂ 2 f S ∂ x ∂ y - ∂ f S ∂ x 2 ∂ 2 f S ∂ y 2 - ∂ f S ∂ y 2 ∂ 2 f S ∂ x 2 ∂ f S ∂ x 2 + ∂ f S ∂ y 2 3 / 2 (14)

φ = c o s - 1 ∂ f S / ∂ x ∂ f S ∂ x 2 + ∂ f S ∂ y 2 1 / 2 ∂ f S ∂ y ≥ 0 2 π - c o s - 1 ∂ f S / ∂ x ∂ f S ∂ x 2 + ∂ f S ∂ y 2 1 / 2 ∂ f S ∂ y < 0 (15)

f ( φ , θ ) = 1 + δ c o s ( n ( φ - θ ) ) (16)

2.3 固相分数计算

在局部固-液界面平衡凝固假设条件下,可以通过杠杆定律计算得到整个界面元胞的固相分数,因此f S

f S = C L * - C e C L * ( 1 - k ) (17)

由 式(13)可知,不同时间步长内局部界面的曲率差异导致C L * Δ f S

Δ f S = 1 1 - k ( C e p r e C L * p r e - C e C L * ) ⋅ f k ( φ , θ ) ⋅ γ ⋅ u N (18)

式中,上标p r e γ 为生长速率调节系数;u N f k ( φ , θ )

f k ( φ , θ ) = 1 + δ k c o s ( n ( φ - θ ) ) (19)

式中,δ k [30 ] 。当(C e p r e C L * p r e C e C L * ) > 0时,界面元胞的Δ f S C e p r e C L * p r e C e C L * ) < 0时,局部固-液界面发生熔化(Δ f S

2.4 捕获规则

FCA模型采用场变量扩散项修正生长速率,故无须限制枝晶形貌、生长方向和捕获规则,元胞捕获时也不再做随机处理。枝晶在生长时采用最简单的捕获规则,即,刚凝固的固相元胞将Moore型邻域内的液相元胞全部捕获,并将液相元胞转变为界面元胞。

2.5 计算流程

采用显式有限差分格式求解溶质传输控制方程,Δ t

Δ t < Δ x 2 4.0 D L (20)

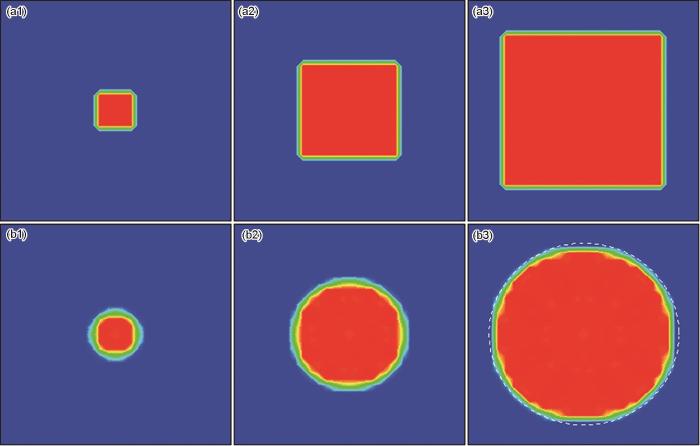

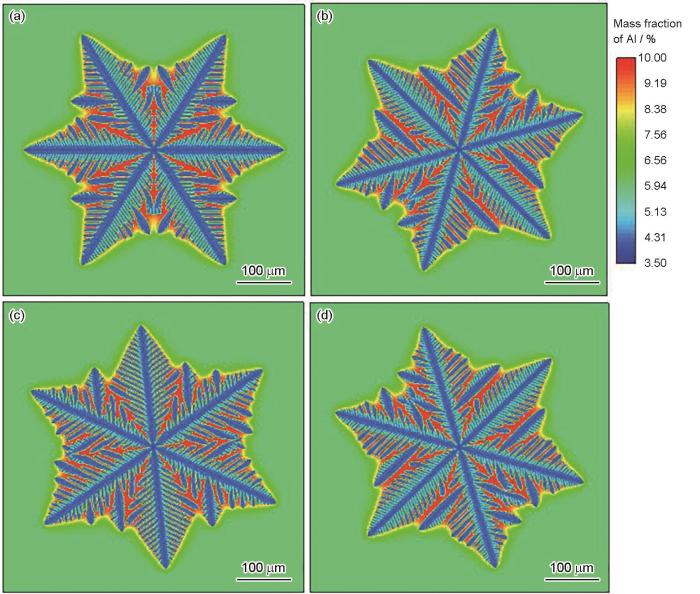

图3 显示了FCA模型的流程图。FCA模型首先进行场变量模块计算,得到的场变量扩散项u N

图3

图3

场变量扩散枝晶生长CA模型计算流程

Fig.3

Flowchart of the CA model for dendritic growth based on field variable diffusion (t —time, Δt —time step, f S —solid fraction, Δ f S

3 模型验证

基于以上建立的模型与计算程序,对等温凝固条件下单个枝晶生长的结果进行验证和分析。从随机择优取向和生长动力学2方面,模拟了具有六重对称特征的Mg-6%Al合金的枝晶形貌,模拟中使用的材料物性参数及计算参数如表1 [13 ] 所示。由于热量传输速率远大于溶质传递速率,因此将模拟区域设置为均匀温度场,只研究溶质扩散对枝晶生长的影响。模拟开始时,在计算域中心随机放置一个晶核。计算域元胞数目为551 × 551,Δ x Δ t

3.1 六重对称枝晶生长模拟

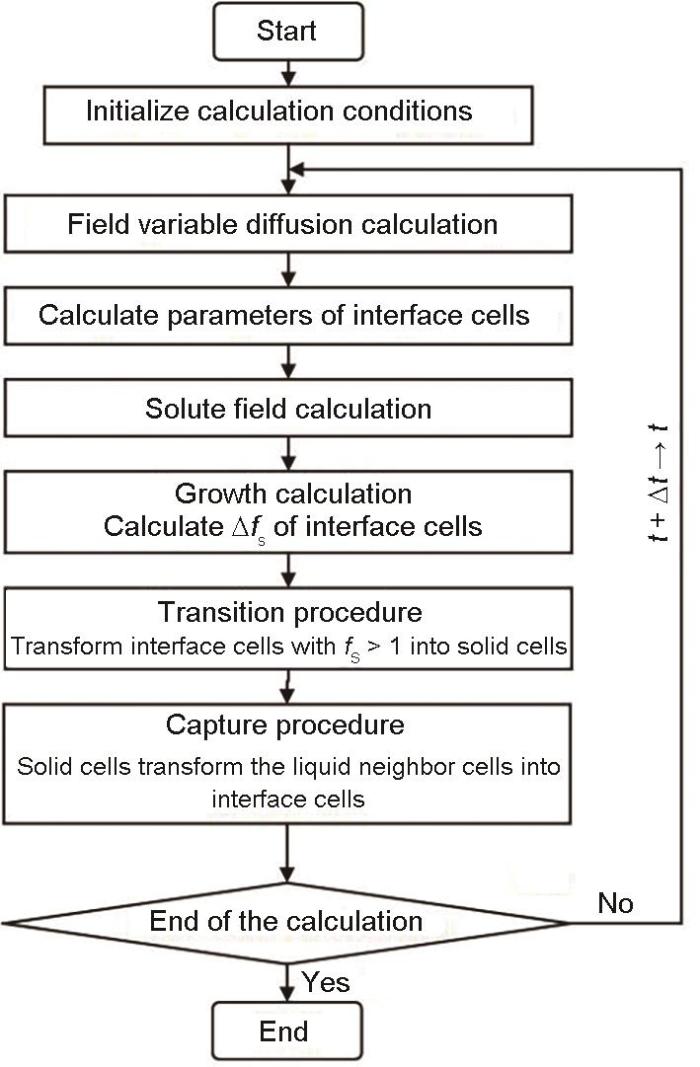

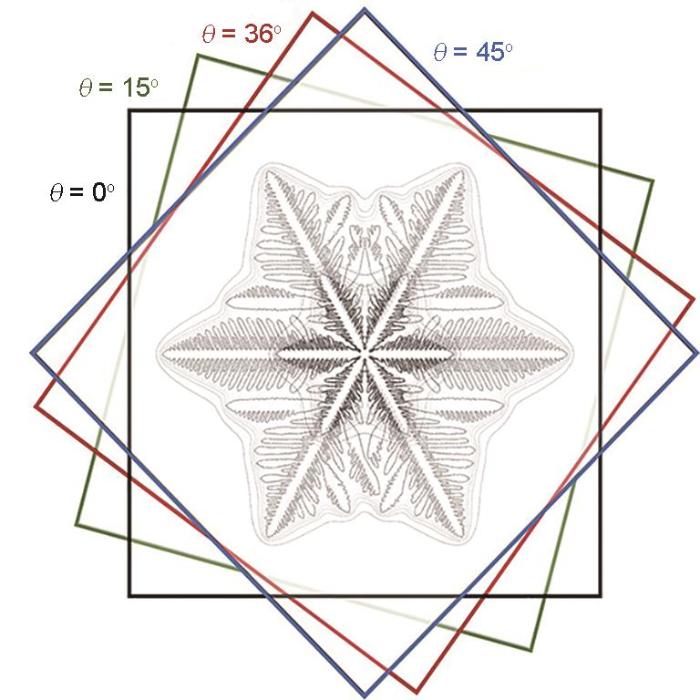

图4 为择优取向为0º、15º、36º及45º的Mg-6%Al合金在凝固时间为0.455 s时的枝晶形貌。计算域元胞数目551 × 551,Δ x Δ T [31 ] 对3 K过冷度Al-4%Cu合金四重对称枝晶形貌和不同择优取向的枝晶形貌进行了模拟,结果表明,所有枝晶的偏转方向均与预设生长角度相符,各枝晶形貌及分支间夹角基本一致。

图4

图4

不同择优取向的Mg-6%Al在凝固时间为0.455 s时的枝晶形貌

Fig.4

Simulated dendrites of Mg-6%Al alloy with different preferred orientations at the solidification time of 0.455 s

(a) 0° (b) 15° (c) 36° (d) 45°

枝晶生长过程是非线性的,对生长动力学的变化非常敏感。为此,提取0.195和0.455 s时刻的枝晶形貌,将图4b~d 中的枝晶顺时针分别旋转15º、36º和45º,对比4个不同择优生长取向下的枝晶形貌,结果如图5 所示。可以看出,不同择优生长角度的枝晶形貌基本重合,但由于二次枝晶和三次枝晶于枝晶间液相溶质富集的影响,生长速率不同,导致二次枝晶臂粗壮程度略有差异。总体来看,不同时刻下主枝晶臂的生长速率和尺寸基本一致,模型实现了正方形网格离散方式下,六重对称枝晶形貌的模拟,不同择优取向下枝晶形貌的各向异性显著降低。

图5

图5

不同择优生长方向的枝晶形貌对比

Fig.5

Comparison of dendritic morphologies with different preferred orientations (θ )

3.2 枝晶尖端生长速率与半径

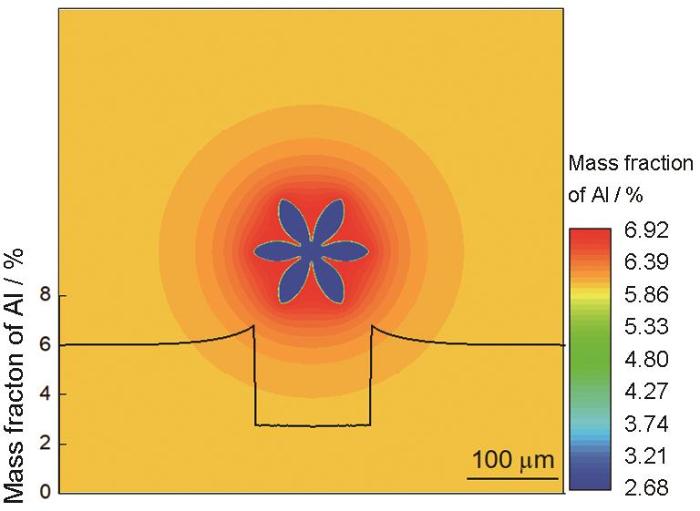

图6 为过冷度为5 K、凝固时间为2.08 s的计算条件下,模拟得到的合金枝晶形貌及浓度场分布,元胞数目551 × 551,Δ x x

图6

图6

Mg-6%Al合金枝晶形貌模拟与水平方向主枝晶臂浓度

Fig.6

Simulated dendrite morphology and concentration of the horizontal main dendrite arms for Mg-6%Al alloy

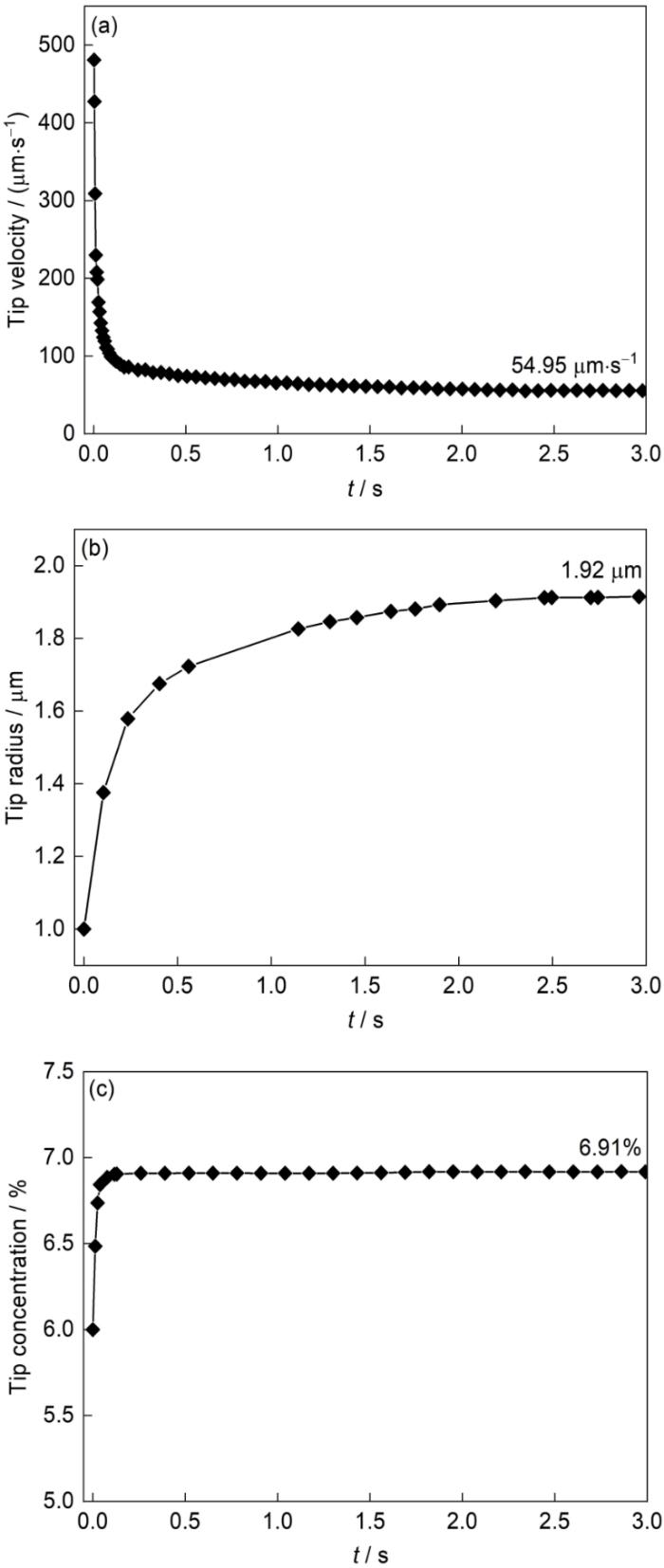

图7 为Mg-6%Al在过冷度为5 K下,枝晶尖端半径、生长速率和溶质浓度随时间的变化关系。

图7

图7

Mg-6% Al合金枝晶尖端特征参数随时间变化

Fig.7

Simulated curves of dendrite tip parameters against time for Mg-6% Al alloy with 5 K under-cooling

(a) tip growth velocity

(b) tip radius

(c) tip concentration

等温凝固过程中,固-液界面的运动是由界面前沿溶质浓度差异引起的溶质扩散所驱动的。初始阶段,液相溶质浓度为初始浓度,固-液界面前沿溶质富集的程度较低,溶质浓度低且过冷度较高,因此,枝晶尖端以相对较高的速率开始生长,如图7a 所示;随着凝固进行,枝晶逐渐增长,枝晶尖端半径也随之增大,如图7b 所示,由溶质再分配释放的溶质富集在固-液界面,固相排出的溶质在固-液界面前沿不断积累,且枝晶生长所排出的溶质速率大于溶质扩散速率,枝晶尖端前沿的浓度迅速增加,导致合金液相线温度降低,过冷度减小,故生长速率降低,如图7c 所示;最后溶质在界面前沿的释放与通过扩散的传输达到动态平衡,枝晶尖端逐渐达到稳态生长阶段。枝晶尖端生长速率在3.0 s时稳定在54.95 μm/s,此时尖端半径为1.92 μm。

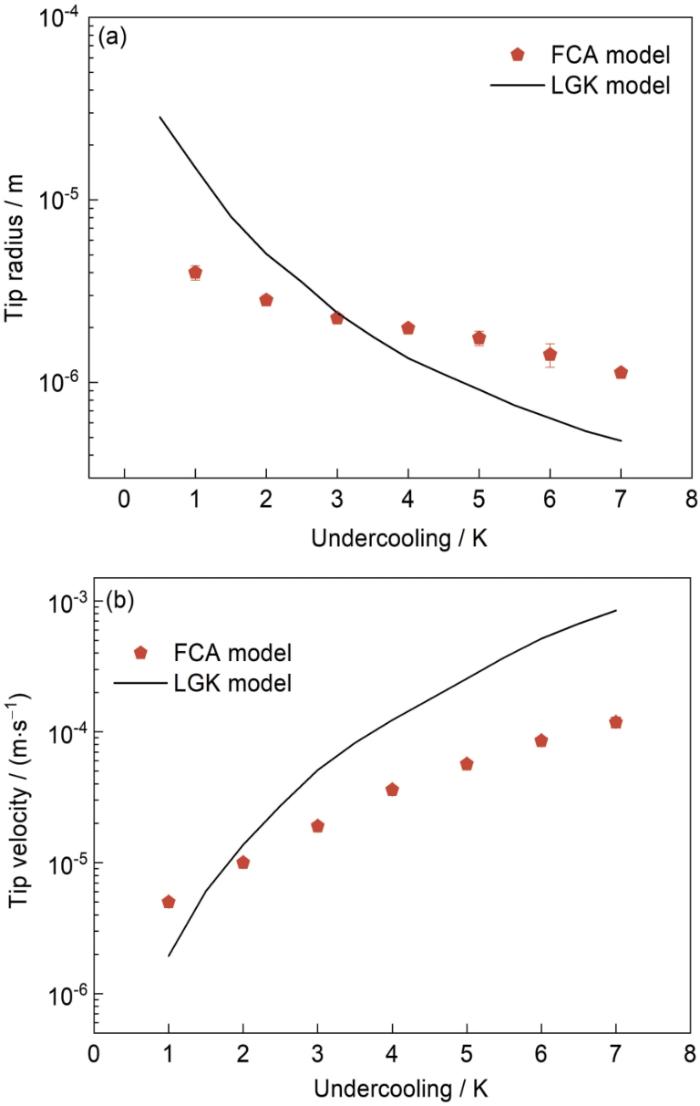

3.3 枝晶尖端稳态特征与LGK 模型预测结果对比

图8 为Mg-6%Al合金在不同过冷度下,模拟得到的枝晶尖端特征与Lipton-Glicksman-Kurz (LGK)模型[32 ] 计算数据的对比结果。两模型预测的生长速率和尖端半径随过冷度变化的趋势相似,即随着过冷度的增大,枝晶尖端稳态生长速率逐渐增加,尖端半径逐渐减小,且2者数量级均为10-5 。刘龙飞[33 ] 基于LGK模型,探讨了过冷度对Mg-Al合金凝固时枝晶尖端生长半径及生长速率的影响,当过冷度从0.5 K增加至5 K时,枝晶尖端生长速率从2 × 10-5 m/s增加到8 × 10-5 m/s,尖端半径从1 × 10-5 m降低至2 × 10-6 m,研究结果与本工作结果在同一数量级,尖端半径和生长速率随过冷度的变化趋势一致。

图8

图8

Mg-6%Al合金枝晶尖端半径和速率与LGK预测结果对比

Fig.8

Comparisons of dendrite tip radius (a) and tip growth velocity (b) from the FCA and Lipton-Glicksman-Kurz (LGK) models for the Mg-6%Al alloy

尖端半径在较低和较高过冷度下存在一定偏差,而尖端生长速率在较高过冷度下存在差异。当过冷度较小时,生长速率低,生长排出的溶质有充足的时间扩散;在枝晶生长到相同长度时,相比于较低的过冷度,过冷度较高时枝晶臂粗化的程度更加明显,导致高过冷度下枝晶尖端平均曲率降低,枝晶半径减小。本工作模型计算结果与LGK模型预测结果在同一数量级,需要说明的是,LGK模型仅求解枝晶尖端形状,未考虑枝晶臂演化和界面曲率对生长速率的影响,枝晶尖端半径的计算和确定方法本身就存在一定偏差,故低过冷度下本模型计算得到的尖端生长速率高于LGK模型;随着过冷度增大,情况相反,本模型计算的尖端生长速率小于LGK模型,Beltran-Sanchez等[11 ] 和Luo等[34 ] 也得到了同样的结论。

4 计算结果及讨论

为验证模型对六重对称合金枝晶生长模拟的适用性,分别对等温凝固和连续冷却下的Mg-6%Al合金的枝晶形貌进行模拟,首先模拟了等温凝固条件下单个等轴枝晶的生长,然后模拟了多个等轴晶的枝晶生长过程。对于Mg-6%Al合金来说,热扩散速率(α T 约为10-5 )远远大于溶质在液相中的扩散速率(D L 约为10-9 ),因此可以认为在枝晶尺度上热量扩散保持平衡态,即等轴晶生长过程中计算域的温度是均匀的。

4.1 等温凝固条件下单个等轴枝晶生长

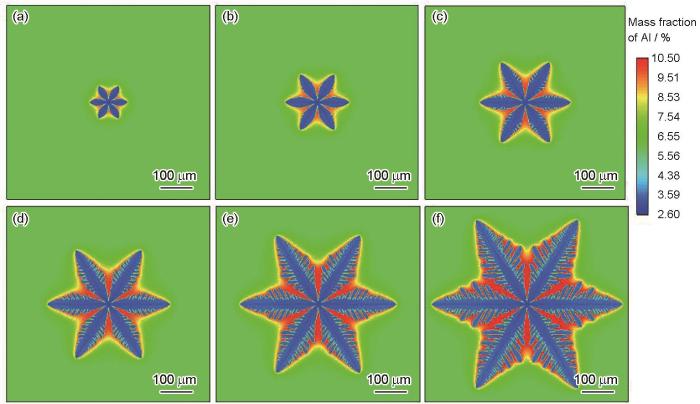

图9 显示了Mg-6%Al合金枝晶形貌随时间的演化,计算域元胞数目650 × 650,Δ x Δ T

图9

图9

Mg-6%Al合金枝晶形貌及溶质浓度随时间演化

Fig.9

Evolutions of dendrite morphologies and solution concentrations of Mg-6%Al alloy with time

(a) 0.16 s (b) 0.28 s (c) 0.40 s (d) 0.52 s (e) 0.64 s (f) 0.76 s

在枝晶生长过程中,枝晶臂粗化,溶质扩散区域逐渐增大。枝晶尖端排出的溶质沿其生长方向和周围两侧扩散,而枝晶臂粗化排出的溶质只能向两侧扩散,故枝晶尖端溶质浓度低于主枝晶臂两侧浓度,进而获得了较大的过冷度,生长速率加快。在枝晶根部,枝晶臂交汇造成溶质富集,枝晶生长受到抑制,根部出现“颈缩”现象。需要指出,如果利用经典的正方形元胞CA模型计算六重枝晶的生长行为,不仅计算中的处理十分繁琐,且不同择优取向枝晶的生长速率也会出现较大的差异。Fu等[35 ] 利用正方形元胞CA模型模拟了AZ91D合金的枝晶形貌,结果表明处于不同方向的主枝晶臂生长速率不一致,且主枝晶臂之间的夹角也不相等,与实际均匀温度场下的枝晶形貌不符。与之相比,本模型模拟得到的6个枝晶臂长度相等,侧枝角度对称,与相场法得到的结果[36 ] 基本一致。

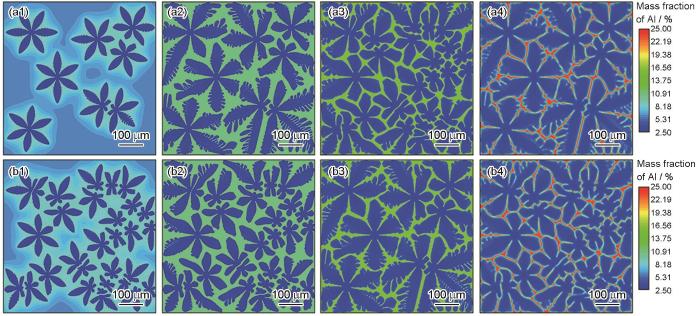

4.2 连续冷却条件下多等轴枝晶生长

模拟了连续冷却条件下Mg-6%Al合金多个等轴晶的枝晶生长过程,计算域网格数目650 × 650,Δ x Δ T 图10a1~a4 和图10b1~b4 分别为随机设置8个和30个晶核,Mg-6%Al合金等轴晶形貌及溶质浓度随时间的演化。晶核数目为8时,在凝固初期(0.48 s),枝晶生长速率较快,主枝晶臂沿其择优取向生长,并且主枝晶臂的两侧产生二次枝晶臂;随着凝固的进行(2.64 s),枝晶周围液相溶质富集,相邻枝晶溶质场的相互作用变得越来越强,使一些枝晶臂偏离其择优取向生长,六重对称的枝晶形貌发生了明显的变化。凝固5.60 s时,溶质在枝晶臂间熔体内进一步富集,导致溶质扩散及尖端生长受到明显抑制。凝固后期(10.00 s),枝晶生长速率进一步降低,Gibbs-Thomson效应导致枝晶臂粗化。晶核数目为30时的枝晶生长规律与8个时基本相同,但由于枝晶的相互阻碍作用较强,二次枝晶臂的发展被抑制。Yin和Felicelli[17 ] 采用正六边形元胞CA模型模拟得到Mg-8.9%Al的枝晶形貌,主枝晶臂只能沿着与x 轴正方向呈60°夹角的方向生长,但无法实现枝晶偏转。本模型采用正方形元胞模拟得到六重对称合金枝晶形貌,与相场法得到的镁合金多枝晶生长形貌和溶质场分布结果[37 ] 大致相符。

图10

图10

Mg-6%Al合金等轴晶形貌及溶质浓度分布随时间演化

Fig.10

Evolutions of simulated equiaxed dendrite morphologies and solution concentrations of Mg-6%Al alloy with dendrite numbers (N ) and time

(a1) N = 8, 0.48 s (a2) N = 8, 2.64 s (a3) N = 8, 5.60 s (a4) N = 8, 10.00 s

(b1) N = 30, 0.48 s (b2) N = 30, 2.64 s (b3) N = 30, 5.60 s (b4) N = 30, 10.00 s

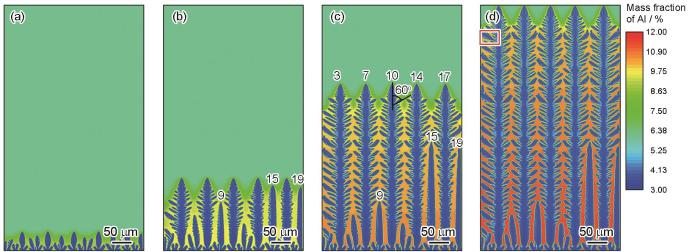

4.3 定向凝固条件下柱状枝晶生长

图11 显示了Mg-6%Al合金定向凝固过程中柱状晶形貌随时间的演化。计算域元胞数目400 × 800,Δ x

图11

图11

Mg-6%Al合金定向凝固柱状晶形貌随时间的模拟结果

Fig.11

Simulated columnar dendritic morphologies during directional solidification of a Mg-6%Al alloy with time

(a) 0.16 s (b) 0.56 s (c) 1.04 s

(d) 1.44 s (The outlined region illustrates the local “necking” phenomenon during dendrite growth)

凝固初期,所有枝晶均沿其择优生长方向发展,与温度梯度方向相近的主枝晶臂生长速率较快,如图11a 所示。随着凝固的进行,出现“竞争生长”现象。择优取向与温度梯度方向相近的枝晶继续生长,主枝晶臂两侧出现了不同程度的侧向分支;由于相邻枝晶的影响,择优取向不利的主枝晶臂生长均受到抑制,与吴孟武和熊守美[13 ] 模拟镁合金定向凝固不同温度梯度和凝固速率下柱状晶的竞争生长观察的现象一致。最终仅有5个枝晶的主枝晶臂继续生长,二次枝晶臂的发展也较完全,且与主枝晶臂间的夹角为60º。由于3# 、17# 枝晶与边界间距较大,溶质浓度较低,在朝向边界的方向均发展出了三次枝晶臂。图11b 和c 标示出了择优生长方向与温度梯度方向一致的枝晶编号。可以看出,9# 、15# 、19# 枝晶虽然取向有利,但在生长过程中受到相邻枝晶二次枝晶臂的阻挡,仍然被逐渐“淘汰”。如图11d 红色方框所示,二次枝晶生长过程中,溶质富集在枝晶根部,产生“颈缩”现象。

5 结论

(1) 通过引入考虑元胞状态变量的场变量梯度泛函及场变量扩散方程,建立了基于场变量扩散的二元合金枝晶生长CA模型,采用“浓度势法”处理溶质扩散和再分配,依据杠杆定理处理界面凝固的生长动力学,引入场变量的扩散方程修正界面元胞的生长速率。对界面元胞的生长行为进行修正,旨在针对具有六重对称合金的枝晶生长及任意择优取向的枝晶生长过程进行模拟。采用“浓度势法”处理溶质扩散和再分配,依据杠杆定理处理界面凝固的生长动力学,引入场变量的扩散方程修正界面元胞的生长速率。

(2) 以Mg-6%Al合金为对象,利用模型对不同凝固条件下的枝晶形貌、稳态特征等进行计算和分析验证。模拟计算结果显示,Mg-6%Al合金稳态生长阶段,模型计算的枝晶尖端生长速率、尖端半径随过冷度的变化趋势与LGK模型预测结果大致相符。

(3) 等温凝固和连续冷却条件下,模型计算的主枝晶臂、二/三次枝晶及其形貌均沿着各自择优取向生长,可反映出凝固前沿溶质富集、枝晶根部“缩颈”以及由Gibbs-Thomson效应导致的枝晶臂粗化等行为。

(4) 定向凝固条件下,择优取向与温度梯度相近的主枝晶臂生长速率高,计算中可观察到枝晶的竞争、淘汰和“缩颈”等现象。

(5) 建立的场变量扩散元胞自动机枝晶生长模型,显著弱化了CA模型枝晶形貌模拟的各向异性,实现了二维平面正方形网格离散方式下,六重对称合金和任意择优取向枝晶生长形貌的计算模拟,原理清晰、易于并行,为元胞自动机法推广至合金凝固组织的三维和跨尺度模拟研究提供参考。

参考文献

View Option

[1]

Kobayashi R Modeling and numerical simulations of dendritic crystal growth

[J]. Physica , 1993 , 63D : 410

[本文引用: 1]

[2]

Kobayashi R A numerical approach to three-dimensional dendritic solidification

[J]. Exp. Math. , 1994 , 3 : 59

[本文引用: 1]

[3]

Karma A Rappel W J Quantitative phase-field modeling of dendritic growth in two and three dimensions

[J]. Phys. Rev. , 1998 , 57E : 4323

[本文引用: 1]

[4]

Karma A Phase-field formulation for quantitative modeling of alloy solidification

[J]. Phys. Rev. Lett. , 2001 , 87 : 115701

[本文引用: 1]

[5]

Yamazaki M Satoh J Ohsasa K et al Numerical model of solidification structure formation in Fe-C alloy with peritectic transformation

[J]. ISIJ Int. , 2008 , 48 : 362

[本文引用: 1]

[6]

Wang W L Ji C Luo S et al Modeling of dendritic evolution of continuously cast steel billet with cellular automaton

[J]. Metall. Mater. Trans. , 2018 , 49B : 200

[7]

Yamazaki M Natsume Y Harada H et al Numerical simulation of solidification structure formation during continuous casting in Fe-0.7mass% C alloy using cellular automaton method

[J]. ISIJ Int. , 2006 , 46 : 903

[8]

Tan W D Bailey N S Shin Y C A novel integrated model combining cellular automata and phase field methods for microstructure evolution during solidification of multi-component and multi-phase alloys

[J]. Comp. Mater. Sci. , 2011 , 50 : 2573

[本文引用: 1]

[9]

Nastac L Numerical modeling of solidification morphologies and segregation patterns in cast dendritic alloys

[J]. Acta Mater. , 1999 , 47 : 4253

[本文引用: 1]

[10]

Yin H Felicelli S D Wang L Simulation of a dendritic microstructure with the lattice Boltzmann and cellular automaton methods

[J]. Acta Mater. , 2011 , 59 : 3124

[本文引用: 1]

[11]

Beltran-Sanchez L Stefanescu D M A quantitative dendrite growth model and analysis of stability concepts

[J]. Metall. Mater. Trans. , 2004 , 35A : 2471

[本文引用: 2]

[12]

Huo L Han Z Q Liu B C Modeling and simulation of microstructure evolution of cast magnesium alloys using CA method based on two sets of mesh

[J]. Acta Metall. Sin. , 2009 , 45 : 1414

[本文引用: 1]

<p>The texture of Mg alloy dendrites is quite different from that of fcc or bcc metals because of the influence of hcp crystal lattice on the dendrite morphology evolutions during solidification. Although the simulations of dendrite morphologies for fcc or bcc metals by cellular automaton (CA) methods have been widely reported, CA simulations of magnesium alloys with hcp crystal lattice have just appeared in recent years. When performing the simulation of Mg alloy dendrites with a CA method on a square mesh, the artificial anisotropy of growth kinetics introduced by the square mesh makes it hard to reflect the texture of Mg alloy dendrites, which shows the six–fold symmetry instead of four–fold symmetry of bcc or fcc metal dendrites.</p><p>In the present paper, a two dimensional CA model has been developed for simulating the dendrite morphology evolution of castMg alloys. The model employs two sets of meshes to perform the numerical simulation, where a hexagonal mesh is used to perform CA calculation to reflect the texture of Mg alloy dendrites, and an orthogonal mesh is used to solve the mass transportation equation. The two sets of meshes are coupled by an interpolation method. By employing the two–set mesh method, the texture of Mg alloy dendrites is well reflected and the undesired artificial growth kinetics introduced by square mesh is avoided. In the model, the growth kinetics of dendrite tips was determined by the difference between local equilibrium and local actual compositions obtained by solving the solute transport equation. With this calculation method for growth kinetics, the solid fraction of interface CA cell can be obtained directly from the solute field, which decreases the computational cost greatly. The model was applied to simulate the single dendrite evolution and columnar dendrite growth of AZ91D Mg alloy, as well as multi–dendrite growth and grain size of Mg–10Gd–2Y–0.5Zr (mass fraction, %) alloy step–shaped castings. To validate the current model, permanent mold sample castings of AZ91D Mg alloy and step–shaped castings of Mg–10Gd–2Y–0.5Zr alloy were produced. Optical metallographic examinations were performed on specimens of these two Mg alloys, and grain sizes were measured on solution treated specimens of Mg–10Gd–2Y–0.5Zr alloy. The simulated and experimental results were compared.</p>

霍 亮 , 韩志强 , 柳百成 基于两套网格的CA方法模拟铸造镁合金凝固过程枝晶形貌演化

[J]. 金属学报 , 2009 , 45 : 1414

[本文引用: 1]

[13]

Wu M W Xiong S M Microstructure simulation of high pressure die cast magnesium alloy based on modified CA method

[J]. Acta Metall. Sin. , 2010 , 46 : 1534

[本文引用: 4]

吴孟武 , 熊守美 基于改进CA方法的压铸镁合金微观组织模拟

[J]. 金属学报 , 2010 , 46 : 1534

DOI

[本文引用: 4]

针对具有快速凝固特征的压铸工艺, 通过热传导反算法得到较准确的压铸温度场,分析压铸镁合金凝固过程冷却曲线, 建立了形核密度随冷却速率变化的形核模型.采用改进CA方法, 建立了适用于镁合金hcp结构的枝晶生长模型. 模型考虑了溶质扩散、成分过冷、曲率过冷以及界面各向异性等重要因素, 实现了镁合金不同角度枝晶生长, 再现了枝晶二次及三次枝晶臂生长, 定向凝固不同温度梯度及凝固速率下的枝晶竞争生长以及三维枝晶生长等特征. 应用所建立的形核及生长模型模拟了AM50镁合金“阶梯”压铸件不同压铸工艺下的凝固组织,模拟结果与实验结 果相吻合.

[14]

Jacot A Rappaz M A two-dimensional diffusion model for the prediction of phase transformations: Application to austenitization and homogenization of hypoeutectoid Fe-C steels

[J]. Acta Mater. , 1997 , 45 : 575

[本文引用: 1]

[15]

Schönfisch B Anisotropy in cellular automata

[J]. Biosystems , 1997 , 41 : 29

PMID

[本文引用: 1]

Time-dependent and stationary patterns produced by standard cellular automata used for various qualitative modeling purposes show various geometric features that reflect the anisotropy of the underlying grid and neighborhood rather than the properties of the physical model itself. We investigate several modifications of cellular automata such as random grids, stochastic local functions, asynchronous evaluations that are designed to avoid anisotropy. We apply these tools to a class of simple totalistic automata simulating contact processes. It appears that random grids are most useful.

[16]

Wei L Lin X Wang M et al A cellular automaton model for the solidification of a pure substance

[J]. Appl. Phys. , 2011 , 103A : 123

[本文引用: 1]

[17]

Yin H B Felicelli S D A cellular automaton model for dendrite growth in magnesium alloy AZ91

[J]. Modell. Simul. Mater. Sci. Eng. , 2009 , 17 : 075011

[本文引用: 2]

[18]

Song Y D Microstructure simulation of magnesium alloy [D]. Dalian : Dalian University of Technology , 2012

[本文引用: 1]

宋迎德 镁合金凝固组织模拟 [D]. 大连 : 大连理工大学 , 2012

[本文引用: 1]

[19]

Zhu M F Stefanescu D M Virtual front tracking model for the quantitative modeling of dendritic growth in solidification of alloys

[J]. Acta Mater. , 2007 , 55 : 1741

[本文引用: 1]

[20]

Rappaz M Gandin C A Probabilistic modelling of microstructure formation in solidification processes

[J]. Acta Metall. Mater. , 1993 , 41 : 345

[本文引用: 1]

[21]

Wang W Lee P D McLean M A model of solidification microstructures in nickel-based superalloys: Predicting primary dendrite spacing selection

[J]. Acta Mater. , 2003 , 51 : 2971

[22]

Yin H Felicelli S D Dendrite growth simulation during solidification in the LENS process

[J]. Acta Mater. , 2010 , 58 : 1455

[23]

Nakagawa M Natsume Y Ohsasa K Dendrite growth model using front tracking technique with new growth algorithm

[J]. ISIJ Int. , 2006 , 46 : 909

[本文引用: 1]

[24]

Liu Z Y Xu Q Y Liu B C Modeling of dendrite growth for the cast Magnesium alloy

[J]. Acta Metall. Sin. , 2007 , 43 : 367

[本文引用: 1]

刘志勇 , 许庆彦 , 柳百成 铸造镁合金的枝晶生长模拟

[J]. 金属学报 , 2007 , 43 : 367

[本文引用: 1]

根据hcp晶体学结构和优先生长方向, 建立了铸造镁合金晶体生长的物理模型, 提出了一种新的随机性模拟方法——虚拟生长中心计算模型. 模型考虑了枝晶生长动力学、各向异性和二次枝晶臂粗化, 采用枝晶形状函数揭示了一 次枝晶和二次枝晶的生长演化过程. 引入坐标变换技术可更快速准确计算任意晶向枝晶的生长捕获. 耦合了微观溶质场计算, 得到了更准确的枝晶生长形貌和溶质分布情况. 对Mg-Al合金定向凝固和等轴晶生长的模拟验证了本模型的正确性.

[25]

Beltran-Sanchez L Stefanescu D M Growth of solutal dendrites—A cellular automaton model

[J]. Int. J. Cast Met. Res. , 2003 , 15 : 251

[本文引用: 1]

[26]

Wu M W Xiong S M Modeling of equiaxed and columnar dendritic growth of magnesium alloy

[J]. Trans. Nonferrous Met. Soc. China , 2012 , 22 : 2212

[本文引用: 1]

[27]

Wang D K Hou Y Q Peng J Y Partial Differential Equation Method for Image Processing [M]. Beijing : Science Press , 2008 : 46

[本文引用: 1]

王大凯 , 侯榆青 , 彭进业 图像处理的偏微分方程方法 [M]. 北京 : 科学出版社 , 2008 : 46

[本文引用: 1]

[28]

Beltran-Sanchez L Stefanescu D M Growth of solutal dendrites: A cellular automaton model and its quantitative capabilities

[J]. Metall. Mater. Trans. , 2003 , 34A : 367

[本文引用: 1]

[29]

Chen J Numerical simulation on solidification microstructures using cellular automaton method [D]. Nanjing : Southeast University , 2005

[本文引用: 1]

陈 晋 基于胞元自动机方法的凝固过程微观组织数值模拟 [D]. 南京 : 东南大学 , 2005

[本文引用: 1]

[30]

Zhu M F Xing L K Fang H et al Progresses in dendrite coarsening during solidification of alloys

[J]. Acta Metall. Sin. , 2018 , 54 : 789

DOI

[本文引用: 1]

Dendrites are the most frequently observed solidification microstructures of metallic alloys. In most solidification processes at low and moderate cooling rates, dendrite coarsening in mushy zones has been recognized as an unavoidable phenomenon that significantly influences microstructures and thereby the properties of the final products. The behavior of dendrite coarsening has received persistent scientific interests owing to its importance in both academic value and practical application. During the last five decades, extensive efforts have been made through theoretical analyses, experimental techniques and numerical simulations for fundamentally understanding the mechanisms of dendrite coarsening during solidification under continuously cooling or isothermal conditions. This paper first gives a brief overview of the progress in the studies of dendrite coarsening. Then, a cellular automaton (CA) model recently proposed by the authors is presented, which involves the mechanisms of both solidification and melting. The model is applied to simulate the microstructural evolution of columnar dendrites of SCN-ACE alloys during isothermal holding in a mushy zone. The CA simulations reproduce the typical dendrite coarsening features as observed in experiments. The role of melting for dendrite coarsening is quantified by comparing the simulation results using the new CA model and a previous CA model that does not include the melting effect. The mechanisms of dendrite coarsening are investigated in detail by comparing the local equilibrium and actual liquid compositions at solid/liquid interfaces. The CA simulations render visualizing how local solidification and melting stimulate each other through the complicated interactions between phase transformation, interface shape variation and solute diffusion.

朱鸣芳 , 邢丽科 , 方 辉 等 合金凝固枝晶粗化的研究进展

[J]. 金属学报 , 2018 , 54 : 789

DOI

[本文引用: 1]

枝晶是一种最常见的金属凝固显微组织。在大多数中低速的凝固过程中,枝晶组织发生粗化是一种不可避免的现象,对最终的凝固组织和产品性能产生重要影响。本文首先简要评述半个多世纪以来关于连续冷却和等温凝固过程中的枝晶粗化在理论研究、实验研究和数值模拟3方面的研究进展。随后,介绍作者课题组最近提出的一个包含凝固和熔化机制的元胞自动机(cellular automaton,CA)模型。采用该CA模型对SCN-ACE合金在固/液两相区等温过程中的枝晶粗化现象进行模拟研究,并对枝晶粗化过程中的凝固/熔化、界面几何形状和溶质扩散之间的复杂相互作用关系进行分析。

[31]

Wei J J Wang X D Yao M Field variable diffusion cellular automaton model for dendritic growth with multifold symmetry for the solidification of alloys

[J]. Modell. Simul. Mater. Sc. Eng. , 2021 , 29 : 075005

[本文引用: 1]

[32]

Lipton J Glicksman M E Kurz W Dendritic growth into undercooled alloy metals

[J]. Mater. Sci. Eng. , 1984 , 65 : 57

[本文引用: 1]

[33]

Liu L F A study on prediction of grain size and grain refining of cast Mg-Al alloys [D]. Wuhan : Wuhan University of Science and Technology , 2017

[本文引用: 1]

刘龙飞 铸造Mg-Al合金晶粒尺寸的预测及细化处理研究 [D]. 武汉 : 武汉科技大学 , 2017

[本文引用: 1]

[34]

Luo S Zhu M Y A two-dimensional model for the quantitative simulation of the dendritic growth with cellular automaton method

[J]. Comput. Mater. Sci. , 2013 , 71 : 10

[本文引用: 1]

[35]

Fu Z N Xu Q Y Xiong S M Microstructure simulation of magnesium alloy

[J]. Mater. Sci. Forum , 2007 , 546-549 : 133

[本文引用: 1]

[36]

Miao J M Jing T Liu B C Numerical simulation of dendritic morphology of magnesium alloys using phase field method

[J]. Acta Metall. Sin. , 2008 , 44 : 483

[本文引用: 1]

Due to Magnesium alloys with hcp crystal structure, we established the phase field model of dendritic growth in two dimensions. Using the model coupled with heat noise, we simulated the process of dendritic growth of Magnesium alloys. From simulation results, some phenomena of dendritic growth were found, such as necking and competitive growth, and there is a high consistency of dendritic morphologies between simulation and experiment. Meanwhile, we analyzed the influence of parameters on dendritic morphology.

缪家明 , 荆 涛 , 柳百成 镁合金枝晶形貌的相场方法模拟

[J]. 金属学报 , 2008 , 44 : 483

[本文引用: 1]

针对hcp晶系的镁合金, 建立了其二维枝晶生长的相场模型. 根据该模型编写模拟程序, 得到了具有六重对称性的晶粒形貌, 并根据模拟结果分析了温度场对其枝晶臂形成的影响; 根据该模型耦合热扰动进行镁合金微观组织模拟, 从计算结果中观察到了枝晶臂相互竞争、改变优先生长方向、颈缩、熔断、融合等现象; 计算得到的枝晶形貌与实验结果较为吻合. 同时还研究了参数的选取对镁合金枝晶发育的影响.

[37]

Yao J P Li X G Long W Y et al Numerical simulation of multiple grains with different preferred growth orientation of magnesium alloys using phase-field method

[J]. Chin. J. Nonferrous Met. , 2014 , 24 : 302

[本文引用: 1]

尧军平 , 李翔光 , 龙文元 等 镁合金不同取向多枝晶生长相场法模拟

[J]. 中国有色金属学报 , 2014 , 24 : 302

[本文引用: 1]

Modeling and numerical simulations of dendritic crystal growth

1

1993

... 合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键.合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径.枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法.弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法.PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难.尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法.CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] . ...

A numerical approach to three-dimensional dendritic solidification

1

1994

... 合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键.合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径.枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法.弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法.PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难.尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法.CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] . ...

Quantitative phase-field modeling of dendritic growth in two and three dimensions

1

1998

... 合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键.合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径.枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法.弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法.PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难.尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法.CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] . ...

Phase-field formulation for quantitative modeling of alloy solidification

1

2001

... 合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键.合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径.枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法.弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法.PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难.尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法.CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] . ...

Numerical model of solidification structure formation in Fe-C alloy with peritectic transformation

1

2008

... 合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键.合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径.枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法.弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法.PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难.尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法.CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] . ...

Modeling of dendritic evolution of continuously cast steel billet with cellular automaton

0

2018

Numerical simulation of solidification structure formation during continuous casting in Fe-0.7mass% C alloy using cellular automaton method

0

2006

A novel integrated model combining cellular automata and phase field methods for microstructure evolution during solidification of multi-component and multi-phase alloys

1

2011

... 合金凝固组织的形态、尺寸和分布等特征主导着材料的最终性能,理解枝晶的形成与演化机制是控制凝固过程的关键.合金凝固过程中的枝晶生长行为是涉及多物理场、非均相和时变性的复杂非线性问题,数值模拟可以精确量化枝晶生长过程中的各种现象及演化规律,是认识凝固微观组织形成机制的重要途径.枝晶生长模拟属于介观尺度的运动界面问题,主要有弥散界面模型和尖锐界面模型2种计算方法.弥散界面模型认为界面是具有一定厚度的边界层,各种物理性质在边界层内连续变化,代表性方法是相场(phase field,PF)法.PF法避免了追踪固-液界面的繁琐过程,易于处理复杂边界形貌[1 ,2 ] 和运动界面[3 ,4 ] 等问题,但PP法计算网格尺度较小,计算量巨大,与宏观尺度的耦合计算十分困难.尖锐界面模型则不考虑界面厚度,界面两侧的物理属性是突变的,代表性方法是元胞自动机(cellular automaton,CA)法.CA模型方法简单,易于实现且计算效率高,广泛应用于许多领域的跨尺度研究[5 ~8 ] . ...

Numerical modeling of solidification morphologies and segregation patterns in cast dendritic alloys

1

1999

... 在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题.在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长.由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍. ...

Simulation of a dendritic microstructure with the lattice Boltzmann and cellular automaton methods

1

2011

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

A quantitative dendrite growth model and analysis of stability concepts

2

2004

... 在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题.在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长.由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍. ...

... 尖端半径在较低和较高过冷度下存在一定偏差,而尖端生长速率在较高过冷度下存在差异.当过冷度较小时,生长速率低,生长排出的溶质有充足的时间扩散;在枝晶生长到相同长度时,相比于较低的过冷度,过冷度较高时枝晶臂粗化的程度更加明显,导致高过冷度下枝晶尖端平均曲率降低,枝晶半径减小.本工作模型计算结果与LGK模型预测结果在同一数量级,需要说明的是,LGK模型仅求解枝晶尖端形状,未考虑枝晶臂演化和界面曲率对生长速率的影响,枝晶尖端半径的计算和确定方法本身就存在一定偏差,故低过冷度下本模型计算得到的尖端生长速率高于LGK模型;随着过冷度增大,情况相反,本模型计算的尖端生长速率小于LGK模型,Beltran-Sanchez等[11 ] 和Luo等[34 ] 也得到了同样的结论. ...

Modeling and simulation of microstructure evolution of cast magnesium alloys using CA method based on two sets of mesh

1

2009

... 在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题.在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长.由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍. ...

基于两套网格的CA方法模拟铸造镁合金凝固过程枝晶形貌演化

1

2009

... 在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题.在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长.由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍. ...

Microstructure simulation of high pressure die cast magnesium alloy based on modified CA method

4

2010

... 基于以上建立的模型与计算程序,对等温凝固条件下单个枝晶生长的结果进行验证和分析.从随机择优取向和生长动力学2方面,模拟了具有六重对称特征的Mg-6%Al合金的枝晶形貌,模拟中使用的材料物性参数及计算参数如表1 [13 ] 所示.由于热量传输速率远大于溶质传递速率,因此将模拟区域设置为均匀温度场,只研究溶质扩散对枝晶生长的影响.模拟开始时,在计算域中心随机放置一个晶核.计算域元胞数目为551 × 551,Δ x Δ t

... 计算采用的Mg-6%Al合金热物性参数[13 ] ...

... Thermophysical properties of Mg-6%Al alloy used in the calculations[13 ] ...

... 凝固初期,所有枝晶均沿其择优生长方向发展,与温度梯度方向相近的主枝晶臂生长速率较快,如图11a 所示.随着凝固的进行,出现“竞争生长”现象.择优取向与温度梯度方向相近的枝晶继续生长,主枝晶臂两侧出现了不同程度的侧向分支;由于相邻枝晶的影响,择优取向不利的主枝晶臂生长均受到抑制,与吴孟武和熊守美[13 ] 模拟镁合金定向凝固不同温度梯度和凝固速率下柱状晶的竞争生长观察的现象一致.最终仅有5个枝晶的主枝晶臂继续生长,二次枝晶臂的发展也较完全,且与主枝晶臂间的夹角为60º.由于3# 、17# 枝晶与边界间距较大,溶质浓度较低,在朝向边界的方向均发展出了三次枝晶臂.图11b 和c 标示出了择优生长方向与温度梯度方向一致的枝晶编号.可以看出,9# 、15# 、19# 枝晶虽然取向有利,但在生长过程中受到相邻枝晶二次枝晶臂的阻挡,仍然被逐渐“淘汰”.如图11d 红色方框所示,二次枝晶生长过程中,溶质富集在枝晶根部,产生“颈缩”现象. ...

基于改进CA方法的压铸镁合金微观组织模拟

4

2010

... 基于以上建立的模型与计算程序,对等温凝固条件下单个枝晶生长的结果进行验证和分析.从随机择优取向和生长动力学2方面,模拟了具有六重对称特征的Mg-6%Al合金的枝晶形貌,模拟中使用的材料物性参数及计算参数如表1 [13 ] 所示.由于热量传输速率远大于溶质传递速率,因此将模拟区域设置为均匀温度场,只研究溶质扩散对枝晶生长的影响.模拟开始时,在计算域中心随机放置一个晶核.计算域元胞数目为551 × 551,Δ x Δ t

... 计算采用的Mg-6%Al合金热物性参数[13 ] ...

... Thermophysical properties of Mg-6%Al alloy used in the calculations[13 ] ...

... 凝固初期,所有枝晶均沿其择优生长方向发展,与温度梯度方向相近的主枝晶臂生长速率较快,如图11a 所示.随着凝固的进行,出现“竞争生长”现象.择优取向与温度梯度方向相近的枝晶继续生长,主枝晶臂两侧出现了不同程度的侧向分支;由于相邻枝晶的影响,择优取向不利的主枝晶臂生长均受到抑制,与吴孟武和熊守美[13 ] 模拟镁合金定向凝固不同温度梯度和凝固速率下柱状晶的竞争生长观察的现象一致.最终仅有5个枝晶的主枝晶臂继续生长,二次枝晶臂的发展也较完全,且与主枝晶臂间的夹角为60º.由于3# 、17# 枝晶与边界间距较大,溶质浓度较低,在朝向边界的方向均发展出了三次枝晶臂.图11b 和c 标示出了择优生长方向与温度梯度方向一致的枝晶编号.可以看出,9# 、15# 、19# 枝晶虽然取向有利,但在生长过程中受到相邻枝晶二次枝晶臂的阻挡,仍然被逐渐“淘汰”.如图11d 红色方框所示,二次枝晶生长过程中,溶质富集在枝晶根部,产生“颈缩”现象. ...

A two-dimensional diffusion model for the prediction of phase transformations: Application to austenitization and homogenization of hypoeutectoid Fe-C steels

1

1997

... 在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题.在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长.由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍. ...

Anisotropy in cellular automata

1

1997

... 在经典的CA模型中,枝晶形貌与生长动力学出现了强烈的各向异性,这是模型计算中无法忽视的关键问题.在枝晶生长模拟中主要表现为两方面:(1) 枝晶对称次数受元胞几何形状的影响十分显著,二维正方形元胞易于模拟四重对称的枝晶形貌[9 ~11 ] ,而正六边形元胞则用于模拟六重对称的枝晶形貌[12 ~14 ] ;(2) 难以模拟具有不同随机择优取向的枝晶生长,即,无强制手段干预时枝晶通常沿网格坐标轴方向生长.由元胞几何特征、邻胞构造与捕获规则等因素导致的各向异性,导致CA模型计算结果偏离实际行为和现象[15 ] ,成为限制CA模型应用和发展的障碍. ...

A cellular automaton model for the solidification of a pure substance

1

2011

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

A cellular automaton model for dendrite growth in magnesium alloy AZ91

2

2009

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

... 模拟了连续冷却条件下Mg-6%Al合金多个等轴晶的枝晶生长过程,计算域网格数目650 × 650,Δ x Δ T 图10a1~a4 和图10b1~b4 分别为随机设置8个和30个晶核,Mg-6%Al合金等轴晶形貌及溶质浓度随时间的演化.晶核数目为8时,在凝固初期(0.48 s),枝晶生长速率较快,主枝晶臂沿其择优取向生长,并且主枝晶臂的两侧产生二次枝晶臂;随着凝固的进行(2.64 s),枝晶周围液相溶质富集,相邻枝晶溶质场的相互作用变得越来越强,使一些枝晶臂偏离其择优取向生长,六重对称的枝晶形貌发生了明显的变化.凝固5.60 s时,溶质在枝晶臂间熔体内进一步富集,导致溶质扩散及尖端生长受到明显抑制.凝固后期(10.00 s),枝晶生长速率进一步降低,Gibbs-Thomson效应导致枝晶臂粗化.晶核数目为30时的枝晶生长规律与8个时基本相同,但由于枝晶的相互阻碍作用较强,二次枝晶臂的发展被抑制.Yin和Felicelli[17 ] 采用正六边形元胞CA模型模拟得到Mg-8.9%Al的枝晶形貌,主枝晶臂只能沿着与x 轴正方向呈60°夹角的方向生长,但无法实现枝晶偏转.本模型采用正方形元胞模拟得到六重对称合金枝晶形貌,与相场法得到的镁合金多枝晶生长形貌和溶质场分布结果[37 ] 大致相符. ...

1

2012

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

1

2012

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

Virtual front tracking model for the quantitative modeling of dendritic growth in solidification of alloys

1

2007

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

Probabilistic modelling of microstructure formation in solidification processes

1

1993

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

A model of solidification microstructures in nickel-based superalloys: Predicting primary dendrite spacing selection

0

2003

Dendrite growth simulation during solidification in the LENS process

0

2010

Dendrite growth model using front tracking technique with new growth algorithm

1

2006

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

Modeling of dendrite growth for the cast Magnesium alloy

1

2007

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

铸造镁合金的枝晶生长模拟

1

2007

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

Growth of solutal dendrites—A cellular automaton model

1

2003

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

Modeling of equiaxed and columnar dendritic growth of magnesium alloy

1

2012

... 鉴于以上原因,CA凝固组织模拟的一项重要内容即在于弱化甚至消除网格依赖性对生长动力学和择优生长方向的影响,代表性研究包括随机性方法(random zig-zag[16 ] )和确定性方法(角点生长算法[17 ,18 ] 、虚拟界面跟踪法[10 ,19 ] 、偏心算法[20 ~23 ] 、坐标系变换[24 ] 及定义多层邻居元胞[25 ] 、类6重对称的邻胞设置[26 ] 等) 2类.上述修正算法在不同程度上弱化了枝晶形貌的各向异性,通常用于模拟单一的四重或六重对称枝晶形貌,难以拓展至多维、多相的合金凝固过程模拟.因此,构建能够实现不同对称次数、不同择优取向枝晶生长的通用CA模型,对于拓展CA方法在合金凝固领域的应用是十分必要的. ...

1

2008

... 采用梯度下降法[27 ] 求解 式(2) ,E ( u ) u ( x , y )

1

2008

... 采用梯度下降法[27 ] 求解 式(2) ,E ( u ) u ( x , y )

Growth of solutal dendrites: A cellular automaton model and its quantitative capabilities

1

2003

... 因此,采用浓度势[28 ] 的方法进行计算,定义浓度势(P ) :液相元胞P = C L P = C S / k P = C L . 式(10) 可以改写为 式(11) : ...

1

2005

... 式中,T T L C 0 m L Γ K m - 1 φ θ f φ , θ K [29 ] 、φ f φ , θ 14 )~(16 ). ...

1

2005

... 式中,T T L C 0 m L Γ K m - 1 φ θ f φ , θ K [29 ] 、φ f φ , θ 14 )~(16 ). ...

Progresses in dendrite coarsening during solidification of alloys

1

2018

... 式中,δ k [30 ] .当(C e p r e C L * p r e C e C L * ) > 0时,界面元胞的Δ f S C e p r e C L * p r e C e C L * ) < 0时,局部固-液界面发生熔化(Δ f S

合金凝固枝晶粗化的研究进展

1

2018

... 式中,δ k [30 ] .当(C e p r e C L * p r e C e C L * ) > 0时,界面元胞的Δ f S C e p r e C L * p r e C e C L * ) < 0时,局部固-液界面发生熔化(Δ f S

Field variable diffusion cellular automaton model for dendritic growth with multifold symmetry for the solidification of alloys

1

2021

... 图4 为择优取向为0º、15º、36º及45º的Mg-6%Al合金在凝固时间为0.455 s时的枝晶形貌.计算域元胞数目551 × 551,Δ x Δ T [31 ] 对3 K过冷度Al-4%Cu合金四重对称枝晶形貌和不同择优取向的枝晶形貌进行了模拟,结果表明,所有枝晶的偏转方向均与预设生长角度相符,各枝晶形貌及分支间夹角基本一致. ...

Dendritic growth into undercooled alloy metals

1

1984

... 图8 为Mg-6%Al合金在不同过冷度下,模拟得到的枝晶尖端特征与Lipton-Glicksman-Kurz (LGK)模型[32 ] 计算数据的对比结果.两模型预测的生长速率和尖端半径随过冷度变化的趋势相似,即随着过冷度的增大,枝晶尖端稳态生长速率逐渐增加,尖端半径逐渐减小,且2者数量级均为10-5 .刘龙飞[33 ] 基于LGK模型,探讨了过冷度对Mg-Al合金凝固时枝晶尖端生长半径及生长速率的影响,当过冷度从0.5 K增加至5 K时,枝晶尖端生长速率从2 × 10-5 m/s增加到8 × 10-5 m/s,尖端半径从1 × 10-5 m降低至2 × 10-6 m,研究结果与本工作结果在同一数量级,尖端半径和生长速率随过冷度的变化趋势一致. ...

1

2017

... 图8 为Mg-6%Al合金在不同过冷度下,模拟得到的枝晶尖端特征与Lipton-Glicksman-Kurz (LGK)模型[32 ] 计算数据的对比结果.两模型预测的生长速率和尖端半径随过冷度变化的趋势相似,即随着过冷度的增大,枝晶尖端稳态生长速率逐渐增加,尖端半径逐渐减小,且2者数量级均为10-5 .刘龙飞[33 ] 基于LGK模型,探讨了过冷度对Mg-Al合金凝固时枝晶尖端生长半径及生长速率的影响,当过冷度从0.5 K增加至5 K时,枝晶尖端生长速率从2 × 10-5 m/s增加到8 × 10-5 m/s,尖端半径从1 × 10-5 m降低至2 × 10-6 m,研究结果与本工作结果在同一数量级,尖端半径和生长速率随过冷度的变化趋势一致. ...

1

2017

... 图8 为Mg-6%Al合金在不同过冷度下,模拟得到的枝晶尖端特征与Lipton-Glicksman-Kurz (LGK)模型[32 ] 计算数据的对比结果.两模型预测的生长速率和尖端半径随过冷度变化的趋势相似,即随着过冷度的增大,枝晶尖端稳态生长速率逐渐增加,尖端半径逐渐减小,且2者数量级均为10-5 .刘龙飞[33 ] 基于LGK模型,探讨了过冷度对Mg-Al合金凝固时枝晶尖端生长半径及生长速率的影响,当过冷度从0.5 K增加至5 K时,枝晶尖端生长速率从2 × 10-5 m/s增加到8 × 10-5 m/s,尖端半径从1 × 10-5 m降低至2 × 10-6 m,研究结果与本工作结果在同一数量级,尖端半径和生长速率随过冷度的变化趋势一致. ...

A two-dimensional model for the quantitative simulation of the dendritic growth with cellular automaton method

1

2013

... 尖端半径在较低和较高过冷度下存在一定偏差,而尖端生长速率在较高过冷度下存在差异.当过冷度较小时,生长速率低,生长排出的溶质有充足的时间扩散;在枝晶生长到相同长度时,相比于较低的过冷度,过冷度较高时枝晶臂粗化的程度更加明显,导致高过冷度下枝晶尖端平均曲率降低,枝晶半径减小.本工作模型计算结果与LGK模型预测结果在同一数量级,需要说明的是,LGK模型仅求解枝晶尖端形状,未考虑枝晶臂演化和界面曲率对生长速率的影响,枝晶尖端半径的计算和确定方法本身就存在一定偏差,故低过冷度下本模型计算得到的尖端生长速率高于LGK模型;随着过冷度增大,情况相反,本模型计算的尖端生长速率小于LGK模型,Beltran-Sanchez等[11 ] 和Luo等[34 ] 也得到了同样的结论. ...

Microstructure simulation of magnesium alloy

1

2007

... 在枝晶生长过程中,枝晶臂粗化,溶质扩散区域逐渐增大.枝晶尖端排出的溶质沿其生长方向和周围两侧扩散,而枝晶臂粗化排出的溶质只能向两侧扩散,故枝晶尖端溶质浓度低于主枝晶臂两侧浓度,进而获得了较大的过冷度,生长速率加快.在枝晶根部,枝晶臂交汇造成溶质富集,枝晶生长受到抑制,根部出现“颈缩”现象.需要指出,如果利用经典的正方形元胞CA模型计算六重枝晶的生长行为,不仅计算中的处理十分繁琐,且不同择优取向枝晶的生长速率也会出现较大的差异.Fu等[35 ] 利用正方形元胞CA模型模拟了AZ91D合金的枝晶形貌,结果表明处于不同方向的主枝晶臂生长速率不一致,且主枝晶臂之间的夹角也不相等,与实际均匀温度场下的枝晶形貌不符.与之相比,本模型模拟得到的6个枝晶臂长度相等,侧枝角度对称,与相场法得到的结果[36 ] 基本一致. ...

Numerical simulation of dendritic morphology of magnesium alloys using phase field method

1

2008

... 在枝晶生长过程中,枝晶臂粗化,溶质扩散区域逐渐增大.枝晶尖端排出的溶质沿其生长方向和周围两侧扩散,而枝晶臂粗化排出的溶质只能向两侧扩散,故枝晶尖端溶质浓度低于主枝晶臂两侧浓度,进而获得了较大的过冷度,生长速率加快.在枝晶根部,枝晶臂交汇造成溶质富集,枝晶生长受到抑制,根部出现“颈缩”现象.需要指出,如果利用经典的正方形元胞CA模型计算六重枝晶的生长行为,不仅计算中的处理十分繁琐,且不同择优取向枝晶的生长速率也会出现较大的差异.Fu等[35 ] 利用正方形元胞CA模型模拟了AZ91D合金的枝晶形貌,结果表明处于不同方向的主枝晶臂生长速率不一致,且主枝晶臂之间的夹角也不相等,与实际均匀温度场下的枝晶形貌不符.与之相比,本模型模拟得到的6个枝晶臂长度相等,侧枝角度对称,与相场法得到的结果[36 ] 基本一致. ...

镁合金枝晶形貌的相场方法模拟

1

2008

... 在枝晶生长过程中,枝晶臂粗化,溶质扩散区域逐渐增大.枝晶尖端排出的溶质沿其生长方向和周围两侧扩散,而枝晶臂粗化排出的溶质只能向两侧扩散,故枝晶尖端溶质浓度低于主枝晶臂两侧浓度,进而获得了较大的过冷度,生长速率加快.在枝晶根部,枝晶臂交汇造成溶质富集,枝晶生长受到抑制,根部出现“颈缩”现象.需要指出,如果利用经典的正方形元胞CA模型计算六重枝晶的生长行为,不仅计算中的处理十分繁琐,且不同择优取向枝晶的生长速率也会出现较大的差异.Fu等[35 ] 利用正方形元胞CA模型模拟了AZ91D合金的枝晶形貌,结果表明处于不同方向的主枝晶臂生长速率不一致,且主枝晶臂之间的夹角也不相等,与实际均匀温度场下的枝晶形貌不符.与之相比,本模型模拟得到的6个枝晶臂长度相等,侧枝角度对称,与相场法得到的结果[36 ] 基本一致. ...

Numerical simulation of multiple grains with different preferred growth orientation of magnesium alloys using phase-field method

1

2014

... 模拟了连续冷却条件下Mg-6%Al合金多个等轴晶的枝晶生长过程,计算域网格数目650 × 650,Δ x Δ T 图10a1~a4 和图10b1~b4 分别为随机设置8个和30个晶核,Mg-6%Al合金等轴晶形貌及溶质浓度随时间的演化.晶核数目为8时,在凝固初期(0.48 s),枝晶生长速率较快,主枝晶臂沿其择优取向生长,并且主枝晶臂的两侧产生二次枝晶臂;随着凝固的进行(2.64 s),枝晶周围液相溶质富集,相邻枝晶溶质场的相互作用变得越来越强,使一些枝晶臂偏离其择优取向生长,六重对称的枝晶形貌发生了明显的变化.凝固5.60 s时,溶质在枝晶臂间熔体内进一步富集,导致溶质扩散及尖端生长受到明显抑制.凝固后期(10.00 s),枝晶生长速率进一步降低,Gibbs-Thomson效应导致枝晶臂粗化.晶核数目为30时的枝晶生长规律与8个时基本相同,但由于枝晶的相互阻碍作用较强,二次枝晶臂的发展被抑制.Yin和Felicelli[17 ] 采用正六边形元胞CA模型模拟得到Mg-8.9%Al的枝晶形貌,主枝晶臂只能沿着与x 轴正方向呈60°夹角的方向生长,但无法实现枝晶偏转.本模型采用正方形元胞模拟得到六重对称合金枝晶形貌,与相场法得到的镁合金多枝晶生长形貌和溶质场分布结果[37 ] 大致相符. ...

镁合金不同取向多枝晶生长相场法模拟

1

2014

... 模拟了连续冷却条件下Mg-6%Al合金多个等轴晶的枝晶生长过程,计算域网格数目650 × 650,Δ x Δ T 图10a1~a4 和图10b1~b4 分别为随机设置8个和30个晶核,Mg-6%Al合金等轴晶形貌及溶质浓度随时间的演化.晶核数目为8时,在凝固初期(0.48 s),枝晶生长速率较快,主枝晶臂沿其择优取向生长,并且主枝晶臂的两侧产生二次枝晶臂;随着凝固的进行(2.64 s),枝晶周围液相溶质富集,相邻枝晶溶质场的相互作用变得越来越强,使一些枝晶臂偏离其择优取向生长,六重对称的枝晶形貌发生了明显的变化.凝固5.60 s时,溶质在枝晶臂间熔体内进一步富集,导致溶质扩散及尖端生长受到明显抑制.凝固后期(10.00 s),枝晶生长速率进一步降低,Gibbs-Thomson效应导致枝晶臂粗化.晶核数目为30时的枝晶生长规律与8个时基本相同,但由于枝晶的相互阻碍作用较强,二次枝晶臂的发展被抑制.Yin和Felicelli[17 ] 采用正六边形元胞CA模型模拟得到Mg-8.9%Al的枝晶形貌,主枝晶臂只能沿着与x 轴正方向呈60°夹角的方向生长,但无法实现枝晶偏转.本模型采用正方形元胞模拟得到六重对称合金枝晶形貌,与相场法得到的镁合金多枝晶生长形貌和溶质场分布结果[37 ] 大致相符. ...