伴随着当代工业的迅速崛起,高性能不锈钢的市场需求日益提高[1~3]。其中,奥氏体不锈钢(austenitic stainless steel,ASS)凭借其优异的耐蚀性、成型性和焊接性等优势,在石油化工、能源存储、生物工程和深海船舶等领域展现出广阔的应用前景[4,5]。作为资源节约型材料的高氮奥氏体不锈钢(high nitrogen austenitic stainless steel,HNASS),更是以强耐磨性、低磁化性和绿色价廉等显著优势,成为钢铁行业关注的焦点[6~8]。通常情况下,HNASS中的最低N含量应达到0.4% (质量分数),如此高含量的N添加可产生间隙固溶强化效果,在一定程度上改善材料的屈服强度[9,10]。然而,以fcc结构为主相的HNASS的室温屈服强度仍然有限(不超过600 MPa)[11~13],难以满足实际工程中大载荷的应用需求。

鉴于此,材料研究者采用合适的热机械加工工艺,向HNASS中引入位错强化、析出强化和细晶强化等多种传统强化机制,以进一步提升其综合力学性能。例如,Odnobokova等[14]针对化学成分为Fe-0.05C-20.74Cr-8.08Ni-15.33Mn-1.04Mo-0.22V-0.11Si-0.72N(质量分数,%,下同)的HNASS,分别在1000 ℃下进行1 h的高温退火和累积压下量为60%的热轧工艺处理,结果表明,热轧态HNASS的屈服强度可达1060 MPa (相较于退火态材料提升2倍多),断裂延伸率保持在21%,位错强化是该材料屈服强度大幅提升的主要原因。Wang等[15]对化学成分为Fe-18.06Cr-17.9Mn-0.46Si-0.62N-0.084C的HNASS在室温下进行累积压下量为70%的冷轧和800 ℃下20 min的完全再结晶退火,获得了屈服强度达910 MPa、断裂延伸率达43%的综合力学性能。存在于奥氏体基体中大量弥散分布的球状Cr2N析出相和细小的再结晶晶粒使该材料具备较高的屈服强度。此外,He等[16]以化学成分为Fe-16.56Mn-17.08Cr-2.34Mo-0.74N-0.06C的HN ASS为研究对象,对其施加累积压下量为60%的冷轧和810 ℃下3 min的部分再结晶退火,获得了屈服强度高达1377 MPa、均匀延伸率为12.6%的综合力学性能。该材料超高的屈服强度得益于经冷变形和退火后获得的非均匀组织,进而诱发位错强化、细晶强化、析出强化和具有局部化学有序(local chemical order,LCO)结构的板条强化等多种机制的协同作用。值得说明的是,在该HNASS中所观察到的LCO板条被证实是在冷轧过程中由间隙原子N和LCO结构相互促进而形成的平面滑移带经退火后演化得来。位于板条内部的LCO结构(由局部化学短程有序(short range order,SRO)和中程有序(medium range order,MRO)结构组成)以及密集的板条边界均可有效地阻碍位错运动并显著提升材料屈服强度。此种LCO板条也被认为是一种可通过热机械处理调控并有效改善材料综合力学性能的新结构。

近年来,深冷轧制(即在深低温环境进行轧制的工艺)作为材料加工领域的一项变革性技术,逐渐步入人们的视线[17~20],已被成功应用于铜合金[21,22]、铝合金[23,24]和钛合金[25]等高性能材料的制备中。在钢铁材料加工领域,深冷轧制技术同样展现出巨大的应用潜力与良好的发展前景。Li等[26]对化学成分为Fe-30Mn-0.3C-Al的高锰钢采用深冷轧制工艺,获得了1100 MPa的屈服强度以及13%的断裂延伸率。在深冷轧制过程中引入的高密度位错和纳米孪晶大幅提升了材料的屈服强度。Singh等[27]研究发现,深冷轧制能够促进304 ASS发生马氏体相变,当轧制变形量由0增加到90%时,该材料的抗拉强度由693 MPa增加到1956 MPa。Xiong等[28]对Fe-25Cr-20Ni ASS研究发现,深冷轧制可促进形变孪晶的生成,且随着轧制变形量的增加,相邻孪晶的间距变小,孪晶与位错交互作用更加强烈,使材料强度显著提升。可见,深冷轧制处理可使钢铁材料获得独特的微观结构并表现出优异的综合力学性能。

综上,本工作将深冷轧制这一材料强韧化手段应用于一种HNASS中,对其在液氮温度下进行小变形量的深冷轧制并获得了由ε-马氏体板条、形变孪晶、LCO板条和密集的位错亚结构组成的非均匀组织。通过宏观力学性能测试和精细的微观结构表征,阐明了由深冷轧制引入的形变微结构与材料强韧化之间的关联,旨在为高强韧金属结构材料的研发提供新思路。

1 实验方法

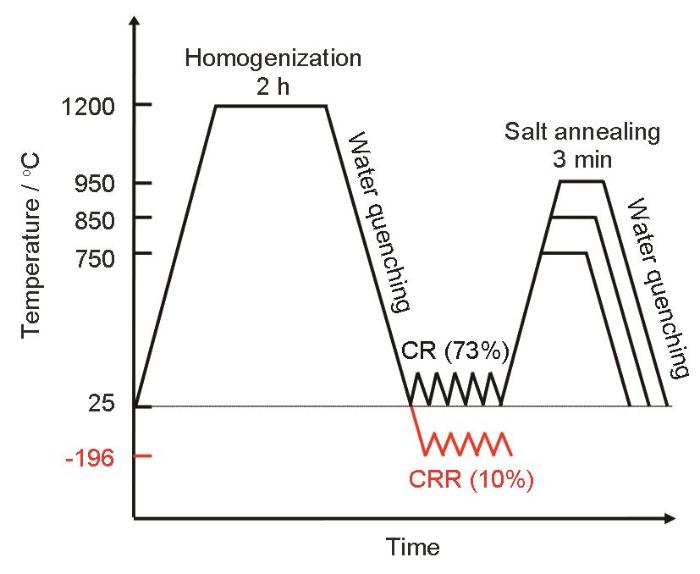

本工作使用的HNASS名义成分为Fe-18.87Cr-10.09Mn-1.12Ni-0.53N-0.18Si-0.04C,由Fe、Cr、Mn、Ni纯金属(纯度> 99.9%)、化合物CrN和硅石在以N2为保护气的真空感应炉和电渣重熔炉中熔铸而成。对不锈钢铸锭在1200 ℃下进行热锻后,于1100 ℃热轧,得到平均厚度为6 mm的热轧板。随后将热轧板在1200 ℃下进行2 h的固溶处理以消除偏析并水淬,得到固溶态(homogenization,HOMO)材料。对HOMO态实验用钢分别在室温下进行累积压下量为73%的多道次冷轧(CR)和液氮温度下总压下量为10%的单道次深冷轧制(cryogenic rolling,CRR),将由不同轧制工艺制备的实验材料分别记为CR73%和CRR10%。作为深冷轧制实验的对照组,将CR73%材料分别在750、850和950 ℃下进行3 min的短时盐浴退火,随后水淬,并将所得材料分别记为A750、A850和A950。样品制备的工艺流程如图1所示。

图1

图1

高氮奥氏体不锈钢热轧板的加工路线示意图

Fig.1

Schematic of processing routes for the high nitrogen austenitic stainless steel (HNASS) hot-rolled plate (CR—cold rolling, CRR—cryogenic rolling)

使用电火花线切割机将上述实验材料制备成狗骨状拉伸试样,其标距长度和宽度分别为13和3 mm。通过机械抛光法去除试样表面氧化层及宏观缺陷后,在AG-XPLUS100kN电子万能试验机上进行应变速率为1 × 10-3 s-1的室温单轴拉伸实验,拉伸方向平行于CR73%和CRR10%板材的轧制方向。使用Smartlab X射线衍射仪(XRD)对材料进行物相分析,CuKα1靶(波长λ = 0.154056 nm),在工作电压和电流分别为40 kV和200 mA的条件下对去除应变层的试样进行测试,扫描范围2θ = 40°~100°,扫描速率5°/min。

使用配备电子背散射衍射(BSE)和能谱(EDS)探头的Ultra Plus场发射扫描电子显微镜(SEM)对不同状态下各实验材料的微观结构进行表征。SEM试样首先经机械抛光得到平整且光亮的表面,而后进行电解抛光以去除试样表面的应变层。使用JEM-2100F透射电子显微镜(TEM)观察材料的微观结构。TEM试样首先经机械抛光至厚度为80 μm,随后从中冲出直径为3 mm的圆片,将圆片继续进行机械抛光至最终厚度为50 μm的箔片。最后使用电解双喷减薄仪在25 V、-25 ℃的条件下对箔片进行最终减薄。上述所用电解液均为10%HClO4 + 90% CH3CH2OH (体积分数)混合溶液。使用中国先进研究堆(CARR)的高分辨中子粉末衍射仪(HRPD)对试样进行中子衍射实验,测定不同状态下HN ASS内的位错密度。所用中子波长为0.18894 nm,扫描步长0.07°。为了保证测试结果的统计性,选择表面经机械抛光的直径6 mm、长25 mm的圆柱体进行测试。在中子衍射实验中,试样以中子束为轴进行旋转以消除织构的影响。

本工作将试样坐标系定义为由3个正交方向构成,分别是材料轧板的轧制方向(RD)、横向(TD)和法向(ND)。其中SEM试样取自轧板的侧轧面(即RD-ND平面),XRD、TEM和中子衍射试样取自轧板的轧面(即RD-TD平面)。

2 实验结果与分析

2.1 力学性能

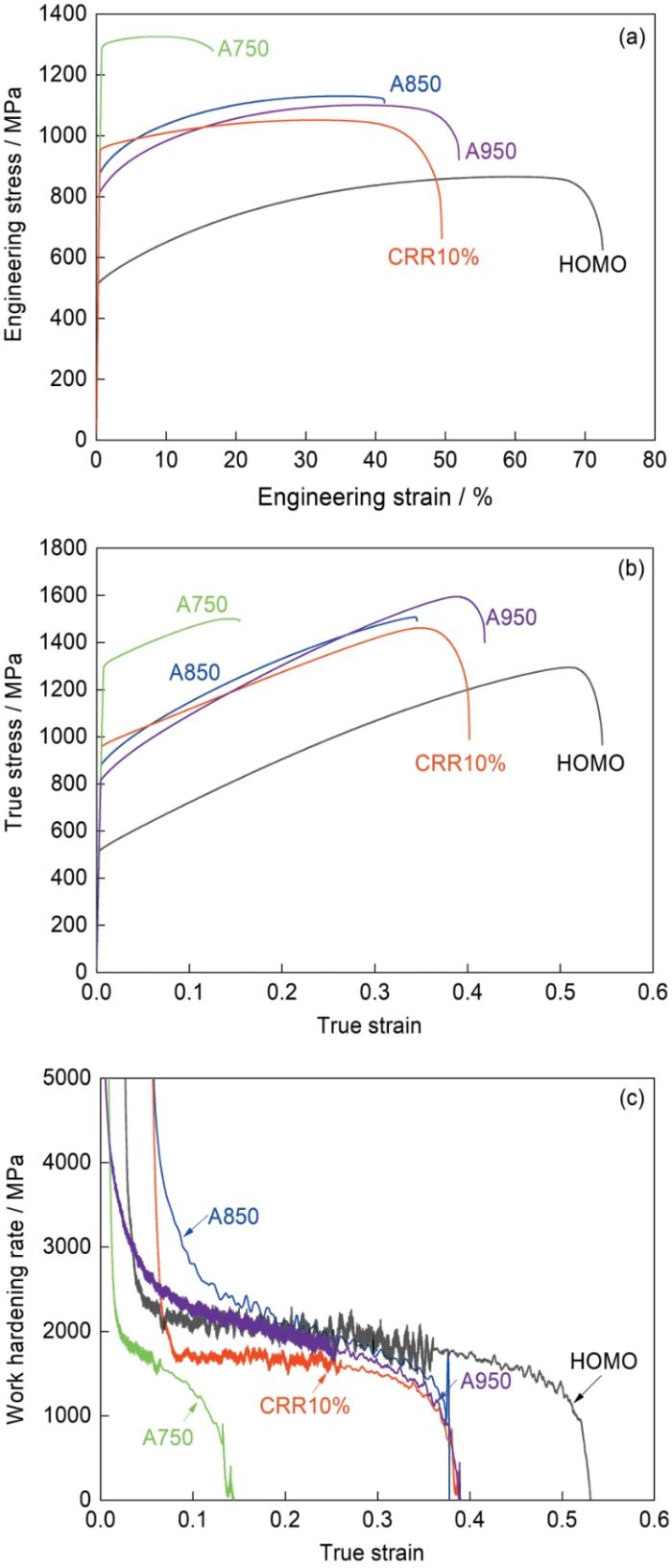

A750、A850、A950、HOMO和CRR10%材料的室温单轴拉伸力学性能测试结果如图2和表1所示。图2a为各材料的工程应力-应变曲线。结果表明,在室温轧制处理的基础上,随着退火温度的升高,材料的屈服强度降低,韧性提升。其中,A850材料获得了较为出色的综合力学性能,其屈服强度、抗拉强度和均匀延伸率分别达到875 MPa、1130 MPa和35%。经过深冷轧制的CRR10%材料获得了947 MPa的屈服强度、1051 MPa的抗拉强度和36%的均匀延伸率,其强度和韧性与A850材料十分接近,且相较于HOMO材料,CRR10%和A850材料的屈服强度分别是其屈服强度的1.86和1.72倍。各材料的真应力-应变曲线以及加工硬化率曲线分别如图2b和c所示。可见,A750、A850、A950、HOMO材料的加工硬化率均随着真应变的增加呈现出锯齿状波动并单调递减,CRR10%材料的加工硬化率在塑性变形初期即快速降低至1709 MPa,并在1709~1829 MPa之间波动至真应变为0.26,随后逐渐降低至断裂。上述结果表明,深冷轧制工艺在简化实验用钢的制备工艺和节约生产成本的前提下,保证了材料的综合力学性能。

图2

图2

A750、A850、A950、HOMO和CRR10%材料的工程应力-应变曲线、真应力-应变曲线及加工硬化率曲线

Fig.2

Egineering stress-strain curves (a), true stress-strain curves (b), work hardening rate vs true strain curves (c) of the A750, A850, A950, HOMO, and CRR10% materials at various states

表1 A750、A850、A950、HOMO和CRR10%材料的力学性能

Table 1

| Steel | Yield strength / MPa | Ultimate tensile strength / MPa | Uniform elongation / % |

|---|---|---|---|

| A750 | 1284 ± 5 | 1325 ± 5 | 8 ± 3 |

| A850 | 875 ± 3 | 1130 ± 3 | 35 ± 2 |

| A950 | 840 ± 2 | 1100 ± 2 | 37 ± 2 |

| HOMO | 509 ± 3 | 865 ± 3 | 60 ± 3 |

| CRR10% | 947 ± 4 | 1051 ± 4 | 36 ± 2 |

2.2 初始微观结构

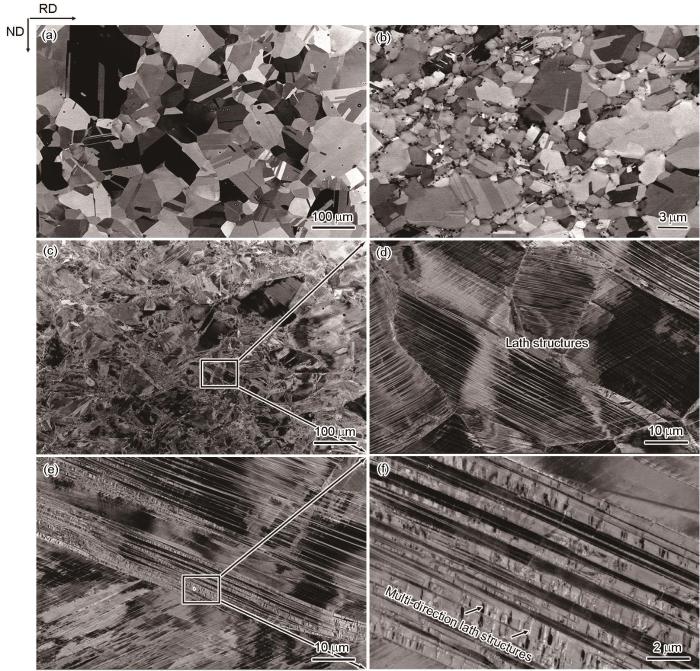

图3

图3

HOMO、A850和CRR10%材料微观组织的SEM背散射电子(BSE)像

Fig.3

SEM-BSE images of the HOMO (a), A850 (b), and CRR10% (c-f) materials (RD—rolling direction, ND—normal direction)

图3c~f为CRR10%材料的微观结构表征结果。可见,经深冷轧制后材料仍保持为近似等轴晶(平均晶粒尺寸为55.73 μm),如图3c所示。图3d为图3c的局部区域放大图。可以看出,在形变晶粒内部排列着密集的板条组织。在部分晶粒内,板条组织呈现出2个方向,相互交叉,显著细化材料微结构(图3d)。图3f为图3e局部区域放大图。可见,在单一方向的板条结构间还出现了沿另一方向排列的短小密集板条结构。据统计,板条的平均宽度(t)为0.32 μm,相邻2个板条之间的平均间距(dspacing)为0.54 μm。根据体积统计分析方法[29,30],利用

经计算,CRR10%材料中板条组织的体积分数高达54%。

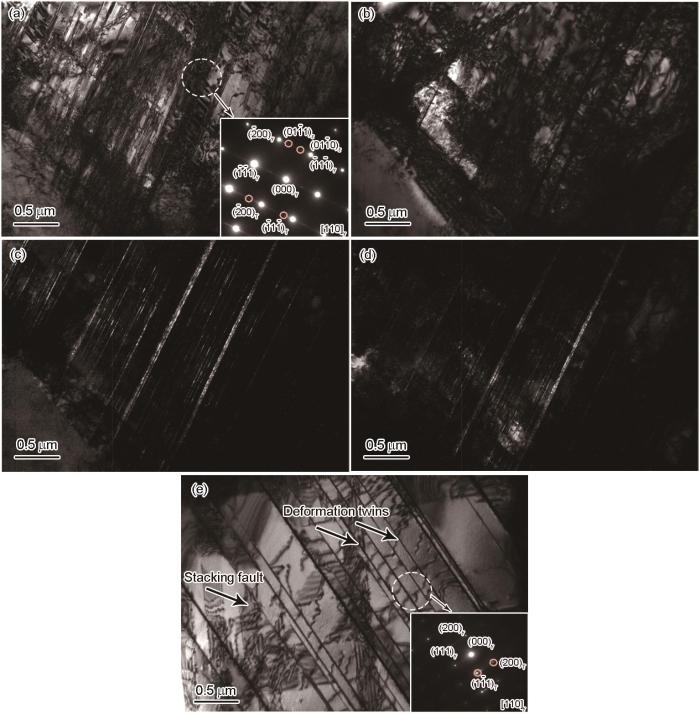

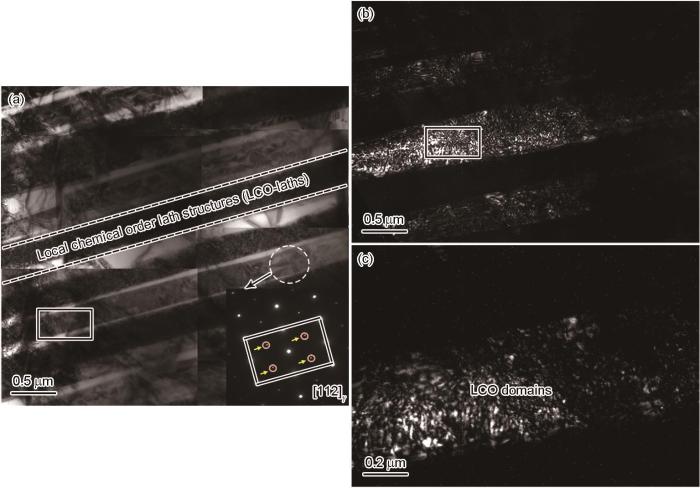

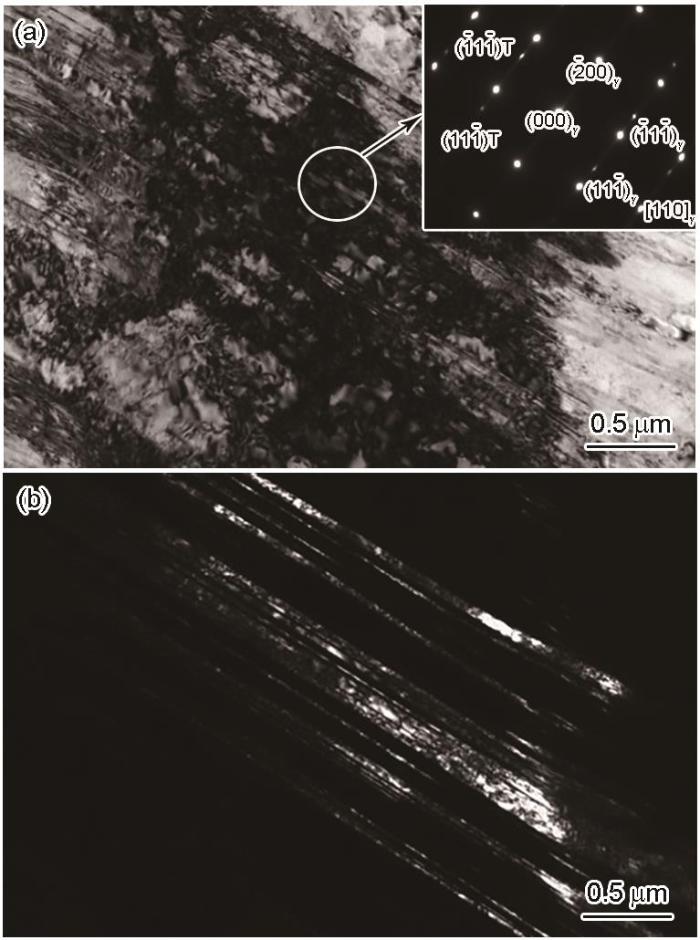

由上述实验结果可知,CRR10%材料屈服强度的显著提升与存在于其中的大量板条组织密切相关。为更进一步确认此种密集板条的微观结构,进而揭示材料获得优异综合力学性能的来源,对其进行TEM表征。图4a为CRR10%材料微观结构的TEM明场像及选区电子衍射(SAED)花样。可见,在奥氏体基体中分布着密集的板条组织,在板条组织之间存在着高密度且交互缠结的位错亚结构。图4a中插图的SAED结果表明,大量的板条组织分别由hcp结构的ε-马氏体和fcc结构的形变孪晶组成。图4b~d分别为对应于图4a区域内奥氏体基体、ε-马氏体和形变孪晶的TEM暗场像。经统计,ε-马氏体板条的平均宽度约为10 nm,相邻板条之间的平均间距约为230 nm。形变孪晶的平均宽度和平均间距分别约为8和210 nm。此外,CRR10%材料中还存在大量的层错结构,如图4e所示。

图4

图4

拉伸变形前CRR10%材料的TEM像及选区电子衍射(SAED)花样

Fig.4

TEM images and the selected area electron diffraction (SAED) patterns (insets) of the CRR10% material before tensile testing

(a) bright-field TEM image and SAED pattern (inset) (b-d) dark-field TEM images of the fcc austenitic matrix (b), hcp ε-martensite laths (c), and fcc deformation twins (d) corresponding to Fig.4a (e) deformation twins and stacking faults, and the corresponding SAED pattern (inset)

图5

图5

拉伸变形前CRR10%材料内部局部化学有序(LCO)板条的TEM像及SAED花样

Fig.5

TEM image and SAED pattern (inset) of the local chemical order lath structures (LCO-laths) inside the CRR10% material before tensile testing

(a) TEM image of the LCO-laths and SAED pattern (inset)

(b) dark-field TEM image of the rectangular area in Fig.5a

(c) closed-up view of the rectangular area in Fig.5b (The LCO domains located inside LCO-laths, as shown in Figs.5b and c)

2.3 形变微结构演化和塑性变形机制

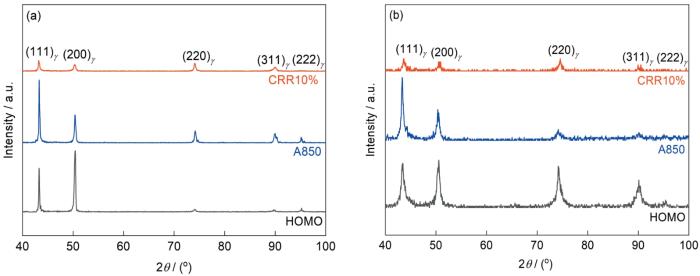

图6

图6

HOMO、A850和CRR10%材料拉伸变形前后的XRD谱

Fig.6

XRD spectra of the HOMO, A850, and CRR10% materials before (a) and after (b) tensile testing

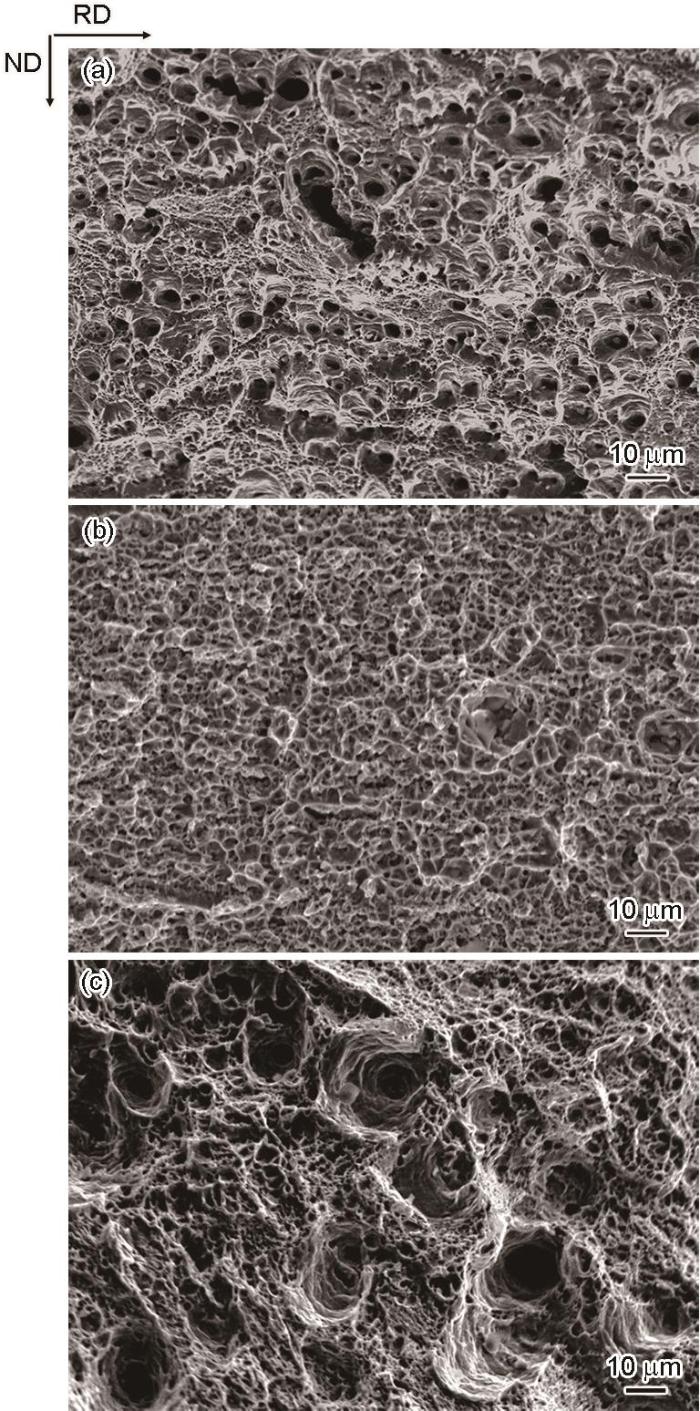

图7

图7

HOMO、A850和CRR10%材料断口形貌的SEM像

Fig.7

SEM images showing the fracture morphologies of the HOMO (a), A850 (b), and CRR10% (c) materials

为了揭示CRR10%材料的塑性变形机制,对其拉伸变形后断口附近区域进行TEM观察,结果如图8所示。奥氏体基体中生成了更加细密的形变孪晶,且在孪晶组织间聚集了高密度的位错。经统计,拉伸变形后形变孪晶的平均宽度约为7 nm,平均间距约为35 nm。与拉伸变形前的孪晶(平均宽度和间距分别约为8和210 nm,如图4d所示)相比,相邻孪晶板条的平均间距显著降低,孪晶密度大幅提升。这表明CRR10%材料在塑性变形过程中发生了显著的孪晶诱导塑性(TWIP)效应。TWIP效应的发生减缓了塑性变形过程的应力集中,迟滞裂纹的萌生与扩展,且细密形变孪晶的生成将进一步阻碍位错运动,使材料保持良好的加工硬化能力和优异的均匀延伸率。

图8

图8

拉伸变形后CRR10%材料断口附近区域的TEM像及SAED花样

Fig.8

Bright-field (a) and dark-field (b) TEM images of the region close to fracture surface of the CRR10% material after tensile testing (Inset in Fig.8a is the SAED pattern)

2.4 深冷轧制材料的高屈服强度来源

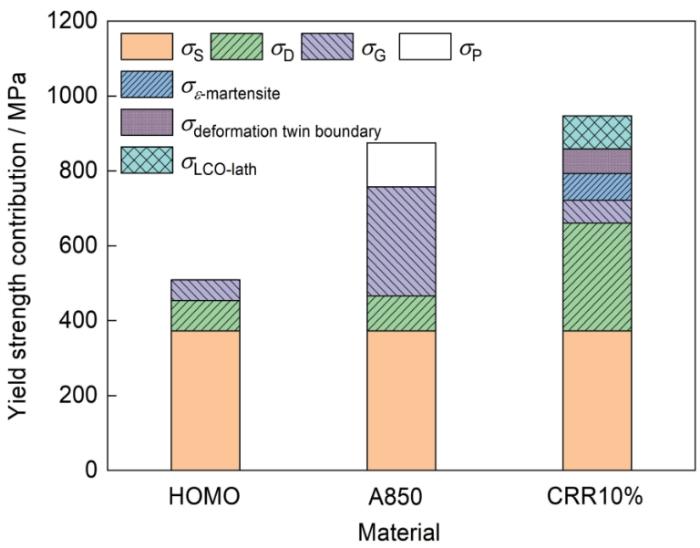

为了揭示CRR10%材料具有高屈服强度的原因,分别对HOMO、A850和CRR10%材料不同强化机制对屈服强度的贡献进行了定量计算。基于本工作微观结构表征结果,HOMO材料的屈服强度(σ0.2(HOMO))被归纳为由位错强化(dislocation strengthening)、晶界强化(grain boundary strengthening)和固溶强化(solid solution strengthening)组成,其对屈服强度的贡献分别为σD、σG、σS。即:σ0.2(HOMO) = σD + σG + σS。A850材料的屈服强度包括了σD、σG、σS和析出强化(precipitation strengthening,σP),即:σ0.2(A850) = σD + σG + σS+ σP。CRR10%材料的屈服强度(σ0.2(CRR10%))则分别来源于σD、σG、σS、ε-马氏体强化(ε-martensite strengthening,σε-martensite)、形变孪晶界强化(deformation twin boundary strengthening,σdeformation twin boundary)和LCO板条强化(LCO-lath strengthening,σLCO-lath),即σ0.2(CRR10%) = σD + σG + σS + σε-martensite + σdeformation twin boundary + σLCO-lath。下面分别对上述提及的各强化贡献进行计算。

2.4.1 位错强化

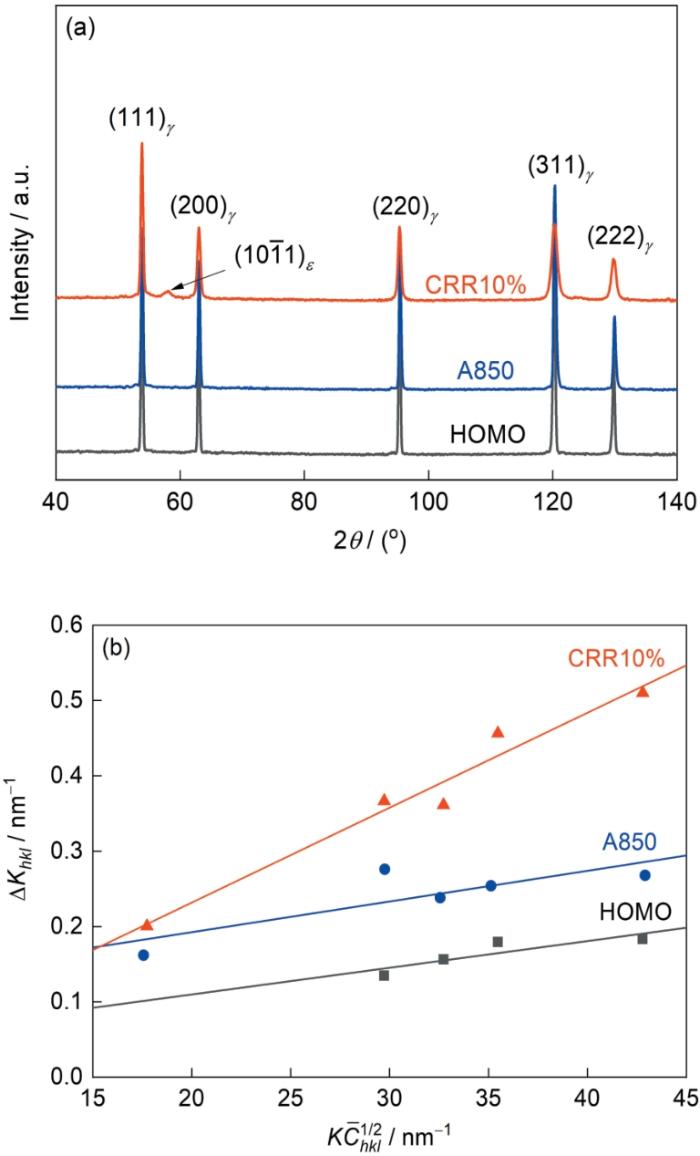

图9

图9

HOMO、A850和CRR10%材料的中子衍射谱及对应的修正Williamson-Hall (MWH)曲线

Fig.9

Neutron diffraction spectra (a) and modified Williamson-Hall (MWH) curves (b) of the HOMO, A850, and CRR10% materials (K = 2sinθ / λ,ΔKhkl = 2cosθ(Δθ) / λ, λ—waverlength, Δθ—full width of half maximum,C̅hkl —average dislocation contrast factor)

式中,Khkl = 2sinθ / λ;ΔKhkl = 2cosθ(∆θ) / λ (Δθ为衍射峰的半高宽);D为平均共格散射区尺寸;

式中,M为Taylor因子(通常取值为3.06);α为体现位错之间交互作用强度的经验常数(在以fcc为基体的合金中,通常取α = 0.2);G为材料的剪切模量(75 GPa[16])。此处,合金内的ρ经中子衍射测定。代入相关数值后计算得到HOMO、A850和CRR10%材料中的σD分别为81、93和288 MPa。

2.4.2 晶界强化

式中,d为材料的平均晶粒尺寸;KH-P为Hall-Petch系数。为了测定实验用钢的KH-P,在箱式电阻炉中对热轧态材料在1250~1400 ℃进行2 h的高温退火,获得了晶粒尺寸分别为119、153、196和237 μm的系列材料。并通过拉伸测试获得其屈服强度分别为532、528、523和520 MPa。通过对d-1/2和σG之间的函数关系进行线性拟合,确定所研究钢的KH-P = 454 MPa·μm1/2。由2.2节可知,HOMO、A850和CRR10%材料的平均晶粒尺寸分别为68.21、2.44和58.73 μm。利用

2.4.3 固溶强化

材料的σS可由HOMO态材料的屈服强度减去σD和σG得到,即σS = σ0.2(HOMO) - σD - σG = 509 - 81 - 55 = 373 MPa。

2.4.4 析出强化

A850材料中的σP由其屈服强度减去σS、σD和σG得到,即σP = σ0.2(A850) - σD - σG - σS = 875 - 93 - 291 - 373 = 118 MPa。

2.4.5 ε-马氏体和形变孪晶界强化

CRR10%材料中的σε-martensite和σdeformationtwin boundary可由下式进行计算:

式中,σ为ε-马氏体板条或形变孪晶引起的强化;此处f为ε-马氏体板条或形变孪晶的体积分数。

根据

2.4.6 LCO板条强化

最后,考虑LCO板条对CRR10%材料屈服强度的贡献。如前文所述,LCO板条对屈服强度的贡献,一方面来源于LCO板条边界引起材料微结构细化带来的强化,另一方面来源于位于其内部的LCO团簇对位错运动的阻碍作用。这里将2者对屈服强度的贡献进行整体考量,即:σLCO-lath = σ0.2 (CRR10%) - (σS + σG +σD + σdeformationtwin boundary + σε-martensite) = 88 MPa。

综上,HOMO、A850和CRR10% 3种材料的屈服强度贡献来源如图10所示。可见,相较于HOMO态材料,A850材料屈服强度的大幅提升主要来源于晶界强化(291 MPa),CRR10%材料屈服强度的提升则主要来源于位错强化(288 MPa)以及由ε-马氏体、形变孪晶和LCO板条组成的密集片层组织引起的强化(225 MPa)。

图10

图10

HOMO、A850和CRR10%材料屈服强度贡献来源

Fig.10

Strengthening contributions to yield strength of the HOMO, A850, and CRR10% materials (σD—dislocation strengthening, σG—grain boundary strengthening, σS—solid solution strengthening, σP—precipitation strengthening, σε-martensite—ε-martensite strengthening,σdeformation twin boundary—deformation twin boundary strengthening, σLCO-lath—LCO-lath strengthening)

3 结论

(1) 仅通过液氮温度下压下量为10%的深冷轧制,即可获得屈服强度、抗拉强度和均匀延伸率分别为947 MPa、1051 MPa和36%的高氮奥氏体不锈钢,相比于利用冷轧结合再结晶退火的传统热机械加工工艺制备的高氮奥氏体不锈钢(最优性能为屈服强度、抗拉强度和均匀延伸率分别为875 MPa、1130 MPa和35%),前者具有较为优越的综合力学性能。

(2) A850和CRR10%材料的屈服强度分别是HOMO态材料的1.72和1.86倍,A850材料屈服强度的提升主要来源于晶界强化(291 MPa)。CRR10%材料屈服强度的提升则主要归因于在深冷轧制过程中引入的密集位错(288 MPa)以及由ε-马氏体板条、形变孪晶和LCO板条组成的密集片层组织引起的强化 (225 MPa)。

(3) CRR10%材料保持了良好的加工硬化能力和均匀延伸率,这归因于在塑性变形过程中显著的孪晶诱导塑性效应和位错滑移的共同作用。

文中补充材料可通过以下网址查看:

参考文献

Enhanced strength-ductility synergy in a new 2.2 GPa grade ultra-high strength stainless steel with balanced fracture toughness: Elucidating the role of duplex aging treatment

[J].

Investigation of laser-powder bed fusion driven controllable heterogeneous microstructure and its mechanical properties of martensitic stainless steel

[J].

Microstructural evolution and mechanical behavior of Custom 465 precipitation hardening stainless steel fabricated via laser powder bed fusion

[J].

Effects of boric acid and lithium hydroxide on the corrosion behaviors of 316LN stainless steel in simulating hot functional test high-temperature pressurized water

[J].

Excellent ductility of an austenitic stainless steel at a high strength level achieved by a simple process

[J].

A review of progress on high nitrogen austenitic stainless-steel research

[J].

Molecular dynamics simulation of Cr-N clusters formation in high nitrogen austenitic stainless steel

[J].

Effects of grain boundary character distribution on hydrogen-induced cracks initiation and propagation at different strain rates in a nickel-saving and high-nitrogen austenitic stainless steel

[J].

Effect of nitrogen content on mechanical properties of 316L (N) austenitic stainless steel

[J].

Effects of nitrogen on the microstructure and mechanical properties of an austenitic stainless steel with incomplete recrystallization annealing

[J].

Multi-heterostructure and mechanical properties of N-doped FeMnCoCr high entropy alloy

[J].

Synergy effect of multi-strengthening mechanisms in FeMnCoCrN HEA at cryogenic temperature

[J].

Effect of tensile deformation on microstructure and corrosion resistance of high nitrogen austenitic stainless steels

[J].

拉伸变形对高氮奥氏体不锈钢显微组织和耐腐蚀性能的影响

[J].

On the strengthening mechanisms of high nitrogen austenitic stainless steels

[J].

Enhancing yield strength of high nitrogen austenitic stainless steel

[J].

Interstitial-driven local chemical order enables ultrastrong face-centered cubic multicomponent alloys

[J].

Texture evolution and temperature-dependent deformation modes in ambient- and cryogenic-rolled nanolayered Zr-2.5Nb

[J].

Cryogenic rolling induces quasi-linear superelasticity with high strength over a wide temperature range in TiNi shape memory alloys

[J].

Achieving strength-ductility synergy in zirconium via ultra-dense twin-twin networks

[J].

Hierarchical multiple precursors induced heterogeneous structures in super austenitic stainless steels by cryogenic rolling and annealing

[J].

Effect of cryogenic rolling and multistage thermo-mechanical treatment on the microstructure and properties of the Cu-0.4Cr-0.39Zn-0.1Mg-0.07Zr alloy

[J].

Effect and mechanism of room temperature rolling, cryogenic rolling and heat treatment on mechanical properties and electrical conductivity of Cu-Ni-Si alloy with continuous directional solidification

[J].

Simultaneously improving the strength and ductility of an Ag-free 2195 Al-Li alloy by T8 treatment with cryogenic pre-rolling

[J].

Influence of substructures on precipitation behavior and mechanical properties of cryogenic rolled Al-Mg-Si alloys during aging treatment

[J].

Work hardening in ultrafine-grained titanium: Multilayering and grading

[J].

Enhancing yield strength and ductility of Fe-Mn-C-xAl (x = 0, 3) high manganese steel by cryogenic rolling

[J].

Mechanical behavior of 304 austenitic stainless steel processed by cryogenic rolling

[J].

Cryorolling effect on microstructure and mechanical properties of Fe-25Cr-20Ni austenitic stainless steel

[J].

Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy

[J].

High dislocation density-induced large ductility in deformed and partitioned steels

[J].

Micromechanical behavior of multilayered Ti/Nb composites processed by accumulative roll bonding: An in-situ synchrotron X-ray diffraction investigation

[J].

The determination of density and distributions of dislocations in deformed single crystals from broadened X-Ray diffraction profiles

[J].

The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice

[J].

Microstructural evolution and mechanical behavior of phase reversion-induced bimodal austenitic steels

[J].

Heterogeneous nano/ultrafine-grained medium Mn austenitic stainless steel with high strength and ductility

[J].