相变与变形过程都可视为热力学驱动下的动力学行为[1,2]。微结构(相)稳定性和机械稳定性可用于判断相变或变形的难易程度,属于纯粹的热力学稳定性,但无法应对相变和变形的非平衡动力学过程。热力学体现相变的驱动力,动力学表现为相变速率而受控于动力学能垒;譬如,为克服相变的表面能和应变能,必须提供足够的热力学驱动力(如化学驱动力或机械驱动力),而随热力学驱动力提高或降低,相变会自发选择动力学能垒减小或增大的机制(如低合金钢奥氏体化后的冷却过程中,随冷速提升而呈现出铁素体-贝氏体-马氏体的组织选择[3]);这体现出了本课题组近年来提出的热力学-动力学相关性概念[4~12],即热-动力学协同或“互斥”,并在多种合金体系的多种相变中得到验证、描述和应用[13~16]。相变包括扩散或切变,即原子的长程或短程运动,甚至是小于一个原子间距的整体位移[1];金属材料的变形大多涉及位错或孪生,是原子在层面间几个原子间距或小于一个原子间距的切变[2]。可见,相变和变形均属于不同级别的原子运动,适用于相变的热-动力学相关性同样适用于变形;根据位错热-动力学[2],流变应力的提高(对应有效驱动力)伴随着位错自由运动能垒的降低,这种热-动力学相关性是强塑性“互斥”现象的物理本源;也就是说,强塑性互斥本身就归属于热-动力学协同。

第三代先进高强钢(third-generation advanced high strength steel,TG-AHSS)以淬火-配分(quenching and partitioning,Q&P)钢[17]、淬火-配分-回火(quenching, partitioning and tempering,Q-P-T)钢[18]、中锰钢[19,20]为代表,以C、Mn、Al、Si元素为主,采用bcc + fcc相复合组织实现高强度与高塑性匹配。其中,bcc组织是强化相基体组织,主要包含马氏体、超细晶铁素体或纳米析出强化相等硬相,以保证材料的强度;fcc亚稳奥氏体在变形中会发生马氏体相变或产生变形孪晶,提高材料加工硬化率,进而提高材料的强塑性。TG-AHSS降低了合金元素含量,并结合了第二代高锰孪生诱导塑性 (twining induced plasticity,TWIP)钢良好的力学性能以及第一代钢的低成本优势,其发展目标是将强塑积提高至30 GPa·%以上,目前已受到国内外学者的广泛关注[20~22]。

本文首先基于热力学稳定性阐明TG-AHSS成分设计的宗旨;其次,基于广义稳定性对几类代表性热处理工艺进行了诠释。在此基础上,从广义稳定性与热-动力学相关性形成的热-动力学贯通性入手,对TG-AHSS的强韧化机制和设计策略进行了总结、归纳和展望。

1 成分工艺设计简述

目前TG-AHSS的热处理工艺设计目标是得到高比例、具有一定稳定性的残余奥氏体,获得具有多相、亚稳和多尺度的3M (multi-phase、meta-stable、multi-scale)组织[27]。多相(multi-phase)指的是多相复合组织,利用马氏体和第二相析出颗粒来提高材料的强度,利用残余奥氏体或铁素体提高材料的塑性与成形性;亚稳(meta-stable)主要是指残余奥氏体在室温下经相变诱导塑性(TRIP)效应转变为马氏体组织或产生TWIP效应,来提高加工硬化率,抑制变形过程中裂纹形核与扩展;多尺度(multi-scale)是指各相基体组织具有不同的形貌、晶粒尺寸、亚结构、板条宽度、缺陷等微观组织[28]。目前已发展出多种热处理工艺,包括从高温到低温的正相变退火工艺(Q&P、Q-P-T工艺等),也包括从低温到高温的逆相变退火工艺(主要针对中锰钢),以及新发展的化学界面工程(chemical boundary engineering,CBE)工艺,同时通过变形(热轧、冷轧以及温轧等)与元素配分来增加变形能、缺陷的存储和残余奥氏体相的稳定化,从而实现TG-AHSS高强、高塑的目标。

2 成分工艺设计及其热-动力学

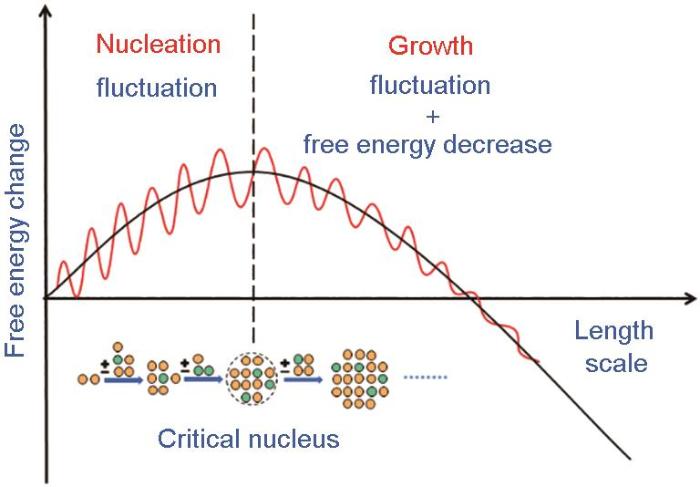

根据热-动力学协同的基本理念[5~7,29],热力学稳定性是联系热力学驱动力和后续形核/长大的枢纽。当驱动力突破热力学稳定性后,才会激活形核/长大动力学机制。随着相变进行,“热力学驱动力-稳定性-形核/长大动力学”这一链条循环重复,直至相变结束。那么,相变如何结束?热力学稳定性体现于热力学驱动力下的相或结构竞争,形核/长大体现于动力学机制的选择,相变演化则体现于转变过程中热力学驱动力的变化及相应形核/长大动力学机制的综合贡献。究其根本,热力学稳定性对应连续发生的相变或变形中的某个静态,决定了相变或变形能否发生或停止;广义稳定性,旨在定量评估某个相变或变形过程的进展程度。利用热力学稳定性和广义稳定性,可以设计形成特定微观组织的工艺路线。

2.1 基于热力学稳定性理解成分设计

相或结构稳定性是用来衡量母相在一定温度、成分和机械力作用下维持稳定的能力。不同的稳定性代表不同热力学驱动力下不同动力学机制的组合,显示出与温度、成分和机械力相关的热-动力学多样性。

对于满足平衡相图基本规律的自发相变而言,只有当应变能和表面能之和平衡了化学驱动力,或动力学能垒过大导致相变过程无法有效进行,自发相变才会停止。对于平衡相图上不存在的非自发相变,必须提供足够大的化学驱动力(或机械驱动力)来克服应变能和表面能的阻碍,相变才能发生。无论自发或非自发相变,究其根本,相变的发生等同于母相热力学稳定性的突破,其临界条件可以根据热力学第一定律表述如下[1]:

同样,对于变形过程,为描述位错核胚形成过程中的能量变化,将经典形核理论结合层错能(γSFE)这一热力学参量,并定义[34]:

式中,n为原子平面的厚度,ρA为单位面积密堆面的原子密度(摩尔量),σ为表面能。通过添加合金化元素可有效提高残余奥氏体的层错能,从而调控变形中产生的对强塑性有利的TRIP或TWIP效应[26]。

2.2 基于广义稳定性理解工艺设计

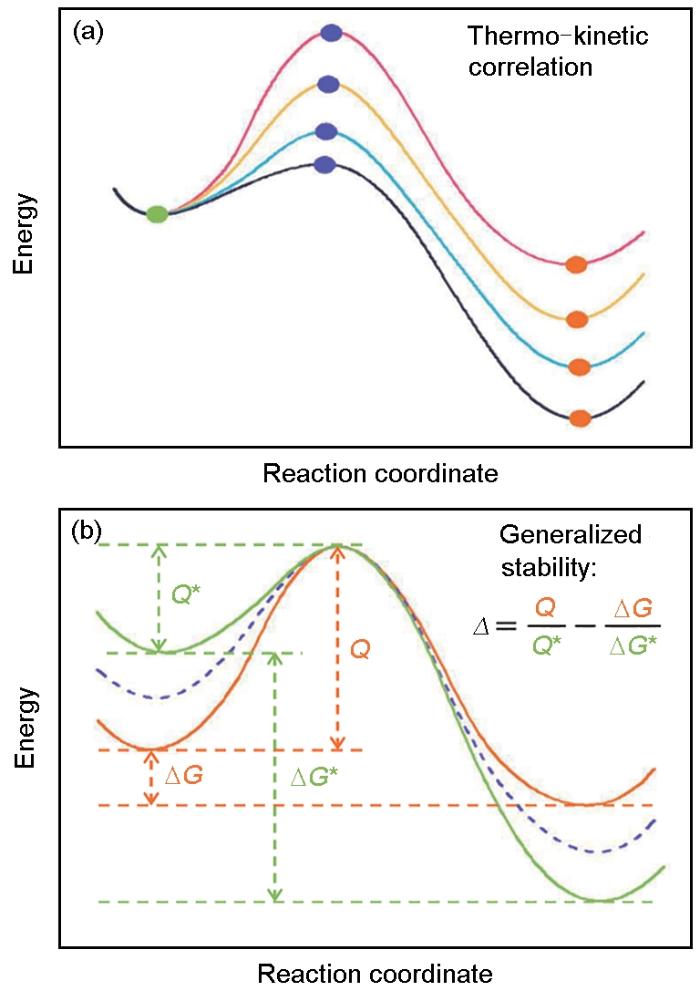

式中,Δ表示广义稳定性,ΔG* 和Q* 以及ΔG和Q分别代表相变或变形中参考态和终态的热力学驱动力和动力学能垒。图1[36]描述了广义稳定性的物理意义:针对介观相变/变形过程,其能量变化曲线上的绿色点与橙色点分别代表结构转变的初态与末态(图1a[36]),并分别对应于图1b[36]中代表微观子过程热-动力学的绿色线与橙色线。可见,任意时间段内完整的介观相变/变形过程都是由众多时刻的微观子过程所组成;当整个介观体系状态从图1a中绿色点演化到橙色点,与之对应,瞬态相变/变形的微观热-动力学便会由图1b中绿色线转变为橙色线,即以紫色点线为中间态。譬如,由相对大热力学驱动力和小动力学能垒控制的初态(参考态)转变为由相对小热力学驱动力和大动力学能垒控制的末态,该过程的可持续性正是由广义稳定性来度量。

图1

图1

热-动力学相关性与广义稳定性的定性展示[36]

Fig.1

Qualitative demonstration of thermo-kinetic correlations and generalized stability (Δ) [36] (ΔG*, ΔG—thermodynamic driving force of reference and final states (in phase transition or deformation), respectively; Q*, Q —kinetic energy barrier of reference and final states (in phase transition or deformation), respectively)

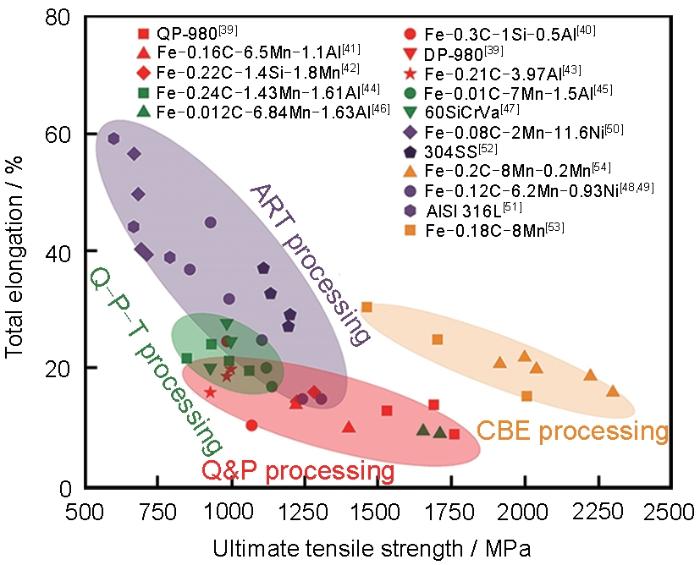

Q&P工艺借助碳化物析出与界面迁移,使得碳约束准平衡(carbon constrained quasi-equilibrium,CCE)[39]热力学和动力学模型变得更加复杂。将CCE模型与Koistinen-Marburger (K-M)方程相结合,理论上能够定量计算出形成最大残余奥氏体的淬火温度,并与实验结果相结合确定最优的热处理工艺参数,获得高比例且较为稳定的残留奥氏体(相成分为10%~20%)与马氏体基体的混合组织。相较于同成分体系的TRIP钢和淬火-回火钢,Q&P钢中高位错密度的马氏体保证了钢的强度,残余奥氏体在变形过程中发生TRIP效应,同时提高了钢的强度与塑性,其力学性能有了较大提高[39~43]。Q-P-T工艺相比于Q&P工艺增加了回火阶段,使基体中弥散析出纳米尺寸的复杂碳化物、过渡碳化物等韧性颗粒,在保证不损害塑性的同时,进一步提高了钢的强度[44~48]。因此,Q&P工艺旨在得到大驱动力的马氏体相变和大广义稳定性的配分过程;Q-P-T工艺还需兼顾大驱动力和大广义稳定性的共格析出过程。

图2

图2

不同热处理工艺下第三代先进高强钢力学性能的比较[39~54]

Fig.2

Comparison of mechanical properties of third-generation of advanced high strength steel (TG-AHSS) in different heat treatment processing[39-54] (Q&P—quenching and partitioning; Q-P-T—quenching, partitioning, and tempering; ART—austenite reverse transformation; CBE—chemical boundary engineering)

3 强韧化机制及其热-动力学

3.1 强韧化机制简述

目前TG-AHSS通过不同的热处理工艺,得到含高比例亚稳奥氏体的3M组织,在变形中通过奥氏体的TRIP效应、TWIP效应、软/硬相的协同作用等,获得优秀的应变硬化效果和塑性。现将目前TG-AHSS中所涉及到的强化、增塑机理总结如下。

3.1.1 亚稳奥氏体的TRIP效应

对于TG-AHSS,无论是正相变退火工艺(Q&P、Q-P-T工艺等),还是逆相变退火工艺(如ART工艺)以及新发展的CBE工艺,均能得到一定含量的亚稳残余奥氏体。塑性变形过程中,在应力或应变诱导下发生马氏体相变,导致材料的局部硬度提高,使该区域继续变形困难,变形向周围强度较低的组织转移,避免过早出现局部应力集中,从而推迟颈缩,提高材料延伸率。TRIP效应通过奥氏体的非扩散型相变而产生,残余奥氏体与新生成的马氏体往往呈共格关系,共格的高界面能阻碍了裂纹扩展。总体来说,奥氏体的TRIP效应能够释放局部应力集中,促进加工硬化及均匀变形,从而同时提高材料的强度、塑性与韧性。

3.1.2 亚稳奥氏体的TWIP效应

在Mn含量相对较高(质量分数> 8%)的TG-AHSS中,奥氏体层错能较高,在拉伸变形中会形成形变孪晶,即TWIP效应[20,22]。孪晶界阻碍位错的滑移,导致位错在孪晶界处塞积,使材料的局部强度提高,孪晶数量进一步增加,不同孪生系统的孪晶之间相互交割,进一步提高了局部强度。同时,变形向低应变区域转移,推迟了颈缩的形成。此外,奥氏体晶粒内部产生的大量细小形变孪晶不断切割奥氏体晶粒,相当于动态的Hall-Petch效应,起到了细晶强化的作用,使得材料的加工硬化能力进一步提高[55]。变形过程中形成的形变孪晶与奥氏体基体呈共格关系,这种共格的晶界可以抑制裂纹的扩展,有利于提高材料的均匀延伸率[56],因此TWIP效应起到对材料的增强、增韧作用。

3.1.3 不同相组织间协调变形

TG-AHSS中不同相(软相奥氏体与硬相马氏体)之间的有效应力/应变配分也起着重要作用。Lorthios等[56]利用同步辐射技术发现钢在弹性变形阶段发生应力配分,其中铁素体应力降低,而贝氏体和奥氏体的应力提高,有助于不同相之间的塑性相容性及变形协调性。Xu等[57]通过原位中子衍射对具有框架结构的马氏体-奥氏体钢拉伸变形时发现,马氏体可以通过晶粒间同步变形和转动及其框架结构表现出本身的塑性,随后两相间动态应力-应变配分诱导双相协同变形,并触发奥氏体相的TRIP效应,形成加工硬化平衡区以提高塑性;同时,双相协同变形和动态应力应变配分能有效抑制界面处的应力集中,促进均匀变形,延迟裂纹萌生。双相钢的抗拉强度超过1.4 GPa,延伸率仍保持在30%。

3.1.4 残余奥氏体吸收位错增塑

3.1.5 位错强化

在TG-AHSS前期的变形处理和淬火工艺中,塑性变形与位移型剪切相变会在淬火马氏体中引入高的位错密度(1016 m-2),产生好的位错强化效应(约1.6 GPa);另外,当组织中位错为可移动位错时,位错胞中的位错会发生释放与滑移,促进均匀塑性变形的发生,使材料塑性进一步提高[8]。

3.1.6 第二相强化

3.2 强韧化机制的热-动力学诠释

不同热力学稳定性的微观组织对应不同广义稳定性的形核和长大;位错演化借助不同的形核和长大(即,位错形核和滑移)来分别体现硬化和软化。借助形核与长大来关联组织形成和组织变形这2类热-动力学组合的机理和行为,是热-动力学贯通性的根本和精髓。

3.2.1 相变与变形中的加工硬化

基于热力学稳定性和广义稳定性的材料设计旨在调控形核与长大,即调控能量的聚集与耗散。如

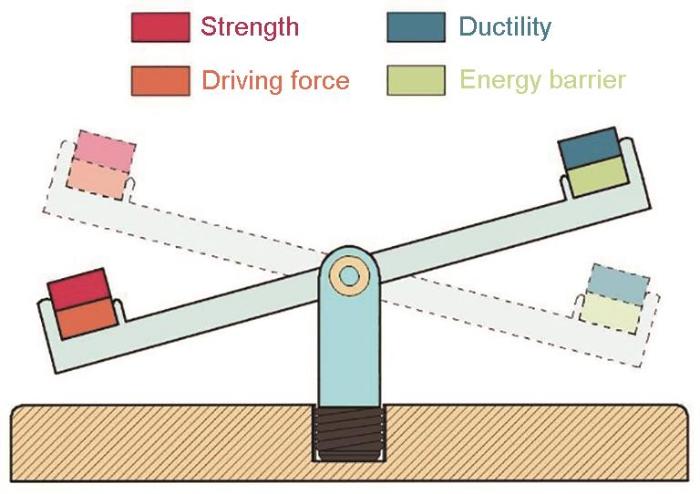

图3

变形属于非自发过程,变形越难发生,外加能量越高,同时,位错形核越优于生长,表现为强度越大,塑性越差,加工硬化越短暂,甚至没有;反之亦然。譬如,提高应变率相当于提高发生变形的外加能量,使位错形核优于生长,表现为强度提升,塑性降低。可见,形核与生长互斥在变形中依旧存在,即强塑性互斥。如图4[36]所示,强塑性的同时提升只能通过提升跷跷板支撑轴高度,进而兼顾大驱动力和大能垒。这完全类似于前述的“尽量提升驱动力使得形核加剧而提高体系能量,同时提高生长能垒使能量提升的过程更持久”。最让业界接受的说法是,如何开发不同的变形机制,使加工硬化持续不断地进行下去。通过设计大驱动力大能垒的微观组织形成过程,变形时,就可以在不牺牲强度的同时提升位错演化的能垒,广义稳定性也会提升。

图4

综上,变形机制的开发,其根本在于微观组织的形成,也就是相变(成分与工艺)的设计。就非自发过程而言,热力学稳定性决定了相变或变形发生所需的外加能量,热力学稳定性越高,相变或变形完成后体系能量提升越大。热-动力学相关性反应了形核与生长的互斥,如何让形核与生长分开处理,是打破该互斥的最佳手段。广义稳定性能定量评估体系能量提升过程的快慢程度。基于此,可以将形核长大与加工硬化关联起来,并以此为抓手进行相变设计。总而言之,大驱动力、大能垒、大广义稳定性的设计策略在于:设计高难度形核事件(或者非均质形核)的同时,使生长过程尽可能持久。下文从热-动力学出发,对3.1节描述的强韧化机制进行诠释。

3.2.2 应变诱导效应导致的高强高塑

与TWIP/TRIP钢相比,普通铁素体钢的位错滑移可认为是低热力学驱动力和低广义稳定性(低动力学能垒)的组合[61,62],这起源于形成其微观组织所涉及的低驱动力和低能垒组合的相变,最终对应于低强度和低塑性;反之亦然。以上策略的基本思路就是,如何让位错难启动但启动后其运动速率较慢或较持久;好的广义稳定性是好的加工硬化的必要条件,是多种机制综合作用来延续优异塑性的体现[63,64]。对于单一过程,如何实现大驱动力形核配合大能垒生长,在于寻找新的形核/长大机制。解决上述问题的基本方案:极端非平衡条件下的形核同相对近平衡长大的组合,譬如,TWIP/TRIP效应作用下的微观组织变形时,点缺陷、微观组织不均匀性、位错、晶界、高度分散的颗粒等均会对位错运动产生作用,导致位错缠结、孪生、马氏体相变或其他变形机制。

3.2.3 共格析出相导致的高强高塑

金属材料中引入第二相粒子是调控强塑性的常见方法之一[65,66]。按照第二相粒子和基底的界面错配度,可分为非共格/半共格粒子和共格粒子。非共格/半共格粒子对应较小的热力学驱动力(即形核能垒高),往往在缺陷处(如晶界、位错等)形成,其生长激活能小,粒子易于粗化,不利于获得高密度、均匀弥散、细小的析出。共格析出对应较大的热力学驱动力(即形核能垒低),生长由体扩散控制,对应较高的生长激活能,粒子难于粗化,利于获得高密度、均匀弥散、细小的析出相。因此,相比于非共格/半共格粒子析出,共格粒子析出受控于大驱动力形核和大能垒生长,对应产生较高的强度和塑性。譬如,传统马氏体时效钢中,主要的强化相通常与基体晶体结构存在巨大差异(即非共格析出),粒子易粗化,往往会促进不均匀析出。Jiang等[67]在马氏体时效钢中引入弥散均匀分布的B2-NiAl型共格析出相,体积密度高达1024 m-3,平均粒径约2.7 nm,最终马氏体钢的屈服强度及抗拉强度分别达1950和2240 MPa,均匀延伸率可达3.8%,延伸率超过8%。类似的,在FeCoNiCr高熵合金中,通过添加不同含量的Ti和Al,在高熵基体中形成大量纳米级弥散分布的共格γ′相,该共格析出具有Ni3(Ti, Al)型L12结构,颗粒直径在15~30 nm,体积分数约为21%,材料的室温屈服强度为645 MPa,抗拉断裂强度甚至超过了1 GPa,塑性延伸率为39%,加工硬化效果显著,展现出优异的综合室温力学性能[68]。上述案例中,共格粒子实现高强高塑的物理机制在于,共格析出粒子在保证高强度的同时,有效阻碍晶内位错运动,实现大驱动力和大能垒的位错运动,这对应于大驱动力和大能垒的共格析出热-动力学。

3.2.4 多过程共生导致的高强高塑

根据热-动力学贯通性,微观组织形成过程的大广义稳定性可以反映于微观组织的变形过程,无论是不同相组织间协调变形(3.1.3节),还是残余奥氏体吸收位错增塑(3.1.4节),其塑性提升根本来源于马氏体相变后的配分过程,即贫碳马氏体、残留奥氏体、贝氏体等的共生过程;多个过程间相近的广义稳定性通过共生进一步得到提高。结合3.2.1节,设计多个不同形核/生长搭配的相变或变形共生(包括连续发生),其根本目的就是尽量通过形核提高体系能量,同时通过生长让能量提升的过程更持久。

对于复杂工艺,多个形核和长大事件交互,譬如,第二相颗粒钉扎界面迁移、晶界/相界交互、缺陷交互提高迁移能垒或降低迁移速率等,均能体现大动力学能垒的效果。微观组织形成时,如果这两类缺陷同时产生,则每一类缺陷对应的广义稳定性均会被提升。根据热-动力学贯通性,微观组织变形时更高的广义稳定性必然拥有更大的机会来促生新的变形机制,进而不断激发大驱动力-小能垒组合的新位错产生。

3.2.5 形核与生长分开导致的高强高塑

如3.2.1节所述,提高相变的热力学驱动力会提升系统能量,所形成组织的强度会提升,在此基础上,高的广义稳定性意味着上述强度提升的过程是缓慢且稳定的,譬如,提升最大抗拉强度的同时,扩展从屈服到颈缩点的应变。然而,同时实现生长的大驱动力和大能垒或位错滑移对应的高流变应力和缓慢速率,在理论上是不可能的。根据热-动力学相关性,热力学驱动力和动力学能垒互斥,即不可能实现单一相变或变形的大驱动力和大能垒。

相变中,通过形核与生长分开,譬如,非均质形核和非热形核通过降低界面能和形核功来体现大驱动力的效果,在等效高形核率的前提下,借助体积扩散控制生长,实现大驱动力形核和大能垒生长[65~71]。变形中,如果先进行位错的形核(譬如,类似于位置饱和形核,预先将可动位错储备起来),随后变形中这些预存在位错只发生长大(整体滑移),即将位错的形核或增殖与滑移分开。在AHSS微观组织形成过程中储存可移动位错,变形中位错存储量增多会保证高的流变应力,同时位错胞中的位错释放与滑移(其速率不再受制于经典的驱动力-能垒互斥原则[2],而是在整体运动时呈现速度相对减缓),促进均匀塑性变形,使材料塑性进一步提高。位错形核与长大(即增殖与滑移)分开等同于大热力学驱动力下提高位错演化的广义稳定性。

3.3 广义稳定性调控

材料相变的启动、不同动力学机制的选择,不同微观组织塑性变形的启动、位错的演化、缺陷的交互、强塑性的搭配等,均体现出共同的设计宗旨:从一个低级别向高级别热-动力学相关性的跨越;而真正可以将微观组织从加工成形到服役变形统一起来的是面向热-动力学贯通性的晶体缺陷演化的广义稳定性。钢铁设计中,热力学稳定性和广义稳定性得到了很好的诠释和应用。由于广义稳定性由控制相变或变形的瞬态热-动力学参量决定,因此以广义稳定性为桥梁,形成微观结构的相变(和/或变形)热力学驱动力和动力学能垒与位错密度反映的流变应力和塑性定量关联。

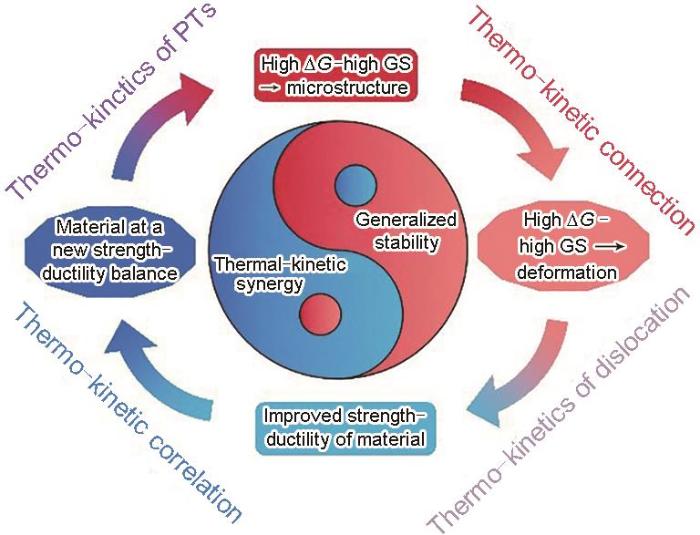

图5中热-动力学协同法则与广义稳定性理论共通共融,这恰好与太极图中“阴”与“阳”的协调类似,正是2者间相辅相成的演化才造就出材料不同的相变/变形行为与力学性能。以“太极图”的左端为材料设计起点顺时针“旋转”,通过调控材料加工制备的前(m-1)个阶段来引发大驱动力-大广义稳定性的相变过程,随后以所获得的微观结构为媒介,借助热-动力学贯通性,将大驱动力-大广义稳定性的相变热-动力学特征传递到最终的变形阶段(即第m阶段),从而使位错热-动力学在满足大驱动力-大广义稳定性判据后使材料在外界载荷下表现出高强度与高塑性;基于热-动力学相关性可知,材料此时应处于一个新的热-动力学或强塑性平衡关系下,并再次回到“太极图”的左端起点。因此,这个通过不断旋转“太极图”进行材料性能优化的过程正是将图4[36]中热-动力学与强塑性的“跷跷板”两端同时提升的有效方法[35,36]。相变中形核长大互斥,所以,长大份额越高,广义稳定性越大,形核份额越高,热力学驱动力越大。变形中位错的形核长大互斥,位错滑移份额越高(可动位错密度越高),广义稳定性越大,位错增殖份额越高(总体位错密度越高),强度越大。因此,位错的广义稳定性变化和塑性变化同频同源,塑性就是位错滑移(可动位错密度,对应于能垒)的归一化减去位错增殖(总体位错密度,对应于驱动力)的归一化。

图5

式中,A1代表由TRIP/TWIP效应产生的硬化,B1代表晶粒粗化导致的软化;Δ1、Δ2,Q1、Q2,及ρ1、ρ2分别为对应的广义稳定性、能垒及位错密度;b是Burgers矢量模;σb是流变应力;μ是剪切模量;C是取决于相互作用位错类型和排列的几何因子;Qy为屈服点时的动力学能垒;ΔGy是屈服点时的热力学驱动力。基于此,应变诱导晶粒粗化对应能垒提高-驱动力下降的位错演化,TRIP/TWIP效应则对应能垒降低-驱动力提升的位错演化。目前研究较多的应力-应变配分导致应力集中推后的现象[57,73],究其根本,在于软相参与硬相的变形过程,从而导致硬相中位错演化的广义稳定性增大,这取决于

3.4 基于广义稳定性的强韧化机制

相变-变形互助式的材料设计:由于相变和变形都是产生缺陷的过程,均会影响热力学驱动力和广义稳定性。相变得到的广义稳定性可以借助变形进行修正;变形的广义稳定性也可以通过相变得以改变。相变和变形可等价地作为不同的模块进行总体的热力学驱动力和广义稳定性计算,进行材料设计。变形中,通过调整温度、应变速率和应变量来调整变形的热力学驱动力和广义稳定性,并作为其中一个模块来调整总体相变的热力学驱动力和广义稳定性。合理地调控相变和变形的比例,实现材料的高强度和高塑性。

发现新的变形机制与组合旧的机理均是创新:是挖空心思去发现新的强韧化机制,还是将已存在的机制组合好?针对这个问题的回答决定了工作的基本路线和方法举措。如果是前者,就需要发现新的相变机理,构造新的组织,这些新组织很可能对应着新的强韧化机制。如何操作?这就需要反复从成分和工艺入手,采用试错法得到不同微观组织,如果发现好的性能,可结合好的性能发现新的强韧化机制,进而确定新的相变机理。如果是后者,面对纷繁复杂的多种强韧化机制,如何把他们搭配和利用好,譬如,设计出一个已有机制的组合并达到好的性能,是目前重要的问题。而具体操作则取决于如何主动且定量地设计成分工艺,使得变形过程中出现被设计好的强韧化机制组合的微观组织。这项任务如果没有热-动力学贯通性的提出和操作,是不可能被谈及的,即取决于作者提出的广义稳定性理论的使用。因此,给予优异组合的机制重构,会带来远远超过某一新机制的好结果。

4 总结和展望

(1) 大驱动力和大广义稳定性的实现隐含着热-动力学协同。一般而言,如果某缺陷A涉及的动力学过程在一定条件下不能实现理论上的大或小广义稳定性,则意味着2类情况有可能发生。首先,在涉及足够小或大的热力学驱动力之前,缺陷A涉及的动力学过程已然被抑制(对于相变)或突破(对于变形中的位错),即热力学稳定性的突破。其次,在缺陷A涉及的动力学过程分别被抑制和突破之前,缺陷B的热力学稳定性已然被突破(譬如,机械诱导),以至于缺陷B涉及的具备更小或更大广义稳定性的动力学过程真实发生。可见,选择不同的相变或变形机制对应着调配不同格局下的热-动力学相关性,究其根本,对应着通过成分和工艺设计来调控热力学驱动力和动力学过程,其目的是调控热力学稳定性和广义稳定性,进而调整硬化和软化的平衡。

(2) 近年来,在形成非均质微结构时,连续形成多尺度同类或不同类缺陷变得越来越具备竞争力和吸引力,这主要源于形成多尺度缺陷时热力学驱动力和动力学能垒的连续演化。形成非均质微观组织时,不同级别的热力学驱动力的复合或集成对应微观组织变形时的屈服强度,而形成多尺度缺陷需要克服的多级别动力学能垒对应变形的不同阶段,即以较高能垒下形成的缺陷对应较大能垒的位错演化。以最大驱动力形成的缺陷往往驻扎在变形的末端提供可能的应变。

(3) 材料加工和材料强韧化借助热-动力学贯通性可以描述为:制造缺陷、抑制缺陷和利用缺陷。加工过程完成后,缺陷的热力学存在决定屈服强度,制造缺陷的热-动力学过程决定了微观组织通过变形热-动力学而体现的加工硬化或塑性,而加工中被抑制的缺陷(譬如,晶粒长大、析出、马氏体相变、孪生、位错滑移等被抑制)有可能在变形中得以释放而进一步提供塑性。据此,对已有的强韧化思路可以总结和归纳为:① 提高缺陷形成的热力学驱动力;② 提高缺陷形成的广义稳定性;③ 倡导多种缺陷形成过程的共生;④ 减小缺陷间广义稳定性的离散性差别;⑤ 尽可能在形成微观组织的加工过程中压制多种晶体缺陷。

参考文献

Thermodynamics and kinetics of slip

[J].

Thermomechanical processing of advanced high strength steels

[J].

Kinetics and microstructural modeling of isothermal austenite-to-ferrite transformation in Fe-C-Mn-Si steels

[J].During the multi-stage processing of advanced high-strength steels, the austenite-to-ferrite transformation, generally as a precursor of the formation of other non-equilibrium or metastable structures, has a severe effect on the subsequent phase transformations. Herein, a more flexible kinetic and microstructural predictive modeling for the key austenite-to-ferrite transformation of Fe-C-Mn-Si steels was developed, in combination with the classical nucleation theory, the general mixed-mode growth model based on Gibbs energy balance, the microstructural path method and the kinetic framework for grain boundary nucleation. Adopting a bounded, extended matrix space corresponding to a single ferrite grain, both soft-impingement and hard-impingement can be naturally included in the current modeling. Accordingly, this model outputs the ferrite volume fraction, the austenite/ferrite interface area per unit volume, and the average grain size of ferrite, which will serve as the input parameters for modeling the subsequent bainite or martensite transformations. Applying the model, this work successfully predicts the experiment measurement of the isothermal austenite-to-ferrite transformation in Fe-0.17C-0.91Mn-1.03Si (wt%) steel at different temperatures and explains why the final-state average grain size of ferrite has a maximum at the moderate annealing temperature. Effectiveness and advantages of the present model are discussed arising from kinetics and thermodynamics accompanied with nucleation, growth and impingement.

Martensitic transition in Fe via Bain path at finite temperatures: A comprehensive first-principles study

[J].

Multi-scale modeling of the complex microstructural evolution in structural phase transformations

[J].

A strategy for designing stable nanocrystalline alloys by thermo-kinetic synergy

[J].Aiming to design stable nanocrystalline (NC) materials, so far, it has been proposed to construct nanostructure stability maps in terms of thermodynamic parameters, while kinetic stabilization has seldom been considered, despite the synergy of thermodynamics and kinetics. Consequently, the thermodynamically stabilized NC materials may be easily subjected to grain growth at high temperatures due to the weakly kinetic stabilization. Starting from the thermo-kinetic synergy, a stabilization criterion is proposed as a function of intrinsic solute parameters (e.g. the activation energy for bulk diffusion and the segregation enthalpy), intrinsic solvent parameters (e.g. the intrinsic activation energy for GB migration and the GB energy) and processing parameters (e.g. the grain size, the temperature and the solute concentration). Using first-principles calculations for a series of combinations between fifty-one substitutional alloying atoms as solute atoms and Fe atom as fixed solvent atom, it is shown that the thermal stability neither simply increases with increasing the segregation enthalpy as expected by thermodynamic stabilization, nor monotonically increases with increasing the activation energy for bulk diffusion as described by kinetic stabilization. By combination of thermodynamic and kinetic contributions, the current stabilization criterion evaluates quantitatively the thermal stability, thus permitting convenient comparisons among NC materials involved by various combinations of the solute atoms, the solvent atoms, or the processing conditions. Validity of this thermo-kinetic stabilization criterion has been tested by current experiment results of Fe-Y alloy and previously published data of Fe-Ni, Fe-Cr, Fe-Zr and Fe-Ag alloys, etc., which opens a new window for designing NC materials with sufficiently high thermal stability and sufficiently small grain size.

Competitions correlated with nucleation and growth in non-equilibrium solidification and solid-state transformation

[J].

非平衡凝固与固态相变中有关形核和长大的竞争研究(英文)

[J].

Bainitic transformation and generalized stability

[J].

Grain boundary-constrained reverse austenite transformation in nanostructured Fe alloy: Model and application

[J].

Grain size stabilization of mechanically alloyed nanocrystalline Fe-Zr alloys by forming highly dispersed coherent Fe-Zr-O nanoclusters

[J].

Kinetic modeling of solid-state partitioning phase transformation with simultaneous misfit accommodation

[J].

A thermo-kinetic correlation for grain growth in nanocrystalline alloys

[J].

An intrinsic correlation between driving force and energy barrier upon grain boundary migration

[J].The migration of grain boundary (GB), which plays a key role in the microstructural evolution of polycrystalline materials, remains mysterious due to the unknown relationship between GB mobility associated with specific geometry and external conditions (e.g. temperature, stress, etc., hence the thermodynamic driving force). Combining the rate equation of GB migration with molecular dynamics simulations, an intrinsic correlation between driving force and energy barrier for the migration of various types of GBs (i.e. twist, symmetric tilt, asymmetric tilt, and mixed twist-tilt) is herein explored, showing the decrease of energy barrier with increasing thermodynamic driving force.

Analysis of elastic-plastic accommodation due to volume misfit upon solid-state phase transformation

[J].

Generalized stability criterion for exploiting optimized mechanical properties by a general correlation between phase transformations and plastic deformations

[J].

Carbon partitioning into austenite after martensite transformation

[J].

Advanced Q-P-T steels with ultrahigh strength-high ductility

[J].

先进超高强度-高塑性Q-P-T钢

[J].首先论述从淬火-分配(Q&P)工艺发展起来的淬火-分配-回火(Q-P-T)工艺以及两者的差异, 总结Q-P-T钢从超高强度到高强塑性的发展,对比先进新型Q-P-T工艺和传统淬火-回火(Q-T)工艺的差异及其对钢力学性能的不同影响, 重点讨论在形变中残留奥氏体对超高强钢塑性增强的微观机制, 为先进高强钢的进一步发展提供组织设计和控制的理论指导.

Medium Mn transformation-induced plasticity steels: Recent progress and challenges

[J].

Recent progress in medium-Mn steels made with new designing strategies, a review

[J].After summarizing the relevant researches on the medium Mn steels in references, two new targets on the tensile properties have been defined. One is that both transformation-induced (TRIP) and twinning-induced plasticity (TWIP) could be realized for the steel with a relatively low Mn content, which exhibits the similar tensile properties to the classical TWIP steels with higher Mn content. The other is to achieve ultrahigh ultimate tensile strength (>1.5 GPa) without sacrificing formability. To achieve these goals, new designing strategies was put forward for compositions and the processing route. In particular, warm rolling was employed instead of the usual hot/cold rolling process because the former can produce a mixture of retained austenite grains with different morphologies and sizes via the partial recrystallization. Consequently, the retained austenite grains have a wide range of mechanic stability so that they can transform to martensite gradually during deformation, leading to enhanced TRIP effect and then improved mechanic properties. Finally, it is succeeded in manufacturing these targeted medium Mn steels in laboratory, some of them even exhibit better tensile properties than our expectation.

Thermomechanical processing of advanced high strength steels

[J].

Medium-manganese steels processed by austenite-reverted-transformation annealing for automotive applications

[J].In the automotive industry, the current development trend of lightweight and low-emission vehicles requests for high-performance materials. Benefiting from an excellent balance of mechanical properties and production cost, medium-Mn steels have attracted extensive interest by materials scientists. Austenite-reverted-transformation annealing plays a vital role in stabilisation of retained austenite and grain refinement, resulting in a considerable amount of retained austenite. Localised deformation phenomenon is usually observed in the ultrafine-grained medium-Mn steels owing to the absence of strain hardening. The occurrence of transformation-induced-plasticity and/or twinning-induced-plasticity effect in austenite improves strain hardening effectively. In the current review, austenite-reverted-transformation annealing treatment routine, mechanical properties and deformation mechanisms and effect of heat treatment on microstructure and mechanical properties of medium-Mn steels are summarised.

Effects of carbon content on mechanical properties of 5%Mn steels exhibiting transformation induced plasticity

[J].

High dislocation density-induced large ductility in deformed and partitioned steels

[J].A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium manganese steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D and P) process produced dislocation hardening but retained high ductility, both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D and P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for the development of high-strength, high-ductility materials.Copyright © 2017 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Effects of heat treatment and alloying elements on the microstructures and mechanical properties of 0.15wt pct C transformation-induced plasticity-aided cold-rolled steel sheets

[J].

Fabrication of an ultrafine-grained structure by a compositional pinning technique

[J].

Performance improvement of steels through M3 structure control

[J].

高性能钢的M3组织调控理论与技术

[J].

Strengthening-toughening mechanism and microstructural control ultra high strength aluminum-containing medium manganese steel

[D].

超高强含铝中锰钢的强韧化机制及组织调控

[D].

Kinetics of F.C.C.→B.C.C. heterogeneous martensitic nucleation—I. The critical driving force for athermal nucleation

[J].

On the controllability of phase formation in rapid solidification of high entropy alloys

[J].

The mechanism of bcc α′ nucleation in single hcp ε laths in the fcc γ→hcp ε→bcc α′ martensitic phase transformation

[J].

Quantitative modeling and experimental verification of carbide precipitation in a martensitic Fe-0.16wt%C-4.0wt%Cr alloy

[J].

Strain-induced transformation behaviour of retained austenite and tensile properties of TRIP-aided steels with different matrix microstructure

[J].

Kinetics of f.c.c.→b.c.c. heterogeneous martensitic nucleation—II. Thermal activation

[J].

Thermo-kinetic connectivity by integrating thermo-kinetic correlation and generalized stability

[J].Designing structured materials with optimized mechanical properties generally focuses on engineering microstructures, which are closely determined by the processing routes, such as phase transformations (PTs) and plastic deformations (PDs). Both PTs and PDs follow inherent trade-off relation between thermodynamic driving force ΔG and kinetic energy barrier Q, i.e., so-called thermo-kinetic correlation. By analyzing nucleation and growth and proposing a conception of negative driving force integrating strain energy, interface energy and any kind of energy that equivalently inhibits the PT itself, ΔGS, unified expressions for the thermo-kinetic correlation and generalized stability (GS) were derived for three kinds of PTs, i.e., diffusive PTs with simultaneously decreased ΔG and increased Q, diffusive PTs with simultaneously increased ΔG and decreased Q, and displacive PTs with simultaneously increased ΔG and decreased Q. This leads to so-called thermo-kinetic connectivity by integrating the thermo-kinetic correlation and the GS, where, by application in typical PTs, it was clearly shown, a criterion of high ΔG-high GS can be predicted by modulating chemical driving force, negative driving force and kinetic energy barrier for diffusion or nucleation. Following thermo-kinetic connectivity, analogous procedure for dislocation evolution upon PDs was performed, and materials design in terms of the high ΔG-high GS criterion was discussed and prospected.

Optimizing mechanical properties of magnesium alloys by philosophy of thermo-kinetic synergy: Review and outlook

[J].

Generalized stability criterion for controlling solidification segregation upon twin-roll casting

[J].Macro- and micro-segregation formed upon twin-roll casting (TRC) can be inherited from sub-rapid solidification to solid-state transformation, even to plastic deformation, thus deteriorating drastically mechanical properties of as-produced thin sheets. Although many works focusing mainly on controlling fields of thermal, concentration and convection have been reported, how to control artificially and quantitatively the segregation using a theoretical connection between processing parameters and solidification models, has not been realized, yet. Regarding it, a systematical framework integrating non-equilibrium dendritic growth and overall solidification kinetics with the TRC parameters, was constructed applying a generalized stability (GS) conception deduced from transient thermodynamic driving force ΔGt and transient kinetic energy barrier $Q_{\text{eff}}^{\text{t}}$ evolving upon solidification. Departing from this framework considering synergy of thermodynamics and kinetics (i.e., thermo-kinetic synergy), a criterion of high ΔGt-high GS guaranteed that the macro (i.e., the centerline) and the micro (i.e., the edge) segregation can be suppressed by increasing ΔGt and GS at the beginning and the ending stage of sub-rapid solidification, respectively. This typical thermo-kinetic combination producing the microstructure can be inherited into the plastic deformation, as reflected by corresponding strength-ductility combinations. This work realized quantitative controlling of TRC by a theoretical connection between processing parameters and solidification models, where, an optimization for sub-rapid solidification segregation using the GS conception including ΔGt and $Q_{\text{eff}}^{\text{t}}$ has been performed.

Microstructures and mechanical properties of three medium-Mn steels processed via quenching and partitioning as well as austenite reversion heat treatments

[J].

The deformation induced martensitic transformation and mechanical behavior of quenching and partitioning steels under complex loading process

[J].

Microstructure and tensile properties of a Nb-Mo microalloyed 6.5Mn alloy processed by intercritical annealing and quenching and partitioning

[J].

Effect of retained austenite stability and morphology on the hydrogen embrittlement susceptibility in quenching and partitioning treated steels

[J].

Microstructural evolution and deformation behavior of a hot-rolled and heat treated Fe-8Mn-4Al-0.2C steel

[J].

Effect of tempering temperature on microstructure and mechanical properties of a low carbon bainitic steel treated by quenching-partitioning-tempering (QPT) process

[J].

Investigation of hierarchical precipitation on bimodal-grained austenite and mechanical properties in quenching-partitioning-tempering steel

[J].

The austenite reversion and co-precipitation behavior of an ultra-low carbon medium manganese quenching-partitioning-tempering steel

[J].

Influence of Cr content and Q-P-T process on the microstructure and properties of cold-coiled spring steel

[J].

Effects of hot/cold deformation on the microstructures and mechanical properties of ultra-low carbon medium manganese quenching-partitioning-tempering steels

[J].

Suppressing precipitation during the reverse transformation from martensite to austenite in a cold-rolled austenite stainless steel

[J].

A novel Cu-Ni added medium Mn steel: Precipitation of Cu-rich particles and austenite reversed transformation occurring simultaneously during ART annealing

[J].

Tailoring the microstructure and mechanical properties of AISI 316L austenitic stainless steel via cold rolling and reversion annealing

[J].

Microstructure-tensile property correlation in 304 stainless steel after cold deformation and austenite reversion

[J].

The influence of silicon additions on the deformation behavior of austenite-ferrite duplex medium manganese steels

[J].

Chemical boundary engineering: A new route toward lean, ultrastrong yet ductile steels

[J].For decades, grain boundary engineering has proven to be one of the most effective approaches for tailoring the mechanical properties of metallic materials, although there are limits to the fineness and types of microstructures achievable, due to the rapid increase in grain size once being exposed to thermal loads (low thermal stability of crystallographic boundaries). Here, we deploy a unique chemical boundary engineering (CBE) approach, augmenting the variety in available alloy design strategies, which enables us to create a material with an ultrafine hierarchically heterogeneous microstructure even after heating to high temperatures. When applied to plain steels with carbon content of only up to 0.2 weight %, this approach yields ultimate strength levels beyond 2.0 GPa in combination with good ductility (>20%). Although demonstrated here for plain carbon steels, the CBE design approach is, in principle, applicable also to other alloys.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works. Distributed under a Creative Commons Attribution NonCommercial License 4.0 (CC BY-NC).

Study on the deformation mechanism of a high-nitrogen duplex stainless steel with excellent mechanical properties originated from bimodal grain design

[J].

Damage observation in a high-manganese austenitic TWIP steel by synchrotron radiation computed tomography

[J].

Mechanical properties and deformation mechanisms of a novel austenite-martensite dual phase steel

[J].

The effect of vanadium micro-alloying on the microstructure and the tensile behavior of TWIP steel

[J].

Transformation from cluster to nano-precipitate in microalloyed ferritic steel

[J].

Precipitation and growth of Laves phase and NbC during aging and its effect on tensile properties of a novel 15Cr-22Ni-1Nb austenitic heat-resistant steel

[J].

Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility

[J].The high-temperature stability and mechanical properties of refractory molybdenum alloys are highly desirable for a wide range of critical applications. However, a long-standing problem for these alloys is that they suffer from low ductility and limited formability. Here we report a nanostructuring strategy that achieves Mo alloys with yield strength over 800 MPa and tensile elongation as large as ~ 40% at room temperature. The processing route involves a molecular-level liquid-liquid mixing/doping technique that leads to an optimal microstructure of submicrometre grains with nanometric oxide particles uniformly distributed in the grain interior. Our approach can be readily adapted to large-scale industrial production of ductile Mo alloys that can be extensively processed and shaped at low temperatures. The architecture engineered into such multicomponent alloys offers a general pathway for manufacturing dispersion-strengthened materials with both high strength and ductility.

Brittle intermetallic compound makes ultrastrong low-density steel with large ductility

[J].

Simultaneously increasing both strength and ductility of Fe-Mn-C twinning-induced plasticity steel via Cr/Mo alloying

[J].

Tuning element distribution, structure and properties by composition in high-entropy alloys

[J].

Precipitation hardening in metals

[J].

Strain hardening mediated by coherent nanoprecipitates in ultrahigh-strength steels

[J].

A precipitation-hardened high-entropy alloy with outstanding tensile properties

[J].

Transformation-induced plasticity in bulk metallic glass composites evidenced by in-situ neutron diffraction

[J].

Effect of microstructure and γ′ precipitate from undercooled DD3 superalloy on mechanical properties

[J].

Rapid solidification of highly undercooled bulk liquid superalloy: Recent developments, future directions

[J].

Grain boundary stability governs hardening and softening in extremely fine nanograined metals

[J].Conventional metals become harder with decreasing grain sizes, following the classical Hall-Petch relationship. However, this relationship fails and softening occurs at some grain sizes in the nanometer regime for some alloys. In this study, we discovered that plastic deformation mechanism of extremely fine nanograined metals and their hardness are adjustable through tailoring grain boundary (GB) stability. The electrodeposited nanograined nickel-molybdenum (Ni-Mo) samples become softened for grain sizes below 10 nanometers because of GB-mediated processes. With GB stabilization through relaxation and Mo segregation, ultrahigh hardness is achieved in the nanograined samples with a plastic deformation mechanism dominated by generation of extended partial dislocations. Grain boundary stability provides an alternative dimension, in addition to grain size, for producing novel nanograined metals with extraordinary properties.Copyright © 2017, American Association for the Advancement of Science.

Gradient cell-structured high-entropy alloy with exceptional strength and ductility

[J].\n For most alloys, conventional or high entropy, increasing strength comes at the cost of poor ductility. Although there are many strategies to break this inverse relationship, Pan\n et al\n. now show that cyclic torsion on a high-entropy alloy enhances strength without degrading ductility (see the Perspective by Yeh). Cyclic torsion creates a gradient of dislocations and low-angle grain boundaries from the surface to the interior that organize into tiny stacking faults and twin when straining begins. These structures allow for the good ductility while simultaneously helping to work harden the alloy. —BG\n