Cu及铜合金由于具有优异的强度、导电性能、导热性能和耐磨性能等而广泛应用于高铁接触线、引线框架、电触头材料等领域[1~4]。Cu-Cr-Zr合金是一种典型的沉淀强化型合金,具有优异的强度和导电性能,但是随着工业应用需求和生产技术的发展,对铜合金性能有了更高的要求。然而,强度和导电性能是一对相互矛盾的性能,其本质上是此消彼长的,在提高铜合金强度的同时不可避免地会对其导电性能造成损害[5]。因此,如何尽可能小地损害导电性能的同时,大幅度提高铜合金的强度是现代铜合金产业发展的重要课题[6]。现阶段,众多工程应用领域对铜合金的性能要求一般为:强度≥ 600 MPa,导电率≥ 80%IACS[7]。为满足新一代铜合金的性能需求,研究者们往往通过微合金化[8~11]和工艺创新及优化[12~16]等方法来调控优化Cu及铜合金的组织结构,从而获得强度和导电率具有良好平衡的高性能铜合金。

对于通过微合金化改善铜合金方面,Guo等[17]研究了Cu-Cr-Nb合金中微合金化元素Nb与Cr之间的相互作用。结果表明,Nb元素可与Cr按原子比2∶1形成高熔点Cr2Nb相,Cr2Nb相在时效期间没有明显粗化而且Cr2Nb硬相可以作为形核质点而细化组织,进而提升铜合金的强度[17,18]。此外有研究指出,Nb元素在铜合金中不与Cu元素发生反应形成中间化合物,而且Nb元素在Cu中的固溶度很低,因此添加Nb元素对铜合金导电率影响不大[17,19,20];此外,Nb元素可在时效过程中促进合金元素从过饱和固溶体中析出,并可以延缓Cr析出相在后续时效过程中的长大,最终可通过微合金化元素Nb获得性能优异的铜合金[17]。本工作借助合金化元素Nb的作用,设计了Cu-1Cr-0.2Zr-0.25Nb (质量分数,%)合金,其中Cr与Nb的原子比超过了2∶1,预期在合金中获得微米级Cr2Nb与纳米级Cr颗粒的双级颗粒分布。通过微-纳双级颗粒协同优化铜合金性能,有望获得兼具高强度与高导电性的铜合金。

在铜合金中,位错、晶粒尺寸、孪晶(孪晶束宽度及体积分数)、析出相(尺寸及体积分数)等对铜合金的性能有着显著的影响[15,21~25]。通常采用塑性变形加工手段对固溶或时效状态的铜合金进行加工而引入上述缺陷及组织结构。有研究[15]表明,采用动态塑性变形及低温搅拌摩擦工艺在Cu-Cr-Zr合金中引入纳米孪晶及纳米晶的混合纳米组织,显著提高了铜合金的强度。在后续的时效析出过程中,混合纳米组织会促进析出相析出并与高密度纳米析出相形成强化的混合纳米组织,通过混合纳米组织复合强化,获得了高性能的铜合金[15,26]。作为一种简单、节能的热机械加工工艺,低温轧制结合时效处理,具有独特的工业化应用优势。Li等[23]通过低温轧制及时效工艺成功制备出大尺寸的Cu-Cr-Zr合金板材,获得了包含细化的变形带、有序的纳米级Cr析出相和纳米变形孪晶的混合纳米组织,合金具有优异的综合性能。低温轧制可以促进铜合金的变形方式由滑移向孪生转变,促进高密度位错和细小纳米晶的形成。在后续的时效处理过程中,高密度位错会促进纳米相的析出,从而得到纳米孪晶、纳米析出相和纳米晶的混合纳米强化组织。同时,合金元素从过饱和固溶体的析出可以使Cu-Cr-Zr合金保持较高的导电率。因此,通过低温轧制及时效处理可优化铜合金的微观组织和析出过程,并使铜合金获得优异的强度及导电性能。

目前,对于低温轧制对Cu-Cr-Zr-Nb合金微观组织演变和性能影响的研究较少。本工作对固溶态Cu-1Cr-0.2Zr-0.25Nb合金进行低温轧制及450℃不同时间的时效处理,研究了不同时效时间下的微观组织及析出相演变,并对其性能及强化机制进行了探究,为Cu-Cr-Zr合金的工业生产及性能优化提供了一种思路。

1 实验方法

选取工业纯Cu (纯度≥ 99.9%)、Cr颗粒(纯度≥ 99.9%)、Cr片(纯度≥ 99.9%)、Zr颗粒(纯度≥ 99.9%)、Nb颗粒(纯度≥ 99.9%)为原材料。利用DHL-400型真空电弧炉炼制Cu-Zr与Cr-Nb中间合金,再在Ar气保护气氛下的ZG-0.01L型真空感应炉中熔炼Cu-1Cr-0.2Zr-0.25Nb合金。首先将Cu片加热到1250℃,保温5 min后,升温至1500℃并加入Cr-Nb中间合金保温15 min,再降温至1180℃并加入Cu-Zr中间合金保温3 min,最后浇注到钢模中。将获得的铸锭首先在箱式炉中进行均匀化处理,均匀化温度为960℃,保温24 h后随炉冷却。随后打磨表面的氧化皮后再进行热轧处理,热轧温度为850℃,每道次的变形量为10%,最终变形量为30%,为了保持温度均匀,每道次之间保温15 min。将热轧后的样品放入箱式炉中在972℃下固溶1 h并水淬。固溶处理后的样品去除氧化层后进行室温轧制(RTR)和低温轧制(CR)处理,室温轧制为在室温(25℃)条件下进行轧制处理;低温轧制为将样品放入液氮中(-196℃)浸泡20 min,待样品表面没有气泡产生后进行轧制处理。在整个轧制过程中每道次变形量为10%,总变形量为90%。最后将轧制后的样品进行最终时效处理,即固溶→60%变形量轧制→中间时效(400℃、120 min)→30%变形量轧制→450℃不同时间(30和300 min)的最终时效处理。样品编号及具体轧制时效工艺参数如表1所示。

表1 Cu-1Cr-0.2Zr-0.25Nb样品的工艺流程

Table 1

| Sample | Process |

|---|---|

| RⅡ | As-solution-treated sample→60%RTR→intermediate aging (400oC, 120 min)→30%RTR |

| CRⅡ | As-solution-treated sample→60%CR→intermediate aging (400oC, 120 min)→30%CR |

| RⅡ-FA30 | As-solution-treated sample→60%RTR→intermediate aging (400oC, 120 min)→30%RTR→FA (450oC, 30 min) |

| CRⅡ-FA30 | As-solution-treated sample→60%CR→intermediate aging (400oC, 120 min)→30%CR→FA (450oC, 30 min) |

| RⅡ-FA300 | As-solution-treated sample→60%RTR→intermediate aging (400oC, 120 min)→30%RTR→FA (450oC, 300 min) |

| CRⅡ-FA300 | As-solution-treated sample→60%CR→intermediate aging (400oC, 120 min)→30%CR→FA (450oC, 300 min) |

采用MH-50 Vickers硬度测试仪进行硬度测试,测试压力为2.94 N,保压时间为15 s。通过Sigmascope SMP 350涡流导电率测试仪进行导电率的测量。拉伸实验均在室温下进行,实验设备为Instron 5500 R万能拉伸试验机。微观组织和面扫描分析通过EPMA-1600型电子探针显微分析仪(EPMA)进行。利用Talos F200x高分辨透射电子显微镜(TEM)对微观组织和纳米析出相进行观察分析,工作电压为200 kV。TEM样品的制备过程为:首先将样品用砂纸湿磨至厚度50 μm,再利用冲孔仪制备获得直径3 mm的圆片,最后采用LETCA EM RES102离子减薄仪制备出合格的中间有孔样品。采用配备Cu钯的EMPYREAN X射线衍射仪(XRD)分析样品的位错密度,位错密度是通过 Convolutional multiple whole profile (CMWP)方法分析计算的。

2 实验结果与分析

2.1 Cu-1Cr-0.2Zr-0.25Nb合金显微组织分析

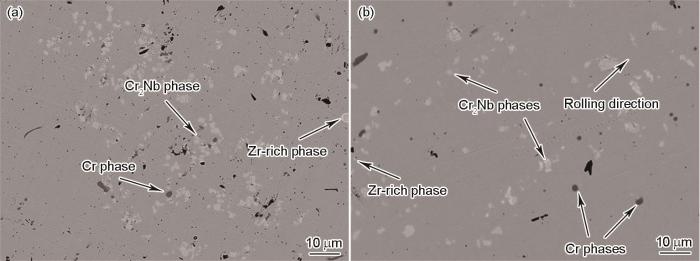

图1a为铸态Cu-1Cr-0.2Zr-0.25Nb合金的EPMA背散射电子像。可以看出,铜合金基体中存在着Cr相、富Zr相以及Cr2Nb相。较为粗大的Cr相大多分布于呈多边形分布的晶界上,晶内的Cr相颗粒尺寸相对较小;富Zr相则倾向于以椭球形在Cu基体中均匀分布,其尺寸大多为10 μm以上;Cr2Nb相呈不规则多边形形貌,弥散分布于铜合金基体中,其尺寸为1~10 μm。图1b为CRⅡ-FA300样品的EPMA背散射电子像。可以看出,经过轧制时效处理过后,少部分Cr相由椭球形转变为扁平状形貌,并沿轧制方向分布,还有部分球状Cr相沿轧制方向分布;富Zr相则主要聚集在Cr相周围,并且其尺寸与铸态相比明显减小;与铸态样品相比,Cr2Nb相由弥散分布转变为沿轧制方向分布,在形貌和尺寸上则没有明显变化。可见,在铸态Cu-1Cr-0.2Zr-0.25Nb合金内部已经形成了微米级的Cr2Nb、Cr和富Zr相,经过轧制时效工艺后,微米级颗粒在形貌和分布上都得到了进一步优化。

图1

图1

铸态Cu-1Cr-0.2Zr-0.25Nb和CRⅡ-FA300样品的EPMA背散射电子像

Fig.1

EPMA backscattered electron images of as-cast Cu-1Cr-0.2Zr-0.25Nb sample (a) and CRⅡ-FA300 sample (b)

图2为CRⅡ-FA300样品沿轧制方向分布的Cr2Nb相的EPMA面扫描分析结果。从图2c和e可以看出,图2a中暗白色区域的Cr和Nb元素含量较高,图2a中A区域暗白色相的定量成分分析结果(图2a中插图)表明Cr元素与Nb元素的原子比为2∶1,由此可以确定暗白色相为Cr2Nb颗粒;从图2d可以看出,Zr元素在Cr2Nb颗粒的周围存在富集现象。图3显示了CRⅡ-FA300样品中细小的核壳第二相颗粒的EPMA面扫描分析结果。从图3c和d可以看出,中心黑色区域为Cr相,在Cr相颗粒周围的白色区域为富Zr相,2者形成了一种核壳结构。此外,需要注意的是,从图3e中可以看出,Nb元素与Cr元素的分布基本一致,表明Nb元素在Cr颗粒内部存在一定的富集现象。图3f统计了球状Cr颗粒的尺寸,其平均尺寸为1.33 μm。综上,在CRⅡ-FA300样品中存在着沿轧向分布的Cr2Nb、Cr和富Zr相颗粒。Nb元素富集在Cr颗粒内部及边界,这与Guo等[17]中在原子尺度观察到的现象类似。

图2

图2

CRⅡ-FA300样品中Cr2Nb相的EPMA面扫分析

Fig.2

EPMA map scanning analyses of Cr2Nb phase in CRⅡ-FA300 sample

(a) backscattered electron image (Inset shows the EDS analysis result of area A)

(b-e) element mappings of Cu (b), Cr (c), Zr (d), and Nb (e) corresponding to Fig.2a

图3

图3

CRⅡ-FA300样品中Cr与Zr颗粒的EPMA面扫分析

Fig.3

EPMA map scanning analyses of Cr and Zr phase in CRⅡ-FA300 sample

(a) backscattered electron image

(b-e) element mappings of Cu (b), Cr (c), Zr (d), and Nb (e) corresponding to Fig.3a

(f) statistics distribution of Cr phase size (dave—average size)

2.2 时效态Cu-1Cr-0.2Zr-0.25Nb合金TEM分析

图4为CRⅡ-FA30样品中析出相的TEM分析。从图4a可以看出,经过30 min时效处理后,大量纳米级Cr相从基体中析出,大部分析出相分布在变形带内部,少量分布在晶界上。从图4b析出相的HRTEM像可以看出,其中存在着可认为是G.P.区的球状的析出相。图4c为图4b中析出相的快速Fourier转换(FFT)图。可以看出,析出相的衍射斑点(圆圈内斑点)与Cu基体类似,这是由于Cr的晶体结构与Cu相同,都为fcc结构,图4d为对应衍射斑的原理图。通过对FFT图进行标定,进一步证实了析出相为fcc结构的Cr相,且与基体具有cube-on-cube位向关系,这与文献[27,28]中关于Cr析出相的研究结果一致。由上述分析可知,通过30 min的短时时效后,Cu-1Cr-0.2Zr-0.25Nb样品中就已经析出大量的纳米级fcc结构的Cr相,且与Cu基体保持共格关系。

图4

图4

CRⅡ-FA30样品中析出相的TEM分析

Fig.4

TEM analyses of CRⅡ-FA30 sample

(a) TEM image of precipitates (b) HRTEM image of precipitates

(c) fast Fourier transformation (FFT) image of precipitates (d) schematic of FFT figure in Fig.4c

图5为CRⅡ-FA300样品中析出相的TEM分析。从图5a所示的TEM明场像中可以看出,Cu-1Cr-0.2Zr-0.25Nb样品时效300 min后,析出相与基体界面处可以观察到Moiré条纹,插图中的选区电子衍射(SAED)花样可发现微弱bcc结构Cr析出相的衍射斑点[29]。图5b为CRⅡ-FA300样品的HRTEM像,图5c和d分别为图5b中A区域与B区域的FFT图像。依据图5c,A区域中的析出相为bcc结构的Cr相。上述分析表明,经过300 min时效后,Cu-1Cr-0.2Zr-0.25Nb合金样品中的部分Cr析出相由fcc结构转变为bcc结构。通过对图5d的FFT图像进行分析,可以看出B区域中的析出相为fcc结构的Cr相,且与基体保持cube-on-cube位向关系。因此,经300 min时效后,Cu-1Cr-0.2Zr-0.25Nb样品中部分与基体呈共格关系的fcc结构Cr纳米析出相已转变为bcc结构的Cr相,剩余部分Cr析出相仍保持fcc结构。

图5

图5

CRⅡ-FA300样品中析出相的TEM分析

Fig.5

TEM analyses of precipitates in CRⅡ-FA300 sample

(a) bright-field TEM image (Inset shows the SAED pattern of precipitates)

(b) HRTEM image of precipitates

(c, d) FFT images of precipitates of region A (c) and region B (d) in Fig.5b

图6

图6

CRⅡ-FA300样品中Cr2Nb相的TEM像及元素分析

Fig.6

TEM image and element maps of Cr2Nb phase in CRⅡ-FA300 sample

(a) TEM image

(b-e) individual element mappings of Cu (b), Cr (c), Zr (d), and Nb (e) corresponding to Fig.6a

(f) combined composition map

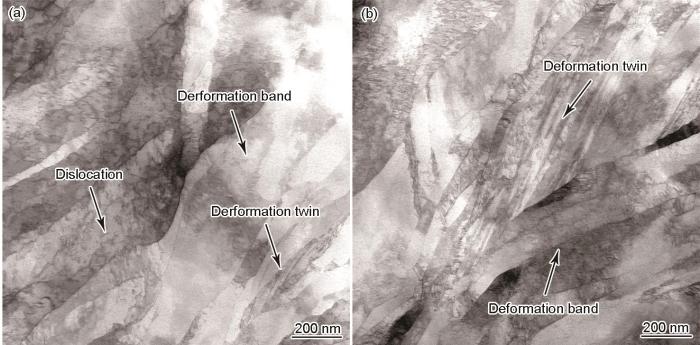

图7

图7

CRⅡ-FA300样品的TEM像

Fig.7

TEM images of CRⅡ-FA300 sample

(a) high-density dislocation (b) deformation twin

图8

图8

RⅡ-FA300样品的TEM像

Fig.8

TEM images of RⅡ-FA300 sample

(a) deformation twin and detwinning (b) precipitates and subgrain

2.3 Cu-1Cr-0.2Zr-0.25Nb合金性能

由于合金元素的固溶度随温度的升高而增加,Cu-1Cr-0.2Zr-0.25Nb样品经过固溶处理后,Zr元素和过量未反应的Cr元素会固溶在Cu基体中经淬火冷却后形成过饱和固溶体。在后续的轧制和时效过程中,固溶原子会以纳米析出相的形式析出,既可以强化合金基体,同时可以大幅减弱对电子的散射,提高材料导电率。

图9为不同轧制时效条件下Cu-1Cr-0.2Zr-0.25Nb合金的工程应力-应变曲线,表2对样品的性能进行了总结。可以看出,未经时效的轧制态样品(CRⅡ)的强度最高,随着时效时间的延长,样品的强度逐渐降低,而导电率逐渐升高,这与析出相的析出行为及位错演变相关。与两步室温轧制(RⅡ)样品相比,同样时效条件下,两步低温轧制(CRⅡ)样品的强度更高,强度差值随时效时间的延长而逐渐减小,而RⅡ与CRⅡ样品的导电率相差则较小。此外,RⅡ样品的伸长率高于CRⅡ样品,且随着时效时间的延长,差别逐渐减小,这与强度的变化趋势一致。随着时效时间的延长,合金的伸长率逐渐增加,从CRⅡ样品的4.9%增加到CRⅡ-FA300样品的8.9%左右。从表2数据可以看出,CRⅡ样品的抗拉强度可达740 MPa,比RⅡ样品高46 MPa,但此时的导电率仅有58.15%IACS。经过30 min时效后,CRⅡ-FA30样品的抗拉强度下降至700 MPa,仍比RⅡ-FA30样品要高31 MPa,此时对应的导电率提高至73.29%IACS。经过300 min时效后,CRⅡ-FA300样品的导电率达到了79.81%IACS左右,此时CRⅡ-FA300样品的抗拉强度为646 MPa,RⅡ-FA300样品的抗拉强度为621 MPa。综上所述,经过两步低温轧制及时效处理,CRⅡ-FA300样品仍然保持着高强度(646 MPa)、高硬度(212 HV)、高导电率(79.81%IACS)、高伸长率(8.9%)。

图9

图9

Cu-1Cr-0.2Zr-0.25Nb样品的工程应力-应变曲线

Fig.9

Engineering stress-strain curves of the Cu-1Cr-0.2Zr-0.25Nb samples

表2 Cu-1Cr-0.2Zr-0.25Nb样品的强度、伸长率、导电率及位错密度

Table 2

| Sample | σs MPa | σb MPa | C %IACS | ρ 1014 m-2 | δ % |

|---|---|---|---|---|---|

| RⅡ | 650 ± 6 | 694 ± 3 | 58.23 ± 0.08 | 28.9 | 6.3 |

| CRⅡ | 694 ± 4 | 740 ± 1 | 58.15 ± 0.06 | 35.9 | 4.9 |

| RⅡ-FA30 | 631 ± 13 | 669 ± 8 | 73.67 ± 0.23 | 20.1 | 8.4 |

| CRⅡ-FA30 | 654 ± 6 | 700 ± 2 | 73.29 ± 0.15 | 22.4 | 6.7 |

| RⅡ-FA300 | 584 ± 8 | 621 ± 2 | 80.27 ± 0.09 | 16.8 | 8.8 |

| CRⅡ-FA300 | 606 ± 9 | 646 ± 1 | 79.81 ± 0.10 | 18.1 | 8.9 |

2.4 Cu-1Cr-0.2Zr-0.25Nb合金强化机制

铜合金常见的强化机制主要有位错强化、析出强化、孪晶强化和固溶强化等。孪晶强化是重要的合金强化方式,纳米孪晶不仅可以有效强化合金,而且孪晶界对导电率的影响要比常规晶界小很多。孪晶强化的主要影响因素有孪晶体积分数和孪晶束宽度。对于变形铜合金,引入孪晶的主要方式就是通过在变形过程中发生孪生,而孪生变形的主要影响因素包括应变速率、层错能和变形温度[31]。在较低的变形温度下,部分铜合金的变形方式可由滑移转变为孪生。在本工作中,通过低温轧制和微合金化在Cu基体中引入变形孪晶,从而强化合金,而且在后续的时效过程中,变形孪晶仍然存在(图7),这说明低温轧制引入的变形孪晶可以在长时间的时效条件下稳定存在,这是时效态Cu-1Cr-0.2Zr-0.25Nb样品获得高强度的原因之一。然而,由于孪晶强化与孪晶束宽度和孪晶体积分数密切相关,因此其对强度的贡献十分有限。固溶强化是指在铜合金中添加一定量的合金元素,并且添加的合金元素以固溶原子的形式存在于Cu基体中,由于固溶原子与Cu原子的尺寸和结构存在差异,在Cu基体中引发晶格畸变并与位错相互作用形成Cottrell气团,从而达到强化合金的目的。由于本工作中添加的合金元素(Cr、Zr、Nb)在Cu基体中的固溶度很低,因此固溶强化对合金强度的贡献也不大。

图10

图10

CRⅡ-FA300样品的XRD谱拟合曲线

Fig.10

Fitting curves of XRD spectra for CRⅡ-FA300 sample

在本工作中,Cu-1Cr-0.2Zr-0.25Nb合金样品经过低温轧制后,基体中产生了大量的位错,而高密度的位错可为中间时效过程中的析出相提供形核质点,从而促进析出过程。从表2可以看出,轧制态(RⅡ、CRⅡ)样品的位错密度要明显高于时效态(RⅡ-FA、CRⅡ-FA)样品,这主要是由于时效过程中发生回复导致位错密度下降。此外,两步低温轧制样品的位错密度明显高于两步室温轧制样品,这一方面是因为低温轧制会抑制位错运动的交滑移及攀移,进而抑制了轧制过程中的动态回复并产生了高密度位错;另一方面在轧制过程中形成的高密度位错有利于时效过程中纳米析出相的形成,而纳米析出相的形成会阻碍第二步轧制过程中位错的移动,促进位错密度增加。位错强化对合金屈服强度的贡献(Δσd)可用下式描述[34]:

表3 屈服强度计算所用的参数

Table 3

| Parameter | Symbol | Unit | Value | Ref. |

|---|---|---|---|---|

| Shear modulus of Cu alloy | G | GPa | 44 | [35] |

| Taylor factor | M | 3.06 | [36] | |

| Burgers vector modulus | b | nm | 0.2556 | [35] |

| Poisson's ratio | ν | 0.33 | [37] | |

| Maximum volume fraction of precipitates | VCr-Max | % | 0.9 | This work |

| Minimum value of conductivity | C0 | %IACS | 29.30 | This work |

| Maximum value of conductivity | CMax | %IACS | 83.46 | This work |

| Transformation fraction of precipitation for CRⅡ-FA300 sample | XCRII-FA300 | % | 93.26 | This work |

| Volume fraction of the precipitates for CRⅡ-FA300 sample | fCRII-FA300 | % | 0.839 | This work |

| Mean radius of the precipitates for CRⅡ-FA300 sample | rCRII-FA300 | nm | 6.1 | This work |

式中,ν为Poisson比;

式中,f为析出相体积分数,可以通过当前状态下析出相析出分数与析出相最大体积分数计算得出[39],即:

式中,X为析出相转变分数,表示样品在不同时效条件下的析出相转变分数,可以通过下式计算:

式中,C表示在某时效条件下合金样品的导电率,C0与CMax分别代表轧制时效过程中导电率的最小值和最大值。通过式(

综上,通过理论计算可以获得通过位错强化和析出强化对CRⅡ-FA300样品屈服强度的贡献总和为518.0 MPa,占总屈服强度近85%。由此可见,对于时效态Cu-1Cr-0.2Zr-0.25Nb合金,位错强化和析出强化机制在合金强化中占主导作用。

3 结论

(1) 经过轧制后,Cu-1Cr-0.2Zr-0.25Nb合金的强度明显提升,但导电率和伸长率较低。即低温轧制态Cu-Cr-Zr-Nb合金的抗拉强度最高,高达740 MPa,导电率仅为58.15%IACS。随着时效时间的延长,合金的导电率和伸长率逐渐提高,强度逐渐降低但仍维持在较高水平。即短时时效后(450℃、30 min),合金的抗拉强度降低至700 MPa,导电率可达73.29%IACS。长时间时效后(450℃、300 min),合金样品获得了优异的综合性能,在导电率达到79.81%IACS左右的同时,屈服强度高达606 MPa,抗拉强度和硬度分别为646 MPa和212 HV,伸长率为8.9%。

(2) 在低温轧制时效的Cu-1Cr-0.2Zr-0.25Nb样品中,在微米尺度获得了均匀分布的微米级Cr与Cr2Nb颗粒,在纳米尺度观察到了Cr2Nb相,获得了细小的纳米级Cr析出相(尺寸约6 nm)。在短时时效(30 min)条件下,Cr元素从过饱和固溶体析出,形成与基体共格的fcc结构Cr纳米析出相,与基体保持cube-on-cube取向;在长时间时效(300 min)条件下,样品中部分fcc结构Cr纳米析出相已转变为bcc结构的Cr相,剩余部分Cr析出相仍保持fcc结构。

(3) 在低温轧制时效的Cu-1Cr-0.2Zr-0.25Nb合金中,位错强化和析出强化机制对合金强化起主导作用。通过理论计算,位错强化和析出强化对CRⅡ-FA300样品的屈服强度贡献分别为292.8和225.2 MPa,占总屈服强度的85%左右。

参考文献

Effect of aging temperature on hard phase evolution of nickel aluminum bronze

[J].

时效温度对镍铝青铜合金的硬质相演变的影响

[J].

High temperature tensile properties and fracture mechanism of ultra-fine grain Cu-Cr-Zr alloy

[J].Cu-Cr-Zr alloy usually applys to the complex environment at high temperature. The mechanical behaviors of alloy are different from the condition of normal temperature. At high temperature, grains and precipitates of ultra-fine grain Cu-Cr-Zr alloy become coarse and it would affect the hot deformation behavior of alloy. To solve the thermal stability of the ultra-fine grain materials, the grain growth mechanism and the driving force of ultra-fine grain materials must be studied, as well as trace elements on the thermal stability mechanism. Tensile properties, microstructure of fracture and fracture mechanism of ultra-fine grain (UFG) Cu-Cr-Zr alloy made by two different treatment methods were studied at the temperature range of room temperature to 600 ℃. The results show that the ultimate tensile strength (UTS) of alloys decreases with increasing temperature. The UTS and elongation of No.1 alloys are about 577.17 MPa and 14.6% at room temperature, respectively. And No.1 alloy start to occur dynamic recrystallization and UTS decreases fast at 300 ℃. The UTS of No.1 alloy are only 59.12 MPa at 600 ℃. The UTS and elongation of No.2 alloy are about 636.71 MPa and 12.1% at room temperature, respectively. The pinning effect by precipitation on grain boundary in the No.2 alloy begins to weaken at 400 ℃. The UTS of No.2 alloy decreases fast and are only 65.20 MPa at 600 ℃. Compared to No.1 alloy, No.2 alloy have better room temperature property and thermal stability. The elongation of all alloys increases with increasing temperature and show superplasticity on elevated temperature. The high temperature tensile fracture morphologies are an intense and deep dimple pattern. The high temperature fracture mechanism is ductile fracture by gathered microporous.

超细晶Cu-Cr-Zr合金的高温拉伸性能及断裂机制

[J].研究了2种变形处理方式下的超细晶Cu-Cr-Zr合金从室温到600 ℃的拉伸性能、断口微观组织特征及其断裂机制. 结果表明: 经4道次等径弯曲通道挤压(ECAP)+时效+4道次ECAP变形处理的合金(No.1试样)的抗拉强度随拉伸温度的升高而降低, 室温时, 合金抗拉强度为577.17 MPa, 延伸率为14.6%; 在300 ℃开始发生动态再结晶软化, 抗拉强度迅速减小, 到600 ℃时抗拉强度仅为59.12 MPa. 经过8道次ECAP+时效变形处理的合金(No.2试样), 室温抗拉强度为636.71 MPa, 延伸率为12.1%; 从400 ℃开始析出相对晶界的钉扎作用开始逐渐减弱, 抗拉强度大幅降低, 600 ℃时的抗拉强度为65.20 MPa. No.2试样比No.1试样具有更好的室温性能和热稳定性. 2种方式处理下合金延伸率随拉伸温度的升高而升高, 在高温下都表现出超塑性. 高温拉伸断口微观形貌为大量密集、深入的韧窝, 其高温断裂机制为微孔聚集的韧性断裂.

Contribution of Zr to strength and grain refinement in Cu-Cr-Zr alloy

[J].

Effect of heavily drawing on the microstructure and properties of Cu-Cr Alloys

[J].

强变形对Cu-Cr合金组织性能的影响

[J].采用冷拉拔方法制备了高强高导Cu-Cr合金导线, 考察了合金界面结构随拉拔变形量的演变, 探讨了界面结构变化与合金性能的关系.结果表明, 随变形量增大, Cu和Cr相均被逐渐拉长成纤维状, 且两相的晶面之间逐渐趋于(111)<sub>Cu</sub>//(110)<sub>Cr</sub>, Cu/Cr界面由非共格关系演变为共格关系, 同时, 通过Cu/Cr界面的互扩散增强. 界面密度的增加是导致电阻率随变形量增加持续增大的主要因素. 界面共格化是造成合金强度增大并趋于恒定的原因.

Composition design, phase transition and fabrication of copper alloys with high strength and electrical conductivity

[J].

高强导电铜合金的成分设计、相变与制备

[J].

Research progress of Cu-Cr-Zr copper alloys with high strength and high conductivity

[J].

高强高导Cu-Cr-Zr系合金的研究进展

[J].

Effects of Mg addition on the microstructure and softening resistance of Cu-Cr alloys

[J].

Effect of initial grain size on hot deformation behaviour of Cu-Cr-Zr-Ti alloy

[J].

Low-temperature annealing behavior and tensile properties of the rapidly solidified Cu3Ag0.5-Zr0.4Cr0.35Nb alloy reinforced by cold rolling

[J].

Effect of thermomechanical treatment on microstructure and properties of Cu-Cr-Zr-Ag alloy

[J].

Improved tensile strength and electrical conductivity in Cu-Cr-Zr alloys by controlling the precipitation behavior through severe warm rolling

[J].

Microstructural, mechanical and tribological properties of ultrafine-grained Cu-Cr-Zr alloy processed by high pressure torsion

[J].

Optimizing the strength, ductility and electrical conductivity of a Cu-Cr-Zr alloy by rotary swaging and aging treatment

[J].

A high strength and high electrical conductivity Cu-Cr-Zr alloy fabricated by cryogenic friction stir processing and subsequent annealing treatment

[J].

Breaking the trade-off relation between strength and electrical conductivity: Heterogeneous grain design

[J].The trade-off relationship between the strength and the electrical conductivity has been the bottleneck restricting the development of conductive metallic materials with high strength and high electrical conductivity. In this study, commercially pure Al wires and commercially pure Cu wires with various grain characteristics were prepared by the cold-drawing process to investigate the influencing mechanisms of grain on strength and electrical conductivity. Surprisingly, the synchronous increase in strength and electrical conductivity may be achieved both for the commercially pure Al wires and commercially pure Cu wires in the later stage of cold-drawing deformation, which shatters the traditional constrictive relationship between the strength and the electrical conductivity. Additionally, the microstructure investigation demonstrates that with the increase of drawing deformation, the axial grains were lengthened, the radial grains were increasingly polished, and the radial <001> texture was transformed to <111> texture. Finally, the heterogeneous microstructures, including heterogeneous grain formation and heterogeneous crystal orientation were formed. The theoretical analysis reveals that the grain width and texture mainly influence the strength, and the grain length primarily influences the electrical conductivity. Consequently, the axial long grain, the radial fine grain, and radial hard orientation texture are proved to be the primary mechanisms causing the synchronous improvement of strength and electrical conductivity of commercially pure Al wires and commercially pure Cu wires. This suggests that the heterogeneous grain design may be considered a useful method to create conductive metallic materials with high strength and high electrical conductivity.

突破强度-导电率制约关系:晶粒异构设计

[J].采用冷拉拔工艺制备了具有不同晶粒特征的工业纯Al线和工业纯Cu线,研究了晶粒对强度和导电率的影响机制。性能测试结果表明,拉拔变形后期,工业纯Al线和工业纯Cu线的强度和导电率同步提高,打破了强度和导电率传统的倒置关系。微观组织观察发现:随着拉拔变形量增大,轴向晶粒被拉长,径向晶粒逐渐细化,径向<001>织构向<111>织构转变,形成了晶粒形状异构和晶体取向异构的微观组织结构。理论分析表明:晶粒宽度和织构主要影响强度,晶粒长度主要影响导电率;提出了轴向长晶粒、径向细晶粒和径向硬取向织构是工业纯Al线和工业纯Cu线强度和导电率同步提高的根本原因。

Microstructure and properties of Cu-Cr-Nb alloy with high strength, high electrical conductivity and good softening resistance performance at elevated temperature

[J].

High-performance dispersion-strengthened Cu-8Cr-4Nb alloy

[J].

Experimental determination and thermodynamic calculation of the phase equilibria in the Cu-Cr-Nb and Cu-Cr-Co systems

[J].

An experimental evaluation of the phase relationships and solubilities in the Nb-Cr system

[J].

Mechanical behaviors of nanotwinned metals and nanotwinned covalent materials

[J].Metallic and covalent materials are important structural materials. Traditional strategies for strengthening materials compromise their ductility and toughness. Recent experimental results show that twinning can simultaneously improve the strength (hardness) and toughness of copper and diamond; as the inverse relationship between the strength and toughness of materials is broken, this has become a hot research topic. By studying the strengthening mechanism of nanotwinned copper and diamond, methods to simultaneously improve strength and toughness may be found. Herein, this paper presents a comprehensive overview of the recent developments in the experimental and theoretical studies of nanotwinned metals and covalent materials. The microstructures, fabrication methods, and mechanical properties of nanotwinned metals and covalent materials are summarized. Further, the strengthening mechanism of nanotwinned metals and the hardening mechanism of covalent materials are introduced. Finally, the research trend on the mechanical behavior of nanotwinned materials is discussed in detail.

纳米孪晶金属和纳米孪晶共价材料的力学行为

[J].

Raising thermal stability of nanograins in a CuCrZr alloy by precipitates on grain boundaries

[J].

Optimization of the balance between high strength and high electrical conductivity in CuCrZr alloys through two-step cryorolling and aging

[J].

The roles of Hf element in optimizing strength, ductility and electrical conductivity of copper alloys

[J].

Influence of high pressure torsion-induced grain refinement and subsequent aging on tribological properties of Cu-Cr-Zr alloy

[J].

Nanostructures and nanoprecipitates induce high strength and high electrical conductivity in a CuCrZr alloy

[J].The mixed nanostructure mainly consisting of nanotwins and nanograins was obtained in a solid solution CuCrZr alloy by means of dynamic plastic deformation at cryogenic temperature. After subsequent aging treatments, the precipitation of Cr at nanometer scale provided further strengthening and brought substantial recovery of electrical conductivity. The aged nanostructured CuCrZr alloy exhibited a high tensile strength of 832 MPa and a high electrical conductivity of 71.2% IACS. The details of precipitation tuned by nanotwin boundaries were demonstrated in this work. The combined strengthening of nanostructures and nanoprecipitates was discussed.

Aging properties of high-strength and high-conductivity Cu-Cr-Zr alloy

[J].

高强高导Cu-Cr-Zr合金时效性能

[J].

Dynamics of phase transformation of Cu-Cr-Zr-Mg alloy

[J].

Cu-Cr-Zr-Mg合金的相变动力学

[J].

The phase transformation and strengthening of a Cu-0.71 wt% Cr alloy

[J].

Development of novel Cu-Cr-Nb-Zr alloys with the aid of computational thermodynamics

[J].

On the stacking fault energy related deformation mechanism of nanocrystalline Cu and Cu alloys: A first-principles and TEM study

[J].

Effect of two-step cryorolling and aging on mechanical and electrical properties of a Cu-Cr-Ni-Si alloy for lead frames applications

[J].

Microstructure evolution, electrical conductivity and mechanical properties of dual-scale Cu5Zr/ZrB2 particulate reinforced copper matrix composites

[J].

Influence of the radial-shear rolling (RSR) process on the microstructure, electrical conductivity and mechanical properties of a Cu-Ni-Cr-Si alloy

[J].

Microstructure and properties of dual-scale particulate reinforced copper matrix composites with superior comprehensive properties

[J].

Correlations between microstructures and properties of Cu-Ni-Si-Cr alloy

[J].

Effects of Co and Si additions and cryogenic rolling on structure and properties of Cu-Cr alloys

[J].

Effects of pre-deformation on precipitation behaviors and properties in Cu-Ni-Si-Cr alloy

[J].