近年来,油气资源已成为战略性资源,提升油气生产效率变得尤为重要[1]。分段压裂技术作为解决压裂效率低的有效途径,广泛应用于提高油气开采效率[2]。其中,压裂球作为多级压裂技术的关键工具之一,需具备足够的坚固性以应对高压环境[3]。在分段压裂过程中,压裂滑套用于分级压裂,因此压裂球必须在高压下保持稳定性[4]。然而,传统的钢或塑料压裂球在压裂完成后难以清除,导致清除过程耗时耗力,进而影响开采效率[5]。Mg-Li合金是目前世界上比重最小的金属结构材料,且由于Li是活泼金属元素,使Mg-Li合金具有高腐蚀速率,因此Mg-Li合金适合应用于石油压裂工具中[6~8]。由于Mg-Li合金在压裂过程中能够较快地被腐蚀,从而简化了清除过程,相比传统材料减少了清除难题和所需的时间[9]。压裂球在工作过程中需要承受一定的压力,因此,除了提升Mg-Li合金的腐蚀速率外,增强其力学性能也同样重要[10~12]。

双相Mg-Li合金基体组织为hcp相和bcc相。这种双相组织显著增加了合金中的相界面,界面之间较容易形成电偶腐蚀[13],这使Mg-Li合金的腐蚀速率显著提高[14]。此外,bcc相的存在对Mg-Li合金的强度产生了负面影响[15],bcc相通常比hcp相的强度和硬度低,因此双相Mg-Li合金的整体强度较低[16,17]。调控Mg-Li合金的腐蚀速率和力学性能有多种方式,涉及到合金化、第二相调控、轧制及挤压等[18~21]。这些方法不仅可以提高合金的力学性能,也会对其腐蚀行为产生显著的影响[22]。合金化方法通过添加不同的合金元素,可以优化合金的微观结构和相组成,从而提高其强度和塑性,同时引入电位差较大的元素会使腐蚀速率有明显提升[23]。Ma等[24]在Mg-Y合金中添加不同含量的Ni元素,使合金的力学性能增强,且由于Ni的电位与Mg相差较大,使合金的腐蚀速率大大提升。第二相调控也是提高Mg-Li合金强度的重要手段[25]。通过控制第二相的种类、形貌和分布,可以优化合金的力学性能;通过增加第二相含量、改变第二相种类,可以增加电偶腐蚀位点并改变第二相与基体之间的电位差,进而影响合金的腐蚀速率[26]。通过挤压和轧制也可以使Mg-Li合金的力学性能和腐蚀行为发生较大的改变[27]。挤压和轧制可以细化合金的晶粒组织,产生大量的位错。这些位错和晶界的增加可以显著提高合金的化学活性和强度[28]。位错和化学活性的增加也会加速腐蚀,位错和拉长的晶界在腐蚀过程中可能成为优先腐蚀的部位,导致腐蚀速率增加[13]。热轧过程中,合金内部缺陷(如位错和晶界)的积累,会加速腐蚀,而新生成的第二相也可能引起电偶腐蚀。Wang等[13]发现,随着轧制变形量的增加,Mg-Li合金的腐蚀速率先减小后增大,轧制后α-Mg相的伸长和破碎增加了相界面的含量,且α-Mg相与β-Li相之间的电位差导致α-Mg/β-Li界面形成电偶腐蚀,从而加速了腐蚀。

Pang等[29]研究表明,Mg-8Li-4Gd-1.5Ni (质量分数,%,下同)合金具有网状的长周期堆垛有序结构相(LPSO相),会对腐蚀造成一定阻碍,室温下失重速率为0.36 mg/(cm2·min),但铸态Mg-Li合金强度较低,一般在150 MPa以下。而热变形可以使网状分布的LPSO相发生改变、块状GdNi3碎裂、发生再结晶,使组织中界面增多,从而使组织内部积累的化学活性增高,最终提高合金的腐蚀速率,并提高合金的强度。

本工作在250 ℃下对Mg-8Li-4Gd-1.5Ni合金进行不同变形量的轧制,对其微观组织、力学性能和腐蚀行为进行了研究。主要目的是揭示该合金在热轧加工过程中其微观结构的变化(特别是LPSO相、α-Mg相及β-Li相的形貌变化和分布)及其对合金力学性能和腐蚀行为的影响机理。

1 实验方法

在Ar气保护的真空感应熔炼炉中制备Mg-8Li-4Gd-1.5Ni合金铸锭,使用的材料为纯Mg (99.9%)、纯Li (99.9%)、Mg-30Gd和Mg-30Ni中间合金。在250 ℃下轧制板材,每道次的下压量为0.3 mm,最终得到了变形量分别为30%、50%、70%和90%的厚度为2 mm的板材。

采用WDW3050电子万能试验机进行力学性能测试,拉伸速率设定为0.5 mm/min,每个实验在室温下重复3次,计算平均值,保证数据的稳定性。利用Apreo S LoVac扫描电子显微镜(SEM)和JED 2200能谱仪(EDS)分析合金腐蚀前和腐蚀2 s、3 s、1 h后表面及截面的组织形貌、元素分布及拉伸断口形貌。通过G2 F200X透射电子显微镜(TEM)对合金的显微组织进行了表征。

采用IM6ex电化学测试系统,利用析氢方法研究热轧后Mg-8Li-4Gd-1.5Ni合金的腐蚀行为。电化学测试采用三电极系统进行,其中Pt电极为对电极,饱和甘汞电极为参比电极,暴露表面积为1 cm2的样品为工作电极。电化学阻抗谱(EIS)测试在室温下进行,频率范围为0.1 Hz~100 kHz,扰动电位为10 mV。用烧杯、滴管和漏斗等玻璃装置进行析氢收集和体积测量,在室温(25 ℃)下将样品在3.0%KCl (质量分数)溶液中浸泡280 min,测量失重速率,并在93 ℃ (大多数井下作业环境的温度)下浸泡30 min,测量样品在3.0%KCl溶液中的失重速率,实验结束后用200 g/L CrO3 + 10 g/L AgNO3溶液洗涤1 min,随后观察腐蚀表面。

2 实验结果及分析

2.1 微观组织

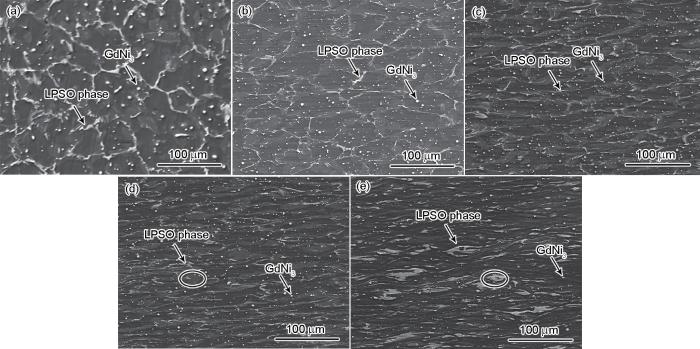

图1为铸态和250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金微观组织的SEM像。合金主要由α-Mg、β-Li、LPSO及GdNi3组成[29]。与铸态合金相比,当变形量为30%时合金形貌变化较小,晶粒略有变形,LPSO相呈网状结构。变形量为50%时,晶粒沿变形方向被拉长,LPSO相开始沿轧制方向分布,网状结构被破坏。在变形量为70%时,较多的组织沿轧制方向呈纤维状,LPSO相之间形成平行分布状态,但还存在较大的块状组织,如图1d中圆圈部分所示。变形量为90%时,大部分组织变为较细的纤维状,轧制变形量增大使LPSO相断裂,由较长的纤维状变为较短的纤维,但是依然存在部分较大的块状组织。

图1

图1

铸态和250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金微观组织的SEM像

Fig.1

SEM images of as-cast (a) and rolled Mg-8Li-4Gd-1.5Ni alloy with deformations of 30% (b), 50% (c), 70% (d), and 90% (e) at 250 oC (Circles in Figs.1d and e show the α-Mg. LPSO—long-period stacking ordered)

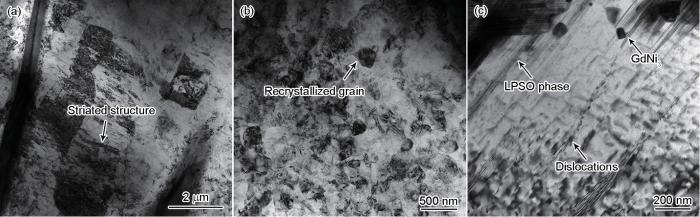

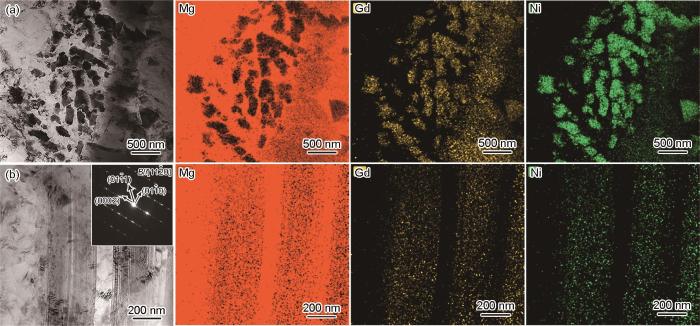

250 ℃下90%轧制变形量Mg-8Li-4Gd-1.5Ni合金的TEM像如图2所示。可以看出,在90%变形量的合金晶粒内部观察到条纹状组织、再结晶晶粒及位错,说明在热轧过程中合金出现动态再结晶现象,且在基体、LPSO相及GdNi3周围均出现了较多的位错[30]。合金发生再结晶和热轧过程中发生组织中相的断裂使部分相保持了块状形貌[31]。图3为250 ℃下轧制变形量为90%的Mg-8Li-4Gd-1.5Ni合金中的GdNi3及LPSO相的TEM像及EDS结果。可见,部分方形第二相在经过90%变形量轧制后碎裂成较多的小块状,且分布较为分散。由EDS结果可知此第二相为GdNi3,并且可以观察到LPSO相发生了弯曲。LPSO的弯曲、第二相的破碎、再结晶、位错密度的增加均会增强合金内部的化学活性[27]。

图2

图2

250 ℃下90%轧制变形量Mg-8Li-4Gd-1.5Ni合金的TEM像

Fig.2

TEM images of rolled Mg-8Li-4Gd-1.5Ni alloy with 90% deformation at 250 oC

(a) striated structure (b) recrystallized grain (c) dislocation

图3

图3

250 ℃下90%轧制变形量Mg-8Li-4Gd-1.5Ni合金的TEM像及EDS结果

Fig.3

TEM images and corresponding EDS element maps of rolled Mg-8Li-4Gd-1.5Ni alloy with 90% deformation at 250 oC

(a) GdNi3 (b) LPSO phase (Inset in Fig.3b show the selected area electron diffraction pattern)

2.2 力学性能

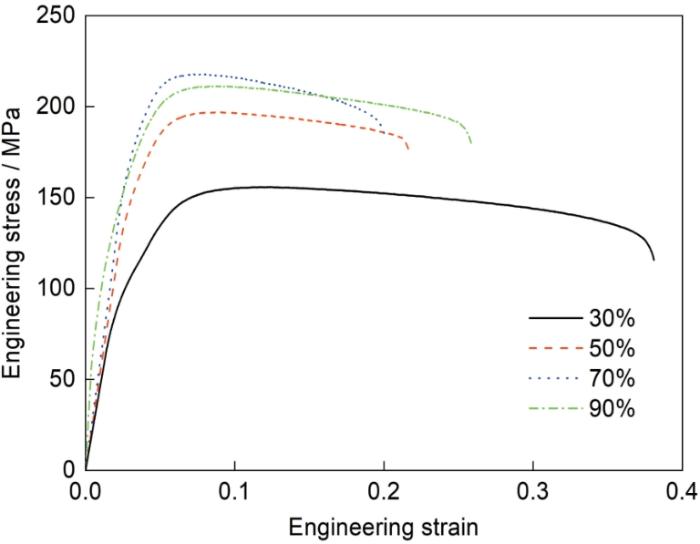

图4为不同轧制变形量Mg-8Li-4Gd-1.5Ni合金的工程应力-应变曲线。可以看出,随着变形量增加合金的抗拉强度先增大后减小。抗拉强度从变形量30%时的151 MPa提高到变形量70%时的217 MPa,提高了44%。随着变形量增加合金的塑性先升高后降低,在变形量为70%时,延伸率依然有17%。曲线总体的趋势是随变形量的增加,强度增高、塑韧性降低,说明发生了加工硬化。合金在轧制过程中位错积累较多,位错开始滑移和变形时就会发生位错缠结和位错塞积。热轧使合金晶粒细化更为明显,也出现较多的再结晶晶粒。因此,Mg-8Li-4Gd-1.5Ni合金的主要强化机制为加工硬化及细晶强化。但是90%变形量的合金强度略低于70%变形量的合金,这可能是因为在轧制过程中90%变形量下发生再结晶的数量更多,细晶强化作用占比更大,而在Mg-Li合金中细晶强化对强度的贡献值低于加工硬化对强度的贡献值[15]。

图4

图4

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金的工程应力-应变曲线

Fig.4

Engineering stress-strain curves of rolled Mg-8Li-4Gd-1.5Ni alloy with different deformations at 250 oC

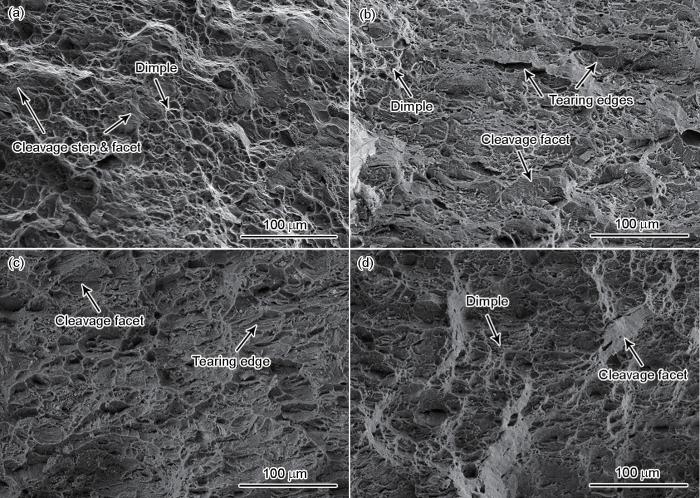

在250 ℃不同轧制变形量下Mg-8Li-4Gd-1.5Ni合金的断口形貌如图5所示。可以看出,合金在30%变形量时断口具有较大、较深的韧窝,但也出现部分解理台阶和解理平面,说明合金仍具有良好的塑性。在变形量为50%时存在部分韧窝,但韧窝变得更小、更浅,且出现更多的解理平面及部分撕裂棱,表明合金的韧性进一步下降。在合金变形量达到70%时,断口中存在大量的撕裂棱,这些撕裂棱较浅且含较多的解理平面,说明此时合金的断裂为韧性及脆性的混合断裂,其韧性较差。而在变形量为90%时,重新出现较多的韧窝,但还存在少量的撕裂棱及解理平面,说明合金的塑性有所提高。

图5

图5

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金的断口形貌

Fig.5

Fracture morphologies of rolled Mg-8Li-4Gd-1.5Ni alloy with deformations of 30% (a), 50% (b), 70% (c), and 90% (d) at 250 oC

2.3 浸泡实验

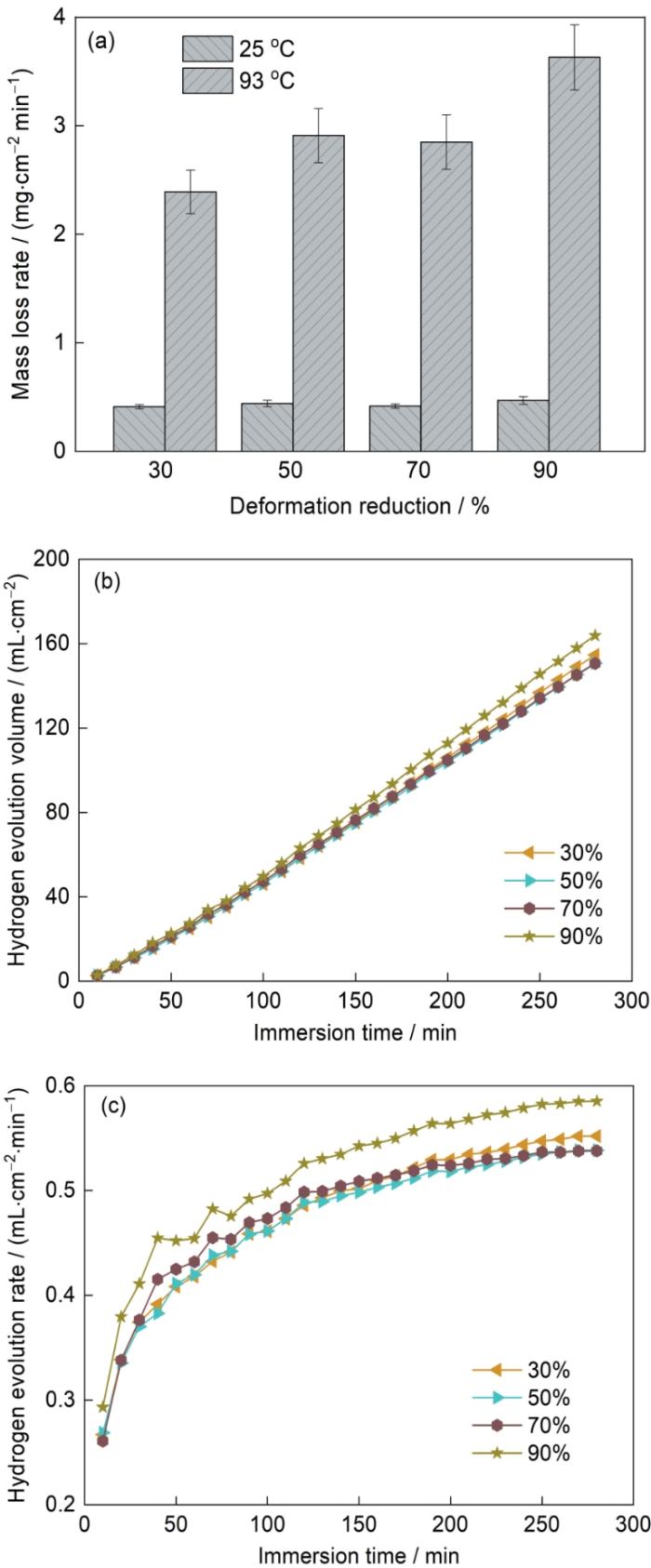

图6为250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中的失重速率、析氢体积及析氢速率。由图6a可知,93 ℃浸泡时的失重速率远高于25 ℃浸泡时的失重速率。变形量为90%时合金具有最高的失重速率,93 ℃浸泡时的失重速率为3.63 mg/(cm2·min),比25 ℃浸泡时的失重速率(0.47 mg/(cm2·min))提高7.72倍。25 ℃时铸态Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡的失重速率为0.36 mg/(cm2·min)[29]。变形量为50%的合金,其失重速率大于变形量为70%的合金,这是由于热轧过程中较大的变形量使LPSO相被拉长、偏转,形成了平行分布的纤维状的LPSO相,可能在腐蚀过程中阻碍腐蚀的扩展[32]。从图6b和c可见,25 ℃浸泡时,随浸泡时间延长析氢体积及析氢速率也不断增大;随变形量的增大析氢体积及析氢速率与失重速率变化趋势相同,90%变形量的合金析氢体积及析氢速率最大。变形量为30%、50%、70%和90%的Mg-8Li-4Gd-1.5Ni合金在浸泡280 min后的析氢体积分别为154.60、150.79、150.62和163.89 mL/cm2。

图6

图6

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中的失重速率、析氢体积和析氢速率

Fig.6

Mass loss rates (a), hydrogen evolution volumes (b), and hydrogen evolution rates (c) of rolled Mg-8Li-4Gd-1.5Ni alloy with different deformations at 250 oC after soaking in 3%KCl solution

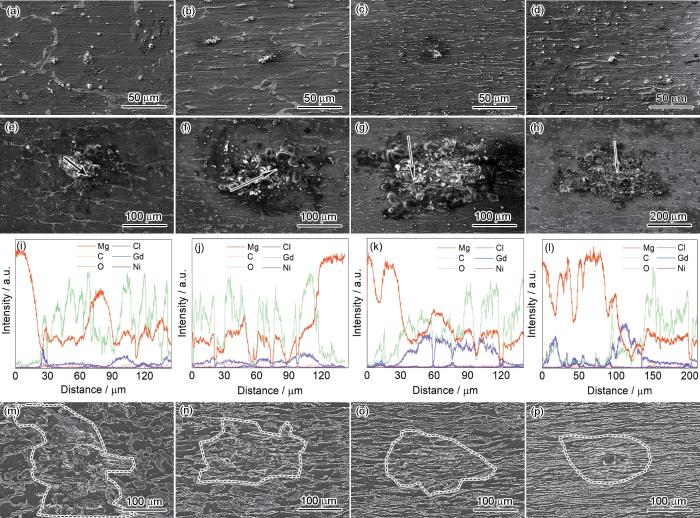

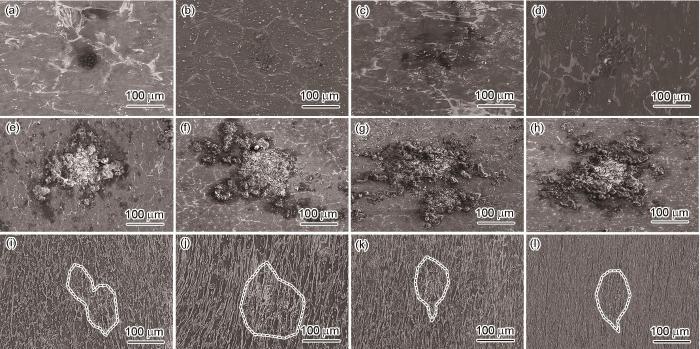

图7a~h为250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡2和30 s后轧制方向-法向(RD-ND)平面上表面形貌的SEM像。从浸泡2 s后的腐蚀形貌(图7a~d)可知,在第二相附近开始出现初始的腐蚀点,并且变形量为90%的合金出现的腐蚀点较多、较大,此时合金发生了电偶腐蚀[13]。腐蚀30 s后,腐蚀类型变为丝状腐蚀(图7e~h)。对浸泡30 s后生成的腐蚀产物进行EDS线扫描,如图7i~l所示,发现浅灰色致密的区域O含量较多,C含量也有所提高,这可能是由于β-Li相最先发生腐蚀生成了Li2CO3[13]。由于Li2CO3较为致密,使腐蚀产物层变形,因此观察到腐蚀产物之间存在裂缝,腐蚀可进一步深入,但β-Li被致密腐蚀产物层覆盖难以进一步腐蚀[7]。后续α-Mg开始腐蚀,形成一些疏松的亮白色腐蚀产物,EDS结果表明亮白色位置的C含量较低而O含量较高,说明此位置的腐蚀产物为MgO或Mg(OH)2[29]。α-Mg形成的亮白色腐蚀产物大部分存在于Li2CO3周围,这种腐蚀产物较为疏松,后续会将Li2CO3覆盖[13]。去除腐蚀产物后的SEM像如图7m~p所示,虚线部分是被腐蚀区域。可见,90%变形量的合金在腐蚀扩展的过程中,沿轧制方向拉长呈纤维状平行分布的LPSO相对腐蚀有所阻碍,因此腐蚀坑沿轧制方向延长。图8a~h为250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡后2和30 s后轧制方向-横向(RD-TD)平面上表面形貌的SEM像。在腐蚀2 s的SEM像(图8a~d)中可观察到腐蚀产物均出现在LPSO相的周围。腐蚀30 s时腐蚀类型为丝状腐蚀,且腐蚀产物存在亮白色及深色2种,分别为MgO、Mg(OH)2或Li2CO3。将腐蚀产物去除后可发现腐蚀产物坑沿轧制方向拉长(图8i~l),这说明腐蚀在向周围的扩展过程中受到部分阻碍。

图7

图7

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡2和30 s后轧制方向-法向(RD-ND)平面上表面形貌的SEM像,浸泡30 s后腐蚀产物的EDS线扫描结果,及去除腐蚀产物后腐蚀表面形貌的SEM像

Fig.7

RD-ND surface SEM images of rolled Mg-8Li-4Gd-1.5Ni alloy with deformations of 30% (a, e), 50% (b, f), 70% (c, g), and 90% (d, h) at 250 oC after soaking in 3%KCl solution for 2 s (a-d) and 30 s (e-h), corrosion products EDS line scaning results along arrows in Figs.7e-h (i-l), and surface SEM images after removal of corrosion products after soaking in 3%KCl solution for 30 s (m-p) (RD—rolling direction, ND—normal direction. Lines in Figs.7m-p show the corrosion regions)

图8

图8

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡后2和30 s后轧制方向-横向(RD-TD)平面上表面形貌的SEM像,及去除腐蚀产物后腐蚀表面形貌的SEM像

Fig.8

RD-TD surface SEM images of rolled Mg-8Li-4Gd-1.5Ni alloy with deformations of 30% (a, e), 50% (b, f), 70% (c, g), and 90% (d, h) at 250 oC after soaking in 3%KCl solution for 2 s (a-d) and 30 s (e-h), and surface SEM images after removal of corrosion products after soaking in 3%KCl solution for 30 s (i-l) (TD—transverse direction)

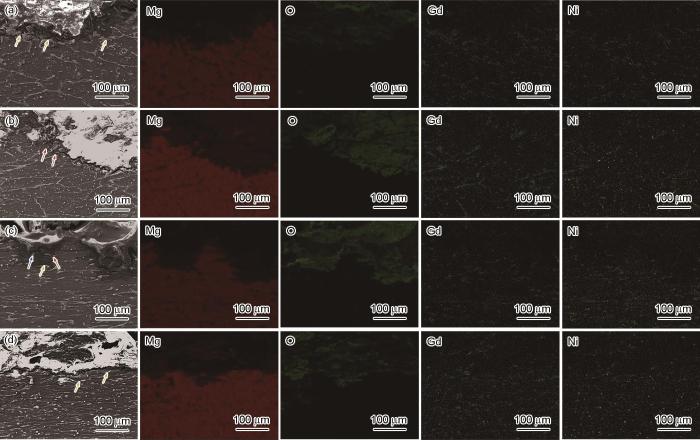

图9为250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡1 h后RD-ND面表面形貌SEM像及EDS面扫描结果。在变形量为30%时LPSO相网状结构连接较为紧密,阻碍腐蚀扩展的位点较多,如图9a中黄色箭头所示。在变形量为50%时,由于轧制变形和再结晶使LPSO相之间间隙较小的部位进一步拉大,导致腐蚀从间隙部位进一步深入,如图9b中红色箭头所示。在变形量为70%时,组织变为层状分布,层层堆叠的LPSO相会阻碍腐蚀向深处扩展,如图9c中黄色箭头所示。但是由于热轧过程中小晶粒的生成使部分组织在轧制过程中并没有形成纤维状,如图9c中蓝色箭头所示。这使腐蚀更易向水平方向扩展,如图9c中红色箭头所示腐蚀部位,从对应的EDS面扫描结果可以明显看到O元素(被腐蚀区域)直接从侧面开始扩展至组织内部。而在变形量为90%时,合金中层与层的间距明显减小,但LPSO相变为短纤维状对腐蚀扩展有一定阻碍,如图9d中黄色箭头所示部位。但是由于轧制变形量较大,250 ℃热轧条件使LPSO相之间有一定间距,再结晶晶粒更多,此位置没有LPSO相的阻碍,使腐蚀能快速向周围扩展[33]。并且变形量越大,合金中位错、再结晶晶粒及断裂变形的LPSO相使合金内部化学活性积累得越高,从而使合金的腐蚀速率提高。

图9

图9

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3%KCl溶液中浸泡1 h后RD-ND面上表面形貌的SEM像及EDS面扫描结果

Fig.9

RD-ND surface SEM images and corresponding EDS element maps of rolled Mg-8Li-4Gd-1.5Ni alloy with deformations of 30% (a), 50% (b), 70% (c), and 90% (d) at 250 oC after soaking in 3%KCl solution for 1 h (Yellow arrows show the area where LPSO phase prevents corrosion, red arrows indicate that the corrosion is spreading further, blue arrow represents bulk LPSO phase)

2.4 电化学测试

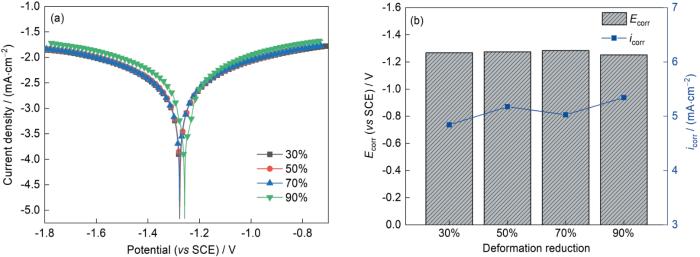

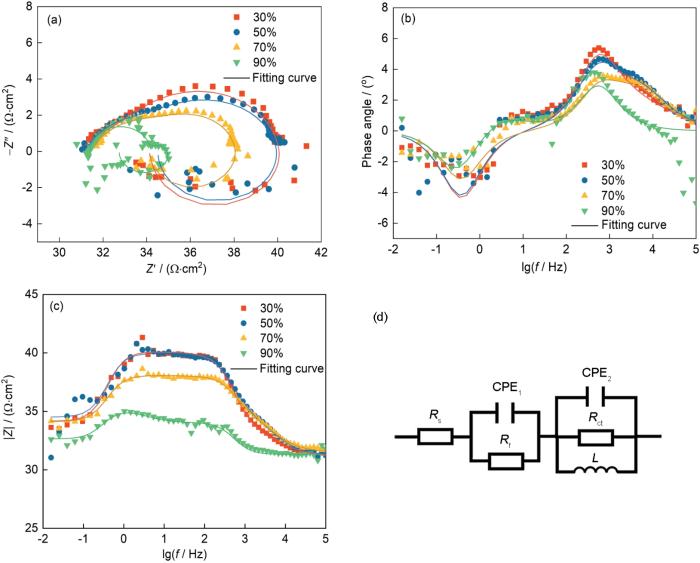

图10

图10

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金的极化曲线及其拟合结果

Fig.10

Polarization curves of rolled Mg-8Li-4Gd-1.5Ni alloy at 250 oC with different deformations (a) and fitting results (b) (SCE—saturated calomel electrode, Ecorr—corrosion potential, icorr—corrosion current density)

图11为250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金的EIS及等效电路。从图11a的Nyquist曲线可知,不同轧制态合金表现出高频和中频范围的2个容抗弧和低频范围的1个感抗弧,分别与腐蚀产物膜中的电荷转移以及合金表面与KCl溶液界面之间的电荷转移反应有关[36]。在高频区电容电路中,轧制变形量为90%的合金呈现最小的半圆,表明电荷转移最活跃,具有最大的电荷转移电阻[37]。随轧制变形量的增加高频容抗弧不断减小,说明腐蚀速率不断加快。90%变形量合金的中频容抗弧最小,说明其腐蚀产物相比其他变形量合金的腐蚀产物更疏松,腐蚀更容易深入[38]。从图11b的相角图可以看到,有2个波峰和1个波谷,分别对应高频容抗弧、中频容抗弧及低频感抗弧。变形量90%的合金,其相位角的峰值和峰宽均小于其他3种变形量的合金,进一步表明其阻抗较小,腐蚀速率最大。由图11c阻抗模量与频率的Bode曲线图可知,阻抗模量从高频到中频增加,然后在低频降低。阻抗模量越小,说明合金腐蚀速率越大。图11d为腐蚀过程的等效电路图,相应的拟合数据如表1所示。其中,Rs表示溶液电阻,它与溶液的电导率有关;CPE1为描述腐蚀膜层电容的常相位角元件,CPE2为描述合金表面及电解液之间的双层电容的常相位角元件;Rf表示表面膜电阻,主要由膜孔隙率和膜孔隙中的溶液电导率决定;Rct表示腐蚀膜与基体表面之间的电荷转移电阻[39];L为低频电感,表明开始形成腐蚀产物膜时,局部腐蚀反应出现。在腐蚀过程中,当Mg和Li接触溶液时,形成Mg2+和Li+,并形成一层腐蚀产物膜,但形成的腐蚀产物膜很快被破坏,腐蚀膜很难阻碍离子扩散,容易形成局部腐蚀[40]。根据表1中的拟合结果,30%、50%、70%和90%轧制变形量的Mg-8Li-4Gd-1.5Ni合金的Rct分别为5.95、5.46、3.94和2.71 Ω·cm2,表明随热轧变形量提高合金腐蚀速率不断提高,变形量90%的合金腐蚀速率最大。

图11

图11

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3.0%KCl溶液中的电化学阻抗谱(EIS)及等效电路图

Fig.11

Electrochemical impedance spectroscopy (EIS) (a-c) and equivalent circuit (d) of rolled Mg-8Li-4Gd-1.5Ni alloy with different deformations at 250 oC after soaking in 3.0%KCl solution

(a) Nyquist curves (Z'—real part of the impedance, Z"—imaginary part of the impedance)

(b) Bode angle plots (f—frequency)

(c) Bode impedance plots (|Z|—mode of impedance)

(d) equivalent circuit (Rs—solution resistance, CPE1—a constant phase element representing the surface film capacitance, Rf—surface film resistance mainly determined by the film porosity and the solution conductivity in the film pores, CPE2—a constant phase element related to the double layer capacitance, Rct—charge transfer resistance at film/substrate interface, L—inductance meaning the collapse of partial protective film)

表1 250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3.0%KCl溶液中的EIS拟合结果

Table 1

Deformation % | Rs Ω·cm2 | CPE1 s | n1 | Rf Ω·cm2 | CPE2 s | n2 | Rct Ω·cm2 | L H |

|---|---|---|---|---|---|---|---|---|

| 30 | 32.94 | 4.84 × 10-4 | 0.63 | 3.22 | 7.06 × 10-5 | 0.96 | 5.95 | 2.31 |

| 50 | 31.24 | 6.05 × 10-5 | 0.82 | 3.28 | 1.07 × 10-4 | 0.92 | 5.46 | 2.17 |

| 70 | 31.46 | 1.11 × 10-4 | 0.80 | 2.67 | 1.01 × 10-4 | 0.77 | 3.94 | 1.61 |

| 90 | 31.42 | 6.57 × 10-2 | 0.83 | 1.33 | 1.13 × 10-4 | 0.99 | 2.71 | 1.37 |

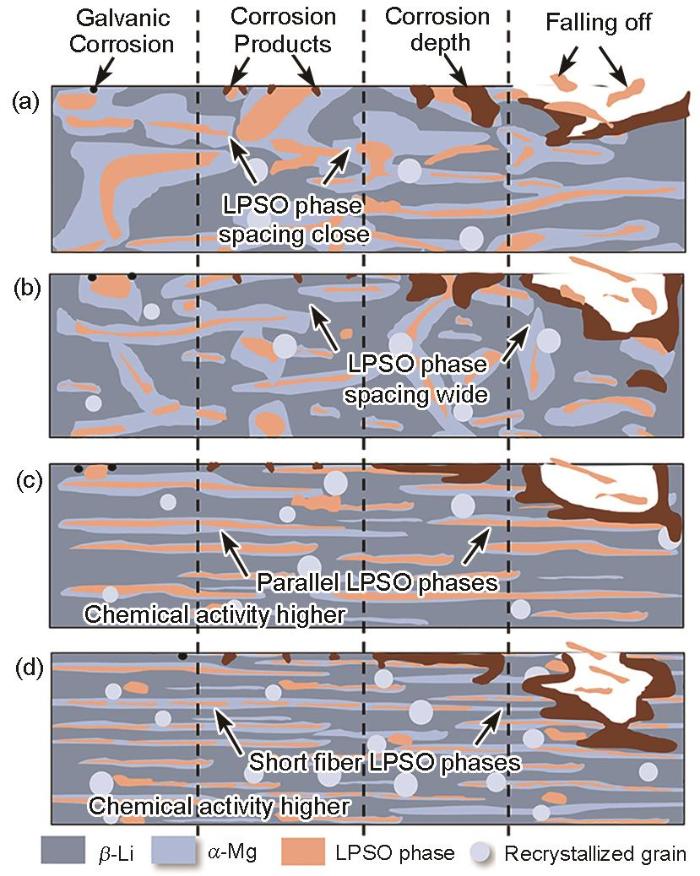

图12为250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3.0%KCl溶液中腐蚀机理示意图。合金腐蚀的发生主要分为4个阶段。第一阶段是LPSO相或GdNi3与基体(或α-Mg与β-Li)之间形成了电偶,并引发电偶腐蚀[29,41]。由于LPSO相和GdNi3的电位较高,α-Mg基体及β-Li基体电位次之,β-Li的电位最低,因此会出现较多的电偶,形成电偶腐蚀[29]。其中存在3种电偶腐蚀:LPSO相与α-Mg基体的电偶腐蚀,其中LPSO相为阴极,α-Mg为阳极;GdNi3与α-Mg/β-Li基体的电偶腐蚀,其中GdNi3为阴极,α-Mg/β-Li基体为阳极;α-Mg基体与β-Li基体的电偶腐蚀,其中β-Li基体为阴极,α-Mg基体为阳极。第二阶段是在电偶周围开始形成许多尺寸较小的腐蚀区。第三阶段是在较小的腐蚀区域周围腐蚀不断扩展。第四阶段,较为疏松的腐蚀产物与基体分离并分散在溶液中,而腐蚀进一步扩展到基体中[42]。如图12a所示,当轧制变形量较小时,第二相之间尤其是LPSO相仍然间距较近,形成类似网状的结构,阻碍腐蚀的扩展。但是随着轧制变形量的增大,合金中发生再结晶从而使LPSO相之间的间距更大,腐蚀可以从间隙中继续向下深入,如图12b所示。轧制变形量越大时LPSO相大部分变为平行状排列,同时再结晶使小部分LPSO相依然保持块状。轧制会不断累积位错,大量LPSO相发生弯曲扭转,形成再结晶晶粒,这些因素综合会使合金具有更高的化学活性。且较大的轧制变形量会使平行状的LPSO相间隙增大增多,使阻碍腐蚀的作用减弱,增加了电偶腐蚀位点,导致腐蚀速率不断增大。

图12

图12

250 ℃下不同轧制变形量Mg-8Li-4Gd-1.5Ni合金在3.0%KCl溶液中的腐蚀机理示意图

Fig.12

Corrosion mechanisms of rolled Mg-8Li-4Gd-1.5Ni alloy with deformations of 30% (a), 50% (b), 70% (c), and 90% (d) at 250 oC after soaking in 3.0%KCl solution

3 结论

(1) 250 ℃下轧制使Mg-8Li-4Gd-1.5Ni合金中的LPSO相由类似网状结构向平行的纤维状转变,90%变形量时LPSO相为短纤维状。再结晶使合金纤维状组织内还存在块状组织。LPSO相的弯曲、GdNi3的破碎、再结晶和位错密度的增加使合金内部的化学活性增强。

(2) 随着轧制变形量的增加,合金的抗拉强度先增加后减小。变形量为70%的合金抗拉强度最高,达到217 MPa,延伸率17%。合金主要的强化机制为加工硬化及细晶强化。

(3) 随着轧制变形量的增大腐蚀速率不断提升。变形量为90%的合金表现出最高的腐蚀速率,93 ℃时失重速率最高,达到3.63 mg/(cm2·min),比25 ℃时的失重速率(0.47 mg/(cm2·min))提高7.72倍;25 ℃时析氢体积163.89 mL/cm2,腐蚀电流密度为5.34 mA/cm2。

(4) 平行纤维状的LPSO相会抑制腐蚀,但随合金变形量的增大,较大的变形与再结晶使平行分布的LPSO相间隙增大增多,电偶腐蚀位点增多,合金腐蚀速率加快。

参考文献

Enhanced mechanical properties and degradation rate of Mg-Ni-Y alloy by introducing LPSO phase for degradable fracturing ball applications

[J].

A review on magnesium alloys for application of degradable fracturing tools

[J].

Effect of trace Ni addition on microstructure, mechanical and corrosion properties of the extruded Mg-Gd-Y-Zr-Ni alloys for dissoluble fracturing tools

[J].Magnesium alloys, a novel functional material for the fabrication of fracturing tools, are being paid more and more attentions recently due to their relatively high mechanical properties and fast dissolubility ability after fracturing. In this study, the novel extruded Mg-10Gd-3Y-0.3Zr-xNi alloys will be reported and their microstructure, mechanical and corrosion behaviors will be also studied. The results show that Ni contents influence phase precipitation behaviors. With adding 0.2 wt% Ni, a large amount of Zr7Ni10 phases will be precipitated insides alpha-Mg matrix, directly leading to degradation of strength and large corrosion rate. With further increasing Ni contents, the precipitation phases can be changed from Mg5RE to 18R-LPSO structure, resulting in higher mechanical properties and faster corrosion rate. Moreover, adding Ni element also change the texture orientation by influencing the precipitation behavior of the alloys. The alloys invented in this paper have attained the highest compressive and tensile properties among all the reported dissoluble magnesium alloys. This work is beneficial in understanding the role of Ni in the magnesium alloys and provides more materials alternatives for the fabrication of dissoluble fracturing tools. (C) 2020 Chongqing University. Publishing services provided by Elsevier B.V. on behalf of KeAi Communications Co. Ltd.

Advances and challenges in hydraulic fracturing of tight reservoirs: A critical review

[J].

Effect of Li content on electromagnetic shielding effectiveness in binary Mg-Li alloys: A combined experimental and first-principles study

[J].

High specific strength Mg-Li-Zn-Er alloy processed by multi deformation processes

[J].

Corrosion behavior of Mg-Li alloys: A review

[J].

Strengthening-toughening methods and mechanisms of Mg-Li alloy: A review

[J].

Development of unconventional gas and technologies adopted in China

[J].

Research progress of soluble magnesium alloy for fracturing temporary plugging tools

[J].

压裂暂堵工具用可溶镁合金的研究进展

[J].

Latest research advances on magnesium and magnesium alloys worldwide

[J].

Structural characterisation and degradation of Mg-Li thin films for biodegradable implants

[J].Freestanding thin films of Mg-Li (magnesium-lithium) alloys with a Li mass fraction between 1.6% (m/m) and 9.5% (m/m) were prepared and studied with respect to their structure and degradation properties. With increasing Li content, the microstructure deviates from hexagonal Mg-Li with strict columnar growth and preferred orientation, and additional cubic Mg-Li and LiCO occur. The corrosion rate was measured in Hanks' balanced salt solution by potentiodynamic polarisation and weight loss measurements to investigate biodegradation. Influences of the orientation, phase and protective layer formation lead to an increase in corrosion from 1.6 to 5.5% (m/m) from 0.13 ± 0.03 to 0.67 ± 0.29 mm/year when measured by potentiodynamic polarisation but a similar corrosion rate for 9.5% (m/m) and 3% (m/m) of Li of 0.27 ± 0.07 mm/year and 0.26 ± 0.05 mm/year.© 2023. Springer Nature Limited.

Effect of rolling ratios on the microstructural evolution and corrosion performance of an as-rolled Mg-8 wt.%Li alloy

[J].In this work, the influence of rolling ratios on microstructural changes and corrosion behavior of an as-rolled Mg-8 wt.%Li alloy in 0.1 mol/L NaCl solution has been investigated. It revealed that with the rolling ratio being increased from 3 to 10, the alpha-Mg phases were elongated and fragmented, whilst the area fraction of exposed beta-Li phases increased. Meanwhile, the corrosion performance of the alloy decreased with the increased rolling ratios. For all the samples, their corrosion processes were quite similar and can have two stages. At the initial stage with the samples being immersed for less than 6 h, the corrosion mainly occurred in beta-Li phases. When the samples were immersed for longer than 6 h, the corrosion attack transferred to alpha-Mg phases and the hydrogen evolution rate was accelerated. (C) 2020 Chongqing University. Publishing services provided by Elsevier B.V. on behalf of KeAi Communications Co. Ltd.

Improving corrosion resistance of Mg-Li alloys by Sn microalloying

[J].

Synergistically improved damping, elastic modulus and mechanical properties of rolled Mg-8Li-4Y-2Er-2Zn-0.6Zr alloy with twins and long-period stacking ordered phase

[J].

Plastic deformation and heat treatment of Mg-Li alloys: A review

[J].As the lightest structural metallic materials, Mg-Li alloys have a bright development prospect in the fields of aerospace, weapon equipment, electronic technology and transportation. In this paper, the research progress of deformation processing and heat treatment of Mg-Li alloys is reviewed, with particular emphasis on the factors affecting the plastic deformation, the effects of plastic deformation on microstructural evolution and mechanical properties, and the heat treatment behavior of Mg-Li alloys. The problems existing in the scale application of Mg-Li alloys are pointed out, and the research focus of Mg-Li alloys in the future are also prospected.

Microstructure and corrosion behavior of as-extruded Mg-6.5Li-xY-yZn alloys

[J].

Research progress on biocompatibility evaluation of biomedical degradable zinc alloys

[J].Zn and its alloys have recently been used as a new class of biodegradable biomedical metals besides magnesium and iron alloys, owing to their moderate corrosion rate and good mechanical properties. In recent years, researchers have rigorously studied the design, processing, and degradation mechanism of Zn alloys, but their biocompatibility has not been well explored. Past research on the biocompatibility of Zn alloys focused on in vitro cytotoxicity, hemolysis, and coagulation, and only a few materials were implanted into animals for characterizing the histocompatibility. Biocompatibility involves complex local and systemic reactions, such as cells, tissues, blood, and immunity. In addition to the physical and chemical properties of the material, the biocompatibility is also affected by interactions between the material and body. In this paper, the chemical and phase compositions of degradable zinc alloys were analyzed, and the biological evaluation methods were clarified. In view of the recent studies on zinc alloy biocompatibility, future research directions were proposed.

医用可降解锌合金的生物相容性评价研究进展

[J].锌合金由于其适宜的腐蚀速率、良好的力学性能,成为继镁合金与铁合金后的一种新型的可降解生物医用金属材料。近年来,研究者对锌合金的设计、加工制备以及降解机理进行了大量研究,但对其体内外生物相容性的研究尚不充分,仅评估了体外细胞毒性、溶血、凝血,少数材料植入动物体内进行了组织相容性的表征。然而生物相容性涉及细胞、组织、血液、免疫等复杂的局部反应和全身反应,除了材料本身的物理化学性质,还受到材料与机体相互作用的影响。本文分析了可降解医用锌合金的化学成分和物相组成,阐明了对其进行生物学评价的方法,并结合锌合金生物相容性研究现状,阐述未来的研究方向。

Numerical simulation and experimental study on porthole die extrusion process of LZ91 Mg-Li alloy

[J].Porthole die extrusion is the dominant process to produce hollow profiles due to its high productivity and capacity in producing complex profiles. In this study, the finite element simulation model of porthole die extrusion of LZ91 Mg-Li alloy was established. The effects of extrusion ratio on strain, temperature and flow velocity were studied, and the welding quality was quantitatively evaluated by means of J criterion. The experiments of porthole die extrusion were carried out by varying extrusion ratios. The microstructures of as-cast, homogenized and extruded LZ91 Mg-Li alloy were examined. The results show that the materials near the bridge surface and at the bottom of the bridge have large deformation, while the materials inside the portholes have small deformation. Moreover, with the increase of extrusion ratio, the effective strain of material is increased. Due to the heat generated by plastic deformation and the heat dissipation caused by profile cooling, the temperature of the material on the top of bridge is increased, while that of the material near the die exit becomes lower. The welding quality in the central area of weld seam is lower than that in the edge area of weld seam. With the increase of extrusion ratio, the welding quality is improved. More nucleation is generated in welding zone due to its large strain, resulting in the formation of fine grains. However, the dynamic recrystallization is not complete in the matrix zone, and some coarse grains still remain. Moreover, the material temperature becomes higher with high extrusion ratio, and the phenomenon of grain growth is observed.

LZ91 Mg-Li合金分流模挤压成形过程数值模拟与实验研究

[J].

Effect of Gd addition on mechanical and microstructural properties of Mg-xGd-2.6Nd-0.5Zn-0.5Zr cast alloys

[J].

Effect of multi-pass compression deformation on microstructure evolution of AZ80 magnesium alloy

[J].Magnesium alloy has a hexagonal close-packed crystal structure, and its plasticity is poor at room temperature. This is primarily due to the small number of movable slip systems at room temperature, which is prone to deformation texture. Therefore, temperature and compression deformation play an important role in the regulation of plastic deformation. In this work, AZ80 magnesium alloy was subjected to multi-pass compression deformation at a constant temperature and step-down temperature. The microstructure of the AZ80 magnesium alloy with different deformation degrees and deformation paths was observed and analyzed using EBSD. In addition, the grain boundary, dislocation density, Schmid factor, and polar figure evolution of the AZ80 magnesium alloy during hot compression deformation were primarily studied. Results show that the comprehensive effect of grain size, twinning, and texture on the plastic regulation of AZ80 magnesium alloy is better than that of single dynamic recrystallization. Moreover, three-time constant-temperature deformation (ε = 0.6) promotes dynamic recrystallization, whereas three-time step-cooling deformation (ε = 0.6) promotes plastic deformation. More 86°{101¯2} <12¯10> tensile twins are produced by reduced grain orientation difference, increased number of low-angle grain boundaries, and increased geometrically necessary dislocation density, which are important factors affecting the plastic regulation of three-time step-cooling deformation (ε = 0.6).

多道次压缩变形对AZ80镁合金微观组织演化的影响

[J].镁合金具有密排六方结构,可动滑移系少导致其室温塑性差,而热加工对调控镁合金塑性有重要作用。本工作对AZ80镁合金分别进行恒温、阶梯降温多道次压缩变形,利用电子背散射衍射(EBSD)技术观察分析了不同变形程度、不同变形路径下AZ80镁合金的微观组织,研究了AZ80镁合金热压缩变形过程中晶界、位错密度、Schmid因子和极图演化规律。结果表明:晶粒尺寸、孪晶、织构综合作用对AZ80镁合金塑性调控的影响优于单一动态再结晶对其塑性调控的影响,恒温三次变形(ε = 0.6) (3P)有利于发生动态再结晶,而阶梯降温三次变形(ε = 0.6) (3P)更有利于塑性变形。晶粒取向差减小、小角度晶界(LAGBs)数量增多、几何必需位错(GND)密度增加3者共同作用产生更多86°{101¯2} <12¯10>拉伸孪晶是影响阶梯降温三次变形塑性调控的重要因素。

Anisotropic corrosion behavior of hot-rolled Mg-8wt.%Li alloy

[J].

Effect of Cu micro-alloying on the microstructure, mechanical and corrosion properties of Mg-Gd-Y-Zn based alloy applied as plugging tools

[J].

Enhanced degradation properties of Mg-Y-Ni alloys by tailoring the LPSO morphology for fracturing tools applications

[J].

Corrosion behavior characterization of as extruded Mg-8Li-3Al alloy with minor alloying elements (Gd, Sn and Cu) by scanning Kelvin probe force microscopy

[J].

Role of the LPSO structure in the improvement of corrosion resistance of Mg-Gd-Zn-Zr alloys

[J].

Grain refinement of as-cast Mg-RE alloys: Research progress and future prospect

[J].Magnesium rare-earth (Mg-RE) alloy castings with a large size and complex structure exhibit versatile prospects in critical aircraft, aerospace, and defense fields owing to their ultralow density, excellent specific strength, and high-temperature resistance. The grain refinement of cast Mg-RE alloys can significantly improve their strength, plasticity, toughness, and casting performance, which are critical for expanding their applications. In this work, the grain refinement mechanism of Mg alloys by introducing RE elements and heterogeneous particles is first discussed based on the classical theory of constitutional supercooling and heterogeneous nucleation. Various grain refinement technologies for Mg-RE alloy casting using chemical and physical methods are comprehensively summarized. Further, the influence of grain refinement on the casting performance, mechanical properties, and corrosion properties of Mg-RE cast alloys is thoroughly discussed. Finally, the deficiencies and development trends of the current grain refinement of Mg-RE alloys are discussed from the point of actual application requirements.

铸造Mg-RE合金晶粒细化行为研究现状与展望

[J].轻质高强耐热的镁稀土(Mg-RE)合金大型复杂铸件在航空航天、国防军工装备轻量化等方面展现出独特的优势。对铸造Mg-RE合金进行晶粒细化处理能够显著改善合金的强度、塑韧性以及铸造工艺性能,对拓宽其应用领域意义重大。本文首先基于成分过冷和异质形核,探讨了稀土元素及外加颗粒对镁合金晶粒细化的影响。归纳了适用于铸造Mg-RE合金的化学、物理细化方法及其作用机制,并系统论述了晶粒细化对铸造Mg-RE合金铸造工艺性能、力学性能及腐蚀性能的影响。最后面向Mg-RE合金的实际应用需求,对其细化处理方面存在的不足和发展趋势进行了探讨。

Microstructure and corrosion behavior of as-extruded Mg-xLi-3Al-2Zn-0.2Zr alloys (x = 5, 8, 11 wt.%)

[J].

Tailoring the degradation rate of magnesium-lithium alloy with alloying elements of gadolinium and nickel

[J].

Thermal stability of microstructures in low-density Ti2AlNb-based alloy hot rolled plate

[J].

低密度Ti2AlNb基合金热轧板微观组织的热稳定性

[J].采用OM、SEM、XRD和TEM研究了低密度Ti<sub>2</sub>AlNb基合金热轧板在600~1100℃保温12 h微观组织的热稳定性。结果表明,Ti<sub>2</sub>AlNb基合金原始态热轧板主要由α<sub>2</sub>、B2以及O相组成,颗粒状的α<sub>2</sub>相分布在B2相基体中。Ti<sub>2</sub>AlNb基合金热轧板600℃保温12 h,颗粒状的α<sub>2</sub>相分布在B2相基体中,B2相基体中分布着大量细小的O相板条。随着温度的升高,合金热轧板800~900℃保温12 h的微观组织由α<sub>2</sub>、B2以及O相三相构成,α<sub>2</sub>相颗粒逐渐球化,O相板条粗化并固溶于B2相基体中。当温度升高至950℃时,B2相基体中的O相板条消失。合金热轧板在950~1000℃保温12 h形成α<sub>2</sub> + B2两相区,α<sub>2</sub>相颗粒球化并趋向于分布在B2相基体的晶界处。当温度升高至1100℃时,合金基体为B2单相,B2晶界处分布着极少量的残留α<sub>2</sub>相颗粒。Vickes显微硬度分布结果显示,随着温度的升高,合金板材在600℃时硬度达到峰值(509 HV),这与大量细小的O相板条有关。

Effect of extrusion plus rolling on damping capacity and mechanical properties of Mg-Y-Er-Zn-Zr alloy

[J].

Enhancement of mechanical properties and corrosion resistance of Mg-Ca alloys through microstructural refinement by indirect extrusion

[J].

A high-specific-strength and corrosion-resistant magnesium alloy

[J].Ultra-lightweight alloys with high strength, ductility and corrosion resistance are desirable for applications in the automotive, aerospace, defence, biomedical, sporting and electronic goods sectors. Ductility and corrosion resistance are generally inversely correlated with strength, making it difficult to optimize all three simultaneously. Here we design an ultralow density (1.4 g cm(-3)) Mg-Li-based alloy that is strong, ductile, and more corrosion resistant than Mg-based alloys reported so far. The alloy is Li-rich and a solute nanostructure within a body-centred cubic matrix is achieved by a series of extrusion, heat-treatment and rolling processes. Corrosion resistance from the environment is believed to occur by a uniform lithium carbonate film in which surface coverage is much greater than in traditional hexagonal close-packed Mg-based alloys, explaining the superior corrosion resistance of the alloy.

A novel computational model for isotropic interfacial energies in multicomponent alloys and its coupling with phase-field model with finite interface dissipation

[J].In this work, a novel computational model for the description of the temperature- and composition-dependent isotropic interfacial energy in multicomponent alloys was first developed in the framework of the CALculation of PHAse Diagram (CALPHAD) approach and implemented in a home-made code. By linking to the open-source code for interfacial energy calculation in alloys, OpenIEC, the databases for isotropic γ/liquid and γ/γ' interfacial energies in Ni-Al, Ni-Cr, Al-Cr, and Ni-Al-Cr systems were then efficiently established. After that, a direct coupling strategy between the current CALPHAD interfacial energy database and the phase-field model with finite interface dissipation was proposed and applied to three-dimensional (3-D) phase-field simulations of the primary γ dendritic growth in both Ni-Al and Ni-Al-Cr alloys during isothermal solidification. The effect of the interfacial energy on the morphology, tip growth rate, and partitioning coefficients in primary γ dendrites of binary Ni-Al and ternary Ni-Al-Cr alloys was investigated by comprehensively comparing the phase-filed simulation results using the composition-/temperature-dependent interfacial energies with those using the constant value. It is anticipated that the presently developed CALPHAD model for interfacial energy is of general validity for different multicomponent alloys and should be integrated with the phase-field model for quantitative simulation of their microstructure evolution.

Comprehensive determination of kinetic parameters in solid-state phase transitions: An extended Jonhson-Mehl-Avrami-Kolomogorov model with analytical solutions

[J].

What activates the Mg surface—A comparison of Mg dissolution mechanisms

[J].Several mechanisms have been proposed to interpret the widely reported phenomenon of Mg corrosion that the hydrogen evolution rate increases with increasing anodic potential or anodic current density. This paper critically analyzed the two main mechanisms, (1) “the incomplete film univalent Mg + ion mechanism” and (2) “the enhanced catalytic activity mechanism”, aiming to clarify the current understanding of the Mg corrosion mechanism and to provide a profound insight into the Mg characteristic electrochemical behavior, anodic polarization accelerating both hydrogen evolution and Mg dissolution. It is expected that the deepened fundamental understanding from this comprehensive mechanistic review will provide a basis of practical applications for Mg alloys and open up a new way to the control of corrosion of Mg alloys in practice.

A self-healing corrosion protection coating with graphene oxide carrying 8-hydroxyquinoline doped in layered double hydroxide on a micro-arc oxidation coating

[J].

Influence of long period stacking ordered phase arrangements on the corrosion behaviour of extruded Mg97Y2Zn1 alloy

[J].

Influence of Ca and Zn on the microstructure and corrosion of biodegradable Mg-Ca-Zn alloys

[J].

Multi-functional superhydrophobic coatings on Mg-Li alloys via SiO2 nano particles assembled surface modification

[J].

The anodic role of Ni-containing LPSO phases during the microgalvanic corrosion of Mg98Gd1.5Ni0.5 alloy

[J].

The electrochemical behaviors of Mg-8Li-0.5Y and Mg-8Li-1Y alloys in sodium chloride solution

[J].