基于汽车减重、安全性及制造成本等多方面需求,作为轻量化设计重要结构材料之一的新一代先进高强钢(AHSS)受到了广泛关注[1~5],新能源汽车的快速发展也对汽车用AHSS的性能提出了新的要求[6]。其中,Mn含量为3%~12% (质量分数)的中锰钢(MMS)因兼具高强度、高塑性、良好的应变强化能力及低廉的合金成本成为新一代AHSS的优选钢种,一直是近年来AHSS研究的热点[7~10]。中锰钢作为一种基于相变诱导塑性(TRIP)效应的AHSS[11~13],利用其内残余奥氏体在变形中发生的TRIP效应获得良好塑性,以此实现高强度与高塑性的配合[14~18],这就要求中锰钢的终态组织中需获得较多数量且稳定性适合的残余奥氏体。目前工业试制中锰钢多是通过奥氏体逆相变(ART)退火处理来获得一定数量的残余奥氏体,即,将中锰钢加热至两相区退火获得超细晶铁素体和残余奥氏体的混合组织,但此过程往往需要长时间的退火处理才能获得满足性能所需的残余奥氏体数量及稳定性的要求。

中锰钢经冷轧后会在回火马氏体基体中引入大量位错,这就使冷轧中锰钢在ART退火处理中极易激发铁素体再结晶发生,形成由超细晶铁素体和残余奥氏体组成的等轴状双相组织[19,20]。这种超细晶双相组织使退火试样极易获得高强度和高延伸率的综合力学性能,但同时导致其在拉伸变形中发生典型的非连续屈服[21~26],表现为在应力-应变曲线中出现因Lüders带传播而引起的屈服点延伸(YPE)现象[27]。在钢板冷成形过程中,Lüders带的形成和传播会恶化钢板的表面质量,这也是制约冷轧中锰钢商业化推广的重要原因之一。对于此问题,学者们提出了多种改善或降低Lüders应变的可行方法。比如,利用两步退火在显微组织中引入具有双峰晶粒尺寸的微观结构,可以避免冷轧中锰钢大屈服点延伸行为[28];通过完全奥氏体化预先热处理将初始变形态组织转变为淬火马氏体,随后通过ART退火将等轴状细晶双相组织转变为板条状组织,也可实现此目的,但这会导致中锰钢屈服强度的降低[22,29,30];在试样中保留部分未再结晶的变形组织用于改善Lüders应变[24,31,32];或通过降低压下率来调整后续退火过程中的铁素体再结晶,通过增加可动位错密度的方式在变形早期即引入高的加工硬化率来抑制Lüders应变等[26,33]。另外一种思路是调整亚稳残余奥氏体的机械稳定性,通过在变形早期形变诱导马氏体相变的发生所致的高加工硬化率来抑制Lüders变形[12,34~36]。对冷轧中锰钢进行多样化微观组织调控仍是提升中锰钢综合力学性能、改善Lüders应变的有效途径。

冷轧中锰钢的退火处理涉及到了铁素体再结晶、奥氏体逆相变以及元素配分等多个转变过程以及它们之间的相互作用,这也为其多样化微观组织调控带来了可能性。本工作采用两步退火法对0.15C-5Mn冷轧中锰钢进行微观组织调控,即采用铁素体再结晶预先调控后的微观组织进行后续常规ART退火处理,以改善冷轧中锰钢的力学性能,并分析再结晶调控对冷轧中锰钢中残余奥氏体的稳定性及力学性能的影响机制。

1 实验方法

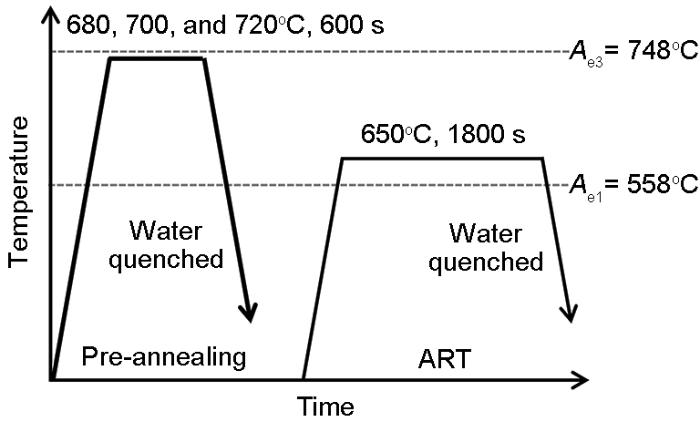

本工作采用0.15C-5Mn冷轧中锰钢,化学成分(质量分数,%)为:C 0.15,Mn 4.7,Al 0.013,P 0.002,S 0.007,Fe余量。利用Thermo-Calc软件的TCFE8数据库计算得到其平衡相转变温度Ae1 (铁素体、奥氏体、渗碳体共存的最低温度)和Ae3 (铁素体、奥氏体共存的最高温度)分别为558和748℃。实验用钢锭采用50 kg真空感应炉熔炼,经1150℃均匀化10 h后锻造成60 mm厚锻坯。锻坯在1200℃均匀化处理2 h后,在1050~900℃之间热轧成3.0 mm厚的热轧板坯,轧后空冷至室温。随后,热轧板经500℃软化退火处理后冷轧至1.5 mm厚。冷轧中锰钢的初始微观组织由变形态回火马氏体基体和渗碳体组成。之后,采用两步退火法对冷轧中锰钢进行热处理,如图1所示。首先通过预先热处理对冷轧中锰钢中的铁素体再结晶进行调控,在680、700和720℃分别对冷轧试样进行时长600 s的等温退火处理并水淬至室温,获得具有不同再结晶铁素体体积分数的3种微观组织。随后对预处理后的试样在650℃进行常规ART退火处理,用以研究再结晶调控对奥氏体逆相变行为及其力学性能的影响。为了对比,对未经预先热处理的试样在650℃进行了1 h等温退火处理,并对退火后试样的微观组织和力学性能进行了分析。为方便叙述,将经过不同温度预退火处理后再进行常规ART处理的热处理试样分别编号为R-ART680、R-ART700和R-ART720,将在650℃退火1 h的常规ART退火试样编号为ART650。

图1

图1

0.15C-5Mn冷轧中锰钢(MMS)两步热处理工艺示意图

Fig.1

Schematic of the thermal cycles used for the heat treatment of the cold-rolled 0.15C-5Mn medium Mn steel (MMS) (Ae3—the highest temperature at which ferrite and austenite phases can coexist in equilibrium. Ae1—the lowest temperature at which ferrite, cementite, and austenite phases can coexist in equilibrium in the steel. ART—austenite reverted transformation)

热处理试样的微观组织采用MERLIN Compact型场发射扫描电子显微镜(SEM)和AZtec EBSD系统(Symmetry)进行表征分析,加速电压为20 kV,扫描步长为35 nm。测试试样沿轧制方向取样,经机械抛光后,再采用SiO2悬浮液进行精细抛光。精细抛光在Buehler VibroMet2型振动抛光仪上进行,抛光时间为3~12 h。利用Talos F200X型场发射透射电子显微镜(TEM)对材料内部的位错结构及各相的微观特征进行进一步表征。TEM试样首先利用电火花线切割机切取厚约0.5 mm的薄片,经手动研磨至厚50~60 µm后冲压出直径为3 mm的圆形薄片试样。利用Struers TenuPol-5型电解双喷减薄仪对试样进行减薄,电解液采用5%高氯酸(低浓度)和95%乙醇(体积分数)的混合溶液,电解温度控制在-30℃左右,电压为30 V。通过AXS D8 Discover X射线衍射仪(XRD)测量试样中残余奥氏体的体积分数,选择(200) α 、(211) α 、(200) γ 、(220) γ 和(311) γ 衍射峰,通过直接对比法获得残余奥氏体的体积分数[37]。测试时设备采用Cu靶,以1°/min的扫描速率在40°~102°的扫描范围(2θ)内进行测试。拉伸实验在Zwick/Roell Z150试验机上进行,拉伸过程采用位移控制方式,夹头的移动速率为恒定速率2.4 mm/min。沿轧制方向制备拉伸试样,标距长度为25 mm,平行段宽度为4 mm,厚度为1 mm。

2 实验结果

2.1 微观组织演变

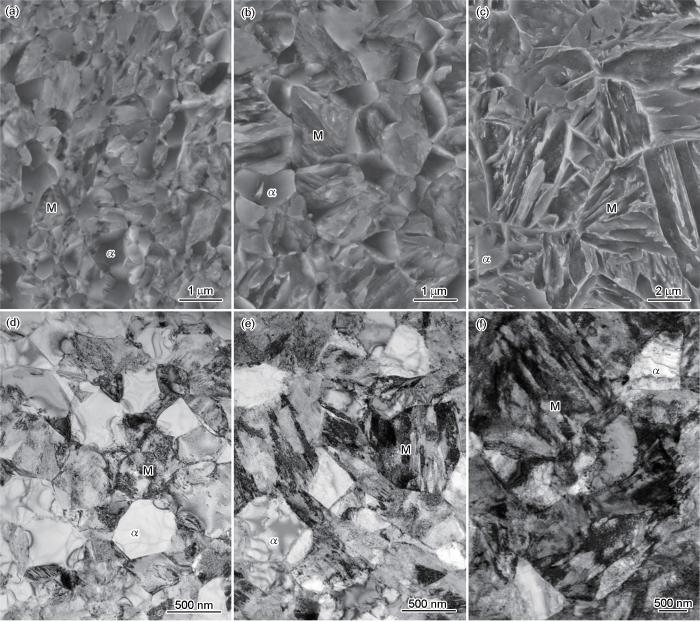

图2为0.15C-5Mn冷轧中锰钢在不同临界区温度下进行预先热处理后的微观组织。可以看出,在680、700和720℃下分别进行预退火处理后,冷轧中锰钢中均已发生了铁素体再结晶,形成了由再结晶铁素体和逆相变奥氏体组成的细晶双相组织。但因所采用的预退火温度高于0.15C-5Mn中锰钢常规ART退火处理的最优温度(获得最多残余奥氏体体积分数的ART温度)[38,39],所形成的奥氏体中的C、Mn浓度较低,导致其热稳定性较低,因此预退火中形成的逆相变奥氏体在冷却过程中会重新转变为马氏体。当冷轧中锰钢在680℃进行预退火时,其显微组织由体积分数为60%的再结晶铁素体和40%的马氏体组成。由于此时的退火温度相对较低,无论铁素体再结晶晶粒还是逆相变奥氏体晶粒均未发生过度长大,预退火后的微观组织保持为均匀分布的等轴状细晶双相结构,如图2a和d所示。当把预退火温度提高到700℃时,奥氏体逆相变会因相变温度的提高而被促进,此时再结晶铁素体的体积分数降低,但再结晶铁素体晶粒仍保持为细小等轴状,晶粒尺寸略有增大(图2b)。同时,部分奥氏体晶粒会发生合并粗化,形成了多种尺寸并存的逆相变奥氏体显微组织,如图2e所示。可以看出,较大尺寸的奥氏体晶粒在冷却过程中转变成新生马氏体后,其内部形成明显的板条状结构。而当预退火温度升高到720℃时,奥氏体相变会进一步被促进,此时再结晶铁素体的体积分数进一步降低至约10%,奥氏体晶粒发生了明显粗化(图2c),冷却至室温后形成尺寸较大的板条马氏体,如图2f所示。可见,通过在不同临界区温度调控铁素体的再结晶,在实现再结晶铁素体体积分数调控的同时,也可获得不同比例及尺寸的多样化新生马氏体组织,为后续常规ART退火中的残余奥氏体控制提供了调控空间。

图2

图2

0.15C-5Mn冷轧MMS在不同临界区温度预退火处理后微观组织的SEM像和TEM明场像

Fig.2

SEM images (a-c) and TEM bright-field images (d-f) showing the microstructures of the cold-rolled 0.15C-5Mn MMS pre-annealed at 680oC (a, d), 700oC (b, e), and 720oC (c, f) (α—ferrite, M—martensite)

为了更清楚地认识预退火处理生成的再结晶铁素体与新生马氏体两相组织内部的亚结构特征,进一步利用EBSD对3种温度下预退火后组织的特征进行了分析,如图3所示。由图可见,所有试样均获得了由等轴状再结晶铁素体和新生马氏体组成的细晶双相组织。随着预退火温度的提高,再结晶铁素体晶粒略有长大,但其晶粒尺寸整体保持在1~2 μm的超细晶水平,表明所形成的双相细晶组织中再结晶铁素体晶粒的粗化被有效抑制。而提高预退火温度大大促进了奥氏体逆相变的发生,奥氏体晶粒之间易发生合并而粗化。奥氏体体积分数随着退火温度的升高急剧增大,奥氏体晶粒的尺寸增长显著,冷却至室温并重新转变为马氏体后在其内部形成了复杂的亚结构。可以看出,新生马氏体晶粒内部生成非常丰富的大角度晶界和亚晶界。此外,当奥氏体重新转变为马氏体时,会在新生马氏体内部引入相变应力。如图3d~f所示,新生马氏体内部的平均取向差(KAM)数值较高,意味着奥氏体在转变成马氏体时在其内部诱发了较多的几何必需位错(GNDs)生成,引入了较大的局部形变储能。这些亚结构及局部储能的存在会大大促进后续奥氏体逆相变的发生。

图3

图3

0.15C-5Mn冷轧MMS在不同临界区温度预退火处理后微观组织的EBSD分析

Fig.3

EBSD band contrast images (a-c) and kernel average misorientation (KAM) maps (d-f) of the cold-rolled 0.15C-5Mn MMS pre-annealed at 680oC (a, d), 700oC (b, e), and 720oC (c, f) (The red, green, and blue lines represent boundaries with misorientations of 2° < θ < 5°, 5° ≤ θ < 15°, and θ ≥ 15°, respectively)

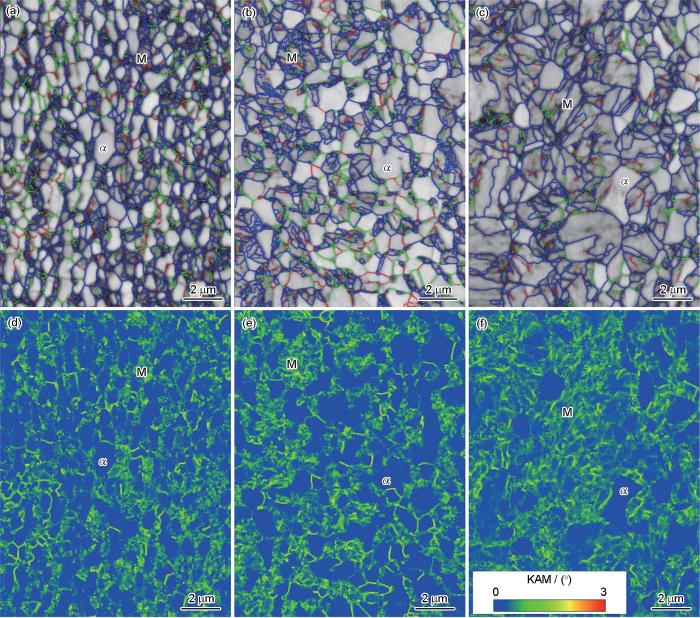

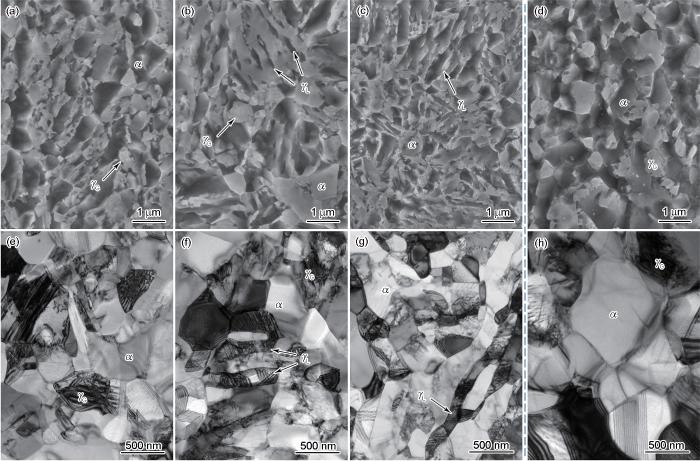

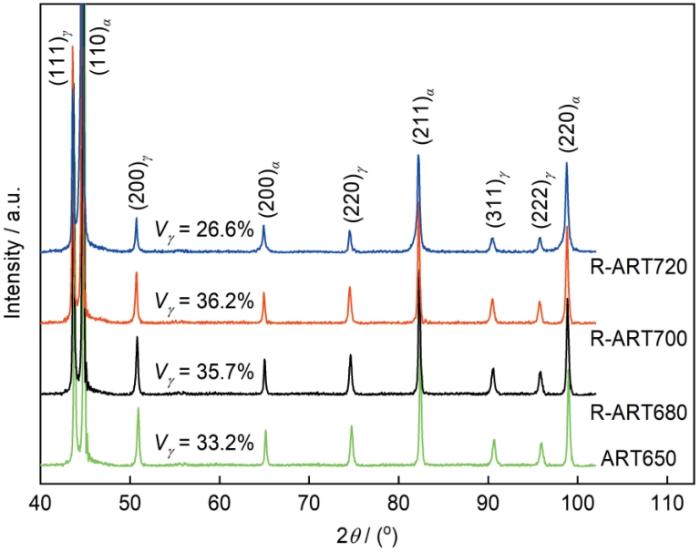

随后,以不同临界区温度预处理后的组织作为初始组织进行常规ART退火处理,即再次将预退火后的试样在650℃等温退火0.5 h,最终获得的微观组织如图4所示。为方便对比,图4中也给出了未经预处理的冷轧试样在650℃等温退火处理1 h后的微观组织(图4d和h)。可以看出,未经预处理的常规ART650试样的微观组织是由等轴状再结晶铁素体和残余奥氏体组成的细晶双相组织;经再结晶调控后再进行ART处理的试样中同样获得了细晶双相组织,但其再结晶铁素体的晶粒明显细化,且所形成的奥氏体呈现出不同形貌、不同尺寸的多样化特征。其中,R-ART680试样的显微组织(图4a和d)继承了680℃预处理试样中(图2a和d)的细晶且等轴的特征。其再结晶铁素体的晶粒尺寸与预退火试样中的晶粒尺寸相似,未发生明显的晶粒长大,但铁素体晶粒尺寸明显小于ART650试样的晶粒尺寸。奥氏体晶粒同样呈现为等轴状,平均晶粒尺寸约为500 nm。XRD结果显示所获得的残余奥氏体的体积分数约为35.7% (图5),高于常规ART650试样中所获得的残余奥氏体量,说明预处理可促进奥氏体逆相变的发生。在R-ART700试样中(图4b和f),除获得等轴状细晶铁素体之外,还获得了2种不同形貌的细晶奥氏体:板条状(γL)和等轴状(γG)。其中,板条状奥氏体主要形成于预处理中生成的较大尺寸的新生马氏体内部,在马氏体板条界面处发生奥氏体逆相变而生成,等轴状奥氏体则主要源于预处理中生成的较小尺寸的新生马氏体。这种情况下获得了约36.2%的残余奥氏体。而对于R-ART720试样(图4c和g),因预处理中已发生了逆相变奥氏体的大规模粗化,等轴状再结晶铁素体体积分数仅占约10%,在随后的常规ART退火中奥氏体逆相变主要发生在新生马氏体板条处,所生成的残余奥氏体主要为板条状,虽然这种情况下仅获得了约26.6%的残余奥氏体,但板条状奥氏体在试样内的分布较均匀,有利于提升中锰钢的均匀变形能力。可见,通过预先调控冷轧中锰钢中的铁素体再结晶,不仅可以控制等轴状再结晶铁素体的体积分数,而且可以形成不同形貌、不同尺寸的残余奥氏体与超细晶再结晶铁素体组成的多样化组织,有利于对其综合力学性能的调控。

图4

图4

0.15C-5Mn冷轧MMS经不同温度预退火并奥氏体逆相变(ART)处理试样及常规ART处理试样的微观组织的SEM像和TEM明场像

Fig.4

SEM images (a-d) and TEM bright-field images (e-h) showing the final microstructures of the cold-rolled 0.15C-5Mn MMS (γG—globular retained austenite, γL—lath-like retained austenite) (a, e) R-ART680 (b, f) R-ART700 (c, g) R-ART720 (d, h) ART650

图5

图5

0.15C-5Mn冷轧MMS经不同温度预退火并ART处理及常规ART处理后的XRD谱

Fig.5

XRD spectra and the measured fractions of retained austenite of the cold-rolled 0.15C-5Mn MMS (Vγ —volume fraction of austenite)

2.2 拉伸性能

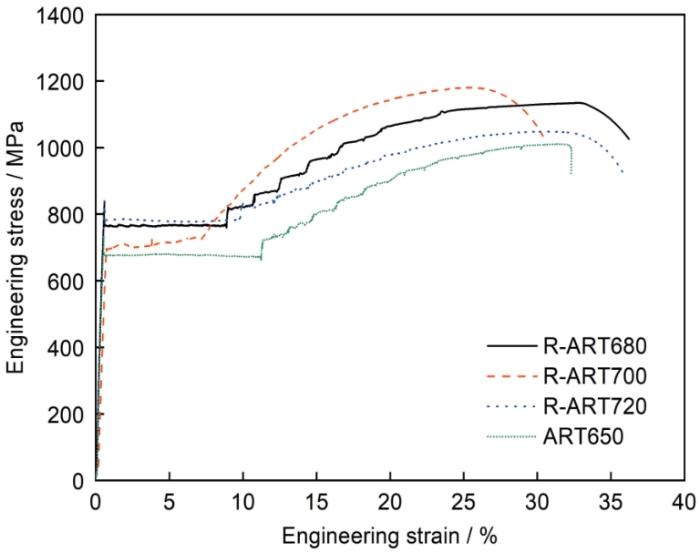

图6为热处理试样进行室温拉伸变形时的应力-应变曲线。可以看出,冷轧中锰钢在650℃等温退火1 h后可以获得抗拉强度1010 MPa、总延伸率32%、强塑积32.3 GPa·%的综合力学性能,表现出较好的强塑性,而经再结晶调控后再进行ART退火处理的试样的综合力学性能获得了进一步提升。与ART650试样相比,R-ART680和R-ART720试样的抗拉强度和延伸率同时提高,其强塑积分别达到了41.1和37.9 GPa·%,强塑性能显著提升。而R-ART700试样的延伸率虽略有降低,但其抗拉强度提升了约200 MPa,达到了1200 MPa,且总延伸率仍保持在31%,仍获得了高达37.2 GPa·%的强塑积。此外,与常规ART处理的试样相比,经过再结晶调控的试样在室温拉伸变形中的Lüders应变明显降低。通常冷轧中锰钢常规ART处理后的试样在拉伸变形的前期会伴随较大的Lüders应变,其通常被认为与残余奥氏体的机械稳定性密切相关[23,30,31]。通过预先调控冷轧中锰钢中的铁素体再结晶,在生成超细晶铁素体的同时,所形成的多样化的奥氏体是提升其强塑性能并抑制Lüders应变的重要原因。

图6

图6

0.15C-5Mn冷轧MMS经不同温度预退火并ART处理及常规ART处理试样的工程应力-应变曲线

Fig.6

Engineering stress-strain curves of the cold-rolled 0.15C-5Mn MMS treated by various thermal cycles

3 分析讨论

3.1 再结晶调控对奥氏体逆相变的影响

本工作采用两步退火对冷轧中锰钢进行热处理。第一步退火选择在较高临界区温度对试样进行预先热处理。由于中锰钢经冷轧变形后在其内部储存了较高的形变储能,而且所采用的退火温度较高,冷轧试样中的铁素体再结晶极易被激发,经较短时间的退火即可完成铁素体再结晶及奥氏体逆相变过程,形成了由等轴状逆转变奥氏体与等轴状再结晶铁素体组成的细晶双相组织[40,41]。同样是由于退火温度较高的缘故,所形成的等轴状奥氏体的热稳定低,在冷却时会转变为马氏体。第二步退火是在较低临界区温度下对试样进行常规ART处理,此时发生的奥氏体逆相变会在预先热处理中形成的等轴状新生马氏体内部进行。由于这些新生马氏体的晶粒尺寸较小,这种晶粒的细化会显著减小C元素的扩散距离[42~44],使之能在较短的时间内完成奥氏体逆转变,显著加快了奥氏体逆相变动力学。由于此时ART热处理的温度较低,重新形成的逆转变奥氏体的热稳定性提高,使之容易残留至室温;同时,在这种情况下,在较高温度预处理中形成的细晶铁素体也不易长大,仍保持为细晶状态,对提升试样的力学性能有利。

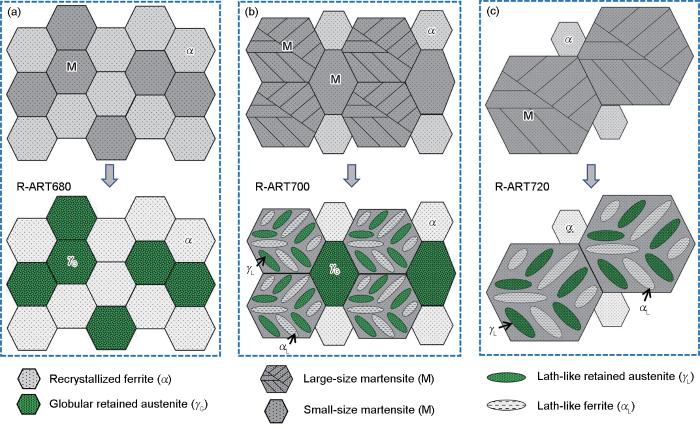

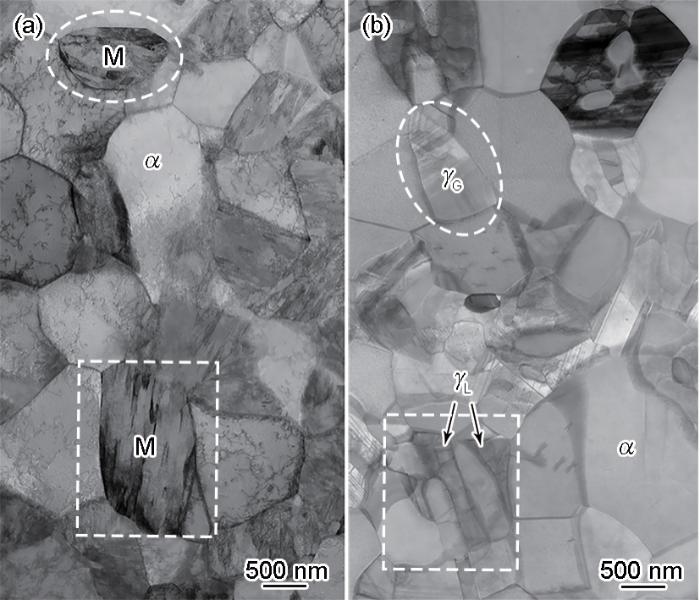

除此之外,如前所述,当第一步热处理选择在不同温度进行时,再结晶铁素体与逆相变奥氏体的体积分数可根据预退火温度的不同进行调控。而且,在实现对再结晶铁素体体积分数调控的同时,奥氏体体积分数及晶粒尺寸也得到了多样化调控。在这种情况下,这些奥氏体转变为新生马氏体之后,为第二步常规ART退火中残余奥氏体的控制提供了丰富的调控空间,其微观组织转变的过程如图7所示。在680℃进行预退火时,所形成的逆相变奥氏体的晶粒细小,再次转变为马氏体时其内部的板条状亚结构的形成被抑制(图2d)。这种情况下,当进行第二步ART处理时,奥氏体在其内部形成,继承了其超细晶特征,如图7a所示。在700℃预退火时,因退火温度提高,部分逆相变奥氏体发生了粗化,于是形成了多种尺寸并存的逆变奥氏体晶粒,当它们在冷却中转变为马氏体后,马氏体内部的亚结构也明显不同。在随后的ART处理中,小尺寸晶粒内重新形成的奥氏体仍会保持细晶等轴的特征,其机理与以上阐述的机理相同;而大尺寸晶粒内部的奥氏体相变会发生在马氏体板条界处,形成板条状的奥氏体。于是,在这种情况下就形成了由2种不同形貌奥氏体组成的异质结构奥氏体,如图7b所示。而当预退火温度提高到720℃时,逆相变奥氏体已发生了大规模粗化,转变为马氏体后在其内部形成了丰富的板条状亚结构。在随后的ART处理中,奥氏体相变主要在这些马氏体板条界面上发生,于是就形成了板条状的细晶奥氏体,如图7c所示。图8所示为经700℃预退火以及预退火后再进行常规ART处理后试样的微观组织。可以看出,在预退火中形成的较小尺寸的马氏体经第二步ART退火处理后转变为等轴状奥氏体,如图中白色虚线圆圈中所示;而较大尺寸的马氏体则转变为板条状奥氏体,如图中白色虚线方框中所示。最终在微观组织中获得了上述2种形貌的细晶奥氏体。

图7

图7

冷轧MMS在不同温度预先调控再结晶后再进行ART处理时微观组织演变的示意图

Fig.7

Schematics showing the microstructure evolution during final ART processes after pre-annealing at intercritical temperatures of 680oC (a), 700oC (b), and 720oC (c) of the cold-rolled MMS

图8

图8

0.15C-5Mn冷轧MMS经700℃预退火及预退火并ART处理后的微观组织的STEM像

Fig.8

STEM images showing the refined microstructures of the cold-rolled 0.15C-5Mn MMS after the pre-annealing at 700oC (a) and then after the final ART heat treatment (b)

3.2 再结晶调控对奥氏体稳定性与力学性能的影响

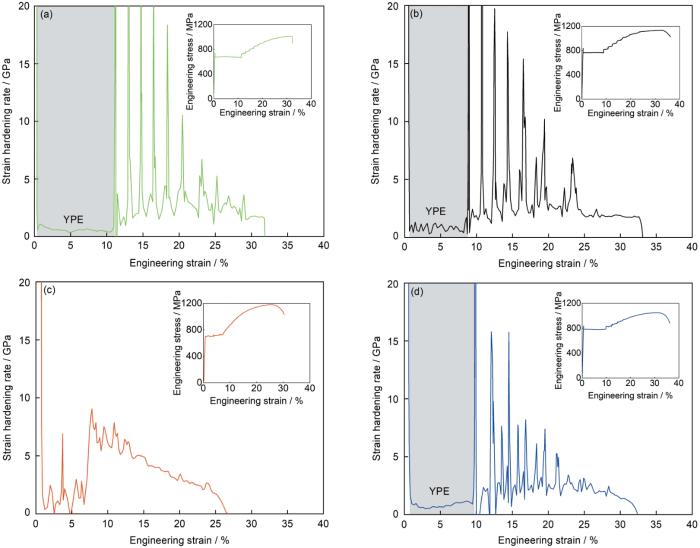

图6结果表明,与常规ART处理的试样相比,冷轧中锰钢经再结晶调控后可使其强塑性获得明显提升,图9为冷轧中锰钢热处理试样室温拉伸变形时的加工硬化率曲线。由图9a可见,常规ART650试样经过应变约11%的Lüders变形后才进入TRIP效应的强化阶段,屈服点延伸(YPE)现象明显。因常规ART热处理的时间较长,所获得的残余奥氏体的机械稳定性较高且其稳定性的一致性较好,这就使得在随后的室温拉伸变形中的TRIP效应延后发生,且形变诱导马氏体相变容易在相对较窄的应变范围内集中发生并导致TRIP效应快速饱和,这也是冷轧中锰钢常规ART处理后的典型特征[22,45,46]。R-ART680试样表现出与ART650试样相似的加工硬化行为,如图9b所示,主要是因为2者具有相似的细晶等轴状的双相微观组织,但R-ART680试样在变形早期的Lüders变形阶段(0.7%~8.0%)即出现了加工硬化率的明显波动,且在较低应变下(8.0%)即进入了TRIP效应强化阶段,YPE明显减小。虽然R-ART680试样的微观组织同为细晶等轴状双相组织,但短时ART处理会使所形成的残余奥氏体的机械稳定性降低,这种情况下,低稳定性的奥氏体在较小应变下即可发生TRIP效应,不仅会使Lüders变形得到抑制,而且所形成的形变诱导马氏体会继续不断参与到后续变形中的强化效应中,使材料的抗拉强度得到提升,同时较高体积分数的奥氏体也能使试样保持高的延伸率。对于R-ART700试样,其内部形成了板条状和等轴状2种不同形貌的细晶奥氏体,其中等轴状奥氏体的机械稳定性低,而板条状奥氏体的机械稳定性高。这种具有不同尺寸异质结构奥氏体的形成使其内部TRIP效应能在较宽应变范围内连续且渐进式持续发生,这也是试样能获得高强度同时保持塑性无明显降低的主要原因。此外,变形初期即发生的TRIP效应所导致的强化作用会协调塑性变形的局域化,进而有效抑制Lüders带的发展[47~49](图9c)。图9d的结果表明,R-ART720试样在变形早期的Lüders变形阶段未出现加工硬化率的波动,说明此时试样中的TRIP效应尚未有效开动,这主要是由于R-ART720试样中的奥氏体主要为板条状细晶奥氏体,其机械稳定性较高而造成的。但因其ART处理时长较短,奥氏体的机械稳定性低于常规ART650试样,其TRIP效应的发生仍使Lüders应变降低,YPE减小,且试样的强塑性优于常规ART处理的试样。

图9

图9

0.15C-5Mn冷轧MMS常规ART处理及在不同温度预退火并ART处理试样的加工硬化率曲线

(a) ART650 (b) R-ART680 (c) R-ART700 (d) R-ART720

Fig.9

Work hardening rate curves of the cold-rolled 0.15C-5Mn MMSs treated by various thermal cycles (Insets show corresponding engineering stress-strain curves as comparisons. YPE—yield point elongation)

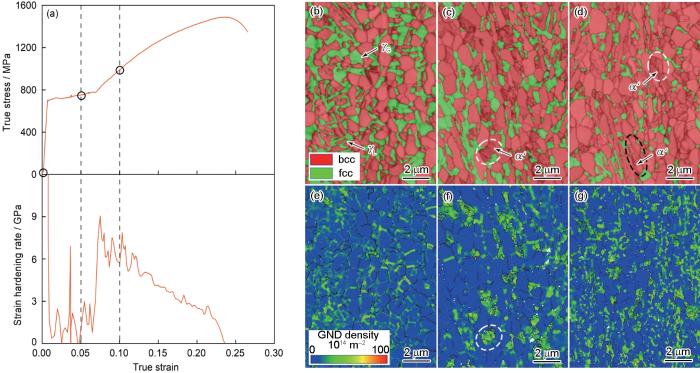

为了更清楚地理解奥氏体机械稳定性对中锰钢强塑性能的影响,进一步利用EBSD对具有2种不同形貌和尺寸奥氏体的R-ART700试样在拉伸变形中的组织演变进行了分析,如图10所示。可以看出,试样中残余奥氏体的体积分数随着应变的增加而降低,而总体GNDs逐渐增加。在拉伸变形的初始阶段,试样中的等轴状奥氏体首先发生TRIP效应而转变为马氏体,如图10c中白色虚线圆圈所示,图中所形成的形变诱导马氏体因其内部应力较高而呈现较低的Kikuchi带衬度。等轴状奥氏体晶粒尺寸相对较大,其内部C、Mn元素的富集程度较低致使机械稳定性较差,其在拉伸变形早期即可发生强烈的TRIP效应,使材料强化效应过早发生进而阻碍Lüders带的扩展。而常规ART处理的试样因其形成的残余奥氏体过于稳定而使TRIP效应延迟发生,同时再结晶铁素体内部较低的位错密度无法抑制Lüders带的扩展而导致大的Lüders应变[21,26]。当真应变增加到0.10时,大部分等轴状残余奥氏体已完成马氏体转变,此时,机械稳定性较高的板条状细晶奥氏体开始发生TRIP效应,进一步协调拉伸应变,这种连续且持续发生的TRIP效应即可使试样获得高强度的同时提高其塑性。可见,调控中锰钢中残余奥氏体的机械稳定性是提升其强塑性能的有效途径之一。

图10

图10

经700℃预退火并ART处理试样的真应力-真应变曲线和相应的加工硬化率曲线及不同变形阶段微观组织的EBSD像

Fig.10

True stress-true strain curve with the corresponding work hardening rate curve (a), EBSD phase distribution maps (b-d) and geometrically necessary dislocations (GNDs) maps (e-g) of the R-ART700 sample when stretching to true strains of ε = 0.0 (b, e), 0.05 (c, f), and 0.10 (d, g), respectively (The white circle areas are identified as the prior globular retained austenite areas, and the black circle area is identified as the prior lath-like retained austenite area)

综上可知,通过在不同温度对冷轧中锰钢中的铁素体再结晶进行预先调控,在最终组织中获得了具有多样化机械稳定性的残余奥氏体,改善了冷轧中锰钢常规ART处理后残余奥氏体单一的缺点,可以实现抑制Lüders应变、提升其力学性能的目的,也为高强塑性冷轧中锰钢制备的工艺优化提供参考。

4 结论

(1) 通过在不同临界区温度预先调控0.15C-5Mn冷轧中锰钢中铁素体再结晶的发生,可形成由不同体积分数及不同晶粒尺寸组成的再结晶铁素体和新生马氏体的双相细晶预处理组织。再经奥氏体逆相变退火后,在最终微观组织中获得了不同体积分数的超细晶再结晶铁素体,还形成了等轴状及板条状2种不同形貌及尺寸的多样化残余奥氏体,并使奥氏体逆相变退火处理的时长大大缩短。

(2) 经不同温度下铁素体再结晶调控后再进行ART处理所生成的多样化残余奥氏体具有较宽的机械稳定性,使奥氏体在拉伸变形过程中表现出多样化的TRIP效应:其中,尺寸较大的等轴状奥氏体的稳定性较低,尺寸较小的板条状奥氏体的机械稳定性较高。多样化残余奥氏体的形成可使中锰钢在变形中的TRIP效应持续发生,使中锰钢获得较高的加工硬化率和延伸率。

(3) 与常规ART处理相比,经铁素体再结晶调控后再进行ART处理使冷轧中锰钢获得了优异的强塑性能,同时改善了Lüders变形。其中,R-ART700试样在总延伸率未明显损失的情况下,其抗拉强度提升了200 MPa,达到了1200 MPa,且Lüders应变被有效抑制。预先调控铁素体再结晶为调整冷轧中锰钢最终微观组织、优化其力学性能提供了可行的途径。

参考文献

The microstructure evolution and tensile properties of medium-Mn steel heat-treated by a two-step annealing process

[J].The martensitic hot-rolled 0.3C-6Mn-1.5Si (wt%) steel was annealed at 630 °C for 24 h to improve its cold rollability, followed by cold rolling and annealing at 670 °C for 10 min. The annealing process was designed based on the capacities of industrial batch annealing and continuous annealing lines. A duplex submicron austenite and ferrite microstructure and excellent tensile properties were obtained finally, proved the above process is feasible. “Austenite memory” was found in the hot-rolled and annealed sample which restricted recrystallization of lath martensite, leading to lath-shaped morphology of austenite and ferrite grains. “Austenite memory” disappeared in the cold-rolled and annealed sample due to austenite random nucleation and ferrite recrystallization, resulting in globular microstructure and refinement of both austenite and ferrite grains. The austenite to martensite transformation contributed most of strain hardening during deformation and improved the uniform elongation, but the dislocation strengthening played a decisive role on the yielding behavior. The tensile curves change from continuous to discontinuous yielding as the increase of cold-rolled reduction due to the weakening dislocation strengthening of austenite and ferrite grains related to the morphology change and grain refinement. A method by controlling the cold-rolled reduction is proposed to avoid the Lüders strain.

Relationship between retained austenite stability and cryogenic impact toughness in 0.12C-3.0Mn low carbon medium manganese steel

[J].

0.12C-3.0Mn低碳中锰钢中残余奥氏体稳定性与低温韧性的关系

[J].

Characteristics of bainitic transformation and its effects on the mechanical properties in quenching and partitioning steels

[J].

Improvement of mechanical properties of a medium-Mn TRIP steel by precursor microstructure control

[J].

Microstructure and tensile properties of a Nb-Mo microalloyed 6.5Mn alloy processed by intercritical annealing and quenching and partitioning

[J].

Revolutionizing car body manufacturing using a unified steel metallurgy concept

[J].Multiple steel grades used in a car body were unified in chemistry to revolutionize automotive manufacturing and recycling.

Effects of intercritical annealing temperature on the tensile behavior of cold rolled 7Mn steel and the constitutive modeling

[J].

退火温度对冷轧7Mn钢拉伸行为的影响及模拟研究

[J].

Enhanced tensile properties of a reversion annealed 6.5Mn-TRIP alloy via tailoring initial microstructure and cold rolling reduction

[J].The feasibility of improving the overall performance of medium Mn steels was demonstrated via tailoring the initial microstructure and cold rolling reduction. The combined effects of cooling patterns after hot rolling (HR) and cold rolling (CR) reductions show: (1) as the cooling pattern varied from furnace cooling (FC) to oil quenching (OQ), the intercritically annealed microstructure was dramatically refined and the fraction of recrystallized ferrite dropped, regardless of CR reductions. This resulted in both high yield/ultimate tensile strengths (YS/UTS) but low total elongation to fracture (El); (2) as the CR reduction increased from 50% to 75%, the OQ-samples after annealing exhibited a more refined microstructure with relatively higher fractions of retained austenite and sub-structure, leading to higher YS and UTS but lower El; whereas the FC samples appeared to exhibit little difference in overall tensile properties in both cases. The differences in microstructural evolution with cooling patterns and CR reductions were explained by the calculated accumulated effective strain (εAES), which was considered to be related to degrees of recovery and recrystallization of the deformed martensite (α’). The optimal tensile properties of ~1?GPa YS and ~40?GPa·% UTS×El were achieved in the OQ-50%CR annealed samples at 650?°C for 1?h. This was quite beneficial to large-scale production of ultra-high strength steels, owing to its serious springback during heavy cold working.

Ensuring combination of strength, ductility and toughness in medium-manganese steel through optimization of nano-scale metastable austenite

[J].

Improved microstructural homogeneity and mechanical property of medium manganese steel with Mn segregation banding by alternating lath matrix

[J].

The effects of the initial microstructure on microstructural evolution, mechanical properties and reversed austenite stability of intercritically annealed Fe-6.1Mn-1.5Si-0.12C steel

[J].

Mechanical response of a medium manganese steel with encapsulated austenite

[J].

Effect of intermediate temperature annealing on the stability of retained austenite and mechanical properties of medium Mn-TRIP steel

[J].

An ultrahigh strength and enhanced ductility cold-rolled medium-Mn steel treated by intercritical annealing

[J].

Correlation between deformation behavior and austenite characteristics in a Mn-Al type TRIP steel

[J].

Influence of tempering temperature on mechanical properties and microstructures of high-Al-contained medium Mn steel having δ-ferrite

[J].

回火温度对含δ铁素体高铝中锰钢力学性能和微观组织的影响

[J].研究了回火温度对含15% δ铁素体(体积分数)的热轧高铝中锰钢显微组织和力学性能的影响。结果表明,钢中长300 μm的δ铁素体经热轧再结晶可被细化分割至大量长3 μm左右竹节状晶粒,且在回火温度高达700℃时尺寸不变。400~500℃回火后,马氏体基体依然维持较高的位错密度且析出细小渗碳体和纳米级VC粒子,屈服强度最高;同时C由马氏体向奥氏体的大量配分提高了奥氏体稳定性,获得了相对持久的加工硬化,最终获得了屈服强度约1500 MPa、抗拉强度1800 MPa和断后延伸率14%的最佳力学性能组合。该钢δ铁素体相一方面由于析出强化、晶粒细化和位错强化而得到显著硬化;另一方面δ铁素体体积分数不高且呈孤岛状嵌在马氏体基体中,这些特征导致该钢屈服强度由马氏体基体而非δ铁素体所决定,因此相比于其他类似Al含量的含δ铁素体中锰钢,屈服强度大幅度提高。

Ultra-high-strength multi-alloyed steel with enhanced cryogenic toughness using thermally stable retained austenite

[J].

Microstructure and mechanical properties of medium Mn steel containing 3%Al processed by warm rolling

[J].

Influence of retained austenite and Cu precipitates on the mechanical properties of a cold-rolled and intercritically annealed medium Mn steel

[J].

Stress-state-dependent deformation and fracture behaviors in a cold-rolled 7Mn steel

[J].

Ultrafine also can be ductile: On the essence of Lüders band elongation in ultrafine-grained medium manganese steel

[J].

Recent progress and future research prospects on the plastic instability of medium-Mn steels: A review

[J].

中锰钢塑性失稳现象的研究进展及未来研究展望

[J].

By controlling recrystallization degree: A plain medium Mn steel overcoming Lüders deformation and low yield-to-tensile ratio simultaneously

[J].

Deformation behavior in cold-rolled medium-manganese TRIP steel and effect of pre-strain on the Lüders bands

[J].

Effects of the austenitizing temperature on the mechanical properties of cold-rolled medium-Mn steel system

[J].

Significance of cold rolling reduction on Lüders band formation and mechanical behavior in cold-rolled intercritically annealed medium-Mn steel

[J].

High strength-toughness combination of a low-carbon medium-manganese steel plate with laminated microstructure and retained austenite

[J].

Fabrication of bimodal-grained Al-free medium Mn steel by double intercritical annealing and its tensile properties

[J].

The effects of the initial martensite microstructure on the microstructure and tensile properties of intercritically annealed Fe-9Mn-0.05C steel

[J].

Effect of intercritical annealing on the Lüders strains of medium Mn transformation-induced plasticity steels

[J].

Flash annealing yields a strong and ductile medium Mn steel with heterogeneous microstructure

[J].

Two-step intercritical annealing to eliminate Lüders band in a strong and ductile medium Mn steel

[J].

Effects of cold rolling reduction ratio on microstructures and tensile properties of intercritically annealed medium-Mn steels

[J].

Microstructural evolution and mechanical behavior of a novel heterogeneous medium Mn cold-rolled steel

[J].

Stabilizing austenite via a core-shell structure in the medium Mn steels

[J].

Ultra-fine heterogeneous microstructure enables high strength-ductility in a cold-rolled medium Mn steel

[J].

Characterization of microstructure obtained by quenching and partitioning process in low alloy martensitic steel

[J].

Observation of the TWIP + TRIP plasticity-enhancement mechanism in Al-added 6 wt pct medium Mn steel

[J].

Combined intercritical annealing and Q&P processing of medium Mn steel

[J].

Yielding behavior of triplex medium Mn steel alternated with cooling strategies altering martensite/ferrite interfacial feature

[J].In this paper, we report the influence of cooling processes on the yielding behavior of a medium Mn steel (MMS) with triplex microstructure, i.e. austenite (γ), ferrite (α) and as-quenched martensite (α'). After the intercritical annealing (IA) at both 725 ℃ and 750 ℃, the steel was subjected to the two cooling processes, i.e. air cooling (AC) and water quenching (WQ). It exhibits the discontinuous yielding after the AC following the IA at 750 ℃ while the continuous yielding after the WQ. Compared with WQ process, both the dilatometry and the microstructural examinations show that the AC process leads to lower Ms temperature, larger retained austenite (RA) fraction and less martensite, the latter is always companied with geometry necessary dislocations (GNDs) generated near the α/α' interfaces. Considering the complexity of nanosized tri-phases in this steel, the presence of martensite with key features in the resultant specimens was systematically examined by atom probe tomography (APT) on the samples prepared by the specific target lift-out method. The APT results directly revealed the C/Mn co-segregation at the α'/α interfaces in the AC samples but not in WQ samples. The numerical simulation results further suggest that the segregation of C and Mn at the α'/α interfaces may be due to different mechanisms. We conclude that the yielding of triplex MMS is determined by both the quantity of GNDs generated near the α/α' interfaces, which increases with martensite fraction, and the extent of their immobilization resulting from the interfacial segregation of solute atoms when the presence of martensite is sufficient. WQ tends to suppress the discontinuous yielding of MMS since the rapid cooling may promote more martensite formed with the increasing quantity of GNDs and prevent the interfacial segregation of both C and Mn.

Recovering the ductility of medium-Mn steel by restoring the original microstructure

[J].

Mechanism of austenite formation from spheroidized microstructure in an intermediate Fe-0.1C-3.5Mn steel

[J].

Effect of Mn pre-partitioning on C partitioning and retained austenite of Q&P Steels

[J].

预先Mn配分处理对Q&P钢中C配分及残余奥氏体的影响

[J].

Microstructure and mechanical properties of V-Nb microalloyed ultrafine-grained dual-phase steels processed through severe cold rolling and intercritical annealing

[J].

The determining role of reversed austenite in enhancing toughness of a novel ultra-low carbon medium manganese high strength steel

[J].

Microstructure and mechanical properties of a novel cold rolled medium-Mn steel with superior strength and ductility

[J].Recently, energy conservation, environmental protection and security are the main factors considered by the automotive manufacturers. Medium-Mn steel with excellent combination of specific strength and ductility have been regarded as the potential candidates for automotive applications. The excellent combination of specific strength and ductility depends on the microstructure under different heat treatment processes of the steels. Therefore, the relationship of the combination of specific strength and ductility and microstructure should be studied in detail. A new alloy system of aluminum-containing medium-Mn steel was developed in this study. The addition of aluminum stabilizes α-ferrite, and facilitates the presence of δ-ferrite during solidification. The addition of Mn and C compensates the effect of aluminum on phase stability and ensures austenite formation. In this investigation, the effects of intercritical annealing temperature on the microstructure and tensile properties of a newly designed cold-rolled aluminum-containing medium-Mn steel (0.2C-5Mn-0.6Si-3Al, mass fraction, %) were investigated by SEM, XRD and uniaxial tensile tests. The tensile results show that an excellent combination of ultimate tensile strength (σb) of 1062 MPa, total elongation (δ) of 58.2% and σb×δ of 61.8 GPa% could be obtained after annealing at 730 ℃. The inverted austenite of the cold-rolled steel coarsenes and gradually changes its morphology from mainly lamellar to mainly equiaxed with increasing intercritical annealing temperature, and a duplex microstructure consisting of multi-scale retained austenite could be obtained at 730 ℃, which possesses suitable mechanical stability and thus presents prolonged transformation-induced plasticity (TRIP) effect during tensile deformation. This kind of sustainable TRIP effect and the cooperative deformation of ferrite are responsible for the superior mechanical properties. The investigation of tensile fracture behavior shows that the nucleation and growth of voids occurred mainly at the interfaces between soft ferrite and hard martensite induced by deformation.

一种新型高强度高塑性冷轧中锰钢的组织和力学性能

[J].研究了两相区退火温度对一种新型冷轧中锰钢(0.2C-5Mn-0.6Si-3Al,质量分数,%)显微组织及拉伸性能的影响。结果表明,在退火温度为730 ℃时,冷轧中锰钢可获得优异的强度与塑性配合,即抗拉强度为1062 MPa,总伸长率为58.2%,强塑积为61.8 GPa%。随着退火温度升高,逆转变奥氏体逐渐粗化,且由片层状组织形态逐渐向等轴状组织形态转变,在一定退火温度下可获得奥氏体晶粒尺寸分布较为宽泛的多尺度的组织形态。这种多尺度组织形态的残余奥氏体具有适当的机械稳定性,能够产生连续不断的相变诱发塑性(TRIP)效应。连续不断的TRIP效应与铁素体在变形过程中的良好配合,是冷轧中锰钢获得高强度、高塑性的主要原因。冷轧中锰钢拉伸断裂的裂纹主要萌生于软相的铁素体(δ-铁素体)及超细晶铁素体与形变诱导马氏体(残余奥氏体)的界面处。

Macroscopic to nanoscopic in situ investigation on yielding mechanisms in ultrafine grained medium Mn steels: Role of the austenite-ferrite interface

[J].

High strength and ductility combination in nano-/ultrafine-grained medium-Mn steel by tuning the stability of reverted austenite involving intercritical annealing

[J].