Development of additive manufacturing technology and industry in China

1

2022

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

我国增材制造技术与产业发展研究

1

2022

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

The influence of Laves phases on the room temperature tensile properties of Inconel 718 fabricated by powder feeding laser additive manufacturing

1

2019

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Microstructure and mechanical property control of GH4169 superalloy produced by selective laser melting

3

2021

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

激光选区熔化成形GH4169合金的组织与性能调控

3

2021

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

Research progress of materials design for metal laser additive manufacturing

1

2023

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

金属激光增材制造材料设计研究进展

1

2023

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Comparative study on the microstructure evolution of selective laser melted and wrought IN718 superalloy during subsequent heat treatment process and its effect on mechanical properties

1

2020

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Overview of the present situation and application of additive manufacturing

2

2021

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

... [6]. ...

增材制造的现状与应用综述

2

2021

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

... [6]. ...

Research progress of laser additively manufactured Inconel 718 superalloy

1

2022

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

激光增材制造Inconel 718高温合金的研究进展

1

2022

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Overview of the development and application of China's additive manufacturing industry

1

2017

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

中国增材制造产业发展及应用情况综述

1

2017

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Research progress in laser metal 3D printing technology

1

2022

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

激光金属3D打印技术的研究进展

1

2022

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Research on status and development trend of laser additive manufacturing

1

2016

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

激光增材制造技术的研究现状及发展趋势

1

2016

... GH4169高温合金能够在恶劣环境中承受高机械和热负荷[1],是涡轮叶片和燃气轮机叶片等高温部件中使用最广泛的镍基高温合金.然而,传统方法制备的GH4169合金存在切削加工困难、刀具磨损严重等问题,此外,具有复杂几何形状、精确尺寸公差和更高机械性能的GH4169零件的成型生产仍然是一个挑战[2, 3].选区激光熔化(selective laser melting,SLM)技术作为近十年发展最快的金属高精度增材制造(additive manufacturing,AM)技术之一[4],为快速成型高精度GH4169零件提供了一个新的解决方案.SLM成型过程有着极高的冷却速率(105~108 K/s)[5],高于电子束选区熔化(electron beam selective melting,EBSM) (104~106 K/s)和定向能量沉积(directed energy deposition,DED) (103~104 K/s)[6]工艺,成型合金晶粒细小,可显著强化成型件的力学性能,所制备的零部件具有尺寸精度高、表面质量好、性能优异等特点[7],在航空航天[8]、船舶工业[9]及医疗器械[10]领域得到了一定的应用,同时在汽车工业、国防安全等国民经济和国家安全核心领域也具有重要的应用前景[6]. ...

Study on heat treatment process and mechanical properties of selective laser melting GH4169 alloy

1

2022

... 与传统工艺不同,SLM过程中熔池经历的超快加热和超快冷却过程导致基体内强化相来不及析出,这是打印态SLM-GH4169合金力学性能低于铸锻件GH4169合金的重要原因[11].激光束与粉末、熔池与粉末床之间存在相互作用,具有复杂的非平衡物理冶金和热物理特性,导致打印过程中产生大量热应力[12],而通过优化工艺参数缓解SLM成型过程导致的残余应力较为困难,并且制造时间和成本增加[13].此外,SLM成型方式为逐层加工,材料打印过程中受到不同的热循环,由于基板和粉末散热效率不一致,实际打印过程中同一层加工幅面也不一定相同,层间温度和冷却时间不同导致微观组织自下而上呈现异质结构[14].SLM成型具有熔池熔道精细结构,与传统制造差异较大,因此需要采取合适的热处理调控微观结构和应力,进而优化合金的力学性能[15]. ...

激光选区熔化GH4169合金的热处理工艺与力学性能研究

1

2022

... 与传统工艺不同,SLM过程中熔池经历的超快加热和超快冷却过程导致基体内强化相来不及析出,这是打印态SLM-GH4169合金力学性能低于铸锻件GH4169合金的重要原因[11].激光束与粉末、熔池与粉末床之间存在相互作用,具有复杂的非平衡物理冶金和热物理特性,导致打印过程中产生大量热应力[12],而通过优化工艺参数缓解SLM成型过程导致的残余应力较为困难,并且制造时间和成本增加[13].此外,SLM成型方式为逐层加工,材料打印过程中受到不同的热循环,由于基板和粉末散热效率不一致,实际打印过程中同一层加工幅面也不一定相同,层间温度和冷却时间不同导致微观组织自下而上呈现异质结构[14].SLM成型具有熔池熔道精细结构,与传统制造差异较大,因此需要采取合适的热处理调控微观结构和应力,进而优化合金的力学性能[15]. ...

A review on residual stress in metal additive manufacturing

1

2024

... 与传统工艺不同,SLM过程中熔池经历的超快加热和超快冷却过程导致基体内强化相来不及析出,这是打印态SLM-GH4169合金力学性能低于铸锻件GH4169合金的重要原因[11].激光束与粉末、熔池与粉末床之间存在相互作用,具有复杂的非平衡物理冶金和热物理特性,导致打印过程中产生大量热应力[12],而通过优化工艺参数缓解SLM成型过程导致的残余应力较为困难,并且制造时间和成本增加[13].此外,SLM成型方式为逐层加工,材料打印过程中受到不同的热循环,由于基板和粉末散热效率不一致,实际打印过程中同一层加工幅面也不一定相同,层间温度和冷却时间不同导致微观组织自下而上呈现异质结构[14].SLM成型具有熔池熔道精细结构,与传统制造差异较大,因此需要采取合适的热处理调控微观结构和应力,进而优化合金的力学性能[15]. ...

Laser powder bed fusion additive manufacturing of maraging steel: A review

1

2023

... 与传统工艺不同,SLM过程中熔池经历的超快加热和超快冷却过程导致基体内强化相来不及析出,这是打印态SLM-GH4169合金力学性能低于铸锻件GH4169合金的重要原因[11].激光束与粉末、熔池与粉末床之间存在相互作用,具有复杂的非平衡物理冶金和热物理特性,导致打印过程中产生大量热应力[12],而通过优化工艺参数缓解SLM成型过程导致的残余应力较为困难,并且制造时间和成本增加[13].此外,SLM成型方式为逐层加工,材料打印过程中受到不同的热循环,由于基板和粉末散热效率不一致,实际打印过程中同一层加工幅面也不一定相同,层间温度和冷却时间不同导致微观组织自下而上呈现异质结构[14].SLM成型具有熔池熔道精细结构,与传统制造差异较大,因此需要采取合适的热处理调控微观结构和应力,进而优化合金的力学性能[15]. ...

Electron and laser-based additive manufacturing of Ni-based superalloys: A review of heterogeneities in microstructure and mechanical properties

1

2022

... 与传统工艺不同,SLM过程中熔池经历的超快加热和超快冷却过程导致基体内强化相来不及析出,这是打印态SLM-GH4169合金力学性能低于铸锻件GH4169合金的重要原因[11].激光束与粉末、熔池与粉末床之间存在相互作用,具有复杂的非平衡物理冶金和热物理特性,导致打印过程中产生大量热应力[12],而通过优化工艺参数缓解SLM成型过程导致的残余应力较为困难,并且制造时间和成本增加[13].此外,SLM成型方式为逐层加工,材料打印过程中受到不同的热循环,由于基板和粉末散热效率不一致,实际打印过程中同一层加工幅面也不一定相同,层间温度和冷却时间不同导致微观组织自下而上呈现异质结构[14].SLM成型具有熔池熔道精细结构,与传统制造差异较大,因此需要采取合适的热处理调控微观结构和应力,进而优化合金的力学性能[15]. ...

Study on the microstructure evolution and dynamic recrystallization mechanism of selective laser melted Inconel 718 alloy during hot deformation

1

2023

... 与传统工艺不同,SLM过程中熔池经历的超快加热和超快冷却过程导致基体内强化相来不及析出,这是打印态SLM-GH4169合金力学性能低于铸锻件GH4169合金的重要原因[11].激光束与粉末、熔池与粉末床之间存在相互作用,具有复杂的非平衡物理冶金和热物理特性,导致打印过程中产生大量热应力[12],而通过优化工艺参数缓解SLM成型过程导致的残余应力较为困难,并且制造时间和成本增加[13].此外,SLM成型方式为逐层加工,材料打印过程中受到不同的热循环,由于基板和粉末散热效率不一致,实际打印过程中同一层加工幅面也不一定相同,层间温度和冷却时间不同导致微观组织自下而上呈现异质结构[14].SLM成型具有熔池熔道精细结构,与传统制造差异较大,因此需要采取合适的热处理调控微观结构和应力,进而优化合金的力学性能[15]. ...

A review of mechanical properties of additively manufactured Inconel 718

1

2019

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Microstructure, crack formation and improvement on nickel-based superalloy fabricated by powder bed fusion

1

2023

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing

1

2017

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

On the microstructural and mechanical properties of post-treated additively manufactured Inconel 718 superalloy under quasi-static and cyclic loading

1

2016

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Effect of homogenization and solution treatments time on the elevated-temperature mechanical behavior of Inconel 718 fabricated by laser powder bed fusion

1

2021

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

The effect of homogenization temperature on the microstructure and high temperature mechanical performance of SLM-fabricated IN718 alloy

1

2021

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Effect of heat treatment on the microstructural evolution of a precipitation-hardened superalloy produced by selective laser melting

3

2019

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

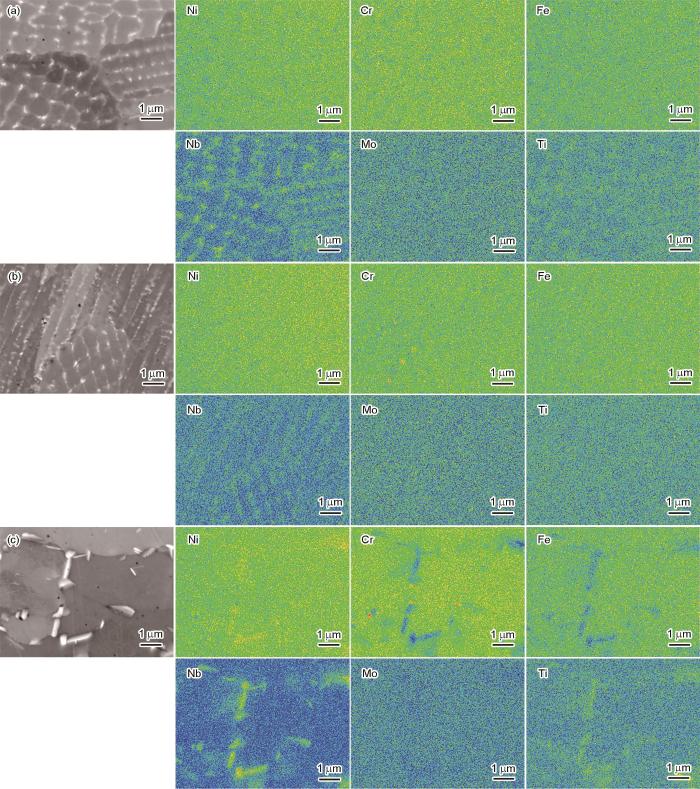

... 从图13b和c沿[100]、[110]带轴的选区电子衍射(SAED)花样可以确定,AB样品中的基体相为fcc结构,未发现γ′/γ″析出相.对胞状组织节点处析出相进行标定,如图13d~f所示.析出相呈不规则形状,并且尺寸不均,通过标定确定析出相为hcp结构,分别从基体[110]带轴和析出相[110]带轴观察,确定该相为Laves相,并得出基体与Laves相的取向关系:[110] γ // [100]Laves,[12] γ // [110]Laves,与文献[33]结果一致.Laves相是一种与基体γ形成的共晶相,结构式为AB2,结合图12 EDS结果,可以确定其分子式为(Ni, Cr, Fe)2(Nb, Mo, Ti),由于Laves相为拓扑密排相,位错难以绕过或切过,容易形成应力集中,Laves相一般被认为是GH4169中的有害相[22],尺寸较大的Laves相在拉伸过程中极易发生断裂,尺寸较小的Laves相由于与基体割裂,导致微孔形成,成为裂纹萌生的起源,对力学性能产生不利影响[33]. ...

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties

1

2019

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Comparison of the structure, mechanical properties and effect of heat treatment on alloy Inconel 718 produced by conventional technology and by additive layer manufacturing

1

2023

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting

1

2012

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Outstanding strength-ductility synergy in Inconel 718 superalloy via laser powder bed fusion and thermomechanical treatment

1

2023

... 由于晶粒形状差异较大,采用等效圆面积统计不能反映晶粒尺寸变化的真实情况,因此采用横向和纵向截距法分别统计晶粒尺寸,结果如表3所示.可见,平均晶粒尺寸为10~20 μm,热处理后晶粒尺寸变化不大,其中XOZ面SA试样晶粒尺寸增大,可能与热处理过程中发生再结晶晶粒长大有关[26]. ...

Microstructure and phase transformation on the surface of Inconel 718 alloys fabricated by SLM under 1050 oC solid solution + double ageing

1

2017

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Revealing the stress corrosion cracking initiation mechanism of alloy 718 prepared by laser powder bed fusion assessed by microcapillary method

1

2022

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Investigation of hydrogen embrittlement properties of Ni-based alloy 718 fabricated via laser powder bed fusion

0

2022

Hydrogen embrittlement behavior of selective laser-melted Inconel 718 alloy

1

2023

... 相对于其他镍基合金,GH4169高温合金SLM成型性较好,相对密度可达99.8%以上[16].由于平行于构建方向(build direction,BD)具有最大冷却梯度,柱状晶粒倾向于沿着构建方向择优生长.一般将平行于构建方向定义为XOZ面,垂直于构建方向定义为XOY面[17].Ni等[18]发现,与XOY面试样相比,XOZ面试样具有较低的极限抗拉强度,但断后延伸率更高,热处理后各向异性性能差异减小.GH4169高温合金的热处理工艺主要包括热等静压[19]、均匀化、固溶以及时效处理,热处理温度、时间[20]、冷却方式以及不同组合工艺对微观组织有显著影响,从而影响性能.研究[21]发现,在1000~1240 ℃温度范围内,晶粒尺寸随着均匀化温度的升高而持续增加,晶粒形态由柱状向等轴状转变,SLM成型过程中的高密度位错缠结逐渐消失.在825~1000 ℃固溶温度范围内,Laves相初步溶解并伴随δ相的生成,适量的δ相会在晶界上起到钉扎作用,从而提高晶界强度,同时抑制晶粒长大,但过量δ相析出会诱导裂纹萌生和扩展,导致力学性能下降[3].同时,Ni等[22]发现,时效处理促进了强化相的完全析出,直接时效后合金强度相较于打印态提高了24.8%.Huang等[23]根据扩散理论,得出固溶温度与时间的经验公式,并通过调整固溶处理的冷却速率和时效时间来控制强化相的数量,实现强度和延展性的匹配.Švec等[24]对常规轧制GH4169高温合金和SLM-GH4169高温合金进行相同热处理,发现热处理后SLM-GH4169高温合金的力学性能与轧制态相当.SLM-GH4169高温合金优异的力学性能与其精细的微观组织密切相关.文献[25~27]依据传统制造中常用的均匀化退火工艺消除偏析,采用较高温度固溶而忽略SLM成型过程中精细组织的优势,研究[28~30]发现,正是这种精细的组织结构,使其裂纹扩展、腐蚀、疲劳以及蠕变等性能较传统材料有显著优势.此外关于SLM-GH4169高温合金热处理工艺的研究大多根据形貌和成分来判断析出相,而从晶体结构及与基体的位相关系分析其析出规律的研究鲜见报道.了解晶体结构与位相关系有助于掌握析出相的析出规律,为工艺优化和热处理调控微观组织和力学性能提供理论依据. ...

Finish machining-induced surface roughness, microhardness and XRD analysis of selective laser melted inconel 718 alloy

1

2018

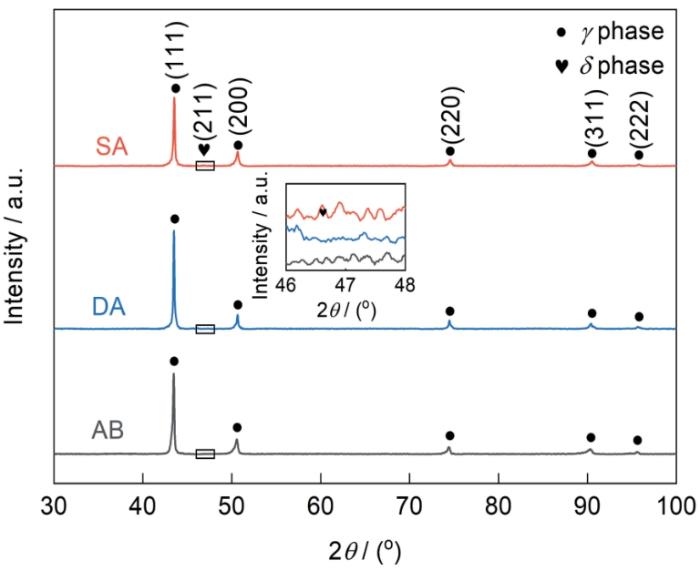

... 图3为GH4169高温合金AB、DA和SA试样的XRD谱.AB、DA和SA试样主要由奥氏体相组成,其中(111)晶面衍射峰强度最高.插图为2θ在46°~48°的局部放大图,其中SA试样有δ相的(211)晶面衍射峰,但衍射峰强度较弱,说明δ相的相对含量较少.根据图3计算γ相衍射峰的晶面间距,结果如表2所示.热处理后晶面间距减小,这是由于热处理后γ′/γ″相析出,γ′/γ″相与γ基体的衍射峰角度相近,但γ′/γ″相的晶胞参数小于γ基体[31],所以热处理后晶面间距减小.在相同外应力的作用下,晶面间距减小,位错运动更难进行[32]. ...

Microstructures and crackling noise of AlxNbTiMoV high entropy alloys

1

2014

... 图3为GH4169高温合金AB、DA和SA试样的XRD谱.AB、DA和SA试样主要由奥氏体相组成,其中(111)晶面衍射峰强度最高.插图为2θ在46°~48°的局部放大图,其中SA试样有δ相的(211)晶面衍射峰,但衍射峰强度较弱,说明δ相的相对含量较少.根据图3计算γ相衍射峰的晶面间距,结果如表2所示.热处理后晶面间距减小,这是由于热处理后γ′/γ″相析出,γ′/γ″相与γ基体的衍射峰角度相近,但γ′/γ″相的晶胞参数小于γ基体[31],所以热处理后晶面间距减小.在相同外应力的作用下,晶面间距减小,位错运动更难进行[32]. ...

Study on the evolution mechanismof grain boundary charicteristics and precipitates of IN718 alloy fabricated by laser additive manufacturing

3

2021

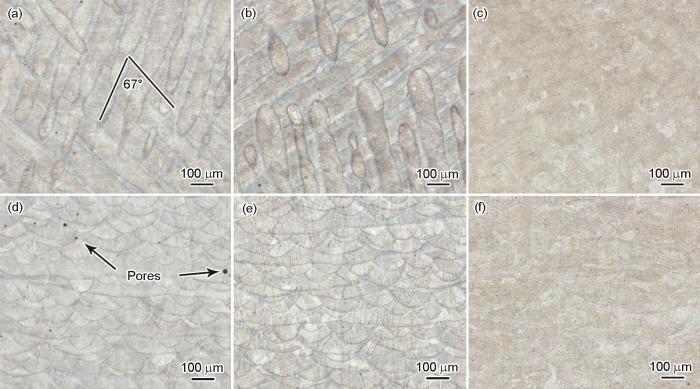

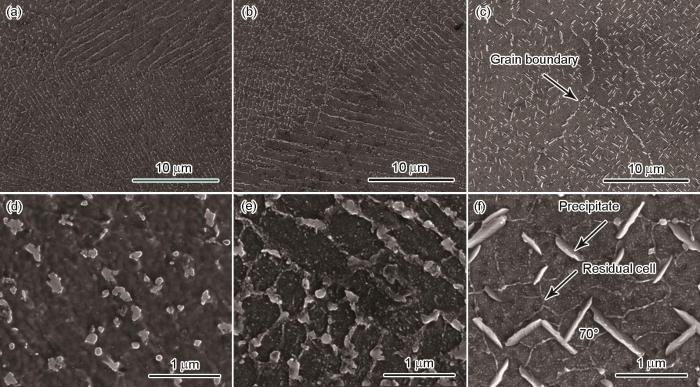

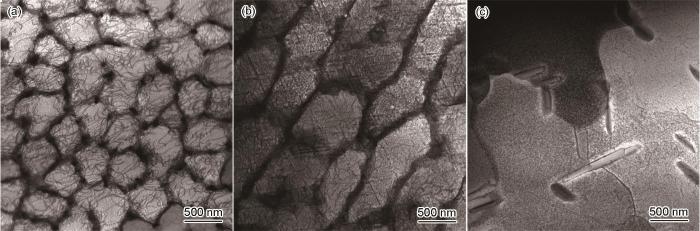

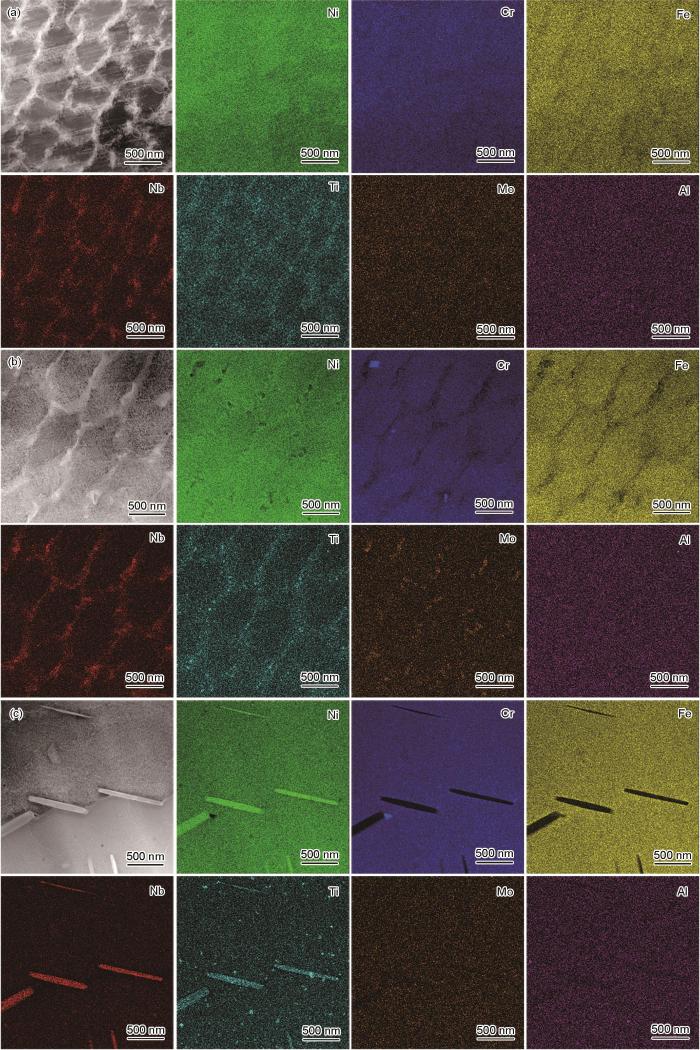

... 图5为GH4169高温合金AB、DA和SA试样显微组织的SEM像.由图5a和d可以看到,SLM成型GH4169试样的组织均匀、细小,具有胞状和柱状晶组成.如图5b和e所示,DA试样的胞状和柱状结构依然存在,内部有颗粒状析出物,平均尺寸约20 nm.图5c和f显示,SA试样中的胞状和柱状结构基本消失,在晶内和晶界均有片状或针状析出物,长度约1 μm,这些片状析出物呈一定角度(约70°)均匀分布在基体中,与立方晶体{111}中晶面夹角为70.53°相接近[33],基体内部有与DA试样相似的颗粒状析出物. ...

... 从图13b和c沿[100]、[110]带轴的选区电子衍射(SAED)花样可以确定,AB样品中的基体相为fcc结构,未发现γ′/γ″析出相.对胞状组织节点处析出相进行标定,如图13d~f所示.析出相呈不规则形状,并且尺寸不均,通过标定确定析出相为hcp结构,分别从基体[110]带轴和析出相[110]带轴观察,确定该相为Laves相,并得出基体与Laves相的取向关系:[110] γ // [100]Laves,[12] γ // [110]Laves,与文献[33]结果一致.Laves相是一种与基体γ形成的共晶相,结构式为AB2,结合图12 EDS结果,可以确定其分子式为(Ni, Cr, Fe)2(Nb, Mo, Ti),由于Laves相为拓扑密排相,位错难以绕过或切过,容易形成应力集中,Laves相一般被认为是GH4169中的有害相[22],尺寸较大的Laves相在拉伸过程中极易发生断裂,尺寸较小的Laves相由于与基体割裂,导致微孔形成,成为裂纹萌生的起源,对力学性能产生不利影响[33]. ...

... [33]. ...

激光增材制造IN718合金晶界特征及析出相演变规律研究

3

2021

... 图5为GH4169高温合金AB、DA和SA试样显微组织的SEM像.由图5a和d可以看到,SLM成型GH4169试样的组织均匀、细小,具有胞状和柱状晶组成.如图5b和e所示,DA试样的胞状和柱状结构依然存在,内部有颗粒状析出物,平均尺寸约20 nm.图5c和f显示,SA试样中的胞状和柱状结构基本消失,在晶内和晶界均有片状或针状析出物,长度约1 μm,这些片状析出物呈一定角度(约70°)均匀分布在基体中,与立方晶体{111}中晶面夹角为70.53°相接近[33],基体内部有与DA试样相似的颗粒状析出物. ...

... 从图13b和c沿[100]、[110]带轴的选区电子衍射(SAED)花样可以确定,AB样品中的基体相为fcc结构,未发现γ′/γ″析出相.对胞状组织节点处析出相进行标定,如图13d~f所示.析出相呈不规则形状,并且尺寸不均,通过标定确定析出相为hcp结构,分别从基体[110]带轴和析出相[110]带轴观察,确定该相为Laves相,并得出基体与Laves相的取向关系:[110] γ // [100]Laves,[12] γ // [110]Laves,与文献[33]结果一致.Laves相是一种与基体γ形成的共晶相,结构式为AB2,结合图12 EDS结果,可以确定其分子式为(Ni, Cr, Fe)2(Nb, Mo, Ti),由于Laves相为拓扑密排相,位错难以绕过或切过,容易形成应力集中,Laves相一般被认为是GH4169中的有害相[22],尺寸较大的Laves相在拉伸过程中极易发生断裂,尺寸较小的Laves相由于与基体割裂,导致微孔形成,成为裂纹萌生的起源,对力学性能产生不利影响[33]. ...

... [33]. ...

Mitigation of scan strategy effects and material anisotropy through supersolvus annealing in LPBF IN718

1

2019

... 图7为GH4169高温合金AB、DA和SA试样的反极图(IPF)面分布图,图7a~c为XOY面,图7d~f为XOZ面.热处理后晶粒形貌变化不明显,晶粒随机取向,无明显织构.SLM成型样品晶粒与锻件均匀等轴晶粒[34]不同,其中XOY面晶粒呈等轴状,XOZ面晶粒呈柱状,并与构建方向平行,XOY面和XOZ面大晶粒周围均分布有细小的晶粒. ...

Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting

2

2016

... 表4为GH4169高温合金的室温拉伸性能.从表4可以看出,热处理态GH4169高温合金的屈服强度、抗拉强度及断后延伸率与锻件[35]相当,均高于AMS 5663对锻造件的标准要求.DA试样的屈服强度及抗拉强度最高,分别比AB试样提高了约96%和50%,而断后延伸率下降幅度为54%.SA试样较DA试样强度有所下降,但断后延伸率上升幅度约20%. ...

... Room-temperature tensile properties of GH4169 superalloy specimens

Table 4| State | Yield strength / MPa | Tensile strength / MPa | Elongation after fracture / % |

|---|

| AB | 654 ± 11 | 961 ± 2 | 33.2 ± 1.6 |

| DA | 1283 ± 24 | 1443 ± 1 | 15.0 ± 1.8 |

| SA | 1238 ± 6 | 1393 ± 2 | 18.0 ± 1.8 |

| Forged[35] | 1192 | 1380 | 19.1 |

| AMS 5663 standards | 1034 | 1276 | 12.0 |

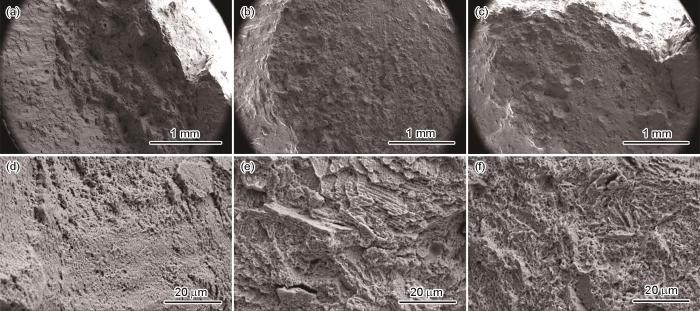

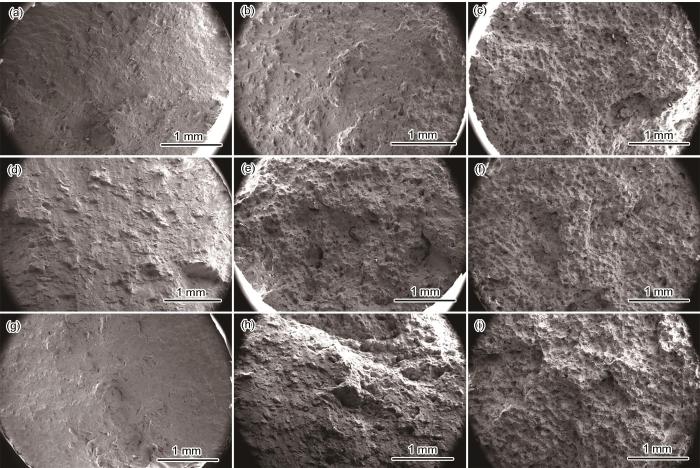

图8为GH4169合金AB、DA和SA试样的室温拉伸断口形貌.低倍观察时均可见台阶解离面,DA和SA试样断面较AB试样更加平整,AB试样有空洞分布在中心区域.高倍下观察时均可见韧窝形成,断裂方式为韧性断裂,AB试样的韧窝较浅,2种热处理态试样的拉伸断口韧窝较深且密集,说明在拉伸过程中承受较高的载荷,表现出较高的抗拉强度及屈服强度,这可归因于晶粒内析出相与位错之间复杂的交互作用.图8e和f显示,热处理态试样内部均发现有裂纹,在晶界附近的裂纹由于应力集中被撕裂,DA试样有明显剪切韧窝(图8e),一般分布在试样边缘由剪切应力切断[36]. ...

IN718 powder characteristics used in selective laser melting and microstructures of selective laser melted IN718 sample

1

2014

... 图8为GH4169合金AB、DA和SA试样的室温拉伸断口形貌.低倍观察时均可见台阶解离面,DA和SA试样断面较AB试样更加平整,AB试样有空洞分布在中心区域.高倍下观察时均可见韧窝形成,断裂方式为韧性断裂,AB试样的韧窝较浅,2种热处理态试样的拉伸断口韧窝较深且密集,说明在拉伸过程中承受较高的载荷,表现出较高的抗拉强度及屈服强度,这可归因于晶粒内析出相与位错之间复杂的交互作用.图8e和f显示,热处理态试样内部均发现有裂纹,在晶界附近的裂纹由于应力集中被撕裂,DA试样有明显剪切韧窝(图8e),一般分布在试样边缘由剪切应力切断[36]. ...

选区激光成形用IN718合金粉末特性及成形件组织结构的研究

1

2014

... 图8为GH4169合金AB、DA和SA试样的室温拉伸断口形貌.低倍观察时均可见台阶解离面,DA和SA试样断面较AB试样更加平整,AB试样有空洞分布在中心区域.高倍下观察时均可见韧窝形成,断裂方式为韧性断裂,AB试样的韧窝较浅,2种热处理态试样的拉伸断口韧窝较深且密集,说明在拉伸过程中承受较高的载荷,表现出较高的抗拉强度及屈服强度,这可归因于晶粒内析出相与位错之间复杂的交互作用.图8e和f显示,热处理态试样内部均发现有裂纹,在晶界附近的裂纹由于应力集中被撕裂,DA试样有明显剪切韧窝(图8e),一般分布在试样边缘由剪切应力切断[36]. ...

On the mechanism of serrated deformation in aged Inconel 718

1

1997

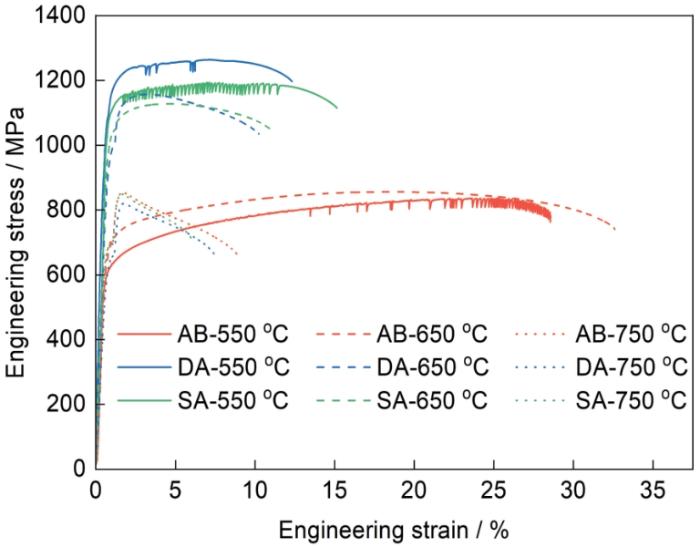

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

Stress drops in serrated flow curves of A15Mg

1

1982

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

Three types of Portevin-Le Chatelier effects: Experiment and modelling

1

2007

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

Serrated plastic flow

1

1984

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

Investigation of temperature dependence of PLC effect in a nickel base superalloy

2

2013

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

... [41]. ...

一种镍基高温合金PLC效应的温度依赖性研究

2

2013

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

... [41]. ...

Dynamic strain aging phenomenon in metals and alloys

1

2001

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

金属和合金中的动态应变时效现象

1

2001

... 图9为GH4169高温合金AB、DA和SA试样的高温拉伸工程应力-应变曲线.550 ℃高温拉伸曲线均出现锯齿现象,锯齿流变现象一般认为发生了Portevin-Le Chatelier (PLC)效应或动态应变时效(dynamic strain aging,DSA)[37,38],从图中可以判断锯齿为C型锯齿[39,40],PLC效应本质上是一种溶质原子与位错相互作用的过程,受溶质原子扩散运动控制,多数合金[41,42]在一定应变速率和温度区间内会发生PLC效应.锯齿流变现象会使高温合金表面质量降低,影响力学性能[41]. ...

In-situ SEM study of temperature-dependent tensile behavior of Inconel 718 superalloy

1

2021

... 550 ℃下拉伸性能与室温性能趋势相一致,DA试样的强度最高,AB试样的断后伸长率最高,但整体强度较室温时下降了10%~14%,断后伸长率减少了3%~4%.650 ℃高温拉伸时锯齿现象消失,DA和SA试样的强度高于锻件650 ℃高温拉伸性能标准要求,与室温强度相比下降20%,断后伸长率低于锻件标准要求(具体数值见表5).值得注意的是,AB试样在650 ℃下的拉伸性能与550 ℃相比有所提高.当测试温度达到750 ℃时,3种状态拉伸曲线趋于一致,呈明显的脆性断裂,强度和塑性显著下降.由于γ″为亚稳态相[43,44],在高于650 ℃时会转变为δ相,γ″共格强化减弱.此外,750 ℃会促进O2沿晶界扩散[45],裂纹扩展速率更快,造成力学性能恶化. ...

Characteristic and mechanism of phase transformation of GH4169G alloy during heat treatment

3

2013

... 550 ℃下拉伸性能与室温性能趋势相一致,DA试样的强度最高,AB试样的断后伸长率最高,但整体强度较室温时下降了10%~14%,断后伸长率减少了3%~4%.650 ℃高温拉伸时锯齿现象消失,DA和SA试样的强度高于锻件650 ℃高温拉伸性能标准要求,与室温强度相比下降20%,断后伸长率低于锻件标准要求(具体数值见表5).值得注意的是,AB试样在650 ℃下的拉伸性能与550 ℃相比有所提高.当测试温度达到750 ℃时,3种状态拉伸曲线趋于一致,呈明显的脆性断裂,强度和塑性显著下降.由于γ″为亚稳态相[43,44],在高于650 ℃时会转变为δ相,γ″共格强化减弱.此外,750 ℃会促进O2沿晶界扩散[45],裂纹扩展速率更快,造成力学性能恶化. ...

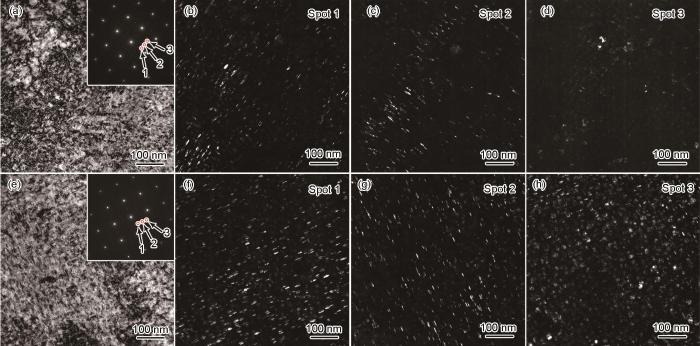

... 在进行TEM观察时,注意到DA和SA试样析出的γ′/γ″有所不同,图14b~d和f~h分别为DA和SA试样中γ′/γ″衍射斑点暗场像.可见,SA试样较DA试样的γ′/γ″含量更高且分布更加均匀,表明固溶处理使元素分布更加均匀.根据文献[51]对γ、γ′、γ″的模拟SAED结果,可以得出斑点暗场像分别为[001] γ′ 和[010] γ″ (图14b和f),[100] γ″ (图14c和g),及[001] γ′ 和[001] γ″ (图14d和h).γ″为体心四方结构,且c / a ≈ 2[52],存在3种变体,与基体形成共格结构,是主要强化相,成分为Ni3Nb,长时间时效会逐渐转变为稳定δ相[44].γ′相由于尺寸较小(约20 nm)分布在γ″相之间,一般认为相较于圆片状γ″相,近球形颗粒为γ′相[53]. ...

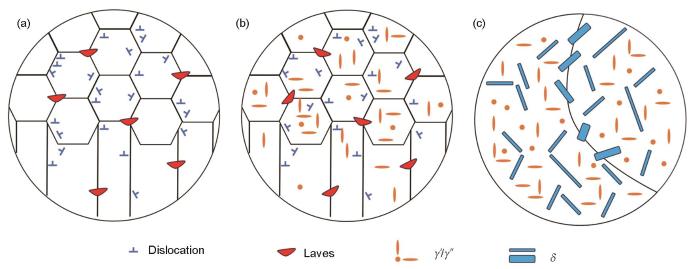

... GH4169高温合金的微观组织演变如图15所示.由于SLM成型属于快速熔化并凝固的过程(图15a),AB试样具有精细的胞状和柱状枝晶结构,在凝固过程中,强化相来不及析出,在枝晶间生成大量的富含Nb、Ti、Mo等强化元素的有害Laves脆性相,导致力学性能较差.而枝晶内部存在高密度位错,没有析出相的阻碍,位错滑移相对容易进行,具有较高的塑性(断后延伸率约为33%).DA处理后位错被γ′/γ″析出相截断(图15b),位错的开动更加困难,力学性能大幅提高.由于γ′/γ″析出相形成以及原子扩散的影响,Laves相与基体共格关系减弱,但DA态温度不能全部溶解Laves相,故DA处理后试样塑性较差(断后延伸率约为15%).SA处理后胞状和柱状结构消失(图15c),晶界显现,δ相呈短棒状在基体内均匀析出,主要沿胞状和柱状边界以及晶界分布.同时,γ′/γ″强化相均匀分布在基体中,δ相和γ″相的析出不断消耗Nb元素,促进Laves相发生溶解,以至观察不到明显的Laves相.δ相是GH4169高温合金中的稳定相,不提供强度[54,55].由于Laves相的溶解,导致SA试样较DA试样强度有所下降,但塑性有所增加(断后延伸率约为18%).SLM成型GH4169高温合金在650 ℃下保持较好的力学性能,但较室温性能有所下降.550 ℃具有锯齿流变现象.650 ℃时AB试样强度提高,这与此温度下γ′/γ″析出有关.当温度到达750 ℃,亚稳态的γ″会转变为δ相[44],力学性能急剧恶化,实际应用场景中应避免服役温度过高.980 ℃固溶时在胞状和柱状边界均匀析出δ相,间接保留了胞状和柱状结构,同时溶解Laves相,在未来应用环境具有一定潜在优势. ...

GH4169G合金热处理期间的相转变特征与机理分析

3

2013

... 550 ℃下拉伸性能与室温性能趋势相一致,DA试样的强度最高,AB试样的断后伸长率最高,但整体强度较室温时下降了10%~14%,断后伸长率减少了3%~4%.650 ℃高温拉伸时锯齿现象消失,DA和SA试样的强度高于锻件650 ℃高温拉伸性能标准要求,与室温强度相比下降20%,断后伸长率低于锻件标准要求(具体数值见表5).值得注意的是,AB试样在650 ℃下的拉伸性能与550 ℃相比有所提高.当测试温度达到750 ℃时,3种状态拉伸曲线趋于一致,呈明显的脆性断裂,强度和塑性显著下降.由于γ″为亚稳态相[43,44],在高于650 ℃时会转变为δ相,γ″共格强化减弱.此外,750 ℃会促进O2沿晶界扩散[45],裂纹扩展速率更快,造成力学性能恶化. ...

... 在进行TEM观察时,注意到DA和SA试样析出的γ′/γ″有所不同,图14b~d和f~h分别为DA和SA试样中γ′/γ″衍射斑点暗场像.可见,SA试样较DA试样的γ′/γ″含量更高且分布更加均匀,表明固溶处理使元素分布更加均匀.根据文献[51]对γ、γ′、γ″的模拟SAED结果,可以得出斑点暗场像分别为[001] γ′ 和[010] γ″ (图14b和f),[100] γ″ (图14c和g),及[001] γ′ 和[001] γ″ (图14d和h).γ″为体心四方结构,且c / a ≈ 2[52],存在3种变体,与基体形成共格结构,是主要强化相,成分为Ni3Nb,长时间时效会逐渐转变为稳定δ相[44].γ′相由于尺寸较小(约20 nm)分布在γ″相之间,一般认为相较于圆片状γ″相,近球形颗粒为γ′相[53]. ...

... GH4169高温合金的微观组织演变如图15所示.由于SLM成型属于快速熔化并凝固的过程(图15a),AB试样具有精细的胞状和柱状枝晶结构,在凝固过程中,强化相来不及析出,在枝晶间生成大量的富含Nb、Ti、Mo等强化元素的有害Laves脆性相,导致力学性能较差.而枝晶内部存在高密度位错,没有析出相的阻碍,位错滑移相对容易进行,具有较高的塑性(断后延伸率约为33%).DA处理后位错被γ′/γ″析出相截断(图15b),位错的开动更加困难,力学性能大幅提高.由于γ′/γ″析出相形成以及原子扩散的影响,Laves相与基体共格关系减弱,但DA态温度不能全部溶解Laves相,故DA处理后试样塑性较差(断后延伸率约为15%).SA处理后胞状和柱状结构消失(图15c),晶界显现,δ相呈短棒状在基体内均匀析出,主要沿胞状和柱状边界以及晶界分布.同时,γ′/γ″强化相均匀分布在基体中,δ相和γ″相的析出不断消耗Nb元素,促进Laves相发生溶解,以至观察不到明显的Laves相.δ相是GH4169高温合金中的稳定相,不提供强度[54,55].由于Laves相的溶解,导致SA试样较DA试样强度有所下降,但塑性有所增加(断后延伸率约为18%).SLM成型GH4169高温合金在650 ℃下保持较好的力学性能,但较室温性能有所下降.550 ℃具有锯齿流变现象.650 ℃时AB试样强度提高,这与此温度下γ′/γ″析出有关.当温度到达750 ℃,亚稳态的γ″会转变为δ相[44],力学性能急剧恶化,实际应用场景中应避免服役温度过高.980 ℃固溶时在胞状和柱状边界均匀析出δ相,间接保留了胞状和柱状结构,同时溶解Laves相,在未来应用环境具有一定潜在优势. ...

Temperature and strain-rate dependence of the elevated temperature ductility of Inconel 718 prepared by selective laser melting

1

2021

... 550 ℃下拉伸性能与室温性能趋势相一致,DA试样的强度最高,AB试样的断后伸长率最高,但整体强度较室温时下降了10%~14%,断后伸长率减少了3%~4%.650 ℃高温拉伸时锯齿现象消失,DA和SA试样的强度高于锻件650 ℃高温拉伸性能标准要求,与室温强度相比下降20%,断后伸长率低于锻件标准要求(具体数值见表5).值得注意的是,AB试样在650 ℃下的拉伸性能与550 ℃相比有所提高.当测试温度达到750 ℃时,3种状态拉伸曲线趋于一致,呈明显的脆性断裂,强度和塑性显著下降.由于γ″为亚稳态相[43,44],在高于650 ℃时会转变为δ相,γ″共格强化减弱.此外,750 ℃会促进O2沿晶界扩散[45],裂纹扩展速率更快,造成力学性能恶化. ...

Hydrogen-assisted cracking behavior of Ni alloy 718: Microstructure, H testing protocol, and fractography

1

2021

... 为进一步明确析出相结构及其演变规律,对试样进行TEM观察.图11为AB、DA和SA试样胞状结构的TEM明场像.可见,AB样品中有大量位错(图11a),并在胞状边界缠绕,位错的滑移使其具有较高的断后伸长率,在胞壁节点处有不规则块状析出相.DA样品中的胞状组织依然存在(图11b),胞内有细小的析出相生成,由于胞内析出相的阻挡,位错滑移较难进行,强度大幅提高,但塑性下降.SA样品中的胞状组织完全消失(图11c),位错不明显,在晶内和晶界有片状或短棒状析出相生成,位于边界的析出相可作为裂纹萌生的起点[46],同时基体内存在细小的析出相. ...

Morphology of γ' and γ'' precipitates and thermal stability of INCONEL 718 type alloys

1

1973

... DA处理后,如图13g所示,在基体内部有细小的短棒状析出相,在[100]带轴下获得具有γ′和γ″的超点阵,经过标定,基体与γ′/γ″相完全共格,与基体取向关系为:[100] γ // [100] γ′ // [100] γ″,一般认为沉淀析出过程中,会先析出γ′相,然后随着时间的延长,γ′周围有片状γ″相析出,当γ′尺寸合适时,γ″会在γ′相周围6个面成立方体式包覆[47].若γ′尺寸小于临界尺寸,由于Nb元素的消耗,会形成单个或层状γ″相.同时在晶界交界处发现Laves相,说明时效过程并不能使Laves相溶解,测试过程中发现DA试样中某些Laves相与基体的取向关系发生偏转,这可能与γ′/γ″析出相的形成导致基体与Laves相界面发生改变有关. ...

Prediction and characterization of variant electron diffraction patterns for γ″ and δ precipitates in an Inconel 718 alloy

1

1999

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

Recent development of triple melt GH4169 alloy

1

2023

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

三联冶炼GH4169合金研究进展

1

2023

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

Dissolution kinetics of Laves phase during homogenization heat treatment of additively manufactured Inconel 718 superalloy

1

2023

... SA处理后,如图13k、m、o所示,与DA试样相同,在基体析出细小的γ′/γ″相,并与基体完全共格,同时发现在晶内和晶界有大量短棒状析出相,980 ℃固溶温度在δ相析出的温度区间内[22],δ相为正交结构,结构式为A3B,晶胞参数a、b、c均不相等,δ相有12种变体[48],在基体[110]带轴下观察到基体与δ相的取向关系:[110] γ // [100] δ,[110] γ // [102] δ.结合图12 EDS结果,可以确定为Ni3(Nb, Ti).黄文普[3]通过差示扫描量热仪(DSC)测量Laves相初始溶解温度为825 ℃,远低于传统制造1140~1160 ℃[49]的初熔温度.此固溶温度下Laves相有更快溶解动力[50],低温溶解现象与SLM成型GH4169的高位错密度和精细微观组织密切相关.在Laves相溶解过程中,由于SLM成型高冷却速率导致组织中枝晶间距十分细小,初始偏析程度较低,扩散距离较短,同时δ和γ″两相的析出降低了基体中Nb元素含量,进一步促进了Laves相的溶解,因此实验中并未发现明显的Laves相残留. ...

Investigations of γ′, γ″ and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting

1

2018

... 在进行TEM观察时,注意到DA和SA试样析出的γ′/γ″有所不同,图14b~d和f~h分别为DA和SA试样中γ′/γ″衍射斑点暗场像.可见,SA试样较DA试样的γ′/γ″含量更高且分布更加均匀,表明固溶处理使元素分布更加均匀.根据文献[51]对γ、γ′、γ″的模拟SAED结果,可以得出斑点暗场像分别为[001] γ′ 和[010] γ″ (图14b和f),[100] γ″ (图14c和g),及[001] γ′ 和[001] γ″ (图14d和h).γ″为体心四方结构,且c / a ≈ 2[52],存在3种变体,与基体形成共格结构,是主要强化相,成分为Ni3Nb,长时间时效会逐渐转变为稳定δ相[44].γ′相由于尺寸较小(约20 nm)分布在γ″相之间,一般认为相较于圆片状γ″相,近球形颗粒为γ′相[53]. ...

Recent progress on evolution of precipitates in Inconel 718 superalloy

1

2016

... 在进行TEM观察时,注意到DA和SA试样析出的γ′/γ″有所不同,图14b~d和f~h分别为DA和SA试样中γ′/γ″衍射斑点暗场像.可见,SA试样较DA试样的γ′/γ″含量更高且分布更加均匀,表明固溶处理使元素分布更加均匀.根据文献[51]对γ、γ′、γ″的模拟SAED结果,可以得出斑点暗场像分别为[001] γ′ 和[010] γ″ (图14b和f),[100] γ″ (图14c和g),及[001] γ′ 和[001] γ″ (图14d和h).γ″为体心四方结构,且c / a ≈ 2[52],存在3种变体,与基体形成共格结构,是主要强化相,成分为Ni3Nb,长时间时效会逐渐转变为稳定δ相[44].γ′相由于尺寸较小(约20 nm)分布在γ″相之间,一般认为相较于圆片状γ″相,近球形颗粒为γ′相[53]. ...

Inconel718高温合金中析出相演变研究进展

1

2016

... 在进行TEM观察时,注意到DA和SA试样析出的γ′/γ″有所不同,图14b~d和f~h分别为DA和SA试样中γ′/γ″衍射斑点暗场像.可见,SA试样较DA试样的γ′/γ″含量更高且分布更加均匀,表明固溶处理使元素分布更加均匀.根据文献[51]对γ、γ′、γ″的模拟SAED结果,可以得出斑点暗场像分别为[001] γ′ 和[010] γ″ (图14b和f),[100] γ″ (图14c和g),及[001] γ′ 和[001] γ″ (图14d和h).γ″为体心四方结构,且c / a ≈ 2[52],存在3种变体,与基体形成共格结构,是主要强化相,成分为Ni3Nb,长时间时效会逐渐转变为稳定δ相[44].γ′相由于尺寸较小(约20 nm)分布在γ″相之间,一般认为相较于圆片状γ″相,近球形颗粒为γ′相[53]. ...

Microstructural evolution and corrosion behaviors of Inconel 718 alloy produced by selective laser melting following different heat treatments

1

2019

... 在进行TEM观察时,注意到DA和SA试样析出的γ′/γ″有所不同,图14b~d和f~h分别为DA和SA试样中γ′/γ″衍射斑点暗场像.可见,SA试样较DA试样的γ′/γ″含量更高且分布更加均匀,表明固溶处理使元素分布更加均匀.根据文献[51]对γ、γ′、γ″的模拟SAED结果,可以得出斑点暗场像分别为[001] γ′ 和[010] γ″ (图14b和f),[100] γ″ (图14c和g),及[001] γ′ 和[001] γ″ (图14d和h).γ″为体心四方结构,且c / a ≈ 2[52],存在3种变体,与基体形成共格结构,是主要强化相,成分为Ni3Nb,长时间时效会逐渐转变为稳定δ相[44].γ′相由于尺寸较小(约20 nm)分布在γ″相之间,一般认为相较于圆片状γ″相,近球形颗粒为γ′相[53]. ...

Effects of Al and Ti additions on precipitation behavior and mechanical properties of Co35Cr25-Fe40 - x Ni x TRIP high entropy alloys

1

2019

... GH4169高温合金的微观组织演变如图15所示.由于SLM成型属于快速熔化并凝固的过程(图15a),AB试样具有精细的胞状和柱状枝晶结构,在凝固过程中,强化相来不及析出,在枝晶间生成大量的富含Nb、Ti、Mo等强化元素的有害Laves脆性相,导致力学性能较差.而枝晶内部存在高密度位错,没有析出相的阻碍,位错滑移相对容易进行,具有较高的塑性(断后延伸率约为33%).DA处理后位错被γ′/γ″析出相截断(图15b),位错的开动更加困难,力学性能大幅提高.由于γ′/γ″析出相形成以及原子扩散的影响,Laves相与基体共格关系减弱,但DA态温度不能全部溶解Laves相,故DA处理后试样塑性较差(断后延伸率约为15%).SA处理后胞状和柱状结构消失(图15c),晶界显现,δ相呈短棒状在基体内均匀析出,主要沿胞状和柱状边界以及晶界分布.同时,γ′/γ″强化相均匀分布在基体中,δ相和γ″相的析出不断消耗Nb元素,促进Laves相发生溶解,以至观察不到明显的Laves相.δ相是GH4169高温合金中的稳定相,不提供强度[54,55].由于Laves相的溶解,导致SA试样较DA试样强度有所下降,但塑性有所增加(断后延伸率约为18%).SLM成型GH4169高温合金在650 ℃下保持较好的力学性能,但较室温性能有所下降.550 ℃具有锯齿流变现象.650 ℃时AB试样强度提高,这与此温度下γ′/γ″析出有关.当温度到达750 ℃,亚稳态的γ″会转变为δ相[44],力学性能急剧恶化,实际应用场景中应避免服役温度过高.980 ℃固溶时在胞状和柱状边界均匀析出δ相,间接保留了胞状和柱状结构,同时溶解Laves相,在未来应用环境具有一定潜在优势. ...

Effect of building direction on anisotropy of mechanical properties of GH4169 alloy fabricated by laser powder bed fusion

1

2023

... GH4169高温合金的微观组织演变如图15所示.由于SLM成型属于快速熔化并凝固的过程(图15a),AB试样具有精细的胞状和柱状枝晶结构,在凝固过程中,强化相来不及析出,在枝晶间生成大量的富含Nb、Ti、Mo等强化元素的有害Laves脆性相,导致力学性能较差.而枝晶内部存在高密度位错,没有析出相的阻碍,位错滑移相对容易进行,具有较高的塑性(断后延伸率约为33%).DA处理后位错被γ′/γ″析出相截断(图15b),位错的开动更加困难,力学性能大幅提高.由于γ′/γ″析出相形成以及原子扩散的影响,Laves相与基体共格关系减弱,但DA态温度不能全部溶解Laves相,故DA处理后试样塑性较差(断后延伸率约为15%).SA处理后胞状和柱状结构消失(图15c),晶界显现,δ相呈短棒状在基体内均匀析出,主要沿胞状和柱状边界以及晶界分布.同时,γ′/γ″强化相均匀分布在基体中,δ相和γ″相的析出不断消耗Nb元素,促进Laves相发生溶解,以至观察不到明显的Laves相.δ相是GH4169高温合金中的稳定相,不提供强度[54,55].由于Laves相的溶解,导致SA试样较DA试样强度有所下降,但塑性有所增加(断后延伸率约为18%).SLM成型GH4169高温合金在650 ℃下保持较好的力学性能,但较室温性能有所下降.550 ℃具有锯齿流变现象.650 ℃时AB试样强度提高,这与此温度下γ′/γ″析出有关.当温度到达750 ℃,亚稳态的γ″会转变为δ相[44],力学性能急剧恶化,实际应用场景中应避免服役温度过高.980 ℃固溶时在胞状和柱状边界均匀析出δ相,间接保留了胞状和柱状结构,同时溶解Laves相,在未来应用环境具有一定潜在优势. ...