Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] 。Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] 。研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一。

热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关。研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升。马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区。朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为。赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性。目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少。Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功。究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] 。而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求。因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力。

本工作针对航空航天领域对高温形状记忆合金的需求,以Ti30 Ni50 Hf20 高温形状记忆合金为研究对象,通过热模拟实验研究该合金在不同温度和变形速率下的热变形行为,建立该合金的本构方程及热加工图,研究热变形工艺对合金流变应力、组织演化的影响,为Ti-Ni-Hf高温形状记忆合金的热加工工艺提供数据支持和理论依据。

1 实验方法

按Ti∶Ni∶Hf = 3∶5∶2的原子配比将高纯海绵Ti、电解Ni以及海绵Hf进行配料,采用真空感应炉进行合金熔炼,打磨后的试样尺寸为直径45 mm、长80 mm,成形后的合金按照GB/T 14265—2017和GB/T 23942—2009测得其化学成分(质量分数,%)为:Ni 36.8,Hf 45.2,Cr 0.004,Fe 0.028,Nb 0.006,C 0.0053,N 0.0024,O 0.043,H 0.0011,Ti余量。利用线切割在合金铸锭上切取直径8 mm、长12 mm的热模拟压缩试样,机加至表面光亮。采用Gleeble-3800热模拟试验机进行热模拟压缩实验,热变形参数为:应变速率0.01、0.1、1和10 s-1 ,变形温度700、800和900 ℃,升温速率10 ℃/s。试样升到实验温度后保温5 min,总压缩变形量为80%,将样品立刻取出水淬,以保留其在高温变形下的组织状态。将原始样品及热压缩后样品线切割后进行机械磨抛,采用体积比为HNO3 ∶HF∶H2 O = 1∶4∶5的腐蚀液对样品进行腐蚀,利用Axiovert 200MAT金相显微镜(OM)进行组织观察。利用Q1000差示扫描量热仪(DSC)进行相变行为测试。

2 实验结果与讨论

2.1 显微组织与相变温度

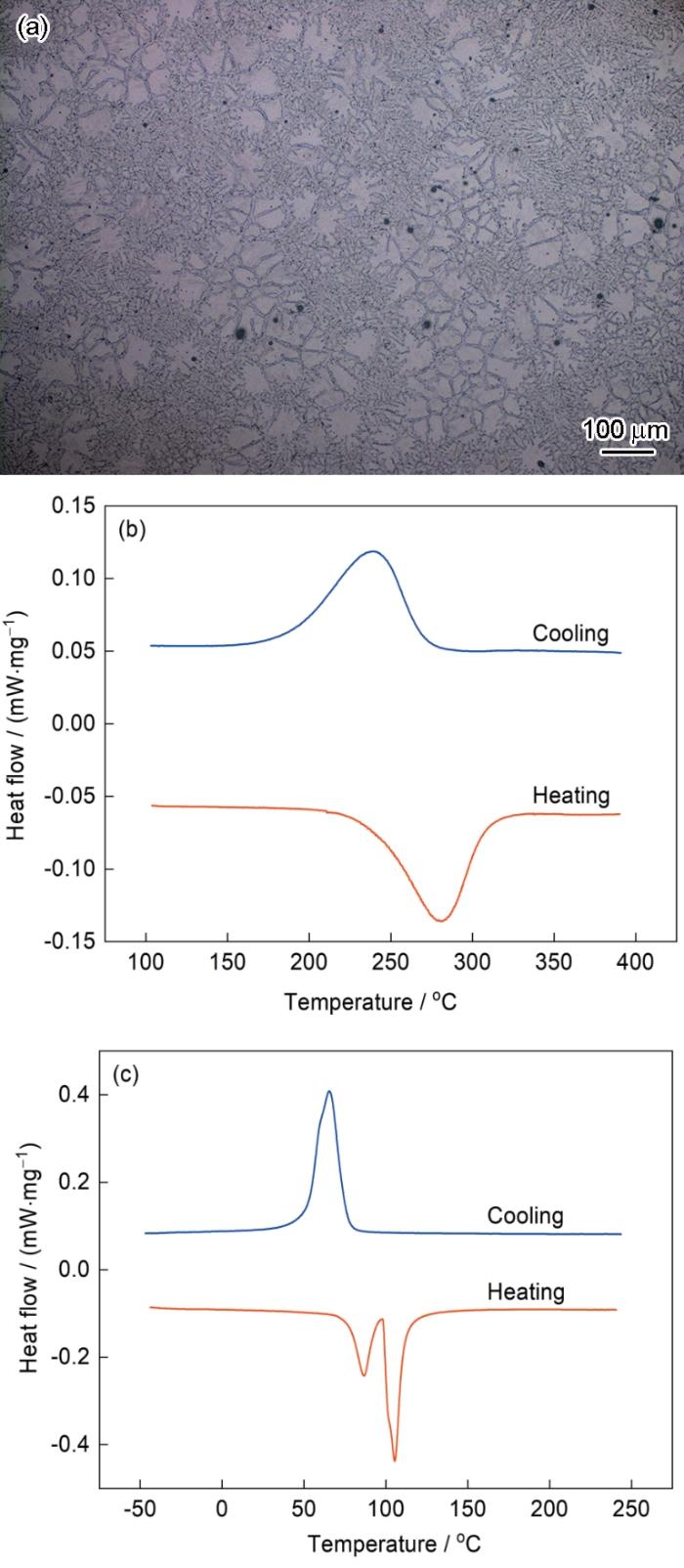

铸态Ti30 Ni50 Hf20 高温形状记忆合金的显微组织OM像和DSC曲线分别如图1a 和b所示。可以看出,铸态Ti30 Ni50 Hf20 高温形状记忆合金的显微组织由枝晶和胞晶构成,马氏体相变开始温度为271 ℃。图1c 为Ti50 Ni50 形状记忆合金的DSC曲线,马氏体相变开始温度为76 ℃。可见,添加Hf元素后的Ti30 Ni50 Hf20 高温形状记忆合金,其马氏体相变开始温度较传统等原子比Ti-Ni合金提高了195 ℃。

图1

图1

铸态Ti30 Ni50 Hf20 高温形状记忆合金的显微组织OM像和DSC曲线及Ti50 Ni50 形状记忆合金的DSC曲线

Fig.1

OM image (a) and DSC curve (b) for as-cast Ti30 Ni50 Hf20 high-temperature shape memory alloy, and DSC curve for as-cast Ti50 Ni50 shape memory alloy (c)

2.2 流变应力- 应变曲线

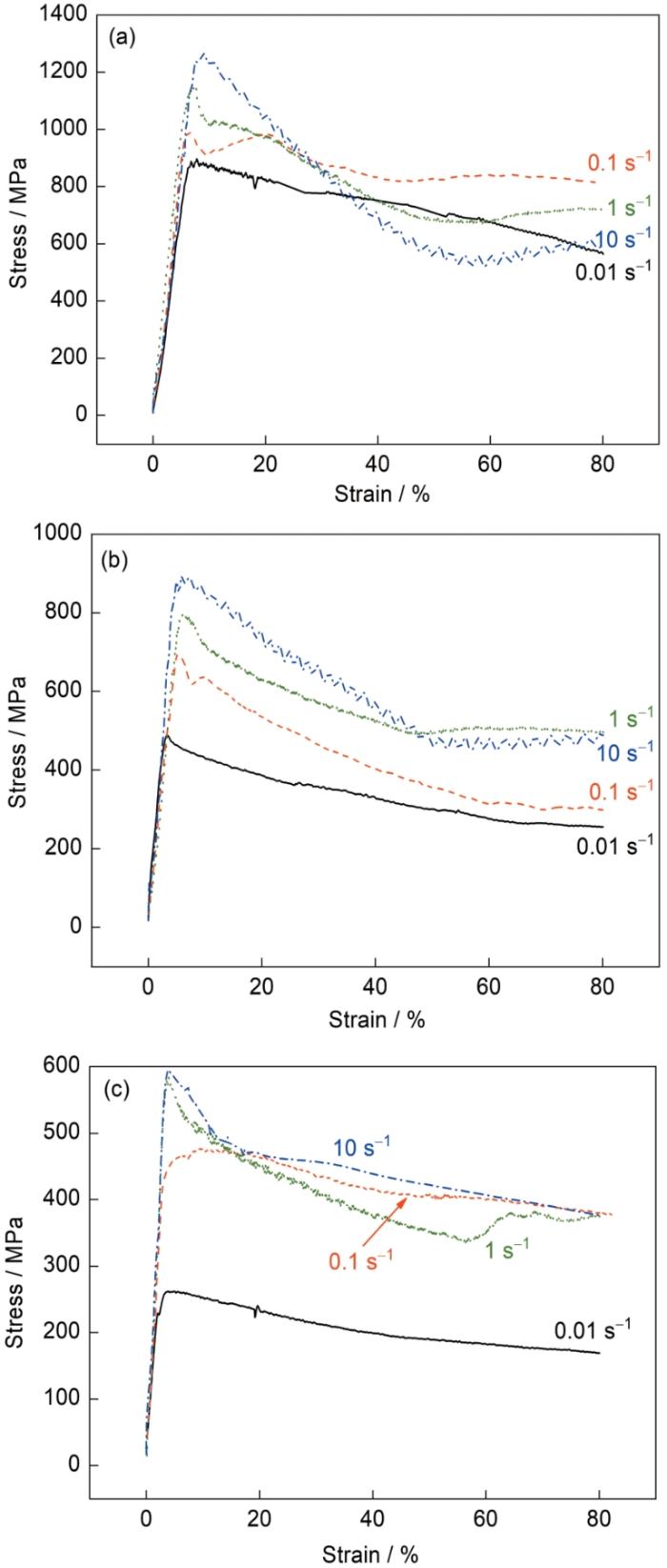

不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示。可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] 。第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化。在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] 。第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] 。

图2

图2

不同温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金应力-应变曲线

Fig.2

Stress-strain curves of Ti30 Ni50 Hf20 high-temperature shape memory alloy at different temperatures and strain rates (ε ˙ )

(a) 700 o C (b) 800 o C (c) 900 o C

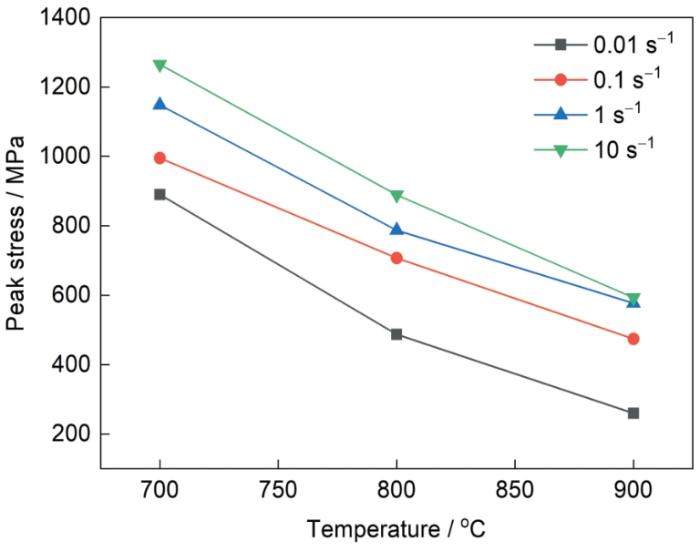

图3 是不同应变速率下峰值应力与变形温度的关系曲线。可以看出,Ti30 Ni50 Hf20 合金热变形的峰值应力与变形温度、应变速率密切相关。在恒定的应变速率下,随变形温度升高合金的峰值应力降低;在恒定的变形温度下,随应变速率升高合金的峰值应力增大。基于图3 曲线的变化规律,Ti30 Ni50 Hf20 合金的热变形峰值应力随变形温度降低或应变速率升高而升高,为负温度及正应变敏感材料[21 ] 。

图3

图3

Ti30 Ni50 Hf20 高温形状记忆合金峰值应力随温度和应变速率变化曲线

Fig.3

Variation curves of peak stress (σ p ) of Ti30 Ni50 Hf20 high-temperature shape memory alloy with temperature and ε ˙

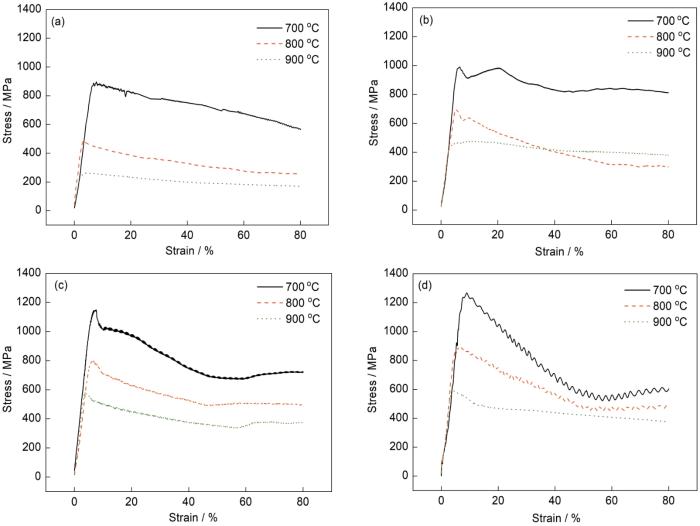

变形温度对Ti30 Ni50 Hf20 合金流变应力的影响规律如图4 所示。可以看出,随着变形温度升高流变应力逐渐减小,达到峰值的应变逐渐减小。这是因为在高温变形过程中,随着变形温度升高,材料的热激活能作用增强,原子间结合力降低,导致晶体在产生滑移时的临界分切应力呈现下降趋势,因此合金的流变应力随温度升高而降低;当流变应力达到峰值后,变形过程中合金内部产生大量位错导致合金发生动态再结晶、动态回复等,致使合金发生软化效应,应力-应变曲线趋于平缓[22 ,23 ] 。

图4

图4

不同变形温度下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线

Fig.4

Stress-strain curves of Ti30 Ni50 Hf20 high-temperature shape memory alloy under different deformation temperatures at strain rates of 0.01 s-1 (a), 0.1 s-1 (b), 1 s-1 (c), and 10 s-1 (d)

2.3 本构方程

由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1)~(3)对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] :

ε ˙ = A 1 σ p n 1 e x p - Q R T ( α σ p < 0.8 ) (1)

ε ˙ = A 2 e x p β σ p - Q R T ( α σ p > 1.2 ) (2)

ε ˙ = A s i n h α σ p n e x p - Q R T (3)

式中,ε ˙ σ p 为峰值应力(MPa);A 、A 1 和A 2 为结构因子(s-1 );n 和n 1 为加工硬化指数;R 为气体常数(8.3145 J/(mol·K));Q 为变形激活能(J/mol);T 为变形温度(K);β 为与材料有关的参数;α 为应力水平参数。当合金在高温变形过程中满足以上3种关系,即式(1)~(3)时,则变形过程中变形激活能与温度无关,对上述公式分别取对数,可以得到:

l n ε ˙ = l n A 1 + n 1 l n σ p - Q R T ( α σ p < 0.8 ) (4)

l n ε ˙ = l n A 2 + β σ p - Q R T ( α σ p > 1.2 ) (5)

l n ε ˙ = l n A + n l n [ s i n h ( α σ p ) ] - Q R T (6)

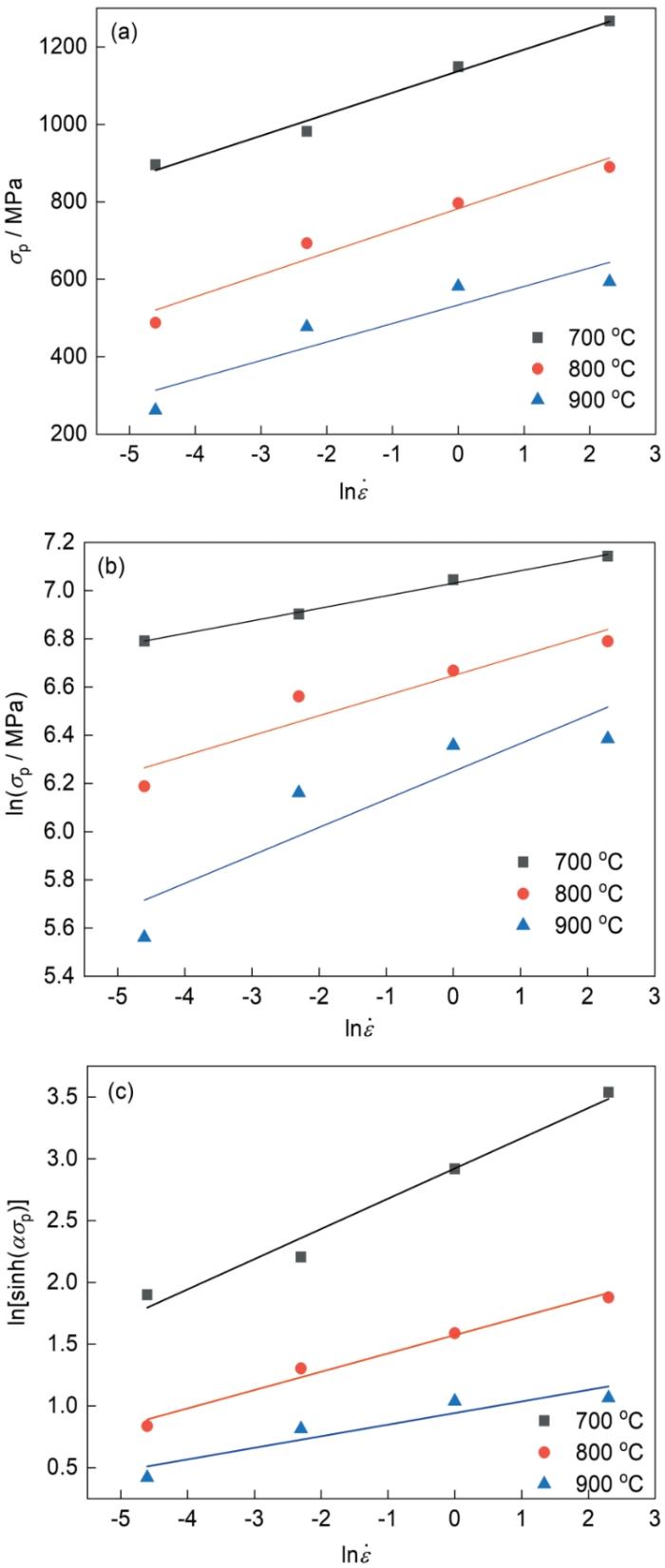

将不同变形温度下Ti30 Ni50 Hf20 高温形状记忆合金的峰值应力(图4 )与应变速率分别代入 式(5)和(6)中,得到的峰值应力与应变速率之间关系图,如图5 所示。其中图5a 的斜率为1 / β ,图5b 的斜率为1 / n 1 ,根据α = β / n 1 ,计算得出n 1 = 12.04,β = 0.018,α = 0.0015。将α 和应变速率代入到 式(6)中建立ln[sinh(ασ p )]与l n ε ˙ 图5c ),结果表明ln[sinh(ασ p )]与l n ε ˙

图5

图5

Ti30 Ni50 Hf20 高温形状记忆合金峰值应力与应变速率的关系

Fig.5

Relationships between σ p and ε ˙ 30 Ni50 Hf20 high-temperature shape memory alloy

(a) σ p -lnε ˙ σ p -lnε ˙

(c) ln[sinh(ασ p )]-lnε ˙ α —stress level parameter)

采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] :

Z = A [ s i n h ( α σ p ) ] n = ε ˙ e x p Q R T (7)

当应变速率一定时,假设在一定范围内Q 保持不变,对 式(7)进行对数转换可以得到:

l n Z = l n A + n l n [ s i n h ( α σ p ) ] = l n ε ˙ + Q R T (8)

l n [ s i n h ( α σ p ) ] = A ' + B ' 1000 T (9)

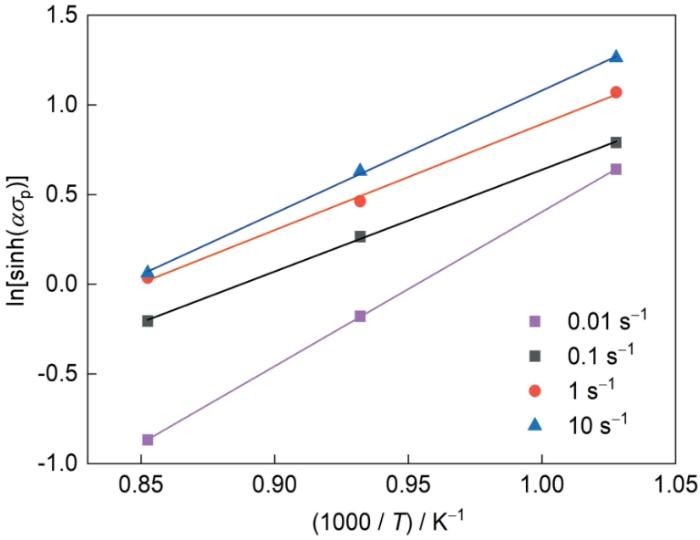

图6

图6

Ti30 Ni50 Hf20 高温形状记忆合金ln[sinh(ασ p )]与1000 / T 的关系

Fig.6

Relationship between ln[sinh(ασ p )] and 1000 / T of Ti30 Ni50 Hf20 high-temperature shape memory alloy

将ln[sinh(ασ p )]与T 代入上 式(9),根据关系式绘制Ti30 Ni50 Hf20 合金ln[sinh(ασ p )]与1000 / T 的关系图,如图6 所示。可见,ln[sinh(ασ p )]与1000 / T 之间符合线性关系。

然后运用Zener-Holloman参数法求解Ti30 Ni50 Hf20 合金高温塑性变形的变形激活能等材料常数。根据 式(6),可以得到[24 ] :

Q = R ∂ l n [ s i n h ( α σ p ) ] ∂ 1 T ε ˙ ∂ l n ε ˙ ∂ l n [ s i n h α σ p ] T (10)

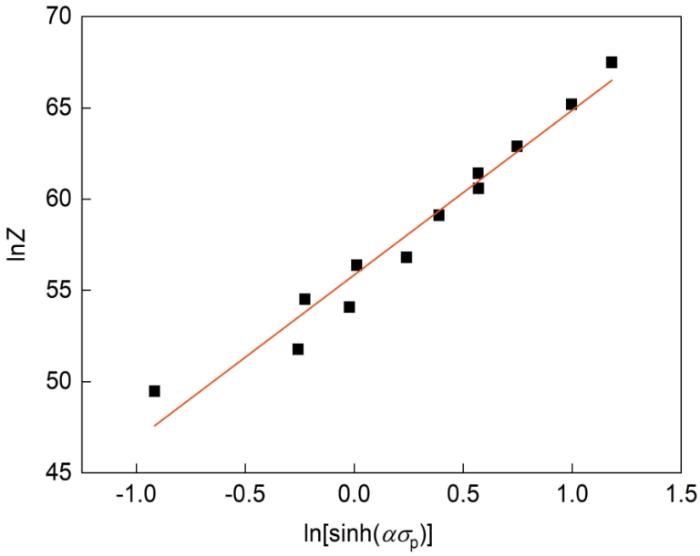

式中,∂ l n [ s i n h ( α σ p ) ] ∂ 1 T ασ p )]-1000 / T 函数关系斜率(图6 ),ε ˙ ∂ l n ε ˙ ∂ l n [ s i n h ( α σ p ) ] ασ p )]-l n ε ˙ 图5c ),将R 和上述2个斜率值代到 式(10)中可求出Q ,将Q 代入 式(7)中可以计算出Z 和lnZ ,绘制出lnZ-ln[sinh(ασ p )]之间的函数关系式,如图7 所示。图7 表明,lnZ -ln[sinh(ασ p )]在应变速率为0.01~10 s-1 和变形温度为700~900 ℃的条件下,符合线性关系,表明本工作实验拟合结果正确。

图7

图7

Ti30 Ni50 Hf20 高温形状记忆合金lnZ 与ln[sinh(α σ p

Fig.7

Relationship between lnZ and ln[sinh(ασ p )] of Ti30 Ni50 Hf20 high-temperature shape memory alloy (Z —Zener-Hollmon parameter)

l n Z - ln[sinh(ασ p )]函数关系的斜率和截距分别为n 和lnA 。计算得出Q = 527.447 kJ/mol,n = 9.59,lnA = 56.2。得到Ti30 Ni50 Hf20 高温形状记忆合金的本构方程为:

ε ˙ = e x p 56.2 - 527.447 R T [ s i n h ( 0.0015 σ p ) ] 9.59 (11)

Z = 2.56 × 10 24 [ s i n h ( 0.0015 σ p ) ] 9.59 = ε ˙ e x p 527.447 8.3145 T (12)

σ p = 1 0.0015 l n Z 56.2 1 9.59 + Z 56.2 2 9.59 + 1 1 2 (13)

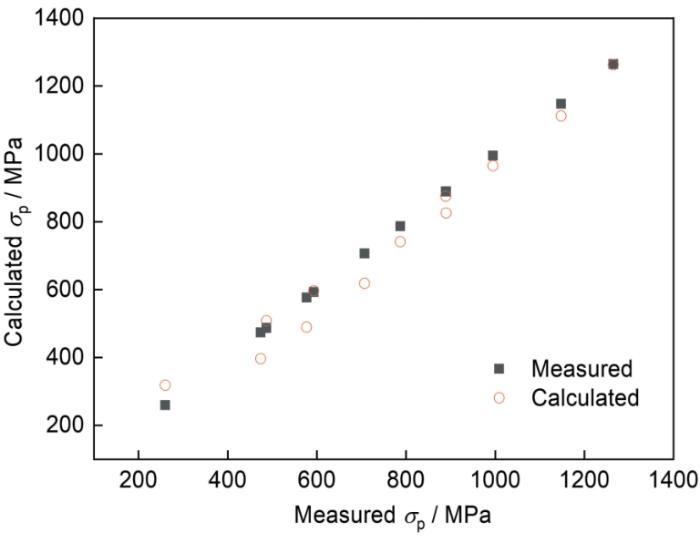

将变形温度和应变速率代入 式(7)求得Z ,再将Z 代入 式(13)中进行Ti30 Ni50 Hf20 高温形状记忆合金本构方程验证,计算出峰值应力,计算值与实验值的对比如图8 所示。可以看出,理论计算值与实验值相吻合,采用上述分析建立的本构方程计算的结果能较好地反映实验结果,因此本工作通过计算建立的本构方程可以很好地表征Ti30 Ni50 Hf20 合金的热变形特性。

图8

图8

Ti30 Ni50 Hf20 高温形状记忆合金峰值应力理论计算值与实验值对比图

Fig.8

Comparisons of measured and calculated peak stresses of Ti30 Ni50 Hf20 high-temperature shape memory alloy

2.4 热变形过程中合金组织变化

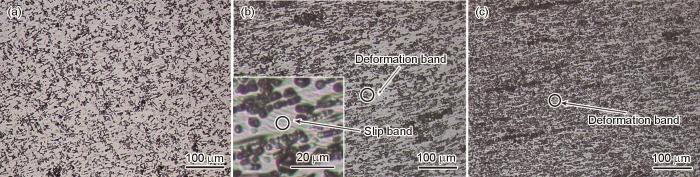

图9 为Ti30 Ni50 Hf20 高温形状记忆合金在应变速率为0.01 s-1 时不同变形温度下显微组织的OM像。可以看出,与原始组织(图1a )相比,枝晶和胞晶消失,变形后合金组织呈现一定的流线特征(图9a 和b )。随着变形温度升高,再结晶现象逐渐显著。当变形温度为800 ℃时(图9b ),在变形带附近出现尺寸较小的再结晶晶粒;当变形温度为900 ℃时(图9c ),大部分晶粒都发生了再结晶,而再结晶的发生也是图4a 中当流变应力达到峰值后迅速降低的主要原因。在再结晶的作用下,合金产生的软化与加工硬化相互抵消,最终导致流变应力达到动态稳定(图4a ),应力-应变曲线则表现为流变应力随变形温度升高趋于平缓[24 ,25 ] 。

图9

图9

应变速率为0.01 s-1 时不同变形温度下Ti30 Ni50 Hf20 高温形状记忆合金显微组织的OM像

Fig.9

OM images for Ti30 Ni50 Hf20 high-temperature shape memory alloy at strain rate of 0.01 s-1 at deformation temperatures of 700 o C (a), 800 o C (b), and 900 o C (c)

图10 为变形温度为900 ℃时,Ti30 Ni50 Hf20 高温形状记忆合金在不同应变速率下变形后显微组织的OM像。可以看到,随着应变速率的增加,合金组织内部变形带更加密集(图10b 和c ),晶粒受挤压变形,在晶粒内部有滑移带产生(图10b ),在变形过程中大量位错缠绕堆积,在应力-应变曲线中表现为流变应力随应变速率的增加而增大(图2 )。

图10

图10

变形温度为900 ℃时Ti30 Ni50 Hf20 高温形状记忆合金在不同应变速率下显微组织的OM像

Fig.10

OM images for Ti30 Ni50 Hf20 high-temperature shape memory alloy at deformation temperature of 900 o C under strain rates of 0.1 s-1 (a), 1 s-1 (b), and 10 s-1 (c) (Inset in Fig.10b shows the slip band)

2.5 热加工图

根据动态材料模型理论,合金热加工过程中单位体积内所吸收的能量(P )与耗散量(G )和耗散系数(J )之间的关系为[24 ] :

P = σ ε = G + J = ∫ 0 ε ˙ σ d ε ˙ + ∫ 0 σ ε ˙ d σ (14)

式中,σ 为应力,ε 为应变。G 和J 在P 中的占比由应变速率敏感指数(m )决定。本工作中Ti30 Ni50 Hf20 合金m 的计算方法如下式[23 ] :

m = ∂ J ∂ G = ε ˙ ∂ σ σ ˙ ∂ ε ˙ = ∂ l n σ ∂ l n σ ε , T (15)

式中,σ ˙ m = 1,J 具有最大值J max = P / 2。

功率耗散系数(η )是材料成形过程中显微组织演变所耗散能量与线性耗散能量的比值,它与J 、J max 和m 的关系如下[24 ] :

η = J J m a x = 2 m 1 + m (16)

ξ ( ε ˙ ) = ∂ l n m m + 1 ∂ l n ε ˙ + m < 0 (17)

式中,ξ σ 和l n ε ˙

l n σ = a + b l n ε ˙ + c ( l n ε ˙ ) 2 + d ( l n ε ˙ ) 3 (18)

根据 式(14)和(17)求出不同温度下的m ,即:

m = b + 2 c l n ε ˙ + 3 d ( l n ε ˙ ) 2 (19)

ξ ( ε ˙ ) = ∂ l n m m + 1 ∂ l n ε ˙ + m = 2 c + 6 d l n ε ˙ m m + 1 + m (20)

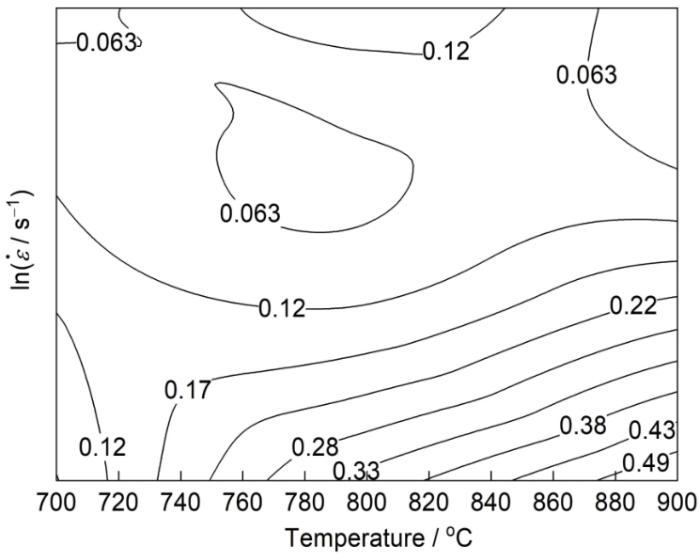

根据 式(16)计算出不同温度、不同应变速率下的η ,在T -l n ε ˙ η 等高线图,即为功率耗散图(图11 )。由图可得,Ti30 Ni50 Hf20 高温形状记忆合金耗散值随变形温度的升高而升高。再将计算得到的不同温度、不同应变速率所对应的ξ T -l n ε ˙ 30 Ni50 Hf20 合金热加工图[26 ~31 ] 。

图11

图11

Ti30 Ni50 Hf20 高温形状记忆合金功率耗散图

Fig.11

Power dissipation diagram of Ti30 Ni50 Hf20 high-temperature shape memory alloy

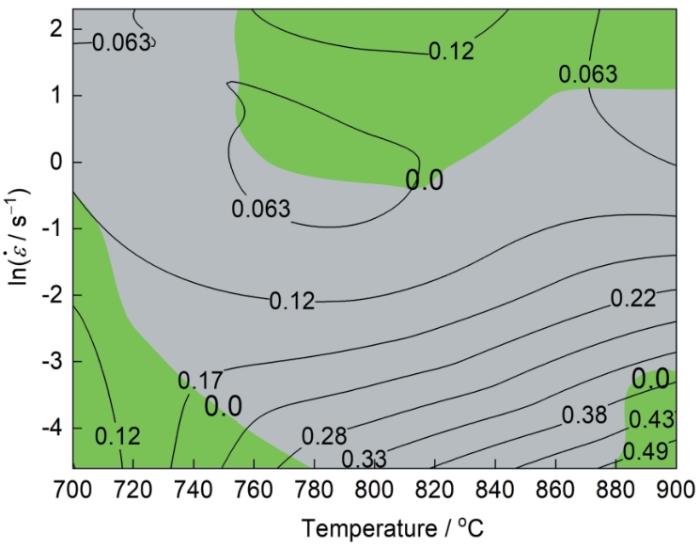

图12 即为Ti30 Ni50 Hf20 高温形状记忆合金的热加工图,等高线代表功率耗散系数,灰色区域代表失稳区域,绿色区域代表可加工区域。可以看出,Ti30 Ni50 Hf20 高温形状记忆合金的可加工区域由3个区域构成:区域I,温度为700~780 ℃,应变速率为0.01~0.69 s-1 的低温、低应变速率区域;区域II,温度为755~900 ℃,应变速率为0.79~9.77 s-1 的高温、高应变速率区域;区域III,温度为880~900 ℃,应变速率为0.01~0.04 s-1 的高温、低应变速率区域。

图12

图12

Ti30 Ni50 Hf20 高温形状记忆合金热加工图

Fig.12

Thermal processing diagram of Ti30 Ni50 Hf20 high-temperature shape memory alloy

区域I和区域II的η 均小于0.14,通常这种情况会发生绝热剪切变形或局部塑性流动。区域III的η 在0.43~0.49之间,是整个功率耗散图中功率耗散系数最大的部分,研究[29 ~31 ] 表明,η 越大,材料的热加工性能越好。依据Ti30 Ni50 Hf20 高温形状记忆合金的热加工图,Ti30 Ni50 Hf20 合金加工性能较差,可加工区域较小,结合实际加工效率等因素,该合金的最优加工参数为:温度880~900 ℃,应变速率0.01~0.04 s-1 。

3 结论

(1) Ti30 Ni50 Hf20 高温形状记忆合金的流变应力随变形温度升高而减小,随应变速率的增加而增大。合金为负温度、正应变敏感材料,计算得到的本构方程为:ε ˙ = e x p 56.2 - 527.447 R T [ s i n h 0.0015 σ ] 9.59

(2) 随变形温度升高合金再结晶现象明显增强,峰值应力降低,随应变速率增加合金晶界相互缠绕曲折程度加剧,导致变形过程中流变应力急剧增加,峰值应力增大。

(3) 建立了Ti30 Ni50 Hf20 高温形状记忆合金的热加工图,其最优加工参数为:温度880~900 ℃,应变速率0.01~0.04 s-1 。

参考文献

View Option

[1]

Singh S Karthick S Palani I A Design and development of Cu-Al-Ni shape memory alloy coated optical fiber sensor for temperature sensing applications

[J]. Vacuum , 2021 , 191 : 110369

[本文引用: 1]

[2]

Chen F Qiu P C Liu Y et al Microstructure and mechanical properties of NiTi shape memory alloys by in situ laser directed energy deposition

[J]. Acta Metall. Sin. , 2023 , 59 : 180

DOI

The NiTi alloy is a key material in aerospace and biomedical fields owing to its excellent superelasticity and high shape memory effect. Laser directed energy deposition (LDED), as an advanced additive manufacturing technology, made the preparation of NiTi alloys with high shape memory effect possible. In this study, the NiTi alloy was fabricated via LDED using Ni and Ti powder feedstock. The microstructure, phase content, and phase transformation of the alloy were analyzed by XRD, phase fitting, SEM, EDS, and DSC. Next, the shape memory effect was tested using compressed cylindrical samples. When the laser energy density was low, several Ni4Ti3 phases were produced in the NiTi alloy. The Ni4Ti3 phase disappeared with an increase in the laser energy density. When the laser energy density was 20.0 J/mm2, the NiTi alloy showed a high compressive breaking strength of 2878 MPa and a compression failure strain of 34.9%, and the sample also showed a shape recovery rate of 88.2% after 20 cyc of compression.

陈 斐 , 邱鹏程 , 刘 洋 等 原位激光定向能量沉积NiTi形状记忆合金的微观结构和力学性能

[J]. 金属学报 , 2023 , 59 : 180

[3]

Es-Souni M Fischer-Brandies H Assessing the biocompatibility of NiTi shape memory alloys used for medical applications

[J]. Anal. Bioanal. Chem. , 2005 , 381 : 557

PMID

The present paper reviews aspects related to the biocompatibility of NiTi shape memory alloys used for medical applications. These smart metallic materials, which are characterised by outstanding mechanical properties, have been gaining increasing importance over the last two decades in many minimal invasive surgery and diagnostic applications, as well as for other uses, such as in orthodontic appliances. Due to the presence of high amounts of Ni, the cytotoxicity of such alloys is under scrutiny. In this review paper we analyse work published on the biocompatibility of NiTi alloys, considering aspects related to: (1) corrosion properties and the different methods used to test them, as well as specimen surface states; (2) biocompatibility tests in vitro and in vivo; (3) the release of Ni ions. It is shown that NiTi shape memory alloys are generally characterised by good corrosion properties, in most cases superior to those of conventional stainless steel or Co-Cr-Mo-based biomedical materials. The majority of biocompatibility studies suggest that these alloys have low cytotoxicity (both in vitro and in vivo) as well as low genotoxicity. The release of Ni ions depends on the surface state and the surface chemistry. Smooth surfaces with well-controlled structures and chemistries of the outermost protective TiO2 layer lead to negligible release of Ni ions, with concentrations below the normal human daily intake.

[4]

Abbas A Hung H Y Lin P C et al Atomic layer deposited TiO2 films on an Equiatomic NiTi shape memory alloy for biomedical applications

[J]. J. Alloys Compd. , 2021 , 886 : 161282

[5]

Ren D C Zhang H B Li S J et al Properties of Ti-Ni pre-alloyed powder used for electron beam melting

[J]. Rare Met. Mater. Eng. , 2020 , 49 : 3218

[本文引用: 1]

任德春 , 张慧博 , 李述军 等 电子束增材制造技术用Ti-Ni预合金粉末性能研究

[J]. 稀有金属材料与工程 , 2020 , 49 : 3218

[本文引用: 1]

[6]

Feng Z W Cui Y Shang Z Y et al Development of NiTiZr high temperature shape memory alloys

[J]. Mater. Rep. , 2016 , 30(suppl.2 ) : 616

[本文引用: 1]

冯昭伟 , 崔 跃 , 尚再艳 等 镍钛锆高温形状记忆合金的研究进展

[J]. 材料导报 , 2016 , 30 (): 616

[本文引用: 1]

[7]

Li Q Q Li Y Ma Y H Research progress of titanium-based high-temperature shape memory alloy

[J]. Mater. Rep. , 2020 , 34 : 148

[本文引用: 1]

李启泉 , 李 岩 , 马悦辉 钛基高温形状记忆合金进展综述

[J]. 材料导报 , 2020 , 34 : 148

[本文引用: 1]

[8]

Canadinc D Trehern W Ma J et al Ultra-high temperature multi-component shape memory alloys

[J]. Scr. Mater. , 2019 , 158 : 83

[本文引用: 1]

[9]

Yi X Y Meng X L Cai W et al Research progress in Ti-Ni-Hf high temperature shape memory alloys

[J]. J. Mater. Eng. , 2021 , 49 (3 ): 31

衣晓洋 , 孟祥龙 , 蔡 伟 等 Ti-Ni-Hf高温形状记忆合金的研究进展

[J]. 材料工程 , 2021 , 49 (3 ): 31

DOI

Ti-Ni-Hf记忆合金因具有高相变温度、相对低廉的价格和高输出功等诸多优点而成为最具潜力的高温形状记忆合金之一。然而,Ti-Ni-Hf记忆合金基体强度低,变形过程中易优先发生塑性变形,从而使其可实现的可恢复应变远低于理论值。目前改善应变恢复特性的措施主要包括:热机械处理(冷轧+退火)、合金化、时效处理、制备单晶合金等。研究表明,Ti-Ni-Hf合金的应变恢复特性与微观组织结构密切相关。本文主要阐述了Ti-Ni-Hf记忆合金在近年来的最新研究进展,包含微观组织结构的演化规律、马氏体相变行为以及力学性能和应变恢复特性,并基于前期研究成果建立了微观组织结构-马氏体相变-力学与应变恢复特性的关联特性。当前,Ti-Ni-Hf高温形状记忆合金冷、热加工性能差是其广泛应用的瓶颈。因此,Ti-Ni-Hf高温记忆合金的粉末冶金和增材制造可能是未来研究的热点与重点。

[10]

Zuo S G Jin X J Jin M J Research progress in high temperature shape memory alloys

[J]. Mater. Mech. Eng. , 2014 , 38 (1 ): 1

[本文引用: 1]

左舜贵 , 金学军 , 金明江 高温形状记忆合金的研究进展

[J]. 机械工程材料 , 2014 , 38 (1 ): 1

[本文引用: 1]

[11]

Meng X K Zhao C W Research progress on Ti-Ni-Hf high temperature shape memory alloy

[J]. Mater. Rep. , 2013 , 27 (3 ): 99

[本文引用: 1]

孟晓凯 , 赵春旺 钛镍铪高温形状记忆合金的研究进展

[J]. 材料导报 , 2013 , 27 (3 ): 99

[本文引用: 1]

[12]

Liao B Cao L F Wu X D et al Hot deformation behavior and processing map of 7A55 aluminum alloy in double thermo-mechanical treatment process

[J]. Nonferrous Met. Eng. , 2021 , 11 (2 ): 1

[本文引用: 1]

廖 斌 , 曹玲飞 , 吴晓东 等 双级形变热处理工艺中7A55铝合金热变形行为及热加工图

[J]. 有色金属工程 , 2021 , 11 (2 ): 1

[本文引用: 1]

[13]

Ma X Xu S Y Zhou G et al Thermal deformation behavior of Ni60 Ti40 shape memory alloy

[J]. China Metall. , 2022 , 32 (9 ): 26

[本文引用: 1]

马 昕 , 许斯洋 , 周 舸 等 Ni60 Ti40 形状记忆合金的热变形行为

[J]. 中国冶金 , 2022 , 32 (9 ): 26

[本文引用: 1]

[14]

Zhu L Z Lu S Q Shu X Y et al Hot deformation behavior and constitutive relationships of Ni-40Ti shape memory alloy

[J]. Spec. Cast. Nonferrous Alloys , 2016 , 36 : 425

[本文引用: 1]

朱乐宗 , 鲁世强 , 舒小勇 等 Ni-40Ti形状记忆合金热变形行为及本构关系的建立

[J]. 特种铸造及有色合金 , 2016 , 36 : 425

[本文引用: 1]

[15]

Zhao Y N Jiang S Y Zhang Y Q et al Hot deformation behavior and processing map of NiTi shape memory alloy

[J]. Appl. Sci. Technol. , 2017 , 44 (1 ): 76

[本文引用: 1]

赵亚楠 , 江树勇 , 张艳秋 等 NiTi形状记忆合金的热变形行为及热加工图

[J]. 应用科技 , 2017 , 44 (1 ): 76

[本文引用: 1]

[16]

Karelin R Komarov V Cherkasov V et al Production, mechanical and functional properties of long-length TiNiHf rods with high-temperature shape memory effect

[J]. Materials , 2023 , 16 : 615

[本文引用: 1]

[17]

Tugrul H O Akgul O Kockar B Creep behavior of 50at%Ni 25at%Ti 25at%Hf high temperature shape memory alloy under constant load

[J]. Mater. Today Commun. , 2022 , 33 : 104827

[本文引用: 1]

[18]

Meng X L Cai W Zheng Y F et al Phase transformation and precipitation in aged Ti-Ni-Hf high-temperature shape memory alloys

[J]. Mater. Sci. Eng. , 2006 , A438 -440 : 666

[本文引用: 2]

[19]

Chen S H Wang Q Y Jiang H C et al Effect of δ -ferrite on hot deformation and recrystallization of 316KD austenitic stainless steel for sodium-cooled fast reactor application

[J]. Acta Metall. Sin. , 2024 , 60 : 367

[本文引用: 1]

陈胜虎 , 王琪玉 , 姜海昌 等 δ -铁素体对钠冷快堆用316KD奥氏体不锈钢热变形行为和动态再结晶的影响

[J]. 金属学报 , 2024 , 60 : 367

DOI

[本文引用: 1]

奥氏体不锈钢中δ-铁素体的存在显著影响热加工过程中奥氏体晶粒度的控制,造成晶粒不均匀现象,关于δ-铁素体对奥氏体动态再结晶行为的影响机制尚不清楚。本工作利用Gleeble-3800热力模拟试验机在1423 K、0.1 s-1条件下进行了铸态样品和均质化处理态样品的热压缩实验,结合SEM、EBSD和TEM等研究了δ-铁素体对热变形行为和动态再结晶的影响。结果表明:1473 K均质化处理14 h可基本消除δ-铁素体,同时伴随着奥氏体晶粒的显著长大,计算表明δ-铁素体向奥氏体的转变速率主要受控于Cr在奥氏体中的扩散。铸态样品变形过程中,δ-铁素体内部、δ-铁素体/奥氏体界面处的塑性变形先于奥氏体相,高温下较软δ-铁素体的存在,造成铸态样品的流变应力明显低于均质化处理态无δ-铁素体样品。随着变形的进行,δ-铁素体易发生动态回复,动态回复引起的软化导致流变应力显著下降。均质化处理态样品的动态再结晶机制是原始奥氏体晶界弓出形核的不连续动态再结晶。而δ-铁素体的存在促进了δ-铁素体/奥氏体界面附近奥氏体的动态再结晶,其机制为连续动态再结晶。铸态样品中的原始奥氏体晶界为不连续动态再结晶的形核位置,2种动态再结晶机制的耦合作用使得铸态样品的动态再结晶程度显著高于均质化处理态样品。

[20]

Li F L Fu R Bai Y R et al Effects of initial grain size and strengthening phase on thermal deformation and recrystallization behavior of GH4096 superalloy

[J]. Acta Metall. Sin. , 2023 , 59 : 855

DOI

[本文引用: 1]

GH4096 alloy were used for disks and shafts of advanced gas turbine engines owing to its excellent properties such as resistance to creep, fatigue, and corrosion as well as microstructure stability up to about 700oC. In this study, GH4096, a hard-to-deform disk superalloy, was processed through an advanced cast and wrought route to avoid the expensive power metallurgy (P/M) route. Many types of full-scale disk forgings possessing homogeneous fine-grained microstructures were successfully carried out, and the ultrasonic inspectability was comparative to that of the alloy produced by the P/M route. The effects of the initial grain size and strengthening phase on hot deformation behavior and dynamic recrystallization (DRX) were studied by OM, SEM, EBSD, and TEM under different deformation parameters. The results showed that as the initial grain size decreased within the temperature range of 1050-1120oC, the flow peak stresses decreased and the fractions of DRX increased. With an increase in the initial grain size, the thermal deformation temperature required for complete dynamic recrystallization decreased, and also the critical strain of dynamic recrystallization decreased. The initial grain size and the strain did not affect the recrystallized grain size when deformed at a sub-solvus temperature. The thermal deformation constitutive equations related to the initial grain sizes were established and the activation energies of thermal deformation related to the original grain sizes were calculated. The effect of γ' phase size on the thermal deformation behavior in as-cast microstructure was studied. In the sub-solvus temperature range, the thermal deformation resistance could be effectively reduced with the increase in the size of γ' phase, the critical strain of DRX was decreased, and the DRX fraction was also increased. The dynamic recrystallization mechanisms related to the γ' phase and initial grain size were also discussed. DRX nucleation takes place at the sub-grains near original grain boundaries for samples with larger initial grain size deformed at sub-solvus temperature. For samples with fine initial grain size, the interface slip of incoherent γ' phase is the significant dynamic softening mechanism during the sub-solvus temperature deformation. For as-cast samples, the main dynamic softening mechanism is original grain boundary bowing out DRX nucleation and coarse second-phase-induced DRX nucleation.

李福林 , 付 锐 , 白云瑞 等 初始晶粒尺寸和强化相对GH4096高温合金热变形行为和再结晶的影响

[J]. 金属学报 , 2023 , 59 : 855

DOI

[本文引用: 1]

以镍基变形高温合金GH4096为研究对象,进行了不同组织状态下的热压缩实验,分析了该合金热变形流变行为特点,并采用OM、SEM、EBSD和TEM等手段研究了热压缩过程中初始晶粒尺寸(晶界面积和数量)和强化相对动态再结晶行为及组织演变的影响。结果表明:在1050~1120℃温度范围内,随着初始晶粒尺寸的减小,峰值流变应力降低,动态再结晶分数增加,实现完全动态再结晶所需热变形温度降低,发生动态再结晶的临界应变降低;在亚固溶温度下热变形时,动态再结晶晶粒尺寸与初始晶粒尺寸和变形量没有相关性;计算了与初始晶粒尺寸相关的热变形激活能,并建立了与热变形前的初始晶粒尺寸相关的热变形本构方程;研究了铸态组织中强化相γ'相形态对热变形行为的影响,在亚固溶温度下热变形时,随着强化相γ'相尺寸的增加,可一定程度降低热变形峰值流变应力,降低动态再结晶的临界应变,提高动态再结晶分数。分析讨论了GH4096合金不同组织状态下的主导动态软化机制。

[21]

Luo L S Wang F X Wu X M et al Hot deformation and processing maps of low cost Ti-Al-V-Fe-O alloy

[J]. Rare Met. Mater. Eng. , 2018 , 47 : 2049

[本文引用: 3]

骆良顺 , 王富鑫 , 吴晓明 等 低成本Ti-Al-V-Fe-O合金热变形行为及热加工图

[J]. 稀有金属材料与工程 , 2018 , 47 : 2049

[本文引用: 3]

[22]

Liu Q Q Lu Y Zhang Y F et al Thermal deformation behavior of Al19.3 Co15 Cr15 Ni50.7 high entropy alloy

[J]. Acta Metall. Sin. , 2021 , 57 : 1299

[本文引用: 3]

刘庆琦 , 卢 晔 , 张翼飞 等 Al19.3 Co15 Cr15 Ni50.7 高熵合金的热变形行为

[J]. 金属学报 , 2021 , 57 : 1299

DOI

[本文引用: 3]

为研究铸态Al19.3Co15Cr15Ni50.7高熵合金的热变形行为,利用Gleeble-3500热模拟试验机对试样进行热压缩实验,获得了在应变速率为0.001~0.1 s-1和变形温度为973~1273 K条件下的真应力-真应变曲线。根据 Arrhenius模型构建该合金应变为0.1~0.7的流变应力下的本构方程,得出不同应变条件下的变形激活能和材料参数,以应变ε为自变量将材料常数进行6次多项式拟合,并对本构方程进行验证。基于动态材料模型的功率耗散理论和失稳判据构建功率耗散图和失稳图,并将2者叠加,得到应变为0.3~0.7的热加工图。结果表明,1273 K时的流变应力曲线呈现明显的动态回复的特征,其他温度下的流变应力曲线呈现动态再结晶的特征,并且流变应力随变形温度的下降或应变速率的提升而提升。建立本构方程并进行验证,判定系数R2 = 0.956,较高的判定系数表明建立的流变应力本构模型能够比较精确地预测合金的流变应力。高温压缩后的SEM结果显示:相比于铸态微观组织,合金经历热变形之后,组织中出现一些空隙与局部塑性流动,长条状的B2相发生了弯折、断裂,且断裂处的长条状B2相被撕裂成连续的片层状。最后基于动态材料模型(DMM)理论计算出热加工图,从而得到优异的热加工区间。

[23]

Bai X H Zhao X C Zhao D L et al Research on thermal deformation behavior of a high carbon Cr5 roll steel

[J]. MW Met. Form. , 2021 , (12 ): 68

[本文引用: 2]

白兴红 , 赵席春 , 赵德利 等 一种高碳Cr5轧辊钢的热变形行为研究

[J]. 金属加工热加工 , 2021 , (12 ): 68

[本文引用: 2]

[24]

Hua S M Zhang P Z Liu Z L et al Hot deformation behavior and hot working map of Cu-0.58Sn alloy

[J]. Nonferrous Met. Eng. , 2021 , 11 (10 ): 40

[本文引用: 6]

花思明 , 张平则 , 刘子利 等 Cu-0.58Sn合金热变形行为和热加工图

[J]. 有色金属工程 , 2021 , 11 (10 ): 40

[本文引用: 6]

[25]

Tian L Ji H B Lei J F et al Study on constitutive relationship for hot deformation of Ti6242s Alloy

[J]. Hot Work. Technol. , 2013 , 42 (20 ): 97

[本文引用: 4]

田 录 , 吉海宾 , 雷家峰 等 Ti6242s合金本构关系的研究

[J]. 热加工工艺 , 2013 , 42 (20 ): 97

[本文引用: 4]

[26]

Huang Y L Wang J B Ling X S et al Research development of hot processing map theory

[J]. Mater. Rep. , 2008 , 22(suppl.3 ): 173

[本文引用: 1]

黄有林 , 王建波 , 凌学士 等 热加工图理论的研究进展

[J]. 材料导报 , 2008 , 22 (): 173

[本文引用: 1]

[27]

Semiatin S L Seetharaman V Weiss I Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure

[J]. Mater. Sci. Eng. , 1999 , A263 : 257

[28]

Bobbili R Madhu V Hot deformation behavior and processing maps of Ti-15Al-12Nb alloy

[J]. Rare Met. , 2022 , 41 : 2316

[29]

Lv B J Peng J Wang Y J et al Dynamic recrystallization behavior and hot workability of Mg-2.0Zn-0.3Zr-0.9Y alloy by using hot compression test

[J]. Mater. Des. , 2014 , 53 : 357

[本文引用: 1]

[30]

Wei L L Pan Q L Zhou J et al Processing maps and flow instability analysis of Al-Zn-Mg-Cu-Zr alloy

[J]. J. Cent. South Univ. (Sci. Technol.) , 2013 , 44 : 1798

韦莉莉 , 潘清林 , 周 坚 等 Al-Zn-Mg-Cu-Zr合金加工图的构建及失稳分析

[J]. 中南大学学报(自然科学版) , 2013 , 44 : 1798

[31]

Lei W G Han D Zhang Y Q et al Hot deformation mechanism and processing map of TC4-DT titanium alloy

[J]. Titanium Ind. Prog. , 2015 , 32 (1 ): 20

[本文引用: 2]

雷文光 , 韩 栋 , 张永强 等 TC4-DT钛合金热变形机制及加工图

[J]. 钛工业进展 , 2015 , 32 (1 ): 20

[本文引用: 2]

Design and development of Cu-Al-Ni shape memory alloy coated optical fiber sensor for temperature sensing applications

1

2021

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

Microstructure and mechanical properties of NiTi shape memory alloys by in situ laser directed energy deposition

0

2023

原位激光定向能量沉积NiTi形状记忆合金的微观结构和力学性能

0

2023

Assessing the biocompatibility of NiTi shape memory alloys used for medical applications

0

2005

Atomic layer deposited TiO2 films on an Equiatomic NiTi shape memory alloy for biomedical applications

0

2021

Properties of Ti-Ni pre-alloyed powder used for electron beam melting

1

2020

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

电子束增材制造技术用Ti-Ni预合金粉末性能研究

1

2020

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

Development of NiTiZr high temperature shape memory alloys

1

2016

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

镍钛锆高温形状记忆合金的研究进展

1

2016

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

Research progress of titanium-based high-temperature shape memory alloy

1

2020

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

钛基高温形状记忆合金进展综述

1

2020

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

Ultra-high temperature multi-component shape memory alloys

1

2019

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

Research progress in Ti-Ni-Hf high temperature shape memory alloys

0

2021

Ti-Ni-Hf高温形状记忆合金的研究进展

0

2021

Research progress in high temperature shape memory alloys

1

2014

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

高温形状记忆合金的研究进展

1

2014

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Research progress on Ti-Ni-Hf high temperature shape memory alloy

1

2013

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

钛镍铪高温形状记忆合金的研究进展

1

2013

... Ti-Ni形状记忆合金(shape memory alloy,SMA)是通过固态相变实现形状记忆效应的一种金属间化合物,具有良好的生物相容性和综合力学性能,但Ti-Ni二元合金的相变温度一般低于100 ℃,这严重制约了Ti-Ni形状记忆合金的应用发展[1 ~5 ] .Ti-Ni基高温形状记忆合金具有较高的马氏体和奥氏体相变温度,可广泛用于制备航空发动机、核电站以及其他高温报警装置中的驱动部件,成为近年来形状记忆合金领域研究的热点方向[6 ,7 ] .研究[8 ~11 ] 表明,添加Hf、Pt和Pd等元素可以有效提升Ti-Ni形状记忆合金的相变温度,其中Ti-Ni-Hf系形状记忆合金具有价格相对低、性能优异等优点,是目前最具有工程化应用前景的高温形状记忆合金之一. ...

Hot deformation behavior and processing map of 7A55 aluminum alloy in double thermo-mechanical treatment process

1

2021

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

双级形变热处理工艺中7A55铝合金热变形行为及热加工图

1

2021

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Thermal deformation behavior of Ni60 Ti40 shape memory alloy

1

2022

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Ni60 Ti40 形状记忆合金的热变形行为

1

2022

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Hot deformation behavior and constitutive relationships of Ni-40Ti shape memory alloy

1

2016

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Ni-40Ti形状记忆合金热变形行为及本构关系的建立

1

2016

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Hot deformation behavior and processing map of NiTi shape memory alloy

1

2017

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

NiTi形状记忆合金的热变形行为及热加工图

1

2017

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Production, mechanical and functional properties of long-length TiNiHf rods with high-temperature shape memory effect

1

2023

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Creep behavior of 50at%Ni 25at%Ti 25at%Hf high temperature shape memory alloy under constant load

1

2022

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

Phase transformation and precipitation in aged Ti-Ni-Hf high-temperature shape memory alloys

2

2006

... 热加工变形行为是考量金属材料实现加工成形的重要因素,Ti-Ni-Hf系金属间化合物的热变形除了受本身属性影响以外,主要与变形温度、应变速率等变形参数有关.研究[12 ] 表明,材料的本构方程能够直接反映热加工工艺参数之间的关系,在此基础上建立的热加工图可以预测材料的加工性能,避开加工失稳区,确保材料成形及性能提升.马昕等[13 ] 研究了Ni60 Ti40 形状记忆合金的热变形特性,结果表明该合金的热变形激活能为213 kJ/mol,具有3个稳定变形区、1个失稳区.朱乐宗等[14 ] 的研究结果表明,多元线性回归法能预测轧制态Ni-40Ti合金的热变形行为.赵亚楠等[15 ] 研究了Ni50.9 Ti49.1 形状记忆合金的热变形行为,结果表明该合金具有负温度、正应变敏感性.目前围绕Ti-Ni形状记忆合金的热变形行为展开了较多研究,但针对Ti-Ni-Hf系高温形状记忆合金的研究较少,主要集中在研究时效温度、时间等对铸造Ti-Ni-Hf高温形状记忆合金组织和性能的影响,而对于热变形后的Ti-Ni-Hf高温形状记忆合金的研究较少.Karelin等[16 ] 在制备Ti-Ni-Hf高温形状记忆合金棒材时发现,只有Hf含量为1.5% (原子分数)的合金成功制备成棒材,其余成分均未成功.究其原因是高Hf含量Ti-Ni-Hf合金具有较高的硬度和脆性,极难进行热变形[10 ,17 ,18 ] .而低Hf含量无法满足航空航天领域对高温形状记忆合金的需求.因此,有必要开展高Hf含量Ti-Ni-Hf系高温形状记忆合金的热变形行为研究,全面理解其热变形能力. ...

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

Effect of δ -ferrite on hot deformation and recrystallization of 316KD austenitic stainless steel for sodium-cooled fast reactor application

1

2024

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

δ -铁素体对钠冷快堆用316KD奥氏体不锈钢热变形行为和动态再结晶的影响

1

2024

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

Effects of initial grain size and strengthening phase on thermal deformation and recrystallization behavior of GH4096 superalloy

1

2023

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

初始晶粒尺寸和强化相对GH4096高温合金热变形行为和再结晶的影响

1

2023

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

Hot deformation and processing maps of low cost Ti-Al-V-Fe-O alloy

3

2018

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

... [21 ]. ...

... 图3 是不同应变速率下峰值应力与变形温度的关系曲线.可以看出,Ti30 Ni50 Hf20 合金热变形的峰值应力与变形温度、应变速率密切相关.在恒定的应变速率下,随变形温度升高合金的峰值应力降低;在恒定的变形温度下,随应变速率升高合金的峰值应力增大.基于图3 曲线的变化规律,Ti30 Ni50 Hf20 合金的热变形峰值应力随变形温度降低或应变速率升高而升高,为负温度及正应变敏感材料[21 ] . ...

低成本Ti-Al-V-Fe-O合金热变形行为及热加工图

3

2018

... 不同变形温度和应变速率下Ti30 Ni50 Hf20 高温形状记忆合金的应力-应变曲线如图2 所示.可以看出,不同变形条件下Ti30 Ni50 Hf20 高温形状记忆合金的热变形流变应力变化趋势可分为3个阶段[19 ~21 ] .第一阶段:在变形初期,随着变形量增加,流变应力快速增大直至达到最大值,该阶段样品内部位错随变形量增加快速增殖,导致合金的变形抗力增大,产生加工硬化.在恒定温度下随着应变速率增加,加工硬化现象更加明显,曲线斜率也更大[18 ] ;第二阶段:随变形量增加,当流变应力达到峰值后,金属内部畸变能不断升高,当其达到一定程度时产生动态回复或动态再结晶,应力随应变增加逐渐降低,出现流动软化现象[20 ] .第三阶段:随变形量继续增大,加工硬化与动态软化逐渐达到动态平衡,流变应力趋于稳定,在图2 中表现为应力-应变曲线最终趋于平缓[21 ] . ...

... [21 ]. ...

... 图3 是不同应变速率下峰值应力与变形温度的关系曲线.可以看出,Ti30 Ni50 Hf20 合金热变形的峰值应力与变形温度、应变速率密切相关.在恒定的应变速率下,随变形温度升高合金的峰值应力降低;在恒定的变形温度下,随应变速率升高合金的峰值应力增大.基于图3 曲线的变化规律,Ti30 Ni50 Hf20 合金的热变形峰值应力随变形温度降低或应变速率升高而升高,为负温度及正应变敏感材料[21 ] . ...

Thermal deformation behavior of Al19.3 Co15 Cr15 Ni50.7 high entropy alloy

3

2021

... 变形温度对Ti30 Ni50 Hf20 合金流变应力的影响规律如图4 所示.可以看出,随着变形温度升高流变应力逐渐减小,达到峰值的应变逐渐减小.这是因为在高温变形过程中,随着变形温度升高,材料的热激活能作用增强,原子间结合力降低,导致晶体在产生滑移时的临界分切应力呈现下降趋势,因此合金的流变应力随温度升高而降低;当流变应力达到峰值后,变形过程中合金内部产生大量位错导致合金发生动态再结晶、动态回复等,致使合金发生软化效应,应力-应变曲线趋于平缓[22 ,23 ] . ...

... 由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1 )~(3 )对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] : ...

... 采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] : ...

Al19.3 Co15 Cr15 Ni50.7 高熵合金的热变形行为

3

2021

... 变形温度对Ti30 Ni50 Hf20 合金流变应力的影响规律如图4 所示.可以看出,随着变形温度升高流变应力逐渐减小,达到峰值的应变逐渐减小.这是因为在高温变形过程中,随着变形温度升高,材料的热激活能作用增强,原子间结合力降低,导致晶体在产生滑移时的临界分切应力呈现下降趋势,因此合金的流变应力随温度升高而降低;当流变应力达到峰值后,变形过程中合金内部产生大量位错导致合金发生动态再结晶、动态回复等,致使合金发生软化效应,应力-应变曲线趋于平缓[22 ,23 ] . ...

... 由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1 )~(3 )对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] : ...

... 采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] : ...

Research on thermal deformation behavior of a high carbon Cr5 roll steel

2

2021

... 变形温度对Ti30 Ni50 Hf20 合金流变应力的影响规律如图4 所示.可以看出,随着变形温度升高流变应力逐渐减小,达到峰值的应变逐渐减小.这是因为在高温变形过程中,随着变形温度升高,材料的热激活能作用增强,原子间结合力降低,导致晶体在产生滑移时的临界分切应力呈现下降趋势,因此合金的流变应力随温度升高而降低;当流变应力达到峰值后,变形过程中合金内部产生大量位错导致合金发生动态再结晶、动态回复等,致使合金发生软化效应,应力-应变曲线趋于平缓[22 ,23 ] . ...

... 式中,σ 为应力,ε 为应变.G 和J 在P 中的占比由应变速率敏感指数(m )决定.本工作中Ti30 Ni50 Hf20 合金m 的计算方法如下式[23 ] : ...

一种高碳Cr5轧辊钢的热变形行为研究

2

2021

... 变形温度对Ti30 Ni50 Hf20 合金流变应力的影响规律如图4 所示.可以看出,随着变形温度升高流变应力逐渐减小,达到峰值的应变逐渐减小.这是因为在高温变形过程中,随着变形温度升高,材料的热激活能作用增强,原子间结合力降低,导致晶体在产生滑移时的临界分切应力呈现下降趋势,因此合金的流变应力随温度升高而降低;当流变应力达到峰值后,变形过程中合金内部产生大量位错导致合金发生动态再结晶、动态回复等,致使合金发生软化效应,应力-应变曲线趋于平缓[22 ,23 ] . ...

... 式中,σ 为应力,ε 为应变.G 和J 在P 中的占比由应变速率敏感指数(m )决定.本工作中Ti30 Ni50 Hf20 合金m 的计算方法如下式[23 ] : ...

Hot deformation behavior and hot working map of Cu-0.58Sn alloy

6

2021

... 由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1 )~(3 )对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] : ...

... 采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] : ...

... 然后运用Zener-Holloman参数法求解Ti30 Ni50 Hf20 合金高温塑性变形的变形激活能等材料常数.根据 式(6) ,可以得到[24 ] : ...

... 图9 为Ti30 Ni50 Hf20 高温形状记忆合金在应变速率为0.01 s-1 时不同变形温度下显微组织的OM像.可以看出,与原始组织(图1a )相比,枝晶和胞晶消失,变形后合金组织呈现一定的流线特征(图9a 和b ).随着变形温度升高,再结晶现象逐渐显著.当变形温度为800 ℃时(图9b ),在变形带附近出现尺寸较小的再结晶晶粒;当变形温度为900 ℃时(图9c ),大部分晶粒都发生了再结晶,而再结晶的发生也是图4a 中当流变应力达到峰值后迅速降低的主要原因.在再结晶的作用下,合金产生的软化与加工硬化相互抵消,最终导致流变应力达到动态稳定(图4a ),应力-应变曲线则表现为流变应力随变形温度升高趋于平缓[24 ,25 ] . ...

... 根据动态材料模型理论,合金热加工过程中单位体积内所吸收的能量(P )与耗散量(G )和耗散系数(J )之间的关系为[24 ] : ...

... 功率耗散系数(η )是材料成形过程中显微组织演变所耗散能量与线性耗散能量的比值,它与J 、J max 和m 的关系如下[24 ] : ...

Cu-0.58Sn合金热变形行为和热加工图

6

2021

... 由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1 )~(3 )对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] : ...

... 采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] : ...

... 然后运用Zener-Holloman参数法求解Ti30 Ni50 Hf20 合金高温塑性变形的变形激活能等材料常数.根据 式(6) ,可以得到[24 ] : ...

... 图9 为Ti30 Ni50 Hf20 高温形状记忆合金在应变速率为0.01 s-1 时不同变形温度下显微组织的OM像.可以看出,与原始组织(图1a )相比,枝晶和胞晶消失,变形后合金组织呈现一定的流线特征(图9a 和b ).随着变形温度升高,再结晶现象逐渐显著.当变形温度为800 ℃时(图9b ),在变形带附近出现尺寸较小的再结晶晶粒;当变形温度为900 ℃时(图9c ),大部分晶粒都发生了再结晶,而再结晶的发生也是图4a 中当流变应力达到峰值后迅速降低的主要原因.在再结晶的作用下,合金产生的软化与加工硬化相互抵消,最终导致流变应力达到动态稳定(图4a ),应力-应变曲线则表现为流变应力随变形温度升高趋于平缓[24 ,25 ] . ...

... 根据动态材料模型理论,合金热加工过程中单位体积内所吸收的能量(P )与耗散量(G )和耗散系数(J )之间的关系为[24 ] : ...

... 功率耗散系数(η )是材料成形过程中显微组织演变所耗散能量与线性耗散能量的比值,它与J 、J max 和m 的关系如下[24 ] : ...

Study on constitutive relationship for hot deformation of Ti6242s Alloy

4

2013

... 由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1 )~(3 )对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] : ...

... 采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] : ...

... 图9 为Ti30 Ni50 Hf20 高温形状记忆合金在应变速率为0.01 s-1 时不同变形温度下显微组织的OM像.可以看出,与原始组织(图1a )相比,枝晶和胞晶消失,变形后合金组织呈现一定的流线特征(图9a 和b ).随着变形温度升高,再结晶现象逐渐显著.当变形温度为800 ℃时(图9b ),在变形带附近出现尺寸较小的再结晶晶粒;当变形温度为900 ℃时(图9c ),大部分晶粒都发生了再结晶,而再结晶的发生也是图4a 中当流变应力达到峰值后迅速降低的主要原因.在再结晶的作用下,合金产生的软化与加工硬化相互抵消,最终导致流变应力达到动态稳定(图4a ),应力-应变曲线则表现为流变应力随变形温度升高趋于平缓[24 ,25 ] . ...

... 根据Prasad材料流变失稳准则[25 ] : ...

Ti6242s合金本构关系的研究

4

2013

... 由Ti30 Ni50 Hf20 高温形状记忆合金在不同温度和应变速率下的应力-应变曲线(图2 )可知,当变形温度一定时,流变应力随应变速率的升高而增大,为表征该高温记忆合金的热变形特性,采用式(1 )~(3 )对其热变形过程中的变形行为进行分析[22 ,24 ,25 ] : ...

... 采用Zener-Holloman参数(Z )分析合金塑性变形过程中温度与应变速率之间的关系,Ti30 Ni50 Hf20 合金本构方程可表示为[22 ,24 ,25 ] : ...

... 图9 为Ti30 Ni50 Hf20 高温形状记忆合金在应变速率为0.01 s-1 时不同变形温度下显微组织的OM像.可以看出,与原始组织(图1a )相比,枝晶和胞晶消失,变形后合金组织呈现一定的流线特征(图9a 和b ).随着变形温度升高,再结晶现象逐渐显著.当变形温度为800 ℃时(图9b ),在变形带附近出现尺寸较小的再结晶晶粒;当变形温度为900 ℃时(图9c ),大部分晶粒都发生了再结晶,而再结晶的发生也是图4a 中当流变应力达到峰值后迅速降低的主要原因.在再结晶的作用下,合金产生的软化与加工硬化相互抵消,最终导致流变应力达到动态稳定(图4a ),应力-应变曲线则表现为流变应力随变形温度升高趋于平缓[24 ,25 ] . ...

... 根据Prasad材料流变失稳准则[25 ] : ...

Research development of hot processing map theory

1

2008

... 根据 式(16) 计算出不同温度、不同应变速率下的η ,在T -l n ε ˙ η 等高线图,即为功率耗散图(图11 ).由图可得,Ti30 Ni50 Hf20 高温形状记忆合金耗散值随变形温度的升高而升高.再将计算得到的不同温度、不同应变速率所对应的ξ T -l n ε ˙ 30 Ni50 Hf20 合金热加工图[26 ~31 ] . ...

热加工图理论的研究进展

1

2008

... 根据 式(16) 计算出不同温度、不同应变速率下的η ,在T -l n ε ˙ η 等高线图,即为功率耗散图(图11 ).由图可得,Ti30 Ni50 Hf20 高温形状记忆合金耗散值随变形温度的升高而升高.再将计算得到的不同温度、不同应变速率所对应的ξ T -l n ε ˙ 30 Ni50 Hf20 合金热加工图[26 ~31 ] . ...

Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure

0

1999

Hot deformation behavior and processing maps of Ti-15Al-12Nb alloy

0

2022

Dynamic recrystallization behavior and hot workability of Mg-2.0Zn-0.3Zr-0.9Y alloy by using hot compression test

1

2014

... 区域I和区域II的η 均小于0.14,通常这种情况会发生绝热剪切变形或局部塑性流动.区域III的η 在0.43~0.49之间,是整个功率耗散图中功率耗散系数最大的部分,研究[29 ~31 ] 表明,η 越大,材料的热加工性能越好.依据Ti30 Ni50 Hf20 高温形状记忆合金的热加工图,Ti30 Ni50 Hf20 合金加工性能较差,可加工区域较小,结合实际加工效率等因素,该合金的最优加工参数为:温度880~900 ℃,应变速率0.01~0.04 s-1 . ...

Processing maps and flow instability analysis of Al-Zn-Mg-Cu-Zr alloy

0

2013

Al-Zn-Mg-Cu-Zr合金加工图的构建及失稳分析

0

2013

Hot deformation mechanism and processing map of TC4-DT titanium alloy

2

2015

... 根据 式(16) 计算出不同温度、不同应变速率下的η ,在T -l n ε ˙ η 等高线图,即为功率耗散图(图11 ).由图可得,Ti30 Ni50 Hf20 高温形状记忆合金耗散值随变形温度的升高而升高.再将计算得到的不同温度、不同应变速率所对应的ξ T -l n ε ˙ 30 Ni50 Hf20 合金热加工图[26 ~31 ] . ...

... 区域I和区域II的η 均小于0.14,通常这种情况会发生绝热剪切变形或局部塑性流动.区域III的η 在0.43~0.49之间,是整个功率耗散图中功率耗散系数最大的部分,研究[29 ~31 ] 表明,η 越大,材料的热加工性能越好.依据Ti30 Ni50 Hf20 高温形状记忆合金的热加工图,Ti30 Ni50 Hf20 合金加工性能较差,可加工区域较小,结合实际加工效率等因素,该合金的最优加工参数为:温度880~900 ℃,应变速率0.01~0.04 s-1 . ...

TC4-DT钛合金热变形机制及加工图

2

2015

... 根据 式(16) 计算出不同温度、不同应变速率下的η ,在T -l n ε ˙ η 等高线图,即为功率耗散图(图11 ).由图可得,Ti30 Ni50 Hf20 高温形状记忆合金耗散值随变形温度的升高而升高.再将计算得到的不同温度、不同应变速率所对应的ξ T -l n ε ˙ 30 Ni50 Hf20 合金热加工图[26 ~31 ] . ...

... 区域I和区域II的η 均小于0.14,通常这种情况会发生绝热剪切变形或局部塑性流动.区域III的η 在0.43~0.49之间,是整个功率耗散图中功率耗散系数最大的部分,研究[29 ~31 ] 表明,η 越大,材料的热加工性能越好.依据Ti30 Ni50 Hf20 高温形状记忆合金的热加工图,Ti30 Ni50 Hf20 合金加工性能较差,可加工区域较小,结合实际加工效率等因素,该合金的最优加工参数为:温度880~900 ℃,应变速率0.01~0.04 s-1 . ...