K4061合金由仿制俄罗斯EK61合金而来[5],主要成分与IN718合金相似[6~8],能在750℃富氧腐蚀性环境下短时使用。与 IN718合金相比,K4061合金降低了Fe含量,并适量添加V和Cu元素[9]。由于Cu燃烧热非常低,可以提升其抗富氧燃烧能力,因此在合金中添加了Cu[10]。然而,Cu元素是高温合金中的有害元素,其含量需要进行严格控制。因此,较高含量的Cu元素对高温合金的显微组织、力学性能等影响鲜有报道。早期研究[11,12]表明,微量的Cu元素主要偏聚于晶界,不利于合金的持久性能。将0.5%Cu (质量分数,下同)加入到K4169中,可降低Laves相的初熔温度与合金的熔点[13,14]。Gwalani等[15]指出,在高熵合金Al0.3CuFeCrNi2中发现了富Cu相。但高含量Cu添加到镍基高温合金中是否会析出富Cu相尚未见报道。最近Detrois等[16]指出,Cu元素不会偏聚于镍基高温合金的晶界上,因此对合金力学性能没有影响。这也与早期的研究矛盾,所以Cu元素在高温合金中的偏析行为以及对其拉伸性能的影响需要深入研究。

因此,本工作在可铸、可锻的K4061合金基础上,通过调整Cu元素含量,在热力学相平衡计算的基础上,结合差示扫描量热技术(DSC)、扫描电镜(SEM)以及透射电镜(TEM)实验,研究了Cu含量(1%~10%)对铸造态K4061合金凝固特性的影响,包括相变温度、凝固路径等;同时,还研究了Cu含量对K4061合金显微组织和拉伸性能的影响,讨论了Cu的偏析行为,以及Cu对强化相尺寸和拉伸强度的影响。

1 实验方法

首先使用Thermo-Calc计算软件和TCNI10 镍基合金热力学数据库,对K4061合金平衡凝固过程进行了初步的计算。随后通过真空感应熔炼炉冶炼25 kg K4061母合金,并将母合金分成5组,再通过降低高燃烧热值元素Fe的含量、提高低燃烧热值元素Cu的含量,冶炼浇注成不同Cu含量的试样,其名义成分如表1所示。采用线切割切取直径5 mm、高度2 mm的试样,打磨去除表面氧化皮,样品称重后进行DSC实验,所用仪器型号为NETZSCH DSC 404 C。样品放在高纯Al2O3坩埚内,升降温过程中采用高纯Ar保护,充气速率为60 mL/min,1000℃以上升温速率为10℃/min。

表1 K4061合金试样的名义成分 (mass fraction / %)

Table 1

| Sample | C | Al | Ti | V | Cr | Fe | Cu | Nb | Mo | Ni |

|---|---|---|---|---|---|---|---|---|---|---|

| K4061 | 0.04 | 0.9 | 0.6 | 0.45 | 16.5 | 14 | 0.55 | 4.75 | 4 | Bal. |

| K4061-2Cu | 0.04 | 0.9 | 0.6 | 0.45 | 16.5 | 12 | 2 | 4.75 | 4 | Bal. |

| K4061-5Cu | 0.04 | 0.9 | 0.6 | 0.45 | 16.5 | 9 | 5 | 4.75 | 4 | Bal. |

| K4061-8Cu | 0.04 | 0.9 | 0.6 | 0.45 | 16.5 | 6 | 8 | 4.75 | 4 | Bal. |

| K4061-10Cu | 0.04 | 0.9 | 0.6 | 0.45 | 16.5 | 4 | 10 | 4.75 | 4 | Bal. |

样品热处理制度为1020℃、3 h,空冷(AC) + 730℃、15 h,AC + 650℃、10 h,AC,热处理后加工成标距段直径5 mm、长度30 mm的拉伸试样,利用CSS-88100电子万能试验机分别进行室温拉伸和750℃高温拉伸实验。将铸态和热处理态试样磨抛后进行电解腐蚀,腐蚀试剂为1 mL HNO3 + 3 mL HCl + 4 mL C3H8O3溶液,电压3 V,时间8 s左右。使用带有能谱分析仪(EDS)的JSM-6301F SEM观察和分析不同Cu含量下合金的微观组织。将试样放于10%高氯酸酒精(体积分数)双喷溶液中制备TEM样品,电压为18 V,温度为-20℃,利用Tecnai G2 20 TEM对其进行了表征。

2 实验结果

2.1 热力学计算

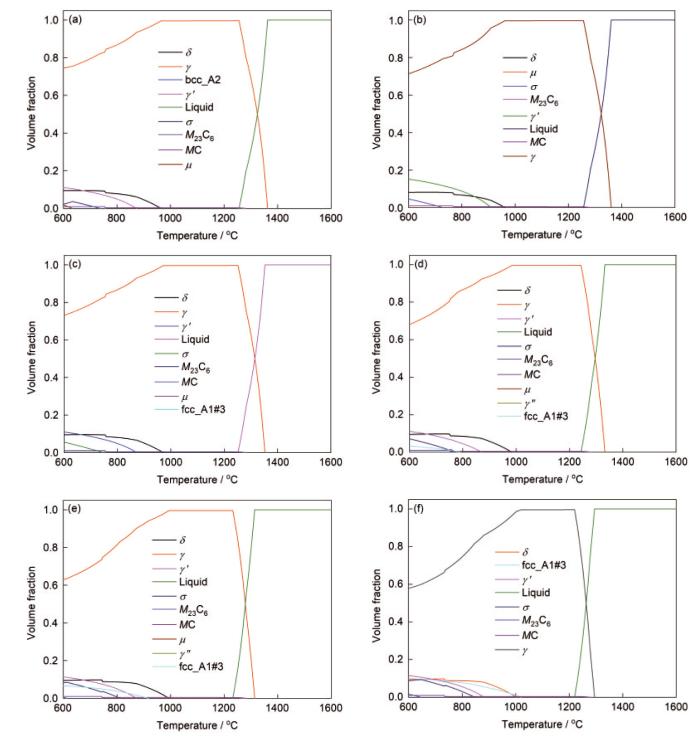

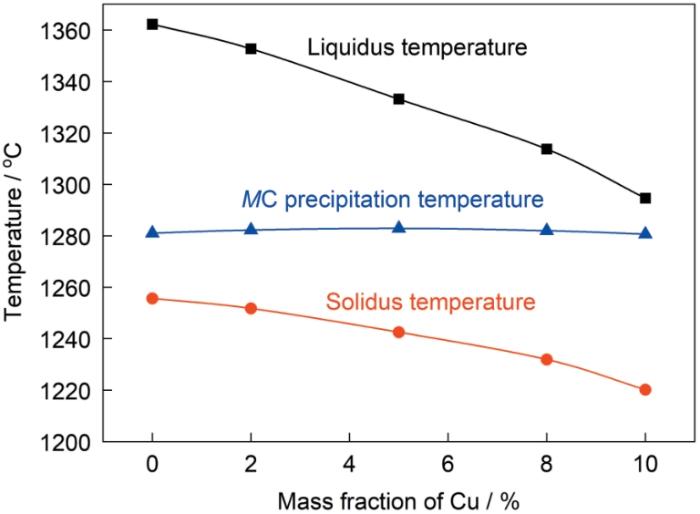

使用Thermo-Calc软件和TCNI10镍基合金热力学数据库,计算了K4061合金以及添加1%、2%、5%、8%和10%的Cu元素下合金的平衡相图,结果如图1所示。可以看出,K4061合金平衡凝固路径为L (液相) → L + γ → L + γ + MC,而其他析出相,如γ'相、M23C6碳化物、δ相和σ相等,均在固态相变过程中析出(图1a)。Cu的添加对于合金平衡凝固路径没有影响,析出相种类大致相同。但是当Cu添加量> 2%时,发现合金中析出一种fcc结构的富Cu相,如图1c~f中所示fcc_A1#3相。图2为K4061合金平衡凝固过程中凝固特征温度与Cu含量的关系。结果表明,液相线和固相线温度随着合金中Cu含量的提高呈线性降低,液相线温度降低幅度更大;MC析出温度基本不变,约在1280℃。表2列出了平衡凝固时,不同Cu含量K4061合金中析出相MC的主要元素种类及其含量。可以看出,MC主要含有Nb和Ti,当Cu添加到K4061合金后,MC合金元素种类和数量没有改变,且无论是高Cu含量合金还是低Cu含量合金,MC中Cu含量均为0,说明Cu并没有溶解于MC中。

图1

图1

不同Cu含量下K4061合金Thermo-Calc平衡态计算结果

Fig.1

Calculated solidification sequences of K4061 alloy with different Cu contents predicted by Thermo-Calc

(a)K4061 (b)K4061-1Cu (c)K4061-2Cu (d)K4061-5Cu (e)K4061-8Cu (f)K4061-10Cu

图2

图2

K4061合金凝固特征温度随Cu含量的变化

Fig.2

Variations of solidification characteristic temperature with Cu content in K4061 alloy by Thermo-Calc

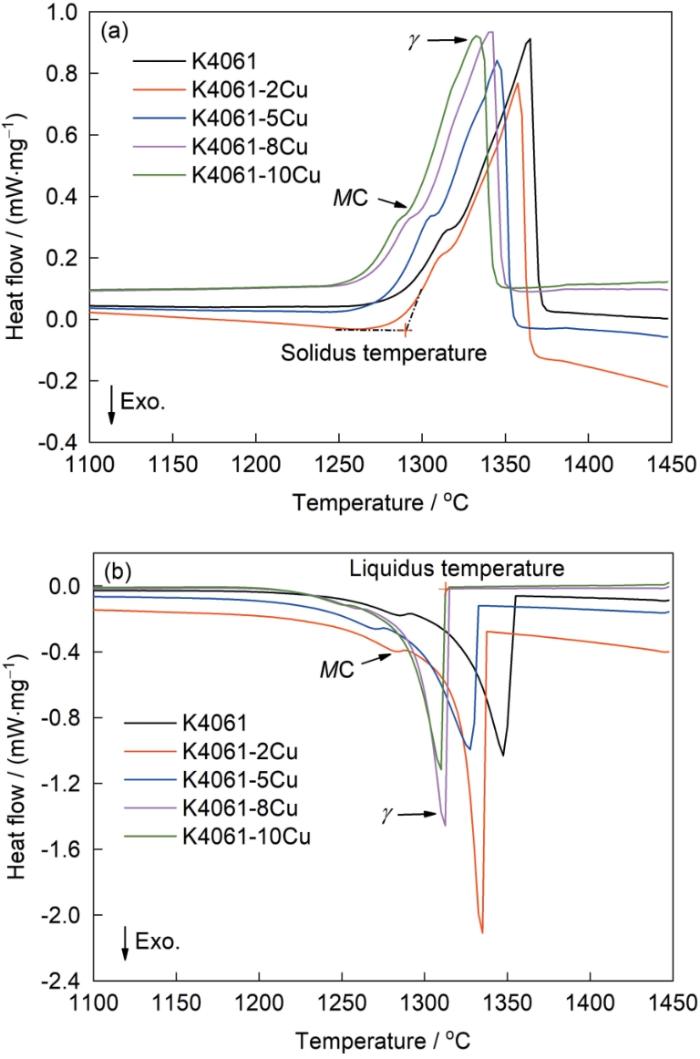

图3

图3

不同Cu含量K4061合金升温与降温DSC曲线

Fig.3

Heating (a) and cooling (b) DSC curves of K4061 alloy with different Cu contents

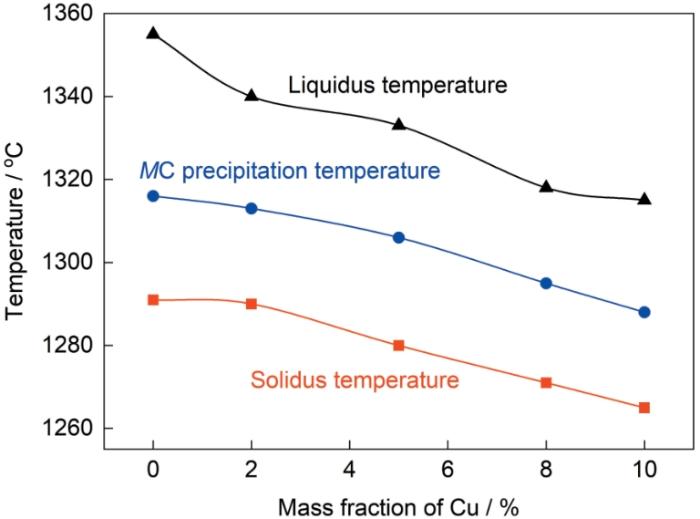

图4

图4

DSC测量的凝固特征温度随Cu含量的变化

Fig.4

Variations of solidification characteristic temperature with Cu content measuring by DSC

图5

图5

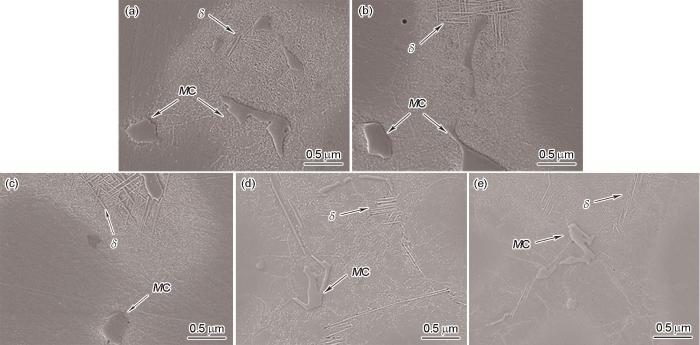

不同Cu含量K4061合金试样铸态组织的SEM像

Fig.5

SEM images of as-cast K4061 (a), K4061-2Cu (b), K4061-5Cu (c), K4061-8Cu (d), and K4061-10Cu (e) alloys

图6

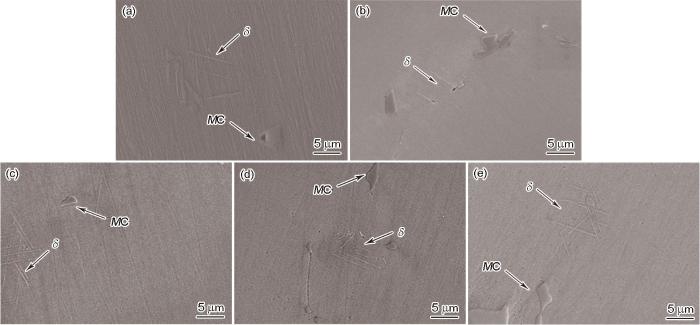

图6

不同Cu含量K4061合金试样热处理态组织的SEM像

Fig.6

SEM images of K4061 (a), K4061-2Cu (b), K4061-5Cu (c), K4061-8Cu (d), and K4061-10Cu (e) alloys after heat treatment

图7

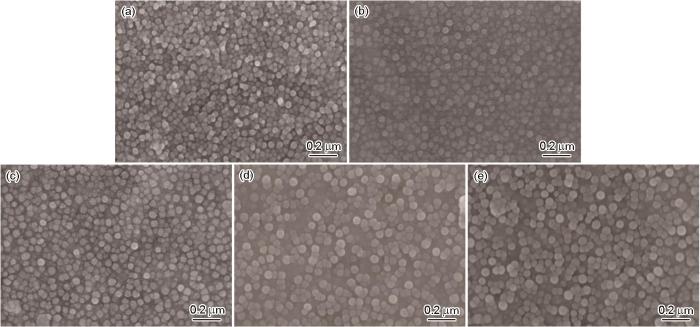

图7

不同Cu含量K4061合金试样热处理后强化相形貌的SEM像

Fig.7

SEM images of γ'/γ" phases in K4061 (a), K4061-2Cu (b), K4061-5Cu (c), K4061-8Cu (d), and K4061-10Cu (e) alloys after heat treatment

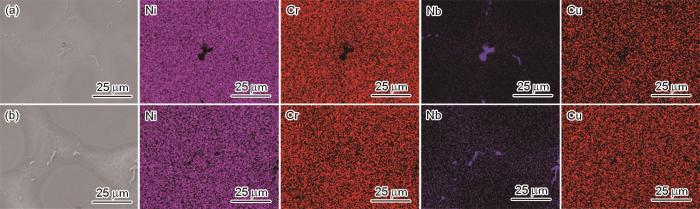

图8

图8

铸态K4061-8Cu和K4061-10Cu合金试样的SEM像和EDS元素面扫描图

Fig.8

SEM images and corresponding EDS element maps of as-cast K4061-8Cu (a) and K4061-10Cu (b) alloys

图9

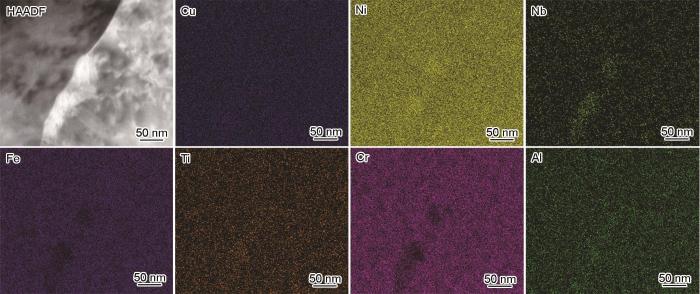

图9

K4061-10Cu合金试样热处理后晶界处的TEM高角环形暗场(HAADF)像和EDS元素面扫描图

Fig.9

TEM high-angle annular dark field (HAADF) image and corresponding element maps of the grain boundary in the K4061-10Cu alloy after heat treatment

图10

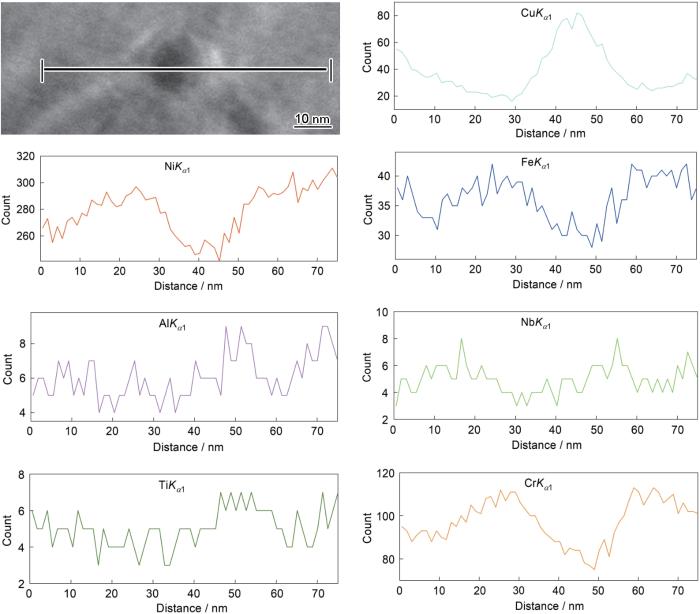

图10

K4061-10Cu合金热处理试样的TEM-HAADF像和EDS元素面扫描图

Fig.10

TEM-HAADF image and corresponding element maps of the K4061-10Cu alloy after heat treatment

表2 Thermo-Calc平衡态计算MC的元素含量结果 (atomic fraction / %)

Table 2

| Sample | C | Ti | Cr | Cu | Nb | Mo |

|---|---|---|---|---|---|---|

| K4061 | 47.36 | 4.89 | 0.24 | 0.00 | 46.74 | 0.75 |

| K4061-2Cu | 47.25 | 4.75 | 0.23 | 0.00 | 47.15 | 0.60 |

| K4061-5Cu | 47.08 | 4.80 | 0.23 | 0.00 | 47.27 | 0.60 |

| K4061-8Cu | 47.31 | 4.52 | 0.23 | 0.00 | 47.37 | 0.55 |

| K4061-10Cu | 47.08 | 4.13 | 0.23 | 0.00 | 48.04 | 0.50 |

图1 不同Cu含量下K4061合金Thermo-Calc平衡态计算结果

(a) K4061 (b) K4061-1Cu (c) K4061-2Cu (d) K4061-5Cu (e) K4061-8Cu (f) K4061-10Cu

2.2 Cu对凝固特征温度的影响

K4061合金以及添加2%、5%、8%和10%的Cu元素合金的DSC曲线如图3所示。图3a所示的升温曲线显示在1100℃以上存在2个熔化峰,分别对应MC和γ基体熔化峰。当达到约1255℃时,γ基体开始熔化,随后MC发生熔化,最后γ基体完全熔化。同样地,降温曲线(图3b)中2个放热峰分别对应液相凝固和MC析出,并且可以看出MC在凝固末期析出。从升温和降温曲线可以看出,当K4061合金中添加了Cu元素之后,合金的固相线温度降低,MC开始熔化的温度也随合金中Cu含量的增加而降低,整体来看合金熔化与凝固都向较低的温度偏移。不同Cu含量下DSC测量的液/固相线温度与MC熔化温度如图4所示。可见,Cu的添加会降低合金的固/液相线温度和MC析出温度,且呈线性关系,这与理论计算结果相吻合。固/液相线温度取决于合金成分,因此加入低熔点的Cu势必然会降低合金固/液相线温度。但是热力学计算得到的MC析出温度与Cu含量没有明显关系,而实验结果表明MC析出温度随Cu含量提高而降低。这是因为,MC的成分是固定的,其析出温度取决于凝固过程中液相中的C和Nb元素成分。因此基于平衡凝固条件计算得到的析出温度必然与存在偏析的真实凝固过程不一致。

2.3 Cu对析出相的影响

2.4 Cu元素偏析行为

由前文可知,当Cu含量大于2%时,会得到一种fcc结构的富Cu相。Gwalani等[15]在铸态Al0.3CuFeCrNi2高熵合金中发现了一种含58.23%Cu (原子分数)的富Cu相;贺玉伟[17]在镍基高温合金中添加< 1.2%Cu (质量分数)时,并没有发现富Cu相,可能的原因是添加的Cu含量较少。因此,本工作对高Cu含量的K4061合金试样进行面扫描,结果如图8所示。可以看出,添加8%和10%的Cu元素的样品中均没有发现Cu元素的富集,这与计算结果不同。这可能与实际凝固过程是非平衡状态有关。而在Al0.3CuFeCrNi2高熵合金中Cu含量高达21.4% (质量分数),本工作中Cu元素的最高添加量为10% (质量分数),推测可能由于Cu含量未达到析出富Cu相的成分范围,因此未发现富Cu相。

Holt和Wallace[11]指出,高温合金中的Cu通常偏聚在晶界;Detrois等[16]在镍基高温合金中添加0.138%Cu (质量分数)时,在晶界处没有发现Cu元素富集的现象。K4061-10Cu热处理后晶界处的TEM高角环形暗场(HAADF)像和EDS元素面扫描结果如图9所示。可以看出,Cu比较均匀地分布在合金中,未发现Cu偏聚于晶界。同样地,在添加2%、5%和8%的Cu元素的合金中,也未发现Cu元素偏聚于晶界的现象。同时,TEM观察发现K4061-10Cu合金中γ'和γ"共生生长,通过元素EDS面扫描结果(图10)可以看出,Cu元素出现富集现象,大致与Al、Ti和Nb元素富集位置相重叠;从图11可以看出,强化相处富集Al、Ti和Nb,贫Fe、Cr,为共生γ'/γ",Cu元素线扫描图有明显的峰,说明Cu元素偏聚于强化相中,这与文献[15]报道一致。

图11

图11

K4061-10Cu合金热处理试样的TEM像和EDS元素线扫描图

Fig.11

TEM image and EDS line scanning results of the K4061-10Cu alloy after heat treatment

2.5 Cu对铸造合金拉伸性能的影响

对不同Cu含量铸造K4061合金热处理后试棒进行室温和750℃拉伸实验,拉伸性能如表3所示。K4061合金室温抗拉强度和屈服强度分别为940和674 MPa,添加2%和5%的Cu元素使得合金室温抗拉强度分别降低了41和60 MPa,屈服强度分别降低了10和41 MPa;添加2%Cu对合金高温拉伸性能基本没有影响,而添加5%Cu使得合金抗拉和屈服强度分别降低了45和40 MPa。可见,Cu元素的添加会对合金的拉伸性能有一定的影响。在误差范围内,Cu元素的添加对铸造K4061合金的延伸率(A)和断面收缩率(Z)基本没有影响。

表3 不同Cu含量铸造K4061合金室温和750℃拉伸性能

Table 3

| Sample | Rm | Rp0.2 | Z | A | ||||

|---|---|---|---|---|---|---|---|---|

| RT | 750oC | RT | 750oC | RT | 750oC | RT | 750oC | |

| K4061 | 940 | 497 | 674 | 458 | 57 | 12 | 27 | 4 |

| K4061-2Cu | 899 | 497 | 664 | 467 | 36 | 17 | 26 | 5 |

| K4061-5Cu | 880 | 452 | 633 | 418 | 36 | 12 | 28 | 7 |

3 分析讨论

3.1 Cu元素的偏聚

根据前文可知,Cu元素没有偏聚到晶界与析出相MC中,而是主要分布在强化相中的团簇(图10)。从图11可以更加明显地看出Cu元素会富集在强化相中,同时结合文献[15,16]所描述的Cu元素的分布,推测Cu在K4061合金强化相中分布也是不均匀的。根据Detrois等[16]的计算结果,Cu和Al之间相互作用能是负值(-0.037 eV/atom),而与其他元素之间的相互作用能是正值,这是导致Cu元素偏聚在Al含量较高的γ'相中的主要原因。此外,从热力学角度考虑,根据图12所示的不同Cu含量下K4061合金强化相的Gibbs自由能(计算温度为730℃),可以看到无论是γ'相或者γ"相,当其中含有少量Cu元素时,其自由能均呈现下降趋势,这很好地解释了实验发现的Cu元素偏聚在强化相中的现象。Gwalani等[15]通过三维原子探针(3D-APT)实验也发现 Al0.3CuCrFeNi2高熵合金中的Cu会偏聚于γ'相,并且根据相成分推断出Cu更倾向于占据γ'相中Ni原子位置。

图12

图12

不同Cu含量下K4061合金γ'相和γ"相的Gibbs自由能

Fig.12

Gibbs energies of γ' (a) and γ" (b) phases in K4061 alloy with different Cu contents

3.2 Cu元素对强化相尺寸的影响

式中,rγ' 为γ'相的半径;rγ'' 为γ"相的半径;ΔGγ - γ' 为γ基体与γ'相的体积自由能之差;σγ - γ' 为γ基体与γ'相的界面能之差。可根据

图13

图13

Cu含量对K4061合金γ'相和γ"相临界形核尺寸的影响

Fig.13

Influences of Cu content on the critical nucleation sizes of γ' and γ" phases

3.3 Cu元素对力学性能的影响

由表3可知,Cu的添加会降低K4061合金的抗拉强度,尤其是添加5%Cu后,抗拉强度下降较明显。文献[19,20]曾报道,IN718合金的强度与强化相的尺寸有关,强化相尺寸的增加会提高合金的屈服强度,且强化相的适宜尺寸为10~50 nm。本工作强化相γ'尺寸统计结果表明,K4061、K4061-2Cu和K4061-5Cu合金强化相尺寸分别为23、 33和34 nm (图7),均处于强化相适宜尺寸范围。然而,由于3个合金强化相尺寸差别不大,可以忽略Cu含量对γ'强化相的影响。因此,本工作主要基于固溶元素的强化效果来讨论Cu元素对合金拉伸强度的影响。首先,在调整合金成分时,添加Cu元素的同时降低了Fe的含量,而其他元素含量保持不变。在高温合金中,虽然Fe和Cu均具有一定的固溶强化效果,但Fe元素的固溶强化系数大约是Cu的1.8倍[21,22],因此Cu含量提高而Fe含量降低必然导致合金基体固溶强化效果降低。

4 结论

(1) K4061合金平衡凝固路径为L → L + γ → L + γ + MC,Cu元素的添加虽然对其平衡凝固路径没有影响,但会降低合金平衡固/液相线温度;在实际凝固过程中,由于Nb等溶质元素的偏析,凝固末期还会析出非平衡的δ相,但整体而言Cu的添加及其含量对K4169合金析出相种类没有影响。

(2) K4061合金中的Cu元素除了固溶在基体中之外,还会偏聚于γ'/γ"共生强化相中,但是即便在Cu含量较高的情况下,仍然没有在晶界处发现Cu元素富集的现象;此外,MC型碳化物中也没有发现Cu元素的偏聚,因此Cu不是碳化物形成元素,但Cu的添加会降低MC型碳化物析出温度。

(3) 随着Cu含量的提高,K4169合金时效过程中析出的γ'/γ''共生强化相尺寸逐渐增大,同时其室温和高温抗拉强度逐渐降低,但其塑性基本保持不变。

参考文献

Influence of microalloying on the plasticity of KhN58MBYuD-VI nickel alloy

[J].

Effect of low temperatures on mechanical and physical properties of high-strength nickel alloy ÉK61-ID and stainless maraging steel Ek49-VD

[J].

Structural changes in alloy ÉK-61 due to cyclic deformation at elevated temperature

[J].

High-temperature ductility of nickel alloys type KhN55MBYu with a high iron content

[J].

Correlation between fracture morphology and microstructural evolution during long-term aging of EK61 superalloy

[J].

Gamma-gamma prime-gamma double prime dual-superlattice superalloys

[J].

Precipitation and clustering in the early stages of ageing in Inconel 718

[J].

Structural characterization of the aged Inconel 718

[J].

Formation of cracks in ÉP202 and ÉK61 alloys in welding of structures of liquid rocket engines

[J].

Metal combustion in high-pressure flowing oxygen

[A].

Impurities and trace elements in nickel-base superalloys

[J].

An elementary overview of the selection of materials for service in oxygen-enriched environments

[A].

Effect of copper on solidification process and segregation in K4169 superalloy

[J].

Cu对K4169合金凝固过程及凝固偏析的影响

[J].

First-principles study on the effect of Cu on Nb segregation in Inconel 718 alloy

[J].Inconel 718 alloy is an Fe-Ni based superalloy precipitation-strengthened by γ″ phase (Ni3Nb) and γ′ phase (Ni3(AlTi)). It has been widely used in aviation, energy, chemicals, and other fields because of its outstanding mechanical properties, resistance to high-temperature oxidation, and corrosion resistance. Because the mechanical properties of Inconel 718 alloy are primarily determined by the γ″ precipitates, Nb becomes one of the most important alloying elements. Due to the high content, large atomic radius, and small partition coefficient of Nb, Nb segregation occurs easily during the solidification process of casting, welding, and laser cladding. The segregation drastically degrades mechanical properties and increases the difficulty of subsequent heat treatment. The composition of Inconel 718 alloy comprises many elements, and some trace elements are inevitably introduced from the raw materials. The interaction of the elements has a certain effect on Nb segregation. In this study, the effect of the interaction of elements caused by doping of Cu on Nb segregation in Inconel 718 alloy was studied by first-principles calculation and experiment. The Ni-Fe-Cr-Nb supercell model was constructed with and without Cu doping. The enthalpy of formation, cohesive energy, state density, electron density difference, and population analysis was calculated. The calculation results show that the doping of Cu reduces the stability of the system. Doping will change the interaction between elements and affects the strength and density distribution ratio of the charged density between atomic bonds in the system. The addition of Cu increases the bond strength between the Fe atoms and Cr atoms and the repulsive force between Fe atoms and Nb atoms in the matrix. The experimental results show that the addition of 0.1%Cu (mass fraction) decreases the segregation of Fe and Cr, but promotes the segregation of Nb. Experimental results and first-principles calculations show that the increase in the repulsive force between the Nb atom and Fe atom, which is caused by the interaction between the alloying elements after doping with Cu, is the essential reason for Cu to promote Nb segregation.

Cu对Inconel 718合金Nb偏析影响机理的第一性原理研究

[J].采用第一性原理计算与实验相结合的方法探究了Cu元素掺杂所造成的元素之间的交互作用对Inconel 718合金Nb偏析的影响。构建了掺杂前后Ni-Fe-Cr-Nb超晶胞模型,计算了掺杂前后各体系的形成热、结合能、态密度、差分电荷密度以及布居分布。计算结果表明,Cu原子的掺杂降低了体系的稳定性;掺杂改变了体系中元素之间的交互作用,影响了原子之间的键合强度及电荷密度分布,Cu的添加增加了基体中Fe原子和Cr原子之间的结合力,但同时也增加了Fe原子和Nb原子之间的排斥力。实验结果表明,微量Cu元素的加入降低了Fe和Cr的偏析,但促进了Nb元素的偏析。第一性原理计算和实验结果表明,Cu掺杂后Nb原子与周围Fe原子间排斥力的增加是Cu促进Nb偏析的本质原因。

Cu assisted stabilization and nucleation of L12 precipitates in Al0.3CuFeCrNi2 fcc-based high entropy alloy

[J].

Partitioning of tramp elements Cu and Si in a Ni-based superalloy and their effect on creep properties

[J].

Study on the effect and mechanism of V, Cu in a new Ni-Cr-Fe-Nb superalloy

[D].

V、Cu在新型Ni-Cr-Fe-Nb高温合金中的作用机理研究

[D].

Coherency strengthening in Ni base alloys hardened by DO22 γ'' precipitates

[J].

Effect of heat treatment on the microstructure and mechanical properties of the modified 718 alloy

[J].

Strengthening mechanisms in polycrystalline nickel-based superalloys

[J].

Modeling solid solution strengthening in nickel alloys

[J].