在日常生活中有大量产生的余热散发到环境中,无法获得有效利用。热电材料作为一种新型“绿色”能源材料,可将此类分散式、低品质废热有效利用起来,实现“热能”与“电能”的直接转换。并且,由于其具有体积小、重量轻、无污染、寿命长和使用过程中无噪音等优点,使得热电材料在解决能源短缺与环境污染问题方面展现出独特优势[1~10]。随着应用场景的变化发展,热电器件微型化、柔性化需求与日俱增[11~15]。然而,在实际应用中,传统的热电合金材料无法紧密贴合具有复杂曲率变化的热源表面(如人体体表或微系统硬件等),器件与弯曲热源之间的不良接触导致热量散失,大大降低了热电器件的转换效率[16~19]。因此,目前传统的热电器件制作方法在物联网传感供电以及可穿戴电子设备等领域很难实现微型化、柔性化。其主要原因有2点:一是传统热电材料往往具有本征的脆性和刚性,切割精度及柔性较差,很难制备出应用于弯曲热源表面的微型热电发电器件;二是传统热电单元的制备、排布和转移方法不易实现微尺寸热电单元的高密度集成。因此,高性能、高密度集成的微型柔性热电器件的研发具有重要意义[20,21]。

目前,对于柔性热电器件的研究与开发主要集中在2个方面。一种是选取有机热电(organic thermoelectric,OTE)材料,利用其优异的本征柔性特点,制备出柔韧性较好的热电器件[22~24]。然而,OTE材料虽具有重量轻、弯曲形变性能好等传统无机热电材料所不具备的优势,但有效的n型聚合物少、热电性能低,制备出的热电器件接触电阻高、热稳定性较差并且电学性能低,因而OTE材料的实际应用受到了限制。另一种是通过优化设计材料与器件的结构[25],采用柔性聚合物材料作为基底来支撑无机热电材料,制备出具有更高热电性能和良好柔性的热电器件。近年来,通过合理设计材料与器件结构,制备高柔性、高性能微型热电器件研究备受关注。目前,对于可弯曲、折叠的柔性热电发电器件(thermal electric generator,TEG)的研发,主要为面内型温差发电器件,无法建立面外温差,且对于温差出现在面外的非平面热源无法获得有效利用,其工作稳定性较差,不利于实际应用[5,9,16,26,27]。例如:Park等[16]报道了一种形状工程热电喷涂TEG,其可在任意形状的表面上制备,但该器件仅适用于出现在面内的温度梯度,无法将实际应用环境中常见的面外温差有效利用起来。特别是随着柔性电子技术的发展,具有超薄、重量轻和高柔韧性的可穿戴TEG取得诸多进展,但面对人体皮肤和不规则自然热源表面发生形态变化时,其不能发生适当的弹性伸缩,无法与热源表面适形接触,往往会严重降低TEG的输出性能。例如,Zhou等[1]设计了一种叶型柔性TEG,其可直接与环境进行热交换,但在人体运动时,由于皮肤具有延展性,因而仅具有柔性的TEG很难在皮肤延展时与皮肤热源表面紧密贴合,导致热量传递过程中损失严重,器件将无法稳定工作。针对柔性TEG的可拉伸性的应用需求,研制可延展拉伸的柔性TEG对于提高器件的输出性能至关重要。然而,现有的可拉伸TEG的研制主要是利用有机半导体、纺织织物和液态金属等材料[20,28~30]。此类TEG已被证明可实现高度的可拉伸性,但由这些材料制成的可拉伸TEG通常需要采用光刻、印刷和喷涂等技术,制备工艺复杂,所需材料价格昂贵,且制成器件输出性能往往偏低,不利于高性能TEG的工业化生产。例如,Jung等[29]通过使用Ag纳米粒子(AgNPs)、石墨烯和聚(3,4-乙烯二氧噻吩∶聚苯乙烯磺酸根) (PEDOT∶PSS)组成的导电油墨在棉质织物上印刷制成柔性、可拉伸TEG。该器件在30 K的温差下产生0.15 mV的输出电压,且在20%应变下输出电压仅降低7%。虽然该TEG表现出良好的稳定性和耐用性,但其制备成本较高,热电性能较低。因此,如何使柔性TEG实现高输出性能的同时兼顾可拉伸性成为一大难点。

考虑到对面外型温差的利用需求及人体等热源表面的复杂曲率变化,要求器件具有可拉伸性,以保证当热源表面形态变化时,器件能正常工作的同时兼顾良好的性能输出。基于此,本工作提出将器件平面二维结构转换为三维立体结构,设计一种柔性、可拉伸变形的微型热电器件,创新性地构建出可用于面外型温差的三维薄膜TEG。通过磁控溅射和物理掩膜,在单壁碳纳米管(single-wall carbon nanotube,SWCNT)薄膜上沉积获得Bi2Te3和Sb1.5Bi0.5Te3纳米晶体复合薄膜做为p/n热电单元。利用静电力吸附转移,以可拉伸变形的拱形聚二甲基硅氧烷(polydimethylsiloxane,PDMS)基底作为柔性基板,将裁剪好的p/n热电薄膜通过静电力贴附于基底上,并在p/n热电单元两端掩膜沉积金电极进行连通,从而获得柔性、可拉伸变形的微型热电发电器件。该微型柔性热电器件在温差为4 K时,输出电压为4.8 mV,其最大输出功率达到2.6 × 10-9 W,功率密度为3.9 × 10-9 W/cm2,器件的最小弯曲半径为3 mm。本工作实现了基于二维薄膜型热电材料构建三维立体微型柔性热电器件,将薄膜材料最佳性能方向与温差方向协调统一,实现温差利用率最大化,为研制柔性、可穿戴热电器件提供了新思路。

1 实验方法

1.1 柔性、可拉伸变形微型热电器件的设计

本工作主要利用SWCNT/Bi2Te3基热电复合薄膜材料优异的柔性及面内热电性,设计构建柔性、可拉伸变形的微型热电器件,具体思路如下:首先,针对Bi2Te3材料自身固有的脆性使其在器件的制备过程中易出现微裂纹等问题,提出制备SWCNT/Bi2Te3基复合薄膜材料,以增强热电材料自身的柔性,从而提高所构建器件的弯曲变形能力。进而,使用一种可拉伸变形的拱形PDMS基底,在保证器件具有良好柔性的同时,也起到对热电复合薄膜进行支撑与保护的作用。

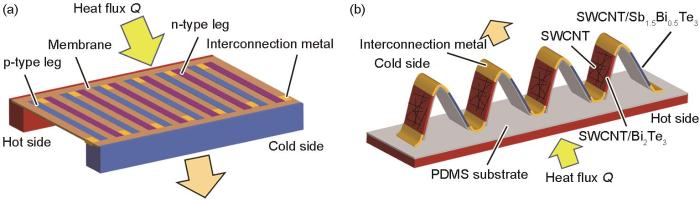

图1

图1

薄膜型热电器件设计图和三维立体拱形热电薄膜器件设计图

Fig.1

Design diagrams of the thin-film thermoelectric device (a) and the 3D arch thermoelectric thin-film device (PDMS—polydimethylsiloxane, SWCNT—single-wall carbon nanotube) (b)

1.2 柔性、可拉伸变形微型热电器件的制备

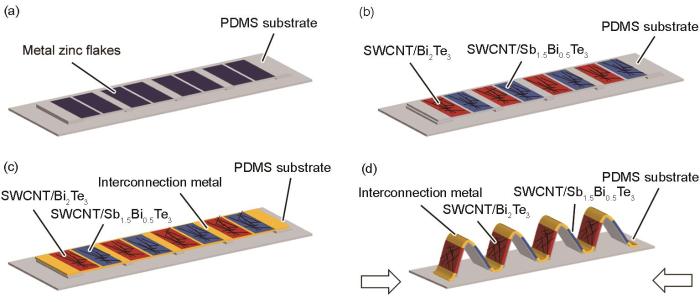

图2为柔性、可拉伸变形微型热电器件的制备流程,主要包括:拱形PDMS基底的制作、热电复合薄膜的制备与转移、p/n热电单元两端金电极的沉积以及收缩基底获得三维立体TEG。

图2

图2

微型柔性热电器件制作流程图

Fig.2

Flow chart of the fabrication of micro-flexible thermoelectric devices

(a) preparation of PDMS flexible substrate (b) transfer thermoelectric films

(c) deposition of gold electrodes (d) three-dimensional thermal electric generator (TEG) device

1.2.1 可拉伸变形的拱形PDMS基底的制作

图3为拱形PDMS基底制作的流程图。首先,将商用100 μm厚的PDMS薄膜裁剪成尺寸为8 mm × 40 mm的长方形薄片,对其进行预置拉伸(拉伸到初始长度的160%),并固定在钛合金片上(图3a1)。使用Spectra-physics Spirit 104-16飞秒激光切割如图3b1所示的50 μm厚金属锌薄片镂空反模板,将其作为金属牺牲层,并紧密贴合在PDMS表面(图3a2)。按照PDMS与固化剂 = 10∶1的质量比称取PDMS混合液,充分搅拌5 min后将混合液浇灌到反模板表面,刮涂后放入真空干燥箱内加热固化(图3a3)。随后,利用飞秒激光加工出如图2b2所示的金属锌薄片镂空模具,作为支撑金属层,并将其放置到与反模具对应的PDMS表面上(图3a4),使用飞秒激光沿图3b2红色虚线切割掉金属锌镂空薄片多余部分,再向支撑金属表面浇灌PDMS混合液,进行二次刮涂,抽真空后加热固化(图3a5)。然后,用刀片切除上层PDMS薄膜两端部分边缘,使金属牺牲层两端暴露出来,用5 mol/L稀HCl对牺牲层金属进行腐蚀(图3a6),待完全反应,即获得如图3c所示可拉伸变形的拱形PDMS基底。

图3

图3

可拉伸变形的拱形聚二甲基硅氧烷(PDMS)基底的制作

Fig.3

Schematics of the fabrication of stretchable and deformable arch PDMS substrate (a1-a6) cross-sectional flow charts of arch PDMS substrate fabrication (a1) stretch PDMS (a2) attach sacrificial layer metal foil(a3) pouring, scraping, and curing PDMS (a4) attach support sheet metal(a5) pouring, scraping, and curing PDMS again (a6) erosion of sacrificial metal flakes (b1, b2) patterned metal zinc flakes for sacrificial metal layer (b1) and supporting metal layer (b2) (c) stretchable deformable arch PDMS substrate

1.2.2 热电复合薄膜的制备与转移

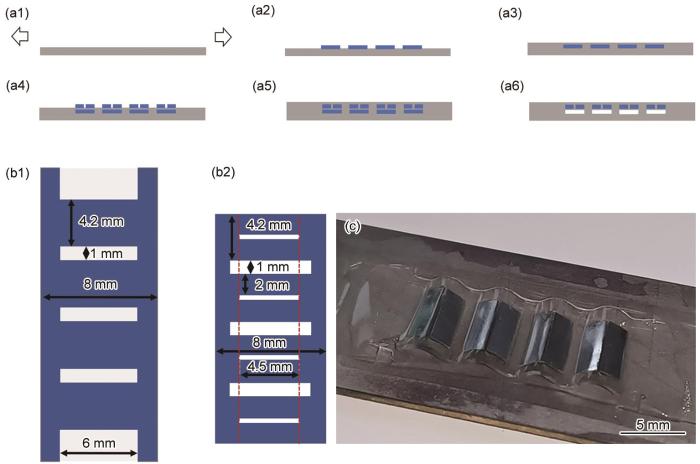

采用浮动催化剂化学气相沉积方法制备自支撑的SWCNT薄膜[32],薄膜中SWCNT管束平均直径约为15 nm,取向随机。首先,将SWCNT薄膜依靠静电力贴附在清洗干净的铜架上,并固定于不锈钢样品盘上,置于磁控溅射腔体中加热进行脱氧处理。在683 K下保温2.5 h后,在SWCNT薄膜上沉积Bi2Te3纳米晶体,经3600 s后,制成n型SWCNT/Bi2Te3复合薄膜,将复合薄膜在磁控腔体中于643 K退火0.5 h,获得n型复合薄膜。通过Bruker DektakXT台阶仪测量该复合膜的厚度为815 nm。采用类似方法,将SWCNT薄膜于643 K保温2.5 h后,将Sb1.5Bi0.5Te3纳米晶溅射沉积到SWCNT薄膜上,2100 s后制成p型SWCNT/Sb1.5Bi0.5Te3复合薄膜。将复合膜在磁控腔体中于603 K原位退火,保温时间0.5 h。测得该p型复合膜的厚度为730 nm。利用飞秒激光机分别切割4片尺寸为2 mm × 4 mm的n型和p型复合薄膜,将4对p/n热电复合薄膜贴附在可拉伸变形的拱形PDMS基底上。图4为转移好含4对p/n热电复合薄膜的器件实物图。

图4

图4

柔性、可拉伸变形微型热电器件实物图

Fig.4

Flexible, stretchable, and deformable micro thermoelectric power generation device

1.2.3 p/n热电单元两端金电极的沉积

利用飞秒激光机在聚酰亚胺上切出含5个4 mm × 1.2 mm和4个4 mm × 0.6 mm长方形孔洞的电极掩膜板,并将其贴附于上述制备的柔性热电复合薄膜上,随后固定到样品盘表面,放入磁控腔体中,在真空度约为10-5 Pa的条件下,于p/n热电单元两端掩膜沉积金电极,导通相邻2个p/n热电单元。最后,释放第1层PDMS薄膜,基底收缩,随之含有支撑金属的PDMS层形成拱形隆起,制成包含4对p/n热电单元的柔性、可拉伸变形的微型热电发电器件,其中每对热电单元中n型SWCNT/Bi2Te3热电复合薄膜的尺寸为2 mm × 4 mm × 0.000815 mm,p型SWCNT/ Sb1.5Bi0.5Te3热电复合薄膜的尺寸为2 mm × 4 mm × 0.000730 mm。

1.3 材料性能的表征方法

采用D8 Discover X射线衍射仪(XRD)和SU70系列场发射扫描电子显微镜(SEM)对n型SWCNT/Bi2Te3热电复合薄膜和p型SWCNT/Sb1.5Bi0.5Te3热电复合薄膜的结晶度及微观结构进行表征,并使用NETZSCH SBA 458 Seebeck系数/电导率测试仪测量2种材料的电导率和Seebeck系数等热电性能。

1.4 微型柔性热电器件的表征方法

使用Keithley 4200 SCS半导体测试仪对微型柔性热电器件的发电性能进行表征,获得不同温差下的伏安特性曲线,并通过公式P = UI (其中,U为输出电压,I为输出电流)计算得到输出功率P。另外,将微型柔性热电器件置于不同曲率半径的玻璃烧杯上,测试器件电阻的变化情况,表征柔性性能。

2 实验结果

2.1 热电复合薄膜的性能表征

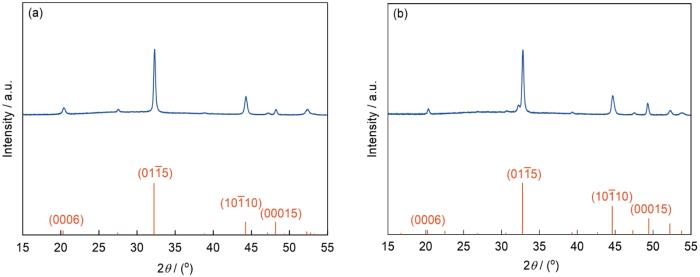

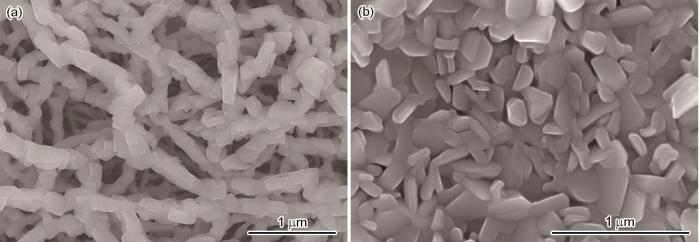

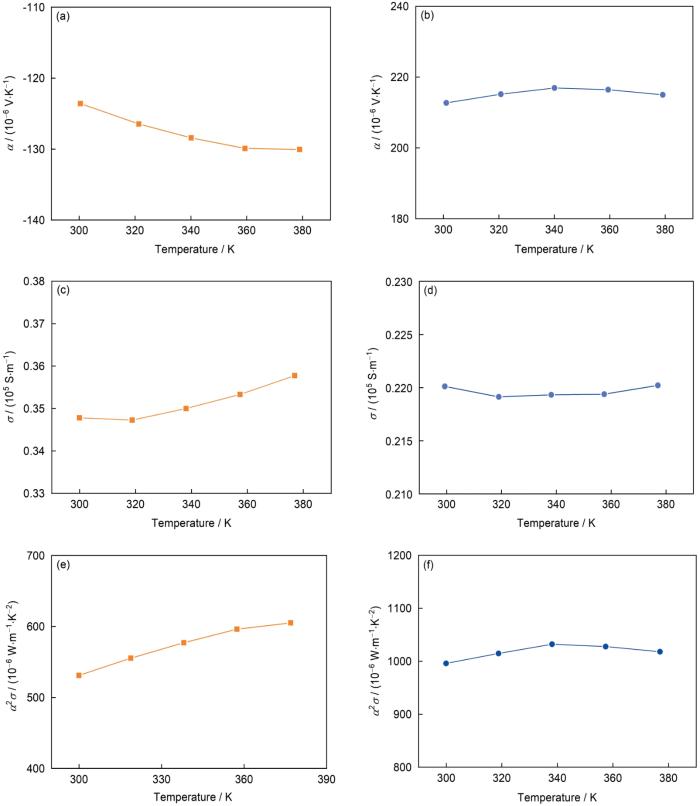

SWCNT/Bi2Te3和 SWCNT/Sb1.5Bi0.5Te3复合薄膜的XRD谱分别如图5所示。2种材料所有的衍射峰均与相应的标准PDF卡片(PDF#15-0863和PDF#49-1713)上的衍射峰对应,表明沉积在SWCNT上的Bi2Te3和Sb1.5Bi0.5Te3均为单相晶体材料。图6为沉积时间为3600 s的SWCNT/Bi2Te3复合薄膜和沉积时间为2100 s的SWCNT/Sb1.5Bi0.5Te3复合薄膜的SEM像。可以看出,生长在SWCNT上的Bi2Te3与Sb1.5Bi0.5Te3纳米晶均具有良好的致密性与结晶度,这与XRD谱结果相一致。图7显示了n型SWCNT/Bi2Te3和p型SWCNT/Sb1.5Bi0.5Te3复合薄膜的热电性能随温度的变化趋势。可以看到,2种材料在室温附近都具有较高的Seebeck系数。所制备的n型SWCNT/Bi2Te3和p型SWCNT/Sb1.5Bi0.5Te3复合薄膜在室温的功率因子分别为6 × 10-4与1.01 × 10-3 W/(m·K2),显示出了良好的室温热电性能。

图5

图5

单壁碳纳米管(SWCNT)/Bi2Te3复合薄膜和SWCNT/Sb1.5Bi0.5Te3复合薄膜的XRD谱

Fig.5

XRD spectra of SWCNT/Bi2Te3 composite film (a) and SWCNT/Sb1.5Bi0.5Te3 composite film (b)

图6

图6

沉积时间为3600 s的SWCNT/Bi2Te3复合薄膜和沉积时间为2100 s的SWCNT/Sb1.5Bi0.5Te3复合薄膜的SEM像

Fig.6

SEM images of SWCNT/Bi2Te3 composite film with deposition time of 3600 s (a) and SWCNT/Sb1.5Bi0.5Te3 composite film with deposition time of 2100 s (b)

图7

图7

n型SWCNT/Bi2Te3复合薄膜与p型SWCNT/Sb1.5Bi0.5Te3复合薄膜的热电性能

Fig.7

Thermoelectric properties of n-type SWCNT/Bi2Te3 composite film (a, c, e) and p-type SWCNT/Sb1.5Bi0.5Te3 composite film (b, d, f) (a, b) Seebeck coefficient (α) (c, d) electrical conductivity (σ) (e, f) power factor (α2σ)

2.2 微型柔性热电器件的性能表征

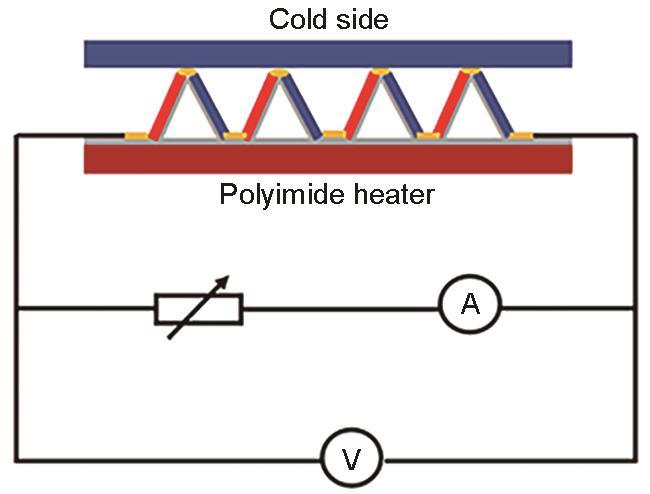

2.2.1 温差发电性能的测试原理

图8为微型柔性热电器件的测试原理图。选用聚酰亚胺加热膜作为热源,对柔性、可拉伸变形的微型热电器件进行控温加热,测试器件的发电性能。将制作好的微型柔性热电器件置于聚酰亚胺加热膜表面进行控温加热,并在测试过程中保持测试空间内温度恒定。在器件两端均固定K型热电偶,并接入温度显示仪表,用于监测器件冷端、热端的实际温度,从而精确监测热电器件冷热两端所构成的温度梯度。通过向聚酰亚胺薄膜输入电流,对器件下表面进行加热,以形成上下表面的温差,监测柔性热电器件的输出电压以及输出电流。保持温差恒定,通过改变外电路负载电阻,测试不同负载条件下电路中电压、电流,计算器件的输出功率。通过调节温度,获得不同温差下的伏安特性曲线。

图8

图8

微型柔性热电器件的测试原理图

Fig.8

Schematic of the test of the miniature flexible thermoelectric device

2.2.2 温差发电性能

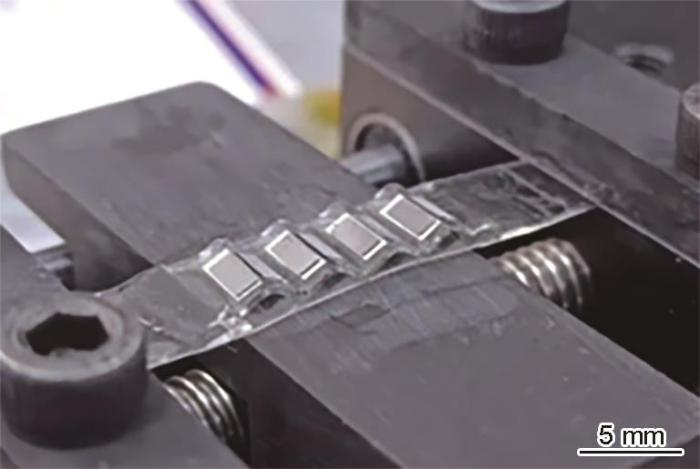

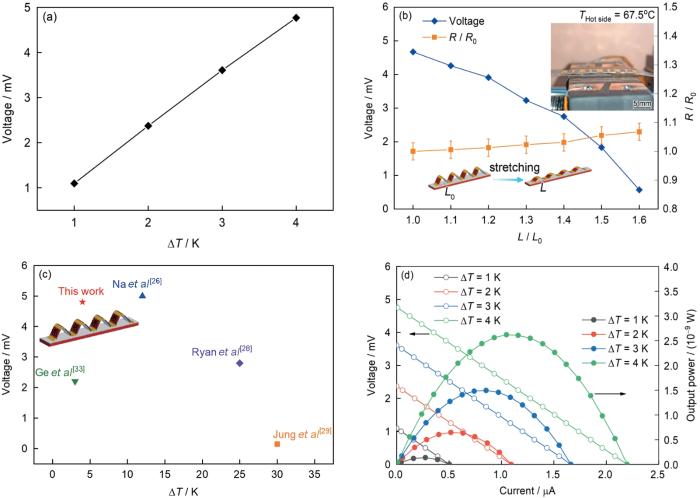

对柔性、可拉伸变形微型热电器件的温差发电性能进行表征,结果如图9所示。通过四线法测量微型柔性热电器件的内阻约为2.2 kΩ。图9a显示了热电器件在不同温差(ΔT= 1、2、3和4 K)下输出电压的测试结果。由于制备器件所采用的p型和n型热电复合薄膜的Seebeck系数的绝对值(|α|)都比较高,当温差为4 K时,得到最大输出电压4.8 mV。图9b显示了器件热端温度为67.5℃时,输出电压与相对电阻(R / R0,R0与R分别为微型柔性热电器件在平面状态下和在弯曲状态下的电阻)随拉伸量变化的曲线,插图为器件拉伸形变示意图和在最大拉伸量(L / L0 = 1.6)下的实物图。随着拉伸量的增加,器件冷-热两端的实际高度逐渐降低,导致温差逐渐下降,器件的输出电压不断减小,但当器件达到最大拉伸量,仍伴随着0.57 mV的输出电压。且在整个拉伸过程中器件相对电阻变化不超过7%,表现出良好的可伸缩性。同时,该微型柔性TEG的发电性能优于部分文献[26,28,29,33]中报道的柔性TEG (见图9c),并与通过结构设计研制的柔性TEG (n型Bi2Te3和p型PEDOT薄膜)的发电性能处于同一水平[26]。

图9

图9

微型柔性热电器件发电性能

Fig.9

Power generation performances of the micro-flexible thermoelectric device

(a) output voltage generated by the micro-flexible thermoelectric device at different temperature differences (ΔT)

(b) changes of power generation performance during the stretching process of the device (Insets show schematic of the tensile deformation of the device and the physical picture of the device under the maximum tensile amount (L / L0 = 1.6),where L0 and L are the lengths of the micro-flexible thermoelectric device before and after stretching, respectively; R0 and R are the resistances of the micro-flexible thermoelectric device before and after stretching, respectively)

(c) normalized output voltages of the devices were compared to several literature data[26,28,29,33]

(d) curves of the output voltage (hollow symbols) and output power (solid symbols) of the micro-flexible thermoelectric device at different ΔT as a function of the output current

输出电压也可通过下式计算得出[5]:

式中,V0为输出电压;N为微型柔性热电器中热电单元的对数,本实验中N为4。

式中,P为器件的输出功率,I为输出电流,Rex为器件的电路外阻,Rin为器件的电路内阻。

由

由于Pmax随着温差的升高而增加,当ΔT = 4 K时,Pmax达到最大值约2.6 × 10-9 W,即最大功率密度3.9 × 10-9 W/cm2,表明该微型柔性热电器件实现了薄膜型器件对面外温差的利用,为柔性热电薄膜发电器件的研究提供了新思路。

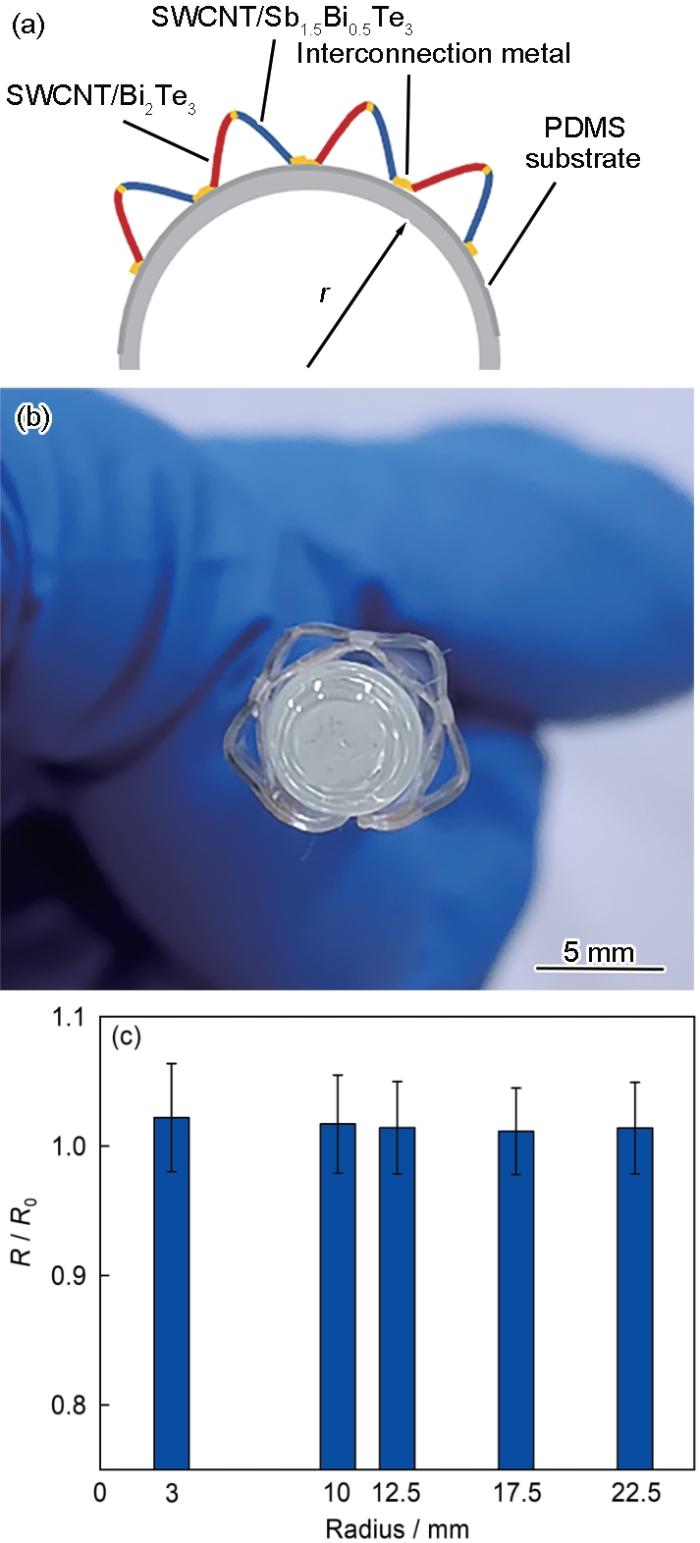

2.2.3 柔性测试

图10

图10

微型柔性热电器件的柔性测试图

Fig.10

Flexibility test charts of the micro flexible thermoelectric device

(a) schematic side view of the device during bend testing (r—bending radius)

(b) flexible demonstration of the device attached to glassware with a radius of 3 mm

(c) graph of the relative change in R / R0 of the device at different bending radii

3 结论

本工作利用SWCNT/Bi2Te3基热电复合薄膜材料良好的柔性及面内热电性能,从器件结构空间维度调控的角度出发,设计制作了柔性化、可拉伸变形的微型热电发电器件。利用预置拉伸的拱形PDMS基底将平面热电材料组装成三维结构热电器件,实现对面外温差的有效利用。该微型柔性热电发电器件在温差为4 K时,输出电压为4.8 mV,其最大输出功率达到2.6 × 10-9 W,功率密度为3.9 × 10-9 W/cm2,器件的最小弯曲半径为3 mm。这种微型柔性热电器件的制备工艺简单易行、成本低廉,为柔性热电薄膜发电器件的研制提供了新思路。

参考文献

Leaf‐inspired flexible thermoelectric generators with high temperature difference utilization ratio and output power in ambient air

[J].

Thermoelectric devices: A review of devices, architectures, and contact optimization

[J].

Advanced thermoelectric design: From materials and structures to devices

[J].

Rationally designing high-performance bulk thermoelectric materials

[J].There has been a renaissance of interest in exploring highly efficient thermoelectric materials as a possible route to address the worldwide energy generation, utilization, and management. This review describes the recent advances in designing high-performance bulk thermoelectric materials. We begin with the fundamental stratagem of achieving the greatest thermoelectric figure of merit ZT of a given material by carrier concentration engineering, including Fermi level regulation and optimum carrier density stabilization. We proceed to discuss ways of maximizing ZT at a constant doping level, such as increase of band degeneracy (crystal structure symmetry, band convergence), enhancement of band effective mass (resonant levels, band flattening), improvement of carrier mobility (modulation doping, texturing), and decrease of lattice thermal conductivity (synergistic alloying, second-phase nanostructuring, mesostructuring, and all-length-scale hierarchical architectures). We then highlight the decoupling of the electron and phonon transport through coherent interface, matrix/precipitate electronic bands alignment, and compositionally alloyed nanostructures. Finally, recent discoveries of new compounds with intrinsically low thermal conductivity are summarized, where SnSe, BiCuSeO, MgAgSb, complex copper and bismuth chalcogenides, pnicogen-group chalcogenides with lone-pair electrons, and tetrahedrites are given particular emphasis. Future possible strategies for further enhancing ZT are considered at the end of this review.

A flexible thermoelectric device based on a Bi2Te3-carbon nanotube hybrid

[J].

Fiber-based flexible thermoelectric power generator

[J].

Flexible thermoelectric materials and devices

[J].

Investigation of CNTs-Bi2Te3 hybrid thermoelectric thin film materials and devices

[D].

碳纳米管-碲化铋复合热电薄膜材料与器件的制备和性能研究

[D].

Investigation on the thermoelectric performance of flexible Bi2Te3/SWCNT hybrids and devices

[D].

柔性Bi2Te3/SWCNT复合热电薄膜材料及器件性能研究

[D].

Printed flexible thermoelectric generators for use on low levels of waste heat

[J].

Flexible thermoelectric generator for human body heat energy harvesting

[J].

Flexible layer-structured Bi2Te3 thermoelectric on a carbon nanotube scaffold

[J].

Nanostructured thermoelectrics

[J].

Self-powered wearable pressure sensing system for continuous healthcare monitoring enabled by flexible thin-film thermoelectric generator

[J].

Flexible thermoelectric materials and generators: Challenges and innovations

[J].

High-performance shape-engineerable thermoelectric painting

[J].Output power of thermoelectric generators depends on device engineering minimizing heat loss as well as inherent material properties. However, the device engineering has been largely neglected due to the limited flat or angular shape of devices. Considering that the surface of most heat sources where these planar devices are attached is curved, a considerable amount of heat loss is inevitable. To address this issue, here, we present the shape-engineerable thermoelectric painting, geometrically compatible to surfaces of any shape. We prepared Bi2Te3-based inorganic paints using the molecular Sb2Te3 chalcogenidometalate as a sintering aid for thermoelectric particles, with ZT values of 0.67 for n-type and 1.21 for p-type painted materials that compete the bulk values. Devices directly brush-painted onto curved surfaces produced the high output power of 4.0 mW cm(-2). This approach paves the way to designing materials and devices that can be easily transferred to other applications.

Binary‐phased nanoparticles for enhanced thermoelectric properties

[J].

Flexible thermoelectric materials and device optimization for wearable energy harvesting

[J].

Structural design of a flexible thermoelectric power generator for wearable applications

[J].

Recyclable, healable, and stretchable high-power thermoelectric generator

[J].

Flexible thermoelectric materials and devices: From materials to applications

[J].

Organic flexible thermoelectric generators: From modeling, a roadmap towards applications

[J].

To enhance the performance of n-type organic thermoelectric materials

[J].

Organic thermoelectric materials: Emerging green energy materials converting heat to electricity directly and efficiently

[J].

Kirigami-based stretchable, deformable, ultralight thin-film thermoelectric generator for BodyNET application

[J].

Preparation of bismuth telluride films with high thermoelectric power factor

[J].

Paper-based origami flexible and foldable thermoelectric nanogenerator

[J].

All-organic textile thermoelectrics with carbon-nanotube-coated n-type yarns

[J].Thermoelectric textiles that are able to generate electricity from heat gradients may find use as power sources for a wide range of miniature wearable electronics. To realize such thermoelectric textiles, both p- and n-type yarns are needed. The realization of air-stable and flexible n-type yarns, i.e., conducting yarns where electrons are the majority charge carriers, presents a considerable challenge due to the scarcity of air-stable n-doped organic materials. Here, we realize such n-type yarns by coating commercial sewing threads with a nanocomposite of multiwalled carbon nanotubes (MWNTs) and poly(-vinylpyrrolidone) (PVP). Our n-type yarns have a bulk conductivity of 1 S cm and a Seebeck coefficient of -14 μV K, which is stable for several months at ambient conditions. We combine our coated n-type yarns with poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate) (PEDOT:PSS) dyed silk yarns, constituting the p-type component, to realize a textile thermoelectric module with 38 n/p elements, which are capable of producing an open-circuit voltage of 143 mV when exposed to a temperature gradient of 116 °C and a maximum power output of 7.1 nW at a temperature gradient of 80 °C.

Scalable and facile synthesis of stretchable thermoelectric fabric for wearable self-powered temperature sensors

[J].

Flexible and transparent organic-inorganic hybrid thermoelectric modules

[J].

Recent advances in flexible thermoelectric films and devices

[J].

Controlled growth of semiconducting and metallic single-wall carbon nanotubes

[J].Single-wall carbon nanotubes (SWCNTs) can be either semiconducting or metallic depending on their chiral angles and diameters. The use of SWCNTs in electronics has long been hindered by the fact that the as-prepared SWCNTs are usually a mixture of semiconducting and metallic ones. Therefore, controlled synthesis of SWCNTs with a uniform electrical type or even predefined chirality has been a focus of carbon nanotube research in recent years. In this Perspective, we summarize recent progress on the controlled growth of semiconducting and metallic SWCNTs by in situ selective etching and by novel catalyst design. The advantages and mechanisms of these approaches are analyzed, and the challenges are discussed. Finally, we predict possible breakthroughs and future trends in the controlled synthesis and applications of SWCNTs.

Meters-long, sewable, wearable conductive polymer wires for thermoelectric applications

[J].