镁合金是密度最低的金属结构材料,具有高比强度和良好的阻尼性能、生物相容性、可回收性以及大储氢容量和高理论比容量等优点,在航空航天、轨道交通、3C制品、生物医学和能源领域具有广阔的应用前景,尤其是在未来新能源汽车中将成为不可或缺的轻量化材料[1,2]。目前应用最多的镁合金零件主要采用铸造和塑性成形[3],然而由于镁合金凝固区间较宽,凝固收缩量较大[4],导致铸件和塑性变形前的铸坯极易发生热裂。相比于Mg-Al系合金,Mg-Zn系合金的凝固温度区间更宽[5],更易萌生热裂纹,严重影响了铸件(坯)的质量。因此,研究Mg-Zn系合金的铸造性能,尤其是对于Mg-Zn系合金的热裂行为的研究就显得至关重要。

1 热裂理论

影响热裂纹萌生及扩展的因素众多且复杂,研究者对热裂的形成机理开展了大量研究,总结并得出认可度最高、适用范围最广的强度理论、液膜理论、晶间搭桥理论和凝固收缩-补偿理论4种基础理论。近年来所提出的新热裂形成机理也多是在这4种热裂理论的基础上开展的。

1.1 强度理论

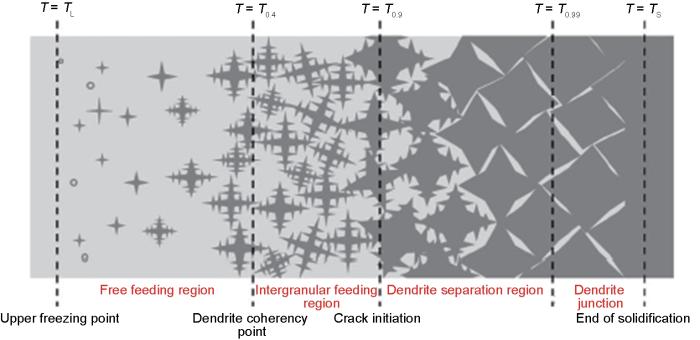

合金凝固过程可分为液相自由补缩区、晶间补缩区、枝晶分裂阶段(易裂区)及枝晶连接4个阶段[9](如图1[10])所示。自枝晶分离阶段开始,已经形核长大的固相骨架随着温度的降低开始凝固收缩,当铸件由于收缩受阻所产生的应力或变形超过合金在该温度下的强度极限或者变形极限时,铸件便会通过开裂来释放应力,即发生热裂。此外,当材料被加热到固相线温度以上时,材料会突然丧失延展性[11];强度也会随着温度的升高而急剧下降,当温度达到材料固相线以上5~30℃时,强度甚至会完全丧失[12],Mg-xZn合金的最大抗拉强度及断裂延伸量在不同固相率下的变化更是如此[13]。但如果凝固收缩不受到阻碍,即使合金在脆性温度区间的强度和塑性较低,也不会出现热裂。因此,基于强度理论可以认为在收缩受阻的情况下,热裂纹的萌生正是由于材料的强度和延展性的下降甚至突然丧失所导致的。

图1

1.2 液膜理论

Sigworth[14]提出的强度理论指出,热裂是在晶间液膜存在的情况下合金丧失强度和塑性所致,但并未明确液膜作用的具体机理。1952年Wray[15]首先提出液膜理论,并经过Saveiko[16]及Campbell[17]的发展而日益完善。液膜理论[18,19]认为,在金属凝固后期凝固收缩和热收缩产生的应力将作用在包裹于枝晶外层或晶粒间的液膜上,其在应力作用下被拉伸而产生形变甚至撕裂。当剩余液相太少,不足以对裂纹进行愈合时,便会产生热裂纹。但是有研究[10]发现,计算的液膜强度与实验中凝固末期实际晶间强度存在着巨大的差距,这表明晶间结合力不是只有液膜来提供,仅依靠液膜理论不能够完全揭示热裂纹的萌生机制。

1.3 晶间搭桥理论

1.4 凝固收缩-补偿理论

2 Mg-Zn系合金热裂敏感性的影响因素

2.1 合金元素

| Element | Maximum solid solution | Main secondary phase formed by | |

|---|---|---|---|

| Mass fraction / % | Atomic fraction / % | alloying element in Mg-Zn alloy | |

| Y | 12.5[27] | 3.75[35] | I (Mg3Zn6Y), W (Mg3Zn3Y2), LPSO (Mg12YZn) |

| Nd | ~3[28] | ~1[35] | Mg12Nd, T-phase ((MgZn)92Nd8) |

| Gd | 23.5[29] | 4.53[35] | W (Mg3Zn3Gd2), I (Mg3Zn6Gd) |

| Al | 12.7[30] | 11.8[35] | Mg17Al12 |

| Zr | 3.8[31] | 1.0[36] | - |

| Ca | 1.35[32] | 0.82[35] | Ca2Mg6Zn3 |

| Cu | 0.013[33] | - | MgZnCu |

| Zn | 6.2[34] | 2.4[35] | MgZn, MgZn2, Mg7Zn3 |

| Sn | 14.5[26] | 3.35[26] | MgZnSn |

2.1.1 Zn元素

纯粹的Mg-Zn二元合金组织粗大,热裂倾向性高,对显微缩孔非常敏感,在实际中很难应用。但可以通过时效硬化来改善Mg-Zn二元合金的强度,及利用合金化改善其性能。研究较多的MgZn系合金有Mg-Zn-RE(Y, Gd, Er)、Mg-Zn-Zr、Mg-Zn-Al、Mg-Zn-Ca及Mg-Zn-Cu系。

2.1.2 RE元素

表2 Mg-Zn-Y系合金热裂敏感性的研究结果[37~47]

Table 2

Alloy mass fraction / % | Alloy with peak HTS mass fraction / % | Alloy with valley HTS mass fraction / % | Processing parameter | |

|---|---|---|---|---|

| Tmold / oC | Tpour / oC | |||

| Mg-1.5Zn-xY (x = 0.2, 2, 4)[37] | Mg-1.5Zn-0.2Y | Mg-1.5Zn-4Y | 250 | 750 |

Mg-4.5Zn-xY (x = 0, 0.4, 0.9, 2)[38] | Mg-4.5Zn-0.4Y Mg-4.5Zn-0.9Y | Mg-4.5Zn-2Y | 250 | 750 |

| Mg-4.5Zn-0.9Y | Mg-4.5Zn, Mg-4.5Zn-2Y | 450 | 750 | |

| Mg-xZn-2xY (x = 1, 1.67, 2.67)[39] | Mg-1.67Zn-3.34Y | Mg-2.67Zn-5.34Y | 250 | 720 |

| Mg-4.5Zn-xY-0.5Zr (x = 0.5, 1, 2, 4, 6)[40] | Mg-4.5Zn-1Y-0.5Zr | Mg-4.5Zn-6Y-0.5Zr | 200 | 720 |

| Mg-1Zn-xY (x = 1, 1.33, 2)[41] | Mg-1Zn-1Y | Mg-1Zn-1.33Y | 250 | 750 |

| Mg-1Zn-xY (x = 1, 2, 3)[42] | Mg-1Zn-1Y | Mg-1Zn-3Y | 250 | 750 |

| Mg-6.5Zn-xY-0.5Zr (x = 1, 2, 4, 6)[43] | Mg-6.5Zn-6Y-0.5Zr | Mg-6.5Zn-2Y-0.5Zr | 200 | 720 |

Mg-5(Zn + Y)-0.5Zr (Mg-2.5Zn-2.5Y-0.5Zr, Mg-3Zn-2Y-0.5Zr, Mg-3.75Zn-1.25Y-0.5Zr, Mg-4.29Zn-0.71Y-0.5Zr)[44] | Mg-3.75Zn-1.25Y-0.5Zr | Mg-2.5Zn-2.5Y-0.5Zr | 200 | 700 |

| Mg-xZn-0.5Y-0.5Zr (x = 1.5, 2.5, 3.5, 4.5)[45] | Mg-1.5Zn-0.5Y-0.5Zr | Mg-4.5Zn-0.5Y-0.5Zr | 280 | 700 |

| Mg-xZn-2Y (x = 0, 0.5, 1.5, 4.5)[46] | Mg-1.5Zn-2Y | Mg-2Y | 250 | 750 |

| Mg-xZn-4Y-0.5Zr (x = 0, 0.5, 1.5, 3)[47] | Mg-1.5Zn-4Y-0.5Zr | Mg-4Y-0.5Zr | 200 | 720 |

(2) Gd元素。Gd元素在Mg中具有较高的固溶度,其能够显著改善镁合金的室温和高温力学性能[49,50]。Srinivasan等[51]和Luo等[52]发现,Mg-xGd合金的热裂敏感性与Gd加入量之间呈“λ”形关系,Mg-2Gd合金热裂敏感性最高。Mg-Zn-Gd合金中,随着Gd含量的增加,组织将由柱状晶及等轴晶的混晶组织逐步向柱状晶组织、混晶组织、等轴晶组织转变[53],能够逐步提高晶粒协调变形及残余液相补缩的能力[54]。当Zn/Gd质量比为0.5时,沿晶界析出LPSO相,其被楔入合金基体的两侧。根据液膜理论,LPSO相能有效提高晶界强度,防止热裂纹沿晶界扩展,有助于提高Mg-Zn-Gd合金的抗热裂性能[55]。

2.1.3 Zr元素

2.1.4 Cu元素

2.1.5 Ca元素

目前,Mg-Zn-Ca系合金热裂研究主要集中在Zn[61,70]、Ca[71,72]含量对合金热裂敏感性的影响(表4[61,70~72])。研究表明,Zn、Ca含量变化会影响该系合金的相组成、晶粒尺寸、凝固温度区间、第二相数量及分布,进而影响合金热裂敏感性。Mg-Zn-Ca系合金的热裂敏感性与Ca含量多遵循反“λ”曲线。Ca含量为1.5%~2.0% (质量分数)时,Mg-6Zn-2Ca[70]与Mg-4Zn-1.5Ca-0.3Zr[72]合金均具有最低的热裂敏感性。Mg-Zn-Ca合金中Zn/Ca原子比小于1.2时,形成Mg2Ca相和Ca2Mg6Zn3相;而Zn/Ca大于1.2时,只形成Ca2Mg6Zn3相[73]。Mg-Zn-Ca合金热裂纹的萌生及扩展过程主要遵循凝固收缩-补偿理论。低熔点共晶相Ca2Mg6Zn3的数量及分布是决定Mg-Zn-Ca合金热裂敏感性的重要因素,其作为凝固末期的残余液相,数量越多,分布越均匀,对热裂纹的补缩效果就越好。

Alloy mass fraction / % | Alloy with peak HTS mass fraction / % | Alloy with valley HTS mass fraction / % | Processing parameter | |

|---|---|---|---|---|

| Tmold / oC | Tpour / oC | |||

| Mg-xZn-0.5Ca (x = 0, 2, 4, 6)[61] | - | Mg-6Zn-0.5Ca | 250 | 750 |

| Mg-4Zn-0.5Ca | Mg-0.5Ca | 450 | 750 | |

| Mg-xZn-2Ca (x = 0, 0.5, 1.5, 4, 6)[70] | Mg-0.5Zn-2Ca, Mg-1.5Zn-2Ca | Mg-6Zn-2Ca | 250 | 750 |

| Mg-1.5Zn-2Ca | Mg-2Ca, Mg-6Zn-2Ca | 450 | 750 | |

| Mg-1.5Zn-xCa (x =1, 2, 3, 4)[71] | Mg-1.5Zn-1Ca | Mg-1.5Zn-4Ca | 200 | 720 |

| Mg-4Zn-xCa-0.3Zr (x = 0.5, 1,1.5, 2)[72] | Mg-4Zn-0.5Ca-0.3Zr | Mg-4Zn-1.5Ca-0.3Zr | 270 | 700 |

2.1.6 Al元素

Mg-Zn-Al系合金是一种有发展前途的低成本高温抗蠕变铸造镁合金[74]。目前,国内外围绕Mg-Zn-Al系合金的设计(合金化或微合金化)、组织及性能控制、热处理强化等方面已经开展了许多研究工作[75],但对其热裂的研究较少。周乐等[8]利用热力学计算对Mg-xZn-yAl (x = 1.5、2.5、4;y = 0.5、3、6)合金的热裂敏感性进行模拟预测,Zn、Al含量(质量分数为1.5%Zn和0~0.75%Al)低的合金热裂敏感性较大。随着Al元素的增加、共晶相(β-Mg17Al12)数量增多,补缩效果增强,从而降低了合金的热裂敏感性[76,77]。此外,合金黏度的降低能够减小共晶液相补缩的阻力,这是降低合金热裂敏感性的又一原因[78]。

2.1.7 合金元素的复合添加

合金化是目前改善镁合金热裂敏感性最常用的手段,复合合金化对提高Mg-Zn合金热裂抗性的效果更好。现有研究结果表明,复合添加Y和Nd[79,23]、Y和Gd[80]、Cu和Y[81]、Al和Sn[82]、Ca和Sn[83,84]、Ca和La[85]及Y和Al[86,87]对降低Mg-Zn系合金热裂敏感性的作用均优于单一添加。如Al和Sn、Ca和Sn、Ca和La的复合添加能够增加合金凝固末期残余液相的数量,增强补缩效果,提高合金的止裂能力。此外,复合合金化使得合金相组成变得丰富,其对降低合金热裂敏感性的作用机制也更加复杂。若在热裂纹萌生前析出的第二相,可以作为晶间桥接,增强晶间的结合能力,从而提高合金的热裂抗性;而热裂纹萌生后析出的第二相则可以作为残余液相对已形成的裂纹进行填充和愈合。如Zhu等[81]在Wang等[66]工作的基础上探讨了Y与Cu的复合加入对Mg-6Zn-0.6Zr (ZK60)合金热裂敏感性的影响。在ZK60-1%Cu (质量分数)合金中加入3.0%Y形成了LPSO相,其作为晶间桥接,提高了合金抵抗凝固收缩的能力;而进一步增加Y含量,组织中形成补缩能力更强的Mg3(Zn, Cu)3Y2相,进一步降低了合金的热裂敏感性。此外,复合合金化引起的第二相种类的变化,会影响晶间桥接的效果,从而影响合金的热裂敏感性[79,80]。如Mg-4.5Zn合金中复合加入Y和Nd元素后,新形成的Mg3Zn3(Y, Nd)2相比Mg3Zn3Y2降低合金热裂敏感性的作用更大[79,23]。Y和Al的复合加入使得Mg-2Zn-(3 + 0.5x)Y-xAl合金中形成了高熔点的Al2Y相,能够细化组织,优化合金补缩路径,进一步提高合金的热裂抗性[86,87]。此外,复合合金化还可以消除单一元素添加对合金热裂敏感性的不利影响。如La的加入会恶化Mg-Zn-Al及Mg-Zn-Al-Ca合金的热裂抗性,而Ca的加入能够降低Mg-Zn-Al合金的热裂敏感性,加入超过0.8%的Ca元素后甚至消除了高La含量对合金热裂抗性带来的不利影响[85]。表5[79~81,83,85~87]列出了Mg-Zn系合金中复合合金化形成的第二相及抑制热裂最好的第二相。

表5 复合加入合金元素后Mg-Zn-X-Y(-Z)合金中的第二相及对合金热裂敏感性降低效果最优的第二相[79~81,83,85~87]

Table 5

Alloy mass fraction / % | Secondary phase in alloy | Most effective secondary phase reducing the HTS of the alloy |

|---|---|---|

Mg-4.5Zn-xY-yNd (x + y = 6, x = 0, 1, 3, 6)[79] | I (Mg3Zn6Y, Mg3Zn6(Y, Nd)), W (Mg3Zn3Y2, Mg3Zn3(Y, Nd)2), T ((MgZn)92Nd8) | W (Mg3Zn3(Y, Nd)2) |

Mg-xZn-7Gd-5Y-0.5Zr (x = 0, 3, 7, 13)[80] | Mg5(Gd, Y), LPSO (Mg12Zn(Gd, Y)), W (Mg3Zn3(Gd,Y)2), I (Mg3Zn6(Gd,Y)) | Mg3Zn3(Gd, Y)2 |

| Mg-6Zn-1Cu-xY-0.6Zr (x = 0, 1, 2, 3)[81] | MgZnCu, I (Mg3YZn6), MgZn2, W (Mg3Y2Zn3, Mg3(Zn, Cu)3Y2) | W (Mg3(Zn, Cu)3Y2) |

| Mg-4Zn-xSn-1Ca (x = 0, 0.5, 1, 2)[83] | CaMgSn, Ca2Mg6Zn3 | Ca2Mg6Zn3 |

| Mg-0.5Zn-4Al-(0.5%-2.0%)Ca-(0.5%-2.0%)La[85] | Al11La3, Al2Ca | Al2Ca |

Mg-2Zn-(3 + 0.5x)Y-xAl (x = 0, 2, 3; atomic fraction, %)[86], Mg-2Zn-3Y-xAl (x = 0, 0.5, 1, 2)[87] | Al2Y + Al3Y, W (Mg3Y2Zn3), LPSO (Mg12ZnY) | Al2Y |

2.2 铸造工艺

2.2.1 模具温度

2.2.2 细化剂

2.2.3 外加电磁场对Mg-Zn系合金热裂敏感性的影响

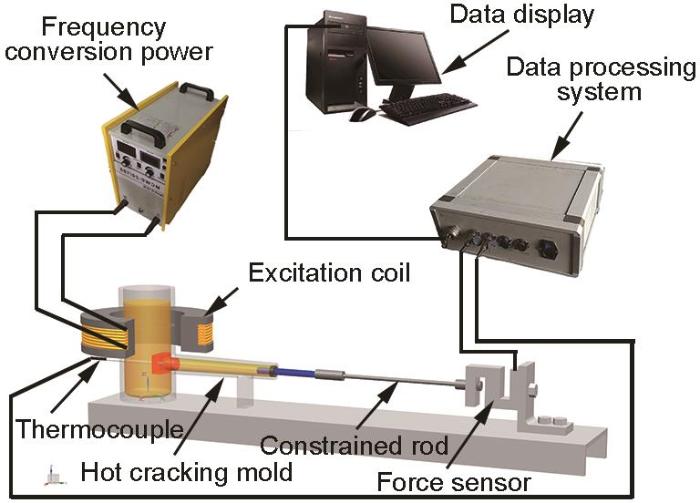

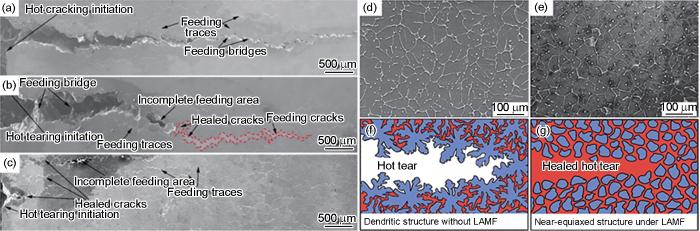

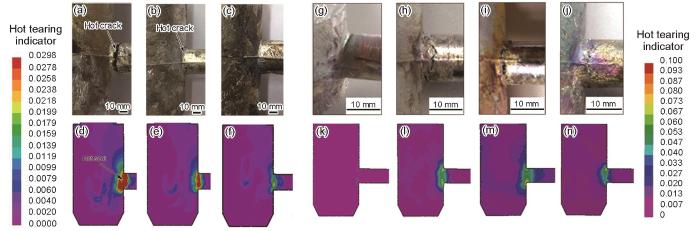

(2) 利用电磁场能够改变镁合金的凝固参数和微观组织,优化补缩通道,改善补缩状态。Zhou等[94]及Bai等[95]在“T”形热裂测试装置外设置交变磁场线圈(图2[96]),分别研究了低频交变磁场(low-frequency alternating magnetic field,LAMF)对Mg-7Zn-1Cu-0.6Zr合金[94] (0.03 T)及Mg-4Zn-1.5Ca合金[95](0~15 A,15 Hz) 热裂敏感性的影响,发现施加适当强度的LAMF后,铸件热节处液相对热裂纹的补缩痕迹清晰可见,大量裂纹被残余液相愈合(图3a~c[95]);合金的组织均得到细化(图3d和e[95]),补缩通道结构得到优化,利于残余液相的补缩,从而提高了合金的止裂能力(图3f和g[96])。此外,在电磁力的作用下,α-Mg枝晶的形成和生长得到抑制,缩短了合金的凝固温度区间及处于易脆弱温度区间的时间,从而提高了合金的热裂抗性。

图2

图3

图3

无磁场及低频交变磁场处理后Mg-4Zn-1.5Ca合金热裂纹部位的SEM像、组织形貌[95]与热裂纹补缩示意图[96]

Fig.3

SEM images of hot tears (a-c) and microstructure morphologies (d, e)[95], and schematics of feeding (f, g)[96] in Mg-4Zn-1.5Ca alloy under natural solidification (a, d, f) and low-frequency alternating magnetic fields (LAMF) (b, c, e, g)

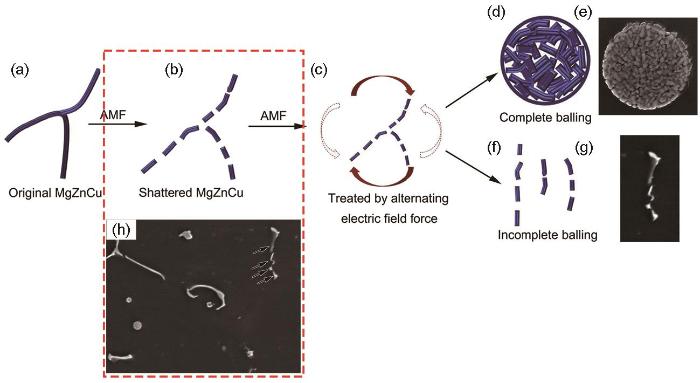

(3) 利用电磁力可以提高合金凝固末期残余液相的补缩能力,愈合热裂纹,起到止裂的作用。根据Feurer理论[97],当凝固收缩体积(SRG)大于晶间残余液相可以填补的体积(SPV)时,即SPV < SRG,就会发生热裂,如

式中,

图4

3 镁合金热裂行为的数值模拟

利用数值模拟可以预测合金化元素、铸件结构尺寸、铸造工艺参数及外场对合金热裂敏感性的影响,但由于糊状区的存在使得合金热裂敏感性的数值模拟更为复杂。目前,已经有成功应用ProCast[100~103]、MAGMAsoft[104]及ABAQUS[104]等软件预测铸件热裂行为及合金热裂敏感性的案例,其中ProCast软件应用较多。ProCast软件能够利用基于糊状区在热裂发生之前可以维持的最大应变率的RDG (Rappaz-Drezet-Gremaud)热裂预测模型的HCS模块及基于Gurson本构模型的热裂指示器(HTI) 2个模块来预测铸件热裂出现的位置及凝固收缩应力集中的区域,RDG模型[105]与Gurson本构模型[104]分别如

式中,G为温度梯度,

式中,HTI

图5

但是,有些合金热裂敏感性的模拟结果也与实验结果不一致,如在计算Mg-Ca合金在不同模具温度(250和450℃)下的热裂敏感性时,模拟结果与实验结果却存在较大的偏差[96]。Bai等[72]对Mg-4Zn-xCa-0.3Zr合金的热裂敏感性进行数值模拟并进行实验验证后发现,当Ca元素的质量分数提高到2%时,模拟结果与实验结果出现差异。这种差异的出现是由于现有模拟软件的镁合金数据库中缺乏一些合金的应力/应变数据,如不同温度下合金的应力或应变随温度变化的对应数据,以及屈服强度等数据。在缺乏上述数据的情况下,模拟仅来自于材料的塑料应变,这将导致预测的不准确性[96],而且模拟软件也无法考虑组织变化对合金热裂敏感性的影响[107]。因此,为了提高合金热裂数值模拟的准确性,未来一方面要不断完善镁合金半固态力学性能的数据库,另一方面还要引入合金组织变化对热裂敏感性的影响。

Zhou等[94]利用COMSOL多物理场模拟软件分别对自然凝固及LAMF下Mg-7Zn-1Cu-0.6Zr合金的凝固行为进行了数值模拟。数值模拟结果表明:LAMF的施加会在镁合金熔体中产生规律变化的电磁力,产生2个较大的流动循环,影响合金的凝固行为,增强熔体的强制对流,促进金属液在凝固期间的流动,延长合金的凝固时间。自然凝固下驱动残余液相参与补缩的驱动力是由裂纹形成后产生的负压而形成的,而当施加LAMF后,由于熔体中的强制对流增强,熔体流速增加,从而驱动了残余液相参与对热裂纹的补缩,降低了合金热裂纹继续扩展的能力。铸件温度场的模拟云图表明,施加LAMF后,在同一时刻熔体的平均温度更高,磁场热效应降低了熔体的凝固速率,增加了熔体在固/液两相区的时间,其模拟结果与实验结果相一致。但目前LAMF对合金热裂行为的数值模拟仅能计算出熔体的温度场和流场的变化,还不能实现对合金凝固收缩应力及应变等的计算,且不能像ProCast软件一样直接获得合金的热裂敏感性系数,无法定量表征外场作用下合金的热裂敏感性。

4 组织对Mg-Zn系合金热裂敏感性的影响

4.1 α-Mg枝晶尺寸及形态的影响

4.1.1 α-Mg枝晶尺寸

式中,

式中,D为晶粒尺寸。因此,同一合金体系下合金的晶粒越细小,合金所能够承受的断裂应力越大,就越不易萌生热裂纹,从而使得合金具有更高的抗热裂性能。

式中,

通过合金化、添加细化剂及施加合适强度的电磁场均会降低Mg-Zn系合金的晶粒尺寸,从而降低Mg-Zn系合金的热裂敏感性。合金化可以使合金元素在晶界堆积,抑制晶粒生长,从而细化组织[43];加入细化剂及Zr元素可以引入异质形核核心细化晶粒[38,60];而施加电磁场所产生的电磁力会造成枝晶破碎,提高合金的形核率[94,95]。与加入细化剂和(或)Zr元素仅是由于晶粒细化减少合金中的应力/应变集中从而降低合金热裂敏感性的作用机制相比,合金化及电磁场对合金热裂敏感性的影响机制要更为复杂。其中,合金化除了使晶粒细化外,还会使得合金中参与补缩已形成热裂纹的第二相含量增加,甚至使得合金中的相组成发生变化,从而改变了对裂纹的填充和愈合能力。而施加电磁场既能够细化晶粒,同时电磁力引起的强制对流提高了残余液相对裂纹的补缩能力及效率。

4.1.2 α-Mg枝晶形态

一般来说,相同合金体系下,等轴晶组织的合金热裂敏感性要明显小于柱状晶和树枝晶组织的合金。Easton等[118]认为:裂纹极易沿着柱状晶的晶界形成,并利于热裂纹的扩展。相反,等轴晶组织能够提高液态金属的补缩特性,使合金适应更高的应变,提高合金热裂抗性,如Srinivasan等[51]发现,随着Mg-Gd合金Gd含量的增加,组织由树枝晶向柱状晶及等轴晶转变,合金热裂抗性提高。半固态合金的强度也是影响热裂敏感性的重要因素之一[110],半固态下材料的抗拉强度及延展性越高,则糊状区的渗透率越低,液相通过固相网的数量增多,裂纹的补缩能力越强,从而使合金具有较好的热裂抗性。因此,通过适当的方法获得等轴晶组织可以提高合金的抗热裂性能。

4.2 第二相的影响

4.2.1 第二相的析出温度

镁合金中第二相析出温度的不同会影响合金的热裂行为。为方便解释,以α-Mg的析出温度(Tα-Mg)为界线,将析出温度高于或低于Tα-Mg的第二相分别命名为高熔点第二相或低熔点第二相。表6概述了第二相种类及不同析出情况对镁合金热裂行为的影响。

表6 第二相种类对镁合金热裂行为的作用机理

Table 6

| Phase | Condition | Effect |

|---|---|---|

| High melting point eutectic phase | Low volume | Increasing the non-uniform nucleation site; refining the grains; |

| increasing the content of the liquid film subjected to shrinkage stress/strain; | ||

| reducing the HTS of the alloy | ||

| High volume | Blocking the feeding channel; | |

| reducing the feeding efficiency of alloy at the end of solidification; | ||

| increasing the HTS of the alloy | ||

Low melting point eutectic phase | Thci < TLMPE | Liquid film theory and intergranular bridging theory: The low melting eutectic phase precipitated before hot tearing initiation acts as “bridges” to fix the grain boundary on both sides. Under the action of surface tension and bridge, the intergranular bonding force improved |

Thci ≥ TLMPE | Liquid film theory: The intergranular binding force is only provided by the surface tension of the liquid film covering the dendrite surface |

(1) 低熔点第二相。根据凝固收缩-补偿理论,合金在“枝晶分离阶段”的补缩能力是其是否产生微孔及萌生热裂纹的关键;而在“固相补缩阶段”,固相蠕变是材料适应凝固收缩和热应力的唯一机制。当合金本身的强度无法承受凝固收缩而产生裂纹以及随后的扩展时,会在局部产生负压,这个负压将驱动残余液相对裂纹进行填充和愈合。而由于枝晶偏析等原因,当α-Mg枝晶形成后,会在枝晶间形成富含合金元素的共晶液相,这些共晶液相的熔点较低,可作为残余液相对裂纹进行填充和愈合。

低熔点第二相的析出温度(TLMPE)与热裂纹萌生温度(Thci)间的关系也会对合金的热裂敏感性产生不同的影响。当Thci略高于或接近于TLMPE时,晶间的结合力仅由覆盖枝晶表面的液相薄膜的表面张力提供;而当Thci低于TLMPE时,热裂纹萌生前该相作为“桥”固定两侧晶粒,其晶间结合力明显高于液相薄膜的表面张力。当热裂纹萌生后,尚未析出的低熔点共晶相可以作为残余液相对已形成的热裂纹进行填充并愈合。相同合金体系中,第2种情况对合金热裂敏感性的降低效果要优于第1种情况[86]。此外,TLMPE越高且第二相与基体结合力越强,对提高晶界强度的贡献越大,合金的热裂敏感性越小。例如,在MgZn x Y2Zr0.06 (x = 0.5、1、1.5)中MgZn0.5Y2Zr0.06及MgZn1Y2Zr0.06合金的Thci略高于或接近于LPSO相的析出温度,其热裂敏感性明显高于Thci低于LPSO相的析出温度的MgZn1.5Y2Zr0.06合金[116]。

4.2.2 第二相含量

通常,铸造镁合金中第二相含量越多,铸件形成热裂纹后能够参与补缩的残余液相也就越多,对已形成热裂纹的填充及愈合作用越明显,合金的热裂倾向性就越小。例如,在Mg-xZn-2xGd合金中,随Zn、Gd加入量的持续增加,组织中的LPSO相和W相数量明显增加,在铸件热裂纹附近观察到参与补缩的残余液相含量增加,减小了铸件热节处的热裂纹体积[53]。此外,在Mg-xZn-2xY合金中,增加Zn和Y元素的加入量,相组成不发生改变,但LPSO相和W相的含量增加使得用于填充愈合裂纹的残余液相的含量增多,从而降低了合金的热裂敏感性[39]。但对于作为“晶间桥”的低熔点共晶相,其数量过多也会破坏补缩通道的连续性,阻碍残余液相对裂纹的补缩,从而恶化合金的止裂能力。

5 凝固特性参数对Mg-Zn系合金热裂敏感性的影响

5.1 凝固温度区间

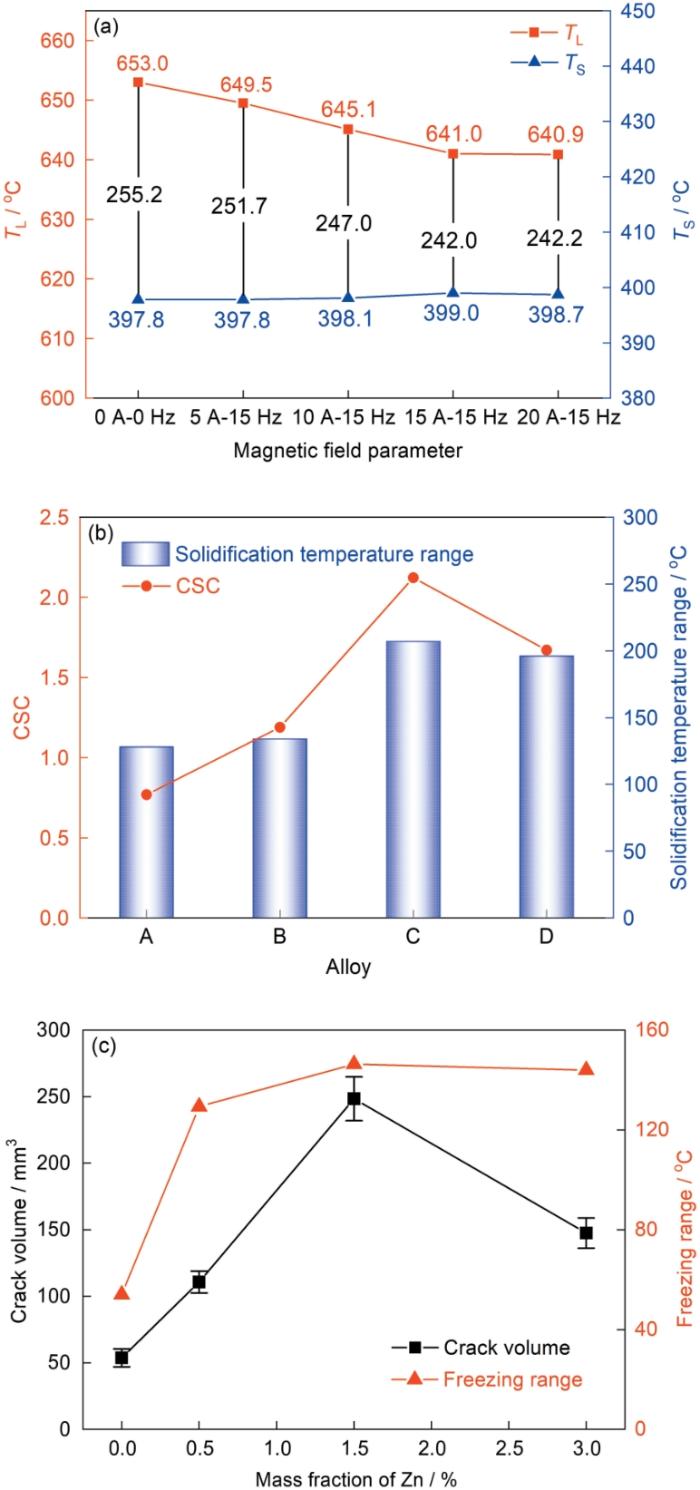

凝固温度区间是影响Mg-Zn系合金热裂敏感性的重要影响因素,将直接决定合金热裂敏感性的大小。在同一合金体系中,具有较宽凝固温度区间的合金往往具有更大的热裂敏感性。通过调整合金成分,可以降低合金热裂敏感性,但会存在相组成发生改变(有新相的析出或消失)和相组成不改变2种情况。随着合金元素加入量的增多,当合金相组成不发生改变时,合金热裂敏感性与凝固温度区间呈正相关关系[66,67,102]。此外,在合金凝固过程中施加LAMF也能达到在不改变相组成的情况下缩短合金的凝固温度区间,从而降低合金的热裂敏感性(图6a[95])的目的。这与合金在凝固过程中处于脆性阶段的时间(tV)变化有关。根据Clyne和Davies理论模型[7],当合金凝固至应力松弛阶段(tR)时,凝固收缩应力处于较低状态,不易产生热裂纹;在tV时间阶段时残余液相极少,凝固收缩应力处于较高水平,此时最易发生热裂缺陷。随着合金元素含量的增加,合金处于tV的时间及温度间隔均减小,从而降低了合金萌生热裂纹的几率。

图6

图6

几种不同合金的凝固温度区间与合金热裂敏感性间的关系[44,47,95]

Fig.6

Solidification temperature range and hot tearing susceptibility of several different alloys

(a) Mg-4Zn-1.5Ca alloy under different strengthes of LAMF[95]

(b) Mg-5(Zn + Y)-0.5Zr alloys (CSC—crack sus-ceptibility coefficient; A: Mg-2.5Zn-2.5Y-0.5Zr alloy, B: Mg-3Zn-2Y-0.5Zr alloy, C: Mg-3.75Zn-1.25Y-0.5Zr alloy, D: Mg-4.29Zn-0.71Y-0.5Zr alloy)[44]

(c) Mg-xZn-4Y-0.5Zr alloy[47]

但当合金中形成了熔点更低的第二相时,由于其固相线温度降低造成凝固区间变大,会明显影响合金的热裂敏感性(图6b[44]和6c[47])。例如:在Mg-Zn-Y系合金中,通过调整Zn/Y比能够获得不同的相组成,与Mg-2.5Zn-2.5Y-0.5Zr及Mg-3Zn-2Y-0.5Zr合金相比,Mg-3.75Zn-1.25Y-0.5Zr及Mg-4.29Zn-0.71Y-0.5Zr合金中生成了熔点更低的I相,合金的凝固温度区间大幅增加(图6b[44]),从而增大了合金热裂敏感性[44]。对Mg-Zn系合金而言,Ca和Y元素对其凝固温度区间改变较为显著(图7[43,72,76]),还要综合考虑第二相对热裂纹填充及愈合作用。

图7

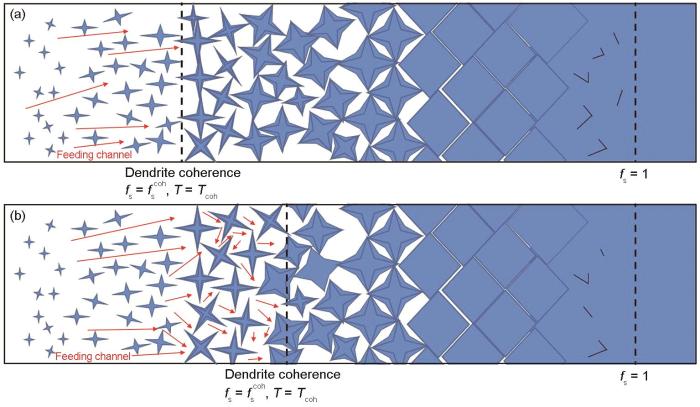

5.2 合金枝晶搭接时的温度及固相分数

在合金凝固的4个阶段中,“枝晶分离阶段”和“固相补缩阶段”对合金热裂的影响至关重要。科研人员利用双热电偶实验装置分别研究了Mg-6.5Zn-xY-0.5Zr[43]、Mg-xZn-2xY[39]及Mg-Zn-Y-Nd-Zr[23]合金的凝固行为。研究结果均表明,合金枝晶搭接温度越低,合金热裂敏感性就越小。由于合金凝固时心部与表层冷却速率不同,枝晶相互搭接后,心部的热量要通过枝晶传递,此时铸件心部温度与表层温度差值的最小值被定义为枝晶搭接温度(Tcoh)。合金凝固过程的示意图如图8所示。一般来说,Tcoh越低,α-Mg的形成时间越长,合金中残余液相的补缩通道越多,残余液相自由补缩的时间越长,对裂纹的填充愈合能力也就越好,因而合金表现出较低的热裂敏感性。枝晶搭接时对应的固相分数(

图8

图8

合金凝固过程示意图

Fig.8

Schematics of alloy solidification process (fs—solid fraction,

(a) the condition of fs is low when dendrite coherency

(b) the condition of fs is high when dendrite coherency

6 总结与展望

总结热裂理论、Mg-Zn系合金热裂敏感性的影响因素及热裂机理,主要有以下几点。

(1) 目前应用较多的热裂理论有强度理论、液膜理论、晶间搭桥理论、凝固收缩-补偿理论,将上述几种热裂理论结合起来能够更好地揭示Mg-Zn系合金的热裂行为及止裂机理。

(2) 复合合金化比单一合金化在降低Mg-Zn系合金热裂敏感性上效果更好,其通过改变第二相相组成及数量,增强晶间结合力、改善补缩效果,克服单一元素添加造成的不利影响,从而提高合金的止裂能力。

(3) 合金的晶粒形态、晶粒尺寸以及第二相都会影响Mg-Zn系合金的热裂倾向。晶粒细化、树枝晶结构的弱化以及柱状晶向等轴晶的转变均能提高Mg-Zn系合金的热裂抗性。此外,第二相数量、析出温度及其与母相的位向关系均会影响合金的热裂行为。

(4) 外加电磁场能够改变Mg-Zn系合金的凝固参数和微观组织,优化补缩通道结构,提高凝固末期残余液相的补缩能力,提高补缩效率,从而降低合金的热裂敏感性。

(5) 利用数值模拟和实验研究相结合的方法能够较精确地获得合金成分、工艺条件、组织变化等对Mg-Zn系合金热裂敏感性的影响规律,有助于从合金凝固过程中的动力学、热力学参数的改变以及应力/应变等微观方面揭示合金的热裂机理。

未来,Mg-Zn系合金的热裂研究应在以下几个方面开展。

(1) 镁合金的设计应综合考虑合金相组成、微观组织、凝固温度区间、糊状区力学性能及黏度、体收缩率等因素。同时,建立测试和评价合金热裂敏感性的统一标准,构建镁合金材料热裂性能数据库,为新型高性能低热裂敏感性镁合金的设计提供依据。

(2) 应基于热裂理论研究镁合金凝固至糊状区后所经历的动态变化(如凝固收缩造成的孔隙、缩松,凝固收缩补偿带来的晶界共晶相偏析,糊状区内组织演变对补缩通道及补缩压力的影响等)及其对合金热裂的影响,进一步明晰镁合金热裂纹萌生及扩展的机理,从而实现更为准确的预测并避免热裂的产生。

(3) 向Mg-Zn系合金中加入Zr、Ti元素,原位引入如Al2RE等高熔点共晶相均能够显著细化合金组织,从而降低合金热裂敏感性,但Zr、Ti合金化温度要求高,Zr收得率低,Ti合金化常以TiB或AlTiB形式加入,易带入杂质元素;原位引入高熔点共晶相的细化效力受合金成分、实际凝固条件等影响。因此,解决上述问题是细化Mg-Zn系合金组织,从而降低合金热裂敏感性的关键。

(4) 外加电磁场能够显著降低镁合金的热裂敏感性,但针对电磁场作用下镁合金凝固行为及组织的演变规律,及其对合金热裂行为的作用机理的研究尚显不足,需开展深入研究。此外,利用大数据、数据挖掘和机器学习等技术手段构建多场耦合作用下镁合金热裂敏感性的预测模型是未来镁合金热裂行为研究的主要方向之一。

参考文献

Latest research advances on magnesium and magnesium alloys worldwide

[J].

Research advances in magnesium and magnesium alloys worldwide in 2020

[J].

Grain refinement of as-cast Mg-RE alloys: Research progress and future prospect

[J].Magnesium rare-earth (Mg-RE) alloy castings with a large size and complex structure exhibit versatile prospects in critical aircraft, aerospace, and defense fields owing to their ultralow density, excellent specific strength, and high-temperature resistance. The grain refinement of cast Mg-RE alloys can significantly improve their strength, plasticity, toughness, and casting performance, which are critical for expanding their applications. In this work, the grain refinement mechanism of Mg alloys by introducing RE elements and heterogeneous particles is first discussed based on the classical theory of constitutional supercooling and heterogeneous nucleation. Various grain refinement technologies for Mg-RE alloy casting using chemical and physical methods are comprehensively summarized. Further, the influence of grain refinement on the casting performance, mechanical properties, and corrosion properties of Mg-RE cast alloys is thoroughly discussed. Finally, the deficiencies and development trends of the current grain refinement of Mg-RE alloys are discussed from the point of actual application requirements.

铸造Mg-RE合金晶粒细化行为研究现状与展望

[J].轻质高强耐热的镁稀土(Mg-RE)合金大型复杂铸件在航空航天、国防军工装备轻量化等方面展现出独特的优势。对铸造Mg-RE合金进行晶粒细化处理能够显著改善合金的强度、塑韧性以及铸造工艺性能,对拓宽其应用领域意义重大。本文首先基于成分过冷和异质形核,探讨了稀土元素及外加颗粒对镁合金晶粒细化的影响。归纳了适用于铸造Mg-RE合金的化学、物理细化方法及其作用机制,并系统论述了晶粒细化对铸造Mg-RE合金铸造工艺性能、力学性能及腐蚀性能的影响。最后面向Mg-RE合金的实际应用需求,对其细化处理方面存在的不足和发展趋势进行了探讨。

Measurement of the thermal expansion coefficient of an Al-Mg alloy at ultra-low temperatures

[J].

Contraction of aluminum alloys during and after solidification

[J].

The influence of composition on solidification cracking susceptibility in binary alloys systems

[J].

Investigations on hot tearing susceptibility and mechanism for Mg-Zn-(Al) alloys

[D].

Mg-Zn-(Al)系合金热裂敏感性及其微观机理研究

[D].

A comprehensive study on solidification (hot) cracking in austenitic stainless steel welds from a microstructural approach

[J].

Solidification behavior and hot tearing mechanism of Mg-Al-Ca series alloys

[D].

Mg-Al-Ca系合金凝固行为及热裂机理研究

[D].

Properties of the Al-Si Alloys at temperatures in the region of the solidus

[J].

Study on the relationship between mushy zone strength and hot cracking of Mg-Zn based magnesium alloys

[D].

Mg-Zn基镁合金的糊状区强度和热裂的关系研究

[D].

The geometry of two-phase aggregates in which the shape of the second phase is determined by its dihedral angle

[J].

Research development of hot tear mechanism for cast alloys

[J].

合金的热裂机理及其研究进展

[J].

The effect of melt composition on solidification cracking of steel, with particular reference to continuous casting

[J].

Comparison between experimental data and theoretical predictions relating to dependence of solidification cracking on composition

[A].

Investigations on testing methods and hot tearing susceptibility on Mg-Zn-Y alloys

[D].

Mg-Zn-Y合金热裂行为测试研究

[D].

Influence of Nd on hot tearing susceptibility and mechanism of Mg-Zn-Y-Zr alloys

[J].

Compensation of Solidification contraction and hot cracking tendency of alloys

[J].Based on analysis to previous research on hot cracking of alloys, a hot cracking model formed through solidification contraction and compensation was proposed. In this model, solidification process of alloy was divided to four stages, quasi-liquid phase stage,compensated stage, uncompensated stage and dendritic bridging stage. Hot cracks started in uncompensated stage. The contraction of inter-dendritic liquid caused cavities between dendrites, then the dendritic bridges broken and hot cracks formed. Fraction range of liquid in uncompensated stage is calculated to be 0.83%-26% and 0.31-9.3% for alloys with equiaxial and columnar grains respectively. The temperature range of uncompensated stage for Al-Si and Al-Cu alloys was calculated. Comparison between theoretical calculation and hot cracking experiments showed that hot cracking tendency of alloys increases with the increase of temperature range of uncompensated stage. The dendritic bridges were first discovered in hot cracks of directionally solidified alloys. The tracks caused by dendritic bridges breaking were also discovered on the section of hot cracks.

凝固收缩补偿与合金的热裂倾向

[J].

Two-phase modeling directed toward hot tearing formation in aluminum direct chill casting

[J].

The application of RE-containing magnesium casting alloys in aviation industry in China

[J].The classification,composition and mechanical properties of RE-containing magnesium casting alloy and the appllcation of RE metals in heat-resistant,high strength with heat resistance and high strength magnesium alloy in China are described in this paper.In addition,the use and production of RE-containing magnesium casting alloy in various type of airplane,engine and accessories are also presented briefly.

铸造稀土镁合金在我国航空工业中的应用

[J].本文叙述了我国铸造稀土镁合金的分类、成分和性能;稀土在热强、高强耐热和高强合金中的应用.此外,简要介绍了铸造稀土镁合金在各种型号飞机、发动机、附件上的生产应用情况.

Effects of Nd/Gd value on the microstructures and mechanical properties of Mg-Gd-Y-Nd-Zr alloys

[J].

Substitution effects of Gd with Nd on microstructures and mechanical properties of Mg-10Gd-0.4Zr alloys

[J].

Recent magnesium alloy development for elevated temperature applications

[J].

Study progress of magnesium alloy and its working technology

[J].

镁合金及其加工技术研究进展

[J].

Effects of Mn and Ca elements on the microstructures of magnesium alloys

[J].

Ca、Mn对镁合金凝固组织的影响

[J].

Microstructures and properties of Mg-2Zn alloys with different Cu contents

[J].

Cu含量对Mg-2Zn合金组织及性能影响研究

[J].

Cast magnesium alloys for elevated temperature applications

[J].

Research progress on corrosion resistance of magnesium alloys in aspect of element solid-solution and precipitation

[J].

元素固溶与析出对镁合金耐蚀性影响的研究进展

[J].合金元素的固溶与析出改变了镁基体相电位和第二相的种类,从而显著影响镁合金的微电偶腐蚀行为。本文综述了元素固溶与析出对镁合金耐蚀性影响的研究现状,总结了典型合金元素在镁合金中固溶析出的典型第二相,重点阐述了基于热力学和动力学分析常见镁合金系中的固溶和析出行为对镁合金的腐蚀行为的影响,指出了良好的镁合金候选材料应具备的条件,提出了提高镁合金本征耐蚀性的设计方法,未来研究重点应通过调控镁合金中合金元素的种类和数量来降低镁合金腐蚀速率,扩大合金应用范围。

The roles of alloying elements in magnesium alloys

[J].

主要合金元素在镁合金中的作用

[J].

Influences of Y additions on the hot tearing susceptibility of Mg-1.5wt.%Zn alloys

[J].

An investigation on hot tearing of Mg-4.5Zn-(0.5Zr) alloys with Y additions

[J].

Effects of Zn and Y on hot-tearing susceptibility of Mg-xZn-2xY alloys

[J].

Effect of yttrium content on hot tearing susceptibility of MgZn4.5Y x Zr0.5 alloys

[J].

钇含量对MgZn4.5Y x Zr0.5合金热裂敏感性的影响

[J].

Effects of the second phase on hot tearing susceptibility of Mg-Zn-Y alloy

[J].

Effect of long-period stacking ordered phase on hot tearing susceptibility of Mg-1Zn-xY alloys

[J].

Hot tearing behavior and microstructure mechanism of Mg-6.5Zn-xY-0.5Zr alloys

[J].

Hot tearing behavior of Mg-5(Zn + Y)-0.5Zr alloys

[J].

Hot tearing defects of as-cast Mg-xZn-0.5Y-0.5Zr alloys

[J].

铸态镁合金Mg-xZn-0.5Y-0.5Zr热裂缺陷研究

[J].

Hot tearing susceptibility of Mg-xZn-2Y alloys

[J].

Solidification pathways and hot tearing susceptibility of MgZn x Y4Zr0.5 alloys

[J].

Effects of solidification behavior of several Mg-Zn-RE (Y, Gd) series alloys on hot tearing mechanism

[D].

几种Mg-Zn-RE(Y, Gd)系合金凝固行为对热裂机制的影响

[D].

The effect of Y, Ce and Gd on texture, recrystallization and mechanical property of Mg-Zn alloys

[J].

Achieving a high-strength binary Mg-15Gd alloy by nano substructure with Gd segregation and nano clusters

[J].

Hot tearing characteristics of binary Mg-Gd alloy castings

[J].

Hot tearing susceptibility of binary Mg-Gd alloy castings and influence of grain refinement

[J].

Researches on the solidification characteristic and mechanical properties of Mg-Zn-Gd-based magnesium alloy

[D].

Mg-Zn-Gd系镁合金的凝固特性及其力学性能研究

[D].

Effect of Gd content on hot-tearing susceptibility of Mg-6Zn-xGd casting alloys

[J].

Study on the coupling behavior and micro-mechanism of solidification and hot tearing of Mg-xZn-2xGd Alloys

[J].

Effect of Zn/Er weight ratio on phase formation and mechanical properties of as-cast Mg-Zn-Er alloys

[J].

Effects of Er on hot cracking susceptibility of Mg-5Zn-xEr magnesium Alloys

[J].

Er对Mg-5Zn-xEr镁合金热裂敏感性的影响

[J].采用优化的RDG (Rappaz-Drezet-Gremaud)热裂模型预测了Mg-5Zn-xEr (x=0.83、1.25、2.5、5,质量分数,%)三元多相合金的铸造热裂敏感性,并利用“约束杆”钢模铸造(CRC)实验评价了该合金的热裂敏感性。结果表明,优化的RDG热裂模型可准确地预测Mg-5Zn-xEr镁合金的热裂敏感性:随着Er含量的增加,合金的热裂敏感性呈先增加后降低的趋势,当Er含量为2.5%时合金的热裂敏感性最高,当Er含量为5.0%时合金的热裂敏感性最低,与实验结果相一致。对铸件凝固曲线、相组成、微观组织等进一步分析表明,当Er含量提高至2.5%时,合金凝固过程发生包晶反应生成I相的同时消耗了液相,并且扩大了合金的凝固温度区间,使合金的热裂敏感性上升;Er含量继续提高至5.0%时,合金在凝固过程中发生L→α-Mg+W的共晶反应,凝固温度区间减小,有利于凝固后期枝晶间裂纹的补缩,显著降低了合金的热裂敏感性。

Hot cracking behaviors of Mg-Zn-Er alloys with different Er contents

[J].

Study on solidification behavior and hot tearing susceptibility of Mg-Zn-Y alloy

[D].

Mg-Zn-Y合金凝固行为及热裂敏感性研究

[D].

Effect of Zn addition on hot tearing behaviour of Mg-0.5Ca-xZn alloys

[J].

Microstructure, electromagnetic shielding effectiveness and mechanical properties of Mg-Zn-Cu-Zr alloys

[J].

Effect of Cu element on microstructure and thermalphysical properties of Mg-Zn alloy

[D].

Cu元素对Mg-Zn系合金显微组织及热物性能影响研究

[D].

Effects of Cu addition on microstructure and mechanical properties of as-cast magnesium alloy ZK60

[J].

Effects of mass ratio of zinc/copper on microstructure and properties of extruded Mg-Zn-Cu-Ce alloys

[J].

Zn/Cu质量比对挤压态Mg-Zn-Cu-Ce合金组织和性能的影响

[J].

Effect of Cu additions on microstructure, mechanical properties and hot-tearing susceptibility of Mg-6Zn-0.6Zr alloys

[J].

Hot tearing behaviors and in-situ thermal analysis of Mg-7Zn-xCu-0.6Zr alloys

[J].

Research on Mg-Zn-Ca alloy as degradable biomaterial

[A].

Role of calcium alloying in magnesium alloys

[J].

Ca合金化在镁合金中的作用

[J].

Hot tearing characteristics of Mg-2Ca-xZn alloys

[J].

Effect of Ca on hot tearing susceptibility of Mg-Zn alloy

[J].In order to clarify the effect of Ca element on the hot tearing susceptibility of Mg-Zn binary alloy, the hot tearing behaviour of Mg-Zn-Ca series alloys was investigated with the self-made “T” type hot tearing testing device through taking Mg-1.5Zn magnesium alloy as a base alloy and adding 1% to 4% Ca element. The microstructures in the hot tearing regions were observed with optical microscope and scanning electron microscope(SEM). In addition, the hot tearing mechanism of Mg-Zn-Ca ternary alloys was analyzed. The results indicate that for the Mg-1.5Zn-<I>x</I>Ca alloys, the volume of hot cracks gradually decreases and the hot tearing susceptibility of the alloys reduces with increasing the content of Ca element. When the hot tearing occurs, the volume fraction of residual liquid phase in the Mg-1.5Zn-<I>x</I>Ca alloys gradually increases, and thus, the feeding effect continuously increases. Moreover, the hot tearing susceptibility gradually decreases with increasing the content of Ca element. For the Mg-Zn-Ca alloys, the feeding materials in the crack regions are the mixture of α-Mg, Ca<SUB>2</SUB>Mg<SUB>6</SUB>Zn<SUB>3</SUB> and Mg<SUB>2</SUB>Ca phases.

Ca对Mg-Zn合金热裂敏感性的影响

[J].

Effect of Ca content on hot tearing susceptibility of Mg-4Zn-xCa-0.3Zr (x = 0.5, 1, 1.5, 2) alloys

[J].

Effects of Ca on microstructure, mechanical and corrosion properties and biocompatibility of Mg-Zn-Ca alloys

[J].

Alloying elements and their effects in Mg-Al based elevated temperature magnesium alloy

[J].

Mg-Al系耐热镁合金中的合金元素及其作用

[J].

Research status of Mg-Zn-Al(ZA) based elevated temperature magnesium alloy

[J].

Mg-Zn-Al(ZA)系耐热镁合金的研究现状

[J].

Effect of Al content on hot-tearing susceptibility of Mg-10Zn-xAl alloys

[J].

Effect of Al content on hot tearing susceptibility of Mg-5Zn-0.6Mn-xAl-0.6Zr alloys

[J/OL].

An approach to studying the hot tearing mechanism of alloying elements in ternary Mg-Zn-Al alloys

[J].

Investigation on hot tearing behavior and its mechanism of Mg-4.5Zn-xY-yNd (x + y = 6, x = 0, 1, 3, 6) alloys

[J].

Effects of Zn content on hot tearing susceptibility of Mg-Zn-Gd-Y-Zr alloys

[J].

Effect of yttrium on hot tearing susceptibility of Mg-6Zn-1Cu-0.6Zr alloys

[J].

Microstructure and tensile properties of the Mg-6Zn-4Al-xSn die cast magnesium alloy

[J].

Study on the hot tearing susceptibility of Mg-4Zn-xSn-1Ca alloys

[J].

Study on hot tearing behavior of Mg-Zn-Sn alloys under magnetic field

[D].

磁场作用下Mg-Zn-Sn合金热裂行为研究

[D].

Optimization of Mg-Zn-Al-Ca-La alloys for the improvement of casting properties and creep resistance

[J].

Influence of Al addition on solidification path and hot tearing susceptibility of Mg-2Zn-(3 + 0.5x)Y-xAl alloys

[J].

An investigation on solidification path and hot tearing tendency of Mg-2Zn-3Y-xAl alloys

[J].

An investigation of the properties of Mg-Zn-Al alloys

[J].

Effects of grain refinement and residual elements on hot tearing of A713 aluminium cast alloy

[J].

Effect of low-frequency electromagnetic casting on the castability, microstructure, and tensile properties of direct-chill cast Al-Zn-Mg-Cu alloy

[J].

Hot tearing susceptibility of AXJ530 alloy under low-frequency alternating magnetic field

[J].

Numerical and experimental studies on solidification of AZ80 magnesium alloy under out-of-phase pulsed magnetic field

[J].

Effects of low frequency electromagnetic field on surface quality, microstructure and hot-tearing tendency of semi-continuous casting ZK60 magnesium alloy billets

[J].

Effect of low frequency alternating magnetic field on hot tearing susceptibility of Mg-7Zn-1Cu-0.6Zr magnesium alloy

[J].

Effect of alternating magnetic fields on hot tearing susceptibility of Mg-4Zn-1.5Ca alloy

[J].

Effect of low-frequency alternating magnetic field strength on hot tearing susceptibility of AXJ530 alloy

[J].

Influence of alloy composition and solidification conditions on dendrite arm spacing

feeding, and

Reducing porosity and optimizing performance for Al-Cu-based alloys with large solidification intervals by coupling travelling magnetic fields with sequential solidification

[J].Porosity is a major casting defect in alloys with large solidification intervals due to the disordered microstructure and broad mushy zones, which decreases badly the mechanical performance. Hence, finding ways to effectively reduce the porosity, further to optimize microstructure and mechanical performance is of great significance. In this regard, the Al-Cu-based alloys with large solidification intervals are continuously processed by coupling the travelling magnetic fields (TMF) with sequential solidification. Additionally, experiments combined with simulations are utilized to comprehensively analyze the mechanism of TMF on the reduction in porosity, including shrinkage porosity and gas porosity, from different perspectives. Current findings determine that downward TMF can effectually optimize together the porosity, microstructure and performance, by inducing the strong long-range directional melt flows, stabilizing the mushy zones, and optimizing the feeding channels and exhaust paths, as well as increasing the driving force of degassing process. Eventually, downward TMF can increase the ultimate tensile strength, yield strength, elongation and hardness from 175.2 MPa, 87.5 MPa, 13.3 % and 80.2 kg mm -2 without TMF to 218.6 MPa, 109.3 MPa, 15.6 % and 95.5 kg mm-2, while reduce the total porosity from 0.95 % to 0.18 %. However, Up-TMF exerts negative effects on the optimization of porosity, microstructure and performance due to the opposite strong directional magnetic force and melt flows. Overall, our study provides an effective way to optimize together the porosity, microstructure and mechanical performance, and reveals their relationship, as well as details the relevant mechanisms of TMF on the porosity reduction from different perspectives.

Characterization of microstructure and nanoscale phase in Mg-15Gd-1Zn (wt.%) alloy fabricated by rotating magnetic field casting

[J].

Numerical modeling of hot tearing formation in metal casting and its validations

[J].

Effect of Ca/Al ratio on hot tearing susceptibility of Mg-Al-Ca alloy

[J].

Experimental investigation and simulation assessment on fluidity and hot tearing of Mg-Zn-Cu system alloys

[J].

Effects of copper content and mold temperature on the hot tearing susceptibility of Mg-7Zn-xCu-0.6Zr alloys

[J].

A review on hot tearing of magnesium alloys

[J].

A new hot-tearing criterion

[J].

Experimental and numerical analysis of hot tearing susceptibility for Mg-Y alloys

[J].

Hot cracking behavior of Mg-5Al-xCa Alloys

[J].

Mg-5Al-xCa合金的热裂行为

[J].

Microstructure evolution of semi solid slurry of AZ91D magnesium alloy under ultrasonic vibration

[D].

超声振动下AZ91D镁合金半固态浆料微观组织演变

[D].

Progress and prospect of solidification research for metallic materials

[J].

金属材料凝固过程研究现状与未来展望

[J].

Recent advances in hot tearing during casting of aluminium alloys

[J].

The hot tearing tendencies of aluminium casting alloys

[J].

A review on hot tearing models in direct chill casting of aluminum alloys

[J].

铝合金半连续铸造过程中热裂模型综述

[J].

Deformation, strength, and fracture above the solidus temperature

[J].

Hot cracking susceptibility of Al-Cu-Li and Al-Cu-Li-Mn alloys

[J].

Mechanical properties in the semi-solid state and hot tearing of aluminium alloys

[J].

Effect of Zn content on hot tearing susceptibility of LPSO enhanced Mg-Zn x -Y2-Zr0.06 alloys with different initial mold temperatures

[J].

Hot-tear susceptibility of aluminum wrought alloys and the effect of grain refining

[J].

The effect of grain refinement and cooling rate on the hot tearing of wrought aluminium alloys

[J].

Effect of addition of minor amounts of Sb and Gd on hot tearing susceptibility of Mg-5Al-3Ca alloy

[J].

Effect of Sn addition on hot tearing susceptibility of AXJ530 alloy

[J].