随着我国航空工业的高速发展,对飞机性能和结构承载的要求越来越高。在质量上,飞机80%以上的重要承力构件为锻件,飞机结构件整体化水平的提升对锻件的组织和性能均匀性及稳定性要求也愈加严格,而国内模锻件尤其是航空模锻件起步较晚,在锻件设计和成形组织均匀性控制等方面与国外有较大差距[1~3]。钛合金具有高比强度、高疲劳强度、良好的耐蚀性,在航空结构模锻件材料中具有不可替代的作用[4,5],基于损伤容限原则设计的高强韧TC21钛合金(名义成分为Ti-6Al-3Mo-2Sn-2Zr-2Nb-1.5Cr-0.1Si,质量分数,%),具有较高抗拉强度(Rm ≥ 1100 MPa)、高断裂韧性(KIC ≥ 70 MPa·m1/2)和较低的疲劳裂纹扩展速率(与TC4相当),已成功用于飞机机体、框架、横梁等关键承力结构锻件[6]。

以往对TC21合金的研究多集中在热变形(锻造、轧制)工艺及热处理制度等对显微组织和力学性能的影响。Wang等[7]将热轧与单次时效结合,热轧导致初生α相(αp)细化,使合金强度升高,而时效导致次生α相(αs)析出,由于αs/β界面强化和αp与β转变组织(βtrans)间的协调变形作用,使合金在强度升高的同时保持一定的延展性。Shao等[8]通过固溶+时效(900℃、1 h、缓冷(BC) + 550℃、4 h、空冷(AC))处理,获得了高强高韧(屈服强度1100 MPa,抗拉强度1220 MPa,面缩33%,延伸率8.5%,断裂韧性63.5 MPa·m1/2)的最佳组合。Lei等[9]研究了不同热处理制度对TC21合金冲击功的影响,发现裂纹萌生能占冲击能量的大部分。周晓虎等[10]采用准β锻造工艺,获得的网篮组织具有较高的抗拉强度(1100 MPa)和断裂韧性(大于90 MPa·m1/2)。Shi等[11]通过不同参数的近等温锻造和固溶时效处理,发现随残余β基体含量的增加,αs/β界面数量增加而强度增加,且当粗大片状α相的长轴与最大剪切应力方向平行时,合金塑性降低。对TC21合金锻后空冷再进行900℃、1 h、AC + 590℃、4 h、AC热处理可以获得优良综合性能,且随着交叉分布的粗大α片层厚度的增加,合金强度降低而断裂韧性提高[12]。对于其他类型钛合金的(近) β锻造工艺也有较多研究[13,14],但针对模锻件等效应变的不同而导致组织和性能差异的研究较少,尤其是热变形及热处理工艺研究多集中于小规格锻件组织和性能的影响,对受尺寸效应造成的工程化大规格锻件的整体均匀性,特别是具有复杂变截面锻件的组织和性能的差异关注较少。不同截面的性能差异,包括同一位置的各向异性,会导致受力不均,影响锻件的可靠性和稳定性。

除了显微组织上的差异,锻件中受不同等效应变影响造成的织构强弱也是影响力学性能及其各向异性的重要因素,特别是含有hcp结构的钛合金,α相中相对较少的滑移系使得晶体取向对合金力学性能的影响较为显著。由于β锻造工艺主要发生在单相区,合金冷却至两相区时,受Burgers取向关系(即(110) β //(0001) α 、<111> β //<11

基于上述2个问题,为了解模锻件等效应变与组织和力学性能间的联系以及共存的残余β相织构与转变α相织构对锻件性能尤其是各向异性的影响,本工作对TC21合金采用常规的β锻造工艺,结合后续固溶+时效热处理,对锻件不同应变处的显微组织和力学性能进行细致对比分析,结合两相织构结果讨论了2种取向的拉伸和冲击各向异性,综合研究宏观流线、β晶粒形态、α相尺寸和两相织构等因素对变截面模锻件力学性能的影响规律。

1 实验方法

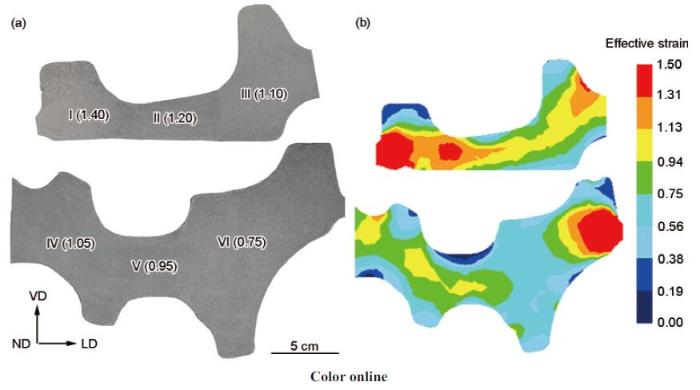

实验所用材料为多火次锻造的TC21合金变截面模锻件,其中最后一火次为β单相区(相变温度Tβ = 970℃)锻造,锻后整体进行固溶+时效处理(910℃、2 h、AC + 575℃、6 h、AC)。模锻件长度超过500 mm,为便于腐蚀,将其切割为两件,表层取5 mm薄片,研磨后置于Kroll's腐蚀剂中浸蚀5 min,低倍形貌见图1a,锻件形状复杂,具有非对称面,截面落差大,肉眼未发现冶金缺陷,无粗晶,流线随形。在薄片端部切取试样,测试得到的化学成分(质量分数,%)为:Al 6.21,Mo 2.78,Nb 1.98,Sn 2.06,Zr 2.17,Cr 1.56,Si 0.02,Fe 0.08,Ti余量。图1b为利用Deform软件模拟得到的等效应变(ε,简称应变)分布图。可以发现锻件整体应变分布不均匀,两端红色区域应变高达1.50,主要是因为锻件两端受挤压变形较为剧烈,边部部分蓝色区域为变形困难区,对锻件服役性能影响不大,本文不做重点讨论。除上述区域外,截面越窄处,应变越高,应变多集中于0.75~1.20。

图1

图1

TC21合金模锻件的低倍形貌和等效应变分布图

Fig.1

Macrostructures (a) and effective strain distributions (b) of TC21 alloy die forgings (Numbers in Fig.1a show the effective strains at locations I-VI, VD—vertical direction, ND—normal direction, LD—lateral direction)

为获得锻件整体组织及性能的变化趋势,依次选择应变分别为1.40、1.20、1.10、1.05、0.95和0.75的6处位置(图1a),切取金相试块,经机械研磨、抛光、腐蚀后,在Axiovert 200 MAT金相显微镜(OM)及TESCAN MIRA3场发射扫描电镜(SEM)上进行组织观察,为便于比较晶粒尺寸的差异,在OM像中用虚线绘出原始β晶粒边界;利用Oxford C-Nano电子背散射衍射(EBSD)表征不同位置的组织及织构特征;由于原始β晶粒尺寸较大,相对于EBSD,采用X射线衍射(XRD)可得到更为全面准确的织构信息,在D8 Discover型XRD上采用Cu靶Kα 辐射源测定宏观织构,利用TEXEval V2.0软件进行归一化计算得到相应的(反)极图和取向分布函数(orientation distribution function,ODF)图;拉伸实验依照GB/T 228.1—2010,取直径为5 mm、标距为25 mm的试样,在配有MakroXtens自动引伸计的Zwick Z050电子万能试验机上进行测试,应变速率为3.3 × 10-7 s-1,Charpy U型缺口冲击试样尺寸为10 mm × 10 mm × 55 mm,横向(lateral direction,LD)试样的开口面为VD (vertical direction)-LD面,法向(normal direction,ND)试样的开口面为ND-LD面,在Zwick/Roell HIT450P冲击试验机上进行测试,并采集载荷-位移曲线,室温下每组实验至少测2支平行试样并取平均值,最后利用SEM进行拉伸和冲击断口观察。

2 实验结果

2.1 TC21合金模锻件的显微组织

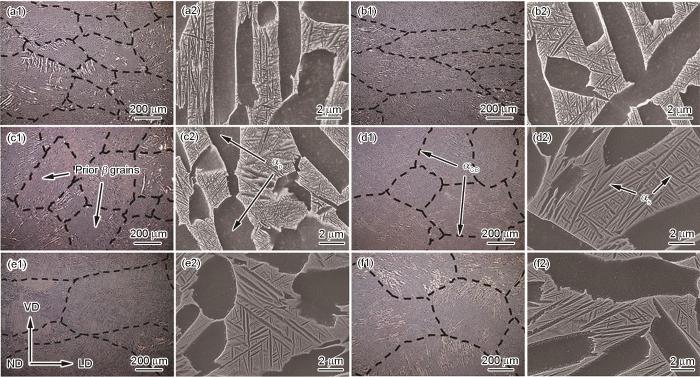

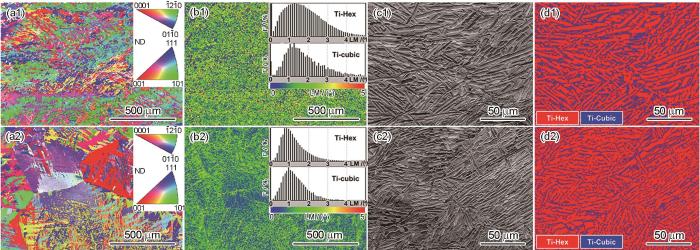

图2为TC21模锻件不同位置处的OM和SEM像。由OM像可看出,单相区锻造后的TC21合金为典型的网篮组织,高应变时的原始β晶粒受锻压呈扁平状(图2a1和b1),Ⅱ处流线明显,晶粒尺寸较小,长宽比约为2.5;应变低处晶粒近似呈等轴状(图2f1),晶粒尺寸较大。另外,SEM像包含片状初生α相(αp)和β转变组织(βt),βt包含细针状次生α相(αs)和残余β相。锻件经β单相区锻造,空冷过程中,将在β基体上析出α片层,在两相区固溶过程中片状αp进一步粗化,在固溶后空冷及时效过程中形成由针状αs和残余β相构成的βt。另外,低应变下显微组织(图2d2~f2)中的针状αs相对高应变(图2a2~c2)具有明显的粗化,这是因为Ⅳ~Ⅵ处截面较大,热处理后冷速较慢,αs得以粗化。

图2

图2

TC21模锻件不同位置处的OM和SEM像

Fig.2

OM (a1-f1) and SEM (a2-f2) images at positions Ⅰ (a1, a2), Ⅱ (b1, b2), Ⅲ (c1, c2), Ⅳ (d1, d2), Ⅴ (e1, e2), and Ⅵ (f1, f2) in TC21 die forgings (αp—primary α phase, αGB—grain boundary α phase, αs—secondary α phase)

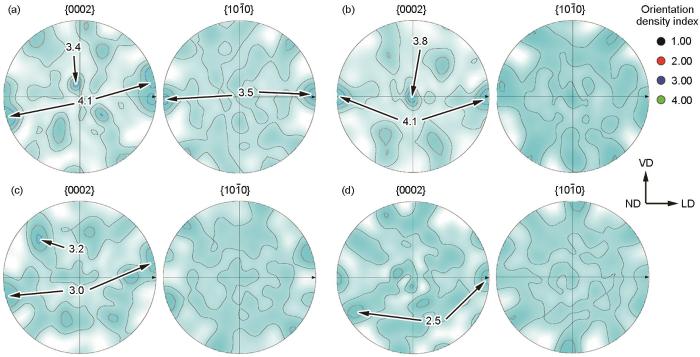

2.2 TC21合金模锻件各相组成的织构演化

图3

图3

图1a中Ⅱ~Ⅵ处的α相{0002}和{10

Fig.3

Pole figures of {0002} and {10

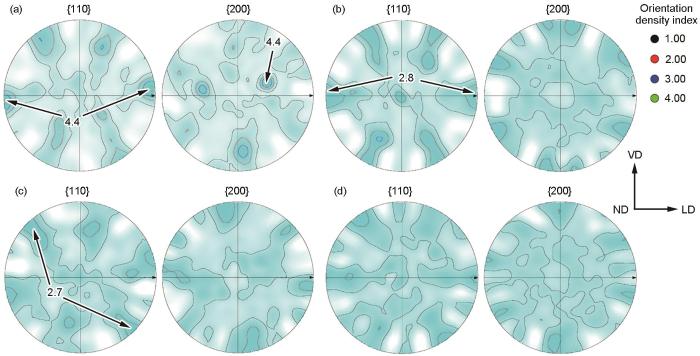

图4

图4

图1a中Ⅱ~Ⅵ处的β相{110}和{200}极图

Fig.4

Pole figures of {110} and {200} for the β phase at positions Ⅱ (a), Ⅲ (b), Ⅴ (c), and Ⅵ (d) in Fig.1a

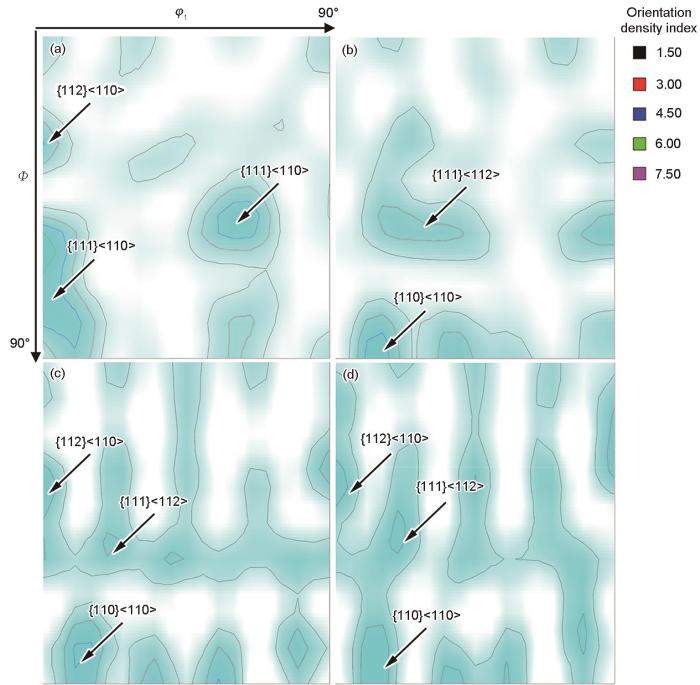

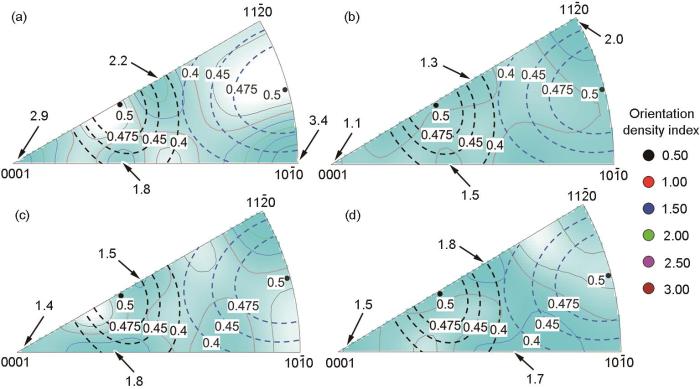

ODF图被广泛用于材料变形过程中β相的织构演化研究,取Euler角φ2 = 45°的ODF图进一步探究锻件不同位置的β相织构演化,结果如图5所示。可以看出,Ⅱ处出现取向密度指数较高的α-fiber{112}<110> (约4.6)和{111}<110> (约7.2)织构,后者取向宽泛,部分与{110}<110>重叠,γ-fiber{111}<110>织构取向密度指数达到5.7 (图5a);Ⅲ处的织构类型变得单一且集中,保留了α-fiber {110}<110>织构,取向密度指数为5.3,α-fiber {112}<110>织构消失,γ-fiber织构变得集中,如取向密度指数3.5的{111}<112>织构(图5b);Ⅴ和Ⅵ处的织构类型相似(图5c和d),α-fiber {112}<110>和{110}<110>的取向密度指数均在4.0以上,另外均有较为宽泛的γ-fiber织构。可以发现,随应变增加至1.20,β相的晶体取向大部分转变为<110>丝织构,这可能是因为平面应变过程中<110>织构具有较高的晶体学稳定性[24]。

图5

图5

图1a中Ⅱ~Ⅵ处的β相的取向分布函数(ODF)图(φ2 = 45°)

Fig.5

Sections (φ2 = 45°) of orientation distribution function (ODF) maps of β phase at positions Ⅱ (a), Ⅲ (b), Ⅴ (c), and Ⅵ (d) in Fig.1a (φ1, φ2, Φ—Euler angles)

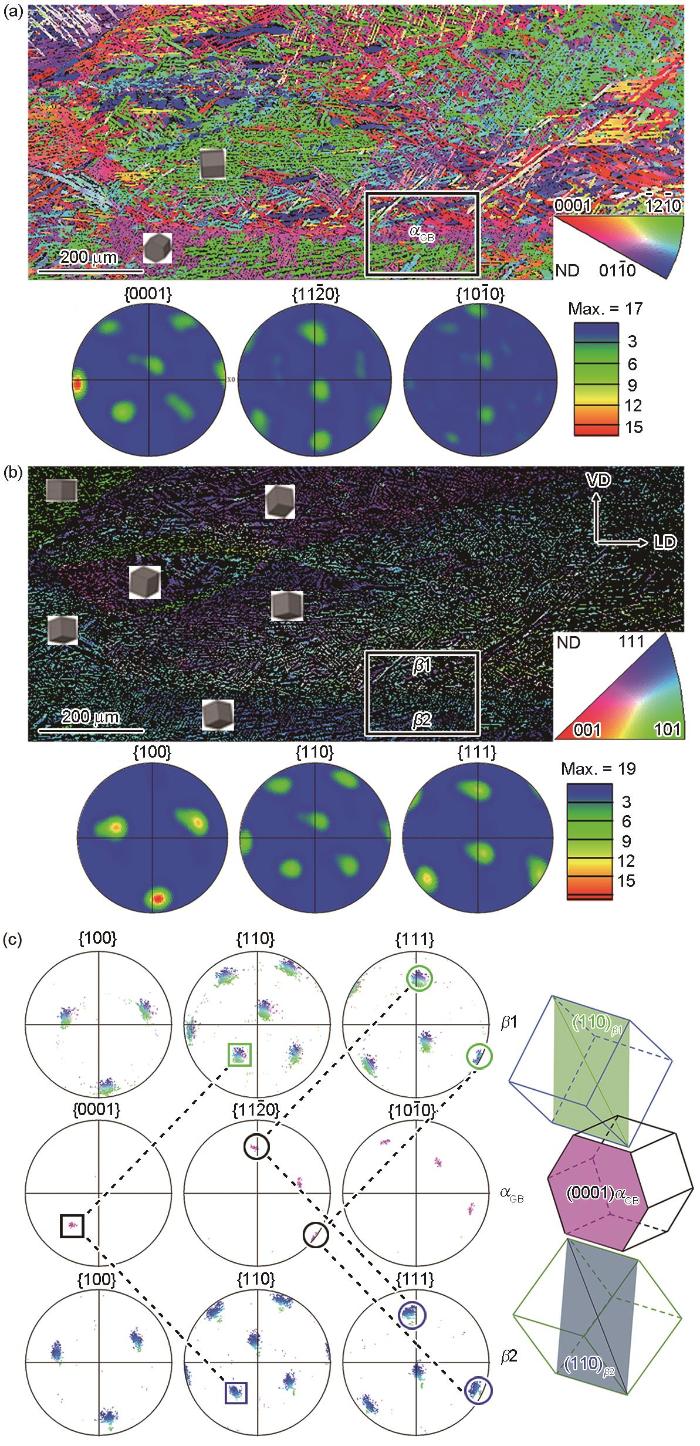

从XRD极图可看出β锻TC21合金热处理后的两相基本符合Burgers关系中的{110} β //{0002} α,EBSD可进一步表征Burgers关系中的<111> β //<11

图6

图6

图1a中Ⅱ处低倍下α + β取向图、极图和αGB与两侧β晶粒的Burgers关系分析

Fig.6

Analyses of low magnified orientation maps and pole figures of α + β and the Burgers orientation relationship between αGB and β grains on both sides at position Ⅱ in Fig.1a

(a) α orientation map and the corresponding pole figures

(b) β orientation map and the corresponding pole figures

(c) pole figures showing that αGB maintains the Burgers orientation relationship with both β1 and β2 in the box

表1 热变形及热处理过程中的TC21合金各相组成织构演化过程

Table 1

| Phase | β forging | α + β solution treatment | Aging treatment |

|---|---|---|---|

| β matrix | <110>//LD | Weaker | Preserved |

| αp | Grain boundary α phase texture | Preserved | Preserved |

| Intragranular α phase texture | Stronger | Preserved | |

| αs | - | - | Several variants (Overlaps αp) |

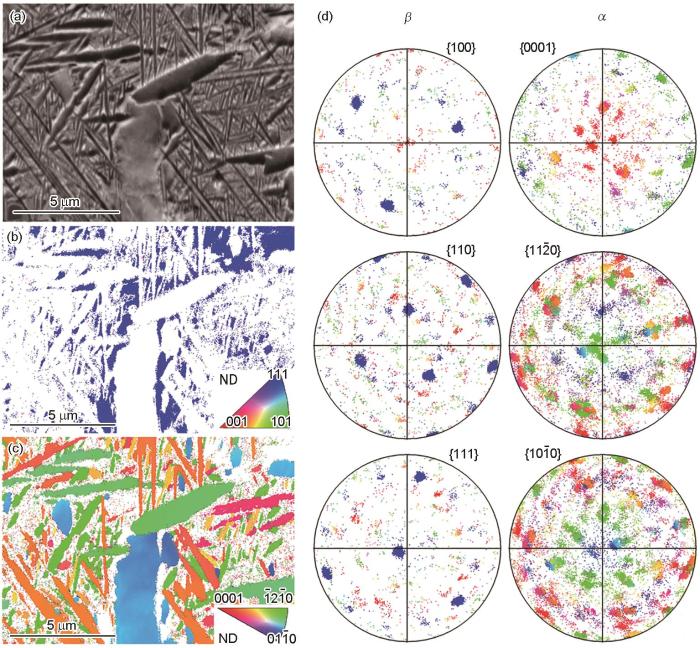

进一步分析时效过程中析出的αs相的晶体取向,利用25 nm步长扫描得到的高倍EBSD像如图7所示。有研究[25]表明,αp的大量存在会显著影响其周围的αs相,使之形成相近的取向。以往的研究[27~29]多采用调控两相区热变形及热处理工艺,获得具有等轴α和片层α的双态组织并研究其取向关系。Leo Prakash等[28]发现αp与β相符合Burgers关系,且αp织构组分与αs的主要织构组分相近;Germain等[29]认为在相变过程中,αp为αs提供了形核位置;Lei等[27]发现TC21合金在两相区热变形会破坏αp与β相间的Burgers关系,而时效析出的αs与β基体符合Burgers关系。本工作中涉及的αs尺寸为纳米级,不易大面积获得其织构信息,但可以推测其时效过程析出的αs取向会受附近的αp取向影响,结合两相极图,说明时效过程中的“蓝色”原始β晶粒析出了多种αs取向,其中也包括与αp重叠的“绿色”和“红色”αs变体(图7d),说明αs相在与β相保持Burgers关系的同时,也会析出与邻近αp相一致的取向,同时会有新的取向形成。由此,假定理想状态下,TC21合金经β锻造形成了<110> β//LD强织构,固溶时效热处理后最终会得到<110> β//LD较强织构和{0002} α 2种较弱织构(2种主要变体),将αs的取向演化过程汇总并完善于表1。

图7

图7

图1a中Ⅱ处高倍SEM像和α + β取向图及相应极图

Fig.7

High magnified SEM image and corresponding α + β orientation maps and pole figures at position Ⅱ in Fig.1a

(a) microstructure of the αp and βt (b) corresponding β orientation map

(c) corresponding α orientation map (d) pole figures

2.3 TC21合金模锻件的室温力学性能

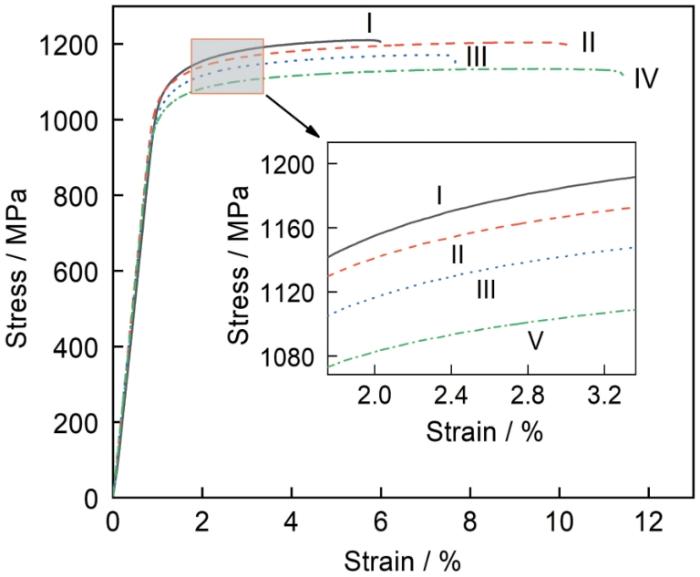

图8为TC21合金模锻件不同位置沿LD的室温拉伸曲线。由图可明显看出不同位置沿LD拉伸的强度变化趋势,锻件整体屈服强度在1000 MPa以上,表2给出了TC21合金模锻件不同位置沿LD的拉伸和冲击性能变化趋势。可见,由Ⅵ到Ⅰ处,随着应变增大,强度呈明显的升高趋势,Ⅰ处屈服强度高出Ⅵ处约70 MPa。整体延伸率在5.0%~11.3%,断面收缩率在11.0%~16.0%,冲击功在27.0 ~ 40.0 J。一般随着应变增大,强度升高的同时塑韧性会有所降低,但由Ⅲ到Ⅱ处,应变由1.10增大到1.20,屈服强度由(1042 ± 6) MPa增加到(1063 ± 5) MPa,强度增加约20 MPa,同时塑韧性仍保持相当水平;同样地,由Ⅵ到Ⅴ处,应变由0.75增大到0.95,抗拉强度升高的同时,塑韧性几乎在锻件中保持最高,这可能与锻造均匀变形区域有关,试样受力时保持了良好的均匀协调变形。由图2也可以看出,Ⅱ与Ⅴ处的β晶粒变形较为均匀,宏观流线较为清晰(图1a)。

图8

图8

TC21合金模锻件不同位置沿LD的室温拉伸曲线

Fig.8

Room temperature tensile curves of TC21 alloy die forgings along LD at different positions (Inset shows the details in the box of the original curves)

表2 TC21合金模锻件不同位置沿横向(LD)的室温力学性能

Table 2

| Position | Rp0.2MPa | RmMPa | A % | Z % | I J |

|---|---|---|---|---|---|

| Ⅰ | 1084 ± 3 | 1210 ± 5 | 5.0 ± 3.3 | 11.0 ± 4.3 | 27.0 ± 1.5 |

| Ⅱ | 1063 ± 5 | 1198 ± 10 | 9.0 ± 1.5 | 14.0 ± 2.5 | 33.0 ± 2.0 |

| Ⅲ | 1042 ± 6 | 1171 ± 7 | 8.0 ± 2.4 | 11.5 ± 3.2 | 32.0 ± 1.0 |

| Ⅳ | 1040 ± 6 | 1156 ± 6 | 8.8 ± 1.5 | 14.5 ± 3.5 | 36.0 ± 2.5 |

| Ⅴ | 1014 ± 2 | 1137 ± 3 | 11.3 ± 1.7 | 16.0 ± 2.4 | 40.0 ± 2.0 |

| Ⅵ | 1010 ± 4 | 1125 ± 4 | 8.0 ± 2.0 | 15.5 ± 2.5 | 38.0 ± 1.5 |

3 分析讨论

3.1 锻件不同位置的性能差异

根据Hall-Petch关系,晶粒尺寸是影响材料强度的关键因素之一,晶粒细化有利于同步提升材料的强度和塑性,且多尺度结构中αs产生的界面强化对材料强度也有重要影响[3]。Wen等[30]研究了TC21合金多尺度结构与强韧性的关系,发现当片层组织中αs宽度增加时,强度降低,塑性和断裂韧性升高。Ye等[31]发现TC21合金强度随时效温度升高而下降,是由β晶粒、α集束等尺寸不变而αs厚度增加引起的。因此当锻件在应变较低(如Ⅴ处)时,由于β晶粒尺寸较大、αs更为粗化使得锻件强度较低而塑韧性稍高。而针对锻件Ⅱ处良好的强塑性匹配,从低倍(图1a)和OM (图2b1)形貌可以看到,Ⅱ处晶粒为扁平状,沿LD方向加载时,拉伸截面内晶粒数量较多,每个晶粒塞积的位错数量较少,应力集中引起的开裂机会较少,裂纹不易萌生也不易传播(晶界曲折多),因此断裂前可承受更多的变形量和吸收更多的能量。

除晶粒形态外,应变造成的织构强弱对拉伸强度也起着重要作用。α相的c轴与加载方向的夹角会影响拉伸过程中滑移系的启动能力,进而影响合金的变形抗力,钛合金变形的难易程度可大致利用基面和柱面滑移的Schmid因子来判断,因为基面<a>型、棱柱<a>型、锥面<a>型和锥面<c + a>型滑移系的临界剪切应力比约为1∶0.9∶1.2∶2.8。基面和柱面滑移的Schmid因子与c轴和加载方向的夹角θ存在如下关系[32]:当θ = 0°时,基面和柱面滑移系的Schmid因子为0,滑移系难激活,此时拉伸强度高,随着加载方向偏离c轴,θ逐渐增大,基面和柱面滑移系的Schmid因子逐渐增大,拉伸强度逐渐降低。因此随着应变增大,由Ⅵ到Ⅲ处,c轴//LD织构的取向密度指数由2.5增加到4.1 (图3),屈服强度由(1010 ± 4) MPa增加到(1042 ± 6) MPa (表2),增幅约30 MPa,而Ⅱ处的{0002}极图与Ⅲ处没有明显变化(图3a),其含有的强<10

研究[25]表明,变形引起的亚结构是滑移系启动和位错运动的首要阻碍,也是影响强度的重要因素。Ⅱ和Ⅵ处的EBSD分析如图9所示。Ⅱ处的晶粒受挤压变形较为严重(图9a1),而Ⅵ处为近等轴晶粒(图9a2),这种晶粒形态与OM像(图2b1和f1)相符。局部取向差(local misorientation,LM)表征的是晶内取向差,通常取向差处于1°~5°时,表明晶内存在亚结构。Ⅱ处LM图整体呈现黄绿色,LM接近正态分布,晶内亚结构比例约为0.75 (图9b1),而Ⅵ处的LM图中小于1°的比例明显增多,晶内亚结构比例约0.55,LM图整体呈现浅绿色(图9b2)。此外,由高倍下的BSE像及相比例分布可知,Ⅱ处的α相占比约74% (图9c1和d1),低于Ⅵ处的α相占比84% (图9c2和d2),是因为Ⅵ处相对低的冷速使得αp析出较多,αp的增多使得合金能够承受更多的塑性变形从而保持较高的塑韧性。

图9

图9

图1a中Ⅱ和Ⅵ处的α + β取向图、局部取向差、BSE像及两相比例分析

Fig.9

Analyses of α + β orientation maps (a1, a2), local misorientations (LMs) (b1, b2), BSE images (c1, c2), and phase proportions (d1, d2) at positions Ⅱ (a1-d1) and Ⅵ (a2-d2) in Fig.1a (Insets in Figs.9b1 and b2 show the frequency (F) distributions of LM)

3.2 锻件高应变处的力学性能各向异性

测得Ⅱ和Ⅴ处分别沿LD和ND的拉伸和冲击性能见表3。高应变Ⅱ处沿LD的拉伸强度比ND高约20 MPa,且塑韧性优于ND,强度各向异性更加明显;低应变Ⅴ处沿不同方向的拉伸强度基本相当,而沿LD的塑韧性同样优于ND。对于两相钛合金模锻件,呈现扁平状的原始β晶粒和两相织构使得塑性变形、断裂模式上存在差异,进而导致力学性能的各向异性。

表3 图1a中Ⅱ和Ⅴ处沿不同方向的拉伸和冲击性能

Table 3

| Position | Direction | Rp0.2 / MPa | Rm / MPa | A / % | Z / % | I / J |

|---|---|---|---|---|---|---|

| Ⅱ | LD | 1063 ± 5 | 1198 ± 10 | 9.0 ± 1.5 | 14.0 ± 2.5 | 33.0 ± 2.0 |

| ND | 1043 ± 3 | 1185 ± 5 | 8.0 ± 2.0 | 10.0 ± 3.5 | 30.9 ± 2.1 | |

| Ⅴ | LD | 1014 ± 2 | 1137 ± 3 | 11.3 ± 1.7 | 16.0 ± 2.4 | 40.0 ± 2.0 |

| ND | 1013 ± 3 | 1138 ± 4 | 6.5 ± 2.5 | 11.0 ± 3.0 | 36.0 ± 3.5 |

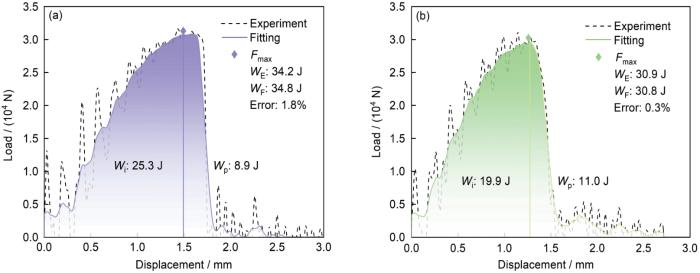

选取各向异性最为显著的高应变Ⅱ处,观察其不同方向的冲击和拉伸断口并分析其断裂机制的差别。图10为Ⅱ处分别沿LD和ND的示波冲击曲线,黑线为实时测试数据,对其进行拟合,WE和WF分别代表实验和拟合冲击功,较小的误差说明拟合度较高。整个冲击断裂过程约为0.3 s,LD和ND试样达到的最大载荷(Fmax)分别为30.73和29.59 kN,对应位移由1.49 mm减小到1.28 mm,表明LD试样韧性优于ND (表3)。与拉伸塑性变化趋势不同的是,在冲击载荷作用下,由于缺口根部的应力集中,载荷急剧增加,达到最大值后,载荷在试样没有明显屈服阶段的情况下快速下降。一般将最大载荷左侧区域的曲线积分定义为裂纹萌生能(crack initiation energy,Wi),表示固有的裂纹萌生阻力,载荷达到最大值时,初始裂纹形成,之后进一步扩展。将载荷最大值右侧的曲线积分定义为裂纹扩展能(crack propagation energy,Wp),表示抵抗裂纹扩展的能力。LD试样的Wi和Wp分别为25.3和8.9 J (图10a),裂纹萌生能占总冲击功能量的74%,而ND试样的裂纹萌生能(Wi = 19.9 J)占总冲击功能量(WF = 30.8 J)的64%,扩展能(11.0 J)占比相较LD试样有所增加(图10b)。趋势相同的是2种试样的冲击功均以裂纹萌生能为主,其他研究[9,34]也表明冲击实验中吸收的能量主要消耗在抗裂纹形成阶段。

图10

图10

图1a中Ⅱ处沿不同方向的典型冲击曲线

Fig.10

Typical displacement-load curves at position Ⅱ in Fig.1a along LD (a) and ND (b) (Fmax—maximum load, WE—impact energy obtained from the experimental curve, WF—impact energy obtained by fitting the curve, Wi—crack initiation energy, Wp—crack propagation energy)

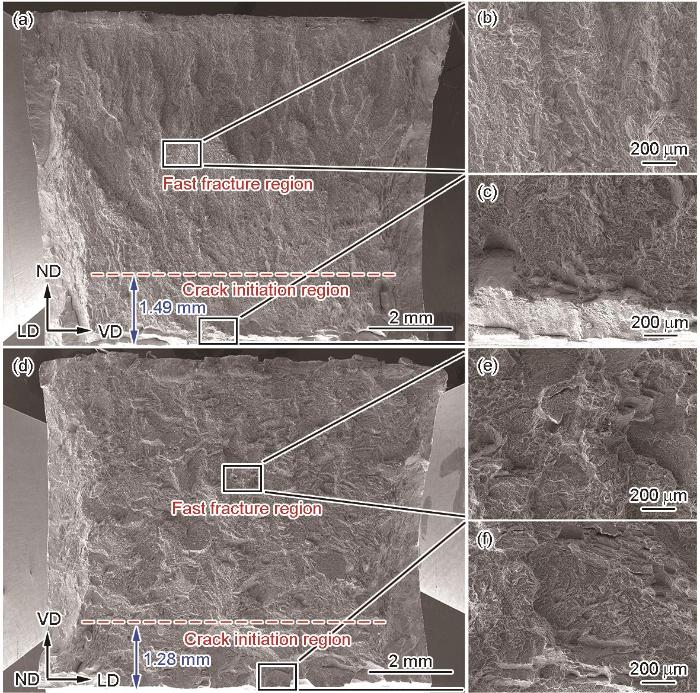

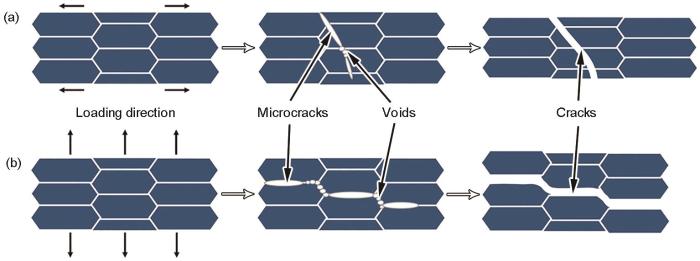

对断口形貌的观察有助于理解不同方向的试样裂纹萌生与扩展阶段的差异。图11为Ⅱ处LD和ND试样的典型冲击断口形貌。LD试样(图11a~c)在裂纹形成区产生较大起伏和较多平行于VD的二次裂纹,主要消耗了萌生能,之后的快速断裂区以大量河流状形貌为主要特征,河流状形貌通常预示着裂纹的迅速扩展,但这种放射性河流状形貌与分层现象也有一定相似之处。Chen等[14]在β锻制备的亚稳β钛合金中阐述了这一分层现象,原始β晶粒通过分层降低了总应力的应力分量,使得单层韧带处于平面应力状态,而平面应力状态的临界应力强度高于平面应变状态,因此可以提供更多的能量释放率以及促进裂纹尖端的钝化,从而获得较高韧性。LD试样没有观察到明显的分层裂纹,主要是因为两相钛合金在锻造冷却过程中发生了大量相转变,原始β晶粒无法像(亚稳) β钛合金一样较为完整地保留。ND试样发生的多是流线层之间的断裂,在裂纹形成区可以发现准解理面的形成(图11d),表面能较低,裂纹沿着层间弱界面扩展,使得总冲击功低于LD试样,而高倍下的快速断裂区依然有层间微裂纹(图11e)和深浅不一的韧窝(图11f),相对LD试样较为平坦的快速断裂区(图11b),前者的裂纹扩展能比例有所增加。

图11

图11

图1a中Ⅱ处沿不同方向的典型冲击断口形貌

Fig.11

Typical impact fracture morphologies at position Ⅱ in Fig.1a along LD (a-c) and ND (d-f)

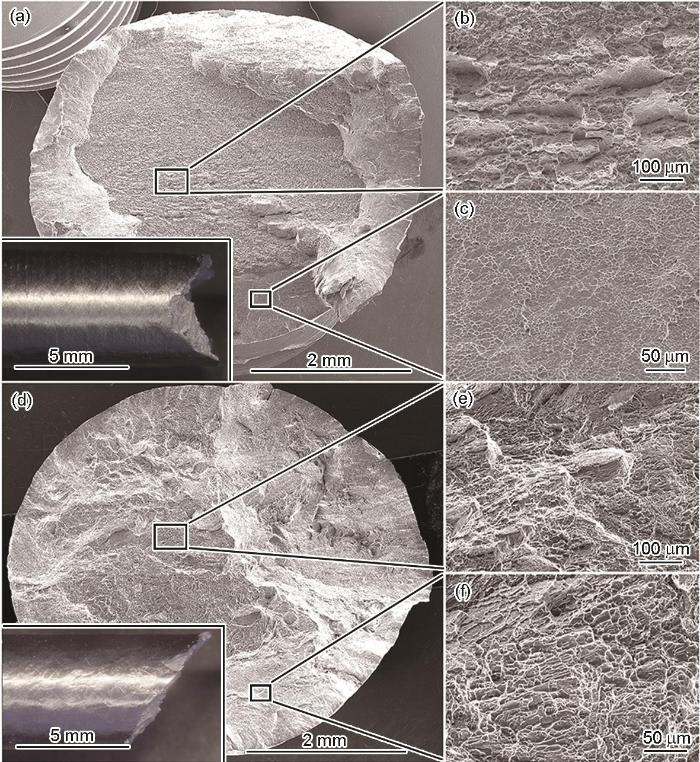

图12为Ⅱ处沿LD和ND的典型拉伸断口形貌。从拉伸断面的侧面宏观形貌可以观察到,LD试样发生了缩颈,断口截面及滑移带可视为与加载方向垂直,试样主要发生正应力断裂(图12a),而ND试样断口截面及滑移带与应力方向近似成45°夹角,发生明显的剪切变形和剪切断裂(图12d),由于45°截面上承受的最大剪切应力低于垂直拉伸方向截面上的最大正应力[25],可以判断ND试样强度低于LD试样,这与表3拉伸强度的各向异性一致。此外,LD试样受到的加载方向平行于宏观流线,并排的流线相互间也具有“分层提高强度”的作用,层间密集且深浅不一的韧窝表明LD试样具有良好的塑性(图12b和c)。ND试样的韧窝尺寸单一,主要表现为沿晶界断裂形成的撕裂棱(图12e和f)。

图12

图12

图1a中Ⅱ处沿不同方向的典型拉伸断口形貌

Fig.12

Typical tensile fracture morphologies at position Ⅱ in Fig.1a along LD (a-c) and ND (d-f) (Insets show the side macro-morphologies of the corresponding tensile fracture)

利用XRD测得Ⅱ和Ⅴ处分别沿LD和ND加载的反极图,并叠加基面(黑色线)和柱面(蓝色线)滑移的Schmid因子等高线,结果如图13所示。高应变Ⅱ处沿LD加载时表现为4处织构(图13a):(1) 靠近<10

图13

图13

图1a中Ⅱ和Ⅴ处分别沿LD和ND加载的反极图

Fig.13

Inverse pole figures at positions Ⅱ (a, b) and Ⅴ (c, d) in Fig.1a along LD (a, c) and ND (b, d) (The black and blue contour lines are the Schmid's factors for basal and prismatic slip in orientation triangle, respectively)

由图13可知,高应变Ⅱ处LD试样中易于变形的α相明显少于ND试样,有研究[15]认为,易于变形的α相越少,拉伸过程中应力越容易集中于某些易变形的α相,从而使得试样塑性较低。由此推测LD拉伸试样塑性应低于ND试样,但数据显示,LD试样具有良好的强塑性匹配,分析认为除α相因素外,流线中的原始β晶粒排布对强塑性匹配起到了重要作用。忽略晶内α片层在合金变形中的影响,原始β晶界可有效阻碍合金变形时位错的滑移穿过,进而影响合金的强塑性,绘制高应变Ⅱ处分别沿LD和ND的拉伸过程示意图(图14)。沿LD拉伸时的截面内晶粒数量明显多于沿ND方向,这种细晶强化是LD试样具有良好强塑性匹配的因素之一。另外当合金受力拉伸时,从发生塑性变形至完全断裂,期间的总塑性形变包含2部分:一部分为裂纹形核,裂纹容易在晶界及交汇等缺陷处形核,此时为塑性变形初期,另一部分发生在微裂纹连接及扩展期间,裂纹倾向于沿着45°的最大切应力方向扩展。当沿LD拉伸时(图14a),裂纹形核长大形成孔洞,孔洞连接产生更多微裂纹,微裂纹扩展受到晶界阻碍易发生偏折,容易出现贯穿晶粒现象,多次的裂纹偏折在宏观上易表现为正应力断裂(图12a),主裂纹扩展的阻力较大且扩展路径长度增加,形变因此更加充分,有缩颈现象,塑韧性表现良好;当沿ND拉伸时(图14b),裂纹的形核位置不变,但当微裂纹扩展时,由于应力方向几乎与晶界垂直,作为I型裂纹,应力做功几乎全部用于微裂纹的扩展,从而受到的阻力较小,裂纹主要在剪切应力作用下沿着原始β晶界扩展,发生剪切断裂(图12b),难以充分变形,故LD试样的塑性要高于ND试样。

图14

图14

图1a中Ⅱ处原始β晶粒沿不同方向的拉伸过程示意图

Fig.14

Schematics of tensile process of prior β grains at position Ⅱ in Fig.1a along LD (a) and ND (b)

4 结论

(1) TC21变截面模锻件因等效应变不同,流线及原始β晶粒尺寸差异较大。随着不同位置处的应变由0.75增加到1.40,β晶粒长宽比增大,流线逐渐清晰,且窄截面处亚结构增多、冷速较快,使得αp含量减少、针状αs逐渐细化,共同导致强度逐渐增加。

(2) 随着应变增大,晶体取向由分散变得集中。经β锻造后,应变1.20处形成<110> β //LD强织构,α相主要为受两侧Burgers关系影响析出的晶界α相和温降与热变形导致的晶内α相2种织构,固溶过程中晶内α相进一步粗化,成为α相的主要织构,而时效析出的αs相除包含αp的主要织构外,也有新变体生成。最终保留<110> β //LD的残余β织构以及{0002} α 2种较弱织构,并由此产生了相应的织构强化。

(3) 锻造导致的扁平状原始β晶粒排布与α + β两相织构共同导致了高应变1.20处的力学性能各向异性。晶粒排布造成的分层现象和截面内晶粒数量差异导致不同取向冲击和拉伸断裂模式上的差异,α相硬取向<0001>//LD方向的织构和β相的{110}密排面使得沿LD拉伸强度高于ND,LD试样有良好的强塑性匹配。

参考文献

Application status and development trend of aeronautical forging technology

[J].

航空锻造技术的应用现状及发展趋势

[J].

Investigations on precision forming technology and manufacture of aviation large die forgings

[D].

大型航空模锻件整体精密成形工艺技术研究与试制

[D].

Toughening high strength titanium alloys through fine tuning phase composition and refining microstructure

[J].Titanium alloys are key materials for applications in major engineering areas, such as aerospace and marine equipment. Studies on structural titanium alloys focus on strengthening and toughening the alloys, especially the latter. The mainstream structural titanium alloys comprise both α and β phases. The optimization of the strength and toughness balance relies on the control of the compositions, volume fractions, and morphologies of both phases. In this study, some recent advances along the above line are reviewed, focusing on studies on the composition design, plastic-deformation mechanism, and microstructure tuning. Rational design of the compositions of both phases improved the deformation coordination within the α phase and across the α/β interface, suppressed the precipitation of brittle ω and α2 phases, and resulted in improved plasticity and toughness through the α-deformation twin and β-deformation-triggered phase transformation. The multiscale microstructure enhanced the strength and toughness of the titanium alloy. Using the abovementioned approaches, a series of titanium alloys with an improved strength-toughness combination were developed and fabricated. Finally, an attempt was made to predict the prospect of technology development in the field of high-strength and high-toughness titanium alloys for various applications.

高强韧钛合金组成相成分和形态的精细调控

[J].

Titanium-based materials: Synthesis, properties, and applications

[J].

Perspectives on titanium science and technology

[J].

Remarkable increase in high-cycle fatigue resistance in a titanium alloy with a fully lamellar microstructure

[J].

Thermomechanical treatment-induced microstructure refinement to optimize mechanical properties of TC21 titanium alloys

[J].

Crack initiation and mechanical properties of TC21 titanium alloy with equiaxed microstructure

[J].

Study on the intrinsic factors determining impact toughness of TC21 alloy

[J].

Influence of quasi-β forging process on microstructure and properties of TC21 titanium alloy large forgings

[J].

准β锻造工艺对TC21钛合金大型锻件组织及性能的影响

[J].以TC21钛合金特大规格棒材及其制备的大型锻件为研究对象,采用准β锻造工艺锻造TC21钛合金,分析了3种不同锻造方案对锻件微观组织和力学性能的影响规律。结果表明:TC21钛合金可在相变点以上一定温度采用准β锻造工艺加工,在不同的加热工艺参数下,通过双重退火进行热处理,均可获得较好的冶金组织和力学性能。TC21钛合金在准β锻造过程中,不同的锻造温度和锻造火次均能获得较好的拉伸性能(1100 MPa左右)和断裂韧性(大于90 MPa·m<sup>1/2</sup>)。在准β锻造过程中,较高的锻造温度有利于获得网篮组织,合金的断裂韧性较高,组织内片层α相存在粗化趋势;较低的准β锻造温度有利于细化微观组织,但锻造后组织中会有少量残余等轴α相存在。在锻造变形量相同的情况下,较少锻造火次可以获得更加细小的微观组织,但锻件不同部位的微观组织形态存在差异。

Microstructure and mechanical properties of TC21 titanium alloy by near-isothermal forging

[J].

Microstructure and mechanical properties of TC21 titanium alloy after heat treatment

[J].

The interdependence of microstructure, strength and fracture toughness in a novel β titanium alloy Ti-5Al-4Zr-8Mo-7V

[J].

Fracture toughness anisotropy of Ti17 billet processed by the β forging

[J].

Microstructure and tensile property of TC4 alloy produced via electron beam rapid manufacturing

[J].<p>Electron beam rapid manufacturing (EBRM) is one of the 3D printing technologies. The main attractions of EBRM technology are its high efficiency and economy in fabricating large, complex near net shape components dielessly and only needing limited machining. In general, the microstructure and texture of titanium alloy can play a significant role in determining its mechanical behaviors. In the present work, the microstructure, texture and tensile property of TC4 alloy produced by electron beam rapid manufacturing (EBRM) are investigated. Results show that the microstructure is comprised of columnar prior <i>β</i> grains that orient parallel to the building direction. The width of the columnar <i>β</i> grains increased rapidly at the initial several build layers, and the subsequent increase rate of the width of the columnar <i>β</i> grains tends to slow down. Fine <i>α</i> lamellae with gradient size are observed inside the columnar prior <i>β</i> grains, which occur because the alloy experiences different complex thermal histories during the EBRM-produced process. The size of <i>α</i> lamellae tends to decrease with the increase of build layers. The XRD result shows that the TC4 alloy has a typical <i>α</i> phase texture, (the <i>c</i>-axes are either concentrated at about 45° or are perpendicular to the building direction). At the same time, the <$10\bar{1}0$> poles are relative to random distribution. For the tensile samples along the electron beam scanning direction, the yield strengths do not show significant change with the increase of build layers, but the tensile strengths increase. The ductility of the alloy also has an upward trend, despite of a slightly decreasing ductility in the top sample. The tensile samples at the bottom of the alloy (10 mm and 20 mm away from the substrate) have similar work hardening exponents, which are lower than the top sample. The top sample shows the highest work hardening exponent. This difference in the tensile properties can be highly attributed to the gradient microstructure. The alloy also presents obvious anisotropy in tensile strength. The tensile sample along the 45° direction has a higher strength than the sample along the <i>X</i> direction, while the tensile sample along the <i>Z</i> direction shows the lowest strength. This anisotropic strength is strongly associated with the <i>α</i> phase texture. When the loading direction is 45° to the building direction, most of the <i>c</i>-axes of <i>α</i> phase are about parallel to the loading direction, showing a "hard" orientation, leading to a higher strength than other oriented samples. Conversely, when the loading direction is along the building direction, most of the <i>α</i> phase present a "soft" orientation, resulting in lower strength compared to the tensile samples along the 45° or the <i>X</i> direction.</p>

电子束快速成形制备TC4合金的组织和拉伸性能分析

[J].

Rolling texture and its effect on tensile property of a near-α titanium alloy Ti60 plate

[J].

The effect of cubic-texture on fatigue cracking in a metastable β titanium alloy subjected to high-cycle fatigue

[J].

Microstructure and texture evolution of a near β titanium alloy Ti-7333 during continuous cooling hot deformation

[J].

Texture evolution and the recrystallization behavior in a near β titanium alloy Ti-7333 during the hot-rolling process

[J].

Influence of macrozones on the fatigue cracking behavior and fracture mechanisms of rolled Ti-6Al-4V alloy

[J].

Effect of texture on fatigue crack path in titanium-6Al-4V

[J].

Anisotropy of fracture toughness in textured titanium-6Al-4V alloy

[J].

Effect of hot deformation parameters on the evolution of microstructure and texture of β phase in TC18 titanium alloy

[J].

热变形参数对TC18钛合金β相组织及织构演变规律的影响

[J].利用SEM及EBSD技术,研究热变形参数(变形方式、变形温度、变形量、应变速率、保温时间)对TC18钛合金β相组织及织构演变规律的影响。结果表明,TC18钛合金在热压缩及两相区热拉伸时,β相均以动态回复为主。在热压缩后,主要形成{100}及{111}织构,在热拉伸后,主要形成{110}织构;在单相区压缩时,随着变形温度升高、变形量提高、应变速率降低,{100}织构比例提高、{111}织构比例降低;在两相区压缩时,随着变形温度升高、变形量提高,{100}织构比例提高、{111}织构比例降低;在两相区拉伸时,随着变形量提高,{110}织构比例逐渐提高。

Effect of simple shear deformation prior to cold rolling on texture and ridging of 16% Cr ferritic stainless steel sheets

[J].

Study on texture and mechanical anisotropy of Ti60 high temperature titanium alloy plates

[D].

Ti60高温钛合金板材织构及力学性能各向异性研究

[D].

Effect of β (110) texture intensity on α-variant selection and microstructure morphology during β→α phase transformation in near α titanium alloy

[J].

Variant selection, coarsening behavior of α phase and associated tensile properties in an α + β titanium alloy

[J].Effect of cooling rates, i.e., air cooling and furnace cooling, after solution in α+β phase-field on variant selection, coarsening behavior of α phase and microstructure evolution were investigated in α+β TC21 alloy. The textures of primary α (αp) and lamellar α (αL) in β phase transformation microstructure (βt) were analysed separately, and the orientation relationship among αp, αL and the parent β phase were studied. In addition, the influence of the microstructure characteristics on the tensile properties was investigated. The results showed that all parent β grains, despite their different orientations, produced 12 ideal αL variants with the same texture components and interweave to form a basketweave βt structure under the air-cooling condition. The αp without Burgers orientation relationship (BOR) with β phase exhibited obviously texture component without overlapping the αL texture component. The volume fraction of αp in the furnace-cooled sample (about 50%) was higher than that of the air-cooled sample (about 12%), while the size of it slightly increased with decreasing the cooling rate. In each β grain, the thick αL in the same orientation formed an α colony. A typical 3 variant colonies which were related to each other were observed. Consequently, the αL spatial orientation distribution showed more heterogeneity. Moreover, the BOR between αp and β and the same orientation of some αL and the surrounding αp grains resulting in the overlapping of αp texture component and αL texture component. At last, the relationship between microstructure and tensile properties was analysed.

The effect of β phase on microstructure and texture evolution during thermomechanical processing of α + β Ti alloy

[J].

Analysis of sharp microtexture heterogeneities in a bimodal IMI 834 billet

[J].

Strength and fracture toughness of TC21 alloy with multi-level lamellar microstructure

[J].

Effect of aging temperature on mechanical properties of TC21 alloy with multi-level lamellar microstructure

[J].

Anisotropic yielding behavior of rolling textured high purity titanium

[J].

Dependence of mechanical properties on the microstructure characteristics of a near β titanium alloy Ti-7333

[J].